At first, the experimental results obtained for global forces acting on MAVs are presented, and then detailed velocity measurements are provided for those configurations that showed the best performance.

3.1. Global Force Measurements

The lift and drag coefficients obtained from the present measurements of an MAV equipped with a flat plate are shown in

Figure 3, for two different Reynolds numbers. Regarding the lift coefficient, in the almost-linear region (α < 20°), there is only a slight dependence on the Reynolds number, as also confirmed by a comparison with reference results obtained at very different Reynolds numbers [

4,

11]. For a proper comparison with the present data, the reference data, obtained for an airfoil (AR → ∞) and for a finite wing (AR = 3.5), respectively, have been corrected to the effective angle of attack, as reported in the previous section. Also, note that all presented data refer to Reynolds numbers lower than those predicted for a full transition to a turbulent regime.

It is important to note that while there is good agreement between the present data and reference data in the linear part of the curve, differences appear when the angle of attack is approaching a stall (20° < α < 25°). For the present low-aspect-ratio MAVs, stall delay is a direct consequence of the presence of tip vortices in comparison to reference data. These data are attained for large-aspect-ratio wings, where no or strongly reduced tip vortices are present [

25]. In addition, in the stall region, as expected, the results are much more Reynolds number-dependent. Concerning the drag coefficient, the present data approach a more parabolic behavior for a small angle of attack in comparison to the reference data. This is to be expected due to the fact that the latter refer to airfoils [

11] or to slender wings [

4].

For MAVs equipped with corrugated and profiled wings, results are provided in

Figure 4. A comparison with the flat-plate configuration will be detailed in the following section, whereas here it is pointed out that for corrugated MAVs, Reynolds number dependence is even more attenuated, also at angles of attack close to stall. Even if the details of the corrugated geometries could be different (angles and lengths of linear elements), comparisons with data by Murphy and Hu [

11] are rather good. For profiled wings, differences are larger, probably due to more relevant modifications of wing profiling between present and reference conditions (profiling material and degree of tension). To this end, it is important to stress again that the present wing profiling is simply obtained by covering corrugations with a deformable film. Again, stall delay is observed for the present low-aspect-ratio MAV wings in comparison to the high-aspect-ratio wings of the reference data.

Once comparisons with some of existing data have been established, a full comparison between all configurations that were tested in the present experiments is presented in

Figure 5. Here, the lift and drag coefficients are given separately, to better highlight differences, only at the largest tested Reynolds number (Re = 1.3 × 10

5), given the substantial Reynolds number independence observed in

Figure 3.

For the lift coefficient (shown on the left in

Figure 5), the best results in terms of the maximum lift coefficient and delayed angle of stall are obtained with the profiled configurations. The corrugated ones are closer to the flat-plate geometry, while the mixed corrugated–profiled configuration shows a drastic reduction. The improvements for profiled configurations are around 0.05 in lift coefficient at α = 10° and around (2–3°) in stall angle at the maximum lift coefficient. As already reported in

Figure 4, these results are in good agreement with results presented in [

11] at similar Reynolds numbers, but not so much with those in [

4] at much smaller Reynolds numbers.

Regarding drag (on the right in

Figure 5), the best performance is related to minimum drag coefficients. Corrugated configurations without any profiling are again ruled out, whereas all profiled configurations, including the mixed one, show drag coefficients similar to or lower than the reference flat-plate configuration. Therefore, it seems that the beneficial effect in comparison to a standard wing configuration is mostly obtained due to wing surface modifications due to elastic profiling, rather than to surface large-scale roughness, due to corrugations.

To summarize the performance of MAVs equipped with different wings, the ratio between the lift and drag coefficients and the so-called polar curves are reported in

Figure 6. In agreement with previous findings, the lift-to-drag ratio, which is also related to wing efficiency in aerodynamics, is definitely superior, more than 1.5 times, for the MAV model equipped with profiled wings. In comparison to the flat-plate configuration, the smoothed profiled corrugation (Profiled 2) also attains good performance. All corrugated wing configurations, including the mixed one, have very poor performance, even in comparison to the flat plate. The polar curves, also reported in

Figure 6, show that the data are close to a parabolic curve in all conditions, which is also indicated in the figure. This is a direct indication of the important effect of tip vortices for the present low-aspect-ratio wings. Indeed, tip vortices induce a dependence of the drag coefficient on the square of the lift coefficient, as obtained from finite wing theory [

25]. Minor deviations from parabolic behavior are due to deviations from the isolated wing configurations, as in the present measurements where whole MAV vehicles are considered.

