The Bioinspired Prosumer—Interactions between Bioinspired Design Methods in the Prosumer Scope

Abstract

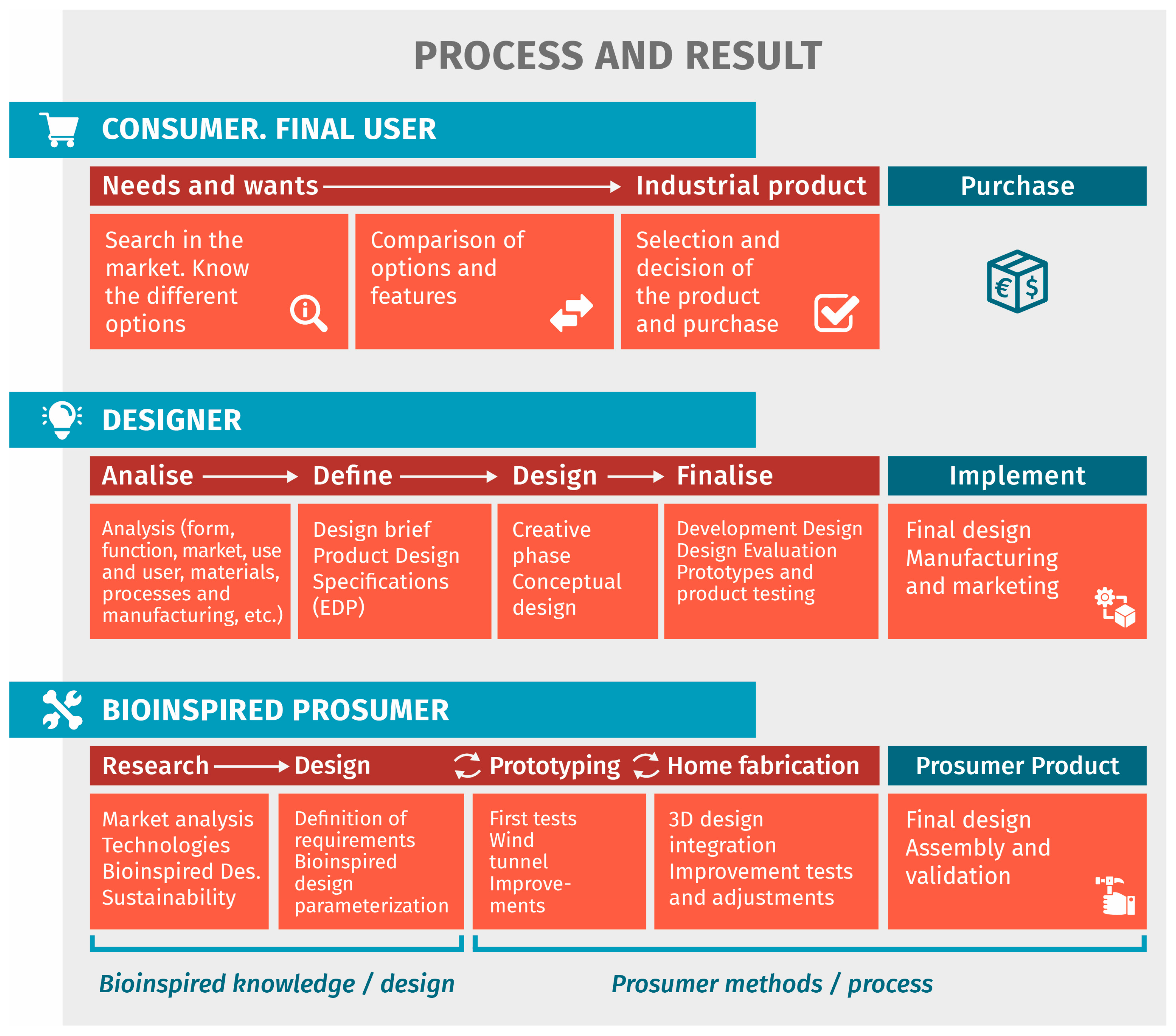

:1. Introduction

2. Materials and Methods

2.1. Research

2.2. Customized Design

2.3. Prototyping

2.4. Manufacturing

2.5. Validation

3. Results

3.1. Research

3.1.1. The Bicycle Flashlight Market

3.1.2. Understanding Microturbines Operation and Performance

3.1.3. Bioinspired Design

3.1.4. Design Brief

3.2. Custom-Made Design

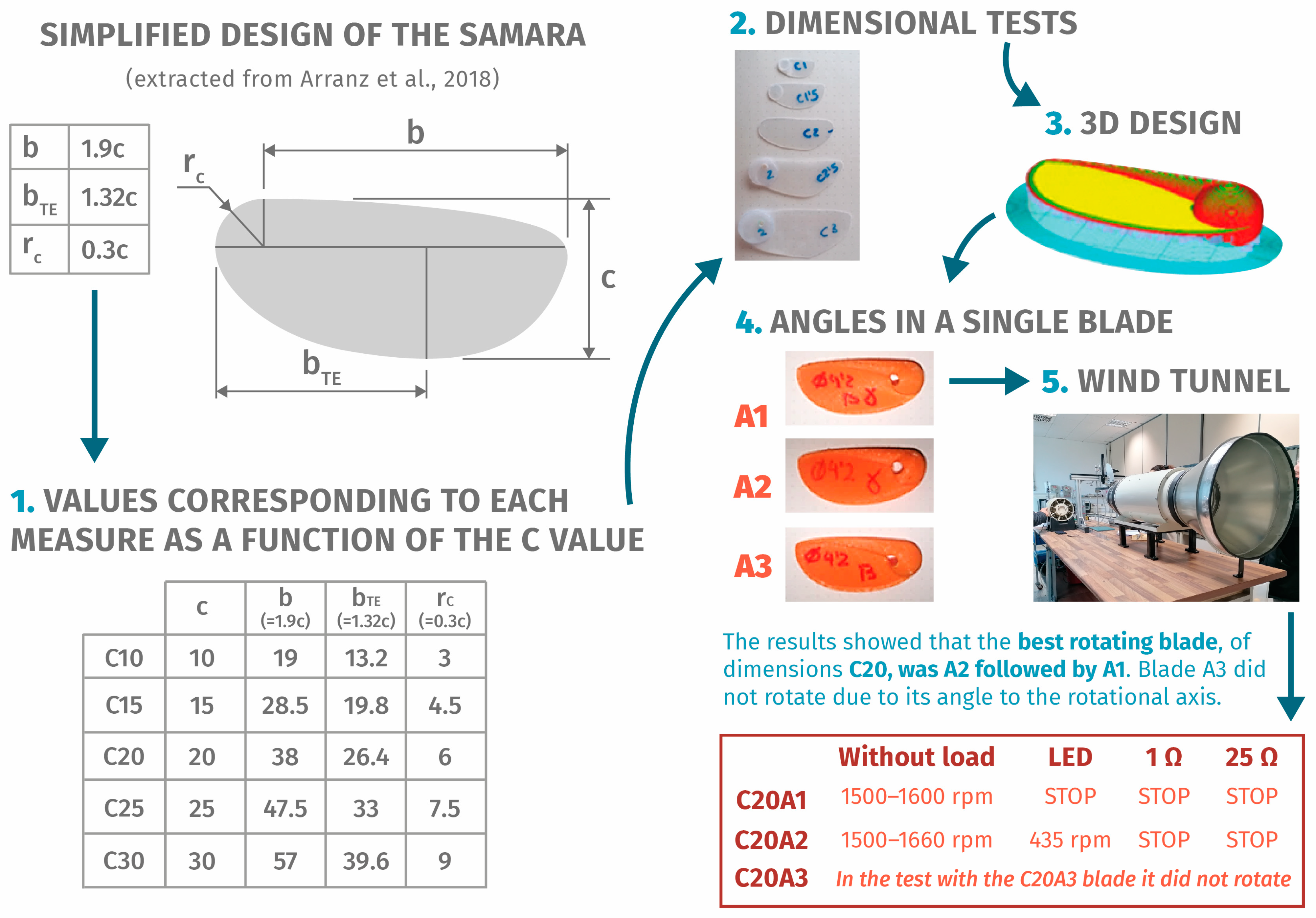

3.3. Prototyping

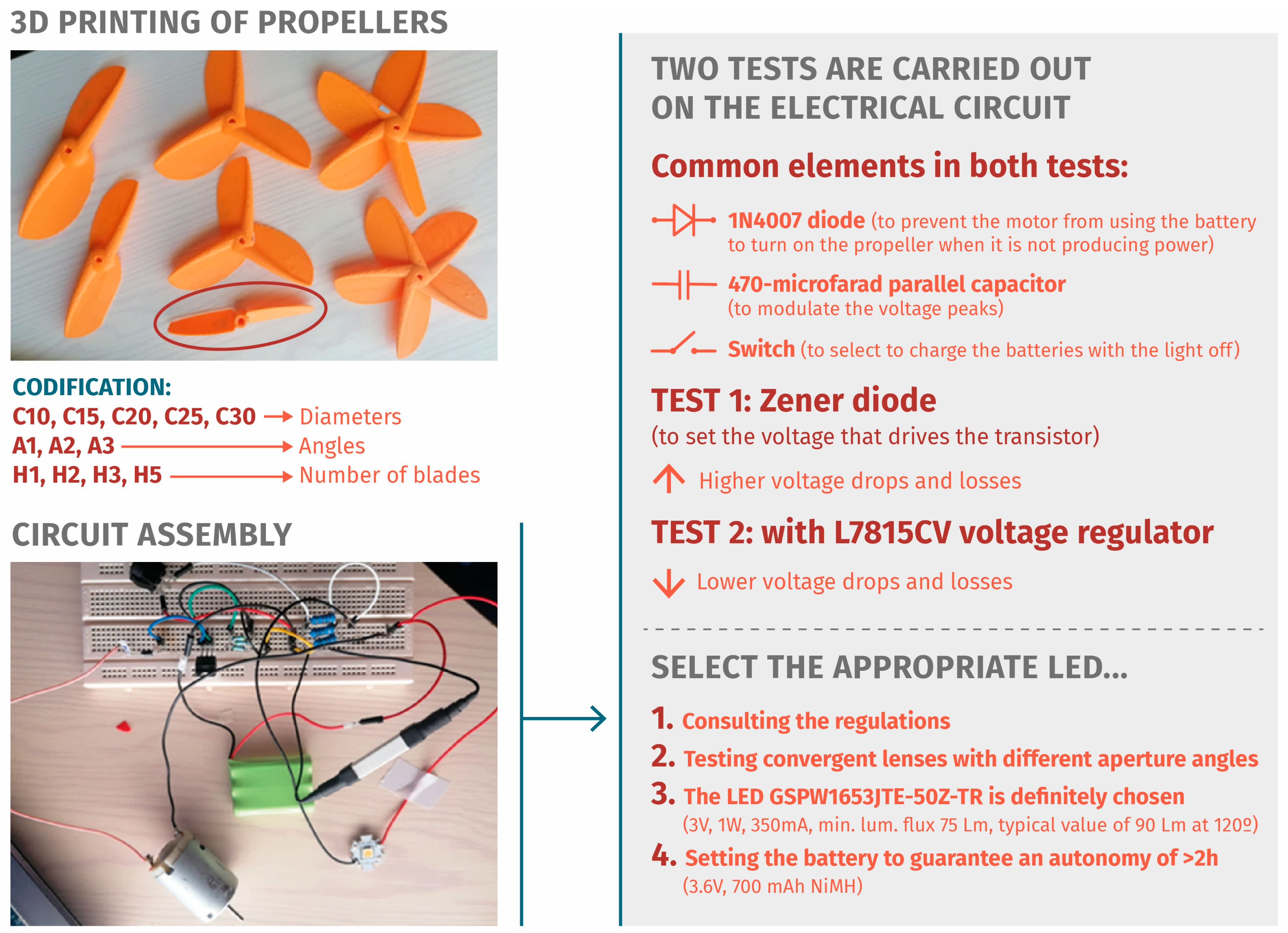

Conceptual Design Review

3.4. Experimentation and Final Validation

3.5. Manufacturing and Home Fabrication

Final Assembly, Adjustment, and Validation

4. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Whitesides, G.M. Bioinspiration: Something for Everyone. Interface Focus 2015, 5, 20150031. [Google Scholar] [CrossRef] [PubMed]

