Experimental Investigation on the Acoustic Insulation Properties of Filled Paper Honeycomb-Core Wallboards

Abstract

1. Introduction

2. Sample Preparation and Experimental Methods

2.1. Model Design and Preparation

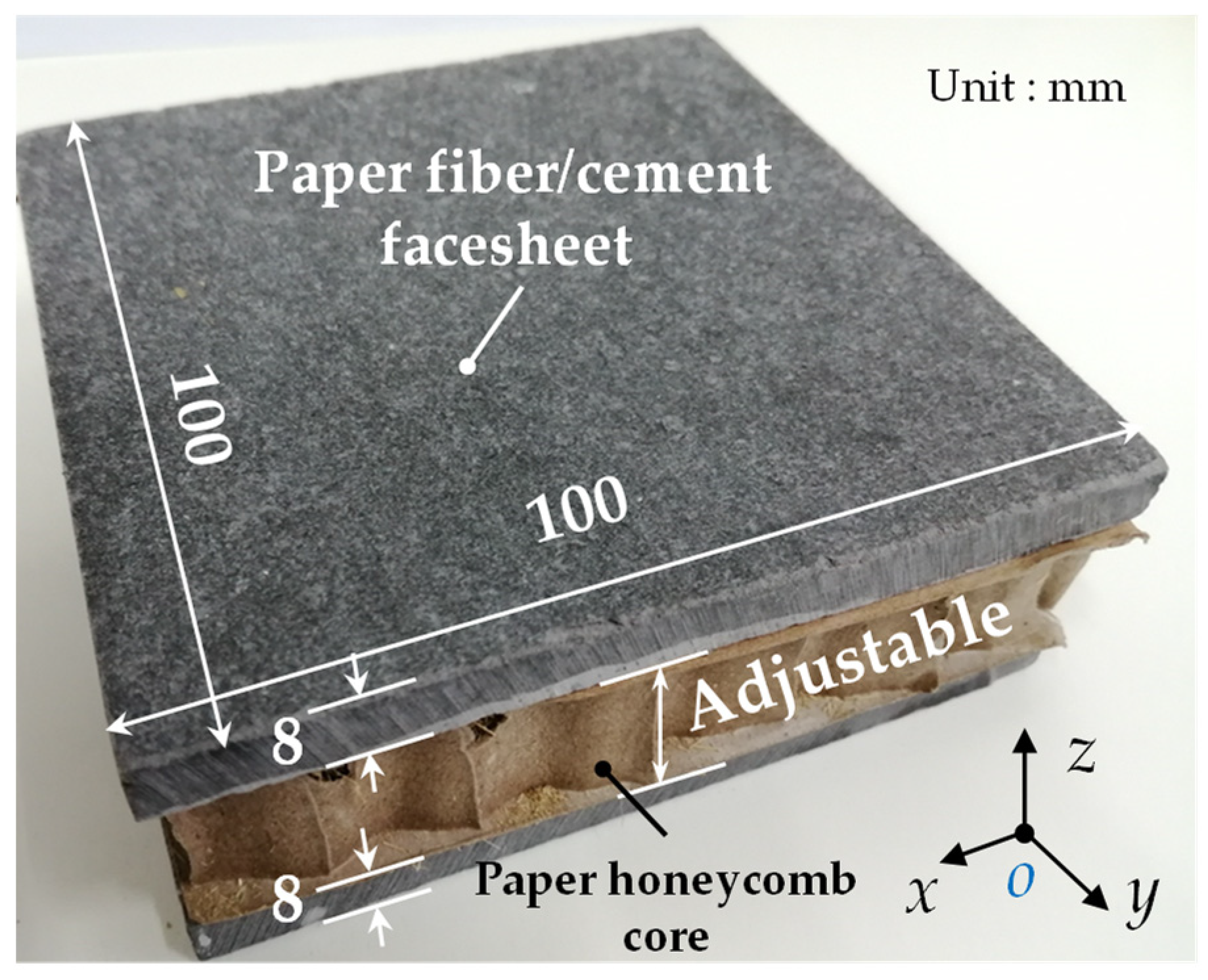

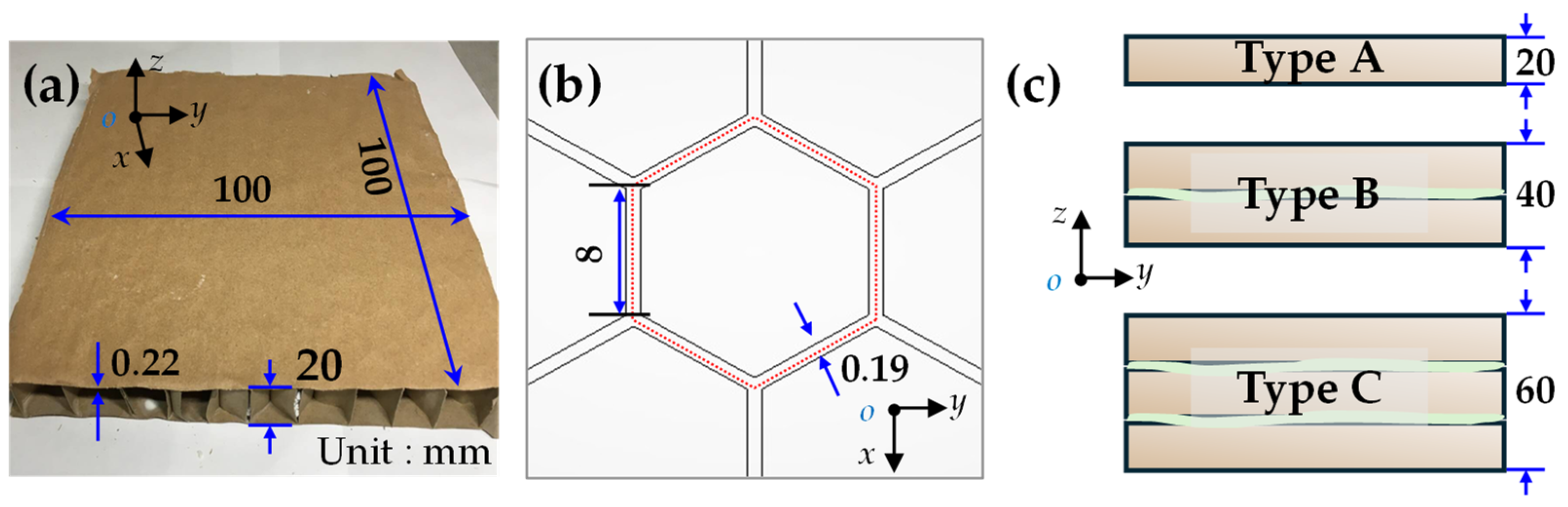

2.1.1. Model Design

- (1)

- Filling materials

- (2)

