Abstract

Geopolymer concrete (GC) has the potential to incorporate recycled concrete aggregates (RCA) obtained from construction and demolition waste. This research aims to review the current state-of-the-art knowledge of the RCA in GC and identify the existing knowledge gaps for future research direction. This paper highlights the essential factors that impact the GC’s mechanical and durability properties. Moreover, the influence of various percentages of coarse and fine RCA and the pattern of their replacement will be assessed. The effect of aluminosilicate material, alkaline activators, and curing regime also will be evaluated. Besides, the durability-related characteristics of this concrete will be analysed. The impact of exposure to a higher temperature, freeze–thaw cycles, marine environment, and acid and alkali attack will be comprehensively reviewed. A literature review revealed that increasing alumina silicate content, such as slag and metakaolin, and increasing the Na2SiO3/NaOH ratio and alkali-activator-to-binder ratio improve the hardened GC. However, increasing slag and metakaolin content and the Na2SiO3/NaOH ratio has an adverse impact on its workability. Therefore, finding the optimum mix design for using RCA in GC is vital. Moreover, there is a scope for developing a self-compacting GC cured at ambient temperature using RCA.

1. Introduction

The construction industry is arguably one of the significant waste sources, generating 40% of the complete solid waste worldwide [1]. This type of waste is generated during a facility’s construction, operation, and end of life [2], 35% of which has been sent to landfills worldwide [3,4]. It has had detrimental impacts on the environment over the years and increased the total construction cost due to the landfill levies and the cost of waste transportation [5].

The linear economy as a conventional strategy is an inappropriate solution for tackling the detrimental impacts of excessive CDW generation and natural resources consumption, so the concept of circular economy (CE) is introduced as a new solution in this regard [6]. CE is defined as a regenerative system with the minimum resource input, waste, pollutants, and energy wastage by slowing and tightening the material and energy loops, which can be accomplished by durable design, maintenance, reusing, repairing, remanufacturing, refurbishment, and recycling [7]. Based on this definition and other relevant literature, the CE helps optimise the raw material consumption, saving the material’s value during the whole lifecycle, preventing further waste generation, and supporting natural resource preservation [6,8]. The CE is also associated with the benefits of recycling and using by-product materials [8,9]. The construction industry can adopt the circular economy well, which has proper capabilities [8,10]. Meanwhile, the CE is considered an integral part of the CDW policies in some countries, such as Australia [11]. This research summarises the state of the art of incorporating the recycled concrete aggregates in a geopolymer concrete that uses industrial by-produced materials, such as fly ash and slag.

Added to the environmental drawbacks of CDW, natural aggregate (NA) resources are in danger of depletion due to the increase in urbanization and the construction industry’s need for a vast amount of concrete, in which 60% to 75% of its volume encompasses NA [12]. Extracting, transporting, and producing specific sizes of NA are energy intensive, and replacing them with recycled concrete aggregates (RCA) can save energy by 90–280 gigawatt hours [13].

In addition, using waste in concrete can decrease many adverse effects of concrete on the environment [14]. To this end, RCA obtained from a demolition building or CDW from landfilled sites has been used instead of NA. For example, Ghorbani et al. [15] replaced 25% of natural coarse aggregates with crushed concrete, while the strength of the ordinary Portland concrete improved. It is also reported that RCA incorporation in ordinary Portland cement (OPC) concrete could increase up to 30% [16]. However, geopolymer concrete provides the opportunity of using more amount of RCA. Lim and Pham [17] replaced all the aggregates with RCA, and compressive strength (CS) reached 46.24 MPa, which is a proper CS for structural application. Hence, geopolymer concrete has the potential to reuse a substantial amount of CDW.

In addition to the detrimental impacts of CDW, the construction industry is responsible for 30% of carbon dioxide generation globally [1]. The cement industry produces 8% of the total CO2 in the world [18]. Every kilogram of Portland cement consumes approximately 1.5 kg of raw material and has around 0.8 kg of CO2 [19]. Due to the high cement usage, concrete is a significant source of carbon emissions in the construction industry. There exist many attempts for CO2 reduction in the construction industry. One attempt is by Davidovits [20]. He suggested replacing Portland cement totally or partially with geopolymer material, such as fly ash (FA), ground-granulated blast-furnace slag (GGBS), silica fume, and red mud metakaolin (MK) and incinerated ash of municipal solid waste. Investigations show that using geopolymer concrete, which does not contain cement, reduces the global warming effect by up to 53% [21]. Besides, replacing RCA in a GC instead of NA minimises the leaching of toxic material, such as arsenic [22,23], chromium, and selenium in a silica fume FA-based GC [23].

The primary question addressed by this review study is: “How do various factors and conditions affect the mechanical and durability properties of a fresh and hardened structural RCA-based geopolymer concrete?” This study aims to review and analyse previous research on using RCA in geopolymer concrete for structural purposes. To this end, the general background to the properties and capabilities of geopolymer concrete for using RCA is presented to demonstrate the importance of using GC for reusing crushed aggregates. The method section provides the technique for retrieving relevant papers. Following that, the essential specifications of RCA-based geopolymer concrete are critically reviewed to evaluate the effect of each factor on the mechanical and durability properties of fresh and hardened geopolymer concrete with RCA.

2. Contextual Background

2.1. Geopolymer Concrete

Geopolymer is an environmental-friendly substitution for ordinary Portland cement, which reduces CO2 generation and reuses industrial by-product material, leading to lower cost. Its mechanical properties are the same as OPC concrete and demonstrate better performance in exposure to fire and harsh conditions [24]. Geopolymer concrete is obtained through the reaction between an alkaline activator and aluminosilicates, which are primarily used as fly ash [25], ground-granulated blast-furnace slag [26], and metakaolin [27].

The most popular and well-established type of GC is FA based. It is because fly ash is a great source of silica and alumina material, which makes it an excellent binder. Curing at a high temperature helps improve the compressive strength of fly-ash-based geopolymer concrete [28]. Curing in high temperatures limits the application of fly-ash-based GC, so slag helps to reduce the heat demand and improves the early-age strength of geopolymer concrete [29]. Unlike fly ash and slag, metakaolin is not an industrial by-product material and is obtained by heating kaolinite at temperatures higher than 500 °C. MK is a reach source of alumina and silica. Because of its highly reactive pozzolanic nature, it quickly reacts with Ca(OH)2, which generates hydrated calcium aluminates and silicon aluminates with the filling properties, improving concrete’s mechanical properties and durability [30].

There is no fixed mix guideline for preparing geopolymer concrete, and it is based on trial and error [31]. In the case of using a liquid alkali activator, the first step is preparing the alkaline solution 12 or 24 h earlier than the time of the experiment, as the dissolution of NaOH causes a high temperature and needs to be cooled before mixing with the other components [32,33]. Regarding mixing CA-based GC, Zhang et al. [34] mixed aluminosilicate precursors and alkaline activators before adding aggregates to obtain the binder of the mixture and then added aggregates. Uğurlu, Karakoç, and Özcan [26] first mixed fine aggregates with the binder and alkaline solution and then added coarse aggregates. Alumina silica material can be added and mixed after mixing aggregates with extra water [35], or in some studies, aggregates and aluminosilicate materials are mixed together simultaneously. Then an alkaline solution is added and mixed [36]. If a superplasticiser is required, it can be added finally [35,36]. However, Mehta and Bhandari [37] added a superplasticiser to the binder of the mixture and then mixed it with the aggregates. As regards better workability, in some cases, extra water is added at the final stage and then mixed thoroughly [36].

Geopolymerisation takes place in three main steps, including (1) the dissolution of Al and Si of an alumina–silica component by the action of OH ions, (2) precursor ions’ transition into monomers, and (3) monomers’ reconvertion to create three-dimensional polymer chains of Si-O-Al-O [38,39]. The polycondensation of hydrolysed aluminate and silicate components leads to the hardening of the geopolymer. The geopolymer component is shown as nM2O.Al2O3.xSiO2. yH2O. M is an alkali metal obtained from alkali activators, such as NaOH, KOH, NaCO3, and Na2SO4. Ions of Na, K, and Ca active Al and Si speed up the reaction [40].

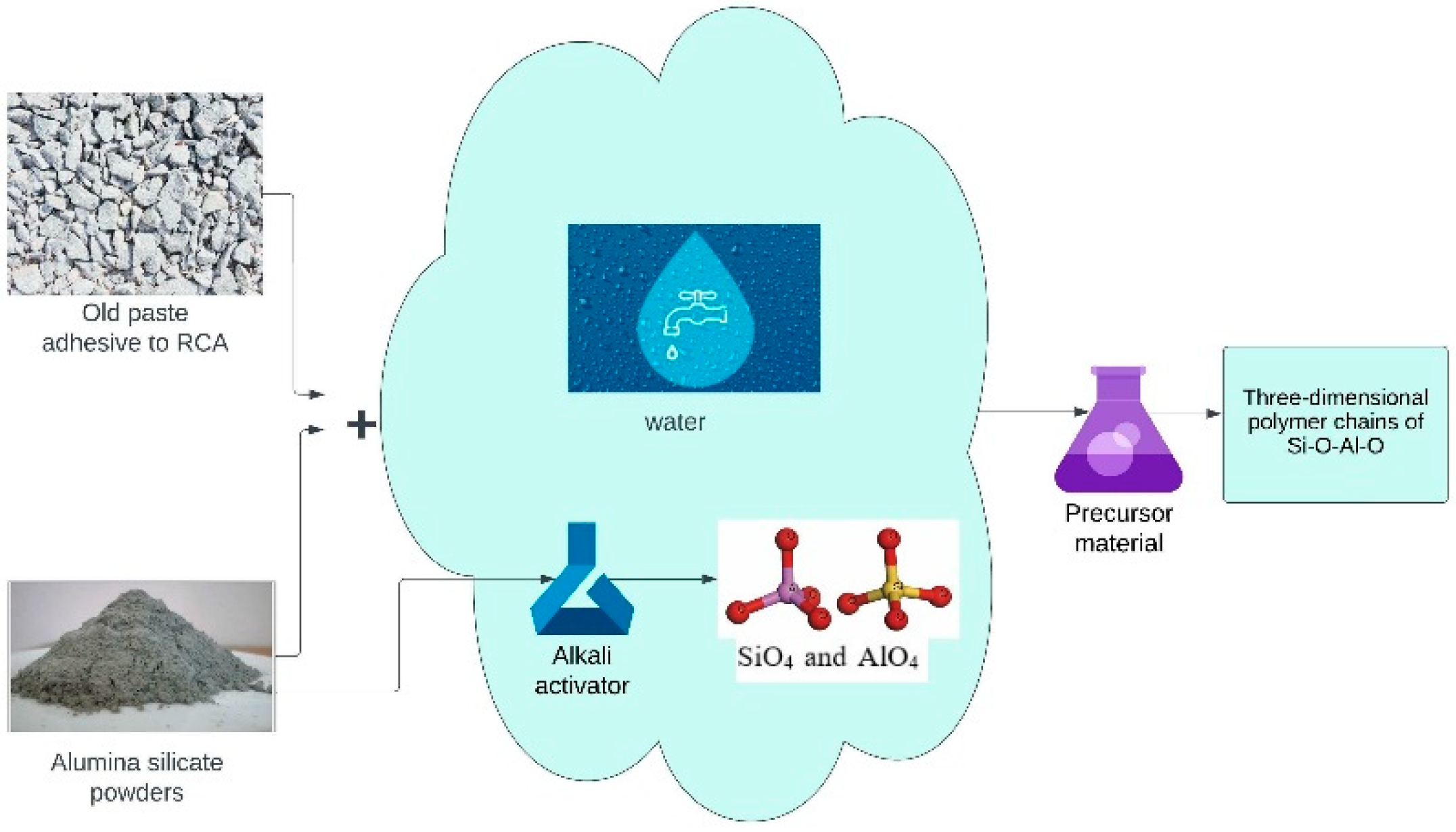

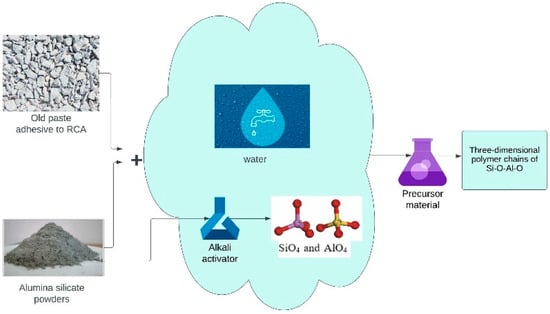

As illustrated in Figure 1, within the mixing of RCA-based GC, at first, alumina silicate powders and old paste adhesive to RCA absorb water, and precursor material is formed. Meanwhile, many monomers of SiO4 and AlO4 are released due to the activation of aluminosilicate material with an alkali activator. Then, SiO4 and AlO4 are rapidly mixed with precursors. Through the continuation of the reaction, the framework grows and is connected. Ultimately, three-dimensional polymer chains of Si-O-Al-O are created [41].

Figure 1.

Reaction mechanism of the geopolymerisation of the RCA-based GC.

2.2. Recycled Concrete Aggregates

RCA consists primarily of three components, including the body of a cement mortar, a mortar-covered gravel, and a gravel fully detached from the mortar. Fine RCA consists of sand particles adhering to cement slurry, sand particles without cement, and a little portion of broken stone. [42]. RCA has greater angles, rougher surfaces, and a more significant surface area than NA, which makes RCA’s chemical and mechanical properties significantly different from NA’s [42].

Although incorporating recycled crushed concrete as aggregates in concrete is environmental preservation, it has some drawbacks. The durability issue is considered the most crucial challenge of using RCA. For example, in one case, adding RCA causes an increase in chloride penetration by 27% [36]. In addition, the old paste around the aggregates causes more porosity than NA-based GC, leading to increased water absorption [43]. For example, replacing 50% of coarse aggregates with RCA results in around 5% enhancement of the initial water absorption rate, increasing to 18% by replacing 100% RCA [33]. In addition, replacing NA with RCA harms the mechanical properties of GC. For instance, replacing 100% NA with fine RCA reduces the tensile and flexural strength of a fly-ash-based GC by 27% and 36%, from 2.6 to 1.9 MPa and from 3.9 to 2.5 MPa, respectively [44]. Above all, RCA decreases the CS due to a lower mechanical characteristic of RCA. As an illustration, replacing 50% RCA in an FA-based GC reduces compressive strength by around 30%. It increases the percentages, resulting in a further drop in compressive strength [45].

Incorporating RCA in GC demonstrates better results compared with OPC concrete, even improves the compressive strength and module of elasticity [34,46], and enhances the interfacial transition zone (ITZ) bond between aggregates and paste compared with OPC-based concrete [47,48]. Despite the porous structure of old cement paste material, the rough surface of crushed aggregates provides better bonding between GC paste and aggregates. The unreacted bonding material fills the pores and cracks, transferring load better than RCA in OPC concrete [44,46,49]. Besides, the alkali-activated bonder in GC causes a reduction in Ca(OH)2 and voids, improving matrix homogeneity, which results in higher compressive strength compared with RCA-based OPC concrete [46]. For example, Zhang, Wan, Wu, and Hu [34] observed a decrease in the compressive strength of OPC concrete by using various amounts of RCA, while they stated that the compressive strength of GC with 30% and 70% RCA is higher than that GC with NA. However, several factors affect the fresh and hardened RCA-based geopolymer concrete’s mechanical and durability properties, which should be analysed to introduce an optimised concrete mix. In this review, most of research on the various methods and techniques is studied and critically examined.

