Abstract

The environmental concerns regarding the production of the most widely consumed cement construction material have led to the need for developing sustainable alternatives. Using recycled industry waste products such as fly ash and slag via geopolymerisation has led to the development of geopolymer cement—an efficient replacement for ordinary Portland cement (OPC). Adopting geopolymer cement and concrete as a construction material reduces greenhouse gas and promotes the recycling of waste products. This study explores the suitability of a unique geopolymer concrete mix made of recycled cementitious materials including industry waste products such as fly ash, micro fly ash and slag for use in aggressive environments. Sorptivity tests are conducted to assess the durability of concrete and indicate the cementitious material’s ability to transmit water through the capillary forces. This study thus reports on the sorptivity characteristics of a newly developed self-compacting geopolymer concrete and two other fibre geopolymer concrete mixes containing 1% (by weight) of 12 mm- or 30 mm-long basalt fibres. The addition of basalt fibres indicated less water absorption and moisture ingress than the mix without fibres. The study used 18 specimens from three geopolymer concrete mixes, and the results showed that adding fibres improved the durability performance in terms of resistance to moisture ingress. Finally, an artificial neural network model is developed to predict the absorption rates of geopolymer concrete specimens using MATLAB. The prediction models reported excellent agreement between experimental and simulated datasets.

1. Introduction

The harmful impacts of conventional Portland cement, including increased carbon footprint and the high susceptibility to aggressive environments, have accelerated the research on alternative sustainable and durable construction materials [1,2,3]. Geopolymer concrete is a sustainable alternative with increasing application in repairing and rehabilitating existing concrete infrastructure [4,5,6,7,8]. Geopolymer concretes produced by the alkali activation of alumino-silicate-rich supplementary cementitious materials, including fly ash and slag, have been proven to offer higher strength and better resistance to aggressive environments [4,5,9,10]. The production process of geopolymer concrete positively contributes to waste resource recovery and recycling, especially in the industry segment, in addition to the reduction in carbon emissions of up to 80% in some cases [2,11,12,13]. The alumino-silicate binders primarily used for geopolymer concrete include various grades of fly ash, which is the combustion by-product of coal-based power plants [14,15,16]. The other common supplementary cementitious material used as the geopolymer binder is the blast furnace slag/ground slag which is a by-product of the ore smelting processes [17,18,19,20]. As waste products, these raw materials are abundant in most countries, offering competitive pricing against the conventional cement concretes [1,2]. The recent research on the mechanical–thermal–chemical and durability characteristics also confirms that the geopolymer concretes outperform traditional cement concrete, especially in fire resistance and chemical resistance, proving to be a sustainable and durable alternative [1,21]. Using industry waste products has also helped reduce the environmental impacts of the metallurgical and mining industries, thus offering ecological benefits and preventing further contamination of soils and water resources [22,23]. The production process of geopolymer concrete also meets the circularity principles in which the reliability of virgin raw materials is drastically reduced [22].

Even with these benefits, the geopolymer concrete exhibits similar brittleness and shrinkage properties to conventional cement concrete [24,25] that still need to be addressed. Previous research indicates that the geopolymer concrete also exhibits concrete-like behaviour while assessing the properties associated with brittleness and susceptibility to cracks. Hence, more studies have focused on the sustainable solution by strengthening the geopolymer concrete with organic, inorganic, or synthetic fibres [26]. Various studies have reported using different types of composites such as glass, carbon, basalt, polyethylene, polypropylene, steel, etc., as fibre reinforcements for geopolymer concrete [27,28]. The random distribution of fibres in geopolymer concrete resists the formation or propagation of cracks and strengthens the structure against internal and external stresses. The cracking and brittleness can also affect the material and structural performance, and extensive studies suggest the incorporation of fibres for improved toughness even in the geopolymer concretes [29]. However, the production process of some of these fibres considered as reinforcing options are energy-intensive or lead to high carbon emissions, diminishing the novelty of the geopolymer concrete. The addition of steel fibres is regarded as one of the most effective solutions. However, the performance of steel-reinforced geopolymer concrete in aggressive or corrosive environments is not fully understood, along with the increased weight of the fibres. The other commonly used fibres are synthetic fibres such as polypropylene (PP). Most reported studies confirm the need for PP fibres coupled with steel or organic fibres for superior performance. Considering the issues of the used fibres, basalt fibres made from simple extrusion of inorganic basalt rocks exhibit good physical, higher tensile, and higher chemical resistance properties, as well as thermo-neutral characteristics. These inorganic fibres with better bonding are also eco-friendly and low-cost, with no toxic emissions in the production process [30,31]. The single processing method without additional chemicals and low-energy requirements makes chopped basalt fibres sustainable and cost-effective [30]. The studies also indicate that the addition of basalt fibres promotes strength betterment for up to 28 days followed by improved ductility properties when used in geopolymer composites [32,33].

The applications of geopolymer concrete for structural repair and rehabilitation works show higher durability properties; however, the knowledge of the long-term performance of the geopolymer composites remains limited, especially in corrosive environments such as marine infrastructural applications [20]. Even though there have been attempts to study the long-term performance of geopolymer composites [34,35] containing synthetic fibres, the studies of Basalt fibre containing geopolymer concrete remains an emerging area of research. With the obvious benefits, there is an increased interest amongst cement and concrete researchers to understand the performance of the chopped basalt fibres when added to geopolymer concrete. There also exists a knowledge gap in the application of chopped basalt fibres for large-scale applications. There also needs to be a consensus on the optimum length of fibre that needs to be added to produce the best-performing cementitious composites.

Furthermore, the soft computing tools and techniques are now being widely adopted by researchers in the field of civil engineering owing to the accuracy in predictions, especially with the trained network models such as artificial neural networks (ANN) [36,37,38]. Artificial neural networks are a soft computing tool that can provide self-learned, logical prediction patterns based on the framework of an input layer for datasets, a hidden layer for nodes assigning weights, and an output layer for targeted results [38,39,40,41]. Since the experimental datasets of properties of geopolymer concrete are comparatively less when compared to the traditional concretes, the adoption of prediction models adds to multiplication of datasets with higher prediction accuracy saving the need for sample preparation [36,42]. Out of the available machine algorithms, the neural network approach makes use of a parallel thinking procedure in which a number of neurons are assigned weights relating to various parameters of input data. The method mimics the human brain, where the hidden neurons which are the dependent variables in the network are correlated with the input parameters to produce the desired output [43,44,45]. With the advanced ability, ANNs are successfully used by various researchers to predict the compressive strength, long-term durability behaviour, and bond-strength prediction, especially for composites containing geopolymer concrete [37,38,46]. Unlike other techniques, ANNs are preferred owing to their higher error tolerance, precision in decision-making, and ability to solve complex non-linear relations [43]. Understanding the suitability of the ANNs, the authors have also included a prediction model for studying the sorptivity trends of the various geopolymer concrete mixes used in this study.

This study thus analyses the workability and mechanical properties of geopolymer concrete modified with various lengths of chopped basalt fibres. The study also aims to provide a preliminary indication of the durability performance of the newly developed geopolymer concrete by the authors within the Deakin University facility which is a self-compacting and ambient cured type of geopolymer concrete [4,5,7,38,47]. This self-compacting geopolymer concrete does not use any ordinary Portland cement or superplasticisers to achieve the cementitious properties [4,5,7,38,47]. The study also assesses the impact of adding basalt fibre to this self-compacting geopolymer concrete by evaluating the water absorption rates and sorptivity potential. Finally, the study also includes a machine learning model that can be used to predict the sorptivity rate of similar geopolymer concrete mixes subjected to short-term as well as long-term exposure in water.

Thus, this research presents a detailed overview of the permeability characteristics of self-compacting geopolymer concrete mixes made from recycled industrial waste products such as fly ash, micro fly ash and slag. Owing to its flowability and self-compacting properties, all the three mixes of the geopolymer concrete used in this study offer a user-friendly, sustainable, and circular solution to the existing challenges in the energy and resource-intensive construction sector. This research is expected to add to the body of knowledge and be a reference for industry professionals to understand the suitability of fibre geopolymer concrete for practical applications.

2. Materials and Methods

2.1. Recycled Binder Materials

The three binder materials used in this study are supplementary cementitious materials, including fly ash, micro fly ash, and slag. These binder materials are produced from various industrial processes such as combustion waste products from coal industries and by-products from the iron and copper manufacturing sector.

The fly ash used for this study is a by-product of the coal combustion processes typically sourced from Gladstone Power Station, Queensland and bagged by Cement Australia Pty. Ltd., Darra, QLD, Australia. The micro fly ash used in this study is a finer grade of fly ash that contains particles of size in the range of 3.5 microns. It is supplied by Fly Ash Australia Pty. Ltd. from the Bayswater Power station, New South Wales, Australia. The fly ash and micro fly ash used in this study are obtained from coal-fired power plants in Australia as mentioned above. These coal combustion products are recycled back into the construction industry by using them as supplementary cementitious materials which otherwise would have ended up in ash pond landfills. The slag, commonly known as the Ground Granulated blast furnace slag, is produced by drying and grinding the granulated blast furnace slag produced by the rapid water quenching of molten slag from the iron and steel manufacturing process. The slag used in this study is produced by milling the granular blast furnace slag with optimised gypsum quantities in a vertical roller miller at the Yarraville grinding facility by Independent Cements Pty. Ltd., Port Melbourne, VIC, Australia.

The chemical composition of the binder materials used in this study is detailed in Table 1 below:

Table 1.

Chemical composition of binder materials [4].

2.2. Chopped Basalt Fibres

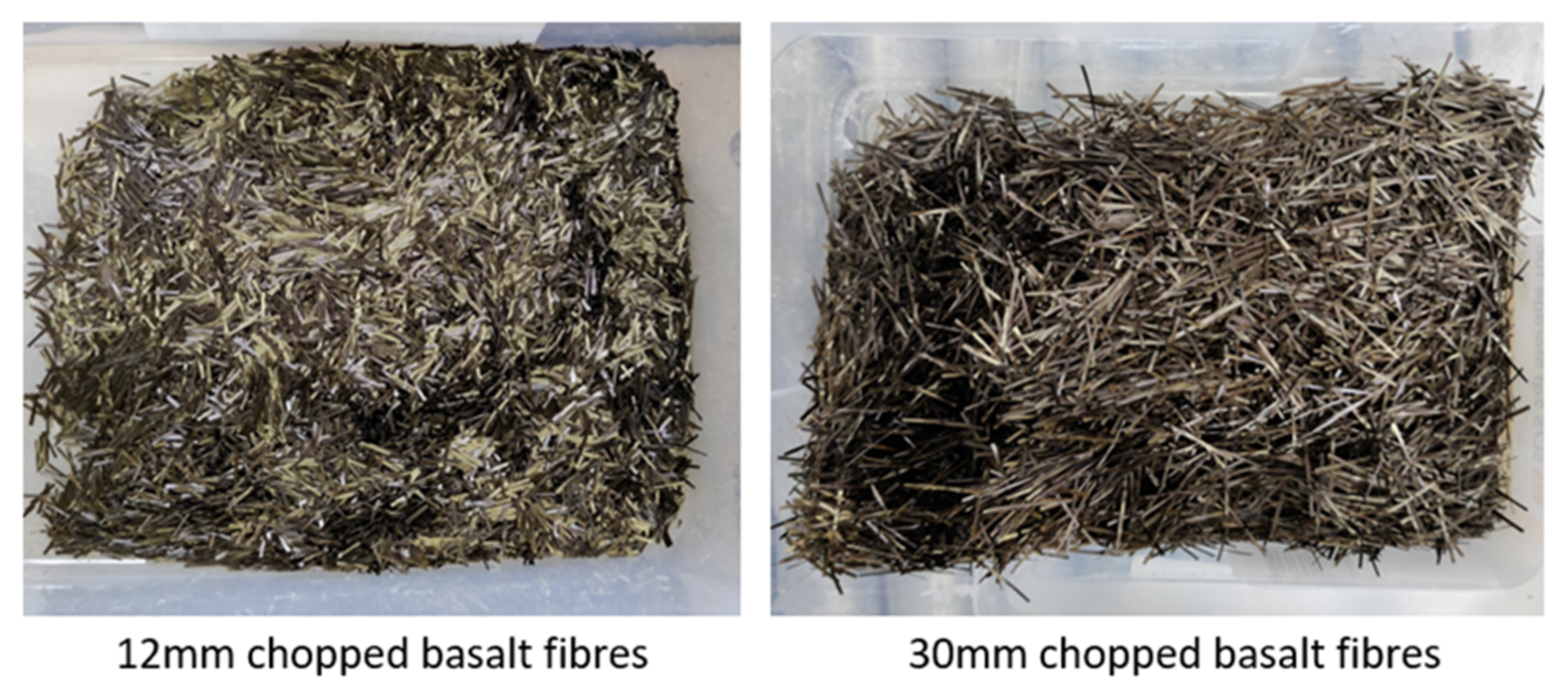

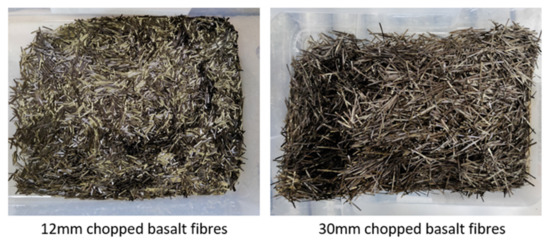

The current study also assesses the sorptivity characteristics of geopolymer concrete modified with chopped basalt fibres. The study thus uses the chopped basalt fibres of two different lengths, 12 mm and 30 mm, for two various geopolymer concrete mixes in the experimental program shown in Figure 1 below.

Figure 1.

Images of 12 mm and 30 mm chopped basalt fibres.

The diameter of both 12 mm and 30 mm lengths of chopped basalt fibres used in this study is 13 μm and the density falls in the range of 2.6–2.8 g/cm3. The aspect ratio of the fibre calculated as the length to the diameter is reported to be 923 for 12 mm-long chopped basalt fibres and 2308 for 30 mm-long chopped basalt fibres. Beyond Materials Group Pty. Ltd. supplied the chopped basalt fibres used in this study.

2.3. Alkali Activator

Unlike the traditional geopolymer concrete mixes, the mix adopted for this study uses a dry/solid activator for the alkali-activation process. Thus, the study uses one-part geopolymer concrete containing Anhydrous sodium metasilicate (Anhy.Na2SiO3) as the only solid activator, supplied by Redox Pty. Ltd., Laverton North, VIC, Australia.

2.4. Aggregates

The geopolymer concrete mixes used in this study fall under the category of self-compacting concrete, complying with the European Guidelines for Self-Compacting Concrete (EFNARC Guidelines), owing to its flowability and self-compaction properties [48]. Thus, the geopolymer concrete mix maintains the ratio of 47% by weight of coarse aggregates to 57% by weight of fine aggregates. Both the aggregates, the basalt coarse aggregate of <14 mm, and the fine aggregate, the river sand of <4.75 mm, were supplied by a local quarry.

2.5. Mix Design

The study uses three different mixes of geopolymer concrete, namely self-compacting geopolymer concrete (SCGC), self-compacting geopolymer concrete with 12 mm chopped basalt fibres (SCGC-B-12) and self-compacting geopolymer concrete with 30 mm chopped basalt fibres (SCGC-B-30). The mix proportions adopted for each of the mixes used in this study are detailed in Table 2 below:

Table 2.

Mix Proportions used in the study.

