Effect of Organic or Inorganic Fertilization on Microbial Flocs Production in Integrated Cultivation of Ulva lactuca with Oreochromis niloticus and Penaeus vannamei

Abstract

1. Introduction

2. Materials and Methods

2.1. Location and Origin of the Animals

2.2. Animal Materials

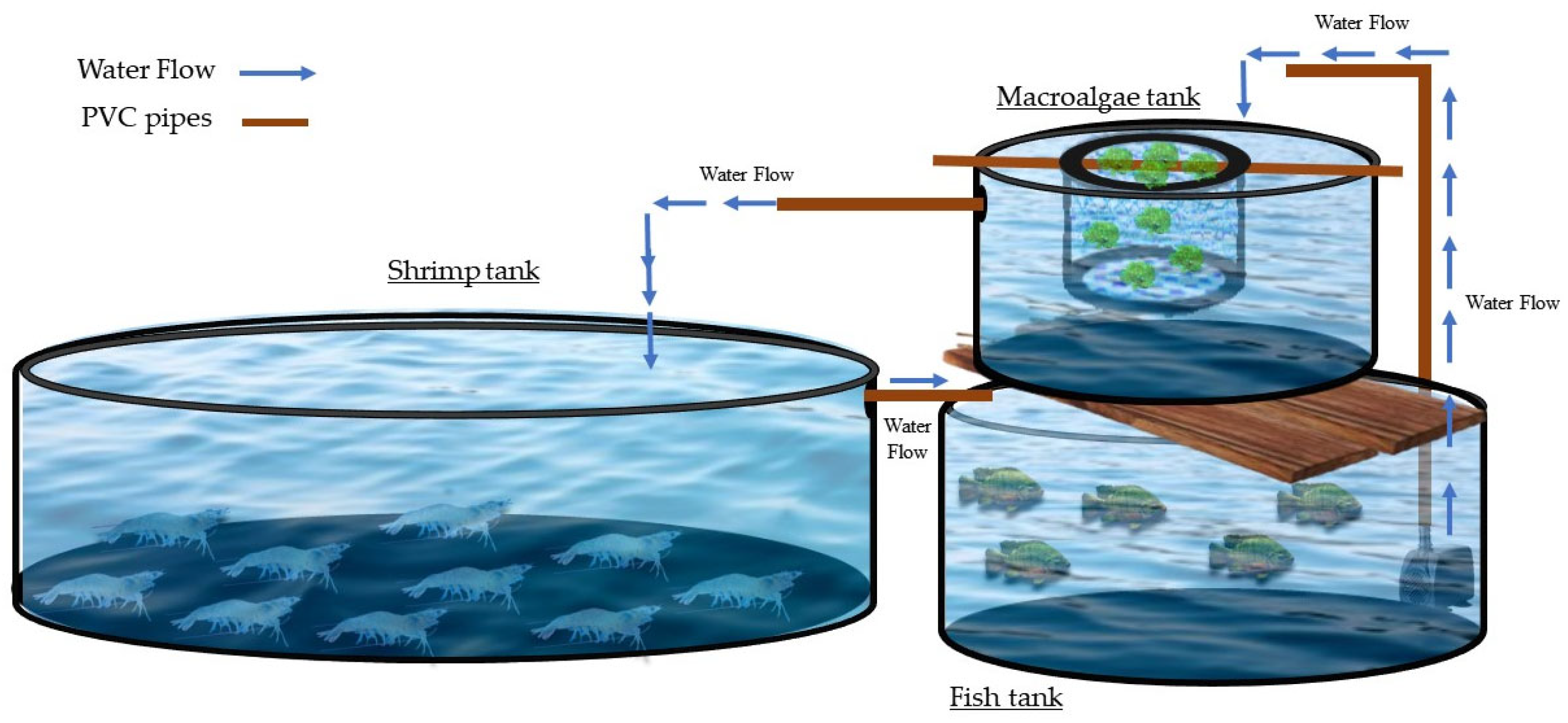

2.3. Experimental Design

2.4. Treatments

2.5. Chemical and Physical Water Parameters

2.6. Macroalgae Growth and Biochemical Analysis

2.7. Feed Management and Performance of the Animals

- − Final average weight (g): final biomass of live animals (g)/total number of animals;

- − Weekly weight gain (g week−1): weight gain (g)/number of weeks;

- − Final biomass (g): ∑ final weight of all live animals (g);

- − Feed conversion rate (FCR) = ∑ feed offered (g)/(biomass gain (g));

- − Survival (%) = (final number of animals/initial number of animals) × 100;

- − Yield (kg m−3): (final biomass (kg)/tank volume (m3);

- − Weight gain rate (%) = 100 × [(final mean weight − initial mean weight)/initial mean weight].

