Integration of Sustainable and Net-Zero Concepts in Shape-Memory Polymer Composites to Enhance Environmental Performance

Abstract

1. Introduction

2. Literature Review

2.1. Sustainable Manufacturing Processes

2.2. Energy Efficiency

2.3. End-of-Life Management Strategies

2.4. Innovative Applications

2.5. Challenges and Future Directions

| Material | Method | Result | Conclusion | Ref. |

|---|---|---|---|---|

| Polyacrylamide Hydrogel | Testing water absorption and shape memory | High water absorption and shape memory | Potential in drug delivery | [40] |

| Gelatin-based Hydrogel | Mechanical property and biocompatibility testing | Biocompatible with good mechanical properties | Used in tissue engineering | [41] |

| Alginate Hydrogel | Biocompatibility and shape recovery testing | High biocompatibility and shape recovery | Applications in wound healing | [42] |

| GelMA Hydrogel | 3D printing and mechanical testing | Good printability and mechanical strength | Used in tissue scaffolding | [43] |

| Material | Method | Result | Conclusion | Ref. |

|---|---|---|---|---|

| Photochromic Compounds | Testing reversible structural changes | Effective shape-memory behavior in response to light | Applications in light-driven actuators | [43] |

| Photoinitiators | Analysis of shape memory efficiency | High efficiency of shape memory | Used in microelectronics | [44] |

| Photochromic Dyes | Testing shape memory properties | Enhanced shape memory properties | Potential in Adaptive Aerodynamics | [45] |

| Carbon Nanotubes (Photo-thermal) | Thermal conductivity and shape memory testing | Improved thermal conductivity and shape memory | Used in soft robotics | [46] |

| Gold Nanoparticles (Photo-thermal) | Thermal response and shape memory testing | Excellent thermal response and shape memory | Potential in biomedical devices | [48] |

| Material | Method | Result | Conclusion | Ref. |

|---|---|---|---|---|

| Polyaniline | Testing electrical conductivity | High electrical conductivity | Applications in bioelectrodes | [53] |

| Polypyrrole | Analysis of electrical and magnetic properties | Enhanced electrical and magnetic properties | Used in neural interfaces | [54] |

| Conductive Polymer Composites | Testing functionality and responsiveness | Improved functionality and responsiveness | Potential in intelligent drug delivery | [55] |

| Carbon Nanotubes and Iron Particles | Testing electrical and magnetic properties | Enhanced electrical and magnetic properties | Applications in energy devices | [56] |

| Carbon Nanotubes and Cobalt Particles | Electromagnetic shielding performance testing | High performance in electromagnetic shielding | Used in environmental sustainability | [57] |

| Material | Method | Result | Conclusion | Ref. |

|---|---|---|---|---|

| Lead Zirconate (PZT) | Ferroelectric domain reorientation under electric field | Demonstrated shape-memory behaviour | Potential for MEMS devices | [34] |

| Barium Titanate | Shape-memory effect under electric fields | Effective shape-memory behaviour in response to electric fields | Applications in sensors | [35] |

| PZT-BaTiO3 Composite | Mechanical properties and shape-memory testing | Enhanced mechanical properties and shape memory | Useful in actuators | [36] |

3. Shape-Memory Materials

3.1. Shape-Memory Ceramics (SMC)

3.2. Shape-Memory Polymers (SMP)

3.3. Shape-Memory Hydrogels (SMH)

4. Light-Responsive Shape Memory Polymer Composites (LSMPC)

4.1. Photochemical LSMPCs

4.2. Photo-Thermal Shape Memory Polymers

5. Intelligent Sustainable Materials

5.1. Cell Traction Force and Microstructures

5.2. Electrically Sensitive Materials

5.3. Conductive Carbon Nanotubes and Magnetic Particles

6. Characterisation of Shape Memory

Thermomechanical Properties and Shape Memory Effects

7. Discussion and Findings

7.1. Energy Harvesting and Storage

7.2. Future Perspectives

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Luo, J.; Zhuo, W.; Xu, B. The bigger, the better? Optimal NGO size of human resources and governance quality of entrepreneurship in circular economy. Manag. Decis. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Shah, M.R.; Khan, M.I.; Asim, M.; Yasin, H.; Baloch, A.S.; Murtaza, G.; Farid, M.Y. Experimental investigation on the effects of different compatibilisers on the mechanical and thermal properties of polypropylene/waste polyvinyl chloride blends. Polym. Test. 2022, 110, 107962. [Google Scholar]

- Miao, L.; Jiang, T.; Lin, S.; Jin, T.; Hu, J.; Zhang, M.; Tu, Y.; Liu, G. Asymmetric forward osmosis membranes from p-aramid nanofibers. Mater. Des. 2020, 191, 108591. [Google Scholar] [CrossRef]

- Trhlíková, O.; Vlčková, V.; Abbrent, S.; Valešová, K.; Kanizsová, L.; Skleničková, K.; Paruzel, A.; Bujok, S.; Walterová, Z.; Innemanová, P.; et al. Microbial and abiotic degradation of fully aliphatic polyurethane foam suitable for biotechnologies. Polym. Degrad. Stab. 2021, 194, 109764. [Google Scholar]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O.; Omigbodun, F.T. 3D Printing of PEEK and its composite to increase biointerfaces as a biomedical material—A review. Colloids Surf. B Biointerfaces 2021, 203, 111726. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Zhuo, W.; Liu, S.; Xu, B. The Optimization of Carbon Emission Prediction in Low Carbon Energy Economy Under Big Data. IEEE Access 2024, 12, 14690–14702. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Ismail, S.O.; Zahedi, M.; Khan, A.; Usman, H. 3D printing and morphological characterisation of polymeric composite scaffolds. Eng. Struct. 2020, 216, 110752. [Google Scholar] [CrossRef]