By considering the amount of measured differences between the geometries shown in

Figure 5 and

Figure 6, it is important to point out that the present results establish the improved performance of profiling over corrugation, regardless of the specific details used in corrugated and profiled wings. So far, results regarding global force indicate that the major advantage obtained from the tested MAV wing configurations is related to the effect of deformation of the wing under local fluid phenomena, so that the local wing shape proves to be more important than local roughness. Detailed velocity measurements over the wing were performed to clarify this aspect.

3.2. Local Velocity Measurements

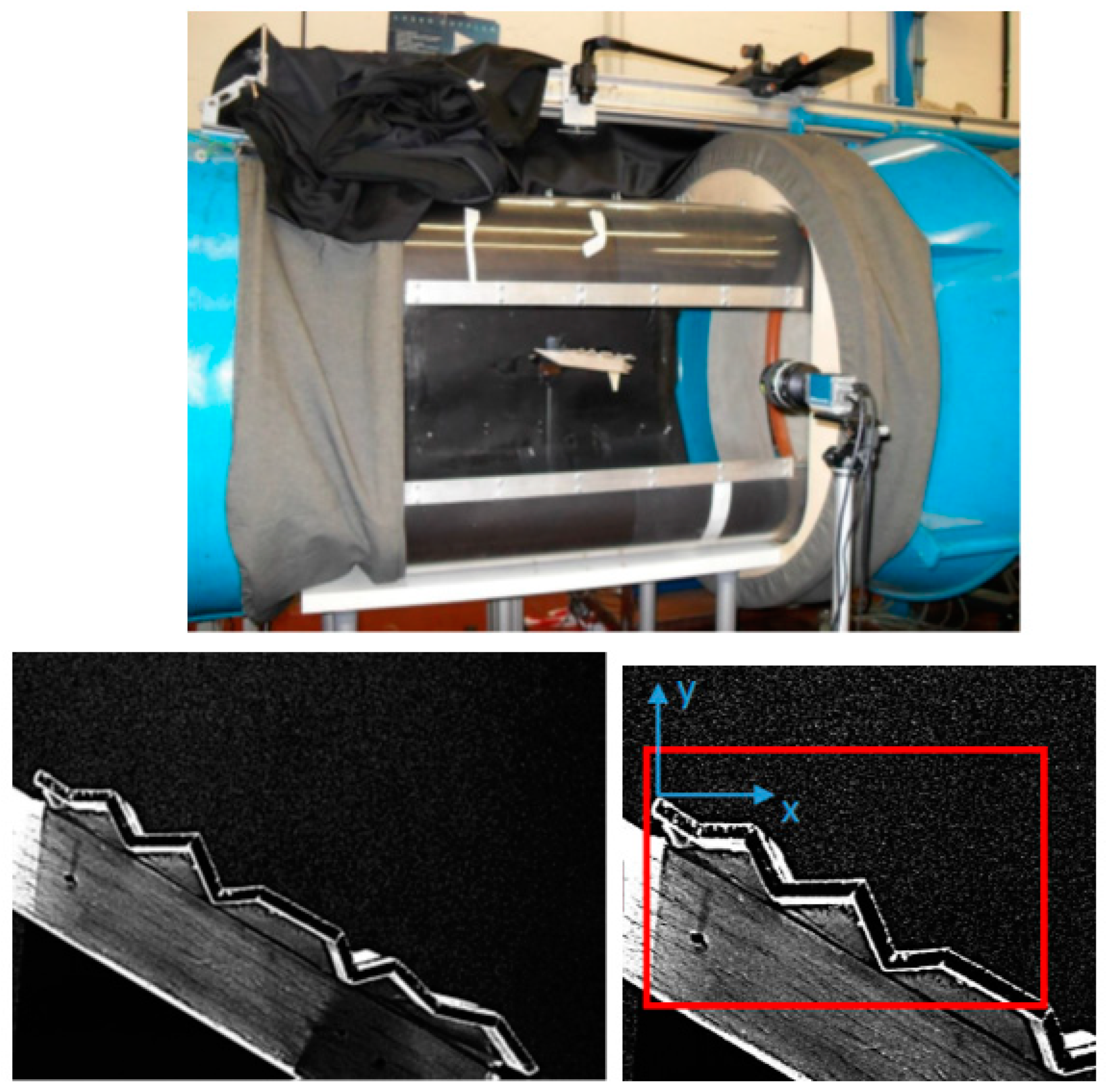

As previously reported, detailed velocity measurements are provided only for the following: the reference flat-plate configuration, the profiled configuration with the best performance and the corrugated configuration. Velocity tests have been performed at a Reynolds number equal to Re = 105.