2.3. Previous Review Studies

Several review studies on RCA-based geopolymer concrete have been published, demonstrating the importance of the outcomes and knowledge building in this field for the research community [50,51,52,53]. However, they do not address all aspects of implementation in the construction industry. A review study by Ye, Xiao, Duan, and Li [51] focused on geopolymer concrete made from recycled brick and concrete powder. They reviewed the effects of some parameters, such as alkaline solution, precursor material, and curing condition, on the concrete’s flowability, compressive strength, and durability. However, they did not study the effect of crushed concrete as the aggregates, and they focused on the mix of CDW, namely, concrete powder and recycled brick. In like manner, Xu, Huang, Liu, Deng, Hui, and Deng [52] conducted a literature review on the various types of aggregates recycled from geopolymer concrete, mudstones, rubber, and so on and their effects on the compressive, tensile, and flexural strength of GC. At the same time, they did not focus on just using aggregates made of crushed OPC concrete. Upshaw and Cai [50] reviewed the progress in utilising fine and coarse aggregates in the concrete and some of their effects. They also reviewed existing studies on various methods for improving the properties of crushed concert aggregates. They did not focus on geopolymer concrete with structural implications. Younis, Salihi, and Ibrahim [53] studied the effect of RCA on the compressive strength and flowability of GC. They did not evaluate the effect of RCA on the durability of the concrete in harsh conditions. Despite previous research, a critical review on the relevant, effective parameters on the properties of RCA-based GC with structural application remains to be found. Therefore, there is a scope for conducting a holistic literature study on using crushed concrete aggregates to produce structural geopolymer concrete.

3. Research Methodology

3.1. Systematic Review

The approach for conducting this research was selected as a systematic review, which is a suitable method for research synthesis to determine and collect international evidence related to a specific research question or research questions, summarize the results, and sometimes draw gaps of knowledge [54]. It aligns with the aim of this study to review the current evidence, synthesise the results, and finally provide a gap of knowledge for further research. The systematic review initially was popular in medical science. However, it is primarily applied in the construction industry [55,56].

3.2. Data Extraction

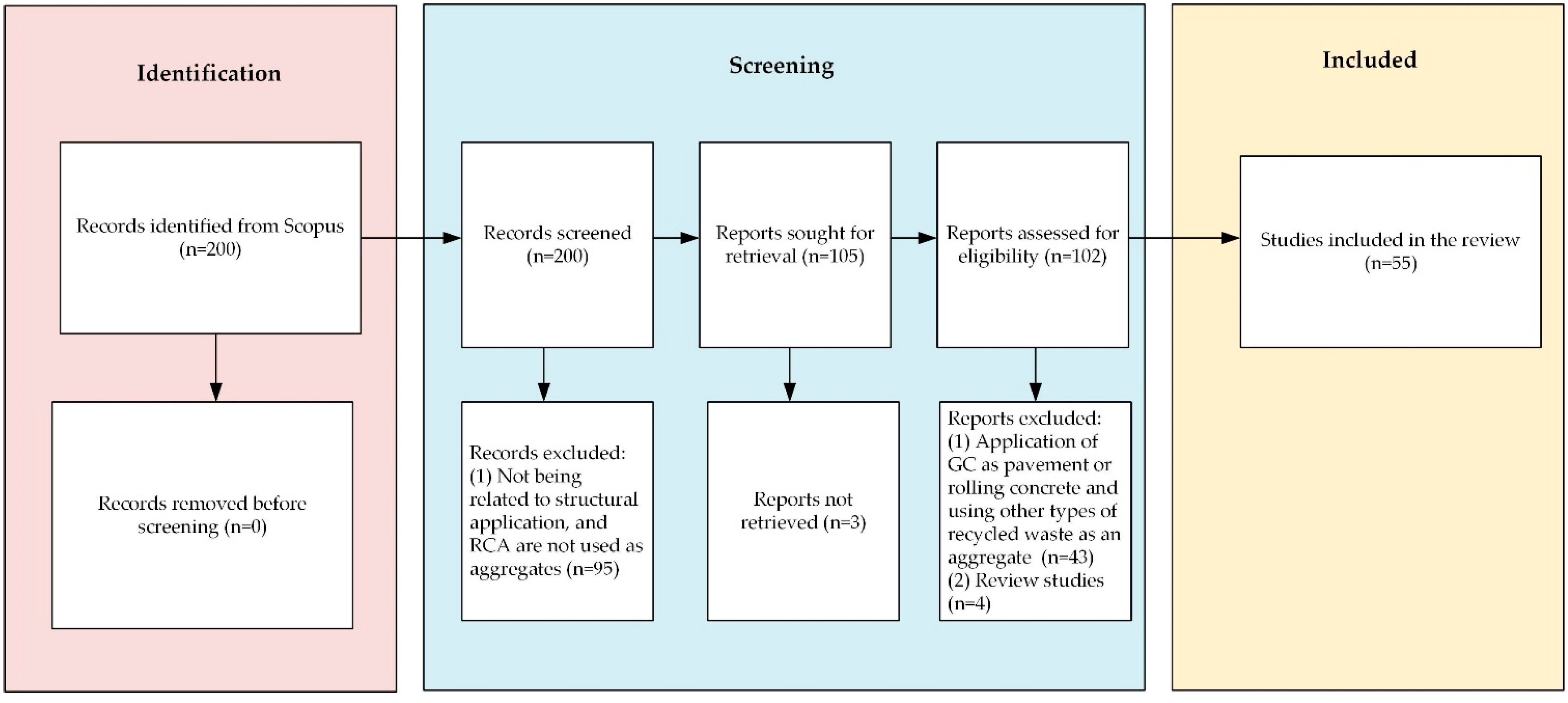

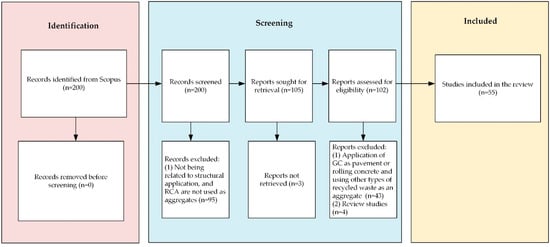

Within this review study, keywords of geopolymer AND (“crushed concrete” OR “recycled concrete” OR “recycled aggregate” OR “crushed aggregate”) are utilised for searching the topic, keywords, and abstract of the papers. Scopus is chosen as a database as this database is considered a proper database in the construction-related literature [2]. The most recent search version was on 4 April 2022, without any time limitation for selecting papers. All papers, including articles, conference proceedings, and book chapters written in English, were chosen for further studies. As illustrated in Figure 2, 200 papers based on the keywords mentioned above were extracted by searching on Scopus. Their title and abstract were thoroughly read based on the criteria of (1) paper must be related to structural applications of the geopolymer concrete and (2) crushed ordinary Portland concrete (OPC) must be used as the recycled aggregates. The excluded papers were about applying geopolymer as pavement or rolling concrete since they are not about the structural application of the GC (criteria 1) and must be excluded. Besides, several papers regarding other types of recycled aggregates, such as steel fibres or polyethylene terephthalate (PET) waste, sludge, crushed clay, or ground mixed recycled aggregates, were excluded, as papers must study the usage of aggregates made from crushed OPC (criteria 2). Therefore, 105 papers were obtained for conducting the literature review on the content of each paper, except that the full text of three papers could not be obtained. After examining the entire scope of the remaining 102 papers, 43 were excluded since some used the mixed CDW as the aggregate and did not focus on the crushed concrete as aggregates. Others were related to produced concrete with a lower compressive strength, unsuitable for structural application, and used in pavement or sub-base or waste concrete as an alumina silicate. Besides, four papers were excluded, as they were review studies and are considered the previous review study in the background section. Hence, this review study was conducted on 55 relevant papers, as illustrated in Table A1.

Figure 2.

PRISMA flowchart of the data screening process (adapted from Page, et al. [57]).

4. Findings and Discussions

4.1. Mechanical Properties of RCA-Based Geopolymers

4.1.1. Effect of Sources of RCA and Their Composition

There exist several sources for RCA. Most of research was conducted on GC with RCA obtained from crushed concrete lab specimens with the specified range of CS [36,41,58,59] or without specified CS [33,44,60,61]. Table A1 summarises experiments conducted on GC with RCA obtained from CDW landfilled sites [17,46] or extracted from a demolished building with specified CS [62,63] or unknown CS [64,65]. There is no agreement among researchers regarding the effect of the parent concrete. Some researchers believe that the quality of the parent concrete does not affect the mechanical specifications of the RCA, while the quality of the RCA is crucial to be considered [66,67]. On the other hand, opponents pointed out that the quality of the concrete is related to its concrete parent specifications [68]. However, Ohemeng et al. [69] stated that RCA obtained from high-strength concrete with CS higher than 50 MPa does not negatively affect the RCA-based concrete but uses low to regular concrete for extracting RCA results in CS drop by up to 30%.

Several properties must be considered regarding concrete aggregates’ physical and chemical properties. The physical properties evaluated by most researchers are summarised in Table 1. Besides, the chemical compositions of RCA and NA are tabulated in Table 2.

Table 1.

Physical specification of NA and RCA.

Table 2.

Chemical composition of RCA and NA.

As illustrated in Table 1, specific gravity, density, dry density, saturated density, bulk density, and apparent density of RCA are lower than those of natural aggregates. It is due to the old paste attached to RCA, which causes a more porous structure than NA [75]. Another reason is the crushing of the parent aggregates to obtain RCA, degrading the structure of the RCA [72]. Moreover, the water absorption of RCA is significantly higher than that of NA. It is also attributed to the porous structure of RCA from the old paste in the aggregates [72]. Furthermore, from the Los Angeles test results on RCA, mass loss is higher than NA due to RCA’s weaker and more brittle structure from the old cement paste in RCA [59,76].

To conclude, three sources of RCA are considered in the relevant literature: crushed concrete lab specimens with or without specified CS, CDW landfilled sites, and demolished buildings with or without specified CS. The physical specifications of specific gravity, density, dry density, saturated density, bulk density, and apparent density of RCA are less than NA, and the mass loss of RCA is higher than that of NA in the Los Angeles test.

4.1.2. Effect of Treatments on RCA

Controlling the water content of RCA is one of the challenges in using recycled aggregate concrete in practices [67]. In most of the literature, RCA is used in the saturated surface condition (SSD) [76,77], which, based on some studies, has a positive effect on the flowability and an adverse impact on CS [36,59,63]. Hence, there is a need to investigate the treatment techniques and their influence thoroughly and develop a recommended practice.

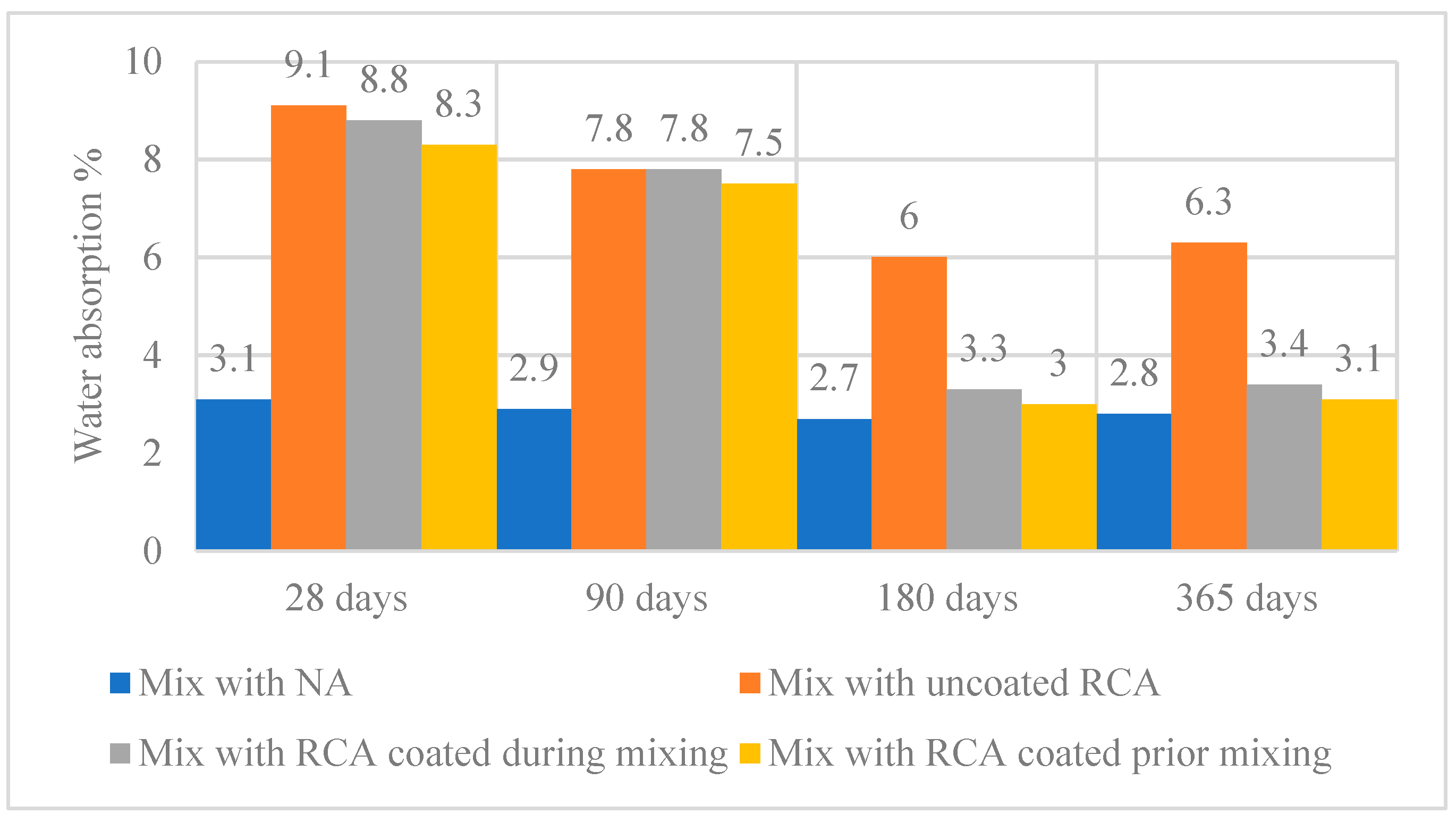

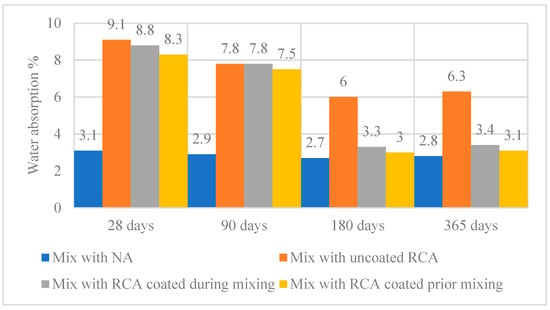

There are several methods for the treatment of RCA to mitigate the adverse effects of using RCA, such as high-water absorption, which is the most unfavourable. These treatments are categorised into two groups, including porosity reduction and reducing an old mortar layer by acid or thermal treatment. As regards porosity reduction, these methods include acceleration carbonation, bio deposition, sodium silicate, nanoparticles, polymer emulsions, and pozzolana material [12]. However, treated RCA is just examined in OPC concrete. For example, for using pozzolana material, Junak and Sicakova [78] used two methods for RCA treatment. One method is coating RCA with geopolymer slurry (FA based with 8 M NaOH and Na2SiO3) in the mixture, leaving it for 30 minutes, adding cement, and finally, adding other materials. Another technique includes coating RCA with geopolymer slurry, being cured at an ambient temperature for 28 days, and then being used for OPC concrete production. As can be observed in Figure 3, both treatment methods significantly decrease the water absorption of the specimens, especially when progressing the time from 28 to 365 days. Moreover, both techniques enhance the compressive strength of the samples to around the same strength of concrete with NA.

