Environmentally Responsive Materials for Building Envelopes: A Review on Manufacturing and Biomimicry-Based Approaches

Abstract

1. Introduction

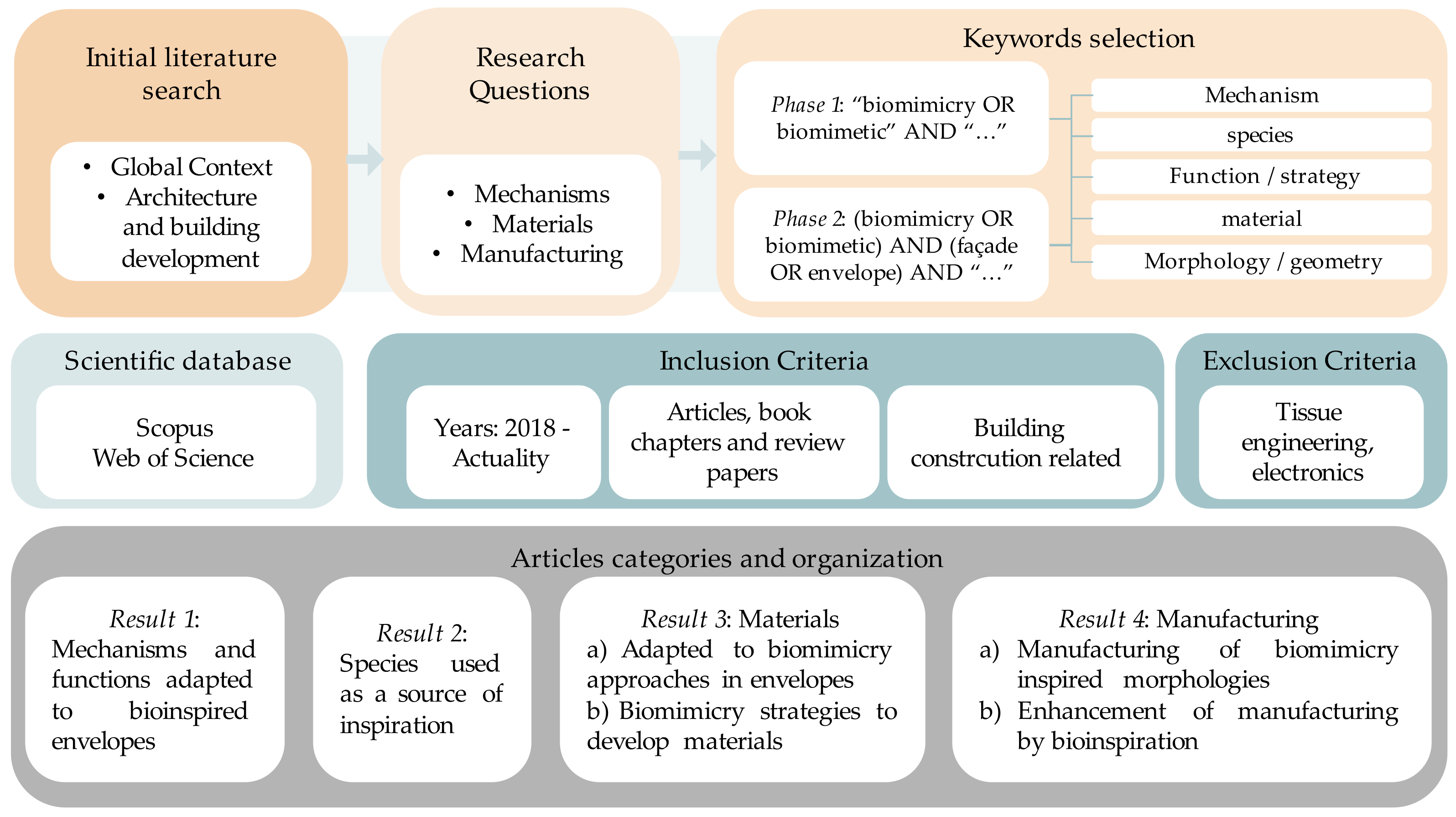

2. Materials and Methods

- R.Q.1. What have been the biomimicry solutions previously adapted to responsive envelopes or related and their mechanisms?

- R.Q.2. How have materials been previously designed or adapted to comply with biomimicry solutions adapted to responsive envelopes?

- R.Q.3. Which manufacturing techniques have been used to comply with biomimicry solutions, or how has biomimicry enhanced manufacturing techniques adapted to responsive envelopes?

- Result 1: Mechanisms and functions adapted to bioinspired envelopes.

- Result 2: Species used as a source of inspiration.

- Result 3: Materials: (a) adapted to biomimicry approaches in envelopes, and (b) biomimicry strategies to develop materials.

- Result 4: Manufacturing: (a) manufacturing of biomimicry-inspired morphologies and (b) enhancement of manufacturing by bioinspiration.

3. Biomimicry in Responsive Envelopes and Applications

3.1. Water-Related Mechanisms

3.2. Heat- and Light-Related Mechanisms

3.3. Kinetic Mechanisms

4. Biomimicry-Based Materials

4.1. Hydrophobic Materials

4.2. Self-Healing Materials

4.3. Biomineralized and Natural Materials

4.4. Composite and Smart Materials

5. Biomimicry-Based Manufacturing Techniques

5.1. Subtractive Manufacturing

5.2. Additive Manufacturing

5.3. Other Manufacturing Techniques

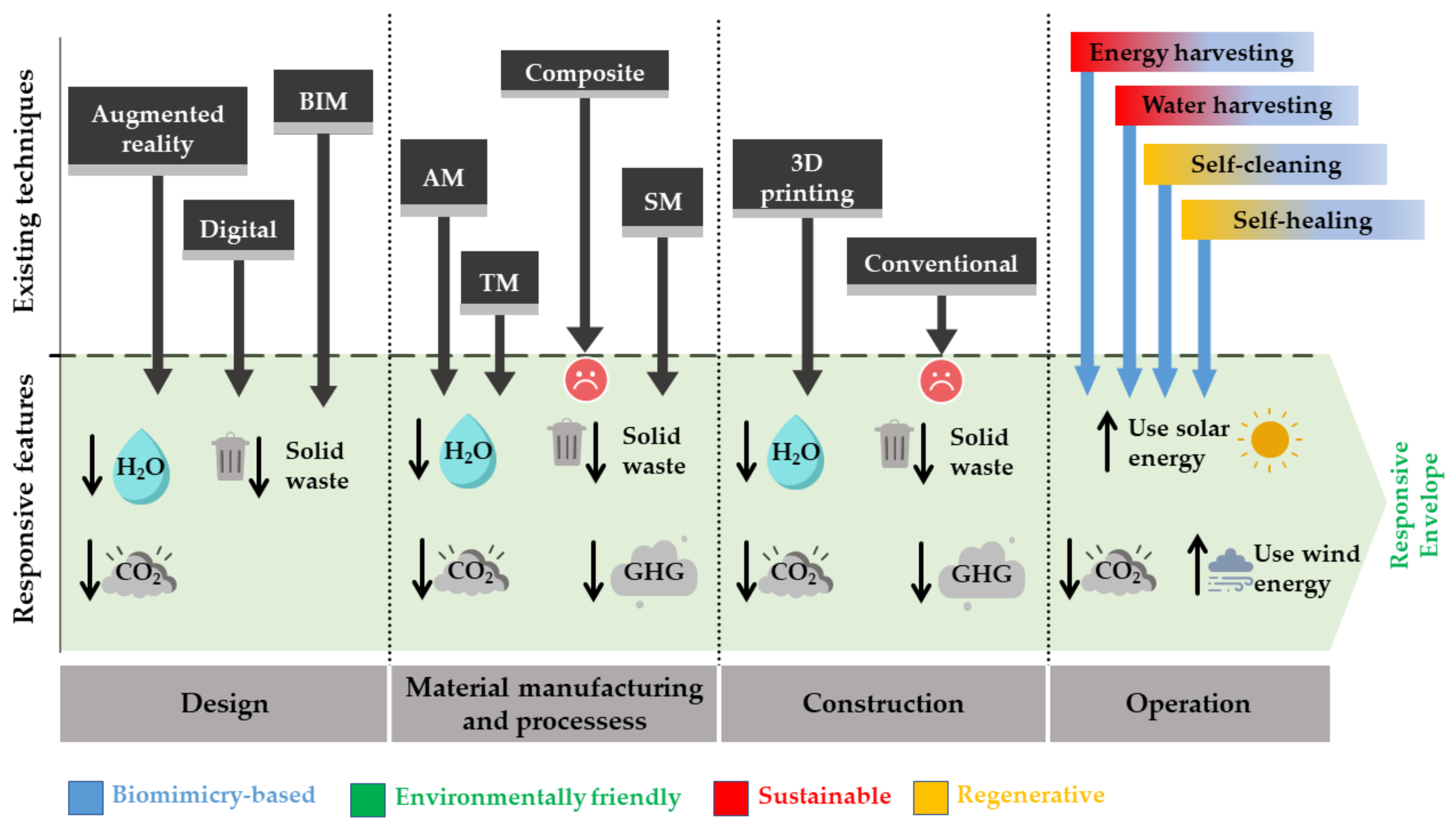

6. Discussion

- What have been the biomimicry solutions previously adapted to responsive envelopes or related and their mechanisms?