- Gong, X.; Wang, Y.; Jiang, L.; Hu, X.; Zhu, Y.; Zhao, H. Mechanical behavior and shape memory effect of NiTi shape memory alloy with gradient microstructure. Mater. Des. 2014, 56, 878–885. [Google Scholar] [CrossRef]

- An, S.Y.; Arunbabu, D.; Noh, S.M.; Song, Y.K.; Oh, J.K. Recent strategies to develop self-healable cross-linked polymeric networks. Chem. Commun. 2015, 51, 13058–13070. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O.; Olawade, D.B. Recent advances in biopolymeric composite materials: Future sustainability of bone-implant. Renew. Sustain. Energy Rev. 2021, 150, 111505. [Google Scholar] [CrossRef]

- Ranjan, N.; Singh, R.; Ahuja, I.S. Preparation of Partial Denture With Nano HAp-PLA Composite Under Cryogenic Grinding Environment Using 3D printing. In Encyclopedia of Renewable and Sustainable Materials; Hashmi, S., Choudhury, I.A., Eds.; Elsevier: Oxford, UK, 2020; pp. 517–522. [Google Scholar] [CrossRef]

- Cui, C.; Kim, D.-O.; Pack, M.Y.; Han, B.; Sun, Y.; Han, L.-H. 4D printing of self-folding and cell-encapsulating 3D microstructures as scaffolds for tissue-engineering applications. Biofabrication 2020, 12, 045018. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Wang, M.; Liang, Y.; Ren, L.; Ren, L. Recent progress in 4D printing of stimuli-responsive polymeric materials. Sci. China Technol. Sci. 2019, 63, 532–544. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Zahedi, S.A.; Balogun, V.A.; Ismail, S.O.; Samad, Y.A. Overview of additive manufacturing biopolymer composites. In Encyclopedia of Materials: Composites; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Agrawal, N.; Arora, B. Self-Healing Polymers and Composites: Extrinsic Routes. Mini-Rev. Org. Chem. 2022, 19, 496–512. [Google Scholar] [CrossRef]

- Invernizzi, M.; Turri, S.; Levi, M.; Suriano, R. 4D printed thermally activated self-healing and shape memory polycaprolactone-based polymers. Eur. Polym. J. 2018, 101, 169–176. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Zahedi, S.A.; Omigbodun, F.T. A systematic review of polymer composite in biomedical engineering. Eur. Polym. J. 2021, 154, 110534. [Google Scholar] [CrossRef]

- Kuang, X.; Chen, K.; Dunn, C.K.; Wu, J.; Li, V.C.F.; Qi, H.J. 3D printing of highly stretchable, shape-memory, and self-healing elastomer toward novel 4D printing. ACS Appl. Mater. Interfaces 2018, 10, 7381–7388. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Arya, S.K. Bio-Inspired Self-Healable Materials. In Self-Smart Materials and Allied Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2021; pp. 435–474. [Google Scholar]

- Bochniak, A.; Hadasz, L.; Ruba, B. Dynamical generalization of Yetter’s model based on a crossed module of discrete groups. J. High Energy Phys. 2021, 2021, 1–52. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Ismail, S.O.; Ikumapayi, O.M.; Kayode, J.F. Impact of rGO-coated PEEK and lattice on bone implant. Colloids Surf. B Biointerfaces 2022, 216, 112583. [Google Scholar] [CrossRef]

- Adak, D.; Bhattacharyya, R.; Barshilia, H.C. A state-of-the-art review on the multifunctional self-cleaning nanostructured coatings for PV panels, CSP mirrors and related solar devices. Renew. Sustain. Energy Rev. 2022, 159, 112145. [Google Scholar] [CrossRef]

- Shobole, A.A.; Wadi, M. Multiagent systems application for the smart grid protection. Renew. Sustain. Energy Rev. 2021, 149, 111352. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Obisesan, O.B.; Oluwole, B.; Adebiyi, V.A.; Usman, H.; Khan, A. Mechanical characterisation of a polymeric scaffold for bone implant. J. Mater. Sci. 2020, 55, 9057–9069. [Google Scholar] [CrossRef]

- Lin, C.; Lv, J.; Li, Y.; Zhang, F.; Li, J.; Liu, Y.; Liu, L.; Leng, J. 4D-Printed Biodegradable and Remotely Controllable Shape Memory Occlusion Devices. Adv. Funct. Mater. 2019, 29, 1906569. [Google Scholar] [CrossRef]

- Hu, F.; Shi, X.; Wei, S.; Qiu, L.; Hu, H.; Zhou, H.; Guo, B. Structural Evolution and Policy Orientation of China’s Rare Earth Innovation Network: A Social Network Analysis Based on Collaborative Patents. Pol. J. Environ. Stud. 2024, 33, 1767–1779. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Adeoye, A.O.; Ismail, M. Analytical optimisation of a nanoparticle of microstructural fused deposition of resins for additive manufacturing. Compos. Part B Eng. 2018, 150, 248–254. [Google Scholar] [CrossRef]