Figure 3.

Effect of coated RCA on the water absorption of concrete (adapted from Junak and Sicakova [78]).

Similarly, Gupta, et al. [79] coated RCA with a mix of sodium silicate, FA, and NaOH and cured them at 85 °C for 24 h. RCA was applied for casting OPC concrete, and also 10% FA and 90% OPC concrete, exposing them to acid attack, demonstrating better results than the cement coated and uncoated RCA-based concrete. In the same way, Junak and Sicakova [80] used a treatment technique for reducing the water absorption of RCA by coating with coal FA and 10 M NaOH to develop a modified RCA-based OPC concrete.

To sum up, most of the studies used SSD RCA, which has an adverse effect on CS. Hence, some treatments on RCA are examined just in OPC-based concrete, and there is no study on incorporating them into geopolymer concrete. Among these techniques, coating RCA with slurry geopolymer material can help to improve CS and water absorption. Thus, there is a need to examine this method for developing RCA-based GC.

4.1.3. Effect of Alumina Silicate Material

As illustrated in Table A1, the aluminosilicate bonding materials used for preparing RCA-based GC include Class F (low calcium) Fly ash, GGBS, fly ash, FA/GGBS, MK, MK/GGBS, ultrafine slag, MK/bottom ash, MK/FA, FA/ferrochrome ash, low-calcium FA/GGBS, waste concrete powder/FA, Class C (high calcium) FA/cement, Class C FA/MK, Class F FA/silica fume, and class C FA.

An increase in the aluminosilicate content of GGBS and MK results in compressive strength enhancement. It can be attributed to using more aluminosilicate content, reducing the adverse effect of adding RCA. A further amount of aluminosilicate helps reduce the negative impact of RCA on CS. For instance, Uğurlu, Karakoç, and Özcan [26] reported an 11.29%, 6.16%, and 5.95% reduction in CS for 300, 400, and 500 kg/m3 of the binder content, respectively, in a GGBS-based GC with 100% RCA. They stated that more binder content reduces the proportion of RCA aggregates. On the other hand, GGBS contains a higher amount of calcium, increasing calcium-alumina-silicate-hydrate (C-A-S-H) gel, improving compressive strength, and declining the adverse effect of using RCA on the strength of GC. In addition, GGBS has a positive role in improving the rigidity of CRA-based GC [26,35].

Moreover, Xie, Wang, Rao, Wang, and Fang [62] observed that increasing GGBS/FA-based GC’s content of GGBS enhances the compressive strength of GC. They also believe that FA cannot generate enough calcium for a strong bond between RCA and geopolymer paste, so a combination of GGBS and FA was suggested for an RCA-based GC. Similarly, Lim and Pham [17] observed improvement in GC strength by increasing the percentage of ultrafine slag (UFS) replacement in a UFS/FA-based GC. They also added extra UFS and observed better CS. Besides, increasing the amount of replacing FA with MK in an RCA-based GC improves the mechanical properties of an RCA-based GC. For instance, if MK replaces 30% FA, the compressive strength improves by 43%, from 32.9 to 47.2 MPa. In addition, 30% MK replacement enhances the splitting tensile and flexural strength by around 30% and 22%, respectively. The improved strength can be attributed to the role of MK particles in speeding up the geopolymerisation and forming a denser microstructure [77]. Furthermore, increasing the ratio of GGBS to MK from 1:1 to 7:3 enhances CS by 39%. It is because GGBS reacts with an alkali activator easier than MK [81]. Moreover, Nuaklong, Sata, Wongsa, Srinavin, and Chindaprasirt [76] examined the effect of replacing Class C FA with Portland cement by 5%, 10%, and 15%, improving CS and reaching a 49 MPa 28-day compressive strength.

In conclusion, increasing the amount of aluminosilicate material, such as GGBS and MK, enhances the CS of RCA-based GC. Moreover, increasing the ratio of GGBS to MK improves CS. Regarding GGBS/FA, UFS/FA, MK/FA, and OPC/FA geopolymer concrete, decreasing the ratio of FA (or increasing the share of the other binder) improves the mechanical properties of GC.

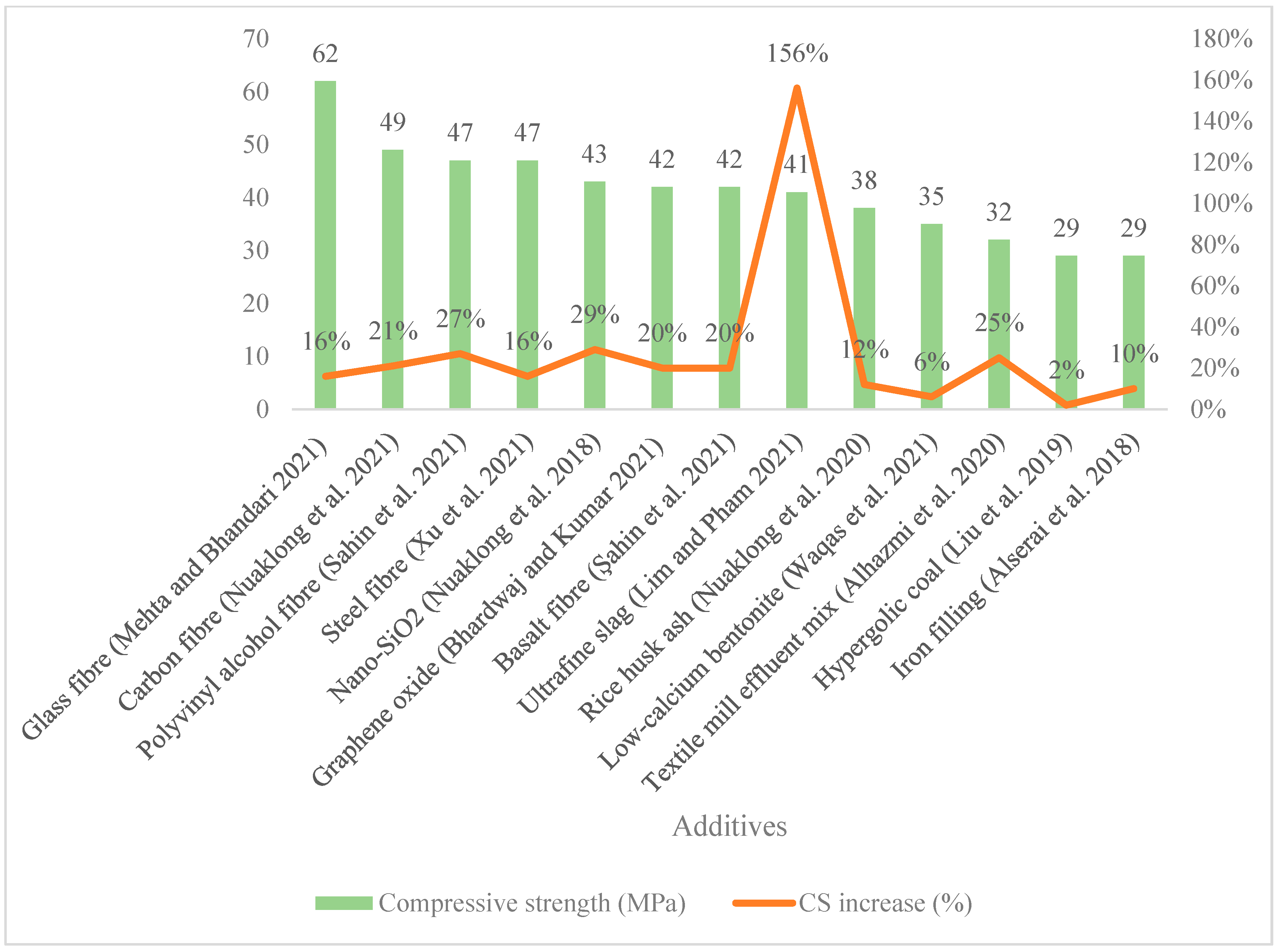

4.1.4. Effect of Additives

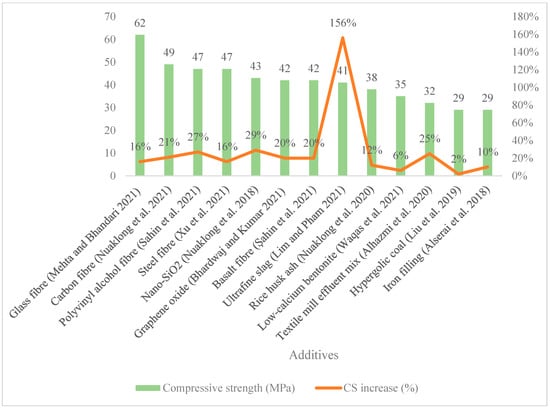

Several additives are reported to help improve RCA-based GC properties, as illustrated in Figure 4 and discussed below.

Figure 4.

Maximum CS for RCA-based GC using various additives [17,32,33,36,37,44,58,59,60,64,70,71,76].

Waqas, Butt, Danish, Alqurashi, Mosaberpanah, Masood, and Hussein [36] used low-calcium bentonite. They replaced 5%, 10%, 15%, and 20% of high-calcium fly ash with bentonite, while they used a NaOH/Na2SiO3 ratio of 2 and a NaOH molarity of 12. They pointed out that replacing 10% of bentonite increased the compressive strength and split tensile strength by 5.71% and 8.69%, respectively, compared with 5% bentonite replacement. They also stated that more than 10% replacement harms the compressive strength. Besides, the effect of bentonite on the compressive strength of GC with RCA is more than that of specimens with NA.

Graphene oxide is another additive that helps improve the compressive strength, flexural strength, and split tensile strength of RCA-based GC when RCA replaces 50% and 100% of its coarse aggregates. 0.05% Graphene oxide increases the compressive strength of GGBS FA-based GC with 50% and 100% RCA by 20.53–21.55% and 9.58–13.59% for ages between 28 and 90 days [33]. Graphene oxide enhances the geopolymerisation reaction [82].

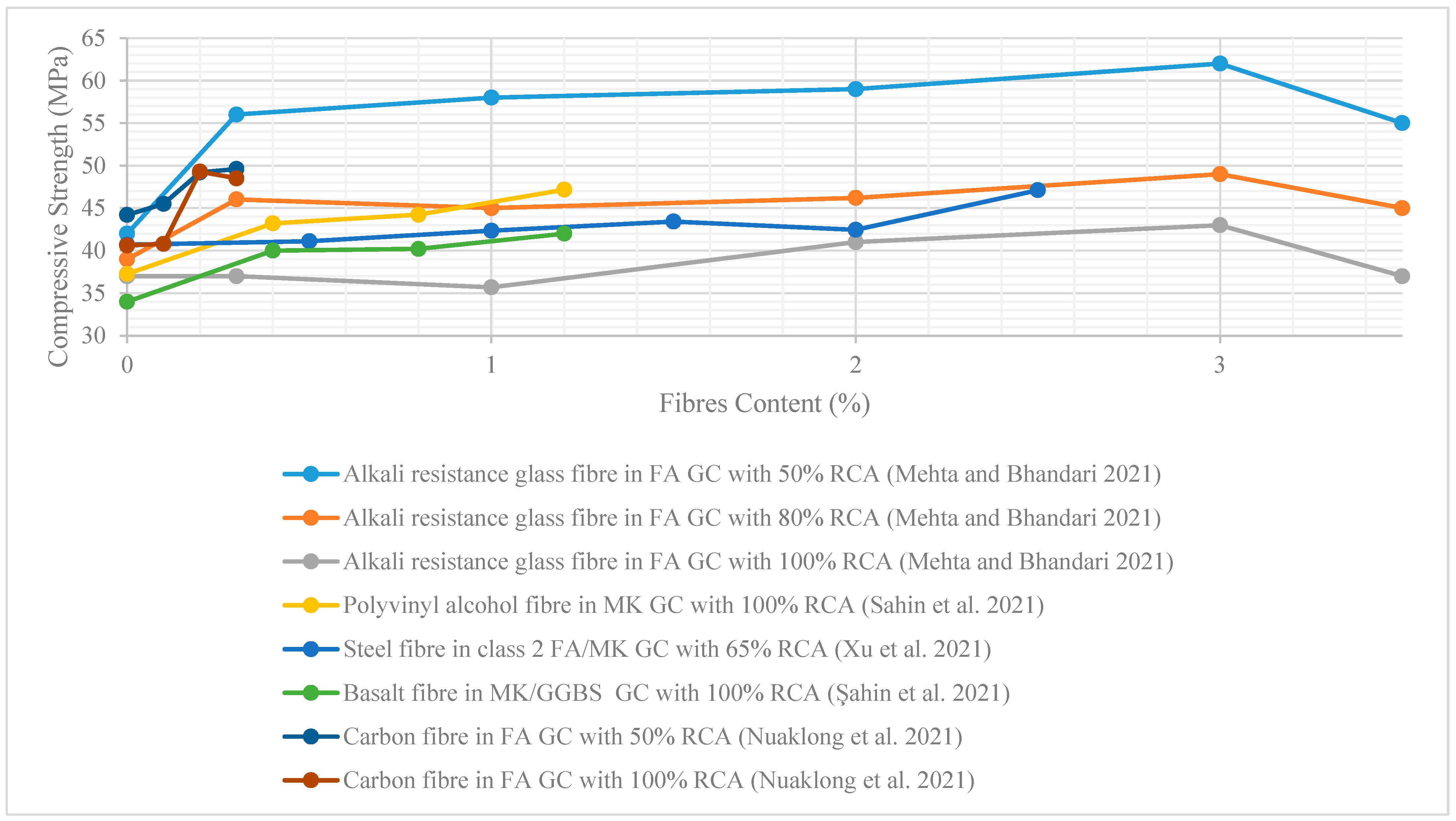

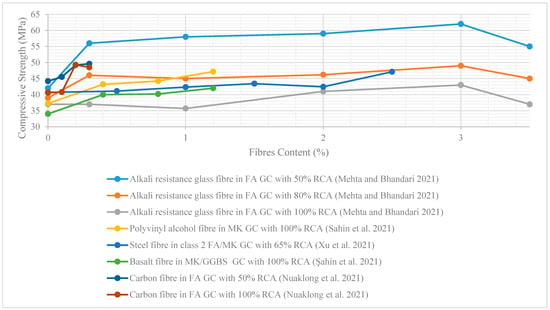

Fibres help decrease the brittleness characteristic of GC, as GC is brittle compared with OPC, and the tensile strength and flexural strength of GC are lower than those of OPC. Besides, fibres improve crack resistance and toughness [83,84]. Moreover, fibres help control the expansion of shrinkage cracks in RCA-based concrete, as adding RCA causes an increment of shrinkage cracks due to the old mortar attached to RCA [85]. Features such as fibre type, dimension, length-to-dimeter ratio (aspect ratio is between 30 and 150), strength, volume fraction, stiffness, and ITZ properties affect GC’s mechanical performance [86]. As illustrated in Figure 5, the impact of a different fibre content on RCA-based GC was studied in the previous literature. Among the studies, Mehta and Bhandari [37] studied the effect of adding alkali-resistant glass fibre on the mechanical properties of RCA-based GC. Glass fibre is made from silicon oxide and zirconium oxide. They found that adding glass fibre positively affects flexural strength by 20%. To this end, they added various amounts of glass fibre, including 0.3%, 1%, 2%, 3%, and 3.5% by the weight of concrete, to a GC with 50%, 80%, and 100% coarse RCA. The best result was reported for the combination of 3% glass fibre and 50% RCA, which increased the 28-day compressive and flexural strengths to 62 and 13 MPa.