- Core formation types

2.1.2. Sample Preparation

2.2. Sound Insulation Performance Test Method and Indicators

3. Results and Discussion

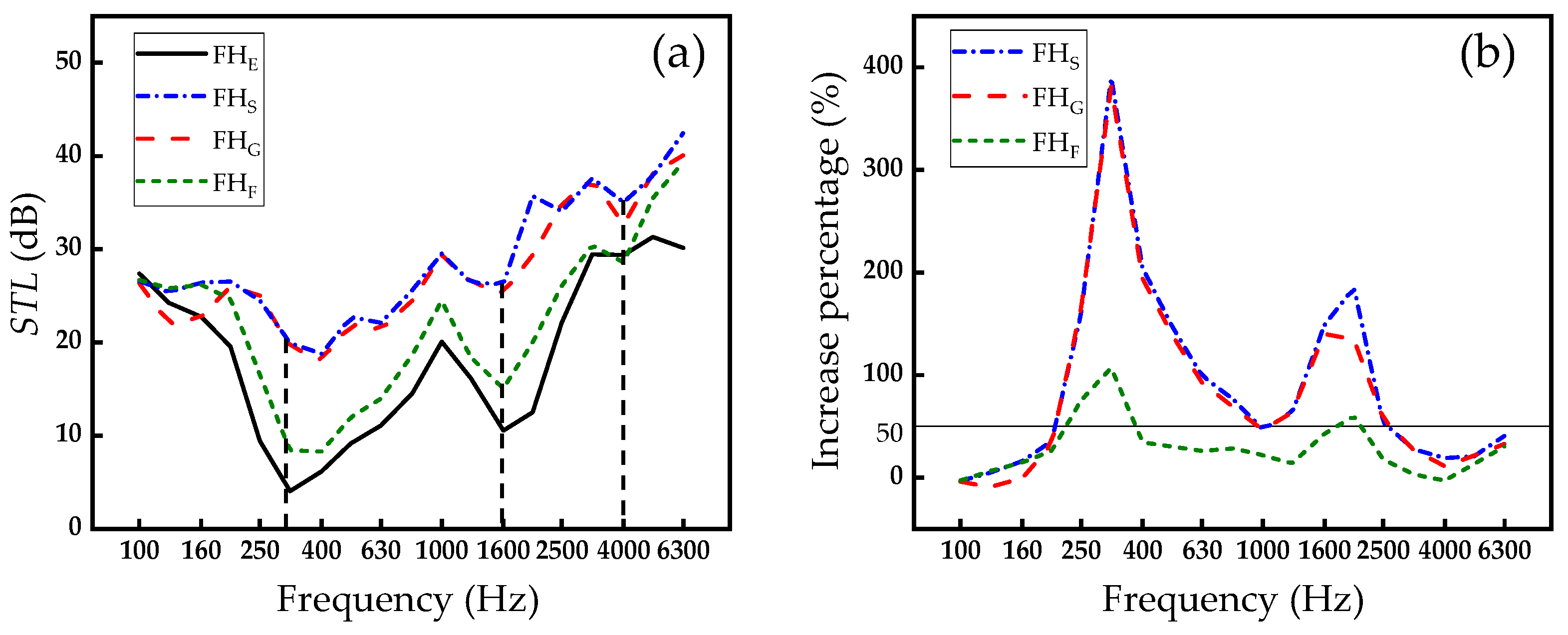

3.1. Influence of Filling Materials

3.2. Influence of Facesheets

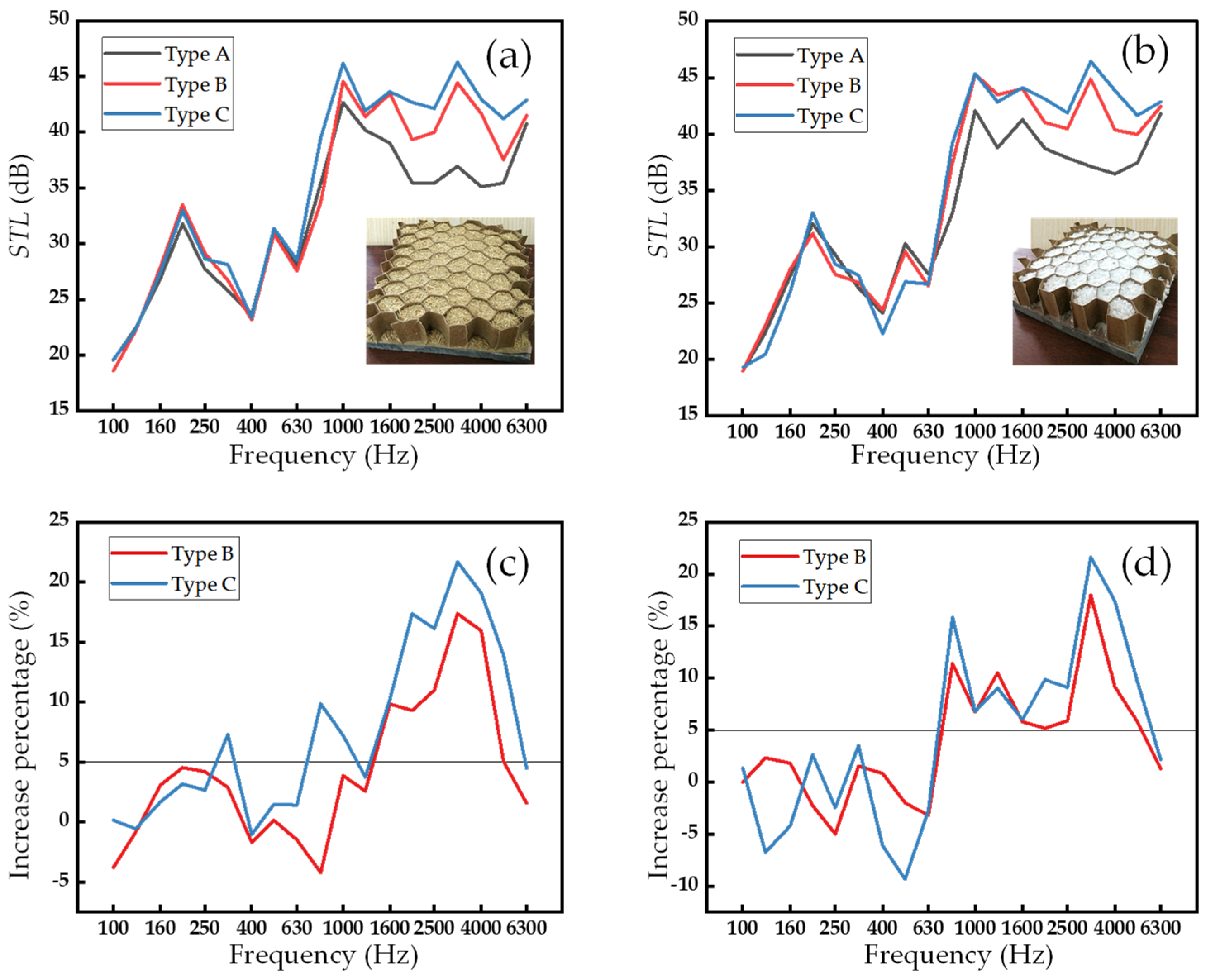

3.3. Influence of Core Type

4. Conclusions

- (1)

- Acoustic impact and mechanism of filling materials: Straw filling and glazed hollow bead filling significantly enhance the sound insulation of FHs. Specifically, the bandwidth with a sound insulation improvement of more than 50% is 2310 Hz for FHS and 2300 Hz for FHG, which is significantly higher than the 560 Hz for FHF. The superior performance is due to the high damping coefficient of straw and glazed hollow bead, making them more effective at absorbing and reflecting sound waves.

- (2)

- Improvement of acoustic performance of structural facesheets: Adding facesheets not only aligns more closely with practical engineering applications but also significantly improves the sound insulation performance of FHW. For instance, the STL of FHWS and FHWG is enhanced across the 100–6300 Hz range with maximum improvements of 74.92% and 86.56%, respectively, compared to FHS and FHG without facesheets. This enhancement is attributed to the increased reflection paths and the damping effect of the adhesive interface.

- (3)

- Acoustic optimization of the core structure: Increasing the number of core units enhances the acoustic performance of FHW. In FHWS, the bandwidth with a sound insulation improvement of over 5% increases from 3500 Hz for two units compared to one unit to 5400 Hz when the core units are increased to three. The improvement in the sound insulation performance of the structure is due to the increased mass and multi-layered structure, which provide more opportunities for scattering and absorbing sound waves.

