Perceived Working Conditions and Intention to Adopt Digital Safety Training in High-Risk Productive Sectors: An Exploratory Study in Manufacturing and Agriculture in Northwest Italy

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Design

2.2. Participants

2.3. Questionnaire

2.4. Data Analysis

3. Results

3.1. Descriptive Statistics and Differences by Groups

3.2. Correlation Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| VW | Vineyard workers |

| MW | Manufacturing workers |

| UCD | User-centered design |

| SPSS | Statistical Package for Social Science |

| INT | interested in adopting safety tools |

| CONT | content |

Appendix A

| Question | Item | ID Code | Scale |

|---|---|---|---|

| SECTION 1: | |||

| sociodemographic information | Select your gender | 1 = male, 0 = female, 2 = other | |

| How old are you? | Open question | ||

| What is your educational qualification | 0 = none, 1 = primary school, 2 = middle school, 3 = high school, 4 = degree, n.a. = I prefer not to answer | ||

| How long have you been working in this field? | Open question | ||

| How many training courses on workplace safety have you attended in the last 5 years? | Open question | ||

| SECTION 2: | |||

| Have you had accidents during work activity resulting in damage in the last 5 years? | For vineyard workers: Fall from machinery/tractor, fall from height, slipping, accident with tractor, accident with other machinery, accident with other equipment, struck, environmental For manufacturing workers: crushed by a vehicle, rollover, run over a vehicle, struck by falling objects, fall from height, electrocution, inhalation of fumes, ocular foreign body, other road accidents | 0 = never, 1 = once, 2 = more than once | |

| Thinking about the work you do, please indicate how true you consider the following statements about working conditions, on a scale from 1 to 4 | My job is dangerous | ACC1 | 1 = not at all, 2 = a little, 3 = quite a lot, 4 = very much |

| My job is tiring | ACC2 | ||

| My job requires great concentration and attention from me | ACC3 | ||

| My job is repetitive and does not involve alternating with other tasks or activities | ACC4 | ||

| My tasks are well-defined | ACC5 | ||

| There is enough manpower to complete the daily work | ACC6 | ||

| There is too much work to do compared to the available time | ACC7 | ||

| I have the possibility to decide my work pace | ACC8 | ||

| My earnings are proportional to my work | ACC9 | ||

| Most accidents are caused by system failures | ACC10 | ||

| Most accidents are caused by human behavior | ACC11 | ||

| I feel well-informed about safety procedures | ACC12 | ||

| There is good communication within my work group | ACC13 | ||

| Which of the following tools and machinery do you use in your work activity? Please indicate, according to you, the level of risk for each tool and machinery that you use, on a scale from 1 to 4 | For vineyard workers: tractor, pruning shears, cultivators, vine shoot shredders, mechanical thinners, manure spreaders, sprayers, grape harvesters, stemmers. | 1 = negligible, 2 = low, 3 = medium, 4 = high | |