Figure 5.

Relationship between fibre content and CS [32,37,44,60,70].

Polyvinyl alcohol (PVA) fibres are another fibre used as an additive in an MK RCA-based GC. The addition of 1.2% PVA increased the compressive and flexural strengths of RCA-based GC by 26.6% and 83.8%, reaching 47.17 MPa and around 9 MPa, respectively [32]. In like manner, Xu, Huang, Liu, Deng, Hui, Deng, Zhao, and Qin [60] used steel fibre in a FA/MK-based geopolymer with RCA. They observed that 28-day compressive strength, tensile strength, and flexural strength increased by 15.72%, 64.1%, and 60.95%, respectively, reaching 47.11 and 5.12, and 7.79 MPa, respectively, while it contained 2.5% steel fibre. It can be attributed to the role of fibres as a bridge to transfer stress. Steel fibres also produce a three-dimensional grid system, enhancing distributing, transmitting, and bearing stress [60]. Additionally, basalt fibre improves the mechanical characteristics of RCA-based MK/GGBS geopolymer concrete. In other words, Basalt fibre helps to enhance 28-day the compressive and flexural strengths by 20% and 57%, reaching 42 and 8.8 MPa [70]. Similarly, adding less than 0.1% carbon fibres (CF) helps to improve the matrix structure of GC, leading to a compact microstructure and increasing the compressive strength by 11% to 21% for 0.2% CF and reducing the adverse effect of RCA replacement in GC. The optimum amount of CF is 0.2%, and further addition does not provide significant compressive strength. CF also improves the splitting tensile and flexural strength by 38% for 50% RCA and 54% for 100% RCA, respectively [44].

The iron filling also increases the compressive strength of an MK RCA-based GC by 2%, 5%, and 10% for 0.5%, 0.75%, and 1% iron filling, respectively. It also enhances the splitting tensile strength, flexural tensile strength, and modulus of elasticity by 32%, 42%, and 11%, respectively, for 1% iron filling. Iron filling fills the pores and improves the concrete’s internal structure [64].

Hypergolic and calcined coal gangues positively impact GC’s compressive and splitting strength. Hypergolic coal gangue demonstrates better results. It not only causes higher strength in NA-based GC but also improves the compressive strength and split tensile strength when replacing 30–50% RCA [71]. Ultrafine slag is another additive material that increases the compressive strength of FA-based GC. 30% of this material can provide 41 MPa compressive strength, while 100% of RCA is used. This effect is due to forming the improved calcium silicate hydrate gel, filling pores, and leading to a denser structure. Ultrafine slag also creates a shell coating around the RCA, reducing the stiffness difference between paste and RCA, resulting in better compressive strength [17].

Alhazmi, Shah, and Mahmood [58] replaced water with three effluents of sugar mill effluent mix (SF), fertilizer mill effluent mix (FF), and textile mill effluent mix (TF), reaching CSs of 16, 23, and 32 MPa. TF demonstrates the best CS improvement from 24 to 32 MPa. However, it harms the mass loss in acid attack tests. Rice husk ash (RHA), an agriculture waste, can be used as a SiO2-reach additive to improve the compressive strength of fly ash RCA-based geopolymer concrete cured in an ambient environment. It reaches a compressive strength of 36–38.1 MPa for the incorporation of 1.2% to 3.6% of the fly ash weight. It is because of the effect of RHA on the Si-O-Si bonds, resulting from having denser hydration products. Moreover, silica oxide increases the amorphous glassy phase, enhancing compressive strength. However, it harms the concrete fire resistance due to reduced voids and pores between paste and aggregate [59].

Adding 1% and 2% nano-SiO2 also improves the compressive strength of FA-based recycled aggregate GC from 32.9 to 39.6 and 42.6 MPa. It is attributed to the generation of a higher amount of silica, increasing the SiO2-to-Al2O3 ratio and leading to a higher amount of Si-O-Si bonds, which are more potent than Al-O-Al. Still, the additional nano-SiO2 harms CS by reducing water evaporation, preventing GC structure formation [76].

To conclude, adding fibres improves the mechanical properties of RCA GC. It is because the fibres bridge the crack region and prevents formation around RCA. The mortar around the RCA causes more pores once it is mixed with paste, producing a weaker bond between them. Therefore, cracks might be formed due to external matters. However, fibres can prevent crack formation [32]. The effect of fibres on the flexural strength is significantly higher, as fibres contribute to tension force resistance during bending, decreasing the generation of the cracks.

4.1.5. Effect of RCA Content

Much research demonstrates the adverse impact of RCA on the compressive strength of GC. On the other hand, observation exists for increasing compressive strength by adding RCA.

Replacing 30% of the coarse aggregates with crushed concrete when using fly ash as a bonding material reduces compressive strength by 13%, from 17.1 to 14.8 MPa for 0% and 30% RCA [87]. Likewise, as regards FA GGBS-based geopolymer concrete, using up to 30% RCA causes a slight decrease in compressive strength, and adding more RCA reduces the compressive strength significantly. Hence, the optimum amount of RCA was 30%. This trend was also observed in split tensile strength [88]. Similarly, in FA/GGBS geopolymer concrete, replacing coarse aggregates with RCA decreased the compressive strength at 28, 56, and 90 days by 1.75–4.46% and 12.89–17.77% for all ages and 50% and 100% RCA replacement, respectively [63]. Bhardwaj and Kumar [33] also confirmed decreasing compressive strength when adding RCA in a GGBS/FA concrete. Replacement of limestone coarse aggregates with RCA in a fly-ash-based GC demonstrates a 9% to 13% decline in compressive strength due to the porous structure of RCA [59].

Incorporating RCA in the geopolymer concrete improves the compressive strength in lower percentages. For example, the 28-day CS of GC increased from 24.27 to 24.51 MPa by adding 30% RCA, rising to 24.91 MPa by 50% RCA, and then dropping to 24.24 MPa by 70% RCA, ultimately reaching 23.58 MPa when 100% RCA was used. Parthiban and Saravana Raja Mohan [89] also examined a 50% RCA replacement as an optimum amount of RCA in GGBS-based GC. Likewise, Kathirvel and Kaliyaperumal [65] considered 50% of RCA as an optimum percentage of RCA in a GGBS-based GC with a CS of about 56 MPa. Similarly, Sanusi, Tempest, Ogunro, and Gergely [22] pointed out that 40% and 50% RCA are the optimum contents in a FA silica fume GC with CSs of 53.2 and 54.7 MPa, respectively. Sanusi, Tempest, and Ogunro [23] reported CS enhancement by 36% from 42 to 57 MPa by 50% RCA replacement.

The porous structure of RCA and the microcracks accrued in the original breakage explain the adverse effect of higher percentages of RCA on the mechanical properties. Although this can improve the fraction between RCA and paste, their attachment becomes weaker. In addition, extra water absorbed by RCA in SSD is more than natural aggregates, resulting in a weaker GC [59,71,90].

However, Tran [91] stated that replacing 100% of coarse RCA decreases the compressive strength by 4.8% compared with NA. The author believes that the properties of normal coarse aggregates and crushed concrete are similar. Krishnan and Purushothaman [92] observed a slight increase in CS when replacing 100% of coarse NA with RCA. They believe that this is due to the incorporation of high-quality RCA. In another research, all the coarse aggregates were replaced by RCA and reached 48 MPa [35]. Similarly, Ren and Zhang [93] observed enhancement in compressive strength when replacing 100% of RCA. RCA’s water absorption results in a lower amount of alkaline solution and higher CS.

Replacement of less than 10% of fine RCA enhances compressive strength, as the fine aggregates can fill the voids among the significant components [94]. However, replacing higher percentages of fine recycled aggregate negatively impacts the compressive strength of GC. It can be attributed to the higher water absorption of the fine RCA, including sand and cement paste, negatively affecting the geopolymerisation by disturbing the alkali activator. For instance, Tran [91] replaced 25%, 50%, 75%, and 100% of the fine aggregates with RCA and found out that increasing the fine RCA results in compressive strength drop, and the optimum amount of fine RCA was reported to be 25% with a reduction of just 2% in compressive strength. Saha et al. [95] also observed a 5.26% CS drop by replacing 25% fine RCA in a FA GGBS-based GC.

The main reasons for the CS improvement in RCA-based GC include: (1) the porous structure of the old paste concrete in RCA, which absorbs the alkaline solution, resulting in partial geopolymerisation in the original ITZ. Besides, the absorption of a more alkaline solution by RCA improves the new ITZ between RCA and the new paste. (2) A higher amount of calcium brought by RCA to the mixture speeds up GC’s hardening. It is due to the C-S-H generation in the existence of the calcium. Moreover, the more refined porous structures provided by calcium enhance the CS. (3) RCA has rougher surfaces, so increasing the amount increases sharp edges, increasing the friction between RCA and geopolymer paste, ultimately enhancing the compressive strength. (4) Adherent mortar around RCA causes a decline in the elastic modulus of GC, leading to little differences between RCA and GC paste. Hence, with the decline in the possibility of fracture. (5) RCA absorbs more water, helping complete the hydration reaction of RCA. (6) An old OPC adhesive to RCA adds calcium and CSH gel formation, enhancing GC’s compressive strength [22,23,71,89,93].

The size of the crushed aggregates also has a critical role in the mechanical properties of the RCA-based concrete. In one experiment, recycled concrete was crushed into pieces smaller than 5, 2, and 1 mm, then incorporated into an MK-based geopolymer. The best result was reported for aggregates with a particle size smaller than 2 mm, where the compressive strength was around 40–45 MPa. However, using particles smaller than 1 mm causes a decline in compressive strength, as their solidification process is faster than geopolymer’s solidification. Besides, bulk density decreases because of trapping gasses, leading to a drop in compressive strength [96]. Zhang, Wan, Wu, and Hu [34] also stated that replacing 70% of coarse aggregates by RCA with a maximum size of 20 mm improves the compressive strength and crack resistance of MK/FA-GC reinforced beams. It might relate to the lower amount of the concrete paste in GC, which distributes stress uniformly. The smaller particles of RCA contain more attached old mortars than coarse RCA, resulting in weaker characteristics of finer RCA [34,97].

To conclude, the effect of RCA content on CS is diverse. Some evidence shows that RCA has an adverse impact on CS, but if RCA is used in the lower content, the negative effect is negligible or even enhances CS in some cases. A further amount of RCA primarily results in reducing CS. However, there is evidence that a total replacement of RCA improves CS. In addition, the size of RCA affects CS. Compared with fine RCA, coarse RCA provides GC with better mechanical properties when replaced with NA.

4.1.6. Effect of Alkali Activator

An alkali activator is needed to geopolymerise active binder material [98]. It can be used as a solid form for a one-part GC or liquid form for a two-part GC [99]. To the author’s knowledge, there is no research on the one-part RCA-based geopolymer concrete. All the relevant studies in this field used liquid alkali activators, of which most types include the combination of sodium hydroxide (NaOH) and sodium silicate (Na2SiO3) [93] or potassium silicate solution [34].

Regarding liquid alkali activators, in most cases, NaOH, which is in the form of flakes or pellets, was mixed in the water to produce the needed concentration of NaOH, which causes a substantial amount of heat, so it should be prepared earlier than the concrete mixture [92]. As discussed below, some alkali-solution-related factors affect the RCA-based GC.