2.8. Statistical Analysis

3. Results

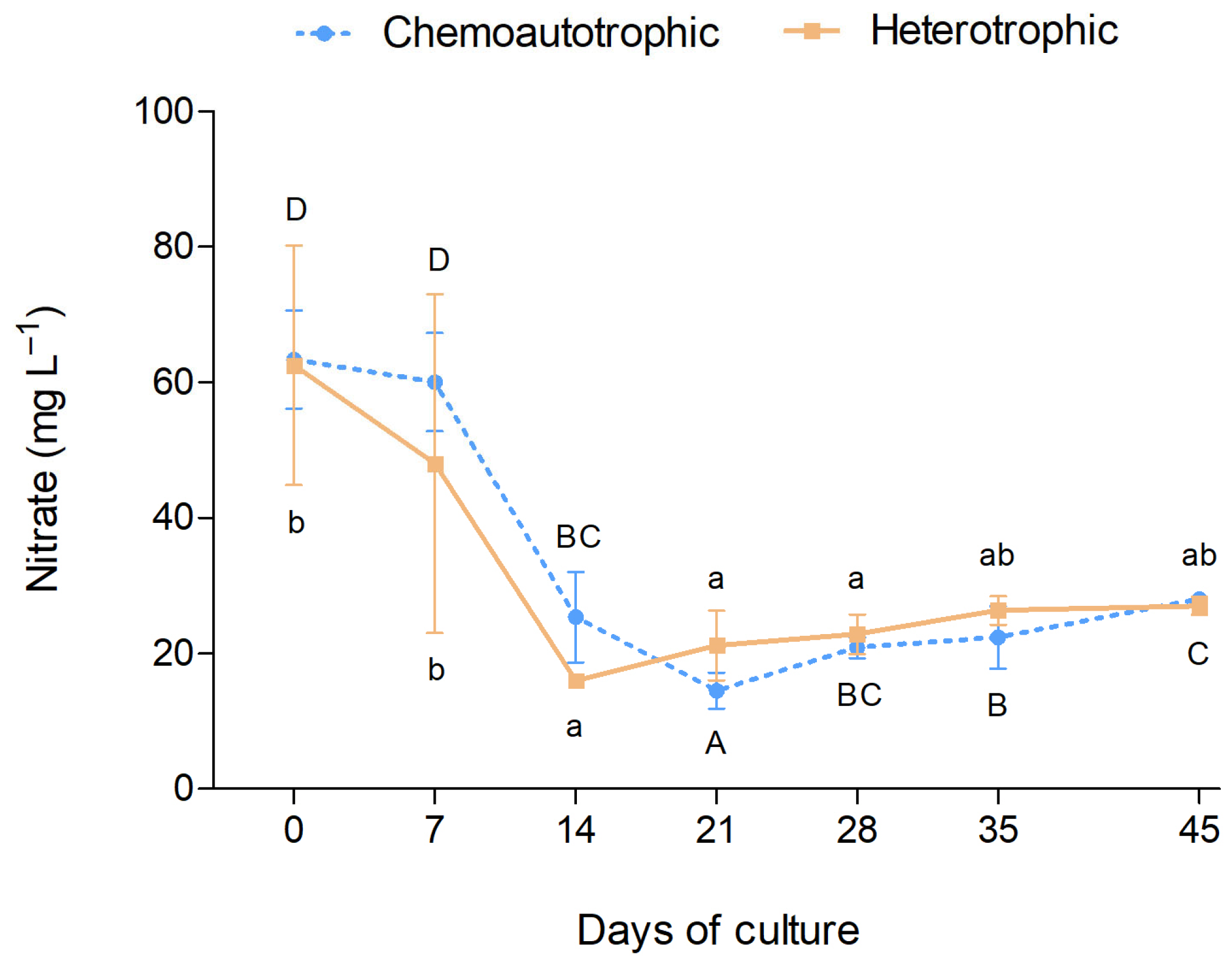

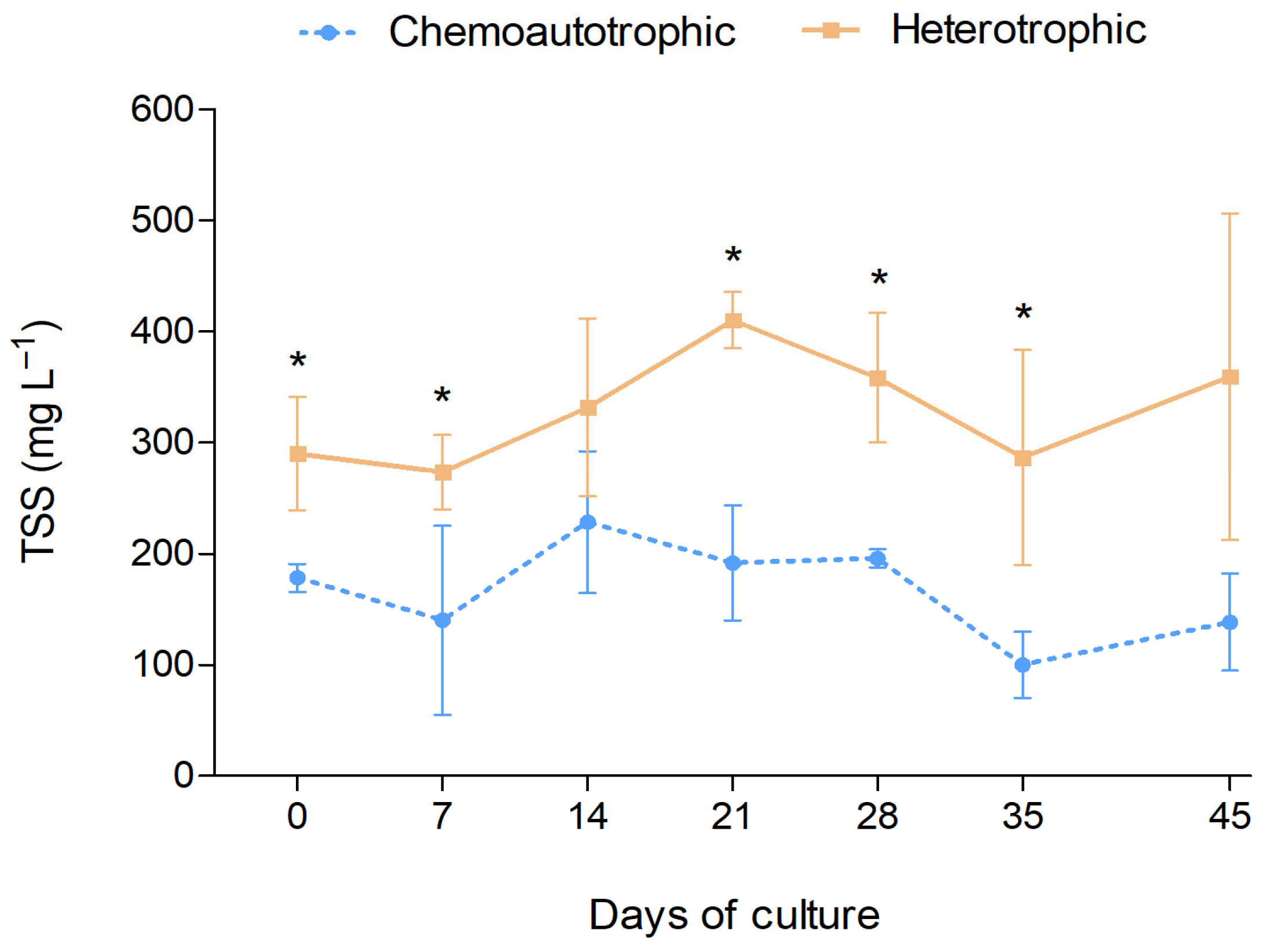

3.1. Physical and Chemical Parameters

| Treatments | ||

|---|---|---|

| Parameters | Chemoautotrophic | Heterotrophic |

| Temperature (°C) | 22.82 ± 0.30 (27.4–15.5) | 22.67 ± 0.38 (27.3–14.9) |

| DO (mg L −1) | 7.06 ± 0.04 (9.9–5.3) | 6.96 ± 0.06 (9.7–5.2) |

| pH | 8.15 ± 0.02 a (8.9–7.7) | 7.89 ± 0.04 b (8.1–7.5) |

| Salinity (g L−1) | 20.20 ± 0.26 (22.1–19.1) | 21.83 ± 0.76 (23.3–20.3) |

| Alkalinity (mg CaCO3 L−1) | 280.00 ± 8.19 a (365.0–155.0) | 189.58 ± 7.02 b (230.0–150.0) |

| TAN (mg L−1) | 0.95 ± 0.07 b (3.1–0.0) | 0.18 ± 0.08 a (1.9–0.0) |

| N—Nitrite (mg L−1) | 7.96 ± 1.16 b (20.0–0.0) | 0.86 ± 0.60 a (5.2–0.0) |

| N—Nitrate (mg L−1) | 26.41 ± 2.72 (68.0–10.0) | 26.04 ± 4.03 (75.0–15.0) |

| P—Phosphate (mg L−1) | 1.04 ± 0.25 (2.0–0.3) | 1.19 ± 0.21 (2.2–0.4) |

| SS (ml L−1) | 0.39 ± 0.21 a (3.0–0.0) | 8.44 ± 2.91 b (15.0–3.0) |

| TSS (mg L−1) | 189.22 ± 26.02 a (270.0–70.0) | 335.38 ± 47.92 b (452.5–175.0) |

| Calcium hydroxide (g L−1) # | 0.29 ± 0.02 b (0.32–0.28) | 0.08 ± 0.03 a (0.10–0.04) |