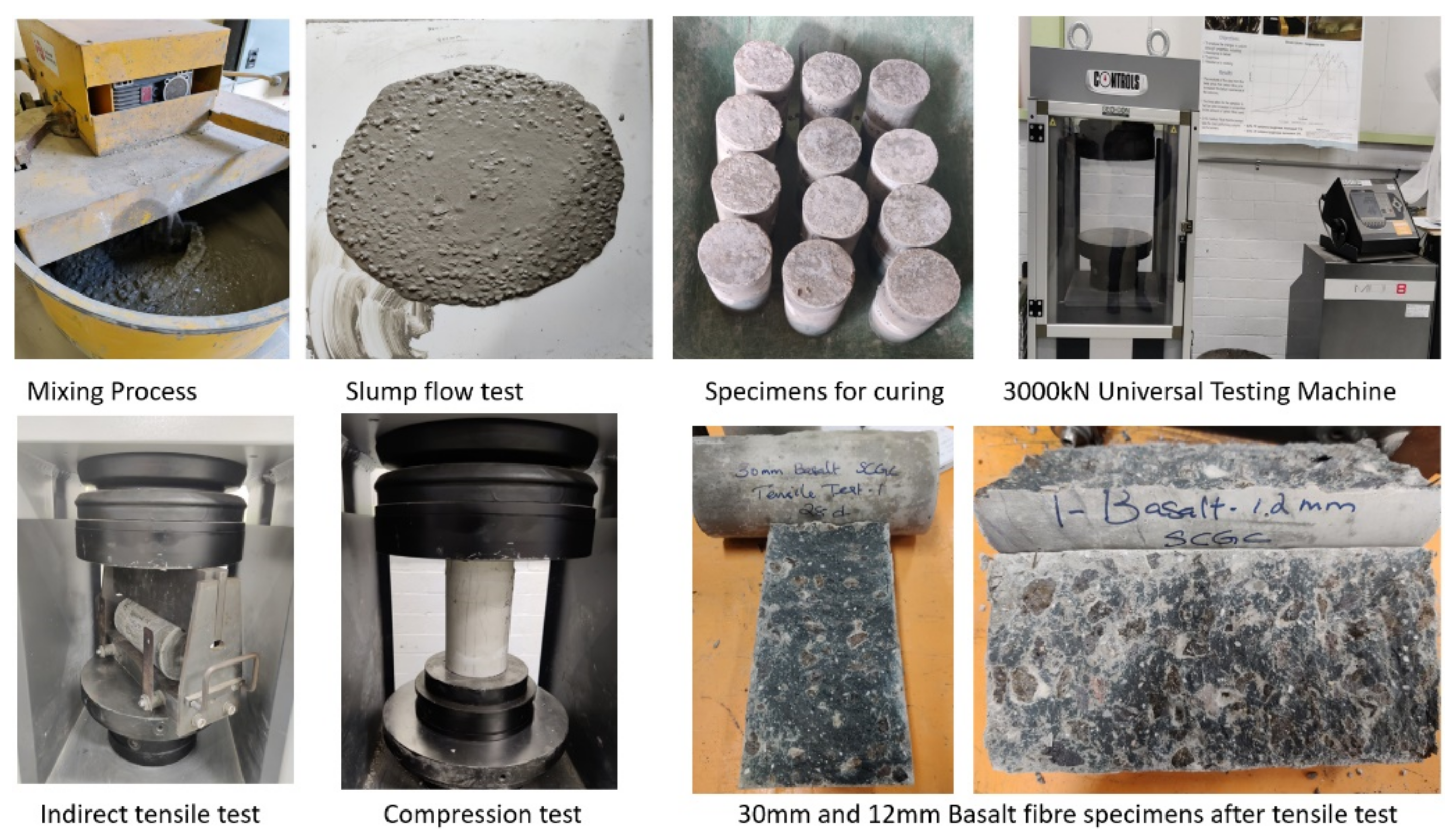

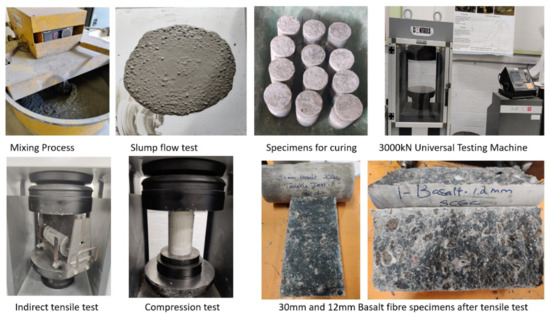

The water binder ratio of the mix is maintained at 0.45 water/binder content to maintain the workability required for the self-compacting geopolymer concrete. The mixing procedure involves two distinct stages, in the first stage, all the binder materials, alkali activator and chopped basalt fibres (if required) are added together and mixed for 4 min, and after that, the calculated water is added. The mixing is continued for 15 min until the required consistency is achieved. The fresh property of the mix is then assessed by the workability tests, including slump flow, and T500 tests, before the casting process [48]. The cylinder specimens are then cast into 100 mm (diameter) mould × 200 mm (height) and subjected to ambient curing for 28 days under laboratory conditions maintained at 23 ± 2 °C at Deakin University, Waurn Ponds Campus, Victoria. The Figure 2 below depicts the various stages of mixing and testing involved in the study.

Figure 2.

Workability and mechanical tests on test specimens.

2.6. Test Methods

Even though the study focuses on the durability characteristics in terms of sorptivity potential, the investigation needs to record the mechanical properties of the hardened cylinder specimens. Thus, the various test methods adopted for the study, including the mechanical tests and the sorptivity, are explained in the following subsections.

2.6.1. Capillary Water Absorption and Sorptivity

The durability of any concrete structure is gauged against the capability to withstand and perform under exposure to harsh or aggressive environments. It is reflected in the pore system resistance within the concrete against the penetration of aggressive salts and chemicals. Thus, capillary water absorption and sorptivity are considered essential parameter in the durability assessment of concrete as it indicates the ability of the concrete specimen to absorb and transmit the water and other liquids under the influence of capillary forces. The sorptivity test thus reports the durability characteristics of an unsaturated concrete specimen to water penetration. The test method adopted in this study conforms to the ASTM C1585–13 [49] standard procedure. It involves a sorptivity assessment and comparison of three different mixes of geopolymer concrete made from recycled cementitious materials. The sorptivity is a time-dependent function and change in mass of the test specimens when exposed to water. Throughout the test procedure, consistent environmental conditions in terms of temperature and relative humidity are maintained using an environmental chamber.

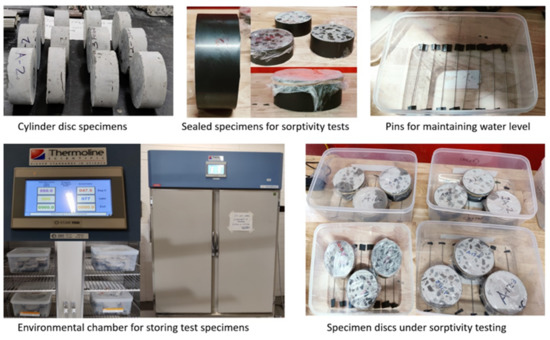

The capillary water absorption and sorptivity tests were conducted on the geopolymer concrete discs of size 100 ± 6 mm (diameter) and 50 ± 3 mm (height), which was cut from test specimens of 100 mm (diameter) × 200 mm (height) which were cured for 28 days [49]. Before the test, the cylinder discs were placed in a temperature and humidity control chamber for three days at 50 ± 2 °C and maintaining a relative humidity of 80 ± 3% [49]. Afterwards, the geopolymer concrete discs were placed in sealed containers holding the temperature at 23 ± 2 °C for 15 days to equilibrise the test specimens [49]. The geopolymer cylinder discs used in this study are sealed from the top using a plastic sheet cover, and the sides are sealed with duct tape to ensure water penetration only through the base surface of the disc. Later, the specimens were placed in containers filled with tap water, maintaining a level of 1–3 mm from the base of the samples using additional support pins. The sorptivity test set-up and the cylinder discs are depicted in Figure 3 below:

Figure 3.

Sorptivity test set-up and test specimens.

The weight of each geopolymer concrete cylinder disc was then recorded at regular intervals as stipulated by the ASTM C1585-13 standard [49]. The procedure is continued until long-term sorptivity is recorded. Before weighing each specimen, the surface water is wiped using a cloth, and the weight is recorded within 30 s. This test helps to record the initial absorption (data recorded from 1 min to 6 h exposure) and secondary absorption (data recorded from 1 day to 7 day exposure). The water absorption (I) according to ASTM C1585-13 is measured as follows:

where:

I = mt/(a × d)

- I = the absorption, mm

- mt = the change in specimen mass in grams, at the time t,

- a = the exposed area of the specimen, in mm2, and

- d = the density of the water in g/mm3.

The slope of the plot of the absorption to the square root of corresponding time gives the sorptivity rate. For a better overview and comparison of the three different mixes used in this study, the long-term sorptivity data was collected until there was no change in mass between the two consecutive readings. For each type of geopolymer concrete mix 6-cylinder discs each were used to study the capillary water absorption and sorptivity studies.

2.6.2. Compressive Strength

A 3000 kN universal testing machine conforming to the Australian Standards, AS 1012.9:2014 [50] was used for the 28-day compression strength tests. The loading rate was maintained at 0.33 MPa/s during compression testing at the Deakin University, Waurn Ponds campus Structures Research laboratory. Three cylinders of 100 mm diameter and 200 mm height for each type of geopolymer concrete mix were used to assess the average 28-day compressive strength.

2.6.3. Indirect Tensile Strength

The indirect tensile strength conforming to the Australian Standards, AS 1012.10:2000, was carried out on the 28-day cured cylinder specimens [51]. The loading rate of 785 N/s was applied using the 3000 kN universal testing machine at the Structures Research Laboratory at Deakin University. Three cylinders for each type of geopolymer concrete mix were used to assess the average 28 day indirect tensile strength. The cylinders had a diameter of 100 mm and height of 200 mm.

3. Results and Discussion

3.1. Workability and Mechanical Properties

The fresh properties, including the flowability of the three different mixes and the mechanical characteristics of 28 day cured specimens, are studied. The addition of chopped basalt fibres reduces the flowability however offered similar compressive strength and tensile strength properties after 28 days of curing. Table 3 below compiles the results of workability and mechanical properties of the three geopolymer concrete mixes from this study.

Table 3.

Workability and Mechanical Properties of the Geopolymer Concrete Mixes.

The test results on the hardened properties indicate that adding fibres did not improve the mechanical properties. It could be attributed to the minimal addition percentage of chopped basalt fibres in the fibre geopolymer concrete mix. The other reason for the slight decline in the mechanical properties can be attributed to the irregular dispersion of the fibres in the geopolymer concrete mix, as reported by other researchers [29]. There was a slight increase in the mass and density of samples with the addition of chopped basalt fibres. It can also be inferred that adding the chopped basalt fibres by 1% (weight/weight of total binders) reduced the slump flow by an average of 12 mm. However, it maintained the flowability requirements within the range of 650–850 mm stipulated by the EFNARC guidelines [48].

3.2. Sorptivity Characteristics of the Geopolymer Concrete Mixes

3.2.1. Sorptivity of the Self-Compacting Geopolymer Concrete (SCGC)

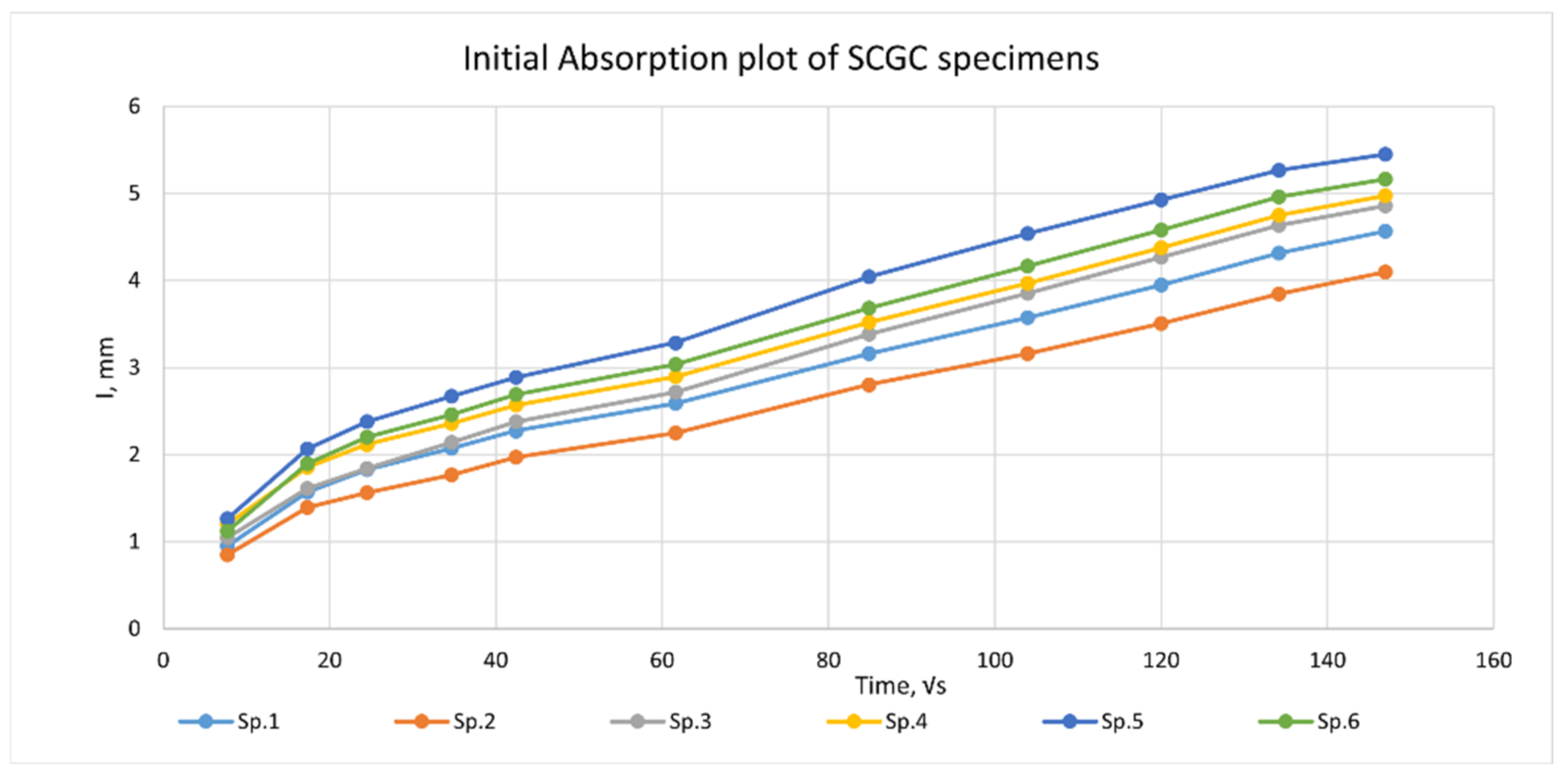

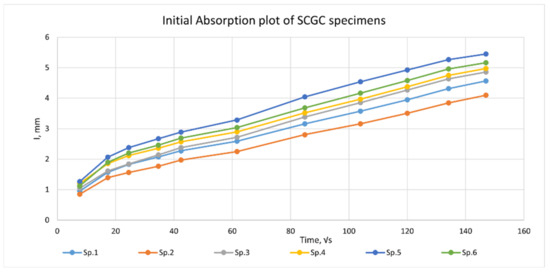

The capillary absorption rate of the geopolymer concrete with self-compacting properties (SCGC) is assessed in this study according to the ASTM C1585-13 standards. The initial absorption characteristics are reported for six samples of the SCGC recorded from 1 min to 6 h, plotted in Figure 4 below.

Figure 4.

Initial absorption plot of SCGC specimens.

The initial absorption trend of the SCGC specimens reports an average sorptivity of 0.025 mm2/s0.5, with all the specimens falling within the range. It is higher than the conventional concrete, which reports an absorption of 0.1 mm compared to the 4 mm for the geopolymer concrete in the first 6 h of surface exposure [52]. This behaviour of the geopolymer concrete is attributed to the porous surface owing to the copious amounts of fines present in the self-compacting mix used in the study.