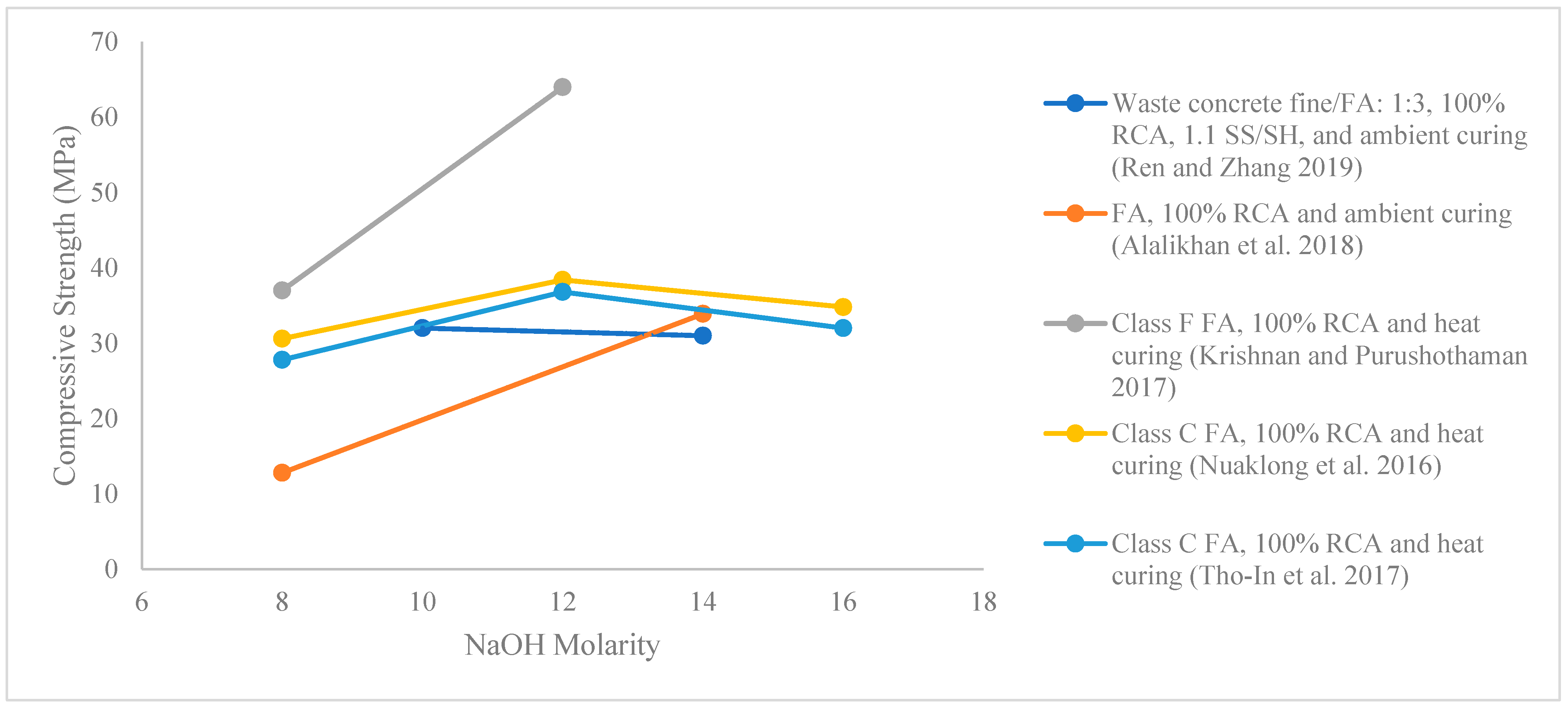

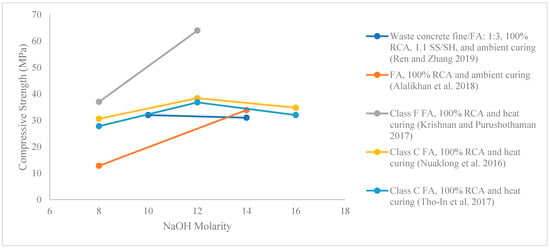

Previous experiments revealed that an increase in NaOH molarity (M) from 8 to 12 improves the compressive strength of RCA-based geopolymer concrete [92]. Nuaklong et al. [100] observed an increase in CS by adding NaOH molarity from 8 to 12 in a FA RCA-based GC and then a drop in CS at 16 M NaOH. Another experiment also confirmed this observation [101]. The reason is that the higher molarity of NaOH provides a higher amount of alkaline, increasing the chain of alumina silicate. Then the reaction between Si and Al tends to be activated. Besides, by curing at a higher temperature, high molarity helps this reaction happen suddenly at the primary age of concrete, leading to enhanced early strength [40]. Besides, Alalikhan, Habelalmateen, and Alhabbobi [25] observed CS enhancement from 8 to 14 NaOH molarity. By contrast, Ren and Zhang [93] observed a slight drop in compressive strength by increasing the NaOH molarity of an RCA-based geopolymer from 10 to 14. They mentioned that this is due to the higher amount of water in 14 M NaOH than 10 M NaOH molarity, resulting in an adverse effect on compressive strength. However, they did not mention the CS for 12 M NaOH. The CS might be increased by adding NaOH molarity from 10 to 12 M NaOH, and then dropped by 14 M NaOH. As illustrated in Figure 6, CS enhancement can be observed between 8 and 12 NaOH molarity, and exceeding the NaOH molarity by more than 12 reduces CS. This finding is also confirmed by Alhawat et al. [102].

Figure 6.

Relationship between NaOH molarity and CS [25,92,93,100,101].

Another factor is sodium silicate modulus. Wang, Bian, Li, Dai, Chen, Jiang, Zhang, Dong, Huang, and Ding [41] stated that the reduction of Na2SiO3 modulus improves the strength of RCA-based GC but increases the brittleness. They prepared seven concrete mixtures with Na2SiO3 moduli of 0.6, 0.9, 1.2, 1.5, 1.8, 2.1, and 2.4, while other parameters remained constant. The highest compressive strength was obtained when the modulus of Na2SiO3 was 0.9. The reason is that decreasing the Na2SiO3 modulus raises the amount of OH− and Na−, activating more alumina, calcium, and silicate ions. It will assist in forming more C-A-S-H gel and sodium aluminosilicate hydrate (N-A-S-H) gel, which results in a denser geopolymerisation structure. Hence, the compressive strength improves [41].

Moreover, the sodium-silicate-to-sodium-hydroxide ratio (SS/SH) is vital for compressive strength. Based on a study by Koushkbaghi et al. [103], three SS/SH ratios of 2, 2.5, and 3 were examined in an MK-based geopolymer with 10% to 30% RCA. More SS/SH increases the geopolymerisation reaction, leading to better compressive strength. However, by increasing the amount of RCA, the effect of SS/SH becomes negligible due to the angular shape of the RCA. Due to the adverse impact of RCA on workability, it is suggested to decrease the SS/SH ratio [74]. However, the effect of SS/SH depends on the type of binder material and curing conditions [103,104].

Moreover, increasing the ratio of alkali activator solution to binder materials (AAS/b) enhances the workability, decreasing the compressive strength. Regarding the higher amount of water absorption of RCA, in some cases, it suggests increasing the alkali-activator-to-binder ratio [72]. For example, in a fine RCA-based FA GC, increasing the alkali-activator-to-binder ratio from 0.4 to 0.6 results in enhancing CS due to the higher amount of alkali activator, which results in a better reaction between the alkali activator and FA [95].

Increasing the NaOH molarity from 8 to 12 can enhance the mechanical properties of the RCA-based GC. Moreover, reducing the sodium silicate modulus causes both CS and brittleness increment, so obtaining the optimum amount of Na2Sio3 modulus is crucial. In addition, increasing the SS/SH ratio improves CS, but it is suggested to decrease SS/SH due to the adverse effect of RCA on workability. In addition, increasing the AAS/B ratio can improve the CS of the RCA-based GC.

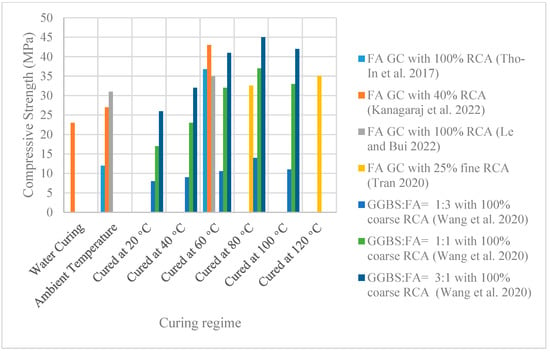

4.1.7. Effect of Curing Regime

Geopolymer concrete can be cured at an ambient temperature; however, higher temperatures can help to improve chemical reactions between silica ions and alumina ions, enhancing compressive strength [75,93]. Besides, the geopolymerisation process accelerates at higher temperatures and increases its compressive strength [105]. Hence, a 28-day compressive strength is higher than a 7-day CS of a GC when the GC is cured at 80 °C for the first 24 h. The reason is that the geopolymerisation is almost completed during the high-temperature curing early age. It minimises compressive strength gain for the rest of its life [35]. Moreover, a higher temperature helps generate a compact aluminosilicate gel, improving the bond between RCA and unreacted aluminosilicate [35]. Not completing geopolymerisation in low-temperature curing could result in unsatisfying compressive and tensile strength [35,61].

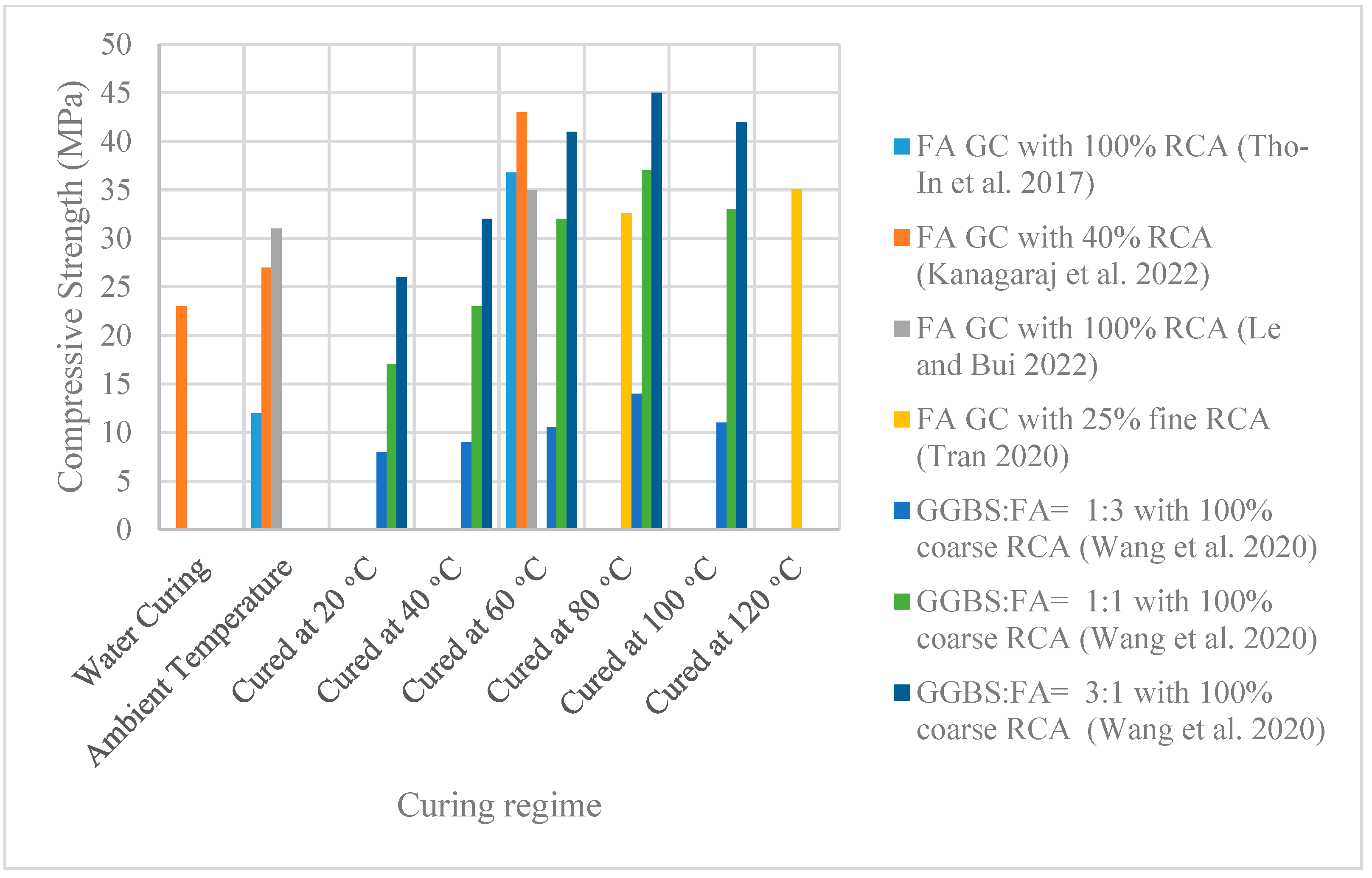

As illustrated in Figure 7, curing at 60 °C for 48 h increases the compressive strength of fly-ash-based GC by 67% [101]. Likewise, Kanagaraj, Kiran, Anand, Al Jabri, and Justin [61] tested FA-based geopolymer concrete with 40% coarse recycled aggregates. They examined three curing techniques of heating in an oven at 60 °C for 24 h, ambient temperature, and water curing. The results obtained by curing at 60 °C improve compressive strength, elastic modulus, and toughness, while the other two curing methods of ambient temperature and water curing are not beneficial. Likewise, curing at 60 °C for 24 h of an FA RCA-based GC demonstrates a 10% improvement in compressive strength, from 30–31 to 34–35 MPa [75]. Delayed ambient temperature settings are a downside of low-calcium GC [106], limiting GC application to just precast concrete. However, GGBS can be used with FA to help receive an early initial setting without elevated temperature and ambient temperature [33].

Figure 7.

Effect of curing regime on CS [35,61,75,91,101].

Regarding the analysis of the curing temperature effects, Tran [91] examined the impact of heating during curing of a fly ash RCA-based GC and pointed out that increasing the temperature from 80 °C for 24 h to 120 °C for 8 h increases the compressive strength by 4–6%. It contrasts with another study on the rising curing temperature, which demonstrates that, at first, the compressive strength of fly-ash-GGBS-based GC increases with a temperature of 80 °C. The compressive strength will decrease, so the optimum temperature was reported to be 80 °C. In other words, between 80 and 100 °C, a reduction in compressive strength was observed [35]. The reason is that a higher temperature harms the microstructure of the GC, resulting in incremental cracks [107].

Researchers have no agreement regarding the optimum curing temperature for geopolymer concrete. Some believe that curing with less than 60 °C of fly ash GC will not improve the compressive strength. However, others argue that 75–85 °C is the optimum temperature. This difference might be due to the usage of various alkali activators. Besides, curing temperature has different effects on multiple aluminosilicates. For instance, regarding fly-ash-GGBS-based geopolymer, although a low temperature is proper for the reaction of GGBS, in higher temperatures, fly ash is dominated [35].

As regards the effect of curing time on compressive strength, geopolymerisation accelerates at first (within the first 12 h). The early strength of GC improves, and if curing continues for 24 h, the strength will increase slowly. Krishnan and Purushothaman [92] stated that curing for up to 24 h enhances geopolymerisation, resulting in a proper bond between alumina and silica. However, curing at a high temperature for a long time has an adverse effect, resulting in microcracks in the geopolymer matrix due to thermal stress [35].

To conclude, a higher temperature helps speed up geopolymerisation, resulting in strong bonding between RCA and unreacted aluminosilicate and enhancing CS. By increasing the temperature of curing, the CS increases at first and then drops by increasing the temperature and continuing heating, so it is crucial to find the optimum temperature and time of curing. Curing at an elevated temperature limits GC application to just precast concrete. Using GGBS with FA helps to cure GC at an ambient temperature, so it is possible to cast in place.

4.2. The Durability of RCA-Based Geopolymer Concrete

Throughout the life cycle of a structure, exposure to a harsh environment impacts concrete performance. These effects include chemical attacks, weathering, degradation, and abrasion. Besides, some factors, chloride penetration, water absorption, sorptivity, submerged absorption, and the existence of too many voids and pores, impact the durability of concrete [108]. In addition, concrete might have severe exposure to high temperatures, a marine environment, freezing and thawing cycles, and acid attack. Replacement of RCA primarily harms durability due to the increment of the voids and pores between the aggregates and paste, so it is of utmost importance to evaluate the durability properties of RCA-based geopolymer concrete.

On the other hand, geopolymer concrete has a more porous structure than OPC concrete due to the alkaline activator and sodium silicate [109]. However, Srinivas and Manoj Anand [110] stated that a 30% RCA content in GC demonstrates better sorptivity and water permeability results than OPC concrete. Despite this, sorptivity and water permeability are slightly affected by adding RCA.

4.2.1. Exposure to a Marine Environment

As regards the evaluation of the durability of structures exposed to a marine environment, a permeability test shall be conducted. Ayub, Mahmood, and Khan [87] did not suggest using RCA-based GC for a marine environment based on a permeability test on FA-based GC. They reported that water penetration in specimens with 30% RCA is higher than that in NA-based GC, and further water penetration can be seen by continuing the tests from 28 to 720 days. It is because of old mortar attached to RCA, which leads to significant water absorption compared with NA-based GC. Besides, they stated that the water penetration of GC is higher than that of OPC due to the effect of the alkaline solution in creating a more porous texture. Additionally, a higher amount of sodium silicate enlarges the pores’ size, negatively affecting water permeability [87,109]. However, Srinivas and Manoj Anand [110] conducted a permeability test on the class F fly ash/GGBS geopolymer with 30% RCA. They observed that although RCA increases permeability, it is in an acceptable range.