- How have materials been previously designed or adapted to comply with biomimicry solutions adapted to responsive envelopes?

- Which manufacturing techniques have been used to comply with biomimicry solutions, or how has biomimicry enhanced manufacturing techniques adapted to responsive envelopes?

7. Conclusions

- In mechanisms and functions adopted for bio-inspired envelopes, species are used as a source of inspiration.

- In materials adapted to biomimetic approaches in envelopes and biomimetic strategies for their development.

- In manufacturing, morphologies are inspired by biomimicry and enhanced through bio-inspiration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Eniveronment Programme. 2021 Global Status Report for Buildings and Construction towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector; United Nations Eniveronment Programme: Nairobi, Kenya, 2021. [Google Scholar]

- Ahamed, M.K.; Wang, H.; Hazell, P.J. From Biology to Biomimicry: Using Nature to Build Better Structures—A Review. Constr. Build. Mater. 2022, 320, 126195. [Google Scholar] [CrossRef]

- Craveiro, F.; Duarte, J.P.; Bartolo, H.; Bartolo, P.J. Additive Manufacturing as an Enabling Technology for Digital Construction: A Perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Hanzl, M. Urban Forms and Green Infrastructure—The Implications for Public Health during the COVID-19 Pandemic. Cities Health 2021, 5, S232–S236. [Google Scholar] [CrossRef]

- Shahda, M.M.; Megahed, N.A. Post-Pandemic Architecture: A Critical Review of the Expected Feasibility of Skyscraper-Integrated Vertical Farming (SIVF). Archit. Eng. Des. Manag. 2022, 10, 1–22. [Google Scholar] [CrossRef]

- Husini, E.M.; Arabi, F.; Shamri, S.L.; Manaf, A.A.; Idris, M.M.; Jamaludin, J. Resillient Living by Optimizing the Building Façade in Designing Post-Covid Housing. Plan. Malays. 2022, 20, 85–98. [Google Scholar] [CrossRef]

- Ramesh, P.; Alagirisamy, B. Achieving sustainability goals through infrastructure modifications: Lessons learnt from COVID-19 pandemic. In Sustainable Cities and Resilience; Pal, I., Kolathayar, S., Eds.; Springer: Singapore, 2022; pp. 57–68. [Google Scholar]

- Pajonk, A.; Prieto, A.; Blum, U.; Knaack, U. Multi-Material Additive Manufacturing in Architecture and Construction: A Review. J. Build. Eng. 2022, 45, 103603. [Google Scholar] [CrossRef]

- Wiedmann, T.; Chen, G.; Owen, A.; Lenzen, M.; Doust, M.; Barrett, J.; Steele, K. Three-Scope Carbon Emission Inventories of Global Cities. J. Ind. Ecol. 2021, 25, 735–750. [Google Scholar] [CrossRef]

- Honarvar, S.M.H.; Golabchi, M.; Ledari, M.B. Building Circularity as a Measure of Sustainability in the Old and Modern Architecture: A Case Study of Architecture Development in the Hot and Dry Climate. Energy Build. 2022, 275, 112469. [Google Scholar] [CrossRef]

- Tang, W.; Niu, Z.; Wei, Z.; Zhu, L. Sustainable Development of Eco-Cities: A Bibliometric Review. Sustainability 2022, 14, 10502. [Google Scholar] [CrossRef]

- Badeche, M. Integrated adaptive facades for building energy efficiency and user’s thermal comfort. In Artificial Intelligence and Heuristics for Smart Energy Efficiency in Smart Cities; Hatti, M., Ed.; Springer International Publishing: Cham, Switzerland, 2022; pp. 882–888. [Google Scholar]

- Rossi-Schwarzenbeck, M.; Figliola, A. Adaptive Building and Skin: An Innovative Computational Workflow to Design Energy Efficient Buildings in Different Climate Zones. J. Green Build. 2019, 14, 1–15. [Google Scholar] [CrossRef]

- Faragalla, A.M.A.; Asadi, S. Biomimetic Design for Adaptive Building Façades: A Paradigm Shift towards Environmentally Conscious Architecture. Energies 2022, 15, 5390. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Zhang, X.; Zhang, H.; Chen, X.; Zhang, L. Adaptive Building Roof Combining Variable Transparency Shape-Stabilized Phase Change Material: Application Potential and Adaptability in Different Climate Zones. Build. Environ. 2022, 222, 109436. [Google Scholar] [CrossRef]

- He, Y.; Zhou, H.; Fahimi, F. Modeling and Demand-Based Control of Responsive Building Envelope with Integrated Thermal Mass and Active Thermal Insulations. Energy Build. 2022, 276, 112495. [Google Scholar] [CrossRef]

- Sommese, F.; Badarnah, L.; Ausiello, G. A Critical Review of Biomimetic Building Envelopes: Towards a Bio-Adaptive Model from Nature to Architecture. Renew. Sustain. Energy Rev. 2022, 169, 112850. [Google Scholar] [CrossRef]

- Attia, S.; Bilir, S.; Safy, T.; Struck, C.; Loonen, R.; Goia, F. Current Trends and Future Challenges in the Performance Assessment of Adaptive Façade Systems. Energy Build. 2018, 179, 165–182. [Google Scholar] [CrossRef]

- Webb, M. Biomimetic Building Facades Demonstrate Potential to Reduce Energy Consumption for Different Building Typologies in Different Climate Zones. Clean Techn Env. Policy 2022, 24, 493–518. [Google Scholar] [CrossRef]

- Romano, R.; Aelenei, L.; Aelenei, D.; Mazzucchelli, E.S. What Is an Adaptive Façade? Analysis of Recent Terms and Definitions from an International Perspective. J. Facade Des. Eng. 2018, 6, 65–76. [Google Scholar] [CrossRef]

- Borkowski, E.; Rovas, D.; Raslan, R. Adaptive Building Envelope Simulation in Current Design Practice: Findings from Interviews with Practitioners about Their Understanding of Methods, Tools and Workarounds and Implications for Future Tool Developments. Intell. Build. Int. 2022, 14, 172–189. [Google Scholar] [CrossRef]

- Sanga, R.; Kilumile, M.; Mohamed, F. Alternative Clay Bricks Inspired from Termite Mound Biomimicry. Case Stud. Constr. Mater. 2022, 16, e00977. [Google Scholar] [CrossRef]

- Benyus, J.M. Biomimicry: Innovation Inspired by Nature, 1st ed.; Morrow: New York, NY, USA, 1997; ISBN 978-0-688-13691-8. [Google Scholar]

- Badarnah, L. Form Follows Environment: Biomimetic Approaches to Building Envelope Design for Environmental Adaptation. Buildings 2017, 7, 40. [Google Scholar] [CrossRef]

- Badarnah Kadri, L. Towards the LIVING Envelope: Biomimetics for Building Envelope Adaptation; Wöhrmann Print Service B.V.: Zutphen, The Netherlands, 2012; ISBN 978-94-6203-200-2. [Google Scholar]

- Imani, N.; Vale, B. Developing a Method to Connect Thermal Physiology in Animals and Plants to the Design of Energy Efficient Buildings. Biomimetics 2022, 7, 67. [Google Scholar] [CrossRef] [PubMed]

- Houda, A.N.E.; Mohamed, D. Advanced building skins inspired from plants adaptation strategies to environmental stimuli: A review. In Proceedings of the 2018 International Conference on Applied Smart Systems (ICASS), Medea, Algeria, 24 – 25 November 2018; pp. 1–7. [Google Scholar]

- Du Plessis, A.; Babafemi, A.J.; Paul, S.C.; Panda, B.; Tran, J.P.; Broeckhoven, C. Biomimicry for 3D Concrete Printing: A Review and Perspective. Addit. Manuf. 2021, 38, 101823. [Google Scholar] [CrossRef]

- Dixit, S.; Stefańska, A. Bio-Logic, a Review on the Biomimetic Application in Architectural and Structural Design. Ain Shams Eng. J. 2023, 14, 101822. [Google Scholar] [CrossRef]

- Fratzl, P.; Weinkamer, R. Nature’s Hierarchical Materials. Prog. Mater. Sci. 2007, 52, 1263–1334. [Google Scholar] [CrossRef]