- Fan, D.; Staufer, U.; Accardo, A. Engineered 3D Polymer and Hydrogel Microenvironments for Cell Culture Applications. Bioengineering 2019, 6, 113. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.F.; Doe, A. Recent advancements in smart nanomaterials for biomedical applications. Int. J. Smart Nano Mater. 2022, 13, 1234567. [Google Scholar]

- Shi, Y.; Hou, X.; Na, Z.; Zhou, J.; Yu, N.; Liu, S.; Xin, L.; Gao, G.; Liu, Y. Bio-inspired Attachment Mechanism of Dynastes Hercules: Vertical Climbing for On-Orbit Assembly Legged Robots. J. Bionic Eng. 2023, 21, 137–148. [Google Scholar] [CrossRef]

- Lin, W.-C.; Fan, F.-Y.; Cheng, H.-C.; Lin, Y.; Shen, Y.-K.; Lai, J.-S.; Wang, L.; Ruslin, M. Optimization Shape-Memory Situations of a Stimulus Responsive Composite Material. Polymers 2021, 13, 697. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, F.; Liu, Y.; Leng, J. 4D printed shape memory polymers and their structures for biomedical applications. Sci. China Technol. Sci. 2020, 63, 545–560. [Google Scholar] [CrossRef]

- Johnson, T.; Lee, M. Innovations in shape-memory polymers for smart textiles. Adv. Funct. Mater. 2023, 33, 2312036. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Y. Advances in sustainable shape-memory materials for environmental applications. Research 2023, 6, 0234. [Google Scholar]

- Chansoria, P.; Asif, S.; Gupta, N.; Piedrahita, J.; Shirwaiker, R.A. Multiscale Anisotropic Tissue Biofabrication via Bulk Acoustic Patterning of Cells and Functional Additives in Hybrid Bioinks. Adv. Health Mater. 2022, 11, 2102351. [Google Scholar] [CrossRef] [PubMed]

- Oladapo, B.I.; Adebiyi, A.V.; Elemure, E.I. Microstructural 4D printing investigation of ultra-sonication biocomposite polymer. J. King Saud Univ. -Eng. Sci. 2019, 33, 54–60. [Google Scholar] [CrossRef]

- Cherief, M.; Belaadi, A.; Bouakba, M.; Bourchak, M.; Meddour, I. Behaviour of lignocellulosic fibre-reinforced cellular core under low-velocity impact loading: Taguchi method. Int. J. Adv. Manuf. Technol. 2020, 108, 223–233. [Google Scholar] [CrossRef]

- Olawumi, M.A.; Oladapo, B.I.; Olugbade, T.O.; Omigbodun, F.T.; Olawade, D.B. AI-Driven Data Analysis of Quantifying Environmental Impact and Efficiency of Shape Memory Polymers. Biomimetics 2024, 9, 490. [Google Scholar] [CrossRef]

- Baker, A.B.; Bates, S.R.; Llewellyn-Jones, T.M.; Valori, L.P.; Dicker, M.P.; Trask, R.S. 4D printing with robust thermoplastic polyurethane hydrogel-elastomer trilayers. Mater. Des. 2018, 163, 107544. [Google Scholar] [CrossRef]

- Zhou, P.; Peng, R.; Xu, M.; Wu, V.; Navarro-Alarcon, D. Path Planning With Automatic Seam Extraction Over Point Cloud Models for Robotic Arc Welding. IEEE Robot. Autom. Lett. 2021, 6, 5002–5009. [Google Scholar] [CrossRef]

- Finkenauer, B.P.; Gao, Y.; Wang, X.; Tian, Y.; Wei, Z.; Zhu, C.; Rokke, D.J.; Jin, L.; Meng, L.; Yang, Y.; et al. Mechanically robust and self-healable perovskite solar cells. Cell Rep. Phys. Sci. 2021, 2, 100320. [Google Scholar] [CrossRef]

- Fisher, S.A.; Tam, R.Y.; Shoichet, M.S. Tissue mimetics: Engineered hydrogel matrices provide biomimetic environments for cell growth. Tissue Eng. Part A 2014, 20, 895–898. [Google Scholar] [CrossRef] [PubMed]

- Kuss, M.A.; Wu, S.; Wang, Y.; Untrauer, J.B.; Li, W.; Lim, J.Y.; Duan, B. Prevascularization of 3D printed bone scaffolds by bioactive hydrogels and cell co-culture. J. Biomed. Mater. Res. Part B Appl. Biomater. 2018, 106, 1788–1798. [Google Scholar] [CrossRef]

- Bajpai, A.; Baigent, A.; Raghav, S.; Brádaigh, C.; Koutsos, V.; Radacsi, N. 4D printing: Materials, technologies, and future applications in the biomedical field. Sustainability 2020, 12, 10628. [Google Scholar] [CrossRef]

- Geng, P.; Zhao, J.; Wu, W.; Ye, W.; Wang, Y.; Wang, S.; Zhang, S. Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament. J. Manuf. Process. 2018, 37, 266–273. [Google Scholar] [CrossRef]

- Rakotondrabe, M.; Janaideh, M.; Bienaim, A.; Xu, Q. Smart materials-based actuators at the micro/nanoscale. In Characterisation, Control and Applications; Springer: New York, NY, USA, 2013. [Google Scholar]