Ayub, Mahmood, and Khan [87] also exposed RCA-based geopolymer concrete to a salt spray in the form of a fog to simulate a marine environment. The potential half-cell tests revealed that RCA-based GC is vulnerable in a marine environment. The pores in GC lead to a higher conductivity, resulting in a higher chloride penetration, increasing the chance of steel corrosion and debonding between concrete and steel bars.

Chloride ion migration is also crucial in marine conditions. If the amount of chloride ion increases on the surface of the steel bars, corrosion will occur, resulting in a volumetric change due to iron rust. It results in spalling the concrete around the steel bars. By using FA, the chloride penetration depth decreases because of creating CSH gel and filling the pores between paste and aggregates, leading to a denser structure and avoiding chloride migration [58]. In addition, Nuaklong, Sata, and Chindaprasirt [77] pointed out that increasing the amount of MK in an MK/FA RCA-based GC increases the chloride penetration depth. It is attributed to the decrease in the amount of FA, which results in a lower amount of calcium that decreases the CSH generation.

Lim and Pham [17] stated that the increment of RCA results in decreasing chloride penetration resistance due to the porous structure of ITZ between RCA and new paste, which produces paths for chloride ion penetration. Nuaklong, Sata, and Chindaprasirt [100] also pointed out that using coarse RCA in a GC results in a higher chloride penetration depth due to higher pores and voids in ITZ among RCA. Additionally, the weaker structure of the old paste attached to RCA helps penetrate chloride. Similarly, Saha, Rajasekaran, and Gupta [95] also observed increasing chloride penetration by incorporating 25% fine RCA.

Some factors affect the chloride migration of RCA-based GC. For instance, a higher NaOH molarity in an FA RCA-based GC decreases the chloride penetration. Increasing the NaOH concentration, Si, and Al results in improved GC polycondensation reaction, reducing pores and chloride migration [100]. Increasing the ratio of the alkali activator to the binder also improves chloride resistance [95].

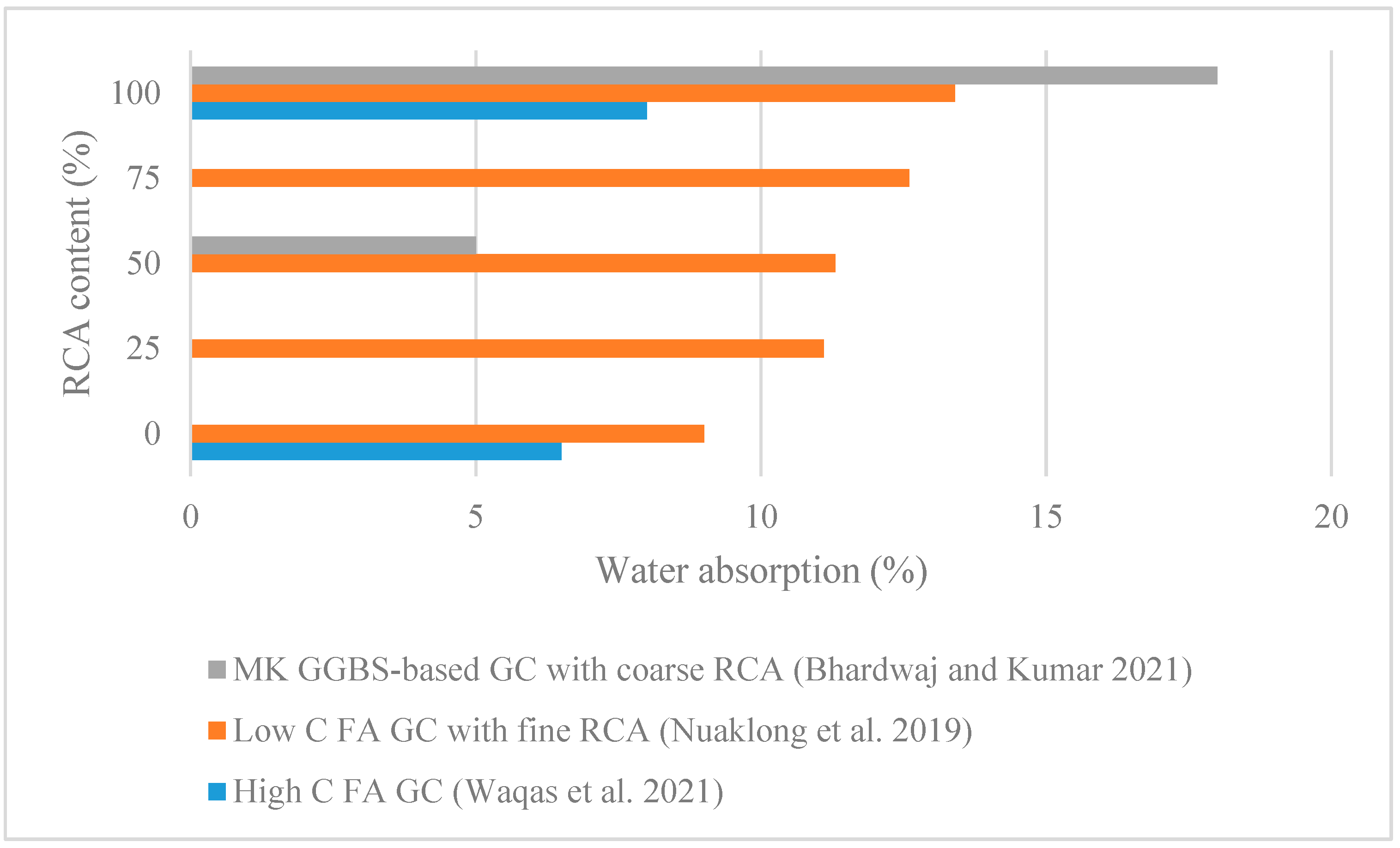

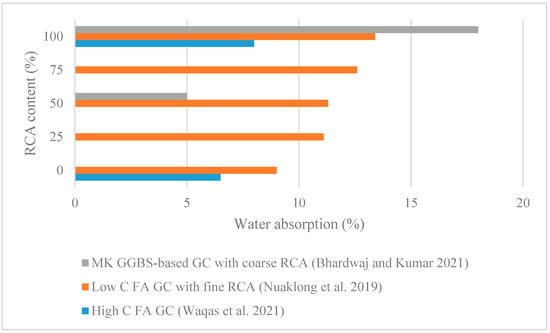

Figure 8 demonstrates that increased RCA results in increased water absorption. As an illustration, by replacing 100% of coarse aggregates with RCA in a GC, water absorption increased by 29%. It might be due to the pores on the surface of RCA [36]. In addition, increasing RCA in a GC causes a higher sorptivity and water absorption [111]. Nuaklong, Wongsa, Sata, Boonserm, Sanjayan, and Chindaprasirt [74] confirmed that increasing the RCA content elevates the water absorption by 11.1%, 11.3%, 12.6%, and 13.4% for 25%, 50%, 75%, and 100% fine RCA compared with zero RCA. A GC with 30% RCA experienced increased water penetration at 28, 90, 180, 365, and 720 days compared with specimens with NA [87].

Figure 8.

Effect of RCA content on water absorption [33,36,74].

Replacement of coarse aggregates only increases water absorption. For instance, incorporating 50% and 100% of coarse aggregates in an MK GGBS-based GC increases the initial water absorption by approximately 5% and 18%, respectively [33]. Ayub, Mahmood, and Khan [87] believed this might be due to higher geopolymer materials and a smaller amount of aggregates in RCA-based than that of GC with NA. As regards salt spray and a potential half-cell test and analysis of the effect of chloride penetration and its impact on steel bars, NA-based GC indicates better results than RCA-based GC. However, the adverse effect of adding RCA to a GC is less than that of adding RCA in OPC concrete [87].

Some materials have a positive effect on the durability properties of RCA-based GC. For instance, adding PVA reduces the porosity ratio due to the role of fibres in preventing microcrack creation and minimising the porosity ratio. PVA also decreases mass loss in the abrasion test [32]. Likewise, graphene oxide helps lower the initial water absorption rate [33], and carbon fibres reduce water absorption [44]. Bentonite also positively impacts water absorption and chloride migration [36]. Besides, replacing 5% to 15% of FA with OPC results in better chloride ion resistance [76].

In conclusion, RCA negatively impacts water permeability and chloride penetration resistance due to the porous structure of ITZ between RCA and old paste, and increasing RCA content results in more water absorption and chloride penetration. However, the negative effect of RCA on the chloride penetration in GC is less than the effect of RCA in OPC concrete. A higher NaOH molarity and AAS/b decrease chloride penetration. Besides, some additives, such as PVA fibres, carbon fibres, bentonite, and graphene oxide, positively impact durability.

4.2.2. Exposure to High Temperature

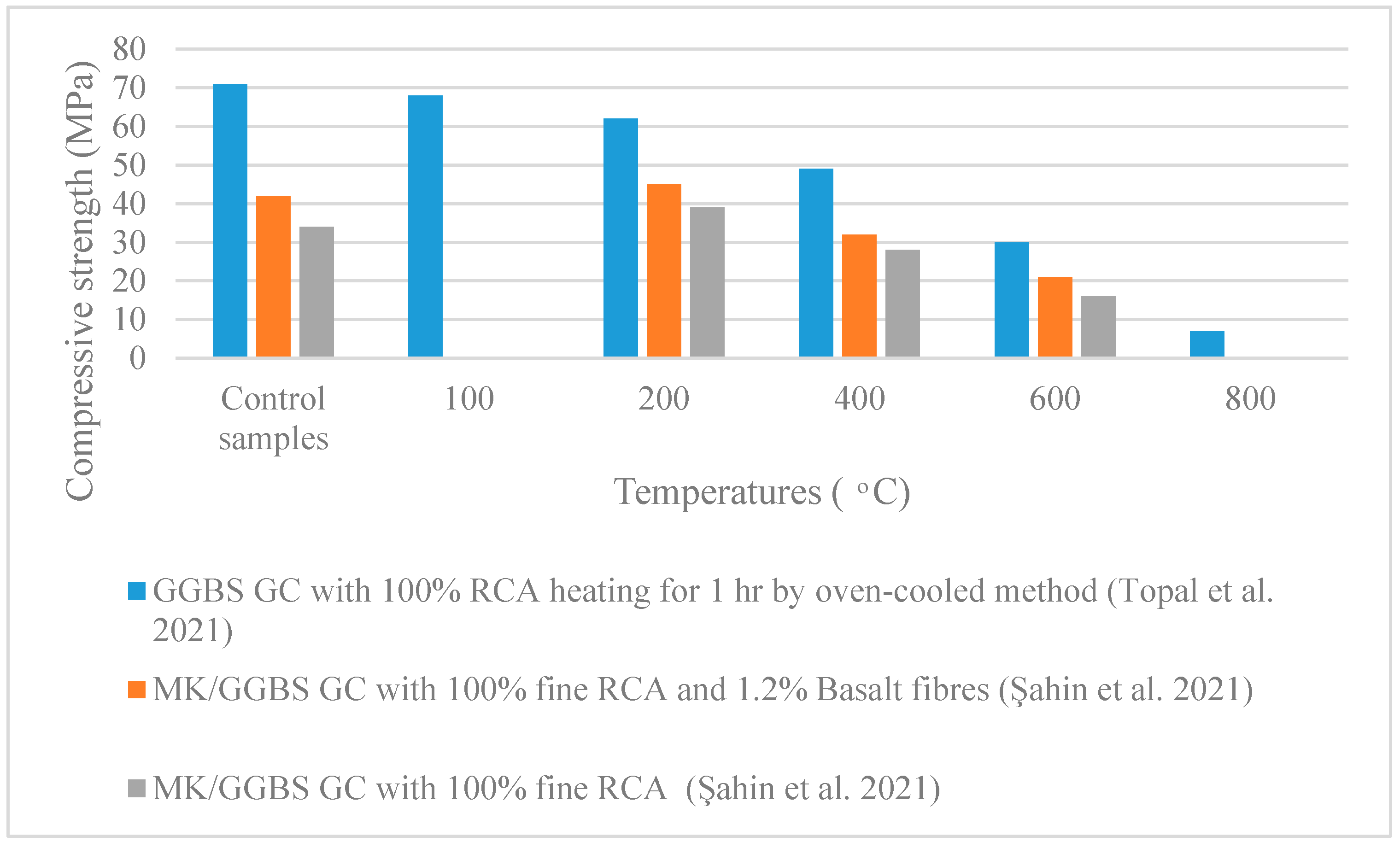

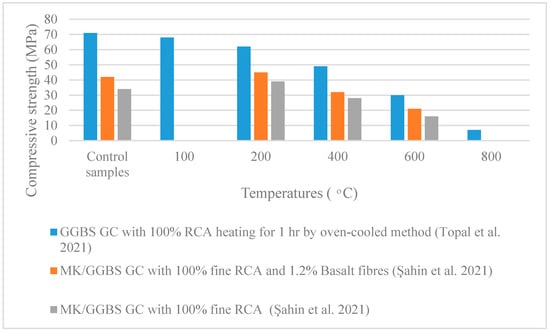

Studying fire safety for a concrete structure design, and exploring which factors affect it, is essential. Exposure to high temperatures decreases compressive strength and flexural strength. While geopolymer concrete shows less spalling and cracks in fire exposure [112], the compressive strength reduces due to the expansion of paste and aggregates at higher temperatures [112]. It is also correlated with the materials, activator, activator-to-binder ratio, and curing regime [113,114]. The adverse effect of high temperature is due to the evaporation of free water in the paste, which results in internal pressure [115]. Once the internal pressure has reached a certain level, the thermal stress in the matrix cannot be sustained, creating cracks on the surface of the concrete and the microcracks in ITZ [116]. Replacement of RCA harms the thermal resistance due to the breakage of RCA at a specific temperature [117]. As illustrated in Figure 9, exposure to elevated temperature decreases CS. For instance, Topal, Karakoç, and Özcan [111] observed a decline in compressive strength by 8%, 40%, 47%, 64%, and 91% for 100, 200, 400, 600, and 800 °C for 1 hour of heating a GGBS-based concrete with 100% RCA. In contrast, Fakhrian, Behbahani, and Mashhadi [73] reported that the adhesive between RCA and GGBS-based concrete paste becomes firmer at higher temperatures. However, Şahin, Uysal, Canpolat, Aygörmez, Cosgun, and Dehghanpour [70] pointed out that the compressive strength of RCA-based MK-based GC with the additive of basalt fibre increases by heating up to around 200 or 300 °C, higher temperature causes compressive strength drop, and the concrete is disintegrated at 800 °C, which might be due to the decomposition of old OPC mortar around the RCA [59].

Figure 9.

Relationship between heating temperature and CS [70,111].

The level of fire damage in the GC microstructure is relevant to the exposure level. For instance, research by Nuaklong, Jongvivatsakul, Pothisiri, Sata, and Chindaprasirt [59] shows that after 30 min of heating, the residual compressive strength of RCA-based FA geopolymer was around 34% higher than its counterpart with NA, which might be because of the decline in the expansion of aggregates with OPC material around the RCA particles. They reported that the compressive strength significantly dropped for 60 min heating, as the calcium hydroxide, which exists in the mortar around the aggregates, began to decompose, destroying the bonding between paste and aggregates. Similarly, based on research by Nuaklong, Jongvivatsakul, Pothisiri, Sata, and Chindaprasirt [59], after 60 min fire exposure at about 900 °C, cracks on the surface of the fly-ash-based GC specimens can be seen due to the escape of evaporated water from the inside of the specimens.