- Jia, Z.; Deng, Z.; Li, L. Biomineralized Materials as Model Systems for Structural Composites: 3D Architecture. Adv. Mater. 2022, 34, 2106259. [Google Scholar] [CrossRef]

- Bucklin, O.; Menges, A.; Amtsberg, F.; Drexler, H.; Rohr, A.; Krieg, O.D. Mono-Material Wood Wall: Novel Building Envelope Using Subtractive Manufacturing of Timber Profiles to Improve Thermal Performance and Airtightness of Solid Wood Construction. Energy Build. 2022, 254, 111597. [Google Scholar] [CrossRef]

- Anton, A.; Reiter, L.; Wangler, T.; Frangez, V.; Flatt, R.J.; Dillenburger, B. A 3D Concrete Printing Prefabrication Platform for Bespoke Columns. Autom. Constr. 2021, 122, 103467. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; De Schutter, G.; Van Tittelboom, K. Extrusion-Based Concrete 3D Printing from a Material Perspective: A State-of-the-Art Review. Cem. Concr. Compos. 2021, 115, 103855. [Google Scholar] [CrossRef]

- Delgado Camacho, D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of Additive Manufacturing in the Construction Industry – A Forward-Looking Review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Hershcovich, C.; van Hout, R.; Rinsky, V.; Laufer, M.; Grobman, Y.j. Thermal Performance of Sculptured Tiles for Building Envelopes. Build. Environ. 2021, 197, 107809. [Google Scholar] [CrossRef]

- Fuchs, D.; Bartz, R.; Kuschmitz, S.; Vietor, T. Necessary Advances in Computer-Aided Design to Leverage on Additive Manufacturing Design Freedom. Int. J. Interact. Des. Manuf. 2022, 16, 1633–1651. [Google Scholar] [CrossRef]

- Al-Qutaifi, S.; Nazari, A.; Bagheri, A. Mechanical Properties of Layered Geopolymer Structures Applicable in Concrete 3D-Printing. Constr. Build. Mater. 2018, 176, 690–699. [Google Scholar] [CrossRef]

- Blanco, J.L.; Dohmann, T.; Julien, J.; Law, J.; Palter, R. Governments Can Lead Construction into the Digital Era. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/governments-can-lead-construction-into-the-digital-era# (accessed on 30 June 2021).

- NBS Enterprises Ltd. National BIM Report; NBS Enterprises Ltd.: Leicester, UK, 2018; p. 27. [Google Scholar]

- Naqeshbandi, N.; Mendonça, P. Digital Fabrication and Crafting for Flexible Building Wall Components: Design and Development of Prototypes. In Proceedings of the ISARC Proceedings, Banff, Canada, 24 May 2019; pp. 537–543. [Google Scholar]

- Ferng, J. Construction: Systemization of Cities Beyond Industry 4.0. CTBUH J. 2021, 2, 46–53. [Google Scholar]

- Allameh, S.M.; Lenihan, A. Introduction to bio-inspired materials: Design, processing and applications. In Biomimicry for Materials, Design and Habitats: Innovations and Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 25–56. ISBN 978-0-12-821053-6. [Google Scholar]

- Eggermont, M.; Shyam, V.; Hepp, A.F. Biomimicry for materials, design and habitats: Innovations and applications. In Biomimicry for Materials, Design and Habitats: Innovations and Applications; Elsevier: Amsterdam, The Netherlands, 2022; p. 569. ISBN 978-0-12-821053-6. [Google Scholar]

- Peeks, M.; Badarnah, L. Textured Building Façades: Utilizing Morphological Adaptations Found in Nature for Evaporative Cooling. Biomimetics 2021, 6, 24. [Google Scholar] [CrossRef]

- Faragllah, R.N. Biomimetic Approaches for Adaptive Building Envelopes: Applications and Design Considerations. Civ. Eng. Arch. 2021, 9, 2464–2475. [Google Scholar] [CrossRef]

- Körner, A.; Born, L.; Bucklin, O.; Suzuki, S.; Vasey, L.; Gresser, G.T.; Menges, A.; Knippers, J. Integrative Design and Fabrication Methodology for Bio-Inspired Folding Mechanisms for Architectural Applications. Comput. -Aided Des. 2021, 133, 102988. Comput. Aided Des. 2021, 133, 102988. [Google Scholar] [CrossRef]

- Teasdale-St-Hilaire, A.; Derome, D.; Fazio, P. Development of an experimental methodology for the simulation of wetting due to rain infiltration for building envelope testing. In Research in Building Physics; Carmeliet, J., Hens, H., Vermeir, G., Eds.; A Balkema Publishers: Leiden, The Netherlands, 2003; pp. 455–462. [Google Scholar]

- Ilomets, S.; Kalamees, T.; Lahdensivu, J.; Kloseiko, P. Impact of ETICS on corrosion propagation of concrete facade. In Sustainable Built Environment Tallinn and Helsinki Conference SBE16 Build Green and Renovate Deep; Kurnitski, J., Ed.; Elsevier Science Bv: Amsterdam, The Netherlands, 2016; Volume 96, pp. 67–76. [Google Scholar]

- Vandemeulebroucke, I.; Caluwaerts, S.; Van Den Bossche, N. Decision Framework to Select Moisture Reference Years for Hygrothermal Simulations. Build. Environ. 2022, 218, 109080. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; Iovane, T.; Mastellone, M.; Mauro, G.M. The Evolution of Building Energy Retrofit via Double-Skin and Responsive Façades: A Review. Sol. Energy 2021, 224, 703–717. [Google Scholar] [CrossRef]

- United Nations Children’s Fund (UNICEF). Unicef Guidance Note Programmatic Approaches to Water Scarcity; UNICEF: New York, NY, USA, 2021. [Google Scholar]

- Kandeal, A.W.; Joseph, A.; Elsharkawy, M.; Elkadeem, M.R.; Hamada, M.A.; Khalil, A.; Eid Moustapha, M.; Sharshir, S.W. Research Progress on Recent Technologies of Water Harvesting from Atmospheric Air: A Detailed Review. Sustain. Energy Technol. Assess. 2022, 52, 102000. [Google Scholar] [CrossRef]

- Guo, Y.; Guan, W.; Lei, C.; Lu, H.; Shi, W.; Yu, G. Scalable Super Hygroscopic Polymer Films for Sustainable Moisture Harvesting in Arid Environments. Nat. Commun. 2022, 13, 2761. [Google Scholar] [CrossRef]

- Kim, H.; Yang, S.; Rao, S.R.; Narayanan, S.; Kapustin, E.A.; Furukawa, H.; Umans, A.S.; Yaghi, O.M.; Wang, E.N. Water Harvesting from Air with Metal-Organic Frameworks Powered by Natural Sunlight. Science 2017, 356, 430–434. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, D.T.; Zhang, X.Y.; Zhang, Z.Z. Modified PDMS with Inserted Hydrophilic Particles for Water Harvesting. Compos. Sci. Technol. 2021, 213, 108954. [Google Scholar] [CrossRef]

- Lee, S.J.; Ha, N.; Kim, H. Superhydrophilic–Superhydrophobic Water Harvester Inspired by Wetting Property of Cactus Stem. ACS Sustain. Chem. Eng. 2019, 7, 10561–10569. [Google Scholar] [CrossRef]

- Lu, H.; Shi, W.; Zhang, J.H.; Chen, A.C.; Guan, W.; Lei, C.; Greer, J.R.; Boriskina, S.V.; Yu, G. Tailoring the Desorption Behavior of Hygroscopic Gels for Atmospheric Water Harvesting in Arid Climates. Adv. Mater. 2022, 34, 2205344. [Google Scholar] [CrossRef]

- Wang, Shengnan; Chen, Kang; Zheng, Xy Recent Progress of Moisture Sorbent for Adsorption-Based Atmospheric Water Harvesting. Chem. Ind. Eng. Prog. 2022, 41, 3636–3647. [CrossRef]

- Ma, Q.; Zheng, X. Preparation and Characterization of Thermo-Responsive Composite for Adsorption-Based Dehumidification and Water Harvesting. Chem. Eng. J. 2022, 429, 132498. [Google Scholar] [CrossRef]

- Liu, X.Y.; Wang, W.W.; Xie, S.T.; Pan, Q.W. Performance Characterization and Application of Composite Adsorbent LiCl@ACFF for Moisture Harvesting. Sci. Rep. 2021, 11, 14412. [Google Scholar] [CrossRef]

- Rajendra Prasad, A.; Jaiganesh, V.; Sunil Babu, S.; Shanawaz, A.M.; Vijay Muni, T.; Venkatesh, V.; Subbiah, R. Performance of Solar Still Powered Water Recovery System from Moist Air. Mater. Today Proc. 2022, 62, 1765–1769. [Google Scholar] [CrossRef]