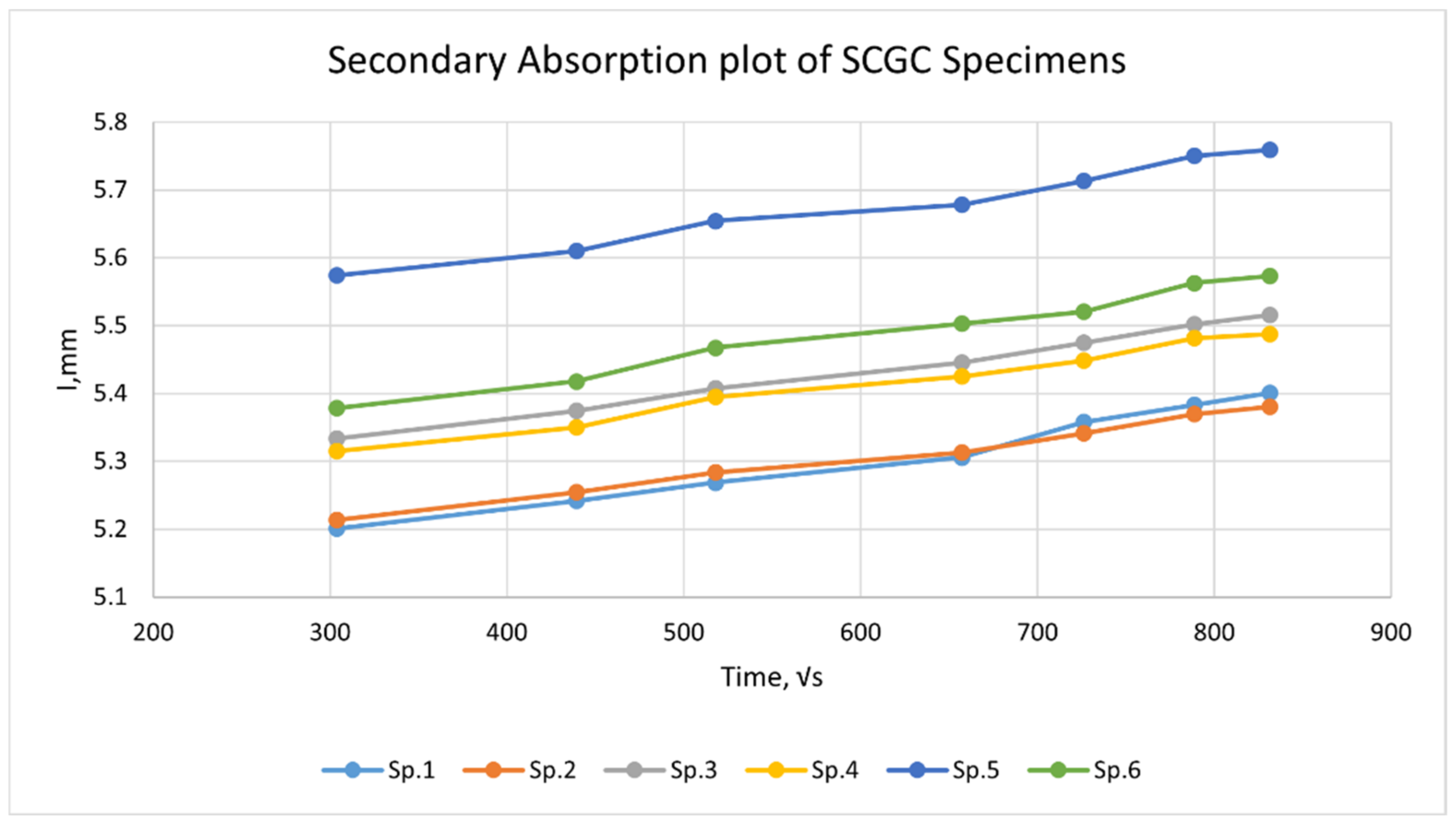

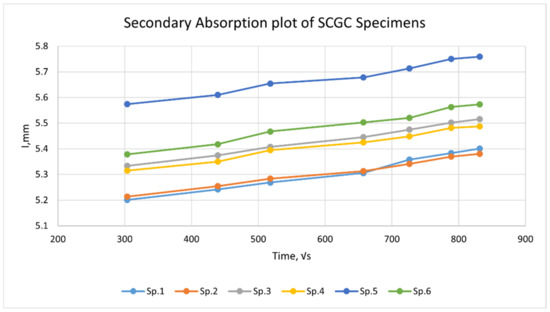

Similarly, the capillary absorption rate of 1 day to 7 days is also recorded to obtain the secondary absorption rate of the SCGC disc samples, as shown in the graph (Figure 5) below:

Figure 5.

Secondary absorption plot of SCGC specimens.

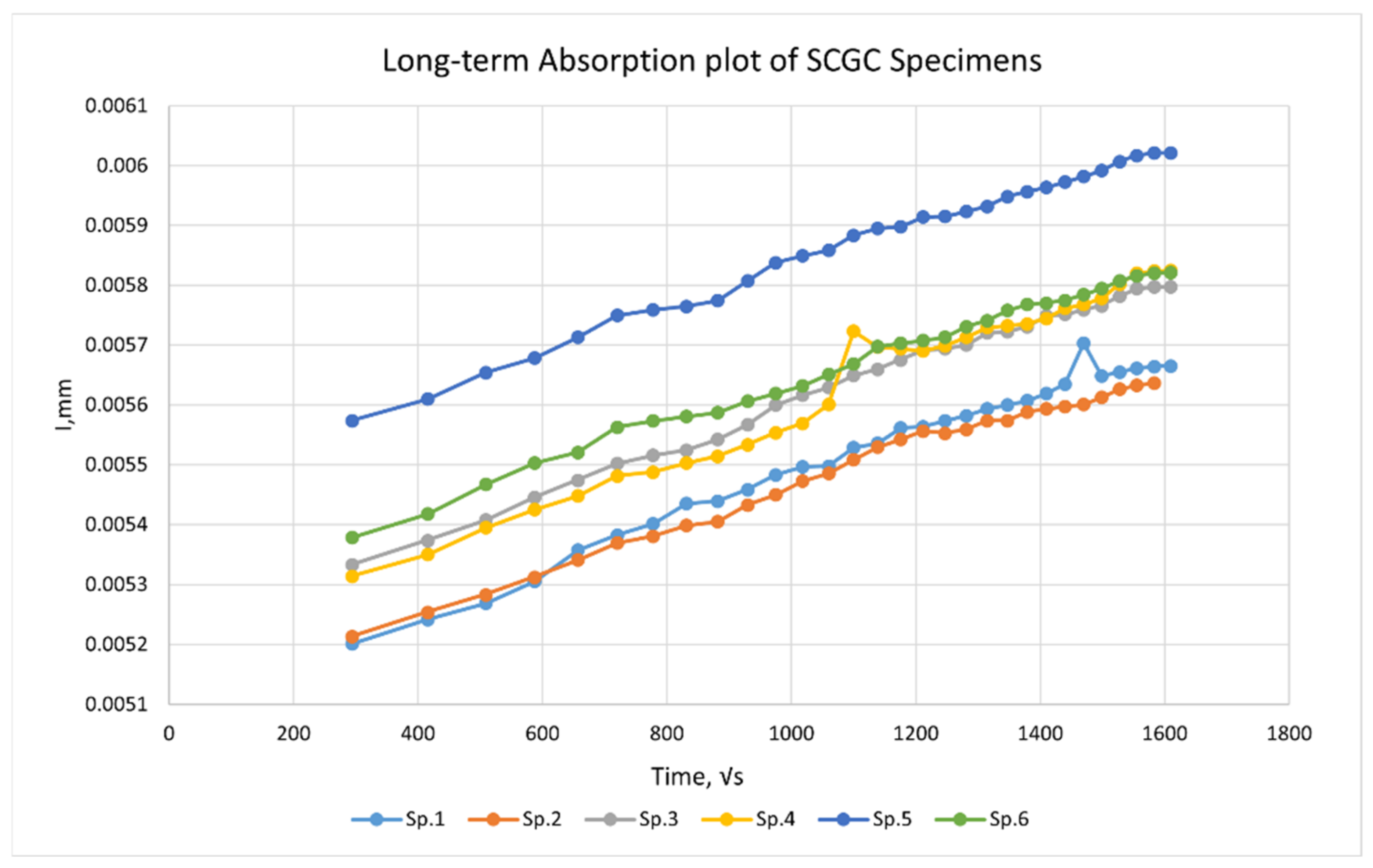

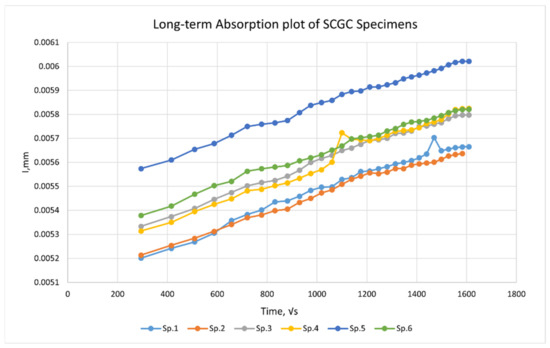

The long-term capillary absorption rate was also recorded for these six samples for up to one month until there was a minor change in the weight of the new geopolymer concrete discs, as depicted in the plot (Figure 6) below.

Figure 6.

Long-term absorption plot of SCGC specimens.

Both the secondary and the long-term absorption depicts a slowing down in the intake of water which showed nearing the saturation point for the geopolymer concrete discs. The sorptivity rates were in the range of 0.003 mm2/s0.5 for secondary exposure, which then tapered down to 3.5 × 10−7 mm2/s0.5 for the specimens under long-term exposure indicating the reaching of saturation point. The correlation coefficient of all the initial, secondary, and long-term plots maintained a value greater than 0.98.

3.2.2. Sorptivity of the Geopolymer Concrete Containing 12 mm Basalt Fibres (SCGC-B-12)

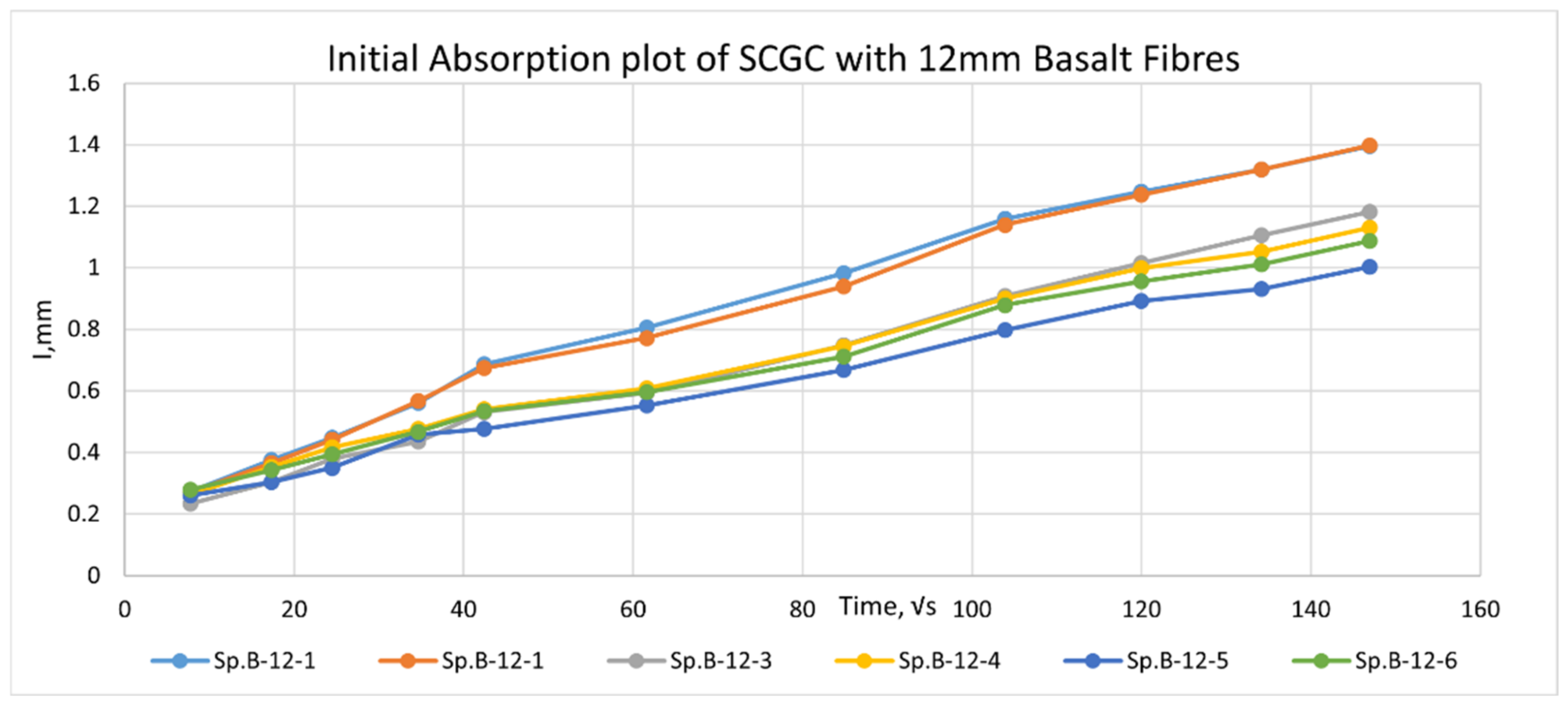

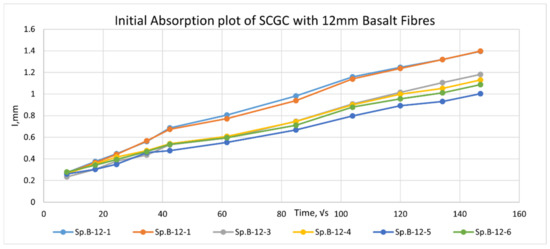

The sorptivity rates were also calculated for the geopolymer concrete mix containing 12 mm-long chopped basalt fibres. The test conducted according to the ASTM C1585-13 standards recorded improved performance compared to the new geopolymer concrete mix without any fibres. The initial absorption rate is recorded from 1 min to 6 h for the SCGC-B-12 mix and is plotted in Figure 7 below.

Figure 7.

Initial absorption plot of SCGC with 12 mm basalt fibres.