In addition, the water absorption and sorptivity of RCA-based geopolymer concrete, exposed to higher temperatures, are higher than those of geopolymer concrete with NA. Further, RCA increases the sorptivity and water absorption cracks and deterioration of the structure at higher temperatures [111].

Some additives have a positive effect on fire resistance. For instance, adding 0.4% PVA increases the compressive strength of RCA-based GC by 26% at 200 °C. PVA has a positive impact on strength, as PVA produces a three-dimensional network that helps keep all the geopolymer components together. However, PVA negatively affects higher temperatures as it is melted, resulting in more pores [32]. Similarly, adding 1.2% basalt fibre increases the compressive and flexural strength of RCA-based GC at 200 °C from 38.99 and 2.26 MPa to 45.16 and 3.6 MPa, respectively [70].

To sum up, RCA has an adverse impact on the CS, water absorption, and sorptivity of GC after exposure to elevated temperature. Higher temperatures result in decreasing the CS and increasing the water absorption and sorptivity. Moreover, increasing the time of heating results in a further reduction in the CS. The PVA and basalt fibre additives improve the mechanical properties of RCA-based GC after exposure to higher temperatures.

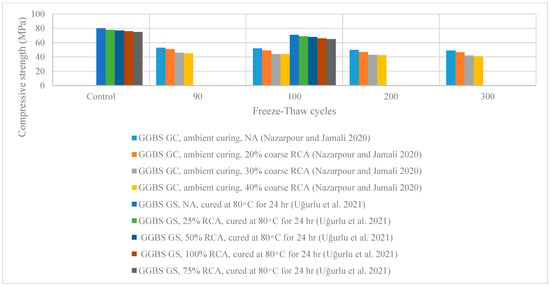

4.2.3. Exposure to Freezing and Thawing

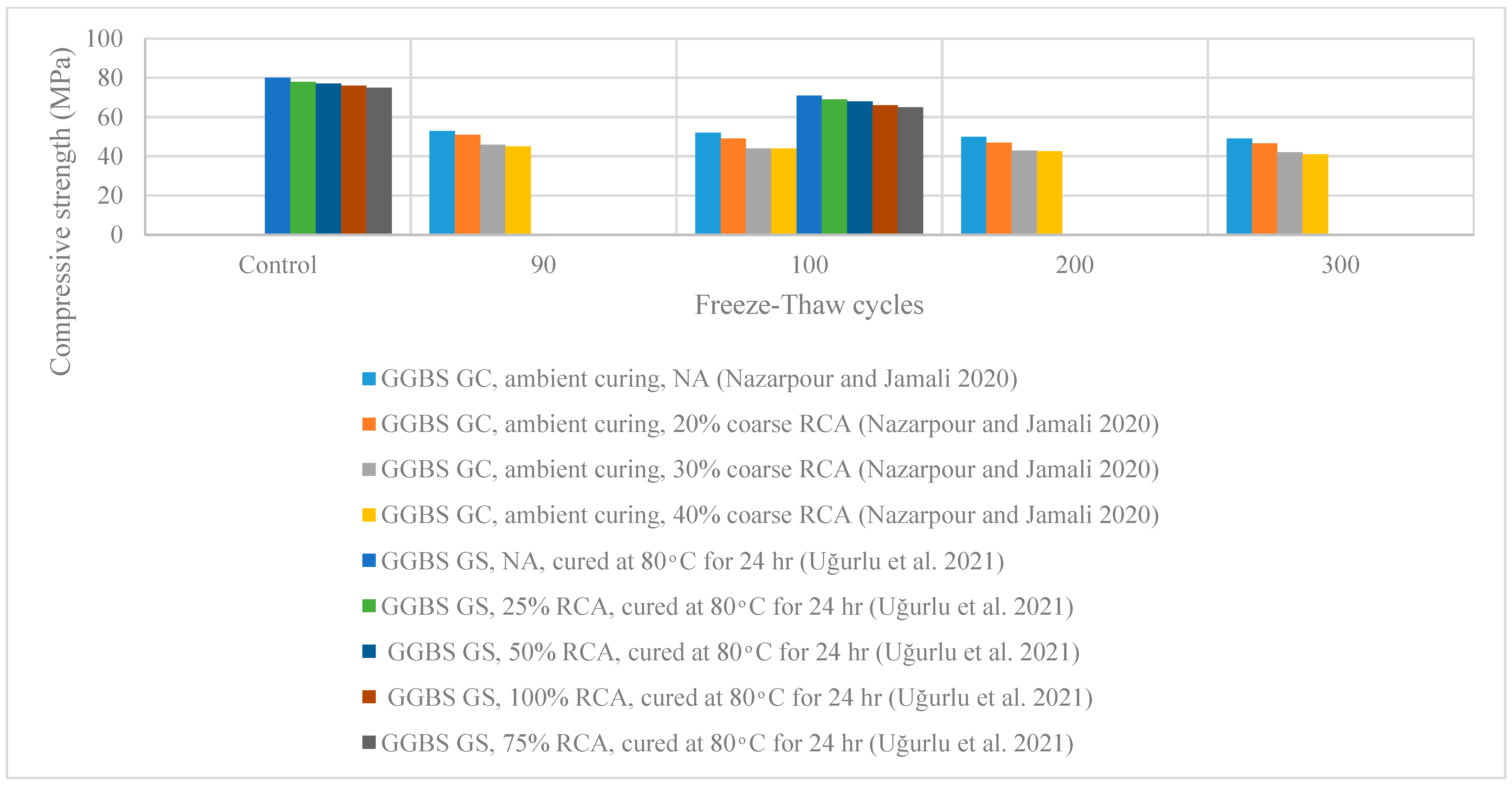

Compared with OPC, geopolymer concrete represents better and improved compressive strength after a freeze–thaw cycle. It is due to the high consumption of pozzolanic materials in GC, especially slag [118]. Pozzolanic reaction continues within the freeze–thaw cycle [119]. Besides, a compacted and dense matrix of geopolymer concrete has an essential role in this regard, so 180 cycles of freezing–thawing cycles, like a curing condition, improve the mechanical properties of MK-based GC with polyvinyl alcohol [118]. Likewise, MK/GGBS-based GC improves compressive strength during freezing–thawing [32].

As depicted in Figure 10, Nazarpour and Jamali [120] reported the proper freeze–thaw durability properties for partial RCA replacement in a GGBS-based GC. However, the CS dropped slightly by around 7–14% for 100, 200, and 300 freeze–thaw cycles. In like manner, Uğurlu, Karakoç, and Özcan [26] reported a 12% to 15% compressive strength drop for 25% to 100% RCA replacement in a GGBS-based GC after 100 cycles of freezing and thawing. Due to the weaker structure and higher water absorption of RCA, continuing the cycle of freezing and thawing of the existing water in the aggregates causes internal stress, leading to the weak structure of GC. In addition, this is the reason for the further reduction in CS by adding more RCA.

Figure 10.

Relationship between the freezing and thawing cycles and CS [26,120].

Some materials positively impact the freeze–thaw resistance of RCA-based geopolymer and even increase the compressive strength of GC after the cycles of freeze and thaw. For instance, 1.2% PVA increases the compressive and flexural strength by 44.80% and 110%, respectively, rather than the identical fibreless specimens and enhances the compressive strength after 180 cycles of freeze–thaw [32]. Likewise, basalt fibres improve the compressive strength of RCA geopolymer concrete by 16% after 180 cycles of freezing–thawing compared with their counterpart without basalt fibres [70]. The positive effect of these two types of fibres is due to the positive impact of fibre networks on mechanical properties and avoiding flattering the microcracks due to the existence of RCA [32].

To conclude, RCA adversely impacts the freeze–thaw durability, and increasing the RCA content results in a further drop in CS after freezing and thawing. However, the negative effect of partial RCA replacement is negligible. Additives of PVA and basalt fibres improve the freeze–thaw resistance of RCA-based GC.

4.2.4. Exposure to Acid and Alkali Attacks

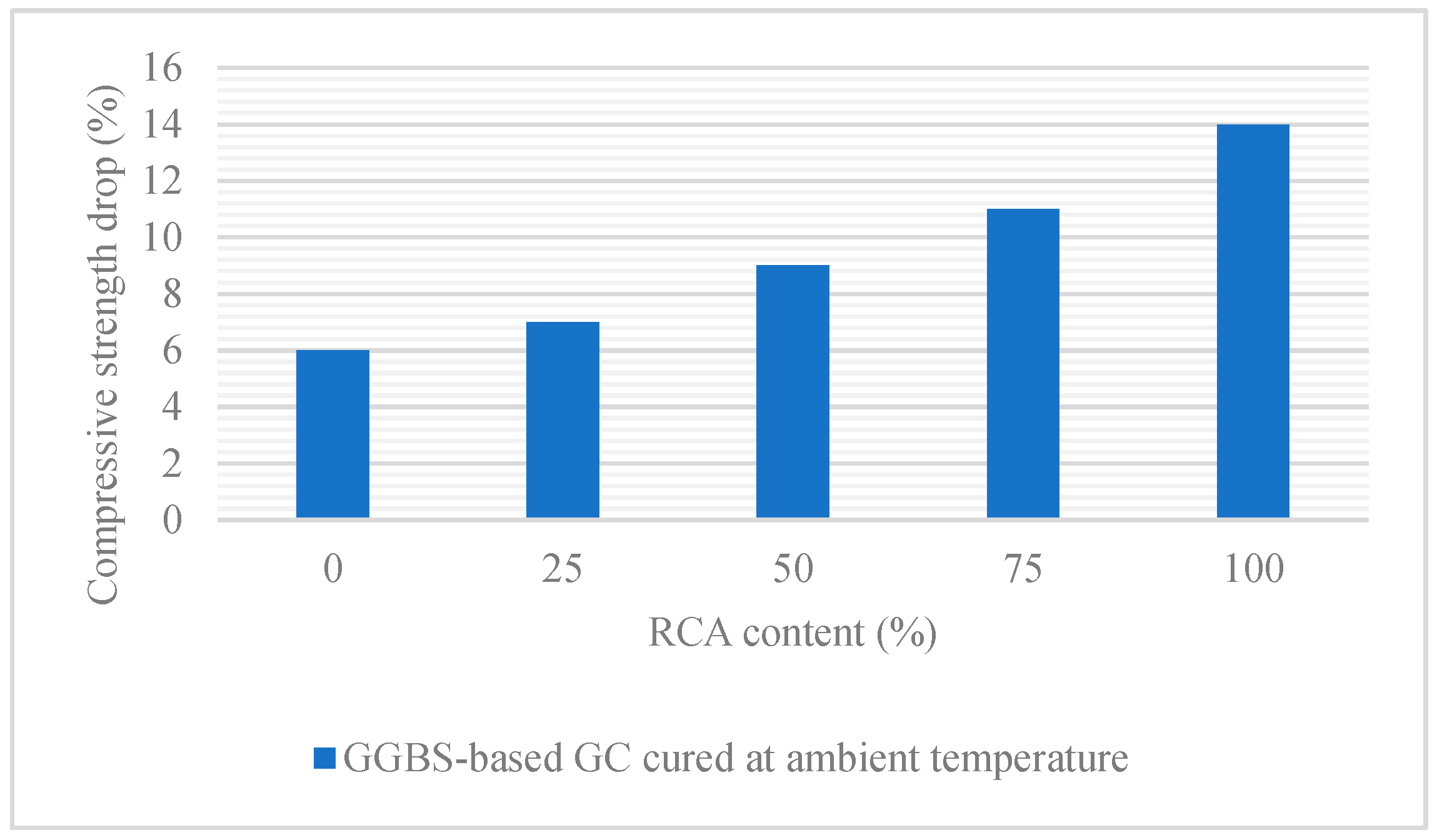

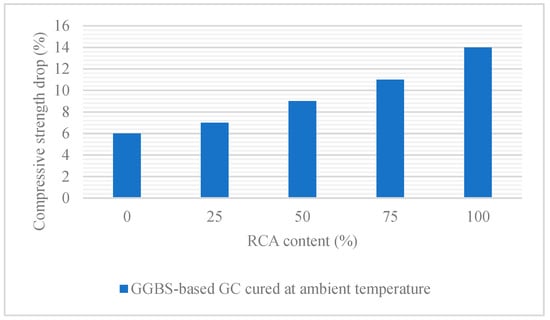

Concrete is alkaline, and contact with acid breaks down its component. Geopolymer concrete demonstrates better acid resistance than OPC concrete, as its water absorption and calcium content are lower than those of OPC, so lower soluble particles will be generated [121]. Waqas, Butt, Danish, Alqurashi, Mosaberpanah, Masood, and Hussein [36], replacing NA with RCA, increases the mass loss in an acid attack. It is because of the cementation paste around RCA. This observation is confirmed by other studies [36,77,95,100]. However, exposing a 25% fine RCA-based FA GC to an alkali solution such as magnesium did not show any mass loss but caused a CS drop. Generally, alkali attacks have better results than acid attacks [95]. As illustrated in Figure 11, the CS loss due to the alkali attack will increase if the RCA percentages increase [89]. This phenomenon is because the reaction of the cement paste in RCA with sulphate generates harmful materials, such as gypsum and ettringite, leading to the CS drop [89].

Figure 11.

Relationship between RCA content and CS drops due to magnesium sulphate exposure (adapted from Parthiban and Saravana Raja Mohan [89]).

Some factors can improve acid resistance. For example, bentonite has a positive effect and decreases the acid attack mass loss. Incorporating 15% bentonite reduces the mass loss of 90-day RCA GC specimens by 12% [36]. Besides, replacing 10% and 20% FA with MK in an MK/FA RCA-based GC demonstrates better acid attack resistance than zero MK [77]. Higher NaOH molarity also improves acid resistance. For example, for 8, 12, and 16 NaOH molarity for FA RCA-based GC, 18.9%, 12.4%, and 10.3% mass losses were observed after 120 days of exposure to sulphuric acid [100]. Increasing the ratio of alkali activator to binder also enhances acid attack resistance, while 25% fine RCA is incorporated in a FA GGBS-based GC [95].

Regarding alkali attacks, increasing the binder content leads to decreased CS loss due to the acid attack. For instance, exposing a GGBS-based GC with 25%, 50%, 75%, and 100% RCA demonstrates 14.4–21.9%, 10.9–19.7%, and 9.1–17.3% CS loss, for 300, 400, and 500 kg/m3 GGBS material, respectively, when it is exposed to 3% MgSO4 solution for 12 weeks. The reason is that increasing the binder content increases the content of geopolymer, leading to a decline in permeability, resulting in less impact of alkali. [26]. Besides, increasing AAS/b decreases the CS drop due to an alkali attack [95].

To sum up, incorporating RCA has adverse effects on the alkali and acid attack resistance of RCA-based GC. Factors such as adding bentonite, replacing 10% to 20% FA with MK, higher NaOH concentration, or increasing the AAS/b ratio can improve acid resistance. Besides, increasing the binder content and increasing AAS/b enhance alkali resistance.