- Lin, C.; Zhang, L.; Liu, Y.; Liu, L.; Leng, J. 4D printing of personalised shape memory polymer vascular stents with negative Poisson’s ratio structure: A preliminary study. Sci. China Technol. Sci. 2020, 63, 578–588. [Google Scholar] [CrossRef]

- Akbari, S.; Sakhaei, A.H.; Kowsari, K.; Yang, B.; Serjouei, A.; Yuanfang, Z.; Ge, Q. Enhanced multimaterial 4D printing with active hinges. Smart Mater. Struct. 2018, 27, 065027. [Google Scholar] [CrossRef]

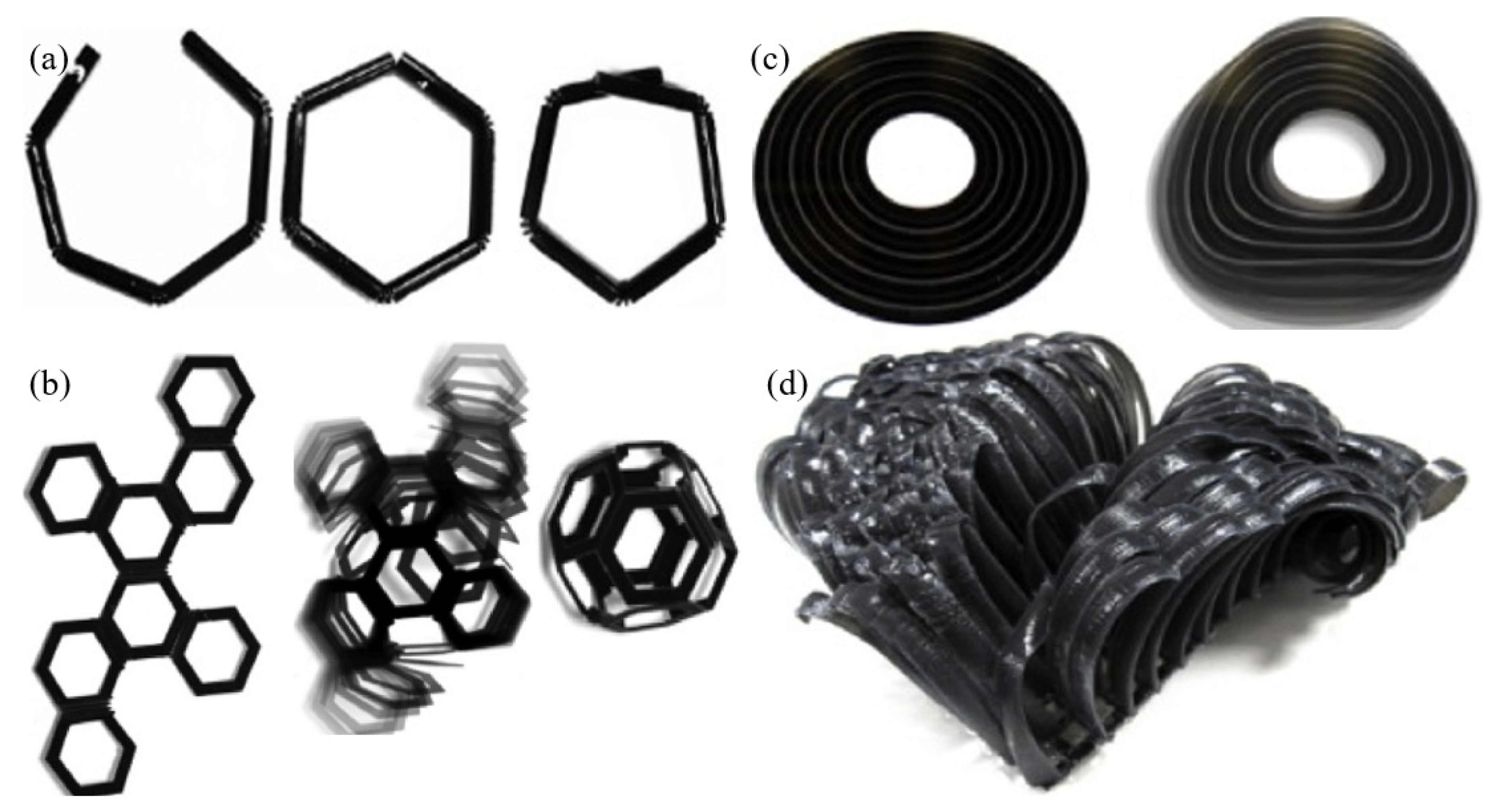

- Liu, G.; Zhao, Y.; Wu, G.; Lu, J. Origami and 4D printing of elastomer-derived ceramic structures. Sci. Adv. 2018, 4, eaat0641. [Google Scholar] [CrossRef] [PubMed]

- Lin, F.; Wang, Z.; Shen, Y.; Tang, L.; Zhang, P.; Wang, Y.; Chen, Y.; Huang, B.; Lu, B. Natural skin-inspired versatile cellulose biomimetic hydrogels. J. Mater. Chem. A 2019, 7, 26442–26455. [Google Scholar] [CrossRef]

- Lauer, A.; Wolf, P.; Mehler, D.; Götz, H.; Rüzgar, M.; Baranowski, A.; Henrich, D.; Rommens, P.M.; Ritz, U. Biofabrication of SDF-1 Functionalized 3D-Printed Cell-Free Scaffolds for Bone Tissue Regeneration. Int. J. Mol. Sci. 2020, 21, 2175. [Google Scholar] [CrossRef]