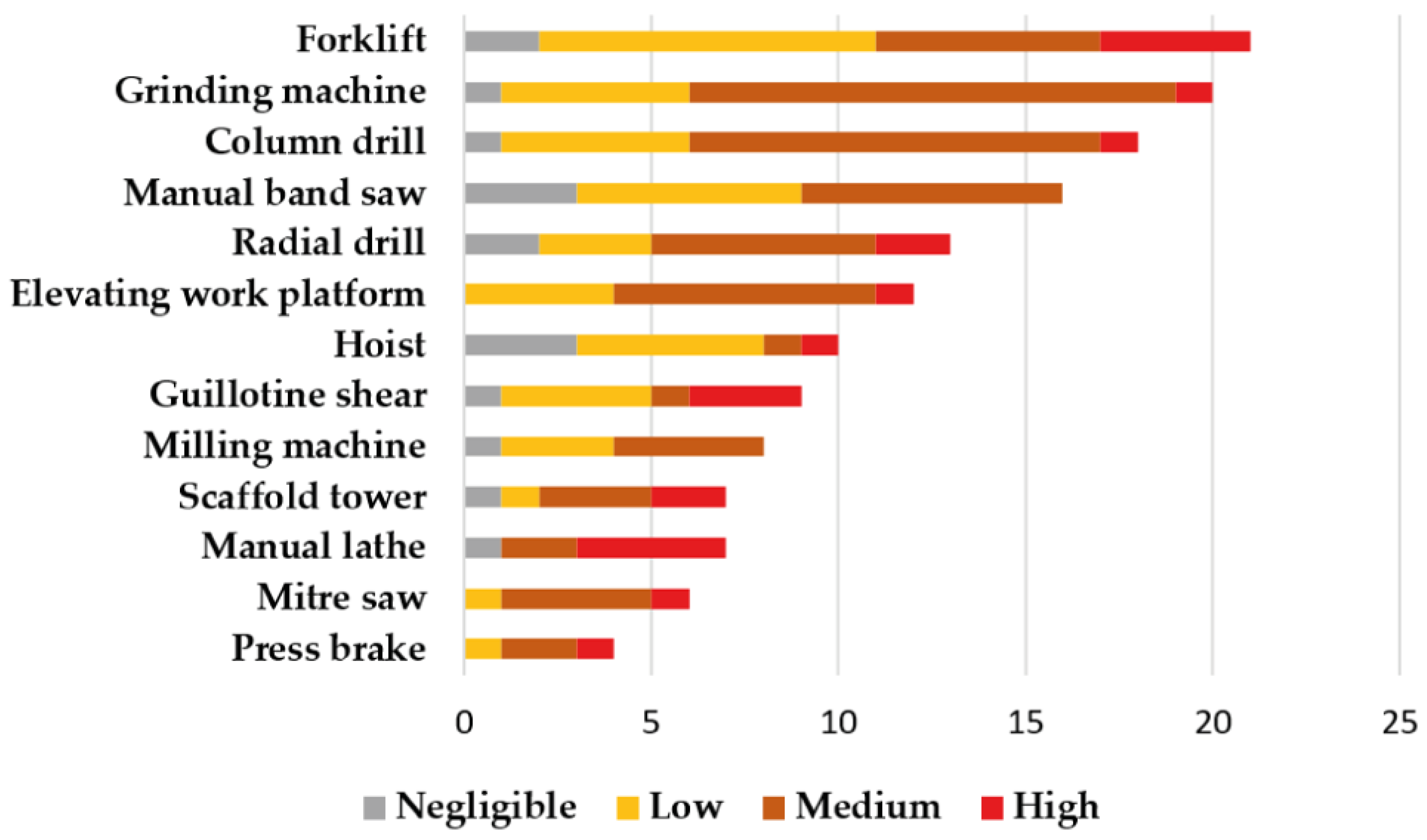

| For manufacturing workers: manual lathe, grinding machine, column drill, radial drill, milling machine, guillotine shear, press brake, manual band saw, miter saw, forklift, scaffold tower, hoist, elevating work platform. | |||

| SECTION 3: | |||

| Please indicate how much time on average you dedicate per day to each of the following activities on digital devices | Reading (e.g., newspapers, blogs, etc.) | TIME1 | 0 = never, 1 = a few minutes, 2 ≤ 30 min, 3 = 30 min to 1 h, 4 = 1–2 h, 5 = more than 2 h |

| Sending and receiving emails | TIME2 | ||

| Using instant messaging apps (e.g., WhatsApp) | TIME3 | ||

| Browsing the internet | TIME4 | ||

| Watching/listening to videos/music | TIME5 | ||

| Checking social media (e.g., Instagram, Facebook) | TIME6 | ||

| Playing games | TIME7 | ||

| Please indicate how interested you would be/are in using digital devices to stay updated/informed about health and safety in the workplace | INT | 1 = Not at all 2 = A little 3 = Enough 4 = A lot | |

| Please indicate how much you agree with the following statements on a scale from 1 to 4: The use of platforms on digital devices as a method of support for training can make safety training... | more accessible | BENEFIT1 | 1 = not at all, 2 = a little, 3 = quite a lot, 4 = very much |

| faster | BENEFIT2 | ||

| more interesting | BENEFIT3 | ||

| more effective | BENEFIT4 | ||

| If you were to use digital devices as a method of support for training, how important do you think each of the following contents should appear on a scale from 1 to 4 | Manual/documentation (e.g., written documentation on procedures and risks) | CONT1 | 1 = not at all, 2 = a little, 3 = quite a lot, 4 = very much |

| Audio lessons/podcasts | CONT2 | ||

| Video lessons | CONT3 | ||

| Practice exercises in the form of quizzes | CONT4 | ||

| Practice exercises in the form of games (e.g., quizzes with scores and rankings) | CONT5 | ||

References

- International Labour Organization. ILO REPORT 2022. Available online: https://www.ilo.org/sites/default/files/wcmsp5/groups/public/%40ed_protect/%40protrav/%40safework/documents/publication/wcms_903140.pdf (accessed on 14 March 2025).

- Eurostat. 2024. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Accidents_at_work_statistics (accessed on 14 March 2025).

- European Agency for Safety and Health at Work. Occupational Safety and Health in Europe: State and Trends 2023 Summary. 2023. Available online: https://osha.europa.eu/sites/default/files/Summary_OSH_in_Europe_state_trends.pdf (accessed on 14 March 2025).

- OSHA. Available online: https://www.osha.gov/agricultural-operations/hazards (accessed on 14 March 2025).

- EU-OSHA—European Agency for Safety and Health at Work. Farm Safety—OSH Issues. Available online: https://oshwiki.osha.europa.eu/en/themes/farm-safety-osh-issues (accessed on 14 March 2025).