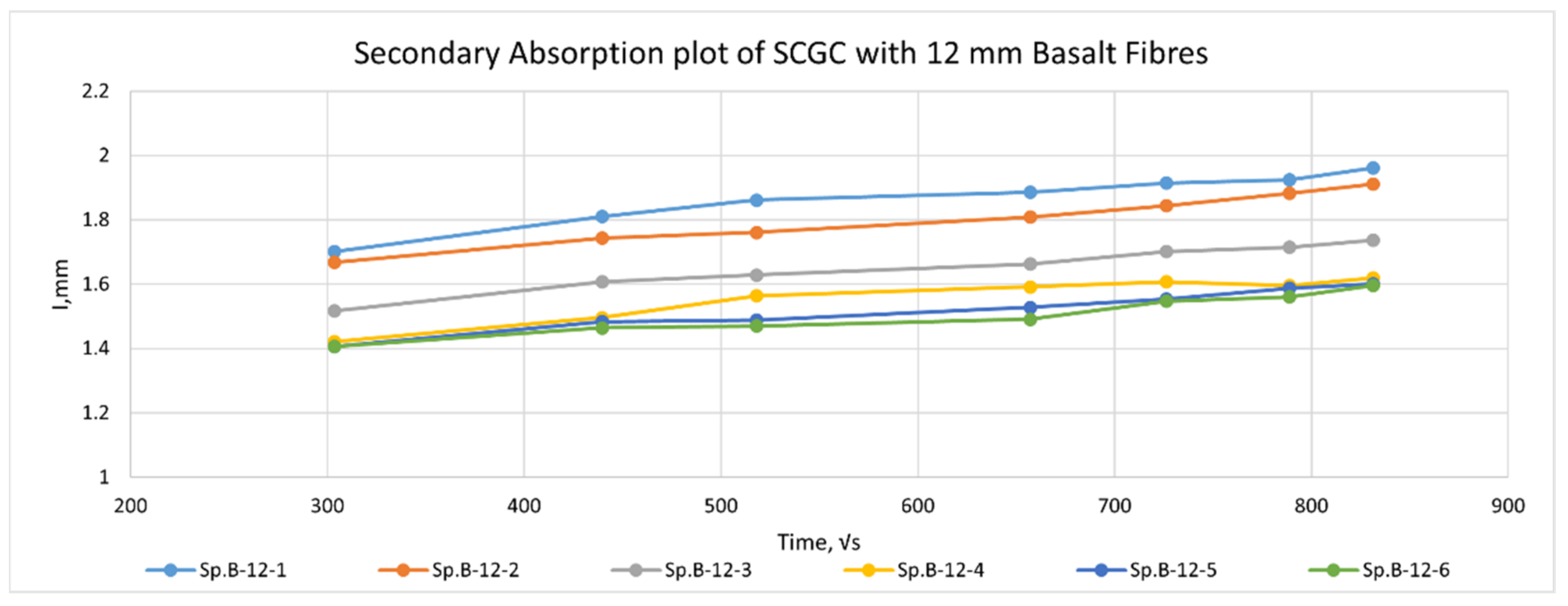

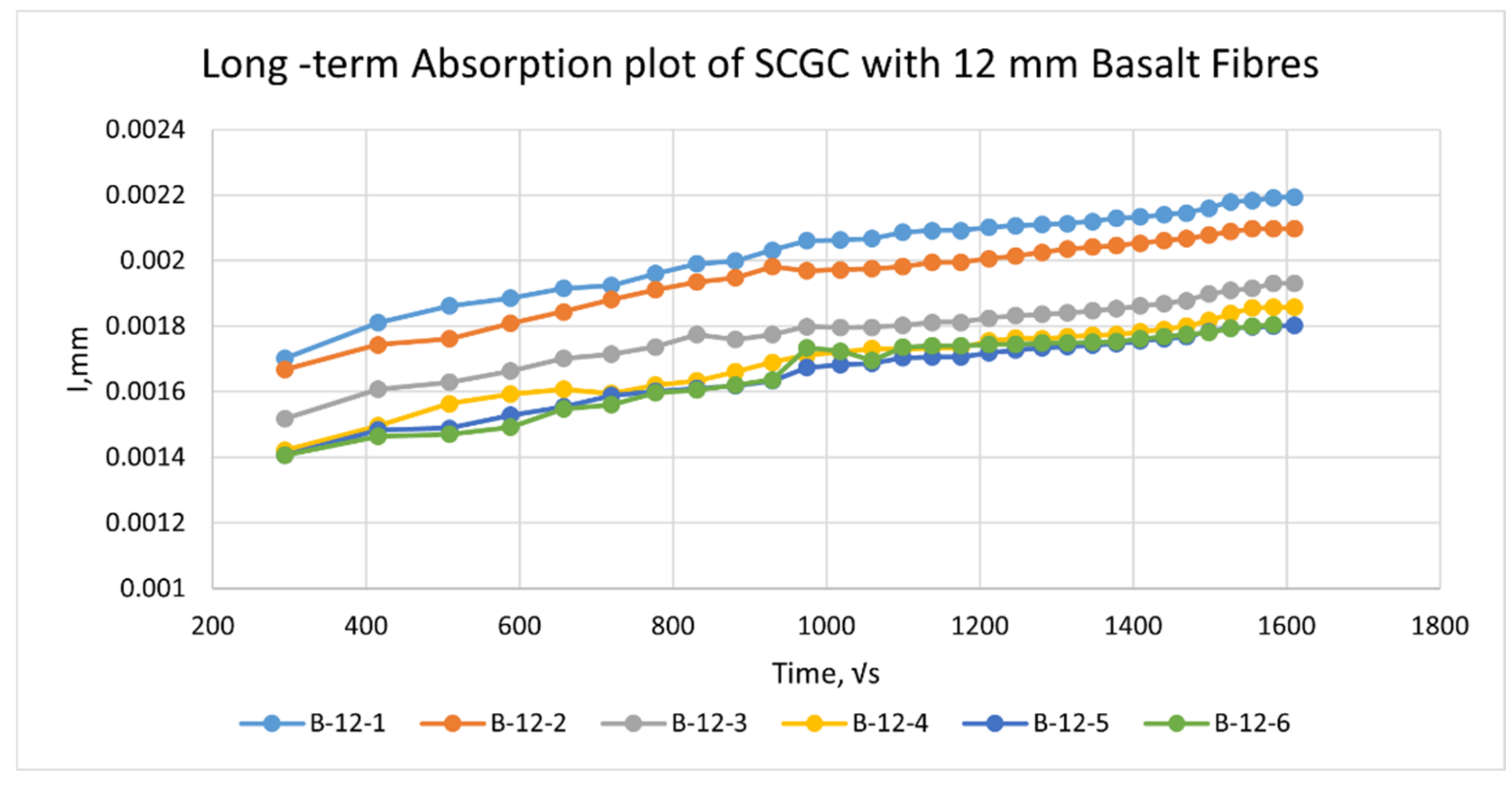

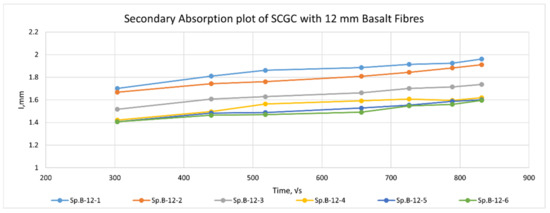

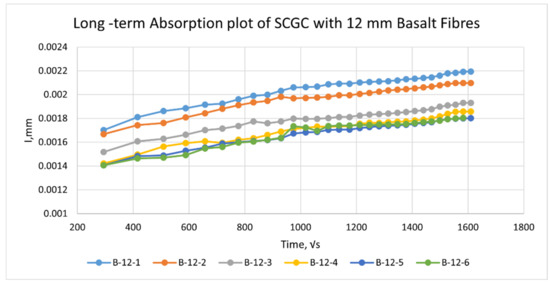

The secondary and long-term absorption rates of the 12 mm basalt fibre-containing mix are also shown in Figure 8 and Figure 9 below:

Figure 8.

Secondary absorption plot of SCGC with 12 mm basalt fibres.

Figure 9.

Long-term absorption plot of SCGC with 12 mm basalt fibres.

The initial absorption rate of the fibre SCGC mix modified with 12 mm basalt fibres was 0.006 mm2/s0.5, followed by even lower rates of 0.0003 mm2/s0.5 after 7 days of exposure and finally reaching 2.9 × 10−7 mm2/s0.5 after 1 month exposure. The correlation coefficient of all the absorption plots was more significant than 0.98. The decrease in the water absorption can be attributed to the ability of the fibres to impede the pore connectivity of the geopolymer concrete framework leading to reduced permeability; however, similar studies on standard concrete without self-compacting properties reported an inverse relation when basalt fibres are added [29,30].