4.3. Properties of Fresh RCA-Based Geopolymer Concrete

4.3.1. Setting Time

The initial setting time in an RCA-based geopolymer concrete depends on the type of binder, binder-to-aggregate (b/A) ratio, hydroxide sodium concentration, SS/SH ratio, water/binder ratio, and RCA content [63,93].

GGBS decreases the initial and final setting time [62]. It is due to the higher amount of calcium that reacts with water, and the existence of an alkali activator expedites it. However, MK reacts with alkali solution, and if FA is replaced with the same amount of MK, this increases both the initial and final setting time. It is due to the higher Ca+2 in FA than in MK [81]. Low-calcium fly ash extends the initial and final setting time to high-calcium fly ash due to the lower amount of CaO, as CaO expedites the setting by fast-producing CSH gel [74]. Using waste concrete fine (WCF) also decreases the initial setting time due to the high amount of calcium in WCF, resulting in CSH production, which generates heat, speeding up the condensation process [93]. Increasing the ratio of b/A also extends the setting time, as a higher b/A means a higher amount of liquid, which lubricates GC and improves the setting time [93]. In addition, the higher molarity of NaOH causes the setting time to extend due to the higher amount of OH−. Besides, increasing the ratio of SS/SH causes condensation among silicate content and leads to an extended setting time. Moreover, the increase in the water/binder ratio increases the setting time [63].

Xie, Chen, Wang, Fang, Zhang, and Liu [81] pointed out that RCA’s application does not significantly affect the setting time, and various amounts of RCA slightly affect the setting time. The reason is that hydration occurs in the paste and ITZ. However, the setting time increased somewhat due to RCA’s extra water. In contrast, Ren and Zhang [93] observed a much shorter initial setting time for RCA-based GC than NA-based GC. They stated that the reason was the rougher surface of RCA than NA. Besides, RCA might break during mixing, absorbing more water and decreasing the initial setting time. However, in another research, increasing the amount of RCA to 100% demonstrates a 10.4% increase in the setting time of a GGBS/FA concrete [63].

In conclusion, the binder materials of GGBS and WCF decrease the setting time due to the higher amount of calcium. However, MK and low-calcium FA extend the setting time. Moreover, increasing the b/A, NaOH molarity, SS/SH ratio, and water/binder ratio raises the setting time.

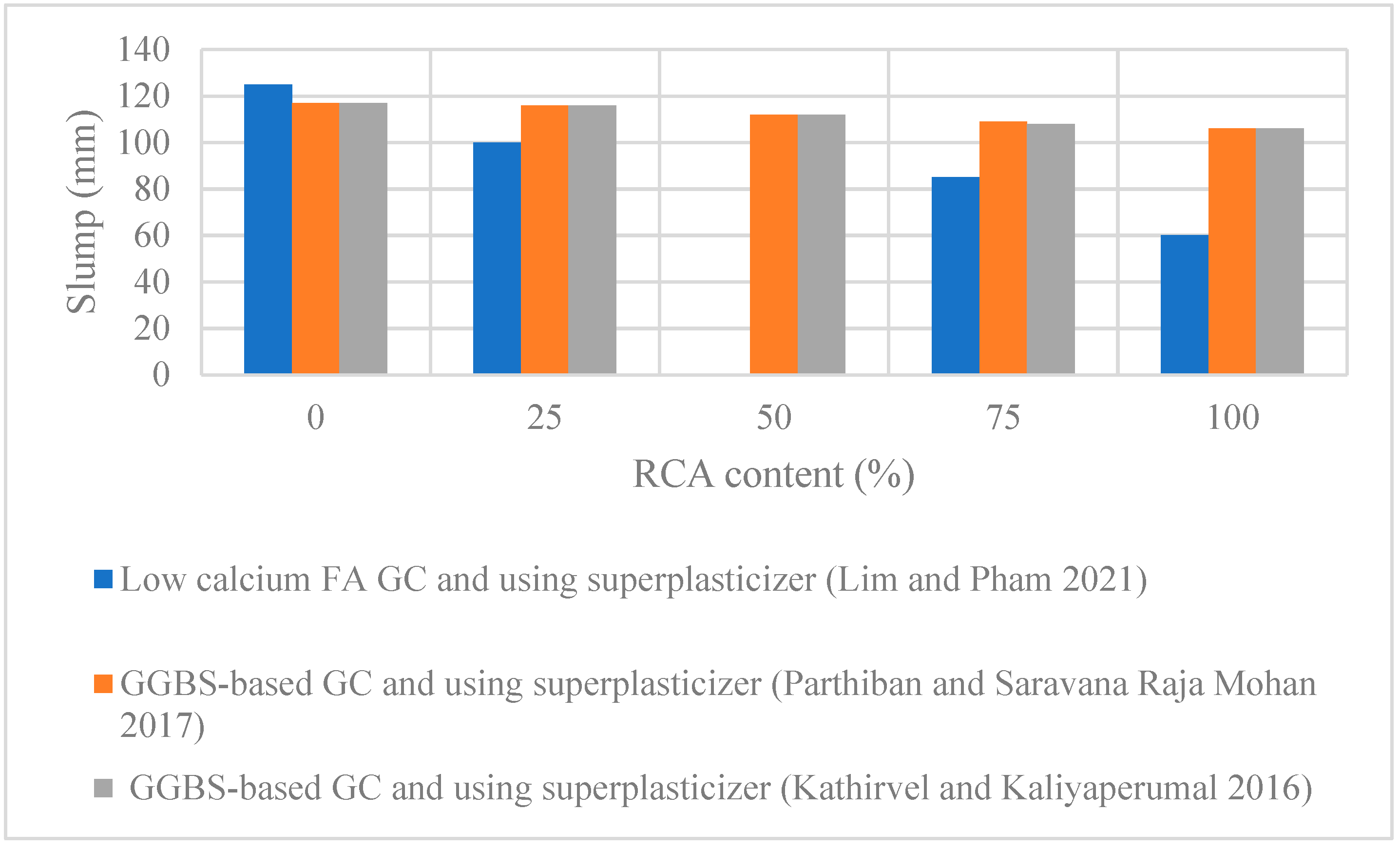

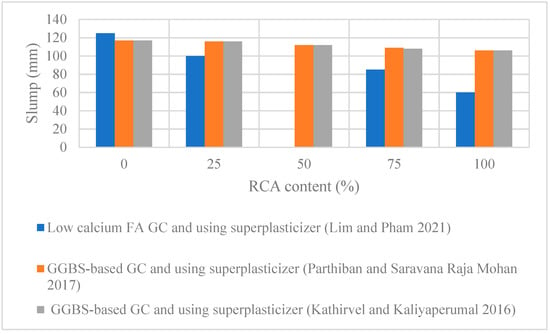

4.3.2. Workability

The effect of RCA content on the slump and workability of fresh GC is diverse. Figure 12 studies state that incorporating RCA in GC leads to more voids, resulting in higher water absorption. Moreover, RCA has a rough surface, which increases the harshness, negatively affecting the workability [122]. For instance, replacing NA with 100% RCA demonstrates a drop in slump from 125 to 60 mm [17]. In like manner, Parthiban and Saravana Raja Mohan [89] observed a decrease in slump from 117 to 106 mm for 0% and 100% RCA, respectively, in a GGBS-based geopolymer. Likewise, Kathirvel and Kaliyaperumal [65] confirmed a drop in slump by adding RCA in developing a GGBS-based GC. They believe that it might be due to the existence of the pores in RCA.

Figure 12.

Adverse effect of RCA on workability [17,65,89].

In contrast, some researchers stated that RCA has no adverse effect on GC workability. For instance, Bhardwaj and Kumar [33] pointed out that additional RCA has no negative impact on workability, as RCA is used as an SSD, and it needs further water to reach the SSD. Likewise, Waqas, Butt, Danish, Alqurashi, Mosaberpanah, Masood, and Hussein [36] stated that RCA helps achieve better workability in a high-calcium FA-based GC due to the more water in GC. Similarly, Nuaklong, Jongvivatsakul, Pothisiri, Sata, and Chindaprasirt [59] pointed out that the slump for an RCA-based GC is 14% higher than its counterpart with natural aggregates. Again, replacing 100% of RCA results in a 10% increase in a slump of GGBS/FA concrete [63]. Furthermore, adding RCA causes an increase in passing ability, viscosity, and segregation. Based on investigations, this is associated with the Na2SiO3/NaOH ratio and the molarity of NaOH [123]. For instance, adding 30% of RCA to a fly-ash-based GC, Na2SiO3/NaOH = 2.5, and molarity 8, viscosity, passing ability, and segregation increased by 18%, 7%, and 4%, respectively [87].

Various factors affect NA-based and RCA-based GC. Regarding the effect of alumina silicate material, the increase in the ratio of GGBS to MK in RCA-based GC from 1:1 to 7:3 results in a lower slump, whereas this improves the compressive strength, even better than OPC. The reason is that a GGBS particle has an angular shape, and its reduction helps workability. Moreover, an MK particle is smaller than a GGBS particle. Increasing them helps to achieve better workability as well. Another reason is that a decline in calcium due to the lower amount of GGBS might help delay condensation and improve workability [81]. Likewise, in a fly ash GGBS GC, increasing the amount of FA or decreasing the amount of GGBS, while the water-to-binder ratio is constant, helps to achieve better workability due to the angular shape of GGBS and the effect of the reaction of high-calcium GGBS [62]. Regarding comparing the effect of MK and FA on the workability of RCA-based GC, increasing the number of MKs results in a slump drop due to the more fine and angular shape of MKs compared with the spherical shape of FA particles [77].

Another influential factor is alkali-activated-solution (AAS)- to-binder ratio (AAS/b). Increasing AAS/b enhances the slump due to the higher amount of AAS. For instance, increasing AAS-to-FA percentage from 0.4 to 0.5 increases the slump by 10% (from 16 to 20 cm) but decreases CS by around 9% [75]. Similarly, Le, Bui, and Tang [72] reported 16, 18, and 20 cm for AAS/FAs of 0.4, 0.45, and 0.5, respectively, while 100% coarse aggregates were replaced by RCA.

Furthermore, the water/binder ratio significantly impacts workability. It increases from 0.3 to 0.5 in a GGBS/FA geopolymer concrete with 100% RCA, resulting in 48.7% workability enhancement [63]. Moreover, increasing the ratio of Na2SiO3 to NaOH also decreases slump by enhancing alkali activator adhesiveness with a higher amount of Na2SiO3 [123]. In addition, increasing the molarity of NaOH leads to a drop in slump, while the water-to-binder ratio remains constant. It is due to the higher amount of alumina and silica due to the higher NaOH molarity, rising geopolymerisation, and stiffness of the concrete [100,123]. For instance, slumps of 750, 740, and 710 mm are reported for 8, 10, and 12 NaOH M, respectively, in RCA-based GC, and the same manner is reported for NA-based GC [123].

The addition of some material has a positive effect on workability. For example, the ultrafine slag particle’s spherical shape and fine ultra slag particle enhance workability [17]. A superplasticiser also improves workability. For instance, lignosulfonate increases the slump of an FA-based GC with 100% coarse RCA by around 2 cm, with a negligible effect on compressive strength [72].

To conclude, RCA has a diverse impact on the workability of GC, and there is evidence for increasing or decreasing the slump due to the RCA incorporation. The factors that help to achieve better workability include: (1) increasing the ratios of AAS/b and w/b; (2) decreasing the ratios of GGBS/MK, GGBS/FA, MK/FA, and SS/SH, and (3) decreasing NaOH molarity, (4) adding ultrafine slag, (5) adding superplasticisers.

4.3.3. Self-Compacting Concrete

Self-compacted geopolymer concrete is concrete with a flowability level that allows it to compact by the gravity load. This type of concrete has been developed to tackle the issue of failure resulting from inappropriate compaction [124]. Regarding the properties of fresh self-compacting concrete, flowability, viscosity, passing ability, and segregation must be evaluated by conducting the tests of the slump, T500 slump-flow or V-funnel, L-box, and segregation resistance (sieve). Based on concrete applications, slump-follow for self-compacting concrete must be between 550 and 850 mm [125].

There are a few studies to produce a self-compacting RCA-based GC. For instance, Ayub, Mahmood, and Khan [87] analysed a self-compacting FA-based geopolymer with 30% RCA and 7% superplasticiser, which was cured at 70 °C for 24 h. They compared it with a GC with 100% natural aggregate. Although the changes in the properties of fresh GC were satisfying, the compressive strength was 14.8 MPa, which is unsuitable for structural applications. In another research for developing a self-compacting RCA-based GC, Salihi and Younis [123] just studied the properties of fresh GC, did not mention curing conditions, and did not consider mechanical and durability properties. Hence, there is a scope for a study on self-compacting RCA-based GC with a CS suitable for structural applications, which will be cured in an ambient environment.

5. Scopes for Further Research

This paper identified the knowledge gap in the relevant literature based on the three main techniques for spotting gaps, including Confusion, Neglect, and Application, which were first introduced in [126] and used in construction-related studies [127]. When there is knowledge regarding the matter, but this information is confusing, and there is no agreement among researchers, this type of gap is considered ‘Confusion’. ‘Neglect’ mode, which is the most common type of gap, happens when there are no reasonable studies regarding the issue, or it is still under research. The gap category is ‘Application’ when it is required to extend, augment, or modify. Accordingly, the following gaps were identified based on this gap-spotting method throughout this review. There is a scope for further research in the following identified gaps.

- Self-compacting RCA-based GC, which can be cured in ambient temperature with CS, ranged in structural application. (Neglect)

- Applying RCA-based GC in a simulated coastal environment. (Neglect)

- Using the solid alkali activator. The previous studies are conducted on a two-part geopolymer concrete using a liquid alkali activator. (Neglect)

- The optimum temperature and time for curing. There is no agreement among researchers on this aspect. (Confusion)

- The effect of RCA on the compressive strength of GC. There is no agreement among researchers on this aspect. Some believe that RCA increases CS, and others state that RCA decreases CS. (Confusion)

- The effect of RCA on the setting time and flowability. There is no agreement among researchers on this aspect. (Confusion)

- The various treatment of RCA applied in GC. There are no studies on this aspect. (Application)

- Identify the optimum amount of GC mix components for developing RCA-based GC. The effect of considerable amounts of silica fume on an FA/silica fume GC. The impact of multiple ratios of waste concrete powder to FA and FA to ferrochrome ash should be considered in future studies. (Application)

6. Discussion and Conclusions

This research reviewed the most important factors influencing the mechanical and durability properties of the fresh and hardened RCA-based geopolymer concrete. The conclusions are drawn and categorised into three groups as below:

- Mechanical properties of RCA-based geopolymer concrete

- There are three sources for RCA in the literature: concrete lab specimens, CDW landfilled, and demolished buildings. Specific gravity, density, dry density, saturated density, bulk density, and apparent density of RCA are less than NA.

- There are some techniques for RCA treatment, including coating aggregates with geopolymer slurry or cement and so on to improve the properties of RCA. However, there is no study on the implications of treated RCA in GC.

- Increasing the aluminosilicate content, such as GGBS in a GGBS-based GC, GGBS in a GGBS FA-based GC, and the amount of UFS in a UFS FA-based GC, GGBS in GGBS an MK-based GC, MK in an MK FA-based GC results in enhancing CS. Besides, increasing the ratio of Portland cement in a Portland cement FA-based GC improves CS.