- Fargnoli, M.; Laurendi, V.; Tronci, M. Design for safety in agricultural machinery. In Proceedings of the DS 60: Proceedings of DESIGN 2010, the 11th International Design Conference, Dubrovnik, Croatia, 17–20 May 2010; pp. 701–710. [Google Scholar]

- Safe Work. Infographic: Manufacturing Industry—Fatalities, Injuries and Solutions. 2022. Available online: https://www.safeworkaustralia.gov.au/resources-and-publications/infographic/infographic-manufacturing-industry-fatalities-injuries-and-solutions (accessed on 14 March 2025).

- Mares Castro, A.; Becerra Rodríguez, M.B.; Hernández Hernández, A.; de Lourdes Oliva Ramos, M. Standardized Work. In Lean Manufacturing in Latin America: Concepts, Methodologies and Applications; García Alcaraz, J.L., Robles, G.C., Realyvásquez Vargas, A., Eds.; Springer: Cham, Switzerland, 2025; Volume 3, pp. 29–54. [Google Scholar] [CrossRef]

- International Labour Organization. Safety and Health in Agriculture. 2011. Available online: https://www.ilo.org/resource/other/safety-and-health-agriculture (accessed on 14 March 2025).

- Dodoo, J.E.; Al-Samarraie, H. Factors leading to unsafe behavior in the twenty first century workplace: A review. MRQ 2019, 69, 391–414. [Google Scholar] [CrossRef]

- Mosher, G.A.; Keren, N.; Freeman, S.A.; Hurburgh, C.R. Development of a safety decision-making scenario to measure worker safety in agriculture. J. Agric. Saf. Health 2014, 20, 91–107. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi, F.; Kalatpour, O.; Moghimbeigi, A.; Mohammadfam, I. Selecting strategies to reduce high-risk unsafe work behaviors using the safety behavior sampling technique and Bayesian network analysis. J. Res. Health Sci. 2017, 17, 372. [Google Scholar]

- Arezes, P.M.; Miguel, A.S. Risk perception and safety behaviour: A study in an occupational environment. Saf. Sci. 2008, 46, 900–907. [Google Scholar] [CrossRef]

- Gonçalves, S.M.P.; da Silva, S.A.; Lima, M.L.; Meliá, J.L. The impact of work accidents experience on causal attributions and worker behaviour. Saf. Sci. 2008, 46, 992–1001. [Google Scholar] [CrossRef]

- Ngueutsa, R.; Kouabenan, D.R. Accident history, risk perception and traffic safe behaviour. Ergonomics 2017, 60, 1273–1282. [Google Scholar] [CrossRef]

- Kouabenan, D.R. Role of beliefs in accident and risk analysis and prevention. Saf. Sci. 2009, 47, 767–776. [Google Scholar] [CrossRef]

- Payani, S.; Law, T.H. An application of the theory of planned behaviour to understand compliance with daytime running headlights law among motorcycle riders. Int. J. Inj. Contr. Saf. Promot. 2020, 27, 188–196. [Google Scholar] [CrossRef]

- Ricci, F.; Chiesi, A.; Bisio, C.; Panari, C.; Pelosi, A. Effectiveness of occupational health and safety training: A systematic review with meta-analysis. J. Workplace Learn 2016, 28, 355–377. [Google Scholar] [CrossRef]

- Burke, M.J.; Sarpy, S.A.; Smith-Crowe, K.; Chan-Serafin, S.; Salvador, R.O.; Islam, G. Relative effectiveness of worker safety and health training methods. Am. J. Public Health 2006, 96, 315–324. [Google Scholar] [CrossRef]

- Kraiger, K.; Aguinis, H. Training effectiveness: Assessing training needs, motivation, and accomplishments. In How People Evaluate Others in Organizations, 1st ed.; London, M., Ed.; Psychology Press: New York, NY, USA, 2001; pp. 203–219. [Google Scholar]

- Samala, A.D.; Bojic, L.; Bekiroğlu, D.; Watrianthos, R.; Hendriyani, Y. Microlearning: Transforming Education with Bite-Sized Learning on the Go—Insights and Applications. Int. J. Interact. Mob. Technol. (iJIM) 2023, 17, 4–24. [Google Scholar] [CrossRef]

- Mehdipour, Y.; Zerehkafi, H. Mobile learning for education: Benefits and challenges. Int. J. Comput. Eng. 2013, 3, 93–101. [Google Scholar]

- Padilla-Castillo, G.; Ortega-Fernández, E.; Rodríguez-Hernández, J. Audiovisual Pills as a Tool for Training and Professional Preparation. Proceedings 2022, 81, 7. [Google Scholar] [CrossRef]

- Zhu, H.; Andersen, S.T. Digital competence in social work practice and education: Experiences from Norway. Nord. Soc. Work Res. 2022, 12, 823–838. [Google Scholar] [CrossRef]