3.2.3. Sorptivity of the Geopolymer Concrete Containing 30 mm Basalt Fibres (SCGC-B-30)

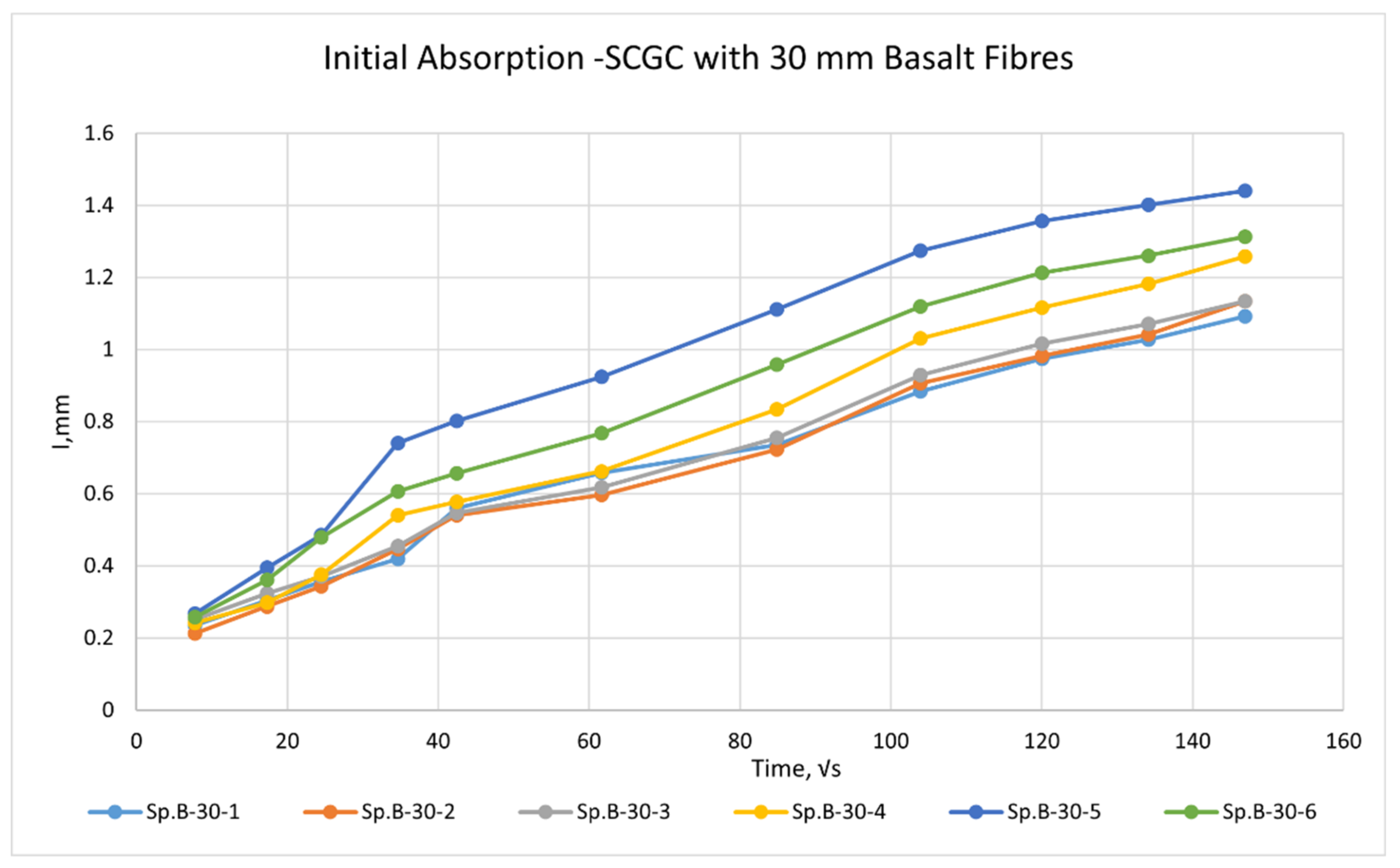

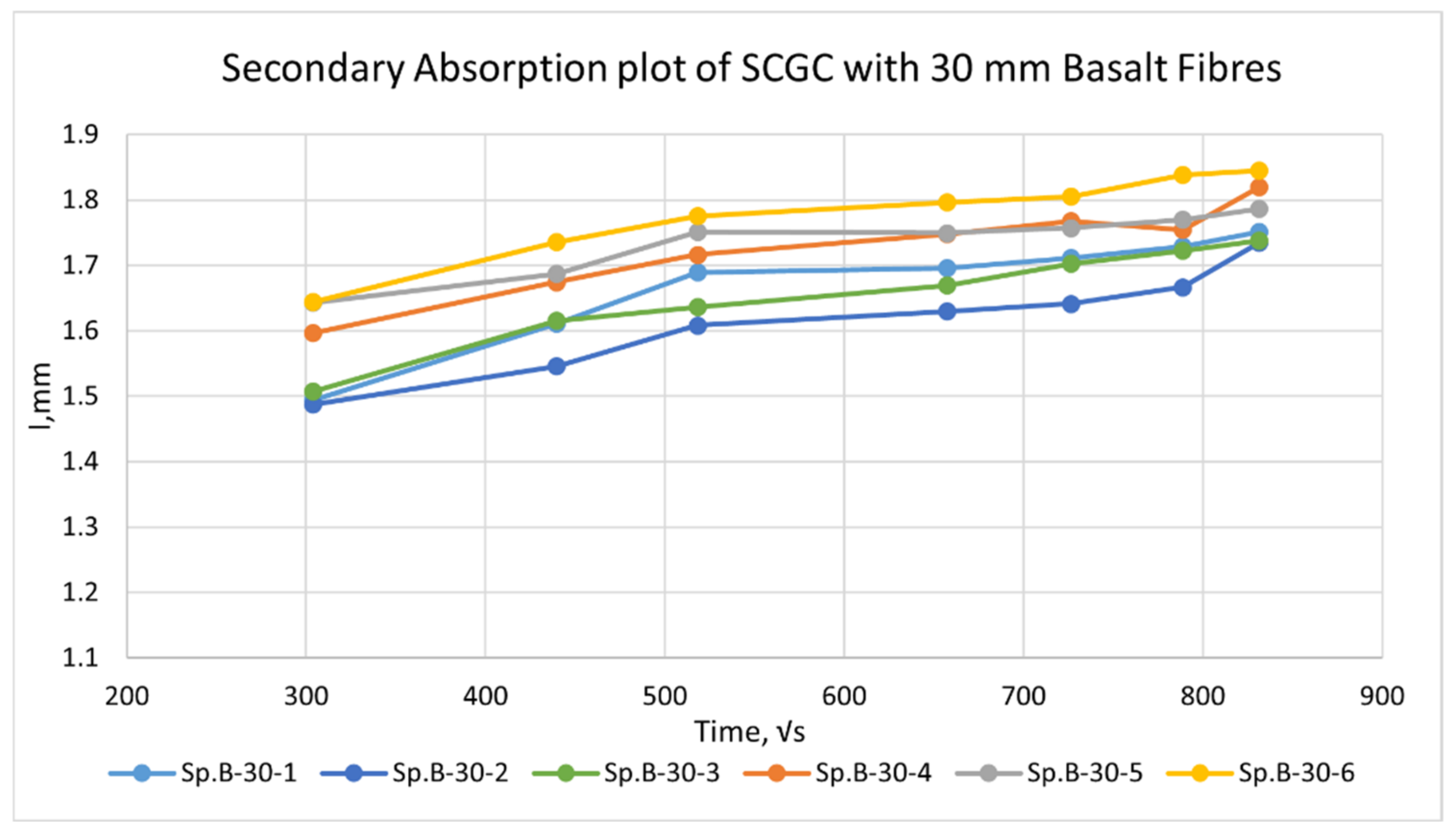

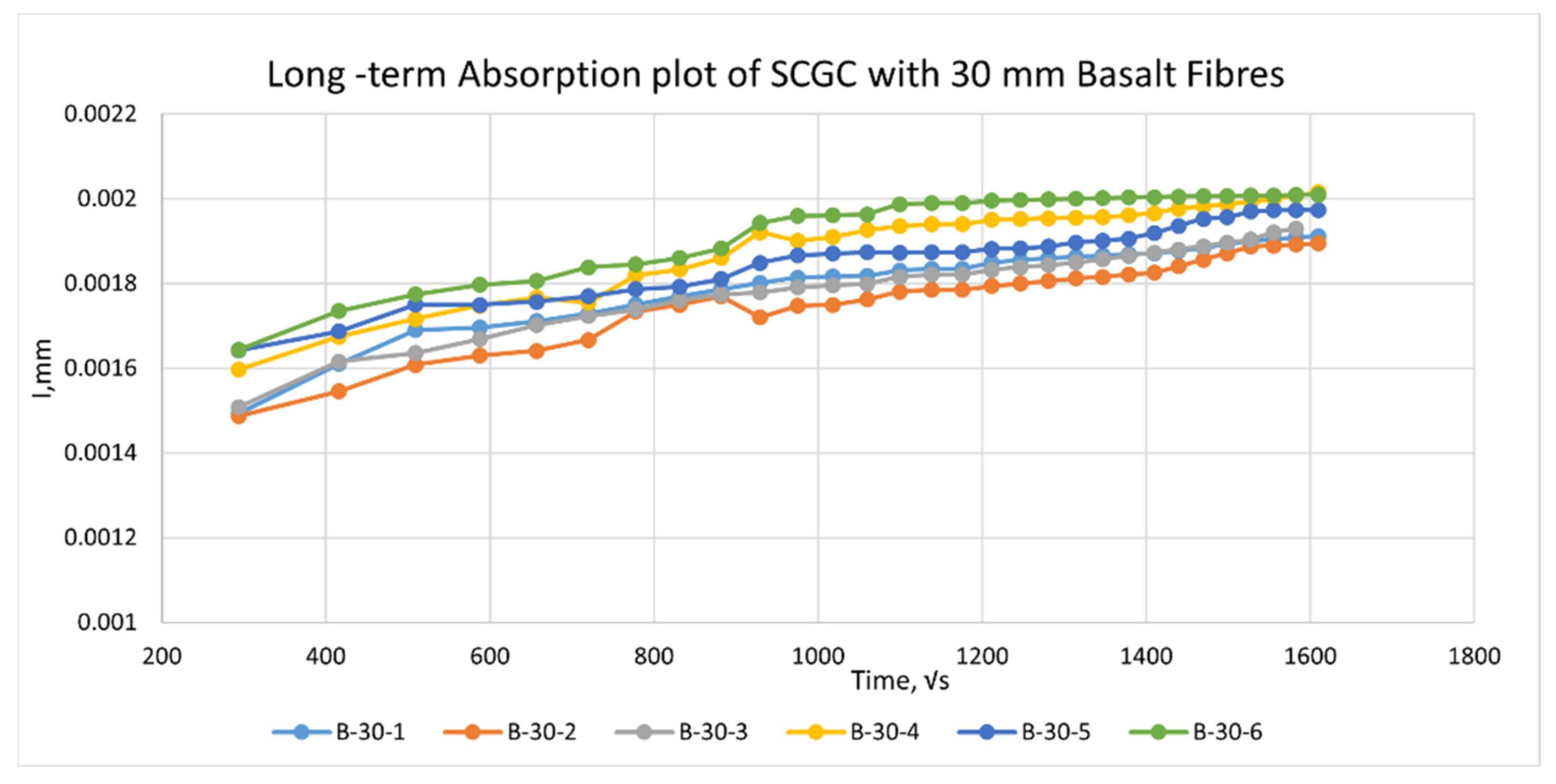

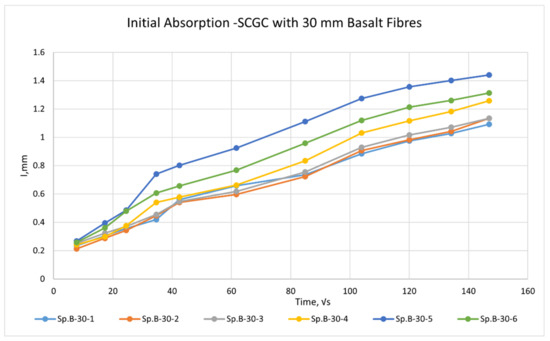

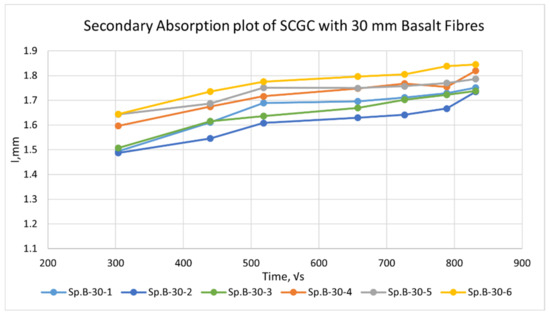

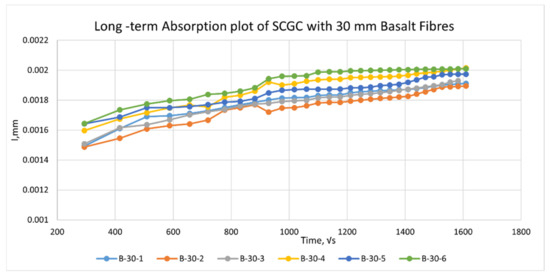

The initial, secondary, and long-term plots for water absorption rates of fibre geopolymer concrete modified by the addition of 30 mm-long chopped basalt fibres are depicted in Figure 10, Figure 11 and Figure 12, shown below:

Figure 10.

Initial absorption plot of SCGC with 30 mm basalt fibres.

Figure 11.

Secondary absorption plot of SCGC with 30 mm basalt fibres.

Figure 12.

Long-term absorption plot of SCGC with 30 mm basalt fibres.

The initial absorption rate of the SCGC mix modified with 30 mm basalt fibres followed a similar trend to that of the mix containing the 12 mm-long chopped basalt fibres. The average initial absorption rate reported as the slope of I to time was 0.007 mm2/s0.5, followed by an even lower rate of 0.0003 mm2/s0.5 after 7 days of exposure and finally reaching 2.56 × 10−7 mm2/s0.5 after 1 month exposure. The correlation coefficient of all the absorption plots for these specimens was also greater than 0.98.

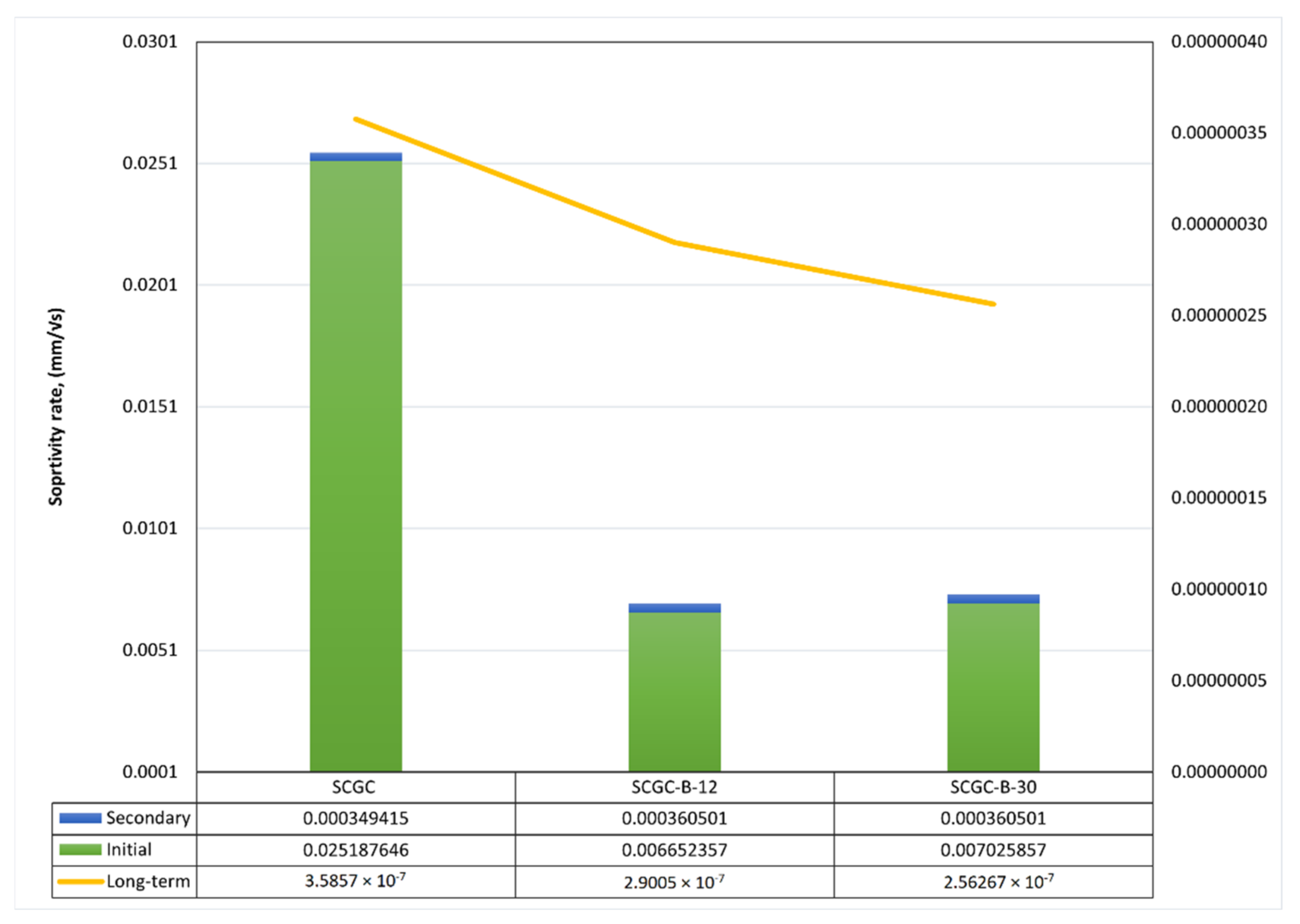

3.3. Comparison of Sorptivity Characteristics

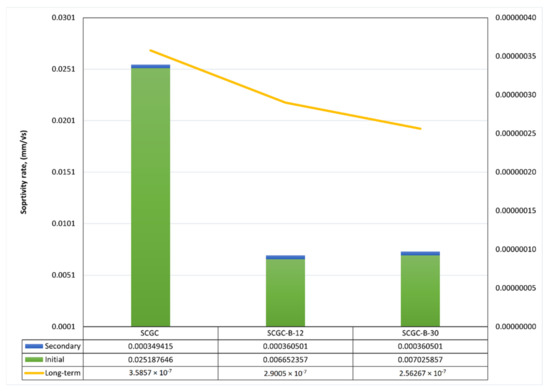

A comparison study on the performance of the three different mixes used in this study is conducted in terms of permeability characteristics. The sorptivity rates of the SCGC, SCGC-B-12 and SCGC B-30 mix is depicted in the plot (Figure 13) below.

Figure 13.

Sorptivity of SCGC, SCGC with 12 mm basalt fibres and 30 mm basalt fibres.

The mix containing chopped basalt fibres of 12 mm lengths reported a drop in initial sorptivity by 73.6%. At the same time, the mixture containing 30 mm-long basalt fibres also reported a similar reduction of 72%, indicating the enhanced permeability properties due to the addition of the fibres. This trend confirms that adding fibres to geopolymer concrete efficiently improves the porosity and permeability of the self-compacting compositions of the geopolymer concrete. The results are identical to those observed by several other researchers, confirming the suitability of basalt fibres in geopolymer concretes. However, the 1% (weight/weight of binders) of the two different fibres did not report a significant difference in sorptivity rates.

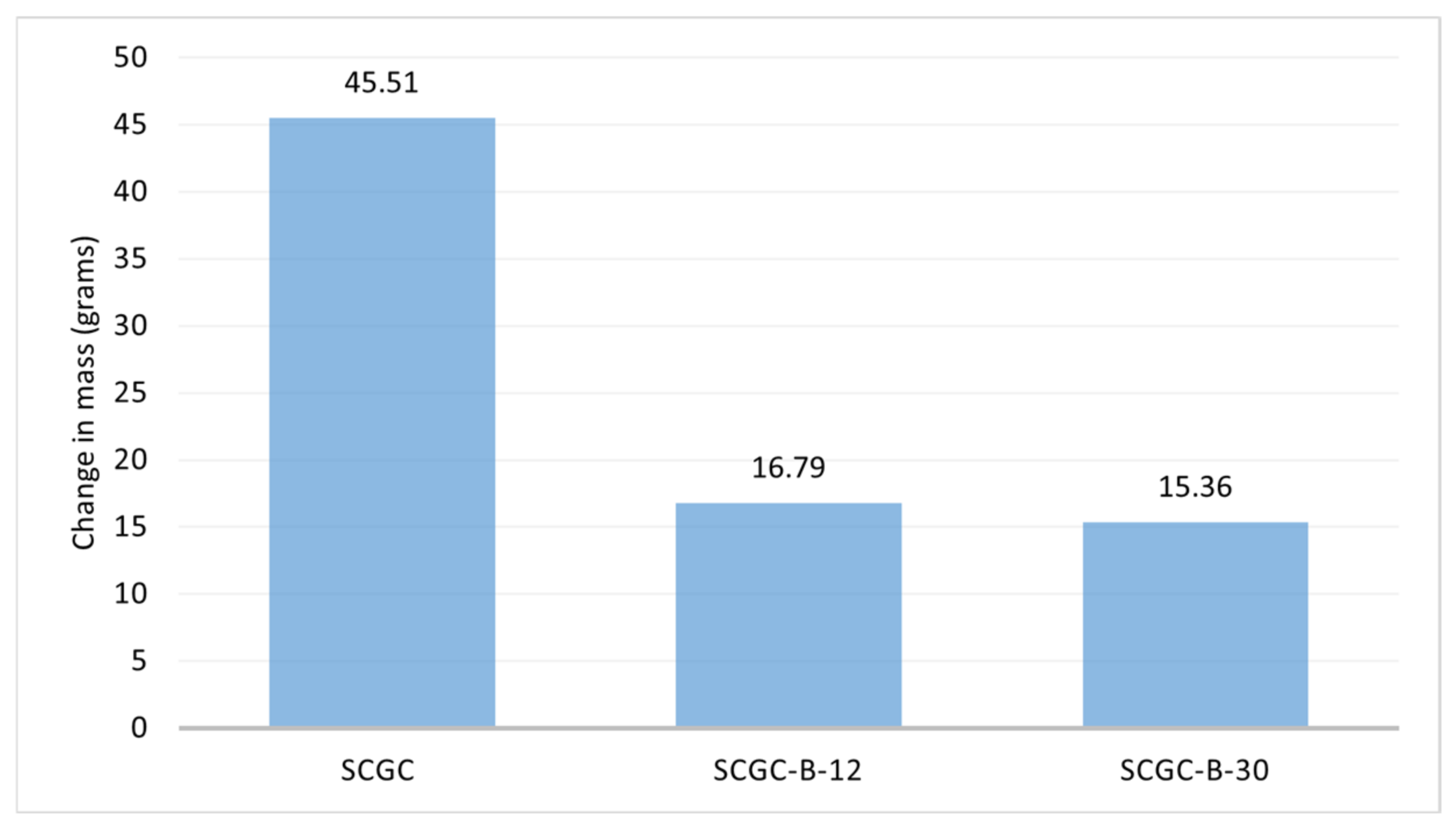

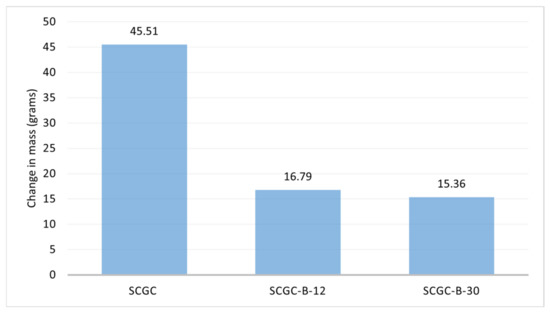

On the other hand, the secondary sorptivity rates indicated a negligible difference in the sorptivity of the three different specimens. It could be due to the early saturation of the SCGC specimens without any fibres. A comparison plot depicting the average change in mass of the specimens spanning over the whole test period of up to one month is illustrated in Figure 14 below.

Figure 14.

Mass change of SCGC, SCGC with 12 mm basalt fibres, and 30 mm basalt fibres until saturation.

The comparison above shows that the SCGC specimen without any chopped basalt fibres had a more significant rate of water absorption, reporting an increase in weight by 45 g compared to the overall weight increase of 16.79 g and 15.36 g of SCGC-B-12 and SCGC-B-30 specimens, respectively. It shows that the addition of 12 mm-long chopped basal fibres indicated a drop in water absorption by 63%. In comparison, adding 30 mm chopped basalt fibres offered a 66% decrease in water absorption, offering increased resistance to water ingress and other related chemicals, improving the durability of the newly developed self-compacting geopolymer concrete mix.

3.4. Artificial Neural Network (ANN) for Prediction of Sorptivity Characteristics

Nowadays, artificial intelligence computational tools such as artificial neural networks (ANN) are widely regarded by researchers worldwide owing to their efficiency in pattern recognition and fitting complex datasets [38]. This prediction method has proven to be much more accurate than the theoretical models and other conventional statistical methods [53,54]. The authors have successfully employed ANN in the earlier studies reporting the prediction of bond strength of SCGC when reinforced with Basalt FRP bars [38].