- (4)

- This experimental study enriches the application of honeycomb plates in sound insulation by introducing paper fiber/cement facesheet straws. The results indicate that the sound insulation performance and strength have been improved, making these plates more promising for applications in non-load-bearing structures. Besides acoustic benefits, straw is a low-cost, environmentally friendly, renewable resource that reduces waste and lowers carbon emissions, making it a green building material. This research provides valuable guidance for promoting filled honeycomb-core sound insulation wallboards in green buildings.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, P.Y.; McKittrick, J.; Meyers, M.A. Biological materials: Functional adaptations and bioinspired designs. Prog. Mater. Sci. 2012, 57, 1492–1704. [Google Scholar] [CrossRef]

- John, G.; Clements-Croome, D.; Jeronimidis, G. Sustainable building solutions: A review of lessons from the natural world. Build. Environ. 2005, 40, 319–328. [Google Scholar] [CrossRef]

- AlAli, M.; Mattar, Y.; Alzaim, M.A.; Beheiry, S. Applications of biomimicry in architecture, construction and civil engineering. Biomimetics 2023, 8, 202. [Google Scholar] [CrossRef]

- Bosia, F.; Dal Poggetto, V.F.; Gliozzi, A.S.; Pugno, N.M. Optimized structures for vibration attenuation and sound control in nature: A review. Matter 2022, 5, 3311–3340. [Google Scholar] [CrossRef]

- Kunzmann, C.; Aliakbarpour, H.; Ramezani, M. Biomimetics design of sandwich-structured composites. J. Compos. Sci. 2023, 7, 315. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, X.; Okabe, Y.; Xie, J.; Xu, M. Beetle elytron plate and the synergistic mechanism of a trabecu-lar-honeycomb core structure. Sci. China Technol. Sci. 2018, 62, 87–93. [Google Scholar] [CrossRef]

- Pan, J.; Zhang, Q.; Li, M.; Cai, J. In-plane bidirectional dynamic crushing behaviors of a novel misplaced reinforced honeycomb. Thin-Walled Struct. 2024, 199, 111856. [Google Scholar] [CrossRef]

- Chen, J.; Guo, Z.; Du, S.; Song, Y.; Ren, H.; Fu, Y. Heat transfer characteristics of straw-core paper honeycomb plates (beetle elytron plates) I: Experimental study on horizontal placement with hot-above and cold-below conditions. Appl. Therm. Eng. 2021, 194, 117095. [Google Scholar] [CrossRef]

- Guo, Z.; Xu, Y.; Chen, J.; Wei, P.; Song, Y. Heat transfer characteristics of straw-core paper honeycomb plates II: Heat transfer mechanism with hot-above and cold-below conditions. Appl. Therm. Eng. 2021, 195, 117165. [Google Scholar] [CrossRef]

- Guo, Z.; Song, Y.; Chen, J.; Xu, Y.; Zhao, C. Relation between the geometric parameters and the composite heat transfer of paper honeycomb plates under cold-above/hot-below conditions and the corresponding influence mechanism. J. Build. Eng. 2021, 43, 102582. [Google Scholar] [CrossRef]

- Sui, N.; Yan, X.; Huang, T.Y.; Xu, J.; Yuan, F.G.; Jing, Y. A lightweight yet sound-proof honeycomb acoustic met-amaterial. Appl. Phys. Lett. 2015, 106, 171905. [Google Scholar] [CrossRef]

- Naify, C.; Sneddon, M.; Nutt, S. Noise reduction of honeycomb sandwich panels with acoustic mesh caps. Proc. Meet. Acoust. 2009, 8, 015002. [Google Scholar] [CrossRef]

- Chandrasekaran, N.K.; Arunachalam, V. State-of-the-art review on honeycomb sandwich composite structures with an emphasis on filler materials. Polym. Compos. 2021, 42, 5011–5020. [Google Scholar] [CrossRef]

- Li, Q.; Yang, D. Mechanical and acoustic performance of sandwich panels with hybrid cellular cores. J. Vi-Bration Acoust. 2018, 140, 061016.1–061016.15. [Google Scholar] [CrossRef]

- Ge, Y.; Xue, J.; Liu, L.; Yang, Y. Preparation and sound insulation of honeycomb composite structures filled with glass fiber. Polym. Compos. 2023, 45, 1649–1663. [Google Scholar] [CrossRef]