- Boulos, M.N.; Maramba, I.; Wheeler, S. Wikis, blogs and podcasts: A new generation of Web-based tools for virtual collaborative clinical practice and education. BMC Med. Educ. 2006, 6, 41. [Google Scholar] [CrossRef]

- Corbalan, R.; Bassand, J.-P.; Illingworth, L.; Ambrosio, G.; Camm, A.J.; Fitzmaurice, D.A.; Fox, K.A.A.; Goldhaber, S.Z.; Goto, S.; Haas, S.; et al. Analysis of outcomes in ischemic vs nonischemic cardiomyopathy in patients with atrial fibrillation: A report from the GARFIELD-AF registry. JAMA Cardiol. 2019, 4, 526–548. [Google Scholar] [CrossRef]

- Williams-Bell, F.M.; Kapralos, B.; Hogue, A.; Murphy, B.M.; Weckman, E.J. Using Serious Games and Virtual Simulation for Training in the Fire Service: A Review. Fire Technol. 2014, 51, 553–584. [Google Scholar] [CrossRef]

- Gao, Y.; Gonzalez, V.A.; Yiu, T.W. The effectiveness of traditional tools and computer-aided technologies for health and safety training in the construction sector: A systematic review. Comput. Educ. 2019, 138, 101–115. [Google Scholar] [CrossRef]

- Godinot, O. SEGAE: A serious game project for agroecology learning. In Proceedings of the 13th European IFSA Symposium, Crete, Greece, 1–5 July 2018; p. 1. [Google Scholar]

- Keepers, M.; Nesbit, I.; Romero, D.; Wuest, T. Current state of research & outlook of gamification for manufacturing. J. Manuf. Syst. 2022, 64, 303–315. [Google Scholar] [CrossRef]

- Hoang, H.G.; Tran, H.D. Smallholder farmers’ perception and adoption of digital agricultural technologies: An empirical evidence from Vietnam. Outlook Agric. 2023, 52, 457–468. [Google Scholar] [CrossRef]

- Cagno, E.; Accordini, D.; Neri, A.; Negri, E.; Macchi, M. Digital solutions for workplace safety: An empirical study on their adoption in Italian metalworking SMEs. Saf. Sci. 2024, 177, 106598. [Google Scholar] [CrossRef]

- Bragatto, P.; Faramondi, L.; Failla, F.; Gnoni, M. Potential and limits of IoT for hazardous job in process industries. Chem. Eng. 2018, 67, 865–870. [Google Scholar]

- ISO 9241-210:2019; Ergonomics of Human-System Interaction—Part 11: Usability: Definitions and Concepts. International Organization for Standardization: Geneva, Switzerland, 2019.

- INAIL Istituto Nazionale per l’Assicurazione Contro Gli Infortuni sul Lavoro. Andamento Degli Infortuni sul Lavoro e delle Malattie Professionali. 2023. Available online: https://www.inail.it/portale/it/inail-comunica/news/notizia.2023.06.salute-e-sicurezza-sul-lavoro-l-industria-manifatturiera-al-centro-del-nuovo-numero-di-dati-inail.html (accessed on 14 March 2025).

- Balaguier, R.; Madeleine, P.; Rose-Dulcina, K.; Vuillerme, N. Trunk kinematics and low back pain during pruning among vineyard workers—A field study at the Chateau Larose-Trintaudon. PLoS ONE 2017, 12, e0175126. [Google Scholar] [CrossRef] [PubMed]

- Faul, F.; Erdfelder, E.; Lang, A.G.; Buchner, A. G* Power 3: A flexible statistical power analysis program for the social, behavioral, and biomedical sciences. Behav. Res. Methods 2007, 39, 175–191. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Routledge: Hillsdale, NJ, 1988. [Google Scholar]

- Caffaro, F.; Roccato, M.; de Paolis, G.; Cremasco, M.M.; Cavallo, E. Promoting farming sustainability: The effects of age, training, history of accidents and social-psychological variables on the adoption of on-farm safety behaviors. J. Saf. Res. 2022, 80, 371–379. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Fang, D. Why operatives engage in unsafe work behavior: Investigating factors on construction sites. Saf. Sci. 2008, 46, 566–584. [Google Scholar] [CrossRef]

- Hon, C.K.; Chan, A.P.; Wong, F.K. An analysis for the causes of accidents of repair, maintenance, alteration and addition works in Hong Kong. Saf. Sci. 2010, 48, 894–901. [Google Scholar] [CrossRef]

- Ministero del Lavoro. Risk Assessment Document—Documento Valutazione dei Rischi. DVR. Available online: https://www.lavoro.gov.it/temi-e-priorita/salute-e-sicurezza/focus-on/commissione-consultiva-permanente/Documents/Modulo-procedure-standardizzate.doc (accessed on 14 March 2025).