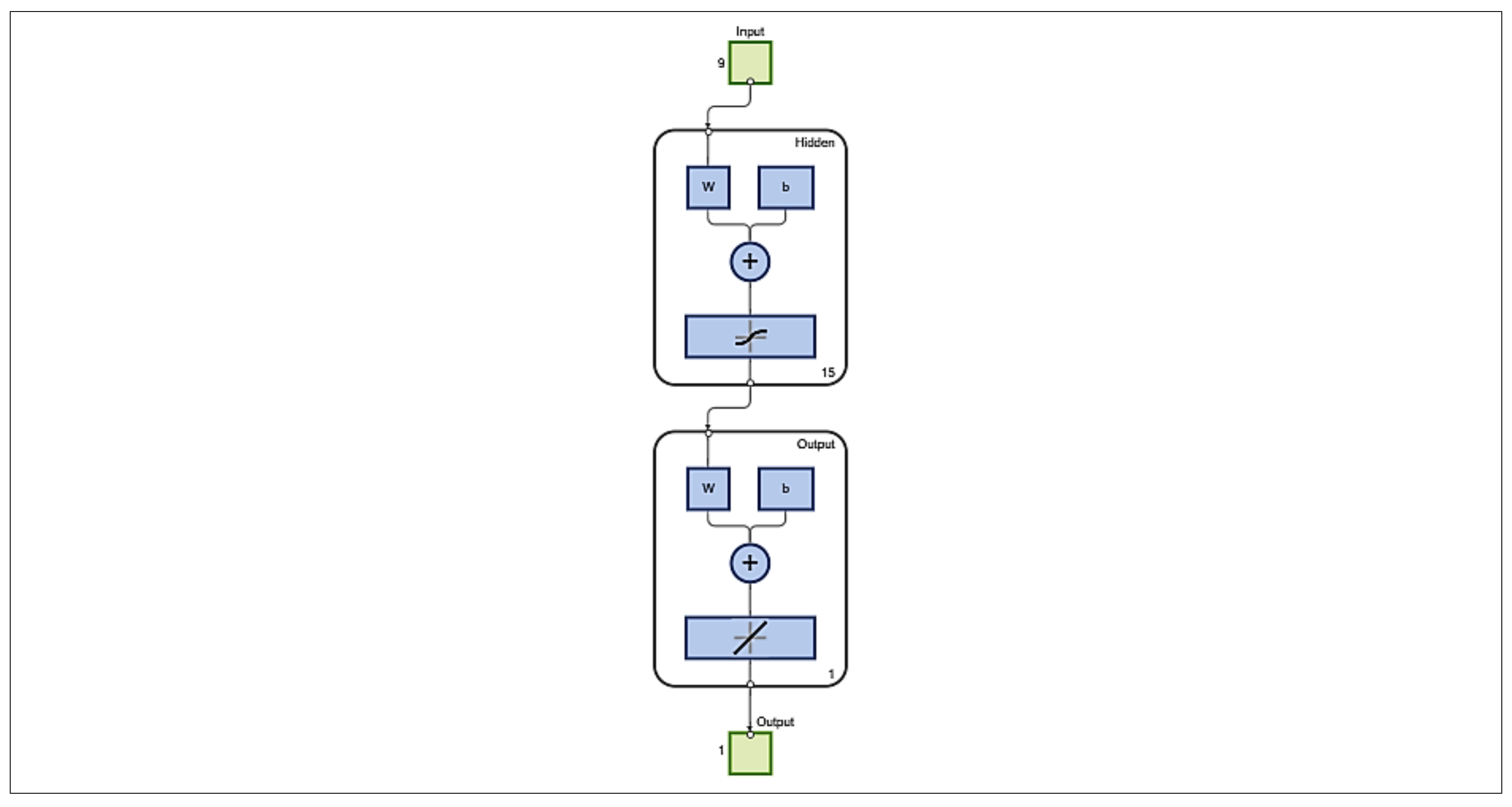

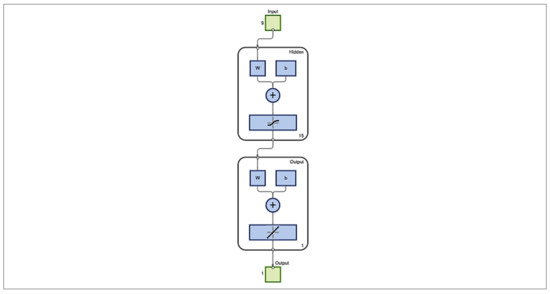

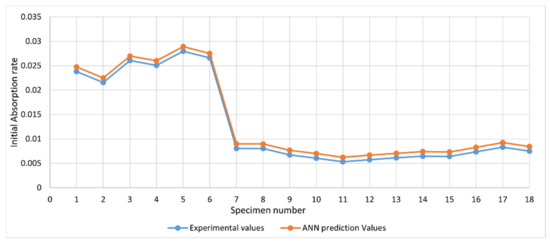

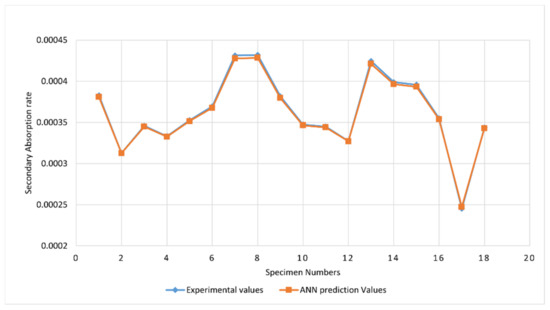

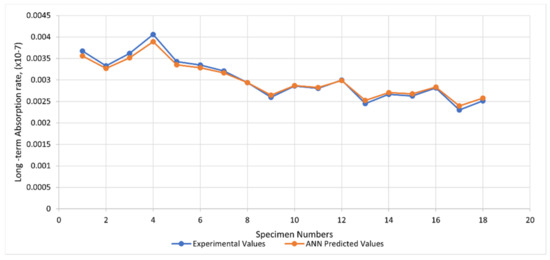

The ANN is successfully employed in this study to predict the SCGC and fibre geopolymer concrete mixes’ initial, secondary, and long-term absorption rates. The ANN results indicated that the prediction equations could be adopted for any type of modified mixes of geopolymer concrete in the future, offering better accuracy. The ANN model generated in this study considers the absorption rates as a function of binder content, basalt fibre content, compressive strength, and the change in mass of the concrete over time. Thus, the input parameters, including fibre content, basalt content, strength, mass change over various time intervals, are correlated with 15 hidden neurons to achieve the desired output of sorptivity rate. The results are validated and compared against the experimentally observed values to report an R2 > 0.99 for the initial, secondary, and long-term absorption rates, confirming the model’s accuracy.

A forward feed network trained with the Levenberg–Marquardt backpropagation (LMBP) algorithm containing nine input parameters, fifteen hidden layers and one output is developed to predict the absorption rates of the geopolymer concrete specimens, as shown in Figure 15 below.

Figure 15.

ANN Framework for two-layered feed-forward network.