- Fu, K.; Moreno, D.; Yang, M.; Wood, K.L. Bio-Inspired Design: An Overview Investigating Open Questions From the Broader Field of Design-by-Analogy. J. Mech. Des. 2014, 136, 111102. [Google Scholar] [CrossRef]

- Wanieck, K.; Fayemi, P.E.; Maranzana, N.; Zollfrank, C.; Jacobs, S. Biomimetics and Its Tools. Bioinspired Biomim. Nanobiomater. 2016, 6, 53–66. [Google Scholar] [CrossRef]

- Ritzer, G.; Dean, P.; Jurgenson, N. The Coming of Age of the Prosumer. Am. Behav. Sci. 2012, 56, 379–398. [Google Scholar] [CrossRef]

- Fiş Erümit, S.; Karakuş Yılmaz, T. Gamification Design in Education: What Might Give a Sense of Play and Learning? Technol. Knowl. Learn. 2022, 27, 1039–1061. [Google Scholar] [CrossRef]

- Millard, J.; Sorivelle, M.N.; Katsikis, O.K.; Unterfrauner, E.; Voigt, C. The Maker Movement in Europe: Empirical and Theo-retical Insights into Sustainability. In Proceedings of the EPiC Series in Computing. ICT4S2018. 5th International Conference on In-formation and Communication Technology for Sustainability; Penzenstadler, B., Easterbrook, S., Venters, C., Ahmed, S.I., Eds.; Epic Computing: Toronto, ON, Canada, 2018; pp. 210–227. [Google Scholar]

- López-Forniés, I.; Asión-Suñer, L. Analysing the Prosumer Opportunity. Prosumer Products’ Success or Failure. J. Eng. Des. 2024, 35, 1–21. [Google Scholar] [CrossRef]

- Lang, B.; Botha, E.; Robertson, J.; Kemper, J.A.; Dolan, R.; Kietzmann, J. How to Grow the Sharing Economy? Create Prosumers! Australas. Mark. J. 2020, 28, 58–66. [Google Scholar] [CrossRef]

- Metta, J.; Bachus, K. Mapping the Circular Maker Movement: From a Literature Review to a Circular Maker Passport. Deliverable 2020, 2, 68. [Google Scholar]

- Jorquera Ortega, A. Fabricación Digital: Introducción al Modelado e Impresión 3D; Serie diseño y autoedición; Jorquera, O., Ed.; Subdirección General de Aprendizaje a lo largo de la vida. Aula Mentor: Madrid, Spain, 2017. [Google Scholar]

- López-Forniés, I. Concept Assessment Using Objective-Based Metrics on Functional Models. In Design Tools and Methods in Industrial Engineering II; Rizzi, C., Campana, F., Bici, M., Gherardini, F., Ingrassia, T., Cicconi, P., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 320–327. [Google Scholar]

- Benyus, J.M. Biomimicry: Innovation Inspired by Nature; Perennial (Harper Collins): New York, NY, USA, 2002; Reprint; ISBN 978-0688160999. [Google Scholar]

- Speck, O.; Speck, D.; Horn, R.; Gantner, J.; Sedlbauer, K.P. Biomimetic Bio-Inspired Biomorph Sustainable? An Attempt to Classify and Clarify Biology-Derived Technical Developments. Bioinspir Biomim. 2017, 12, 011004. [Google Scholar] [CrossRef]