- Mallakpour, S.; Tabesh, F.; Hussain, C.M. 3D and 4D Printing: From innovation to evolution. Adv. Colloid Interface Sci. 2021, 294, 102482. [Google Scholar] [CrossRef]

- Tamay, D.G.; Usal, T.D.; Alagoz, A.S.; Yucel, D.; Hasirci, N.; Hasirci, V. 3D and 4D Printing of Polymers for Tissue Engineering Applications. Front. Bioeng. Biotechnol. 2019, 7, 164. [Google Scholar] [CrossRef]

- Muehlenfeld, C.; Roberts, S.A. 3D/4D Printing in Additive Manufacturing: Process Engineering and Novel Excipients. In 3D and 4D Printing in Biomedical Applications; Maniruzzaman, M., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2019; pp. 1–23. [Google Scholar] [CrossRef]

- Adam, G.; Benouhiba, A.; Rabenorosoa, K.; Clévy, C.; Cappelleri, D.J. 4D printing: Enabling technology for microrobotics applications. Adv. Intell. Syst. 2021, 3, 2000216. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, F.; Zhai, W.; Cheng, S.; Li, J.; Wang, Y. Unraveling of Advances in 3D-Printed Polymer-Based Bone Scaffolds. Polymers 2022, 14, 566. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Kayode, J.F.; Akinyoola, J.O.; Ikumapayi, O.M. Shape memory polymer review for flexible artificial intelligence materials of biomedical. Mater. Chem. Phys. 2023, 293, 126930. [Google Scholar] [CrossRef]

- Ahmed, J. Recent Advances of Novel Materials for 3D/4D Printing in Biomedical Applications. In 3D and 4D Printing in Biomedical Applications; Maniruzzaman, M., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2019; pp. 239–271. [Google Scholar] [CrossRef]

- Ahmed, K.; Shiblee, M.N.I.; Khosla, A.; Nagahara, L.; Thundat, T.; Furukawa, H. Recent progresses in 4D printing of gel materials. J. Electrochem. Soc. 2020, 167, 037563. [Google Scholar] [CrossRef]

- Xie, H.; Yang, K.-K.; Wang, Y.-Z. Photo-cross-linking: A powerful and versatile strategy to develop shape-memory polymers. Prog. Polym. Sci. 2019, 95, 32–64. [Google Scholar] [CrossRef]

- Ahmed, A.; Arya, S.; Gupta, V.; Furukawa, H.; Khosla, A. 4D printing: Fundamentals, materials, applications and challenges. Polymer 2021, 228, 123926. [Google Scholar] [CrossRef]

- Ahn, S.; Byun, J.; Joo, H.; Jeong, J.; Lee, D.; Cho, K. 4D Printing of Continuous Shape Representation. Adv. Mater. Technol. 2021, 6, 2100133. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Zahedi, S.A. Improving bioactivity and strength of PEEK composite polymer for bone application. Mater. Chem. Phys. 2021, 266, 124485. [Google Scholar] [CrossRef]

- Alshebly, Y.S.; Nafea, M.; Ali, M.S.M.; Almurib, H.A. Review on recent advances in 4D printing of shape memory polymers. Eur. Polym. J. 2021, 159, 110708. [Google Scholar] [CrossRef]

- Champeau, M.; Heinze, D.A.; Viana, T.N.; de Souza, E.R.; Chinellato, A.C.; Titotto, S. 4D Printing of Hydrogels: A Review. Adv. Funct. Mater. 2020, 30, 1910606. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Kayode, J.F.; Karagiannidis, P.; Naveed, N.; Mehrabi, H.; Ogundipe, K.O. Polymeric composites of cubic-octahedron and gyroid lattice for biomimetic dental implants. Mater. Chem. Phys. 2022, 289, 126454. [Google Scholar] [CrossRef]

- Dong, K.; Ke, H.; Panahi-Sarmad, M.; Yang, T.; Huang, X.; Xiao, X. Mechanical properties and shape memory effect of 4D printed cellular structure composite with a novel continuous fiber-reinforced printing path. Mater. Des. 2020, 198, 109303. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, C.; Rehman, H.U.; Zheng, X.; Li, H.; Liu, H.; Hedenqvist, M.S. Shape-Memory Polymeric Artificial Muscles: Mechanisms, Applications and Challenges. Molecules 2020, 25, 4246. [Google Scholar] [CrossRef]

- Wei, Z.G.; Sandstroröm, R.; Miyazaki, S. Shape-memory materials and hybrid composites for smart systems: Part I Shape-memory materials. J. Mater. Sci. 1998, 33, 3743–3762. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, X.; Liu, Y.; Ramakrishna, S. Review of mechanisms and deformation behaviors in 4D printing. Int. J. Adv. Manuf. Technol. 2019, 105, 4633–4649. [Google Scholar] [CrossRef]

- Deshmukh, K.; Houkan, M.T.; Al Maadeed, M.A.; Sadasivuni, K.K. Introduction to 3D and 4D printing technology: State of the art and recent trends. 3d 4d Print. Polym. Nanocompos. Mater. 2020, 1, 1–24. [Google Scholar]