- LaPotin, A.; Zhong, Y.; Zhang, L.; Zhao, L.; Leroy, A.; Kim, H.; Rao, S.R.; Wang, E.N. Dual-Stage Atmospheric Water Harvesting Device for Scalable Solar-Driven Water Production. Joule 2021, 5, 166–182. [Google Scholar] [CrossRef]

- Yang, M.; Wang, S.-Q.; Liu, Z.; Chen, Y.; Zaworotko, M.J.; Cheng, P.; Ma, J.-G.; Zhang, Z. Fabrication of Moisture-Responsive Crystalline Smart Materials for Water Harvesting and Electricity Transduction. J. Am. Chem. Soc. 2021, 143, 7732–7739. [Google Scholar] [CrossRef]

- Lv, D.; Zheng, S.; Cao, C.; Li, K.; Ai, L.; Li, X.; Yang, Z.; Xu, Z.; Yao, X. Defect-Enhanced Selective Ion Transport in an Ionic Nanocomposite for Efficient Energy Harvesting from Moisture. Energy Environ. Sci. 2022, 15, 2601–2609. [Google Scholar] [CrossRef]

- Han, X.; Zhang, W.; Che, X.; Long, L.; Li, M.; Li, C. Synergetic and Persistent Harvesting of Electricity and Potable Water from Ambient Moisture with Biohybrid Fibrils. J. Mater. Chem. A 2022, 10, 8356–8363. [Google Scholar] [CrossRef]

- Nandakumar, D.K.; Zhang, Y.; Ravi, S.K.; Guo, N.; Zhang, C.; Tan, S.C. Solar Energy Triggered Clean Water Harvesting from Humid Air Existing above Sea Surface Enabled by a Hydrogel with Ultrahigh Hygroscopicity. Adv. Mater. 2019, 31, e1806730. [Google Scholar] [CrossRef]

- Vogel, S.; Müller-Doblies, U. Desert Geophytes under Dew and Fog: The “Curly-Whirlies” of Namaqualand (South Africa). Flora-Morphol. Distrib. Funct. Ecol. Plants 2011, 206, 3–31. [Google Scholar] [CrossRef]

- Malik, F.T.; Clement, R.M.; Gethin, D.T.; Krawszik, W.; Parker, A.R. Nature’s Moisture Harvesters: A Comparative Review. Bioinspir. Biomim. 2014, 9, 031002. [Google Scholar] [CrossRef]

- Koch, K.; Barthlott, W. Superhydrophobic and Superhydrophilic Plant Surfaces: An Inspiration for Biomimetic Materials. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 1487–1509. [Google Scholar] [CrossRef]

- El-Maghraby, H.F.; Alhumaidi, A.; Alnaqbi, M.A.; Sherif, M.; Tai, Y.; Hassan, F.; Greish, Y.E. Bioinspired Asymmetric Surface Property of Functionalized Mesh to Maximize the Efficiency of Fog Harvesting. ChemNanoMat 2022, 8, e202200327. [Google Scholar] [CrossRef]

- Caldas, L.; Andaloro, A.; Calafiore, G.; Munechika, K.; Taube, B.; Oliveira, M.; Cabrini, S. Water Harvesting from Fog Using Building Envelopes: Part II. Water Environ. J. 2018, 32, 466–475. [Google Scholar] [CrossRef]

- Darmanin, T.; Guittard, F. Superhydrophobic and Superoleophobic Properties in Nature. Mater. Today 2015, 18, 273–285. [Google Scholar] [CrossRef]

- Xie, H.; Huang, H.-X.; Mi, H.-Y. Gradient Wetting State for Droplet Transportation and Efficient Fog Harvest on Nanopillared Cicada Wing Surface. Mater. Lett. 2018, 221, 123–127. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Liu, L.; Chen, Y.; Chu, M.; Sun, H.; Shan, W.; Chen, Y. 3D-Printed Cactus-Inspired Spine Structures for Highly Efficient Water Collection. Adv. Mater. Interfaces 2020, 7, 1901752. [Google Scholar] [CrossRef]

- Shi, Y.; Kim, K. Fabrication of Hydrophilic and Hydrophobic Membranes Inspired by the Phenomenon of Water Absorption and Storage of Cactus. Front. Mater. 2022, 9, 966692. [Google Scholar] [CrossRef]

- Luo, Y.-Q.; Song, F.; Xu, C.; Wang, X.-L.; Wang, Y.-Z. Bioinspired Fabrication of Asymmetric Wood Materials for Directional Liquid Manipulation and Transport. Chem. Eng. J. 2020, 383, 123168. [Google Scholar] [CrossRef]

- Masrahi, Y.S. Glochids Microstructure and Dew Harvesting Ability in Opuntia stricta (Cactaceae). J. King Saud Univ. Sci. 2020, 32, 3307–3312. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Zhao, J.; Guo, J.; Zhang, S.; Sherazi, T.A.; Ambreen; Li, S. Bioinspired Superhydrophilic-Hydrophobic Integrated Surface with Conical Pattern-Shape for Self-Driven Fog Collection. J. Colloid Interface Sci 2018, 530, 247–281. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Wang, C.; Huang, Q.; Wang, Z.; Gong, X.; Ramakrishna, S. 3D-Printed Spider-Web Structures for Highly Efficient Water Collection. Heliyon 2022, 8, e10007. [Google Scholar] [CrossRef]

- Tang, X.; Liu, H.; Xiao, L.; Zhou, M.; Bai, H.; Fang, J.; Cui, Z.; Cheng, H.; Li, G.; Zhang, Y.; et al. A Hierarchical Origami Moisture Collector with Laser-Textured Microchannel Array for a Plug-and-Play Irrigation System. J. Mater. Chem. A 2021, 9, 5630–5638. [Google Scholar] [CrossRef]

- Feng, R.; Song, F.; Xu, C.; Wang, X.-L.; Wang, Y.-Z. A Quadruple-Biomimetic Surface for Spontaneous and Efficient Fog Harvesting. Chem. Eng. J. 2021, 422, 130119. [Google Scholar] [CrossRef]

- Li, C.; Yu, C.; Zhou, S.; Dong, Z.; Jiang, L. Liquid Harvesting and Transport on Multiscaled Curvatures. Proc. Natl. Acad. Sci. USA 2020, 117, 23436–23442. [Google Scholar] [CrossRef]

- Wu, Y.; Li, H.; Wen, L.; Men, D.; Hang, L.; Liu, D.; Liu, G.; Cai, W.; Lyu, X.; Li, Y. Bionic PDMS Film with Hybrid Superhydrophilic/Superhydrophobic Arrays for Water Harvest. Surf. Innov. 2018, 6, 141–149. [Google Scholar] [CrossRef]

- Zhu, H.; Huang, Y.; Lou, X.; Xia, F. Beetle-Inspired Wettable Materials: From Fabrications to Applications. Mater. Today Nano 2019, 6, 100034. [Google Scholar] [CrossRef]

- Rupp, A.I.K.S.; Houette, T.; Gutierrez, F.; Guiducci, L.; Gruber, P. Breathing skins workshop: A hands-on investigation of bio-inspired foldable structures for temperature and humidity control in buildings. In Proceedings of the Bioinspiration, Biomimetics, and Bioreplication IX, Denver, CO, USA, 3–7 March 2019; SPIE: Bellingham, WA, USA; Volume 10965, pp. 192–209. [Google Scholar]

- Holstov, A.; Farmer, G.; Bridgens, B. Sustainable Materialisation of Responsive Architecture. Sustainability 2017, 9, 435. [Google Scholar] [CrossRef]

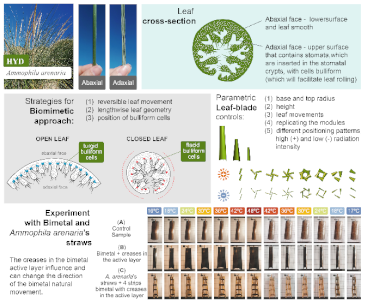

- De Andrade, T.A.B.; Beirão, J.N.D.C.; de Arruda, A.J.V.; Cruz, C. The Adaptive Power of Ammophila Arenaria: Biomimetic Study, Systematic Observation, Parametric Design and Experimental Tests with Bimetal. Polymers 2021, 13, 2554. [Google Scholar] [CrossRef]

- Huiskes, A.H.L. Ammophila arenaria (L.) Link (Psamma arenaria (L.) Roem. et Schult.; Calamgrostis arenaria (L.) Roth). J. Ecol. 1979, 67, 363–382. [Google Scholar] [CrossRef]

- Chergui, A.; Hafid, L.E.; Melhaoui, M. Characteristics of Marram Grass (Ammophila arenaria L.), Plant of The Coastal Dunes of The Mediterranean Eastern Morocco: Ecological, Morpho-Anatomical and Physiological Aspects. J. Mater. Environ. Sci. 2017, 8, 3759–3765. [Google Scholar]

