Challenges and Emerging Trends in Toner Waste Recycling: A Review

Abstract

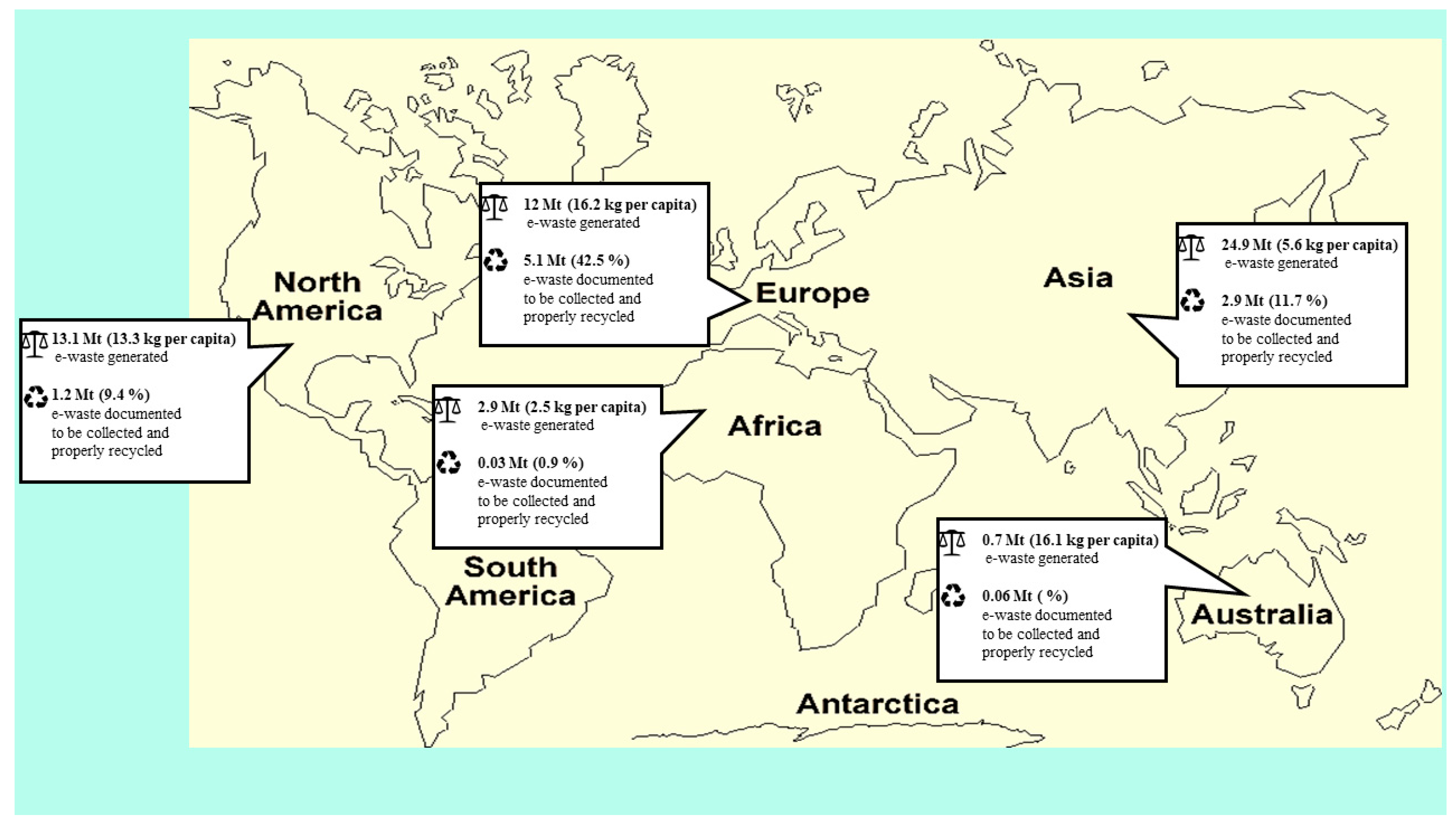

:1. Introduction

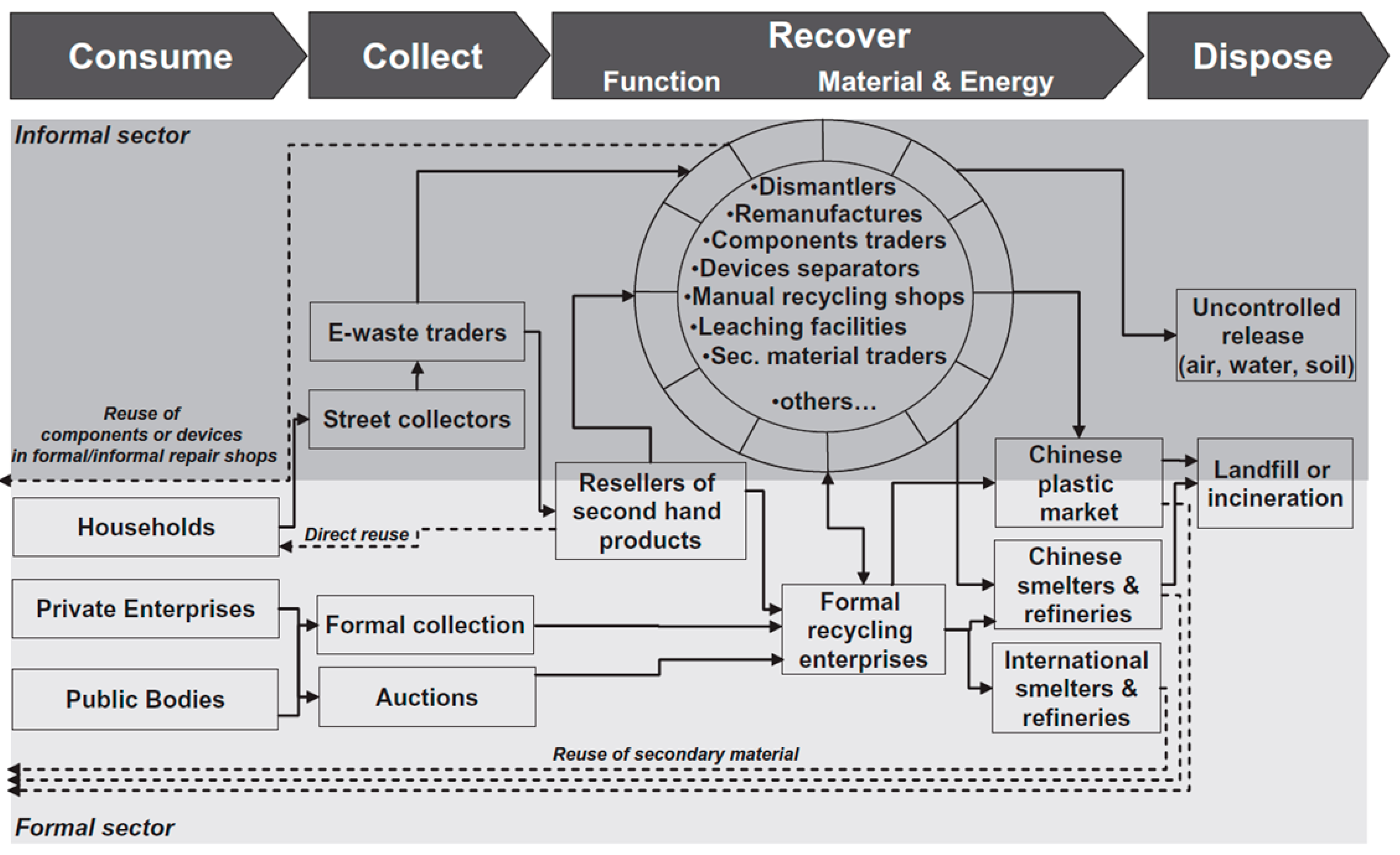

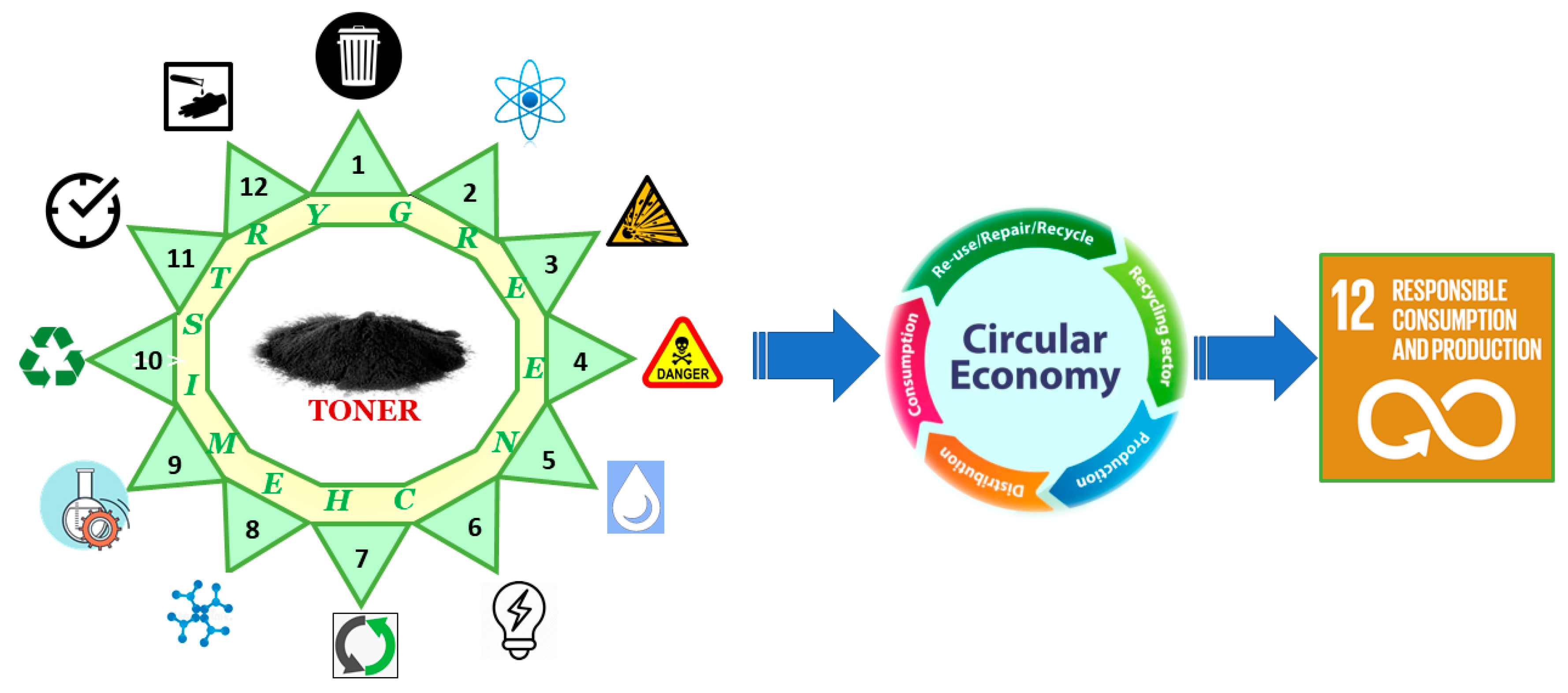

2. Composition of Toners

3. Challenges in Recycling Toner Waste

- Lack of awareness of the toxic effect of waste toners among the end users and those involved in informal recycling;

- Inaccessible and insufficient collection points for systematic collection of waste toners;

- Inherent stability of toners, which makes recycling/reusing difficult;

- Lack of strict legislation and governance in e-waste management, especially in developing countries;

- Uncontrolled growth of informal recycling sector;

- Pollution arising from irresponsible processing of waste toners.

- It is impossible to identify the producer of a particular toner at the end of use.

- Waste toners need to be collected at accessible locations. Toners of different compositions will be collected together. Unified recycling methods are needed to treat the mixture. In this case, the cost and responsibility of recycling has to be borne by the government and the producer cannot be held responsible. Common treatment/recycling plants, such as ETPs (Effluent Treatment Plants) for treating industrial effluents, need to be commissioned by local governments.

- Local xerographic and printing shops might not use branded toners for their devices.