- Asión Suñer, L.; López Forniés, I. El Diseño Modular en la Creación de Productos Para Prosumer; Universidad de Zaragoza: Zaragoza, Spain, 2022. [Google Scholar]

- Pentelovitch, N.; Nagel, J.K. Understanding the Use of Bio-Inspired Design Tools by Industry Professionals. Biomimetics 2022, 7, 63. [Google Scholar] [CrossRef]

- López-Forniés, I.; Asión-Suñer, L. Prosumer Concept: Current Status and Possible Future Developments. Dyna 2023, 98, 439–441. [Google Scholar] [CrossRef] [PubMed]

- López-Forniés, I.; Asión-Suñer, L. Self-Commissioning, Intuition and Prosumer. Proy. Ind. Des. J. 2023, 56, 109–137. [Google Scholar] [CrossRef]

- Mead, T.; Coley, D.; Borden, D.S. Navigating the Tower of Babel: The Epistemological Shift of Bioinspired Innovation. Biomimetics 2020, 5, 60. [Google Scholar] [CrossRef]

- Barbosa, J.; Arruda, A.; Laila, T.; Moura, E. Biomimicry as Metodological Tool for Technical Emancipation of Peripheral Countries. In Advances in Ergonomics in Design; Rebelo, F., Soares, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 349–356. [Google Scholar]

- Bobbe, T.; Krzywinski, J.; Woelfel, C. A Comparison of Design Process Models from Academic Theory and Professional Practice. In DS 84: Proceedings of the DESIGN 2016 14th International Design Conference; DESIGN SOCIETY: Dubrovnik, Croatia, 2016; Volume DS 84. [Google Scholar]

- Fayemi, P.E.; Wanieck, K.; Zollfrank, C.; Maranzana, N.; Aoussat, A. Biomimetics: Process, Tools and Practice. Bioinspir Biomim. 2017, 12, 011002. [Google Scholar] [CrossRef] [PubMed]

- Salgueiredo, C.F.; Hatchuel, A. Beyond Analogy: A Model of Bioinspiration for Creative Design. Artif. Intell. Eng. Des. Anal. Manuf. 2016, 30, 159–170. [Google Scholar] [CrossRef]

- Nielsen, K.R. Policymakers’ Views on Sustainable End-User Innovation: Implications for Sustainable Innovation. J Clean. Prod. 2020, 254, 120030. [Google Scholar] [CrossRef]

- BenMahmoud-Jouini, S.; Midler, C. Unpacking the Notion of Prototype Archetypes in the Early Phase of an Innovation Process. Creat. Innov. Manag. 2020, 29, 49–71. [Google Scholar] [CrossRef]

- Hodges, S.; Fraser, M. Citizen Manufacturing: Unlocking a New Era of Digital Innovation. IEEE Pervasive Comput. 2022, 21, 42–51. [Google Scholar] [CrossRef]

- Asión-Suñer, L.; López-Forniés, I. Review of Product Design and Manufacturing Methods for Prosumers. In Advances on Mechanics, Design Engineering and Manufacturing III. JCM 2020. Lecture Notes in Mechanical Engineering International Joint Conference on Mechanics, Design Engineering & Advanced Manufacturing; Roucoules, L., Paredes, M., Eynard, B., Morer Camo, P., Rizzi, C., Eds.; Springer Nature: Cham, Switzerland, 2021; pp. 128–134. [Google Scholar] [CrossRef]

- Asión-Suñer, L.; López-Forniés, I. Adoption of Modular Design by Makers and Prosumers. A Survey. Proc. Des. Soc. 2021, 1, 355–364. [Google Scholar] [CrossRef]

- Asión-Suñer, L.; López-Forniés, I.; Rostomyan, G. Conceptualization of modular products for the prosumer. A design workshop. Dyna 2023, 98, 23–28. [Google Scholar] [CrossRef]

- Autodesk, Inc. Instructables. Available online: https://www.instructables.com/ (accessed on 27 June 2024).