- Susilowati, I.H.; Kurniawidjaja, L.M.; Nugraha, S.; Nasri, S.M.; Pujiriani, I.; Hasiholan, B.P. The prevalence of bad posture and musculoskeletal symptoms originating from the use of gadgets as an impact of the work from home program of the university community. Heliyon 2022, 8, e11059. [Google Scholar] [CrossRef]

- Davis, F.D. Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Q. 1989, 13, 319–340. [Google Scholar] [CrossRef]

- Simha, P.; Lalander, C.; Vinnerås, B.; Ganesapillai, M. Farmer attitudes and perceptions to the re–use of fertiliser products from resource–oriented sanitation systems–The case of Vellore, South India. Sci. Tot. Environ. 2017, 581, 885–896. [Google Scholar] [CrossRef]

- Jo, H.; Park, H.; Baek, S.; Kang, E.K. Low back pain in farmers: The association with agricultural work management, disability, and quality of life in Korean farmers. Hum. Factors Ergon. Manuf. Serv. Ind. 2017, 27, 156–165. [Google Scholar] [CrossRef]

- Elliott, K.C.; Lincoln, J.M.; Flynn, M.A.; Levin, J.L.; Smidt, M.; Dzugan, J.; Ramos, A.K. Working hours, sleep, and fatigue in the agriculture, forestry, and fishing sector: A scoping review. Am. J. Ind. Med. 2022, 65, 898–912. [Google Scholar] [CrossRef] [PubMed]

- Tucker, P. The impact of rest breaks upon accident risk, fatigue and performance: A review. Work. Stress 2023, 17, 123–137. [Google Scholar] [CrossRef]

- Kirkhorn, S.R.; Earle-Richardson, G. Repetitive motion injuries. In Agricultural Medicine: A Practical Guide; Lessenger, J.E., Ed.; Springer: New York, NY, USA, 2006; pp. 324–338. [Google Scholar]

- Benos, L.; Tsaopoulos, D.; Bochtis, D. A Review on Ergonomics in Agriculture. Part I: Manual Operations. Appl. Sci. 2020, 10, 1905. [Google Scholar] [CrossRef]

- Gattamelata, D.; Fargnoli, M. Development of a new procedure for evaluating working postures: An application in a manufacturing company. Int. J. Environ. Res. Public Health 2022, 19, 15423. [Google Scholar] [CrossRef]

- Torres, D.; Pimentel, C.; Matias, J.C. Characterization of tasks and skills of workers, middle and top managers in the industry 4.0 context. Sustainability 2023, 15, 6981. [Google Scholar] [CrossRef]

- Nordlöf, H.; Wiitavaara, B.; Winblad, U.; Wijk, K.; Westerling, R. Safety culture and reasons for risk-taking at a large steel-manufacturing company: Investigating the worker perspective. Saf. Sci. 2015, 73, 126–135. [Google Scholar] [CrossRef]

- Wells, R.; Mathiassen, S.E.; Medbo, L.; Winkel, J. Time—A key issue for musculoskeletal health and manufacturing. Appl. Ergon. 2007, 38, 733–744. [Google Scholar] [CrossRef]

- Hobbs, M.; Klachky, E.; Cooper, M. Job satisfaction assessments of agricultural workers help employers improve the work environment and reduce turnover. Calif. Agric. 2020, 74, 30–39. [Google Scholar] [CrossRef]

- Liu, X.; Huang, G.; Huang, H.; Wang, S.; Xiao, Y.; Chen, W. Safety climate, safety behavior, and worker injuries in the Chinese manufacturing industry. Saf. Sci. 2015, 78, 173–178. [Google Scholar] [CrossRef]

- Mazzei, A. Internal communication for employee enablement: Strategies in American and Italian companies. Corp. Commun. Int. J. 2014, 19, 82–95. [Google Scholar] [CrossRef]

- Nugraha, H.D.; Kosasih, D.P.; Kasda, K.; Djohar, A.A.; Komaro, M. Model of essential employability skills framework for machine operator. J. Pendidik. Vokasi 2020, 10, 188–202. [Google Scholar] [CrossRef]

- Soudière, T. Farmers’ Decision Regarding Involvement in Conservation Projects and Communication Preferences: A Case Study of an EU H2020 Project. Master’s Thesis, Liège Université, Liège, Belgium, 2023. [Google Scholar]

- Li, J.; Herd, A.M. Shifting practices in digital workplace learning: An integrated approach to learning, knowledge management, and knowledge sharing. Hum. Resour. Dev. Int. 2017, 20, 185–193. [Google Scholar] [CrossRef]

- Caponecchia, C. It won’t happen to me: An investigation of optimism bias in occupational health and safety. J. Appl. Soc. Psychol. 2010, 40, 601–617. [Google Scholar] [CrossRef]