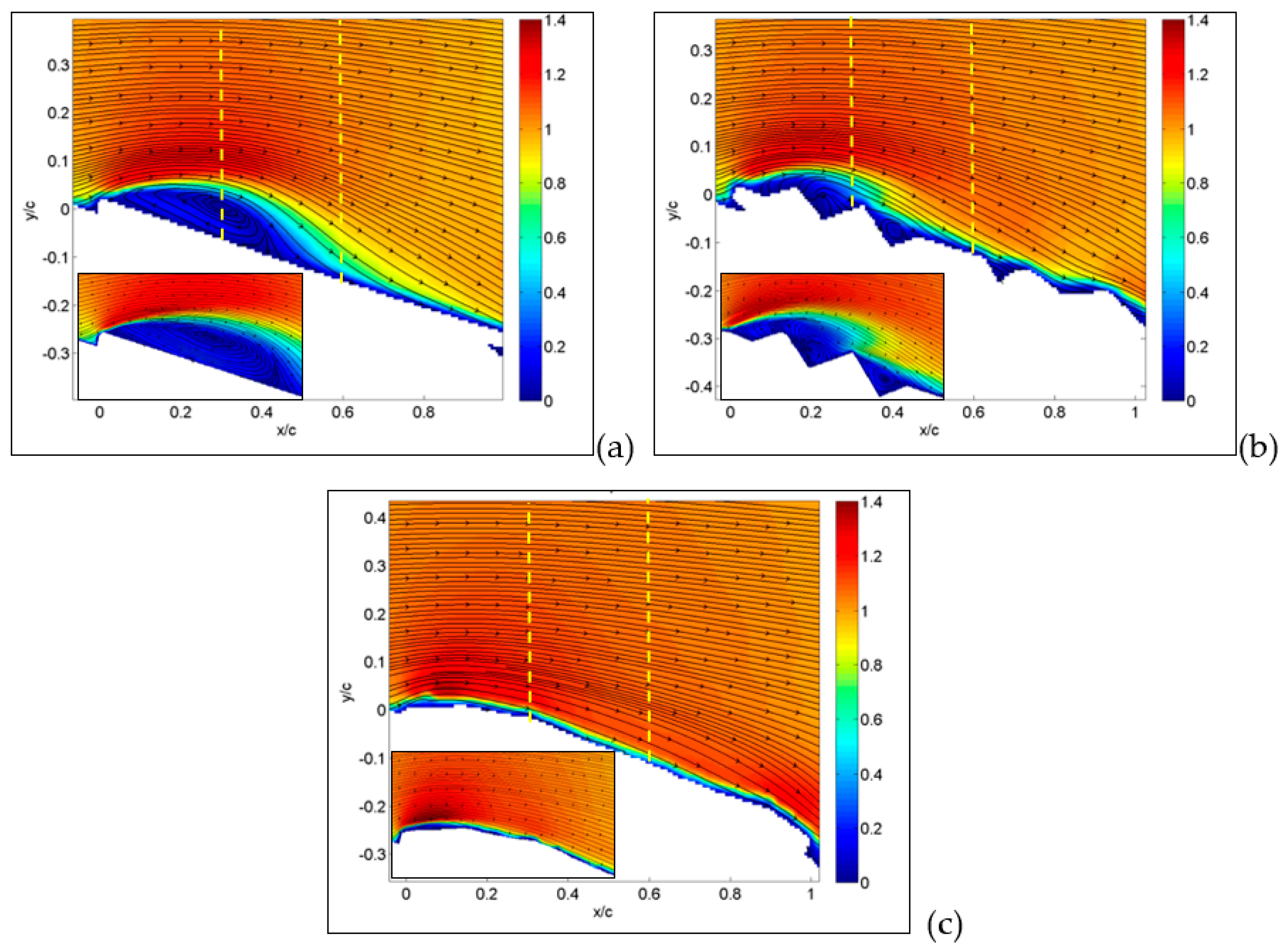

The first result deals with an angle of attack equal to 15° for the large-field-of-view image, as reported in

Figure 7, where absolute values of velocity and streamlines are presented. This angle of attack is in the middle of the region where the lift coefficient is almost linear and the drag coefficient is nearly parabolic. In these conditions, the MAV with a flat plate (a) already shows a separation region starting from the wing leading edge, indicated in dark blue in the figure. As expected, over the upper part of the wing surface, there is an increase in velocity in comparison to free-stream conditions.