- Kong, K.; Inoue, N.; Sakuma, T. Sound insulation characteristics of a layered structure using perforated honeycomb panel. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings; Institute of Noise Control Engineering: Wakefield, MA, USA, 2020; Volume 261, pp. 376–383. [Google Scholar]

- Fahey, D.J.; Dunlap, M.; Seidl, R.J.; Forest Products Laboratory. Thermal Conductivity of Paper Honeycomb Cores and Sound Absorption of Sandwich Panels; USDA, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1953. [Google Scholar]

- Huang, W.; Ng, C. Sound insulation improvement using honeycomb sandwich panels. Appl. Acoust. 1997, 53, 163–177. [Google Scholar]

- Ge, Y.; Xue, J.; Liu, L.; Wan, H.; Yang, Y. Advances in multiple assembly acoustic structural design strategies for honeycomb composites: A review. Mater. Today Commun. 2024, 38, 108013. [Google Scholar] [CrossRef]

- Fan, X.; Cui, H.; Hong, M. Analysis of acoustic performance of honeycomb sandwich panels based on Virtual.Lab Acoustics. Noise Vib. Control. 2017, 37, 3968. (In Chinese) [Google Scholar]

- Jung, J.; Hong, S.; Song, J.; Kwon, H. Acoustic insulation performance of a honeycomb panel using a transfer matrix method. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2018, 232, 392–401. [Google Scholar] [CrossRef]

- Arunkumar, M.; Pitchaimani, J.; Gangadharan, K.V.; Babu, M. Influence of nature of core on vibro acoustic behavior of sandwich aerospace structures. Aerosp. Sci. Technol. 2016, 56, 155–167. [Google Scholar] [CrossRef]

- Saffar, S. Acoustic modeling of honeycomb structures for second load direction with damping consideration. Build. Acoust. 2022, 29, 263–294. [Google Scholar] [CrossRef]

- Xie, S.; Yang, S.; Yang, C.; Wang, D. Sound absorption performance of a filled honeycomb composite structure. Appl. Acoust. 2020, 162, 107202. [Google Scholar] [CrossRef]

- Jang, E. Sound absorbing properties of selected green material—A review. Forests 2023, 14, 1366. [Google Scholar] [CrossRef]

- Mamtaz, H.; Fouladi, M.H.; Al-Atabi, M.; Namasivayam, S.N. Acoustic absorption of natural fiber composites. J. Eng. 2016, 2016, 5836107. [Google Scholar] [CrossRef]

- Hao, N.; Song, Y.; Wang, Z.; He, C.; Ruan, S. Utilization of silt, sludge, and industrial waste residues in building materials: A review. J. Appl. Biomater. Funct. Mater. 2022, 20, 22808000221114709. [Google Scholar] [CrossRef]

- Yang, X.; Chen, C.; Yang, B. Performance comparison between glazed hollow bead and closed-cell expanded perlite. New Build. Mater. 2009, 4, 42–44. [Google Scholar]

- Villaquirán-Caicedo, M.A.; Perea, V.N.; Ruiz, J.E.; López, E.F. Mechanical, physical and thermoacoustic properties of lightweight composite geopolymers. Ing. Compet. 2022, 24, 8. [Google Scholar] [CrossRef]

- Kaiming, Q. Briefly talk about the acceptability control of thermal insulation glazed hollow bead mortar of high building external wall. J. World Archit. 2017, 1, 7–9. [Google Scholar] [CrossRef]

- Nechita, P.; Năstac, S. Foam-formed cellulose composite materials with potential applications in sound insulation. J. Compos. Mater. 2017, 52, 747–754. [Google Scholar] [CrossRef]

- Kia Motors Corporation. Soundproof Material Using Polyurethane Foam from Car Seat and Fabrication Process Thereof. CN103507349A, 2014. Available online: https://patents.google.com/patent/CN103507349A/en (accessed on 25 August 2024).