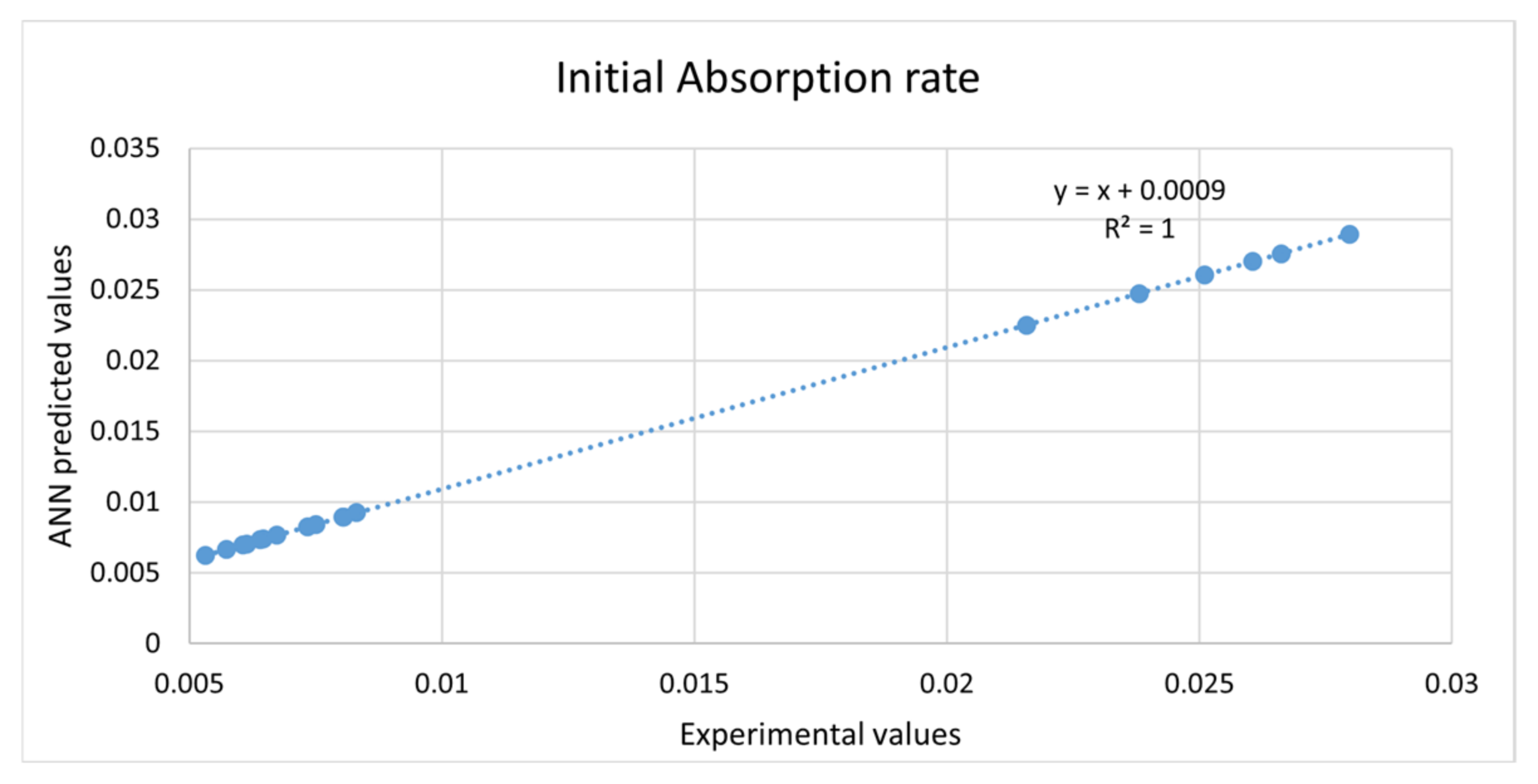

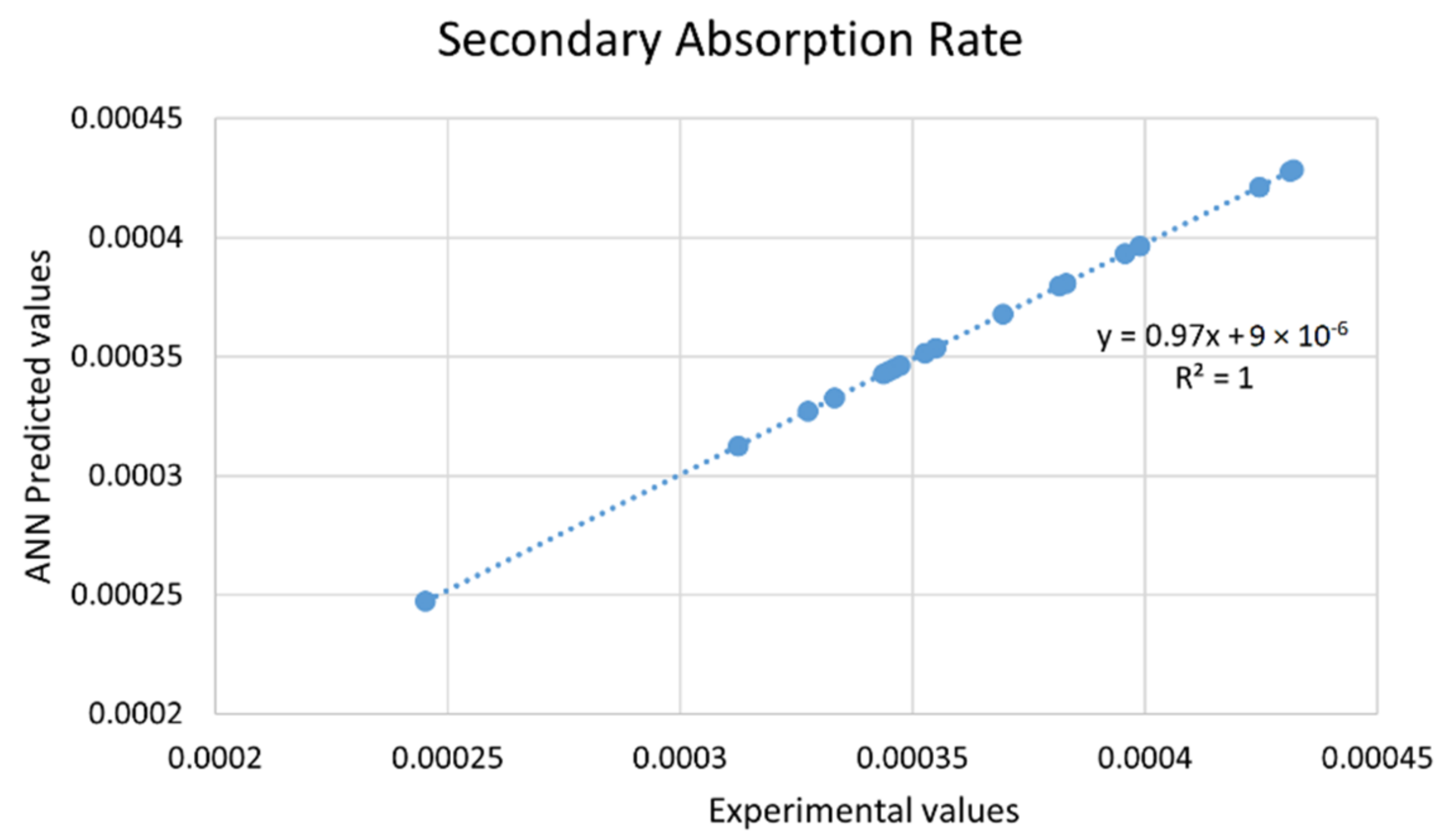

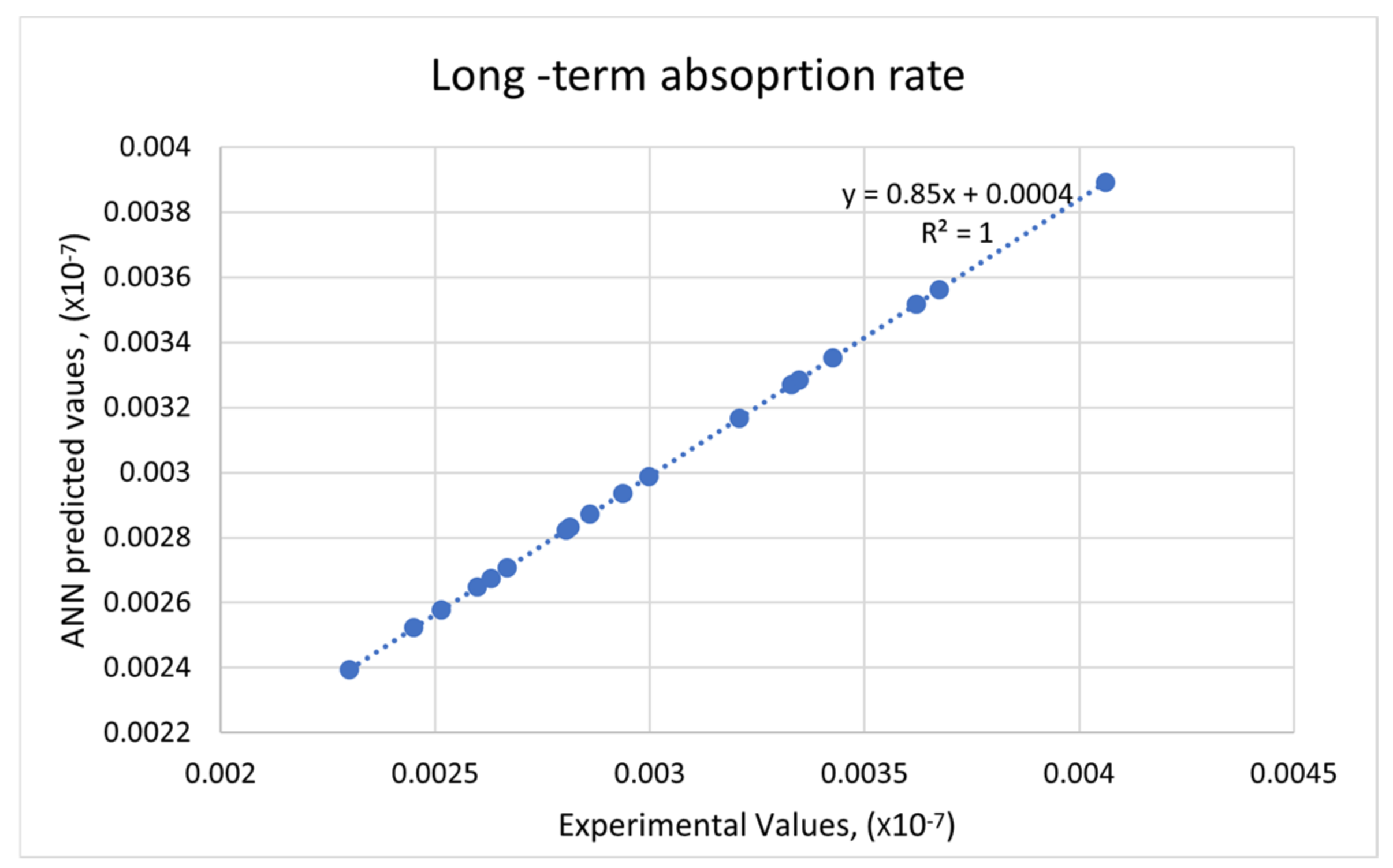

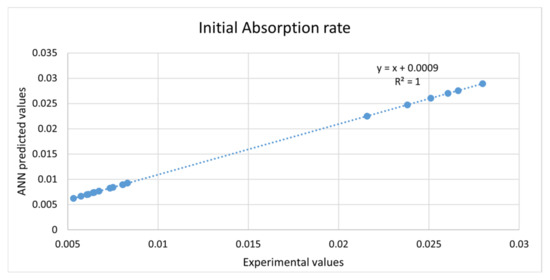

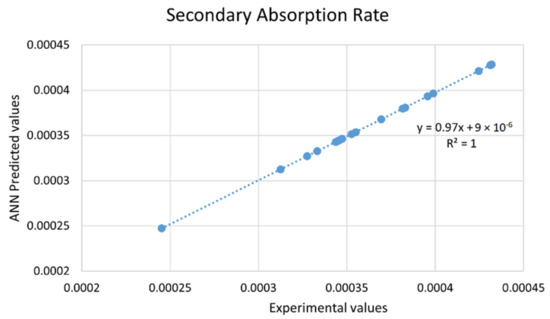

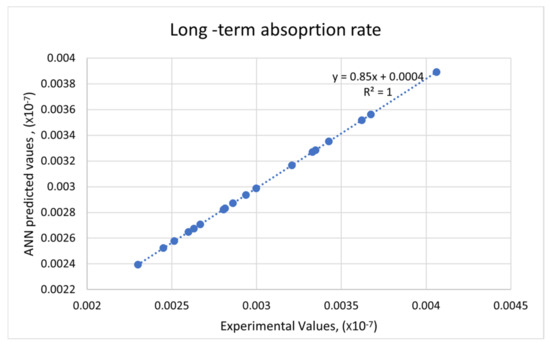

The hidden layers are neurons which consist of a logistic sigmoid activation function to run the model containing 70% of the sample size for training, 15% for validation and 15% for testing. The test runs for initial, secondary, and long-term absorption rates returned a correlation coefficient greater than 0.99 for the training, validation, and test datasets. The results of the prediction values against experimental values are depicted in Figure 16, Figure 17 and Figure 18 below for initial sorptivity, secondary sorptivity and long-term sorptivity. The R2 values are a perfect fit against the observed values for all three sorptivity rates.

Figure 16.

Initial absorption rate—correlation between ANN and experimental values.

Figure 17.

Secondary absorption rate—correlation between ANN and experimental values.

Figure 18.

Long-term absorption rate—correlation between ANN and experimental values.

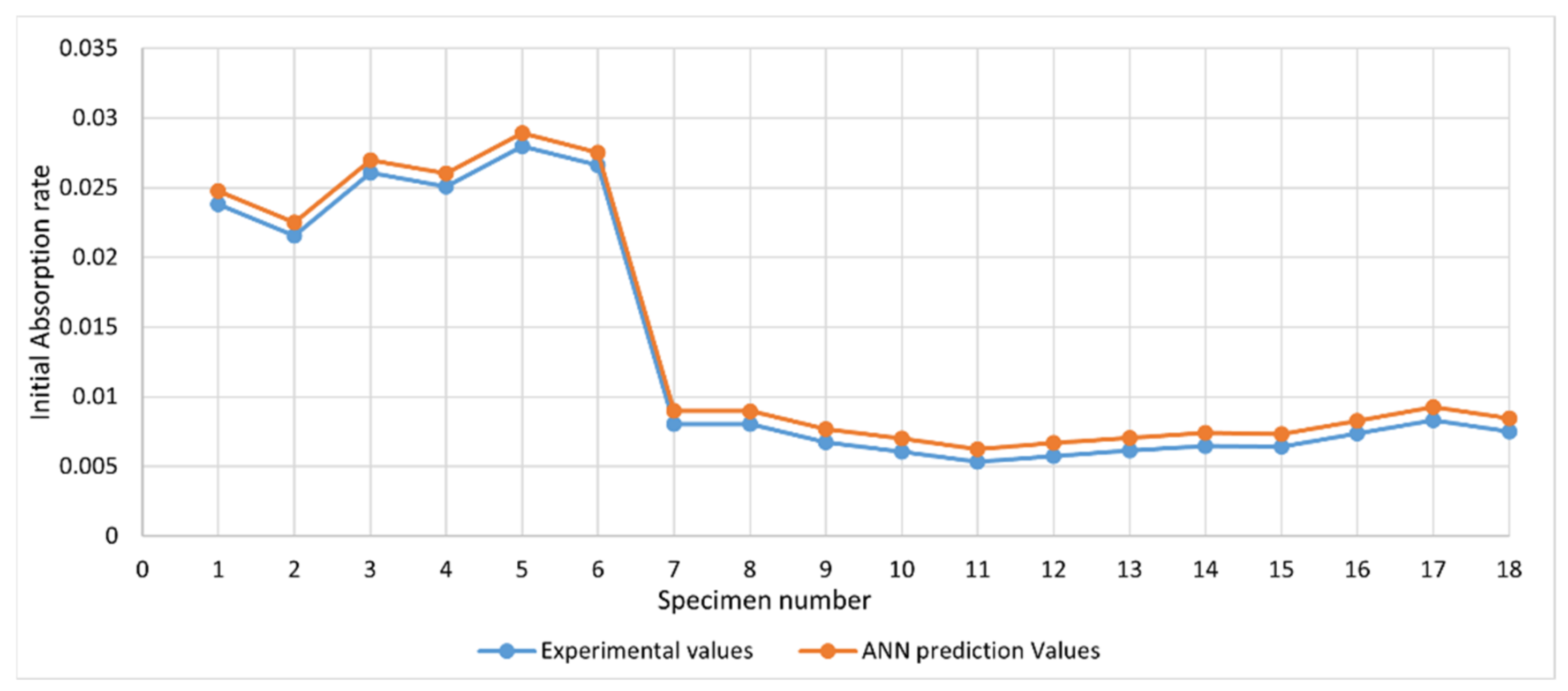

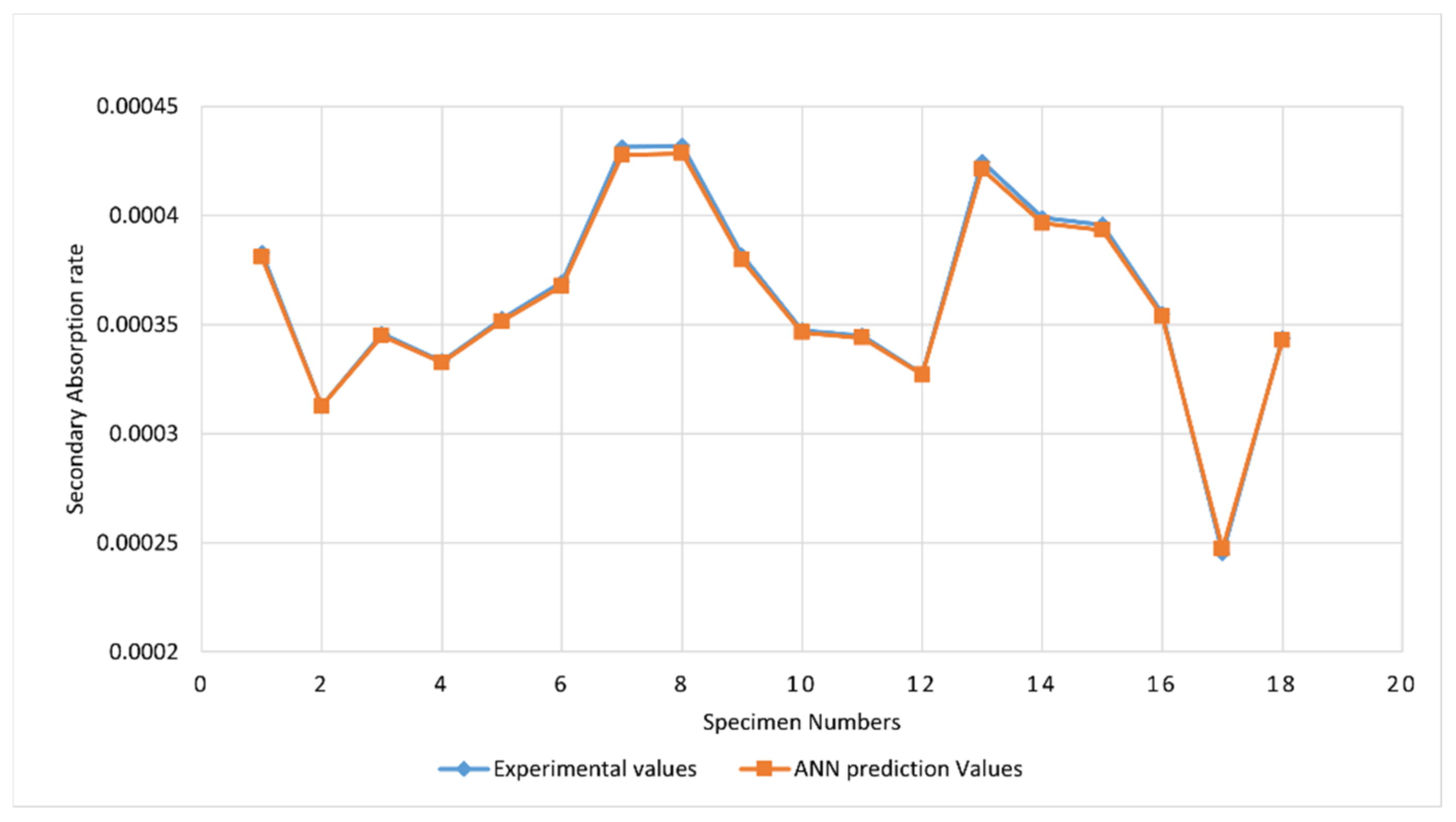

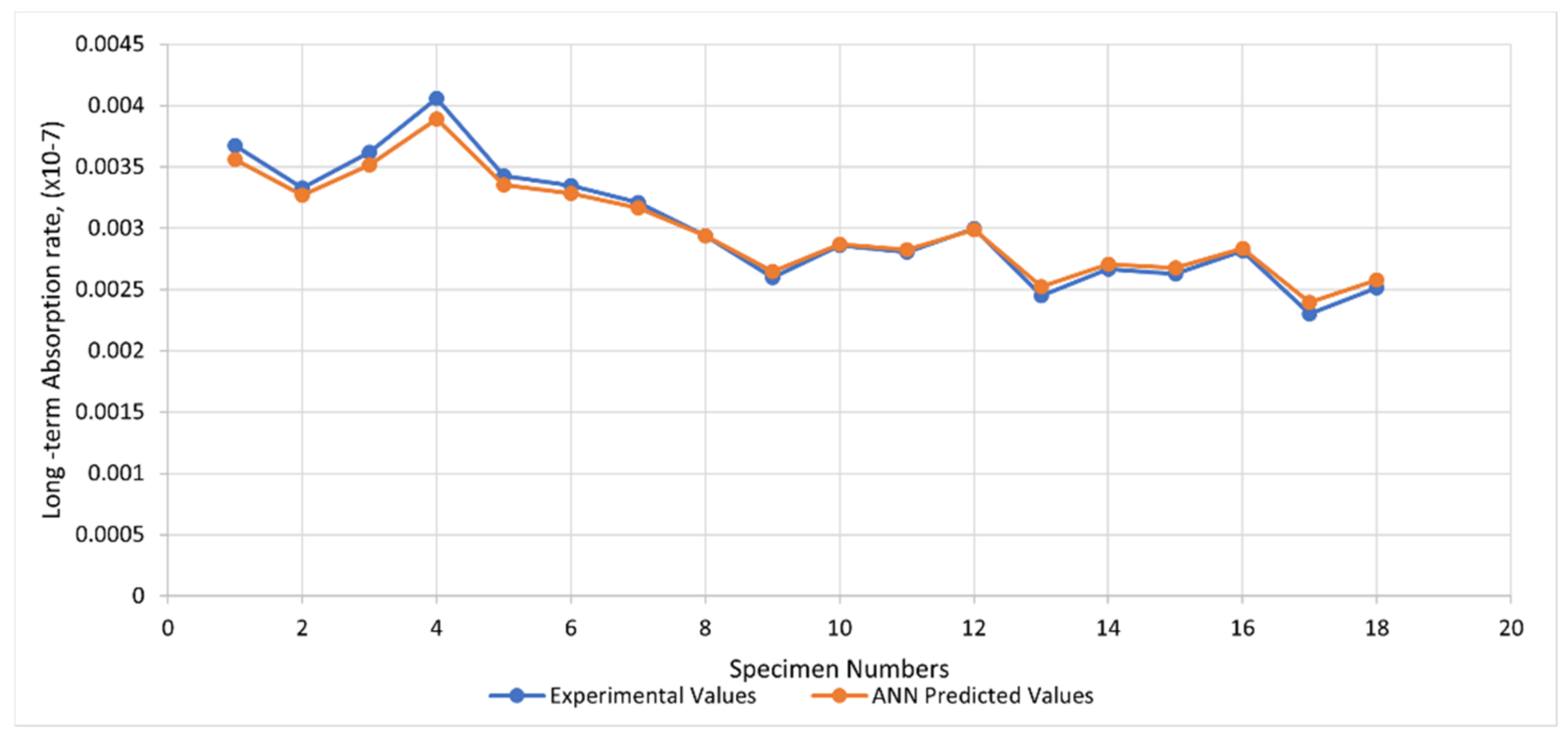

Similarly, a graphical plot depicting the experimentally recorded and ANN predicted sorptivity rates for each of the 18 specimens used in this study is also displayed in Figure 19, Figure 20 and Figure 21 below, describing the prediction accuracy of the ANN model.

Figure 19.

ANN vs. experimental—initial absorption rate of test specimens.

Figure 20.