This view is confirmed in the inset, obtained from measurements on a smaller field of view, i.e., with a higher resolution. The origin of separation is clearly related to the flat plate leading edge.

For the corrugated case (b), the separation is significantly reduced in comparison to the flat plate, and velocity decrements are observed in cavity regions over the upper part of the wing. The inset shows how recirculation is generated in each cavity of the corrugated wing. For the MAV with a profiled wing, even in the detailed flow view, no separation and no relevant reductions in velocity over the wing surface were observed, except for the boundary layer close to the surface.

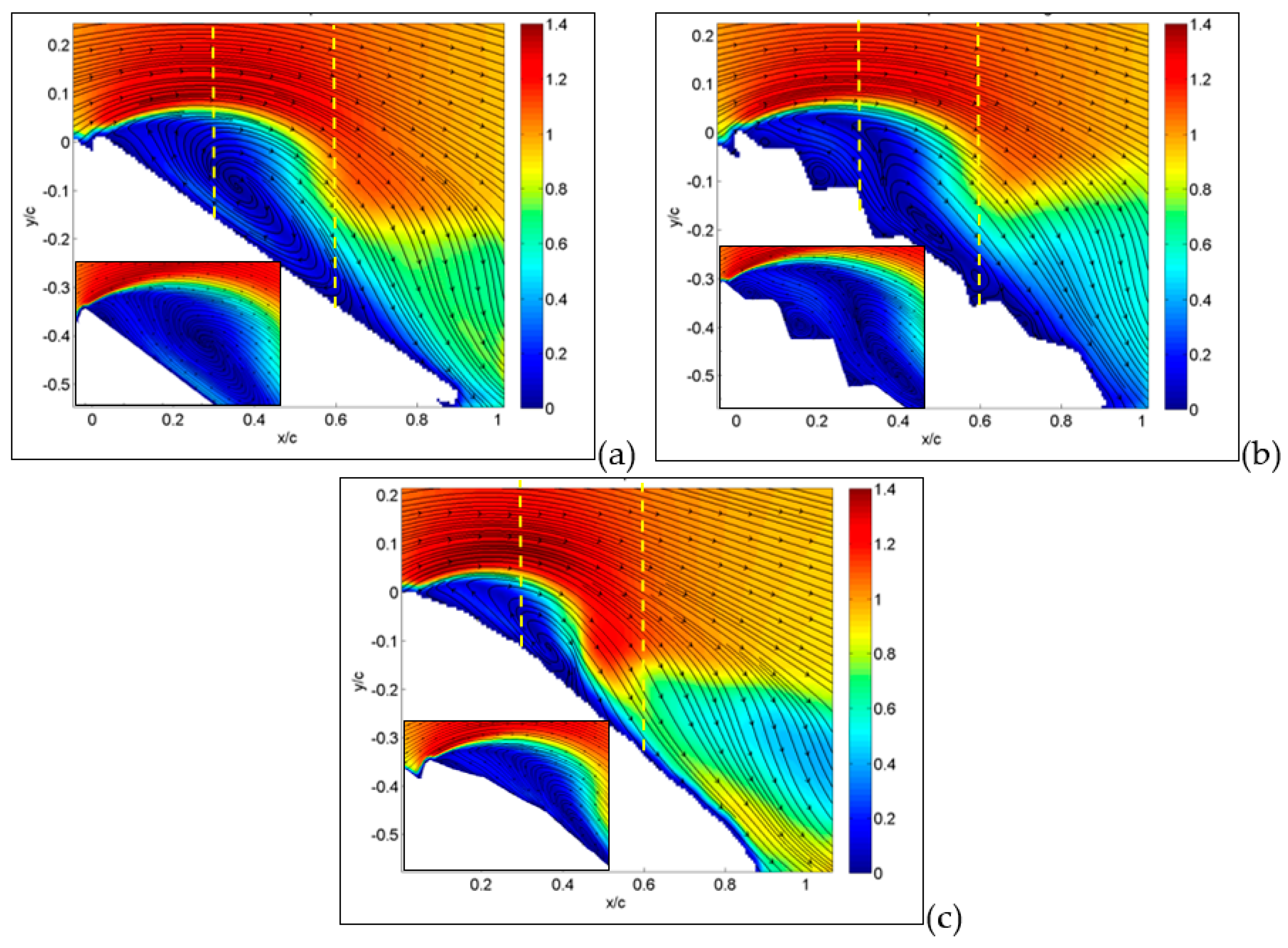

The situation is quite different when the angle of attack is increased up to 30°, which is the angle of stall for corrugated configuration. As shown in

Figure 8a,b, for the MAV with flat and corrugated wings, large separations are now clearly visible, extending over almost the entire upper surface, in a similar way for the two.