- Mohammadi, B.; Ershad-Langroudi, A.; Moradi, G.; Fouladi, M.H. Foam for sound insulation. In Polymeric Foams: Applications of Polymeric Foams; American Chemical Society: Washington, DC, USA, 2023; Volume 2, pp. 253–272. [Google Scholar]

- Chen, J.; Liu, Y.; Guo, Z.; Zhu, N.; Zhang, X. Mechanical properties of an energy-efficient straw-filled honeycomb plate with cement-based skins under a hammer impact test. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 7858–7869. [Google Scholar] [CrossRef]

- Zhang, X.; Long, B.; Sun, J.; Li, Z.; Jia, Z.; Gu, J. Design and fabrication of PVAc-based inverted core/shell (ICS) structured adhesives for improved water-resistant wood bonding performance: I. Influence of chemical grafting. Interna-Tional J. Adhes. Adhes. 2020, 98, 102522. [Google Scholar] [CrossRef]

- Thakur, A.G.; Rao, T.E.; Mukhedkar, M.S.; Nandedkar, V.M. Application of Taguchi method for resistance spot welding of galvanized steel. ARPN J. Eng. Appl. Sci. 2010, 5, 22–26. [Google Scholar]

- Shehata, S. Straw Wastes from an Environmental Disaster to ECO-Board towards a Sustainable Urban Environment. Procedia Environ. Sci. 2016, 34, 539–546. [Google Scholar] [CrossRef]

- Ye, D.; Wang, C.; Xi, J.; Li, W.; Wang, J.; Miao, E.; Xing, W.; Yu, B. Construction of sustainable and highly efficient fire-protective nanocoatings based on polydopamine and phosphorylated cellulose for flexible polyurethane foam. Int. J. Biol. Macromol. 2024, 272, 132639. [Google Scholar] [CrossRef] [PubMed]

- Hao, N.; Wang, Z.; Song, Y.; Ruan, S.; He, C.; Dong, Z. Free vibration and sound transmission properties of beetle elytron plate: Structural parametric analysis. Heliyon 2022, 8, e11683. [Google Scholar] [CrossRef] [PubMed]

- Łebkowska, M.; Załęska-Radziwiłł, M.; Tabernacka, A. Adhesives based on formaldehyde– environmental problems. Biotechnologia. J. Biotechnol. Comput. Biol. Bionanotechnol. 2017, 98, 53–65. [Google Scholar]

- Oliazadeh, P.; Farshidianfar, A.; Crocker, M.J. Experimental study and analytical modeling of sound transmission through honeycomb sandwich panels using SEA method. Compos. Struct. 2022, 280, 114927. [Google Scholar] [CrossRef]

- ISO 10140-1:2021; Acoustics—Laboratory Measurement of Sound Insulation of Building Elements Part 1: Application Rules for Specific Products. International Organization for Standardization: Geneva, Switzerland, 2021.

- Dijckmans, A.; Vermeir, G.; Lauriks, W. Sound transmission through finite lightweight multilayered structures with thin air layers. J. Acoust. Soc. Am. 2010, 128, 3513–3524. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, Y.Z.; Li, X.Y.; Lin, Z.; Wu, Q.Q.; Wu, L.Z. Sound transmission across locally resonant honeycomb sandwich meta-structures with large spatial periodicity. J. Acoust. Soc. Am. 2023, 154, 2609–2624. [Google Scholar] [CrossRef]

- Wang, S.; Xiao, Y.; Tang, Y.; Wu, J.; Teng, W.; Wen, J. Sound insulation mechanisms and behavior of lightweight metamaterial plate. J. Mech. Eng. 2023, 59, 94–109. (In Chinese) [Google Scholar]

- Du, Y. The Analysis of Sound Insulation Characteristics of Membrane-Honeycomb Sandwich Panel Composite Structure. Master’s Thesis, Dalian University of Technology, Dalian, China, 2020. (In Chinese). [Google Scholar]