- Andreu, A.; Su, P.-C.; Kim, J.-H.; Ng, C.S.; Kim, S.; Kim, I.; Lee, J.; Noh, J.; Subramanian, A.S.; Yoon, Y.-J. 4D printing materials for vat photopolymerization. Addit. Manuf. 2021, 44, 102024. [Google Scholar] [CrossRef]

- Alshahrani, H.A. Review of 4D printing materials and reinforced composites: Behaviors, applications and challenges. J. Sci. Adv. Mater. Devices 2021, 6, 167–185. [Google Scholar] [CrossRef]

- del Barrio, J.; Sánchez-Somolinos, C. Light to shape the future: From photolithography to 4D printing. Adv. Opt. Mater. 2019, 7, 1900598. [Google Scholar] [CrossRef]

- Chu, H.; Yang, W.; Sun, L.; Cai, S.; Yang, R.; Liang, W.; Yu, H.; Liu, L. 4D Printing: A Review on Recent Progresses. Micromachines 2020, 11, 796. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Guo, Y.; Xie, B.; Jin, F.; Ma, L.; Zhang, H.; Li, Y.; Chen, X.; Hou, M.; Gao, J.; et al. Lightweight and drift-free magnetically actuated millirobots via asymmetric laser-induced graphene. Nat. Commun. 2024, 15, 4334. [Google Scholar] [CrossRef]

- Saba, N.; Tahir, P.M.; Jawaid, M.; Fouad, H. Recent advances in nanoclay/natural fibers hybrid composites. Compos. Sci. Technol. 2021, 203, 108563. [Google Scholar]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Triple shape memory polymers by 4D Printing. Smart Mater. Struct. 2018, 27, 065010. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Ismail, S.O.; Adebiyi, A.V.; Omigbodun, F.T.; Olawumi, M.A.; Olawade, D.B. Nanostructural interface and strength of polymer composite scaffolds applied to intervertebral bone. Colloids Surf. A Physicochem. Eng. Asp. 2021, 627, 127190. [Google Scholar] [CrossRef]

- Albrektsson, T.; Jemt, T.; Mölne, J.; Tengvall, P.; Wennerberg, A. On inflammation-immunological balance theory—A critical apprehension of disease concepts around implants: Mucositis and marginal bone loss may represent normal conditions and not necessarily a state of disease. Clin. Implant. Dent. Relat. Res. 2018, 21, 183–189. [Google Scholar] [CrossRef] [PubMed]

- Alcala-Orozco, C.R.; Cui, X.; Hooper, G.J.; Lim, K.S.; Woodfield, T.B. Converging functionality: Strategies for 3D hybrid-construct biofabrication and the role of composite biomaterials for skeletal regeneration. Acta Biomater. 2021, 132, 188–216. [Google Scholar] [CrossRef] [PubMed]

- Oladapo, B.I.; Oshin, E.A.; Olawumi, A.M. Nanostructural computation of 4D printing carboxymethylcellulose (CMC) composite. Nano-Struct. Nano-Objects 2020, 21, 100423. [Google Scholar] [CrossRef]

- Wang, L.; Chen, H. Development of high-strength composite materials with enhanced durability. Compos. Sci. Technol. 2019, 184, 107866. [Google Scholar] [CrossRef]

- Arévalo-Alquichire, S.; Valero, M. Castor Oil Polyurethanes as Biomaterials. In Elastomers; Çankaya, N., Ed.; InTech: Rijeka, Yugoslavia, 2017; pp. 137–157. [Google Scholar]

- Oladapo, B.I.; Daniyan, I.A.; Ikumapayi, O.M.; Malachi, O.B.; Malachi, I.O. Microanalysis of hybrid characterisation of PLA/cHA polymer scaffolds for bone regeneration. Polym. Test. 2020, 83, 106341. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, L.; Song, H.; Ni, C.; Wu, J.; Zhao, Q.; Xie, T. 4D printing of a digital shape memory polymer with tunable high performance. ACS Appl. Mater. Interfaces 2019, 11, 32408–32413. [Google Scholar] [CrossRef]

- Choong, Y.Y.C.; Maleksaeedi, S.; Eng, H.; Yu, S.; Wei, J.; Su, P.-C. High speed 4D printing of shape memory polymers with nanosilica. Appl. Mater. Today 2019, 18, 100515. [Google Scholar] [CrossRef]

- Chen, H.; Liu, X.; Zhang, Y.; Wang, T.; Li, J. Recent advances in materials design for high-performance energy storage devices. Mater. Des. 2020, 194, 108561. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Y.; Wang, H.; Zhang, J. Recent advances in two-dimensional materials for electronic and optoelectronic applications. Solid State Commun. 2019, 300, 113782. [Google Scholar]

- Zhang, Y.; Li, X.; Huang, Y.; Zhao, Y.; Ma, Y. Multifunctional shape-memory materials for adaptive structures. Adv. Mater. 2018, 30, 1706539. [Google Scholar] [CrossRef]

- Smith, M.; Johnson, T.; Brown, A. Advances in the thermal and oxidative stability of biodegradable polymers: A review. Polym. Degrad. Stab. 2021, 188, 109579. [Google Scholar]

- Wang, S.; Li, Q.; Zhang, Y.; Liu, Z. Recent advances in the mechanical testing of polymers: Challenges and opportunities. Polym. Test. 2019, 79, 106383. [Google Scholar]