ANN vs. experimental—secondary absorption rate of test specimens.

Figure 21.

ANN vs. experimental—long-term absorption rate of test specimens.

4. Conclusions

This study assesses the durability of the self-compacting and fibre geopolymer concrete mixes concerning their permeability and water absorption rates. The study adopted two other fibre geopolymer concrete mixes modified by adding 12 mm- and 30 mm-long chopped basalt fibres. The knowledge of the durability properties of these novel geopolymer concrete mixes is a step forward in widening the application of this sustainable concrete in harsh weather/aggressive environments. The ANN prediction model incorporated in this study can be used for generating knowledge on the water absorption capacity and long-term sorptivity of similar geopolymer concrete mixes, contributing to the body of knowledge. The significant conclusions based on the experimental observations and prediction model are highlighted below:

- The water absorption rates of the SCGC specimens containing chopped basalt fibres were lower by around 72% for the initial 6 h of exposure, stabilising for the 7 days and long-term exposure until saturation of the test specimens.

- The weight change of specimens was significant for SCGC mix without any fibres reporting an increase of up to 5.5% until the samples were completely saturated. In contrast, the models containing 12 mm and 30 mm chopped basalt fibres reported a rise of only 1.86% and 1.96%, respectively, at saturation compared to the initial weight of dry specimens.

- The addition of 12 mm- and 30 mm-long fibres at 1% by weight of total binders has improved the permeability characteristics of the geopolymer concrete mix. However, it reported a slight decrease in the mechanical and flowability properties for the compressive strength, tensile strength, and slump flow.

- Adding chopped basalt fibres can offer improved permeability and denser geopolymer concrete. However, there is a need for more research on the optimisation of the chopped basalt fibre length and the need for investigating other weight ratios of fibre quantities.

- The ANN prediction model confirmed an excellent alignment between the experimental observations and model predictions, offering a new sorptivity prediction model for geopolymer concrete mixes.

Author Contributions

S.K.R.: Methodology, Investigation, Writing—Original Draft; R.A.-A.: Supervision, Writing—Review and Editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors gratefully acknowledge the material assistance received from Independent Cements, Melbourne, and Fly Ash Australia for supplying the Slag and Micro fly ash respectively for our research work. The authors also acknowledge the Chopped Basalt fibres supplied by Beyond Materials Group Pty. Ltd. The authors also extend their gratitude for wholehearted support from Technical Staff—Lube Veljanoski and Michael Shanahan to complete the experimental investigation at the Structures Laboratory, Deakin University.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wei, X.; Ming, F.; Li, D.; Chen, L.; Liu, Y. Influence of water content on mechanical strength and microstructure of alkali-activated Fly Ash/GGBFS mortars cured at cold and polar regions. Materials 2020, 13, 138. [Google Scholar] [CrossRef] [Green Version]

- Mohajerani, A.; Suter, D.; Jeffrey-Bailey, T.; Song, T.; Arulrajah, A.; Horpibulsuk, S.; Law, D. Recycling waste materials in geopolymer concrete. Clean Technol. Environ. Policy 2019, 21, 493–515. [Google Scholar] [CrossRef]

- Van Deventer, J.S.J.J.; Provis, J.L.; Duxson, P. Technical and commercial progress in the adoption of geopolymer cement. Miner. Eng. 2012, 29, 89–104. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. A newly developed self-compacting geopolymer concrete under ambient condition. Constr. Build. Mater. 2021, 267, 121822. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. Marine Geopolymer Concrete—A Hybrid Curable Self-Compacting Sustainable Concrete for Marine Applications. Appl. Sci. 2022, 12, 3116. [Google Scholar] [CrossRef]

- Imtiaz, L.; Rehman, S.K.U.; Ali Memon, S.; Khizar Khan, M.; Faisal Javed, M. A Review of Recent Developments and Advances in Eco-Friendly Geopolymer Concrete. Appl. Sci. 2020, 10, 7838. [Google Scholar] [CrossRef]

- Rahma, S.K.; Al-Ameri, R. The Need for a User Friendly Geopolymer Concrete-Ongoing Research. Proc. Concr. 2021. Available online: http://www.ciaconference.com.au/concrete2021/pdf/full-paper_43.pdf (accessed on 13 July 2022).

- Rahmawati, C.; Aprilia, S.; Saidi, T.; Aulia, T.B. Current development of geopolymer cement with nanosilica and cellulose nanocrystals. J. Phys. Conf. Ser. 2021, 1783, 012056. [Google Scholar] [CrossRef]

- Omer, L.M.; Gomaa, M.S.; Sufe, W.H.; Elsayed, A.A.; Elghazaly, H.A. Enhancing corrosion resistance of RC pipes using geopolymer mixes when subjected to aggressive environment. J. Eng. Appl. Sci. 2022, 69, 1. [Google Scholar] [CrossRef]

- Goswami, A.P. Determining physico-chemical parameters for high strength ambient cured fly ash-based alkali-activated cements. Ceram. Int. 2021, 47, 29109–29119. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. An overview of geopolymers derived from industrial by-products. Constr. Build. Mater. 2016, 127, 183–198. [Google Scholar] [CrossRef]

- Dhasindrakrishna, K.; Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Progress, current thinking and challenges in geopolymer foam concrete technology. Cem. Concr. Compos. 2021, 116, 103886. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Greenhouse Gas Emissions Due to Concrete Manufacture; Elsevier Inc.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Rizaldi, N.; Abdurrahman, H.; Wijaya, M.F.; Wibisono, G.; Olivia, M. Durability of fly ash geopolymer hybrid concrete in seawater, sulfuric acid, and fire resistant-A review. J. Phys. Conf. Ser. 2021, 2049, 012088. [Google Scholar] [CrossRef]

- Júnior, L.U.D.T.; Taborda-Barraza, M.; Cheriaf, M.; Gleize, P.J.P.; Rocha, J.C. Effect of bottom ash waste on the rheology and durability of alkali activation pastes. Case Stud. Constr. Mater. 2022, 16, e00790. [Google Scholar] [CrossRef]

- Diaz, E.I.; Allouche, E.N.; Eklund, S. Factors affecting the suitability of fly ash as source material for geopolymers. Fuel 2010, 89, 992–996. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S. Greenhouse gas emissions of different fly ash based geopolymer concretes in building construction. J. Clean. Prod. 2018, 204, 399–408. [Google Scholar] [CrossRef]

- Trabacchin, G.; Ayala, D.D.; Stegemann, J.; Zhang, M. Bond Behaviour of Basalt FRP bars in Geopolymer Concrete. In Proceedings of the 1st International Conference in Low-Carbon Cement & Concrete Technology, London, UK, 23–26 June 2019; pp. 1–4. [Google Scholar]

- Al-Majidi, M.H.; Lampropoulos, A.; Cundy, A.; Meikle, S. Development of geopolymer mortar under ambient temperature for in situ applications. Constr. Build. Mater. 2016, 120, 198–211. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Shumuye, E.D.; Shiying, T.; Wang, Z.; Zerfu, K. Eco-friendly fibre reinforced geopolymer concrete: A critical review on the microstructure and long-term durability properties. Case Stud. Constr. Mater. 2022, 16, e00894. [Google Scholar] [CrossRef]

- Dombrowski, K.; Weil, M.; Buchwald, A. Geopolymer Binders Part 2: Development and Optimization of Geopolymer Concrete Mixtures for Strong and Durable External Wall Units. ZKG Int. 2008, 61, 70–80. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-41149137204&partnerID=40&md5=b8b95fb663010b110e2b49cddd842566 (accessed on 13 July 2022).

- Łach, M.; Kluska, B.; Janus, D.; Kabat, D.; Pławecka, K.; Korniejenko, K.; Guigou, M.D.; Choińska, M. Effect of Fiber Reinforcement on the Compression and Flexural Strength of Fiber-Reinforced Geopolymers. Appl. Sci. 2021, 11, 10443. [Google Scholar] [CrossRef]

- Wu, H.; Qian, X.Q.; Li, C.Z.; Li, F. Ecological Environment and Technology of Concrete; Key Engineering Materials: 2011; Volume 477. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85086682638&partnerID=40&md5=6e81d7d029b508f3bbffa4e22e5c2d12 (accessed on 13 July 2022).

- Girgin, Z.C.; Yıldırım, M.T. Usability of basalt fibres in fibre reinforced cement composites. Mater. Struct. 2016, 49, 3309–3319. [Google Scholar] [CrossRef]

- Krishna, R.S.; Shaikh, F.; Mishra, J.; Lazorenko, G.; Kasprzhitskii, A. Mine tailings-based geopolymers: Properties, applications and industrial prospects. Ceram. Int. 2021, 47, 17826–17843. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Z.; Xu, W.; Zhao, X.; Zhang, L.; Wang, Y.; Niu, D. Flexural Behavior and Prediction Model of Basalt Fiber/Polypropylene Fiber-Reinforced Concrete. Int. J. Concr. Struct. Mater. 2022, 16, 1–16. [Google Scholar] [CrossRef]

- Shaikh, F.; Haque, S. Behaviour of Carbon and Basalt Fibres Reinforced Fly Ash Geopolymer at Elevated Temperatures. Int. J. Concr. Struct. Mater. 2018, 12, 35. [Google Scholar] [CrossRef] [Green Version]

- High, C.; Seliem, H.M.; El-Safty, A.; Rizkalla, S.H. Use of basalt fibers for concrete structures. Constr. Build. Mater. 2015, 96, 37–46. [Google Scholar] [CrossRef]

- John, V.J.; Dharmar, B. Influence of basalt fibers on the mechanical behavior of concrete—A review. Struct. Concr. 2021, 22, 491–502. [Google Scholar] [CrossRef]

- Adesina, A. Performance of cementitious composites reinforced with chopped basalt fibres–An overview. Constr. Build. Mater. 2021, 266, 120970. [Google Scholar] [CrossRef]

- Hu, X.; Guo, Y.; Lv, J.; Mao, J. The Mechanical Properties and Chloride Resistance of Concrete Reinforced with Hybrid Polypropylene and Basalt Fibres. Materials 2019, 12, 2371. [Google Scholar] [CrossRef] [Green Version]

- Korniejenko, K.; Mucsi, G.; Halyag, N.P.; Szabó, R.; Mierzwiński, D.; Louda, P. Mechanical Properties of Basalt Fiber Reinforced Fly Ash-Based Geopolymer Composites. KnE Eng. 2020, 2020, 86–100. [Google Scholar] [CrossRef] [Green Version]

- Le, C.H.; Louda, P.; Buczkowska, K.E.; Dufkova, I. Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite. Polymers 2021, 13, 751. [Google Scholar] [CrossRef]

- Pasupathy, K.; Sanjayan, J.; Rajeev, P.; Law, D.W. The effect of chloride ingress in reinforced geopolymer concrete exposed in the marine environment. J. Build. Eng. 2021, 39, 102281. [Google Scholar] [CrossRef]

- Pasupathy, K.; Cheema, D.S.; Sanjayan, J. Durability performance of fly ash-based geopolymer concrete buried in saline environment for 10 years. Constr. Build. Mater. 2021, 281, 122596. [Google Scholar] [CrossRef]

- Tang, Y.X.; Lee, Y.H.; Amran, M.; Fediuk, R.; Vatin, N.; Kueh, A.B.H.; Lee, Y.Y. Artificial Neural Network-Forecasted Compression Strength of Alkaline-Activated Slag Concretes. Sustainability 2022, 14, 5214. [Google Scholar] [CrossRef]

- Mashrei, M.A.; Seracino, R.; Rahman, M.S. Application of artificial neural networks to predict the bond strength of FRP-to-concrete joints. Constr. Build. Mater. 2013, 40, 812–821. [Google Scholar] [CrossRef]

- Rahman, S.K.; Al-Ameri, R. Experimental Investigation and Artificial Neural Network Based Prediction of Bond Strength in Self-Compacting Geopolymer Concrete Reinforced with Basalt FRP Bars. Appl. Sci. 2021, 11, 4889. [Google Scholar] [CrossRef]

- Asteris, P.G.; Kolovos, K.G.; Douvika, M.G.; Roinos, K. Prediction of self-compacting concrete strength using artificial neural networks. Eur. J. Environ. Civ. Eng. 2016, 20, s102–s122. [Google Scholar] [CrossRef]

- Alnedawi, A.; Al-Ameri, R.; Nepal, K.P. Neural network-based model for prediction of permanent deformation of unbound granular materials. J. Rock Mech. Geotech. Eng. 2019, 11, 1231–1242. [Google Scholar] [CrossRef]

- Haddad, R.; Haddad, M. Predicting fiber-reinforced polymer–concrete bond strength using artificial neural networks: A comparative analysis study. Struct. Concr. 2020, 22, 38–49. [Google Scholar] [CrossRef]

- Karimipour, A.; Jahangir, H.; Eidgahee, D.R. A thorough study on the effect of red mud, granite, limestone and marble slurry powder on the strengths of steel fibres-reinforced self-consolidation concrete: Experimental and numerical prediction. J. Build. Eng. 2021, 44, 103398. [Google Scholar] [CrossRef]

- Chong, B.W.; Othman, R.; Jaya, R.P.; Hasan, M.M.; Sandu, A.; Nabiałek, M.; Jeż, B.; Pietrusiewicz, P.; Kwiatkowski, D.; Postawa, P.; et al. Design of Experiment on Concrete Mechanical Properties Prediction: A Critical Review. Materials 2021, 14, 1866. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Rahai, A.; Sebt, M.H. Artificial neural network and genetic programming for predicting the bond strength of GFRP bars in concrete. Mater. Struct. Constr. 2015, 48, 1581–1602. [Google Scholar] [CrossRef]

- Zinkaah, O.H.; Al-Rifaie, A.; Alhawat, M.M. Predictability of existing standard codes for the flexural strength of beams produced from alkali-activated concrete. AIP Conf. Proc. 2021, 2404, 080031. [Google Scholar] [CrossRef]

- Gao, J.; Koopialipoor, M.; Armaghani, D.J.; Ghabussi, A.; Baharom, S.; Morasaei, A.; Shariati, A.; Khorami, M. Evaluating the bond strength of FRP in concrete samples using machine learning methods. Smart Struct. Syst. 2020, 26, 403–418. [Google Scholar] [CrossRef]

- Rahman, S.; John, K.; Kafle, B.; Al-Ameri, R. Structural Performance of Modular Sandwich Composite Floor Slabs Containing Basalt FRP-Reinforced Self-Compacting Geopolymer Concrete. Appl. Sci. 2022, 12, 4246. [Google Scholar] [CrossRef]

- Efnarc, F. Specification and Guidelines for Self-Compacting Concrete; European Federation for Specialist Construction Chemicals and Concrete Systems: Farnham, UK, 2002. [Google Scholar]

- ASTM C1585-13; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2013; Volume 41, pp. 1–6. [CrossRef]

- AS 1012.9:2014; Methods of Testing Concrete. Method 9: Compressive Strength Tests: Concrete, Mortar and Grout Specimens. Aust. Stand. Aust. Ltd.: Sydney, Australia, 2014.

- AS 1012.10-2000; Methods of Testing Concrete-Determination of Indirect Tensile Strength of Concrete Cylinders. Standards Australia: Sydney, Australia, 2000.

- Rahimireskati, S.; Ghabraie, K.; Garcez, E.O.; Al-Ameri, R. Improving sorptivity and electrical resistivity of concrete utilising biomedical polymeric waste sourced from dialysis treatment. Int. J. Sustain. Eng. 2021, 14, 820–834. [Google Scholar] [CrossRef]

- Aquino, K.P.S.; Caisip, J.S.; Placiente, A.N.I.; Reyes, E.C.; Calilung, M.G.V. Application of artificial neural network in determination of sorptivity model of concrete with varying percent of replacement of sand to copper slag. In Proceedings of the 2017 IEEE 9th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Manila, Philippines, 1–3 December 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Najigivi, A.; Khaloo, A.; Abdul Rashid, S. An artificial neural networks model for predicting permeability properties of nano silica–rice husk ash ternary blended concrete. Int. J. Concr. Struct. Mater. 2013, 7, 225–238. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).