- Autodesk Instructables Wind Turbine. Available online: https://www.instructables.com/search/?q=wind%20turbine&projects=all (accessed on 27 June 2024).

- Lin, Z.C.; Hong, G.E.; Cheng, P.F. A Study of Patent Analysis of LED Bicycle Light by Using Modified DEMATEL and Life Span. Adv. Eng. Inform. 2017, 34, 136–151. [Google Scholar] [CrossRef]

- Surya, S. Development of Wind Torch for Bicycles. In Proceedings of the 2014 IEEE Region 10 Humanitarian Technology Conference (R10 HTC), Chennai, India, 6–9 August 2014; pp. 1–4. [Google Scholar]

- Tummala, A.; Velamati, R.K.; Sinha, D.K.; Indraja, V.; Krishna, V.H. A Review on Small Scale Wind Turbines. Renew. Sustain. Energy Rev. 2016, 56, 1351–1371. [Google Scholar] [CrossRef]

- Arranz, G.; Moriche, M.; Uhlmann, M.; Flores, O.; García-Villalba, M. Kinematics and Dynamics of the Auto-Rotation of a Model Winged Seed. Bioinspir Biomim. 2018, 13, 036011. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.K.; Ahmed, M.R. Blade Design and Performance Testing of a Small Wind Turbine Rotor for Low Wind Speed Applications. Renew. Energy 2013, 50, 812–819. [Google Scholar] [CrossRef]

- Okda, Y.M. El Design Methods of Horizontal Axis Wind Turbine Rotor Blades. Int. J. Ind. Electron. Drives 2015, 2, 135–150. [Google Scholar] [CrossRef]

- Bar-Cohen, Y. Biomimetics—Using Nature to Inspire Human Innovation. Bioinspir Biomim. 2006, 1, P1–P12. [Google Scholar] [CrossRef]

- Bar-Cohen, Y. Biomimetics: Biologically Inspired Technologies; Bar-Cohen, Y., Ed.; CRC/Taylor & Francis: Boca Raton, FL, USA, 2006; ISBN 0849331633/9780849331633. [Google Scholar]

- Vincent, J.F.V.; Bogatyreva, O.A.; Bogatyrev, N.R.; Bowyer, A.; Pahl, A.-K. Biomimetics: Its Practice and Theory. J. R. Soc. Interface 2006, 3, 471–482. [Google Scholar] [CrossRef]

- Cohen, E.A.; Vogel, S. Cat’s Paws and Catapults: Mechanical Worlds of Nature and People; WW Norton & Company: New York, NY, USA, 2010; ISBN 0393319903/9780393319903. [Google Scholar]

- Keshwani, S.; Casakin, H. Comparing Analogy-Based Methods—Bio-Inspiration and Engineering-Domain Inspiration for Domain Selection and Novelty. Biomimetics 2024, 9, 344. [Google Scholar] [CrossRef]

- Full, R.J.; Bhatti, H.A.; Jennings, P.; Ruopp, R.; Jafar, T.; Matsui, J.; Flores, L.A.; Estrada, M. Eyes Toward Tomorrow Program Enhancing Collaboration, Connections, and Community Using Bioinspired Design. Integr. Comp. Biol. 2021, 61, 1966–1980. [Google Scholar] [CrossRef] [PubMed]

- Zakaria, M.Y.; dos Santos, C.R.; Dayhoum, A.; Marques, F.D.; Hajj, M.R. Modeling and Prediction of Aerodynamic Characteristics of Free Fall Rotating Wing Based on Experiments. IOP Conf. Ser. Mater. Sci. Eng. 2019, 610, 012098. [Google Scholar] [CrossRef]

- Azuma, A.; Yasuda, K. Flight Performance of Rotary Seeds. J. Theor. Biol. 1989, 138, 23–53. [Google Scholar] [CrossRef]

- Yasuda, K.; Azuma, A. The Autorotation Boundary in the Flight of Samaras. J. Theor. Biol. 1997, 185, 313–320. [Google Scholar] [CrossRef]