However, as recovered by the inspection of the small portions of the leading edge, while there is only a major large separation in the case of the flat plate, there are several recirculation regions in the case of the corrugated wing, related to each cavity. It seems that these are responsible for the large part of separation.

On the other hand, the separation is only at the starting level for the MAV with a profiled wing, as observed in

Figure 8c. Moreover, there is a clear reattachment of the fluid around one half of the chord, which indicates a partial recover of lift, as reported in

Figure 5. This situation is also almost unchanged up to an angle of attack of 36°, shown in

Figure 9, where the flow field is fully separated for the flat-plate and corrugated configurations, while being quite largely separated for the profiled case. In this last case, there is still a small portion of the wing’s upper surface (almost 25%) with flow still attached, still giving some lift so far.

In order to obtain information on the nature of the separation regions, detailed instantaneous and average vorticity maps are presented in

Figure 10, for an incidence angle equal to 15° and for a large field of view. For each MAV configuration, the average vorticity map (on the left) and one instantaneous plot (on the right) are shown, so that it is possible to derive how the average is obtained from moving instantaneous vortices.

Considering the flat plate (

Figure 10a), on average, it is possible to observe a well-defined layer, detaching exactly from the plate leading edge. By looking at the instantaneous plot, it is noticed how this layer is composed by clockwise vortices (in red) generated at the leading edge, over several counter-clockwise vortices (in blue) close to the flat plate surface. This sequence generates an adverse layer in the average plot (in blue), which is maintained down to the reattachment point, where the attached boundary layer growth restarts (in red, indicated by the black arrow).

For the corrugated wing, at this angle of incidence, the situation is similar, but as noticed, the presence of corrugation enables the reduction in the vorticity layer and the generation of less organized instantaneous clockwise and counter-clockwise vortices. This reduces the extension of the adverse layer and of the separation region, being replaced by a sequence of vortices in the wake of each corrugation.

When the wing is profiled, as in the third MAV configuration, the vorticity layer is fully attached to the curved upper surface, without separation and with no individual vortices in the instantaneous plot. The same analysis is repeated for an angle of incidence equal to 30°, as shown in

Figure 11. The first two cases, the flat plate and corrugated wing (

Figure 11a,b), point out a larger extension of the upper vorticity layer in the average field in comparison to the situation at a smaller angle of attack. In addition, a larger number of counter-clockwise vortices is observed in the instantaneous plots. So far, the overall picture confirms that separation takes place over the entire wing upper surface. From this point of view, the flow dynamics over the flat plate and the corrugated wing are not different. On the other hand, the profiled wing still shows a limited vorticity layer extension in comparison to the other two configurations. Vortex reattachment over the wing upper surface is attained around 50% of the chord, similarly to the other two configurations at a lower angle of incidence.

The last quantity to be considered from velocity measurements is the

rms of velocity retaining information on turbulent fluctuations. The contribution of each velocity component to such fluctuations is similar, so they are presented together in

Figure 12. For the flat plate, shown in

Figure 12a, the wing leading edge acts as a sharp turbulence generator, i.e., an abrupt change in geometry that stimulates large turbulence fluctuations all over the separation region. For the corrugated condition, shown in

Figure 12b, turbulence generation also includes the first corrugation and is overlapped with sharp turbulence generation over the second corrugation, as indicated by the arrow in the small-field-of-view enlargement. The interaction between these two large fluctuation regions allows flow reattachment on a shorter distance in comparison to the flat plate. On the other hand, no major generation of turbulence is obtained for the profiled wing, as shown in

Figure 12c. When the angle of attack is increased up to 30°, as shown in

Figure 13, this phenomenon is even more evident, but in this case, turbulence generation from corrugations is not sufficiently strong to interact with that from the leading edge. Therefore, there is no reattachment for corrugated and flat-plate configurations, as shown in

Figure 13a,b, whereas it is observed for the profiled condition, as shown in

Figure 13c.