- Sarri, D.; Lisci, R.; Vieri, M. A body impedance-based safety system for electrical pruning tools. Chem. Eng. Trans. 2017, 58, 127–132. [Google Scholar]

- Trbojević, N.; Ribarić, I.; Vranješ, B. Reduction of hazard levels on CNC machines. Acta Tech. Corviniensis-Bull. Eng. 2021, 14, 127–130. [Google Scholar]

- Kulinska, E.; Dendera-Gruszka, M. Hazards in the production process, characteristics and methods of risk elimination. SJMULF 2018, 50, 244–252. [Google Scholar] [CrossRef]

- Dado, M.; Kotek, L.; Hnilica, R.; Tůma, Z. The application of virtual reality for hazard identification training in the context of machinery safety: A preliminary study. Manuf. Technol. 2018, 18, 732–736. [Google Scholar] [CrossRef]

- ILO Encyclopedia. Lathes. 2011. Available online: https://www.iloencyclopaedia.org/part-xiii-12343/metal-processing-and-metal-working-industry/item/679-lathes (accessed on 14 March 2025).

- Tuktur, W.R. Heavy Machinery, Amputations and Industrial Accidents. Heavy Mach. 2017, 7, 68–74. [Google Scholar]

- Jafari, M.J.; Saghi, F.; Alizadeh, E.; Zayeri, F. Relationship between risk perception and occupational accidents: A study among foundry workers. J. Egypt. Public Health Assoc. 2019, 94, 24. [Google Scholar] [CrossRef]

- Dodoo, J.E.; Al-Samarraie, H.; Alzahrani, A.I.; Tang, T. XR and Workers’ safety in High-Risk Industries: A comprehensive review. Saf. Sci. 2025, 185, 106804. [Google Scholar] [CrossRef]

- Dodoo, J.E.; Al-Samarraie, H.; Alzahrani, A.I.; Lonsdale, M.; Alalwan, N. Digital innovations for occupational safety: Empowering workers in hazardous environments. Workplace Health Saf. 2024, 72, 84–95. [Google Scholar] [CrossRef] [PubMed]

- Andone, I.; Błaszkiewicz, K.; Eibes, M.; Trendafilov, B.; Montag, C.; Markowetz, A. How age and gender affect smartphone usage. In Proceedings of the 2016 ACM International Joint Conference on Pervasive and Ubiquitous Computing: Adjunct, Heidelberg, Germany, 12–16 September 2016; pp. 9–12. [Google Scholar] [CrossRef]

- Meyer, J. Older Workers and the Adoption of New Technologies; (No. 07-050 [rev.]); ZEW Discussion Papers: Mannheim, Germany, 2009. [Google Scholar]

- Angelini, D. Aging Population and Technology Adoption; (No. 2023-01); Department of Economics, University of Konstanz: Konstanz, Germany, 2023. [Google Scholar]

- Nanthini, T.; Karunagari, K. Effectiveness of video-assisted teaching program on safety measures followed by the employees working in the silica-based industry in Puducherry, India. Indian J. Occup. Environ. Med. 2016, 20, 31–34. [Google Scholar] [CrossRef] [PubMed]

- INAIL Istituto Nazionale per l’Assicurazione Contro gli Infortuni sul Lavoro. Infortuni in Agricoltura, tra il 2018 e il 2022 Confermato il Trend Decrescente. 2024. Available online: https://www.inail.it/portale/it/inail-comunica/news/notizia.2024.04.infortuni-in-agricoltura-tra-il-2018-e-il-2022-confermato-il-trend-decrescente.html (accessed on 14 March 2025).

- Women in Manufacturing Foundation. Available online: https://worldmanufacturing.org/women-in-manufacturing/ (accessed on 14 March 2025).

- EU-CAP Network 2022. Women in the New CAP. Available online: https://eu-cap-network.ec.europa.eu/news/women-new-cap_en (accessed on 14 March 2025).

- Bagagiolo, G.; Vigoroso, L.; Caffaro, F.; Cavallo, E. Determinants of eco-innovation in the agricultural machinery sector: The case of small and medium enterprises in the Piedmont region (Italy). Environ. Dev. Sustain. 2024, 26, 25849–25869. [Google Scholar] [CrossRef]

- Falcão, R.N.R.; Vrana, M.; Hudek, C.; Pittarello, M.; Zavattaro, L.; Moretti, B.; Strauss, P.; Liebhard, G.; Li, Y.; Zhang, X.; et al. Farmers’ perception of soil health: The use of quality data and its implication for farm management. Soil Use Manag. 2024, 40, e13023. [Google Scholar] [CrossRef]

- European Commission. 2022 Annual Report on the Labour Market Situations of Immigrants in Italy. 2022. Available online: https://migrant-integration.ec.europa.eu/library-document/2022-annual-report-labour-market-situations-immigrants-italy_en (accessed on 14 March 2025).