| Water exchange (m−3) & | 2.0 ± 2.0 a | 0.0 ± 0.0 a |

| Removal rate | ||

| Nitrate (%) | 56.47 ± 4.93 | 57.00 ± 7.00 |

| Phosphate (%) | 47.75 ± 4.75 b | 56.14 ± 1.14 a |

3.2. Macroalgae Growth and Biochemical Analysis

| Treatments | ||

|---|---|---|

| Chemoautotrophic | Heterotrophic | |

| Initial mean weight (g–FW) | 502.76 ± 0.65 | 502.64 ± 0.44 |

| Biomass gain (g–FW) | 964.63 ± 290.57 | 708.11 ± 141.70 |

| Protein (%) | 15.13 ± 0.56 b | 18.49 ± 0.56 a |

| Chlorophyll-a (mg g−1) | 2.20 ± 0.02 | 2.18 ± 0.06 |

| Chlorophyll-b (mg g−1) | 3.28 ± 0.02 | 3.26 ± 0.08 |

| Carotenoids (mg g−1) | 0.06 ± 0.00 | 0.04 ± 0.02 |

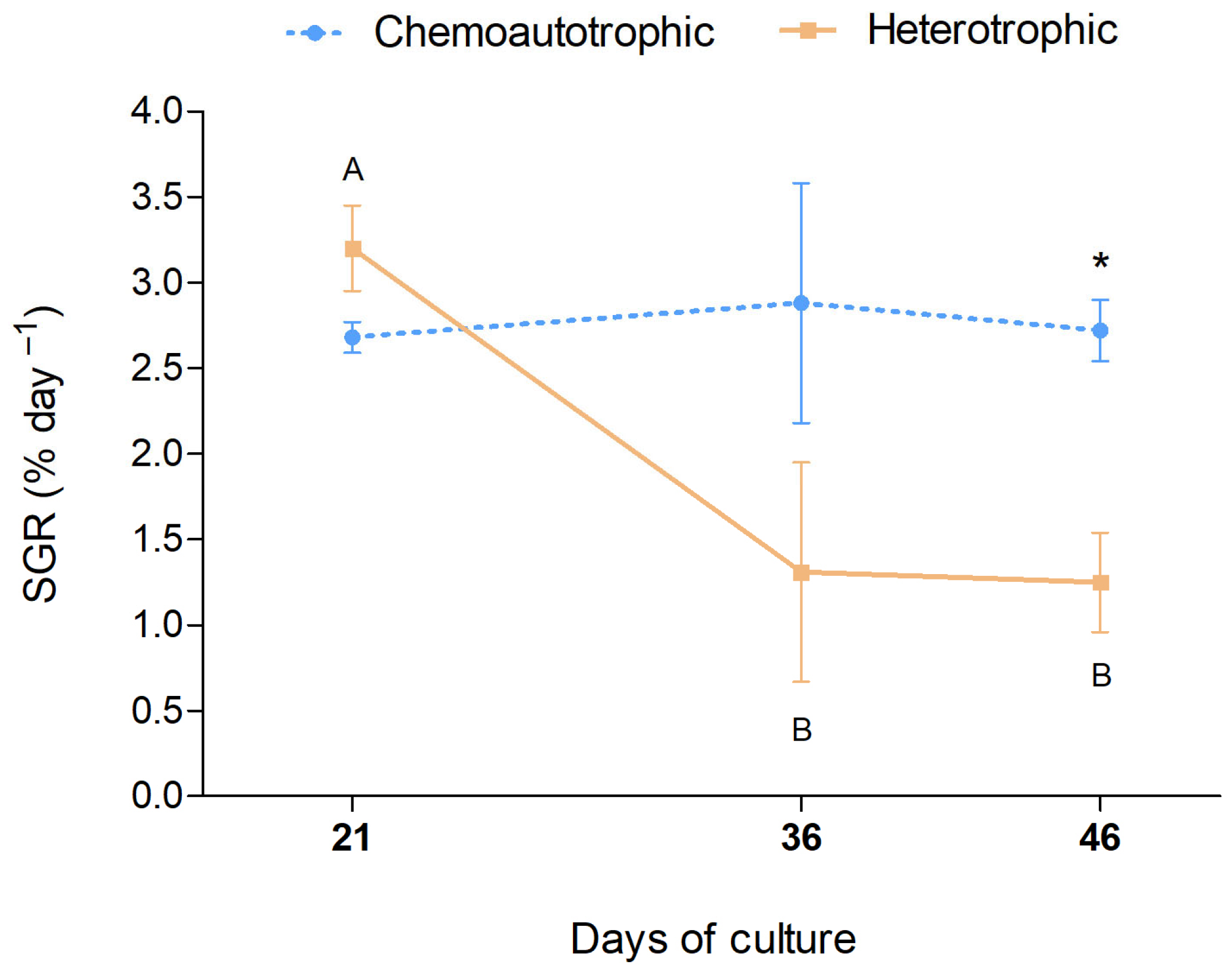

3.3. Performance of the Animals

| Treatments | ||

|---|---|---|

| Chemoautotrophic | Heterotrophic | |

| Shrimp | ||

| Final mean weight (g) | 9.60 ± 0.60 | 10.75 ± 0.49 |

| WWG (g week−1) # | 0.41 ± 0.10 | 0.60 ± 0.08 |

| Final biomass (kg) | 10.02 ± 0.43 | 10.79 ± 0.60 |

| FCR ## | 2.16 ± 0.38 | 2.36 ± 0.24 |

| Survival (%) | 84.71 ± 4.50 | 84.08 ± 5.22 |

| Fish | ||

| Final mean weight (g) | 447.55 ± 1.05 b | 456.25 ± 3.25 a |

| WWG (g week−1) # | 5.93 ± 0.18 b | 7.38 ± 0.55 a |

| Final biomass (kg) | 2.89 ± 0.54 | 2.98 ± 0.25 |

| FCR ## | 1.03 ± 0.10 | 1.18 ± 0.02 |

| Survival (%) | 90.48 ± 16.50 | 95.24 ± 8.25 |

| WGR (%) ### | 8.63 ± 0.25 b | 10.74 ± 0.79 a |

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gordalina, M.; Pinheiro, H.M.; Mateus, M.; da Fonseca, M.M.R.; Cesário, M.T. Macroalgae as Protein Sources—A Review on Protein Bioactivity, Extraction, Purification and Characterization. Appl. Sci. 2021, 11, 7969. [Google Scholar] [CrossRef]

- Wan, A.H.L.; Davies, S.J.; Soler-Vila, A.; Fitzgerald, R.; Johnson, M.P. Macroalgae as a Sustainable Aquafeed Ingredient. Rev. Aquac. 2019, 11, 458–492. [Google Scholar] [CrossRef]

- Chopin, T. Marine Aquaculture in Canada: Well-Established Monocultures of Finfish and Shellfish and an Emerging Integrated Multi-Trophic Aquaculture (IMTA) Approach Including Seaweeds, Other Invertebrates, and Microbial Communities. Fisheries 2015, 40, 28–31. [Google Scholar] [CrossRef]

- Queirós, A.S.; Circuncisão, A.R.; Pereira, E.; Válega, M.; Abreu, M.H.; Silva, A.M.S.; Cardoso, S.M. Valuable Nutrients from Ulva rigida: Modulation by Seasonal and Cultivation Factors. Appl. Sci. 2021, 11, 6137. [Google Scholar] [CrossRef]