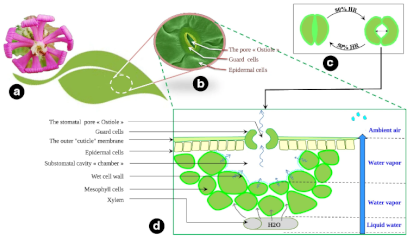

- Teraa, S.; Bencherif, M. From Hygrothermal Adaptation of Endemic Plants to Meteorosensitive Biomimetic Architecture: Case of Mediterranean Biodiversity Hotspot in Northeastern Algeria. Environ. Dev. Sustain. 2021, 24, 10876–10901. [Google Scholar] [CrossRef]

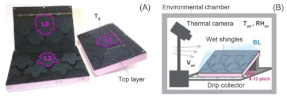

- Rupp, A.I.K.S.; Gruber, P. Chapter 16—A Case Study in Biomimetic Roofing: Moisture Dissipation from Leaf-Shaped Shingles. In Biomimicry for Materials, Design and Habitats; Eggermont, M., Shyam, V., Hepp, A.F., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 467–487. ISBN 978-0-12-821053-6. [Google Scholar]

- Jalali, S.; Aliabadi, M.; Mahdavinejad, M. Learning from Plants: A New Framework to Approach Water-Harvesting Design Concepts. Int. J. Build. Pathol. Adapt. 2021, 40, 405–421. [Google Scholar] [CrossRef]

- Sun, Y.; Sui, X.; Wang, Y.; Liang, W.; Wang, F. Passive Anti-Icing and Active Electrothermal Deicing System Based on an Ultraflexible Carbon Nanowire (CNW)/PDMS Biomimetic Nanocomposite with a Superhydrophobic Microcolumn Surface. Langmuir 2020, 36, 14483–14494. [Google Scholar] [CrossRef]

- Keskas, I.; Bourbia, F.; Mohammadi, M.; Calautit, J. Geo-Solar Segmentation Mechanism: An Early Design Stage Method for Building Solar Morphing. Sol. Energy 2022, 246, 302–319. [Google Scholar] [CrossRef]

- Anzaniyan, E.; Alaghmandan, M.; Montaser Koohsari, A. Design, Fabrication and Computational Simulation of a Bio-Kinetic Façade Inspired by the Mechanism of the Lupinus Succulentus Plant for Daylight and Energy Efficiency. Sci. Technol. Built Environ. 2022, 28, 1456–1471. [Google Scholar] [CrossRef]

- Wienold, J.; Christoffersen, J. Evaluation Methods and Development of a New Glare Prediction Model for Daylight Environments with the Use of CCD Cameras. Energy Build. 2006, 38, 743–757. [Google Scholar] [CrossRef]

- Samuel, A.K.; Mohanan, V.; Sempey, A.; Garcia, F.Y.; LAGIERE, P.; Bruneau, D.; Mahanta, N. A Sustainable approach for a climate responsive house in UAE: Case study of SDME 2018 baitykool project. In Proceedings of the 2019 International Conference on Computational Intelligence and Knowledge Economy (ICCIKE), Dubai, United Arab Emirates, 11–12 December 2019; pp. 816–823. [Google Scholar]

- Wang, F.; Zhang, X.; Wang, H.; Li, Y.; Dong, Y.; Lin, B.; Liang, H.; Cheng, Z. An Energy-Efficient Glass Using Biomimetic Structures with Excellent Energy Saving Features in Both Hot and Cold Weather. J. Quant. Spectrosc. Radiat. Transf. 2022, 286, 108180. [Google Scholar] [CrossRef]

- Charpentier, L.; Cruz, E.; Nenov, T.; Guidoux, K.; Ware, S. Pho’liage: Towards a kinetic biomimetic thermoregulating façade. In Bionics and Sustainable Design; Palombini, F.L., Muthu, S.S., Eds.; Environmental Footprints and Eco-Design of Products and Processes; Springer Nature: Singapore, 2022; pp. 367–401. ISBN 978-981-19181-2-4. [Google Scholar]

- Srisuwan, T. The Application of an Adaptive Soft Structure for Lightweight Facades. In Proceedings of International Structural Engineering and Construction; ISEC Press: Fargo, ND, USA, 2022; Volume 9, p. AAE-08-1. [Google Scholar]

- Panyaa, D.; Seo, J.H.; Park, H.J.; Lee, W.J.; Choo, S. A Study of Kinetic Façade Modelling Performance Using Virtual Reality. In Proceedings of the ISARC Proceedings, Banff, Canada, 21–24 May 2019; 2019; pp. 356–359. [Google Scholar]

- Speck, T.; Poppinga, S.; Speck, O.; Tauber, F. Bio-Inspired Life-like Motile Materials Systems: Changing the Boundaries between Living and Technical Systems in the Anthropocene. Anthr. Rev. 2022, 9, 237–256. [Google Scholar] [CrossRef]

- Körner, A.; Born, L.; Mader, A.; Sachse, R.; Saffarian, S.; Westermeier, A.S.; Poppinga, S.; Bischoff, M.; Gresser, G.T.; Milwich, M.; et al. Flectofold—A Biomimetic Compliant Shading Device for Complex Free Form Facades. Smart Mater. Struct. 2018, 27, 017001. [Google Scholar] [CrossRef]

- Mader, A.; Langer, M.; Knippers, J.; Speck, O. Learning from Plant Movements Triggered by Bulliform Cells: The Biomimetic Cellular Actuator. J. R. Soc. Interface 2020, 17, 20200358. [Google Scholar] [CrossRef]

- Tan, Y.; Hu, B.; Song, J.; Chu, Z.; Wu, W. Bioinspired Multiscale Wrinkling Patterns on Curved Substrates: An Overview. Nano-Micro Lett 2020, 12, 101. [Google Scholar] [CrossRef]

- Mole, M.A.; Rodrigues DÁraujo, S.; van Aarde, R.J.; Mitchell, D.; Fuller, A. Coping with Heat: Behavioural and Physiological Responses of Savanna Elephants in Their Natural Habitat. Conserv. Physiol. 2016, 4, cow044. [Google Scholar] [CrossRef]

- Cheng, Z.; Han, H.; Wang, F.; Yan, Y.; Shi, X.; Liang, H.; Zhang, X.; Shuai, Y. Efficient Radiative Cooling Coating with Biomimetic Human Skin Wrinkle Structure. Nano Energy 2021, 89, 106377. [Google Scholar] [CrossRef]

- Kay, R.; Katrycz, C.; Nitièma, K.; Jakubiec, J.A.; Hatton, B.D. Decapod-Inspired Pigment Modulation for Active Building Facades. Nat. Commun. 2022, 13, 4120. [Google Scholar] [CrossRef]

- Lin, S.; Zhao, L.; Feng, J. Predicted Changes in the Distribution of Antarctic Krill in the Cosmonaut Sea under Future Climate Change Scenarios. Ecol. Indic. 2022, 142, 109234. [Google Scholar] [CrossRef]

- Bukatov, M.V. Babiy manifestation of downward solar radiation flux in the variability of sea ice concentration and krill fishery in the antarctic. In Processes in GeoMedia; Springer: Cham, Switzerland, 2021; Volume II, ISBN 978-3-030-53521-6. [Google Scholar]

- Callies, A.; Wessels, A.; Bett, A.W.; Bläsi, B.; Höhn, O. Effect of Feature Size on the Reflective Behaviour of the MorphoColorTM Concept. In Proceedings of the Photonics for Solar Energy Systems IX, SPIE, Strasbourg, France, May 24 2022; Volume 12150, pp. 7–14. [Google Scholar]

- Quinn, G. Structural Analysis for the Pneumatic Erection of Elastic Gridshells. Structures 2020, 28, 2276–2290. [Google Scholar] [CrossRef]

- Dahy, H. Materials as a Design Tool’ Design Philosophy Applied in Three Innovative Research Pavilions Out of Sustainable Building Materials with Controlled End-Of-Life Scenarios. Buildings 2019, 9, 64. [Google Scholar] [CrossRef]

- Goss, D.; Penick, C.; Grishin, A.; Bhate, D. Bio-inspired design and additive manufacturing of cellular materials. In Biomimicry for Aerospace; Elsevier: Amsterdam, The Netherlands, 2022; pp. 141–185. ISBN 978-0-12-821075-8. [Google Scholar]

- Zheng, S.; Velho, A.; Ross, K.; Chen, H.; Li, L.; Zolotovsky, K. Self-Cleaning Surface Architectures from Chitin Biomaterials—Computational and Experimental Methodology; CUMINCAD: Ghent, Belgium, 2022; pp. 91–100. [Google Scholar]