| Variable | Viticulture | Manufacturing | |

|---|---|---|---|

| Mean (SD) | |||

| Age (years) | 40.05 (18.70) | 36.38 (11.58) | |

| Work experience (years) | 12.8 (15.14) | 15.11 (11.16) | |

| Training courses (N) | 2.98 (2.60) | 3.23 (1.67) | |

| N (%) | |||

| Education 1 | Elementary school | 6 (15) | 0 (0) |

| Middle school | 16 (40) | 14 (35.90) | |

| High school | 16 (40) | 23 (58.97) | |

| University degree | 2 (5) | 2 (5.13) | |

| Profession | Winegrowers 2 | 40 (100) | 0 (0) |

| Technicians | 0 (0) | 11 (28.20) | |

| Assemblers/maintainers | 0 (0) | 19 (48.72) | |

| Specialized machine operators | 0 (0) | 9 (23.08) | |

| Variable | Viticulture | Manufacturing | Comparison by Group of Workers |

|---|---|---|---|

| Mean (SD) | p | ||

| ACC1 | 2.68 (0.83) 1 | 2.41 (0.79) | 0.128 |

| ACC2 | 3.18 (0.75) 1 | 2.34 (0.77) | 0.000 2 |

| ACC3 | 3.38 (0.67) 1 | 3.56 (0,60) 1 | 0.189 |

| ACC4 | 2.13 (1.07) | 1.62 (0.82) | 0.024 2 |

| ACC5 | 3.25 (0.81) 1 | 2.77 (0.81) 1 | 0.008 2 |

| ACC6 | 2.70 (0.82) 1 | 2.97 (0.71) 1 | 0.121 |

| ACC7 | 2.70 (0.76) 1 | 2.33 (0.74) | 0.041 2 |

| ACC8 | 2.98 (0.92) 1 | 2.44 (0.85) | 0.009 2 |

| ACC9 | 2.63 (0.95) 1 | 2.64 (0.90) 1 | 0.831 |

| ACC10 | 1.93 (0.66) | 1.90 (0.55) | 0.981 |

| ACC11 | 3.05 (0.78) 1 | 3.03 (0.63) 1 | 0.808 |

| ACC12 | 3.25 (0.74) 1 | 3.28 (0.51) 1 | 0.858 |

| ACC13 | 3.20 (0.65) 1 | 2.12 (0.75) | 0.000 2 |

| Variable | Viticulture | Manufacturing | Comparison by Group of Workers |

|---|---|---|---|

| Mean (SD) | p | ||

| TIME1 | 2.03 (1.42) | 2.15 (1.11) | 0.429 |

| TIME2 | 1.83 (1.39) | 1.72 (1.59) | 0.476 |

| TIME3 | 2.98 (1.27) | 3.10 (1.43) | 0.519 |

| TIME4 | 3.05 (1.20) | 3.42 (1.27) | 0.100 |

| TIME5 | 2.68 (1.51) | 2.56 (1.50) | 0.730 |

| TIME6 | 2.35 (1.64) | 2.54 (1.54) | 0.625 |

| TIME7 | 0.95 (1.24) | 1.10 (1.62) | 0.953 |

| INT | 2.70 (0.82) | 3.05 (0.65) | 0.064 |

| BENEFIT1 | 2.65 (0.83) | 3.10 (0.68) | 0.014 1 |

| BENEFIT2 | 2.98 (0,80) | 3.28 (0.72) | 0.087 |

| BENEFIT3 | 2.65 (0,80) | 2.77 (0.74) | 0.475 |

| BENEFIT4 | 2.75 (0,84) | 2.87 (0.70) | 0.384 |

| CONT1 | 2.63 (0.90) | 3.00 (0.76) | 0.053 |

| CONT2 | 2.70 (0.76) | 3.03 (0.81) | 0.043 1 |

| CONT3 | 3.10 (0.84) | 3.03 (0.78) | 0.661 |

| CONT4 | 2.50 (0.78) | 2.67 (0.74) | 0.350 |

| CONT5 | 2.95 (0.88) | 2.77 (0.81) | 0.344 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1-Age | 1 | |||||||||||||