- Troell, M.; Joyce, A.; Chopin, T.; Neori, A.; Buschmann, A.H.; Fang, J.G. Ecological Engineering in Aquaculture—Potential for Integrated Multi-Trophic Aquaculture (IMTA) in Marine Offshore Systems. Aquaculture 2009, 297, 1–9. [Google Scholar] [CrossRef]

- Resende, L.; Flores, J.; Moreira, C.; Pacheco, D.; Baeta, A.; Garcia, A.C.; Rocha, A.C.S. Effective and Low-Maintenance IMTA System as Effluent Treatment Unit for Promoting Sustainability in Coastal Aquaculture. Appl. Sci. 2022, 12, 398. [Google Scholar] [CrossRef]

- Holanda, M.; Wasielesky, W.; de Lara, G.R.; Poersch, L.H. Production of Marine Shrimp Integrated with Tilapia at High Densities and in a Biofloc System: Choosing the Best Spatial Configuration. Fishes 2022, 7, 283. [Google Scholar] [CrossRef]

- Poli, M.A.; Legarda, E.C.; de Lorenzo, M.A.; Pinheiro, I.; Martins, M.A.; Seiffert, W.Q.; do Nascimento Vieira, F. Integrated Multitrophic Aquaculture Applied to Shrimp Rearing in a Biofloc System. Aquaculture 2019, 511, 734274. [Google Scholar] [CrossRef]

- de Souza, R.L.; de Lima, E.C.R.; de Melo, F.P.; Ferreira, M.G.P.; de Souza Correia, E. The Culture of Nile Tilapia at Different Salinities Using a Biofloc System. Rev. Cienc. Agron. 2019, 50, 267–275. [Google Scholar] [CrossRef]

- Li, E.; Chen, L.; Zeng, C.; Chen, X.; Yu, N.; Lai, Q.; Qin, J.G. Growth, Body Composition, Respiration and Ambient Ammonia Nitrogen Tolerance of the Juvenile White Shrimp, Litopenaeus vannamei, at Different Salinities. Aquaculture 2007, 265, 385–390. [Google Scholar] [CrossRef]

- Natori, M.M.; Sussel, F.R.; Santos, E.D.; Previero, T.D.C.; Viegas, E.M.M.; Gameiro, A.H. Desenvolvimento Da Carcinicultura Marinha No Brasil e No Mundo: Avanços Tecnológicos e Desafios. Informações econômicas 2011, 41, 61–73. [Google Scholar]

- FAO. State of the World Fisheries and Aquaculture—2022 (SOFIA); FAO: Rome, Italy, 2022; ISBN 9789251072257. [Google Scholar]

- Brito, L.O.; Arantes, R.; Magnotti, C.; Derner, R.; Pchara, F.; Olivera, A.; Vinatea, L. Water Quality and Growth of Pacific White Shrimp Litopenaeus vannamei (Boone) in Co-Culture with Green Seaweed Ulva lactuca (Linaeus) in Intensive System. Aquac. Int. 2014, 22, 497–508. [Google Scholar] [CrossRef]

- Legarda, E.C.; da Silva, D.; Miranda, C.S.; Pereira, P.K.M.; Martins, M.A.; Machado, C.; de Lorenzo, M.A.; Hayashi, L.; do Nascimento Vieira, F. Sea Lettuce Integrated with Pacific White Shrimp and Mullet Cultivation in Biofloc Impact System Performance and the Sea Lettuce Nutritional Composition. Aquaculture 2021, 534, 736265. [Google Scholar] [CrossRef]

- de Morais, A.P.M.; Santos, I.L.; Carneiro, R.F.S.; Routledge, E.A.B.; Hayashi, L.; de Lorenzo, M.A.; do Nascimento Vieira, F. Integrated Multitrophic Aquaculture System Applied to Shrimp, Tilapia, and Seaweed (Ulva ohnoi) Using Biofloc Technology. Aquaculture 2023, 572, 739492. [Google Scholar] [CrossRef]

- Crab, R.; Avnimelech, Y.; Defoirdt, T.; Bossier, P.; Verstraete, W. Nitrogen Removal Techniques in Aquaculture for a Sustainable Production. Aquaculture 2007, 270, 1–14. [Google Scholar] [CrossRef]

- Ferreira, G.S.; Santos, D.; Schmachtl, F.; Machado, C.; Fernandes, V.; Bögner, M.; Schleder, D.D.; Seiffert, W.Q.; Vieira, F.N. Heterotrophic, Chemoautotrophic and Mature Approaches in Biofloc System for Pacific White Shrimp. Aquaculture 2021, 533, 736099. [Google Scholar] [CrossRef]

- Ebeling, J.M.; Timmons, M.B.; Bisogni, J.J. Engineering Analysis of the Stoichiometry of Photoautotrophic, Autotrophic, and Heterotrophic Removal of Ammonia-Nitrogen in Aquaculture Systems. Aquaculture 2006, 257, 346–358. [Google Scholar] [CrossRef]

- Gaona, C.A.P.; de Almeida, M.S.; Viau, V.; Poersch, L.H.; Wasielesky, W. Effect of Different Total Suspended Solids Levels on a Litopenaeus vannamei (Boone, 1931) BFT Culture System during Biofloc Formation. Aquac. Res. 2017, 48, 1070–1079. [Google Scholar] [CrossRef]

- Furtado, P.S.; Poersch, L.H.; Wasielesky, W. Effect of Calcium Hydroxide, Carbonate and Sodium Bicarbonate on Water Quality and Zootechnical Performance of Shrimp Litopenaeus vannamei Reared in Biofloc Technology (BFT) Systems. Aquaculture 2011, 321, 130–135. [Google Scholar] [CrossRef]