- Dong, C.; Jiang, W.; Wu, S.; Yang, L. Mechanical properties and applications of carbon fiber reinforced polymer composites. Compos. Part A Appl. Sci. Manuf. 2018, 110, 149–162. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Y.; Zhang, H.; Wang, T.; Li, M. Recent progress in the design and application of polymer-based nanocomposites. Polymer 2022, 247, 124667. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Liu, C.; Zhuang, Y.; Lu, X. Recent advances in bioactive scaffolds for regenerative medicine: From bioinspired design to clinical applications. Acta Biomater. 2020, 104, 48–64. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, H.; Zhao, X.; Li, Y.; Zhou, X. Design and development of high-performance nanocomposites: Recent progress and future challenges. Mater. Des. 2019, 182, 107345. [Google Scholar]

- Liu, X.; Zhang, Y.; Li, J.; Wang, H.; Chen, Y. Advanced photocatalytic materials for water treatment: Insights into the design and applications. Chem. Eng. J. 2021, 418, 128917. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, J.; Wang, Y. Recent advances in the thermal stabilisation of polymers for high-temperature applications. Polym. Degrad. Stab. 2019, 166, 109681. [Google Scholar]

- Zhou, Z.; Liu, Y.; Wang, J.; Zhang, Q. Recent progress in two-dimensional materials for high-performance supercapacitors. Solid State Commun. 2018, 284, 113842. [Google Scholar]

- Li, J.; Wang, X.; Zhang, Y.; Chen, H.; Liu, Y. Recent advances in carbon-based materials for supercapacitors: Design, fabrication, and applications. Carbon 2022, 195, 124563. [Google Scholar]

- Wang, J.; Liu, X.; Li, Y.; Zhang, Q.; Sun, X. High entropy alloys: Emerging materials for advanced functional applications. J. Alloys Compd. 2020, 847, 156837. [Google Scholar] [CrossRef]

- Yang, G.; Zhu, C.; Du, D.; Lin, Y. Graphene-based materials for biosensing and bioimaging. Nano Today 2018, 19, 401–425. [Google Scholar]

- Nguyen, A.T.; Gómez-Rivadulla, M.; Andilla, J.; Zimmermann, E.A.; Montero, L. Multifunctional biomaterials for bone tissue regeneration. Biomaterials 2021, 276, 120601. [Google Scholar]

- Deng, Y.; Yang, J.; Peng, Y.; Li, M. Recent advances in wearable biosensors for personalised health monitoring. Biosens. Bioelectron. 2019, 132, 110573. [Google Scholar]

- Turnbull, G.; Clarke, J.; Picard, F.; Riches, P.; Jia, L.; Han, F.; Li, B. 3D bioactive composite scaffolds for bone tissue engineering. Acta Biomater. 2018, 77, 78–89. [Google Scholar] [CrossRef] [PubMed]

- Oladapo, B.I.; Olawumi, M.A.; Olugbade, T.O. Innovative Orthopedic Solutions for AI-Optimized Piezoelectric Implants for Superior Patient Care. Appl. Sci. 2024, 14, 7457. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Chen, W.; Zhang, Q.; Xu, Z. Recent advances in the degradation and stabilisation of polyolefins. Polym. Degrad. Stab. 2022, 198, 109704. [Google Scholar]

- Bai, H.; Shi, G.; Li, C. Conducting polymer hydrogels as a new class of biomaterials. Synth. Met. 2020, 263, 116839. [Google Scholar]

- Huang, Y.; Zhang, B.; Feng, J.; Zhang, L.; Chen, Y. Insights into the adsorption mechanism of sulfamethazine on two-dimensional graphitic carbon nitride. J. Colloid Interface Sci. 2018, 523, 208–218. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, L.; Wu, Q.; Zhang, Z.; Wang, C.; Zhang, Y.; Lu, J. Advanced strategies towards tunable and high-performance mesoporous carbon materials for supercapacitors. Carbon 2021, 178, 119834. [Google Scholar]

- Zhu, C.; Yang, H.; Cheng, H.; Wang, Z.; Zhang, Y.; Liu, H.; Shao, M. Dual-ion hybrid supercapacitors based on carbon nanomaterials. Carbon 2019, 153, 108–116. [Google Scholar]

| Material | Method | Result | Conclusion | Ref. |

|---|---|---|---|---|

| Shape-Memory Ceramics (SMC) | ||||

| Lead Zirconate (PZT) | Ferroelectric domain reorientation under electric field | Demonstrated shape-memory behaviour | Potential for MEMS devices | [34] |

| Barium Titanate | Evaluation of shape-memory effect under electric fields | Effective shape-memory behaviour in response to electric fields | Applications in sensors | [35] |

| PZT-BaTiO3 Composite | Testing mechanical properties and shape-memory effects | Enhanced mechanical properties and shape memory | Useful in actuators | [36] |

| Shape-Memory Polymers (SMP) | ||||

| Polyurethane | Analysis of elasticity and shape recovery | High elasticity and shape recovery | Potential in biomedical applications | [37] |

| Polylactic Acid (PLA) | Comparison of mechanical properties | Biodegradable with good mechanical properties | Useful in smart textiles | [38] |

| Epoxy-based SMP | Thermal stability and shape-memory effect testing | Improved thermal stability and shape memory | Applications in aerospace | [39] |

| Shape-Memory Hydrogels (SMH) | ||||

| Polyacrylamide Hydrogel | Testing water absorption and shape memory | High water absorption and shape memory | Potential in drug delivery | [40] |