| 2-Educ | 0.154 | 1 | ||||||||||||

| 3-Train | 0.290 | 0.470 ** | 1 | |||||||||||

| 4-ACC1 | 0.228 | −0.179 | −0.084 | 1 | ||||||||||

| 5-ACC10 | −0.024 | −0.412 ** | −0.420 ** | −0.034 | 1 | |||||||||

| 6-ACC11 | 0.155 | −0.110 | −0.034 | 0.443 ** | 0.207 | 1 | ||||||||

| 7-INT | −0.193 | −0.141 | −0.053 | 0.030 | 0.149 | −0.025 | 1 | |||||||

| 8-CONT1 | 0.029 | 0.052 | 0.055 | −0.106 | 0.011 | −0.222 | 0.400 * | 1 | ||||||

| 9-CONT2 | −0.443 ** | 0.042 | −0.020 | 0.013 | 0.033 | −0.046 | 0.509 ** | 0.235 | 1 | |||||

| 10-CONT3 | −0.047 | −0.075 | −0.320 * | 0.350 * | −0.036 | 0.061 | 0.360 * | 0.175 | 0.557 ** | 1 | ||||

| 11-CONT4 | −0.196 | 0.039 | −0.017 | −0.326 * | −0.069 | −0.304 | 0.509 ** | 0.613 ** | 0.304 | 0.093 | 1 | |||

| 12-CONT5 | −0.384 * | −0.057 | −0.064 | −0.006 | −0.088 | −0.023 | 0.370 * | 0.240 | 0.366 * | 0.314 * | 0.505 ** | 1 | ||

| 13-BENEF 1 | 0.077 | 0.101 | 0.084 | −0.057 | −0.083 | −0.148 | 0.512 ** | 0.359* | 0.279 | 0.364 * | 0.369 * | 0.305 | 1 | |

| 14-TIME 2 | −0.339 * | −0.142 | 0.069 | −0.125 | 0.013 | −0.132 | 0.179 | 0.020 | 0.168 | −0.12 | 0.400 * | 0.516 ** | 0.196 | 1 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1-Age | 1 | |||||||||||||

| 2-Educ | −0.183 | 1 | ||||||||||||

| 3-Train | 0.131 | 0.137 | 1 | |||||||||||

| 4-ACC1 | −0.121 | −0.061 | 0.108 | 1 | ||||||||||

| 5-ACC10 | −0.049 | 0.148 | 0.328 * | 0.071 | 1 | |||||||||

| 6-ACC11 | 0.154 | 0.035 | 0.011 | −0.008 | 0.276 | 1 | ||||||||

| 7-INT | −0.164 | 0.179 | −0.136 | 0.132 | 0.096 | 0.003 | 1 | |||||||

| 8-CONT1 | 0.061 | 0.191 | 0.242 | 0.243 | 0.174 | −0.321 * | 0.125 | 1 | ||||||

| 9-CONT2 | 0.048 | 0.061 | −0.165 | 0.077 | 0.123 | 0.008 | 0.250 | −0.142 | 1 | |||||

| 10-CONT3 | 0.045 | 0.190 | 0.146 | −0.158 | 0.295 | 0.145 | 0.026 | 0.172 | 0.386 * | 1 | ||||

| 11-CONT4 | −0.008 | 0.003 | 0.002 | 0.044 | 0.036 | 0.054 | 0.220 | 0.247 | −0.066 | 0.111 | 1 | |||

| 12-CONT5 | −0.273 | 0.264 | 0.283 | 0.050 | 0.278 | −0.039 | 0.146 | −0.192 | 0.358 * | 0.170 | 0.092 | 1 | ||

| 13-BENEF 1 | −0.113 | −0.047 | −0.017 | 0.266 | 0.104 | −0.055 | 0.462 ** | 0.115 | 0.047 | 0.099 | 0.323 * | −0.073 | 1 | |

| 14-TIME 2 | −0.673 ** | 0.101 | 0.01 | −0.040 | 0.129 | 0.149 | 0.177 | −0.084 | −0.182 | −0.014 | −0.018 | 0.343 * | −0.062 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sguaizer, F.; Vigoroso, L.; Micheletti Cremasco, M.; Caffaro, F. Perceived Working Conditions and Intention to Adopt Digital Safety Training in High-Risk Productive Sectors: An Exploratory Study in Manufacturing and Agriculture in Northwest Italy. Safety 2025, 11, 51. https://doi.org/10.3390/safety11020051

Sguaizer F, Vigoroso L, Micheletti Cremasco M, Caffaro F. Perceived Working Conditions and Intention to Adopt Digital Safety Training in High-Risk Productive Sectors: An Exploratory Study in Manufacturing and Agriculture in Northwest Italy. Safety. 2025; 11(2):51. https://doi.org/10.3390/safety11020051

Chicago/Turabian StyleSguaizer, Francesco, Lucia Vigoroso, Margherita Micheletti Cremasco, and Federica Caffaro. 2025. "Perceived Working Conditions and Intention to Adopt Digital Safety Training in High-Risk Productive Sectors: An Exploratory Study in Manufacturing and Agriculture in Northwest Italy" Safety 11, no. 2: 51. https://doi.org/10.3390/safety11020051

APA StyleSguaizer, F., Vigoroso, L., Micheletti Cremasco, M., & Caffaro, F. (2025). Perceived Working Conditions and Intention to Adopt Digital Safety Training in High-Risk Productive Sectors: An Exploratory Study in Manufacturing and Agriculture in Northwest Italy. Safety, 11(2), 51. https://doi.org/10.3390/safety11020051