- Furtado, P.S.; Campos, B.R.; Serra, F.P.; Klosterhoff, M.; Romano, L.A.; Wasielesky, W. Effects of Nitrate Toxicity in the Pacific White Shrimp, Litopenaeus vannamei, Reared with Biofloc Technology (BFT). Aquac. Int. 2015, 23, 315–327. [Google Scholar] [CrossRef]

- Macedo, C.F.; Sipaúba-Tavares, L. Eutrophication and Water Quality in Pisciculture: Consequences and Recommendations. Bol. Do Inst. De Pesca 2010, 36, 149–163. [Google Scholar]

- Brandão, H.; Xavier, Í.V.; Santana, G.K.K.; Santana, H.J.K.; Krummenauer, D.; Wasielesky, W. Heterotrophic versus Mixed BFT System: Impacts on Water Use, Suspended Solids Production and Growth Performance of Litopenaeus vannamei. Aquac. Eng. 2021, 95, 102194. [Google Scholar] [CrossRef]

- Krummenauer, D.; Samocha, T.; Poersch, L.; Lara, G.; Wasielesky, W. The Reuse of Water on the Culture of Pacific White Shrimp, Litopenaeus vannamei, in BFT System. J. World Aquac. Soc. 2014, 45, 3–14. [Google Scholar] [CrossRef]

- Carvalho, A.; de Oliveira Costa, L.C.; Holanda, M.; Poersch, L.H.; Turan, G. Influence of Total Suspended Solids on the Growth of the Sea Lettuce Ulva lactuca Integrated with the Pacific White Shrimp Litopenaeus vannamei in a Biofloc System. Fishes 2023, 8, 163. [Google Scholar] [CrossRef]

- Copertino, M.D.S.; Tormena, T.; Seeliger, U. Biofiltering Efficiency, Uptake and Assimilation Rates of Ulva clathrata (Roth) J. Agardh (Clorophyceae) Cultivated in Shrimp Aquaculture Waste Water. J. Appl. Phycol. 2009, 21, 31–45. [Google Scholar] [CrossRef]

- Duke, C.S.; Litaker, W.; Ramus, J. Effects of the Temperature, Nitrogen Supply and Tissue Nitrogen on Ammonium Uptake Rates of the Chlorophyte Seaweeds Ulva Curvata and Codium Decorticatum. J. Phycol. 1989, 25, 113–120. [Google Scholar] [CrossRef]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Waste Water, 16th ed.; American Public Health Association: Washington, DC, USA, 1989. [Google Scholar]

- UNESCO. Chemical Methods for Use in Marine Environmental Monitoring; Intergovernmental Oceanographic Commission: Paris, France, 1983. [Google Scholar]

- Aminot, A.; Chaussepied, M. Manuel Des Analyses Chimiques En Milieu Marin; Centre National pour L’exploitation des Océans: Paris, France, 1983. [Google Scholar]

- Baumgarten, M.D.G.Z.; De Barros Rocha, J.M.; Niencheski, L.F.H. Manual de Análises Em Oceanografia Química; FURG: Rio Grande, Brazil, 1996. [Google Scholar]

- Wasielesky, W.; Krummenauer, D.; Lara, G.; Fóes, G. Cultivo de Camarões Em Sistema de Bioflocos: Realidades e Perspectivas. 2013, 15, 30–36. Revista ABCC.

- Loureiro, R.R.; Reis, R.P.; Critchley, A.T. In Vitro Cultivation of Three Kappaphycus alvarezii (Rhodophyta, Areschougiaceae) Variants (Green, Red and Brown) Exposed to a Commercial Extract of the Brown Alga Ascophyllum nodosum (Fucaceae, Ochrophyta). J. Appl. Phycol. 2010, 22, 101–104. [Google Scholar] [CrossRef]

- Lichtenthaler, H.K.; Wellburn, A.R. Determinations of Total Carotenoids and Chlorophylls a and b of Leaf Extracts in Different Solvents. Biochem. Soc. Trans. 1983, 11, 591–592. [Google Scholar] [CrossRef]

- Barbarino, E.; Lourenço, S.O. An Evaluation of Methods for Extraction and Quantification of Protein from Marine Macro- and Microalgae. J. Appl. Phycol. 2005, 17, 447–460. [Google Scholar] [CrossRef]

- Jory, D.E.; Cabrera, T.R.; Dugger, D.M.; Fegan, D.; Lee, P.G.; Lawrence, L.; Jackson, C.J.; Mcintosh, R.P.; Castañeda, J.I.; Al, B.; et al. A Global Review of Shrimp Feed Management: Status and Perspectives. Aquaculture 2011, 318, 104–152. [Google Scholar]

- Hammer, Ø.; David, A.; Harper, T.; Paul, D. Ryan National Knowledge Resource Consortium -a National Gateway of S&T on-Line Resources for CSIR and DST Laboratories. Curr. Sci. 2013, 105, 1352–1357. [Google Scholar]

- Messyasz, B.; Rybak, A. Abiotic Factors Affecting the Development of Ulva Sp. (Ulvophyceae; Chlorophyta) in Freshwater Ecosystems. Aquat. Ecol. 2011, 45, 75–87. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, J.C. Acute Toxicity of Ammonia on Litopenaeus vannamei Boone Juveniles at Different Salinity Levels. J. Exp. Mar. Bio. Ecol. 2001, 259, 109–119. [Google Scholar] [CrossRef]