- Azuma, A.; Okuno, Y. Flight of a Samara, Alsomitra Macrocarpa. J. Theor. Biol. 1987, 129, 263–274. [Google Scholar] [CrossRef]

- Ulrich, E.R.; Pines, D.J.; Humbert, J.S. From Falling to Flying: The Path to Powered Flight of a Robotic Samara Nano Air Vehicle. Bioinspir Biomim. 2010, 5, 045009. [Google Scholar] [CrossRef] [PubMed]

- Nave, G.K.; Hall, N.; Somers, K.; Davis, B.; Gruszewski, H.; Powers, C.; Collver, M.; Schmale, D.G.; Ross, S.D. Wind Dispersal of Natural and Biomimetic Maple Samaras. Biomimetics 2021, 6, 23. [Google Scholar] [CrossRef] [PubMed]

- El Makdah, A.M.; Sanders, L.; Zhang, K.; Rival, D.E. The Stability of Leading-Edge Vortices to Perturbations on Samara-Inspired Rotors: A Novel Solution for Gust Resistance. Bioinspir Biomim. 2020, 15, 016006. [Google Scholar] [CrossRef]

- Gaitan-Aroca, J.; Sierra, F.; Contreras, J.U.C. Bio-Inspired Rotor Design Characterization of a Horizontal Axis Wind Turbine. Energies 2020, 13, 3515. [Google Scholar] [CrossRef]

- Ikeda, T.; Tanaka, H.; Yoshimura, R.; Noda, R.; Fujii, T.; Liu, H. A Robust Biomimetic Blade Design for Micro Wind Turbines. Renew. Energy 2018, 125, 155–165. [Google Scholar] [CrossRef]

- Mulligan, R. Bio-Inspired Aerofoils for Small Wind Turbines. Renew. Energy Power Qual. J. 2020, 18, 753–758. [Google Scholar] [CrossRef]

- Siram, O.; Saha, U.K.; Sahoo, N. Blade Design Considerations of Small Wind Turbines: From Classical to Emerging Bio-Inspired Profiles/Shapes. J. Renew. Sustain. Energy 2022, 14, 042701. [Google Scholar] [CrossRef]

- Herrera, C.; Correa, M.; Villada, V.; Vanegas, J.D.; García, J.G.; Nieto-Londoño, C.; Sierra-Pérez, J. Structural Design and Manufacturing Process of a Low Scale Bio-Inspired Wind Turbine Blades. Compos. Struct. 2019, 208, 1–12. [Google Scholar] [CrossRef]

- McKegney, J.M.; Shen, X.; Zhu, C.; Xu, B.; Yang, L.; Dala, L. Bio-Inspired Design of Leading-Edge Tubercles on Wind Turbine Blades. In Proceedings of the 2022 7th International Conference on Environment Friendly Energies and Applications (EFEA), Bagatelle, Mauritius, 14–16 December 2022; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2022. [Google Scholar]

- Omidvarnia, F.; Sarhadi, A. Nature-Inspired Designs in Wind Energy: A Review. Biomimetics 2024, 9, 90. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Directorate-General for Mobility and Transport Traffic Rules and Regulations for Cyclists. Available online: https://road-safety.transport.ec.europa.eu/eu-road-safety-policy/priorities/safe-road-use/cyclists/traffic-rules-and-regulations-cyclists-and-their-vehicles_en (accessed on 22 November 2023).

- Memestra. Hollow Wood Surfboard-Plywood and Cedar. Available online: https://www.Instructables.Com/Hollow-Wood-Surfboard/ (accessed on 13 October 2022).