- Collins, C.M.; Safiuddin, M. Lotus-Leaf-Inspired Biomimetic Coatings: Different Types, Key Properties, and Applications in Infrastructures. Infrastructures 2022, 7, 46. [Google Scholar] [CrossRef]

- Chung, D.; Wen, J. Building Envelope Moisture Transport in the Context of Assembly Aging and Uncertainty. Technol. Archit. Des. 2019, 3, 221–233. [Google Scholar] [CrossRef]

- Recart, C.; Sturts Dossick, C. Hygrothermal Behavior of Post-Retrofit Housing: A Review of the Impacts of the Energy Efficiency Upgrade Strategies. Energy Build. 2022, 262, 112001. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Le, P.H.; Daver, F.; Murdoch, B.J.; Ivanova, E.P.; Adhikari, B. Robust and Eco-Friendly Superhydrophobic Starch Nanohybrid Materials with Engineered Lotus Leaf Mimetic Multiscale Hierarchical Structures. ACS Appl. Mater. Interfaces 2021, 13, 36558–36573. [Google Scholar] [CrossRef]

- Dou, L.; Si, Y.; Yu, J.; Ding, B. Semi-Template Based, Biomimetic-Architectured, and Mechanically Robust Ceramic Nanofibrous Aerogels for Thermal Insulation. Nano Res. 2022, 15, 5581–5589. [Google Scholar] [CrossRef]

- Shahsavari, R.; Hwang, S.H. Bioinspired Cementitious Materials: Main Strategies, Progress, and Applications. Front. Mater. 2020, 7, 62. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Q.; Ashour, A.; Han, B. Self-Healing Cement Concrete Composites for Resilient Infrastructures: A Review. Compos. Part B Eng. 2020, 189, 107892. [Google Scholar] [CrossRef]

- Cremaldi, J.C.; Bhushan, B. Bioinspired Self-Healing Materials: Lessons from Nature. Beilstein J. Nanotechnol. 2018, 9, 907–935. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Labrincha, J.A. Biotech Cementitious Materials: Some Aspects of an Innovative Approach for Concrete with Enhanced Durability. Constr. Build. Mater. 2013, 40, 1136–1141. [Google Scholar] [CrossRef]

- du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Hesse, P.R. A Chemical and Physical Study of the Soils of Termite Mounds in East Africa. J. Ecol. 1955, 43, 449–461. [Google Scholar] [CrossRef]

- Moskaleva, A.; Safonov, A.; Hernández-Montes, E. Fiber-Reinforced Polymers in Freeform Structures: A Review. Buildings 2021, 11, 481. [Google Scholar] [CrossRef]

- Gil Pérez, M.; Rongen, B.; Koslowski, V.; Knippers, J. Structural Design, Optimization and Detailing of the BUGA Fibre Pavilion. Int. J. Space Struct. 2020, 35, 147–159. [Google Scholar] [CrossRef]

- Allameh, S.M.; Miller, R.; Allameh, H. Mechanical properties of 3D printed biomimicked composites. In Proceedings of the Volume 12: Materials: Genetics to Structures; American Society of Mechanical Engineers: Pittsburgh, PA, USA, 2018; p. V012T11A001. [Google Scholar]

- Liu, J.; Li, S.; Fox, K.; Tran, P. 3D Concrete Printing of Bioinspired Bouligand Structure: A Study on Impact Resistance. Addit. Manuf. 2022, 50, 102544. [Google Scholar] [CrossRef]

- Sangiorgio, V.; Parisi, F.; Fieni, F.; Parisi, N. The New Boundaries of 3D-Printed Clay Bricks Design: Printability of Complex Internal Geometries. Sustainability 2022, 14, 598. [Google Scholar] [CrossRef]

- Dong, L.; Wang, Y.; Li, H.X.; Jiang, B.; Al-Hussein, M. Carbon Reduction Measures-Based LCA of Prefabricated Temporary Housing with Renewable Energy Systems. Sustainability 2018, 10, 718. [Google Scholar] [CrossRef]

- Adamu, M.; Alanazi, F.; Ibrahim, Y.E.; Alanazi, H.; Khed, V.C. A Comprehensive Review on Sustainable Natural Fiber in Cementitious Composites: The Date Palm Fiber Case. Sustainability 2022, 14, 6691. [Google Scholar] [CrossRef]

- Ibn-Elhaj, S.; Mounir, S.; Khabbazi, A.; Sarghini, H. Effect of Clay’s Multilayer Composites Material on the Energy Efficiency of Buildings. J. Compos. Sci. 2022, 6, 151. [Google Scholar] [CrossRef]

- Institut d’Arquitectura Avançada de Catalunya CO-MIDA—Institute for Advanced Architecture of Catalonia. Available online: https://iaac.net/project/co-mida-en/ (accessed on 15 October 2022).

- Thompson, D.; Augarde, C.; Osorio, J.P. A Review of Current Construction Guidelines to Inform the Design of Rammed Earth Houses in Seismically Active Zones. J. Build. Eng. 2022, 54, 104666. [Google Scholar] [CrossRef]

- Zaryoun, M.; Hosseini, M. Lightweight Fiber-Reinforced Clay as a Sustainable Material for Disaster Resilient Architecture of Future Buildings. Archit. Eng. Des. Manag. 2019, 15, 430–444. [Google Scholar] [CrossRef]

- Mu, B.; Zhang, A.; Wang, A. Biomimetic superhydrophobic cobalt blue/clay mineral hybrid pigments with self-cleaning property and different colors. In Springer Proceedings in Earth and Environmental Sciences; Springer: Berlin/Heidelberg, Germany, 2019; pp. 427–431. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, J. Biomimetic Super Anti-Wetting Coatings from Natural Materials: Superamphiphobic Coatings Based on Nanoclays. Sci. Rep. 2018, 8, 12062. [Google Scholar] [CrossRef]

- Srivatsa, S.; Paćko, P.; Mishnaevsky, L.; Uhl, T.; Grabowski, K. Deformation of Bioinspired MXene-Based Polymer Composites with Brick and Mortar Structures: A Computational Analysis. Materials 2020, 13, 5189. [Google Scholar] [CrossRef]

- Evers, K.; Falco, S.; Grobert, N.; Todd, R.I. Nacre-like Alumina with Unique High Strain Rate Capabilities. J. Eur. Ceram. Soc. 2020, 40, 417–426. [Google Scholar] [CrossRef]

- Zhu, M.; Zhang, F.; Chen, X. Bioinspired Mechanically Interlocking Structures. Small Struct. 2020, 1, 2000045. [Google Scholar] [CrossRef]

- Kakisawa, H.; Sumitomo, T. The Toughening Mechanism of Nacre and Structural Materials Inspired by Nacre. Sci. Technol. Adv. Mater. 2011, 12, 064710. [Google Scholar] [CrossRef]

- Mirkhalaf, M.; Zhou, T.; Barthelat, F. Simultaneous Improvements of Strength and Toughness in Topologically Interlocked Ceramics. Proc. Natl. Acad. Sci. USA 2018, 115, 9128–9133. [Google Scholar] [CrossRef]

- Mostert, J.-P.; Kruger, J. Interlocking 3D printed concrete filaments through surface topology modifications for improved tensile bond strength. RILEM Bookseries; In Third RILEM International Conference on Concrete and Digital Fabrication: Digital Concrete 2022; Springer: Cham, Switzerland, 2022; Volume 37, pp. 235–240. [Google Scholar] [CrossRef]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A Critical Review of 3D Printing in Construction: Benefits, Challenges, and Risks. Arch. Civ. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Nycz, A.; Noakes, M.; Cader, M. Additive Manufacturing—A New Challenge for Automation and Robotics. Adv. Intell. Syst. Comput. 2018, 743, 3–13. [Google Scholar] [CrossRef]

- Eswaran, M.; Bahubalendruni, M.V.A.R. Challenges and Opportunities on AR/VR Technologies for Manufacturing Systems in the Context of Industry 4.0: A State of the Art Review. 2022, 65, 260–278. J. Manuf. Syst. 2022, 65, 260–278. [Google Scholar] [CrossRef]

- Wang, W.; Guo, Q.; Yang, Z.; Jiang, Y.; Xu, J. A State-of-the-Art Review on Robotic Milling of Complex Parts with High Efficiency and Precision. Robot. Comput. Integr. Manuf 2023, 79, 102436. [Google Scholar] [CrossRef]

- Jia, Z.; Ma, J.; Song, D.; Wang, F.; Liu, W. A Review of Contouring-Error Reduction Method in Multi-Axis CNC Machining. Int. J. Mach. Tools Manuf. 2018, 125, 34–54. [Google Scholar] [CrossRef]

- Arashpour, M.; Miletic, A.M.; Williams, N.; Fang, Y. Design for Manufacture and Assembly in Off-Site Construction: Advanced Production of Modular Facade Systems. In Proceedings of the 35th ISARC, Berlin, Germany, 22–25 July 2018; 2018; pp. 224–229. [Google Scholar]

- ISO/ASTM ISO/ASTM 52900:2021(En); Additive Manufacturing—General Principles—Fundamentals and Vocabulary. 2021.