- De Lara, G.R.; Poersch, L.H.; Wasielesky, W., Jr. The Quantity of Artificial Substrates Influences the Nitrogen Cycle in the Biofloc Culture System of Litopenaeus vannamei. Aquac. Eng. 2021, 94, 102171. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, J.C. Acute Toxicity of Nitrite on Litopenaeus vannamei (Boone) Juveniles at Different Salinity Levels. Aquaculture 2003, 224, 193–201. [Google Scholar] [CrossRef]

- Carneiro, M.A.D.A. Estudo Do Crescimento, Eficiência de Biofiltração e Cinética de Absorção de Nutrientes (N-NH, N-NO e P-PO43) Da Macroalga Gracilaria cervicornis (Turner). Master’s Thesis, Universidade Federal do Rio Grande do Norte, Rio Grande, Brazil, 2007. [Google Scholar]

- Hanisak, M.D. The Use of Gracilaria tikvahiae (Gracilariales, Rhodophyta) as a Model System to Understand the Nitrogen Nutrition of Cultured Seaweeds. Hydrobiologia 1990, 204–205, 79–87. [Google Scholar] [CrossRef]

- Da Silva, K.R.; Wasielesky, W.; Abreu, P.C. Nitrogen and Phosphorus Dynamics in the Biofloc Production of the Pacific White Shrimp, Litopenaeus vannamei. J. World Aquac. Soc. 2013, 44, 30–41. [Google Scholar] [CrossRef]

- Massocato, T.F.; Robles-Carnero, V.; Moreira, B.R.; Castro-Varela, P.; Pinheiro-Silva, L.; da Silva Oliveira, W.; Vega, J.; Avilés, A.; Bonomi-Barufi, J.; Rörig, L.R.; et al. Growth, Biofiltration and Photosynthetic Performance of Ulva Spp. Cultivated in Fishpond Effluents: An Outdoor Study. Front. Mar. Sci. 2022, 9, 981468. [Google Scholar] [CrossRef]

- Tsagkamilis, P.; Danielidis, D.; Dring, M.J.; Katsaros, C. Removal of Phosphate by the Green Seaweed Ulva lactuca in a Small-Scale Sewage Treatment Plant (Ios Island, Aegean Sea, Greece). J. Appl. Phycol. 2010, 22, 331–339. [Google Scholar] [CrossRef]

- Zirino, A.; Elwany, H.; Facca, C.; Maicu’, F.; Neira, C.; Mendoza, G. Nitrogen to Phosphorus Ratio in the Venice (Italy) Lagoon (2001–2010) and Its Relation to Macroalgae. Mar. Chem. 2016, 180, 33–41. [Google Scholar] [CrossRef]

- Rathod, M.; Mody, K.; Basha, S. Efficient Removal of Phosphate from Aqueous Solutions by Red Seaweed, Kappaphycus alverezii. J. Clean. Prod. 2014, 84, 484–493. [Google Scholar] [CrossRef]

- Chopin, T.; Buschmann, A.H.; Halling, C.; Troell, M.; Kautsky, N.; Neori, A.; Kraemer, G.P.; Zertuche-González, J.A.; Yarish, C.; Neefus, C. Integrating Seaweeds into Marine Aquaculture Systems: A Key toward Sustainability. J. Phycol. 2001, 37, 975–986. [Google Scholar] [CrossRef]

- de Alencar, J.R.; Junior, P.A.H.; Celino, J.J. Cultivo de Camarão Branco Litopenaeus vannamei (Boone, 1931) Com a Macroalga Ulva lactuca Linneaus (Chlorophyta) No Tratamento de Efluentes Em Sistema Fechado de Recirculação. Rev. Biol. e Ciências da Terra 2010, 10, 117–137. [Google Scholar]

- Carvalho, A.; de Oliveira Costa, L.C.; Holanda, M.; Gonçalves, M.; Santos, J.; Costa, C.S.B.; Turan, G.; Poersch, L.H. Growth of the Macroalgae Ulva lactuca Cultivated at Different Depths in a Biofloc Integrated System with Shrimp and Fish. Phycology 2023, 3, 280–293. [Google Scholar] [CrossRef]

- Martins, M.A.; da SILVA, V.F.; Tarapuez, P.R.; Hayashi, L.; Vieira, F.D.N. Cultivation of the Seaweed Ulva Spp. With Effluent from a Shrimp Biofloc Rearing System: Different Species and Stocking Density. Bol. do Inst. Pesca 2020, 46, 1–6. [Google Scholar] [CrossRef]

- Pires, C.M.; Bazzo, G.C.; Barreto, P.L.M.; do Espírito Santo, C.M.; Ventura, T.F.B.; Pedra, A.G.L.M.; Rover, T.; McGovern, M.; Hayashi, L. Cultivation of the Red Seaweed Kappaphycus alvarezii Using Biofloc Effluent. J. Appl. Phycol. 2021, 33, 1047–1058. [Google Scholar] [CrossRef]

- Biancacci, C.; Visch, W.; Callahan, D.L.; Farrington, G.; Francis, D.S.; Lamb, P.; McVilly, A.; Nardelli, A.; Sanderson, J.C.; Schwoerbel, J.; et al. Optimisation of At-Sea Culture and Harvest Conditions for Cultivated Macrocystis pyrifera: Yield, Biofouling and Biochemical Composition of Cultured Biomass. Front. Mar. Sci. 2022, 9, 951538. [Google Scholar] [CrossRef]

- Mabeau, S.; Fleurence, J. Seaweed in Food Products: Biochemical and Nutritional Aspects. Trends Food Sci. Technol. 1993, 4, 103–107. [Google Scholar] [CrossRef]