- Hoogvliet, N. (Ed.) Studio Nienke Hoogvliet Fish Leather; Drukkerij Tienkamp: Den Haag, The Netherlands, 2017. [Google Scholar]

| Phases | Objectives | Actions and Methods |

|---|---|---|

| Research | Understanding the market for flashlights and microturbines Search for bioinspired references; know the biological principle of the seeds Understanding sustainability and circular economy issues Defining needs | Market analysis, similar features/functionality Microturbine analysis Bioinspired case studies Sustainable design rule integration Writing the brief |

| Customized Design | Conceptual design; custom-made design Establish the dimensions of the blades for the first tests Know how the wind tunnel works | Conceptual design; preliminary design of blades and schematic or grid of component blocks Recover old motors, LED, and lenses for testing |

| Prototyping | Experimentation and validation Tests with recovered generators and various LED final tests Calculation of electrical components | Three-dimensional printing, first tests Wind tunnel laboratory experimentation Electrical circuit design and optimization |

| Manufacturing | Carrying out the geometric design Integrating all components Three-dimensional printing final esthetic design | Three-dimensional printing; esthetic design Adjustment of anchorages on bicycles |

| Validation | Actual assembly, adjustment and testing | First real tests of the prosumer product |

| Component | Specifications |

|---|---|

| Light | One 1–3 W LED; focusing/converging lens |

| Legal | A white light source that must reach at least 150 m with an illumination of 4–60 candelas (12.6 Lm to 188.5 Lm at 120°) and facing forward in the direction of the axis of motion [57] |

| Power | Autonomous charging by bicycle movement; micro-wind turbine; use of rechargeable batteries type AA or AAA |

| Circuit | Electronic circuit board for battery charging and illumination; selector for charging or charging with illumination |

| Generator | Recycled motors from old appliances |

| Fabrication | Three-dimensional printing; recycled and recyclable materials |

| Sustainability | Introduce sustainability rules through the recovery and reuse of materials and components |

| b = c·1.9 (m) | Swept Area (m2) | Theoretical Power P (W) | Resistor (Ω) | Voltage (V) | Current (mA) | Speed (r.p.m) | Turbine Power Pt (W) | Cp = Pt/P | |

|---|---|---|---|---|---|---|---|---|---|

| H5C30 (led 5W) | 0.057 | 0.0102 | 5.91 | 25 | 7.8 | 160 | 5762 | 1.248 | 0.211 |

| H5C30 (led 5W) | 0.057 | 0.0102 | 5.91 | 56 | 9.4 | 120 | 6153 | 1.128 | 0.191 |

| H2C25 (led 5W) | 0.048 | 0.0071 | 4.10 | 25 | 7.24 | 142 | 5075 | 1.028 | 0.250 |

| H2C30 (led 1W) | 0.057 | 0.0102 | 5.91 | 25 | 8.2 | 120 | 5870 | 0.984 | 0.166 |

| H5C30 (led 1W) | 0.057 | 0.0102 | 5.91 | 25 | 7.7 | 125 | 7000 | 0.963 | 0.163 |

| Dron (led 5W) | 0.025 | 0.0020 | 1.14 | 39 | 4.87 | 50 | 2860–2900 | 0.2435 | 0.214 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Forniés, I.; Asión-Suñer, L.; Sarvisé-Biec, A. The Bioinspired Prosumer—Interactions between Bioinspired Design Methods in the Prosumer Scope. Biomimetics 2024, 9, 539. https://doi.org/10.3390/biomimetics9090539

López-Forniés I, Asión-Suñer L, Sarvisé-Biec A. The Bioinspired Prosumer—Interactions between Bioinspired Design Methods in the Prosumer Scope. Biomimetics. 2024; 9(9):539. https://doi.org/10.3390/biomimetics9090539

Chicago/Turabian StyleLópez-Forniés, Ignacio, Laura Asión-Suñer, and Alba Sarvisé-Biec. 2024. "The Bioinspired Prosumer—Interactions between Bioinspired Design Methods in the Prosumer Scope" Biomimetics 9, no. 9: 539. https://doi.org/10.3390/biomimetics9090539

APA StyleLópez-Forniés, I., Asión-Suñer, L., & Sarvisé-Biec, A. (2024). The Bioinspired Prosumer—Interactions between Bioinspired Design Methods in the Prosumer Scope. Biomimetics, 9(9), 539. https://doi.org/10.3390/biomimetics9090539