- Dey, D.; Srinivas, D.; Panda, B.; Sitharam, T.G. Processing of Cementitious Materials for 3D Concrete Printing. In Industry 4.0 and Advanced Manufacturing; Lecture Notes in Mechanical Engineering; Springer Nature: Singapore, 2022; pp. 283–291. ISBN 978-981-19056-1-2. [Google Scholar]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive Manufacturing: Technology, Applications, Markets, and Opportunities for the Built Environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of Additive Manufacturing Applications towards Environmental Sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Adaloudis, M.; Bonnin Roca, J. Sustainability Tradeoffs in the Adoption of 3D Concrete Printing in the Construction Industry. J. Clean. Prod. 2021, 307, 127201. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of Additive Manufacturing: The Circular Economy of Materials and Environmental Perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Fruggiero, F.; Lambiase, A.; Bonito, R.; Fera, M. The Load of Sustainability for Additive Manufacturing Processes. Procedia Manuf. 2019, 41, 375–382. [Google Scholar] [CrossRef]

- Khalid, M.; Peng, Q. Sustainability and Environmental Impact of Additive Manufacturing: A Literature Review. Comput. Aided Des. Appl. 2021, 18, 1210–1232. [Google Scholar] [CrossRef]

- Çalışkan, C.İ.; Arpacıoğlu, Ü. Additive Manufacturing on the Façade: Functional Use of Direct Metal Laser Sintering Hatch Distance Process Parameters in Building Envelope. Rapid Prototyp. J. 2022, 28, 1808–1820. [Google Scholar] [CrossRef]

- Felbrich, B.; Wulle, F.; Allgaier, C.; Menges, A.; Verl, A.; Wurst, K.-H.; Nebelsick, J.H. A Novel Rapid Additive Manufacturing Concept for Architectural Composite Shell Construction Inspired by the Shell Formation in Land Snails. Bioinspiration Biomim. 2018, 13, 026010. [Google Scholar] [CrossRef]

- Halloran, J.W. Ceramic Stereolithography: Additive Manufacturing for Ceramics by Photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- He, L.; Fei, F.; Wang, W.; Song, X. Support-Free Ceramic Stereolithography of Complex Overhanging Structures Based on an Elasto-Viscoplastic Suspension Feedstock. ACS Appl. Mater. Interfaces 2019, 11, 18849–18857. [Google Scholar] [CrossRef]

- James, T. Out and about Looking at Crinkle Crankle Walls. Proc. Hist. Assoc. 2009, 32. [Google Scholar]

- Finke, B.; Hesselbach, J.; Schütt, A.; Tidau, M.; Hampel, B.; Schilling, M.; Kwade, A.; Schilde, C. Influence of Formulation Parameters on the Freeform Extrusion Process of Ceramic Pastes and Resulting Product Properties. Addit. Manuf. 2020, 32, 101005. [Google Scholar] [CrossRef]

- Jinsong, C.; Enquan, B.; Dazhi, H.; Yunfei, D.; Xuhui, Q. Extrusion Freeforming-Based 3D Printing of Ceramic Materials. Mater. Trans. 2020, 61, 2236–2240. [Google Scholar] [CrossRef]

- Martínez-Rocamora, A.; García-Alvarado, R.; Casanova-Medina, E.; González-Böhme, L.F.; Auat-Cheein, F. Parametric Programming of 3D Printed Curved Walls for Cost-Efficient Building Design. J. Constr. Eng. Manag. 2020, 146, 04020039. [Google Scholar] [CrossRef]

- Pessoa, S.; Guimarães, A.S.; Lucas, S.S.; Simões, N. 3D Printing in the Construction Industry—A Systematic Review of the Thermal Performance in Buildings. Renew. Sustain. Energy Rev. 2021, 141, 110794. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Upasiri, I.; Nagaratnam, B.; Poologanathan, K.; Gatheeshgar, P.; Tsavdaridis, K.D.; Nuwanthika, D. Finite Element Modelling to Predict the Fire Performance of Bio-Inspired 3D-Printed Concrete Wall Panels Exposed to Realistic Fire. Buildings 2022, 12, 111. [Google Scholar] [CrossRef]

- Wang, B.; Yao, X.; Yang, M.; Zhang, R.; Huang, J.; Wang, X.; Dong, Z.; Zhao, H. Mechanical Performance of 3D Printed Concrete in Steam Curing Conditions. Materials 2022, 15, 2864. [Google Scholar] [CrossRef]

- van den Heever, M.; du Plessis, A.; Bester, F.; Kruger, J.; van Zijl, G. A Mechanistic Evaluation Relating Microstructural Morphology to a Modified Mohr-Griffith Compression-Shear Constitutive Model for 3D Printed Concrete. Constr. Build. Mater. 2022, 325, 126743. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, J.-H. 3D Concrete Printing: A Systematic Review of Rheology, Mix Designs, Mechanical, Microstructural, and Durability Characteristics. Materials 2021, 14, 3800. [Google Scholar] [CrossRef] [PubMed]

- van den Heever, M.; du Plessis, A.; Kruger, J.; van Zijl, G. Evaluating the Effects of Porosity on the Mechanical Properties of Extrusion-Based 3D Printed Concrete. Cem. Concr. Res. 2022, 153, 106695. [Google Scholar] [CrossRef]

- Asprone, D.; Menna, C.; Bos, F.P.; Salet, T.A.M.; Mata-Falcón, J.; Kaufmann, W. Rethinking Reinforcement for Digital Fabrication with Concrete. Cem. Concr. Res. 2018, 112, 111–121. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J. Reinforcement Method for 3D Concrete Printing Using Paste-Coated Bar Penetrations. Autom. Constr. 2021, 127, 103694. [Google Scholar] [CrossRef]

- Liu, M.; Wang, L.; Ma, G.; Li, W.; Zhou, Y. U-Type Steel Wire Mesh for the Flexural Performance Enhancement of 3D Printed Concrete: A Novel Reinforcing Approach. Mater. Lett. 2023, 331, 133429. [Google Scholar] [CrossRef]

- Sippach, T.; Dahy, H.; Uhlig, K.; Grisin, B.; Carosella, S.; Middendorf, P. Structural Optimization through Biomimetic-Inspired Material-Specific Application of Plant-Based Natural Fiber-Reinforced Polymer Composites (NFRP) for Future Sustainable Lightweight Architecture. Polymers 2020, 12, 3048. [Google Scholar] [CrossRef]

- Rosinha, I.P.; Gernaey, K.V.; Woodley, J.M.; Krühne, U. Topology optimization for biocatalytic microreactor configurations. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2015; Volume 37, pp. 1463–1468. ISBN 978-0-444-63429-0. [Google Scholar]

- Gaudillière, N.; Duballet, R.; Bouyssou, C.; Mallet, A.; Roux, P.; Zakeri, M.; Dirrenberger, J. Building applications using lost formworks obtained through large-scale additive manufacturing of ultra-high-performance concrete. In 3D Concrete Printing Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 37–58. ISBN 978-0-12-815481-6. [Google Scholar]

- Abdallah, Y.K.; Estévez, A.T. 3D-Printed Biodigital Clay Bricks. Biomimetics 2021, 6, 59. [Google Scholar] [CrossRef]

- Nguyen-Van, V. Mechanical Evaluations of Bioinspired TPMS Cellular Cementitious Structures Manufactured by 3D Printing Formwork; AIP Publishing LLC: Melville, NY, USA, 2021; Volume 2428. [Google Scholar]

- Dielemans, G.; Briels, D.; Jaugstetter, F.; Henke, K.; Dörfler, K. Additive Manufacturing of Thermally Enhanced Lightweight Concrete Wall Elements with Closed Cellular Structures. J. Facade Des. Eng. 2021, 9, 59–72. [Google Scholar] [CrossRef]

- Xing, Y.; Jones, P.; Bosch, M.; Donnison, I.; Spear, M.; Ormondroyd, G. Exploring Design Principles of Biological and Living Building Envelopes: What Can We Learn from Plant Cell Walls? Intell. Build. Int. 2018, 10, 78–102. [Google Scholar] [CrossRef]

- Whitesides, G.M.; Ostuni, E.; Takayama, S.; Jiang, X.; Ingber, D.E. Soft Lithography in Biology and Biochemistry. Annu. Rev. Biomed. Eng. 2001, 3, 335–373. [Google Scholar] [CrossRef]