- Peñalver, R.; Lorenzo, J.M.; Ros, G.; Amarowicz, R.; Pateiro, M.; Nieto, G. Seaweeds as a Functional Ingredient for a Healthy Diet. Mar. Drugs 2020, 18, 301. [Google Scholar] [CrossRef]

- Ganesan, M.; Mairh, O.P.; Eswaran, K.; Subba Rao, P.V. Effect of Salinity, Light Intensity and Nitrogen Source on Growth and Composition of Ulva fasciata Delile (Chlorophyta, Ulvales). Indian J. Mar. Sci. 1999, 28, 70–73. [Google Scholar]

- Silva, A.F.R.; Abreu, H.; Silva, A.M.S.; Cardoso, S.M. Effect of Oven-Drying on the Recovery of Valuable Compounds from Ulva rigida, Gracilaria Sp. and Fucus vesiculosus. Mar. Drugs 2019, 17, 90. [Google Scholar] [CrossRef] [PubMed]

- Fillit, M. Seasonal Changes in the Photosynthetic Capacities and Pigment Content of Ulva rigida in a Mediterranean Coastal Lagoon. Bot. Mar. 1995, 38, 271–280. [Google Scholar] [CrossRef]

- Buck, B.H.; Troell, M.F.; Krause, G.; Angel, D.L.; Grote, B.; Chopin, T. State of the Art and Challenges for Offshore Integrated Multi-Trophic Aquaculture (IMTA). Front. Mar. Sci. 2018, 5, 165. [Google Scholar] [CrossRef]

- Wyban, J.; Walsh, W.A.; Godin, D.M. Temperature Effects on Growth, Feeding Rate and Feed Conversion of the Pacific White Shrimp (Penaeus vannamei). Aquaculture 1995, 138, 267–279. [Google Scholar] [CrossRef]

- Ahmad, I.; Babitha Rani, A.M.; Verma, A.K.; Maqsood, M. Biofloc Technology: An Emerging Avenue in Aquatic Animal Healthcare and Nutrition. Aquac. Int. 2017, 25, 1215–1226. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Zahedi, S.; Mohammadi, A. Integrated Multitrophic Aquaculture (IMTA) as an Environmentally Friendly System for Sustainable Aquaculture: Functionality, Species, and Application of Biofloc Technology (BFT). Environ. Sci. Pollut. Res. 2022, 29, 67513–67531. [Google Scholar] [CrossRef] [PubMed]

- Zimmermann, S.; Kiessling, A.; Zhang, J. The Future of Intensive Tilapia Production and the Circular Bioeconomy without Effluents: Biofloc Technology, Recirculation Aquaculture Systems, Bio-RAS, Partitioned Aquaculture Systems and Integrated Multitrophic Aquaculture. Rev. Aquac. 2023, 15, 22–31. [Google Scholar] [CrossRef]

- Marinho, G.; Nunes, C.; Sousa-Pinto, I.; Pereira, R.; Rema, P.; Valente, L.M.P. The IMTA-Cultivated Chlorophyta Ulva Spp. as a Sustainable Ingredient in Nile Tilapia (Oreochromis niloticus) Diets. J. Appl. Phycol. 2013, 25, 1359–1367. [Google Scholar] [CrossRef]

- Valente, L.M.P.; Araújo, M.; Batista, S.; Peixoto, M.J.; Sousa-Pinto, I.; Brotas, V.; Cunha, L.M.; Rema, P. Carotenoid Deposition, Flesh Quality and Immunological Response of Nile Tilapia Fed Increasing Levels of IMTA-Cultivated Ulva spp. J. Appl. Phycol. 2016, 28, 691–701. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvalho, A.; Brandão, H.; Zemor, J.C.; Cardozo, A.P.; Vieira, F.N.; Okamoto, M.H.; Turan, G.; Poersch, L.H. Effect of Organic or Inorganic Fertilization on Microbial Flocs Production in Integrated Cultivation of Ulva lactuca with Oreochromis niloticus and Penaeus vannamei. Fishes 2024, 9, 191. https://doi.org/10.3390/fishes9060191

Carvalho A, Brandão H, Zemor JC, Cardozo AP, Vieira FN, Okamoto MH, Turan G, Poersch LH. Effect of Organic or Inorganic Fertilization on Microbial Flocs Production in Integrated Cultivation of Ulva lactuca with Oreochromis niloticus and Penaeus vannamei. Fishes. 2024; 9(6):191. https://doi.org/10.3390/fishes9060191

Chicago/Turabian StyleCarvalho, Andrezza, Hellyjúnyor Brandão, Julio C. Zemor, Alessandro Pereira Cardozo, Felipe N. Vieira, Marcelo H. Okamoto, Gamze Turan, and Luís H. Poersch. 2024. "Effect of Organic or Inorganic Fertilization on Microbial Flocs Production in Integrated Cultivation of Ulva lactuca with Oreochromis niloticus and Penaeus vannamei" Fishes 9, no. 6: 191. https://doi.org/10.3390/fishes9060191

APA StyleCarvalho, A., Brandão, H., Zemor, J. C., Cardozo, A. P., Vieira, F. N., Okamoto, M. H., Turan, G., & Poersch, L. H. (2024). Effect of Organic or Inorganic Fertilization on Microbial Flocs Production in Integrated Cultivation of Ulva lactuca with Oreochromis niloticus and Penaeus vannamei. Fishes, 9(6), 191. https://doi.org/10.3390/fishes9060191