The reason the profiled configuration still performs so well at such a large angle of incidence is that the deformation and oscillations of the profiled surface generate increased turbulence intensity (larger than 30%) in comparison to other two cases. This reduces the energy of the incoming flow, being converted to turbulence, so it allows flow reattachment—even at this large incidence angle—and the deviation of turbulence production towards the wing surface.

It is interesting to see that for an angle of incidence as large as 36°, as presented in

Figure 14a,b for the flat plate and corrugated wings, turbulence production is moved very far from the wing upper surface. This indicates that complete flow separation occurs for these conditions. On the other hand, for the profiled wing, as shown in

Figure 14c, the region of large turbulence fluctuations is still close to the wing upper surface, allowing a small amount of flow reattachment on the wing surface.

From previous plots, global information has been derived, whereas more detailed comparisons can be made by considering profiles along a line, as reported in the following section. Hereafter, profiles are taken along the vertical direction as in the yellow dashed lines plotted in

Figure 7,

Figure 8 and

Figure 9. So far, in

Figure 15, profiles of normalized streamwise velocity at a distance from the leading edge equal to x/c = 0.3 are compared for the three tested MAV configurations and for angles of incidence equal to 15°, 30° and 36°. In these plots, consider that position y/c = 0 corresponds to the wing surface, where velocity must vanish, whereas moving to the right corresponds to increasing distance from the surface.

At 15° (

Figure 15a), only the MAV equipped with a flat plate already shows a separation region with negative streamwise velocities, with the other two showing more or less steep profiles with positive velocities (no separation). At an angle of 30° (

Figure 15b), all three profiles show separation, though it is less extended for the profiled configurations in comparison to the other two, which are quite similar. The last plot at 36° confirms this picture, also indicating similarity between the three, so that it is possible to state that separation for all conditions originated in the form of a leading-edge stall (stall from the initial part of the wing).

In

Figure 16, this comparison is reported at a distance from the leading edge equal to x/c = 0.6. Also, profiles at this position are indicated by yellow dashed lines in

Figure 7,

Figure 8 and

Figure 9. From previous results, at this position, separation is expected only around stall angles or larger. Indeed, at an angle of incidence equal to 15° (

Figure 16a), all three configurations presented a large positive velocity gradient, thus confirming that separation and related recirculation still did not reach this position and that the flow was still attached here. For an angle equal to 30° (

Figure 16b), a small recirculation appeared for the corrugated and flat-plate configurations, whereas the profiled one still exhibited a positive gradient followed by extended regions of almost constant velocity, equal to around 0.4–0.5 times the free stream velocity. This last behavior indicates that for the profiled configuration, the external flow is not trapped in a recirculation region but still flows over the wing surface, even if not as efficiently as in pre-stall conditions. For an angle of incidence equal to 36° (

Figure 16c), corrugated and flat-plate data show separation over large distances from wing surface. Again, they followed a similar behavior, whereas the profiled configuration remained attached, with a constant-velocity region extending at a large distance from the wing surface.

The detailed vertical profiles of

rms streamwise velocity are reported in

Figure 17 and

Figure 18 at the same axial distances and incidence angles as in the last two figures. Yellow dashed lines indicate the positions of these vertical profiles in

Figure 12,

Figure 13 and

Figure 14. For the flat plate, at α = 15° (

Figure 17a), fluctuations are very large (over 30%) in a region close to the wing surface (y/c = 0.2 for the flat plate). This is just the region where a layer formed by moving small-scale vortices is present. A similar situation is observed for the corrugated MAV, albeit with smaller intensity. For the profiled condition, only a small increase in

rms is observed towards the wing surface (around 5%). This indicates that no production of turbulence is present in this case. When the angle of incidence is increased, as shown in

Figure 17b,c, the situation is very similar between the three configurations. High fluctuations (over 25%) are observed at different distances from the wing surface, increasing with the angle of incidence and depending on the specific configuration. The flat-plate and corrugated configurations are more and more similar as the angle of attack increases.

When profiles are compared at a distance x/c = 0.6 and a small angle of incidence, as shown in

Figure 18a, all

rms profiles are equivalent to those observed close to solid walls, i.e., a continuous increase in turbulence intensity for decreasing wall distance and then a rapid decrease to zero at the wall (y/c = 0), indicating almost no separation. At an angle of 30°, as shown in

Figure 18b, the peak due to separation in the external region starts to appear in the flat-plate and corrugated configurations, whereas the profiled one still keeps an almost regular increase towards the wall, as in the case of no separation. Lastly, at 36°, as shown in

Figure 18c, the separation extends all over the investigated region for all configurations.