- Riedel, D.; Mizaikoff, B. Surface Imprinted Micro- and Nanoparticles. In Comprehensive Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2019; Volume 86, pp. 153–191. ISBN 978-0-444-64266-0. [Google Scholar]

- Zhang, R.; Xiang, B.; Wang, Y.; Tang, S.; Meng, X. A Lotus-Inspired 3D Biomimetic Design toward an Advanced Solar Steam Evaporator with Ultrahigh Efficiency and Remarkable Stability. Mater. Horiz. 2022, 9, 1232–1242. [Google Scholar] [CrossRef]

- Kechagias, J.; Chaidas, D.; Vidakis, N.; Salonitis, K.; Vaxevanidis, N.M. Key Parameters Controlling Surface Quality and Dimensional Accuracy: A Critical Review of FFF Process. Mater. Manuf. Process. 2022, 37, 963–984. [Google Scholar] [CrossRef]

- Landrum, N.E.; Mead, T. Sustainability in the biom*. In Bionics and Sustainable Design; Palombini, F.L., Muthu, S.S., Eds.; Environmental Footprints and Eco-design of Products and Processes; Springer Nature: Singapore, 2022; pp. 1–15. ISBN 978-981-19181-2-4. [Google Scholar]

- Chen Austin, M.; Solano, T.; Tejedor-Flores, N.; Quintero, V.; Boya, C.; Mora, D. Bio-inspired approaches for sustainable cities design in tropical climate. In Bionics and Sustainable Design; Palombini, F.L., Muthu, S.S., Eds.; Environmental Footprints and Eco-design of Products and Processes; Springer Nature: Singapore, 2022; pp. 333–365. ISBN 978-981-19181-2-4. [Google Scholar]

| Role Model | Mimicked Features and Mechanisms | Application | Approach | Schematic Representation | Ref |

|---|---|---|---|---|---|

| Marram grass (Ammophila arenaria) | Reversible leaf-rolling mechanism Closing path of the bulliform cells Lengthwise cone-leaf closure shape Cross-section morphology | Shape-changing bi-metal material with potential for thermal and radiative responsive shading facades | Numerical and experimental |  | [90] |

| Silene Amphorina | Transpiration phenomenon through the plant’s leaf stomata, focusing on the opening and closing mechanisms as a response to the degree of the environmental humidity | Metereosensitive biomimetic envelope to enhance the indoor hygrothermal comfort behavior of the Royal Tulip Hotel in northeastern Algeria | Numerical |  | [93] |

| Oak sun leaves | Dissected shape to achieve faster heat and moisture dissipation Aerodynamical behavior due to the leaves’ lobes and border tips | Residential-grade fast-drying shingles for graded roofing and leveraged evaporative cooling | Experimental |  | [94] |

| Cactus, Eremopyrum orientale, and Salsola crassa | Cone-like structures for moisture harvesting Effective droplet transport mechanism of a Voronoi pattern surface | Water harvesting system for a building envelope panel | Theoretical | - | [95] |

| Lotus leaves | Papillary structure of the lotus leaf surface | Biomimetic nanocomposite film with a superhydrophobic surface | Experimental |  | [96] |

| Solar behavior | Sunshine motif acting as a solar envelope | Biomimetic solar cells mounted on glass PV panels for a self-sustaining, eco-responsive solar house (BAITYKOOL) | Theoretical and Experimental | - | [100] |

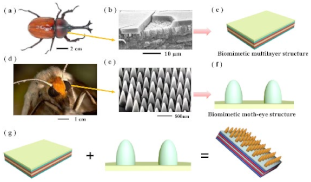

| Hercules beetle’s cuticle Moth eye | The spongy multilayer structure of the Hercules beetle to improve the infrared reflectivity The microscopic convex structure of the moth eye to reduce the visible light reflectivity | Biomimetic energy-efficient glass | Numerical |  | [101] |

| Animal fur and blood perfusion | Insulating mechanism of animal fur | Fur-inspired building envelope | Numerical | - | [19] |

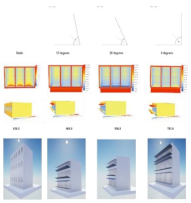

| Lupinus Succulentus | Sun-tracking kinetic mechanism | Kinetic facade prototype to enhance thermal and visual comfort of the occupants | Numerical |  | [98] |

| Leaves | Sun-tracking mechanisms of leaves | Panels that optimally harness sunlight during the day | Virtual reality |  | [104] |

| Bird-of-paradise flower (Strelitzia reginae) | The perch-like mechanisms of the petal sheath that activates during pollination by applying mechanical pressure | Facade shading system (Flectofin®) | Experimental | - | [105] |

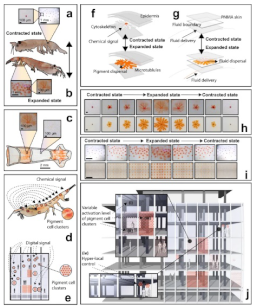

| Aquatic carnivorous waterwheel plant (Aldrovanda vesiculosa) Italian striped bug (Graphosoma italicum) | The millimeter-sized snap traps of the Aldrovanda vesiculosa used for feeding The flexible hinge zones of the Graphosoma italicum structure | Facade shading system (Flectofold) | Experimental | ||

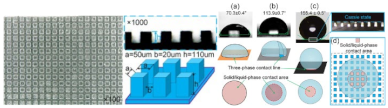

| Elephants’ wrinkles | Evaporative cooling mechanisms of the elephants’ wrinkles by mimicking texture, depth, and morphology | Textured facade panel | Experimental |  | [49] |

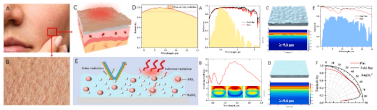

| Humans’ wrinkles | Wrinkled surface to enhance optical features | Biomimetic radiative cooling coating material (Bio-RC coating) | Experimental |  | [110] |

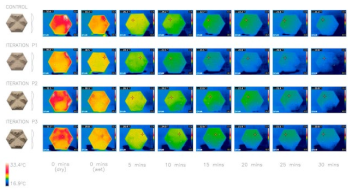

| Antarctic krill (E. superba) | The pigment modulation of the Antarctic krill (E. superba) that reacts to sunlight intensity | Active building facade using reversible fluid injections to control optical transmission | Experimental and numerical |  | [111] |

| Material | Reactive Response/Property | Role Model | Manufacturing/Fabrication Process | Ref |

|---|---|---|---|---|

| Polydimethylsiloxane (PDMS) | Superhydrophobicity | Nelumbo Nucifera lotus leaves | soft-imprinting lithography | [1,2] |

| Silica nanoparticles (SNPs) | Thermal insulator | Natural honeycomb | Sol-gel-based electrospinning Spin-coating Roller coating | [1,3,4] |

| Concrete | Self-healing | Bacteria | Incorporating suitable healing materials to concrete and then using conventional processes | [5,6] |

| Enhanced brittle properties and toughness | Nacre | Additive manufacturing | [7] | |

| Better printing patterns Increased energy absorption, peak impact force, impact duration, and porosity | Bouligand structure in the dactyl club of mantis shrimp | Additive manufacturing | [8] | |

| Insulation | Elephant’s wrinkles | CNC mold fabrication Vacuum molding Concrete casting | [9] | |

| Enhanced mechanical resistance | Topological interlocking in nature | Additive manufacturing | [10] | |

| Clay | Enhanced resistance to cracking | Physiology | Additive manufacturing | [11] |

| Variable increases in strength depending on the amount of cellulose added to the mix | Termites | Molding | [12] | |

| Superhydrophobicity | Lotus leaf | Mix preparation under magnetic stirring | [13] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega Del Rosario, M.D.L.Á.; Beermann, K.; Chen Austin, M. Environmentally Responsive Materials for Building Envelopes: A Review on Manufacturing and Biomimicry-Based Approaches. Biomimetics 2023, 8, 52. https://doi.org/10.3390/biomimetics8010052

Ortega Del Rosario MDLÁ, Beermann K, Chen Austin M. Environmentally Responsive Materials for Building Envelopes: A Review on Manufacturing and Biomimicry-Based Approaches. Biomimetics. 2023; 8(1):52. https://doi.org/10.3390/biomimetics8010052

Chicago/Turabian StyleOrtega Del Rosario, Maria De Los Ángeles, Kimberly Beermann, and Miguel Chen Austin. 2023. "Environmentally Responsive Materials for Building Envelopes: A Review on Manufacturing and Biomimicry-Based Approaches" Biomimetics 8, no. 1: 52. https://doi.org/10.3390/biomimetics8010052

APA StyleOrtega Del Rosario, M. D. L. Á., Beermann, K., & Chen Austin, M. (2023). Environmentally Responsive Materials for Building Envelopes: A Review on Manufacturing and Biomimicry-Based Approaches. Biomimetics, 8(1), 52. https://doi.org/10.3390/biomimetics8010052