| Gelatin-based Hydrogel | Mechanical property testing and biocompatibility analysis | Biocompatible with good mechanical properties | Used in tissue engineering | [41] |

| Alginate Hydrogel | Evaluation of biocompatibility and shape recovery | High biocompatibility and shape recovery | Applications in wound healing | [42] |

| Photochemical LSMPCs | ||||

| Photochromic Compounds | Testing reversible structural changes | Effective shape-memory behaviour in response to light | Applications in light-driven actuators | [43] |

| Photoinitiators | Analysis of shape memory efficiency | High efficiency of shape memory | Used in microelectronics | [44] |

| Photochromic Dyes | Testing shape memory properties | Enhanced shape memory properties | Potential in Adaptive Aerodynamics | [45] |

| Photo-Thermal Shape Memory Polymers | ||||

| Carbon Nanotubes | Thermal conductivity and shape memory testing | Improved thermal conductivity and shape memory | Used in soft robotics | [46] |

| Carbon Black | Analysis of light-to-heat conversion efficiency | High efficiency of light-to-heat conversion | Applications in minimally invasive tools | [47] |

| Gold Nanoparticles | Testing thermal response and shape memory | Excellent thermal response and shape memory | Potential in biomedical devices | [48] |

| Cell Traction Force and Microstructures | ||||

| Iron Oxide Nanoparticles | Testing cell alignment and migration | Enhanced cell alignment and migration | Applications in tissue engineering | [49] |

| Magnetic Nanoparticles | Analysis of cell traction forces | Controlled cell traction forces | Used in biosensing devices | [50] |

| Magnetic Hydrogel | Testing biocompatibility and mechanical performance | High biocompatibility and mechanical performance | Potential in regenerative medicine | [51] |

| Iron Oxide Nanoparticles | Testing cell alignment and migration | Enhanced cell alignment and migration | Applications in tissue engineering | [52] |

| Electrically Sensitive Materials | ||||

| Polyaniline | Testing electrical conductivity | High electrical conductivity | Applications in bioelectrodes | [53] |

| Polypyrrole | Analysis of electrical and magnetic properties | Enhanced electrical and magnetic properties | Used in neural interfaces | [54] |

| Conductive Polymer Composites | Testing functionality and responsiveness | Improved functionality and responsiveness | Potential in intelligent drug delivery | [55] |

| Conductive Carbon Nanotubes and Magnetic Particles | ||||

| Carbon Nanotubes and Iron Particles | Testing electrical and magnetic properties | Enhanced electrical and magnetic properties | Applications in energy devices | [56] |

| Carbon Nanotubes and Cobalt Particles | Analysis of performance in electromagnetic shielding | High performance in electromagnetic shielding | Used in environmental sustainability | [57] |

| Carbon Nanotubes and Magnetic Hydrogel | Testing mechanical and magnetic properties | Improved mechanical and magnetic properties | Potential in waste management | [58] |

| Thermomechanical Properties and Shape Memory Effects | ||||

| Polyurethane SMP | Testing elastic modulus and shape recovery | High elastic modulus and shape recovery | Used in biomedical implants | [59] |

| Epoxy-based SMP | Analysis of thermal stability and mechanical properties | Enhanced thermal stability and mechanical properties | Applications in aerospace | [60] |

| Polylactic Acid (PLA) SMP | Comparison of thermomechanical properties | Biodegradable with good thermomechanical properties | Used in smart textiles | [61] |

| Material | Method | Result | Conclusion | Ref. |

|---|---|---|---|---|

| Polyurethane | Analysis of elasticity and shape recovery | High elasticity and shape recovery | Potential in biomedical applications | [37] |

| Polylactic Acid (PLA) | Mechanical property comparison | Biodegradable with good mechanical properties | Useful in smart textiles | [38] |

| Epoxy-based SMP | Thermal stability and shape-memory testing | Improved thermal stability and shape memory | Applications in aerospace | [39] |

| Polyurethane SMP | Elastic modulus and shape recovery testing | High elastic modulus and shape recovery | Used in biomedical implants | [59] |

| PLA SMP | Thermomechanical property comparison | Biodegradable with good thermomechanical properties | Used in smart textiles | [61] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olawumi, M.A.; Omigbodun, F.T.; Oladapo, B.I. Integration of Sustainable and Net-Zero Concepts in Shape-Memory Polymer Composites to Enhance Environmental Performance. Biomimetics 2024, 9, 530. https://doi.org/10.3390/biomimetics9090530

Olawumi MA, Omigbodun FT, Oladapo BI. Integration of Sustainable and Net-Zero Concepts in Shape-Memory Polymer Composites to Enhance Environmental Performance. Biomimetics. 2024; 9(9):530. https://doi.org/10.3390/biomimetics9090530

Chicago/Turabian StyleOlawumi, Mattew A., Francis T. Omigbodun, and Bankole I. Oladapo. 2024. "Integration of Sustainable and Net-Zero Concepts in Shape-Memory Polymer Composites to Enhance Environmental Performance" Biomimetics 9, no. 9: 530. https://doi.org/10.3390/biomimetics9090530

APA StyleOlawumi, M. A., Omigbodun, F. T., & Oladapo, B. I. (2024). Integration of Sustainable and Net-Zero Concepts in Shape-Memory Polymer Composites to Enhance Environmental Performance. Biomimetics, 9(9), 530. https://doi.org/10.3390/biomimetics9090530