- Arunkumar, M.; Jagadeesh, M.; Pitchaimani, J.; Gangadharan, K.; Babu, M.L. Sound radiation and transmission loss characteristics of a honeycomb sandwich panel with composite facings: Effect of inherent material damping. J. Sound Vib. 2016, 383, 221–232. [Google Scholar] [CrossRef]

- Van Belle, L.; Claeys, C.; Deckers, E.; Desmet, W. The impact of damping on the sound transmission loss of locally resonant metamaterial plates. J. Sound Vib. 2019, 461, 114909. [Google Scholar] [CrossRef]

- Son, L.; Rahman, A.; Bur, M. The Effect of Wing Spar Cross-Sectional Profile Variation on the Unmanned Aerial Vehicle (UAV) Natural Frequency. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1062, 012032. [Google Scholar]

- Shen, C.; Zhang, Q.; Chen, S.; Xia, H.; Jin, F. Sound transmission loss of adhesively bonded sandwich panels with pyramidal truss core: Theory and experiment. Int. J. Appl. Mech. 2015, 7, 1550013. [Google Scholar] [CrossRef]

- Wang, D.; Xie, S.; Feng, Z.; Liu, X.; Li, Y. Investigating the Effect of Dimension Parameters on Sound Transmission Losses in Nomex Honeycomb Sandwich. Appl. Sci. 2019, 10, 3109. [Google Scholar] [CrossRef]

- Toyoda, M.; Sakagami, K.; Takahashi, D.; Morimoto, M. Effect of a honeycomb on the sound absorption character-istics of panel-type absorbers. Appl. Acoust. 2011, 72, 943–948. [Google Scholar] [CrossRef]

- Li, S.; Xu, D.; Wu, X.; Jiang, R.; Shi, G.; Zhang, Z. Sound insulation performance of composite double sandwich panels with periodic arrays of shunted piezoelectric patches. Materials 2021, 15, 490. [Google Scholar] [CrossRef]

- Nurzyński, J. Sound insulation of bulkhead panels. Appl. Acoust. 2021, 179, 108061. [Google Scholar] [CrossRef]

| Material Name | Size (mm) | Density (kg·m−3) | Elastic Modulus (GPa) | Damping Coefficient (N·s·m−1) | Poisson’s Ratio | Manufacturer | Photograph |

|---|---|---|---|---|---|---|---|

| Sun-dried rice straw chaff | 1~5 | 50~150 | 0.5~3.5 | 0.02~0.1 | 0.2~0.4 | Rural Area (Lianyungang City, Jiangsu Province, China) |  |

| Glazed hollow bead | 1~5 | 50~200 | 0.3~1.5 | 0.01~0.05 | 0.2~0.3 | Zhongsen Perlite Application Co., Ltd. (Xinyang, China) |  |

| Polystyrene foam particles | 3~5 | 10~50 | 0.03~0.1 | 0.005~0.02 | 0.3~0.35 | Yishi Yijia Composite Material Products Co., Ltd. (Guangzhou, China) |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Yang, H.; Zhu, N.; Chen, J. Experimental Investigation on the Acoustic Insulation Properties of Filled Paper Honeycomb-Core Wallboards. Biomimetics 2024, 9, 528. https://doi.org/10.3390/biomimetics9090528

Song Y, Yang H, Zhu N, Chen J. Experimental Investigation on the Acoustic Insulation Properties of Filled Paper Honeycomb-Core Wallboards. Biomimetics. 2024; 9(9):528. https://doi.org/10.3390/biomimetics9090528

Chicago/Turabian StyleSong, Yiheng, Haixia Yang, Nanxing Zhu, and Jinxiang Chen. 2024. "Experimental Investigation on the Acoustic Insulation Properties of Filled Paper Honeycomb-Core Wallboards" Biomimetics 9, no. 9: 528. https://doi.org/10.3390/biomimetics9090528

APA StyleSong, Y., Yang, H., Zhu, N., & Chen, J. (2024). Experimental Investigation on the Acoustic Insulation Properties of Filled Paper Honeycomb-Core Wallboards. Biomimetics, 9(9), 528. https://doi.org/10.3390/biomimetics9090528