- There is no mechanism to monitor, quantify, and document the usage and disposal of toners.

- Information labels on recyclability are not available on toner products.

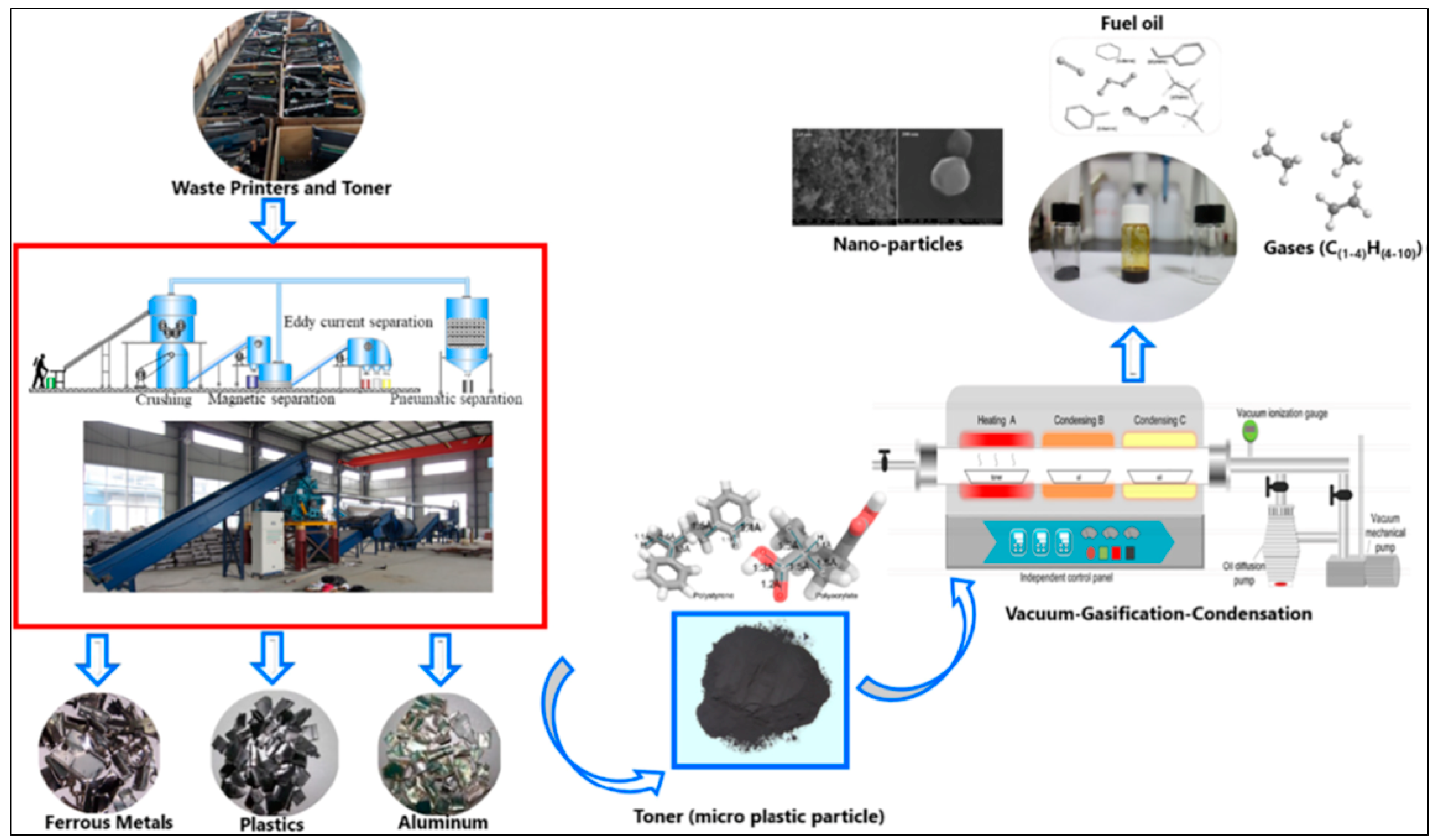

4. Emerging Trends in Recycling Toner Waste

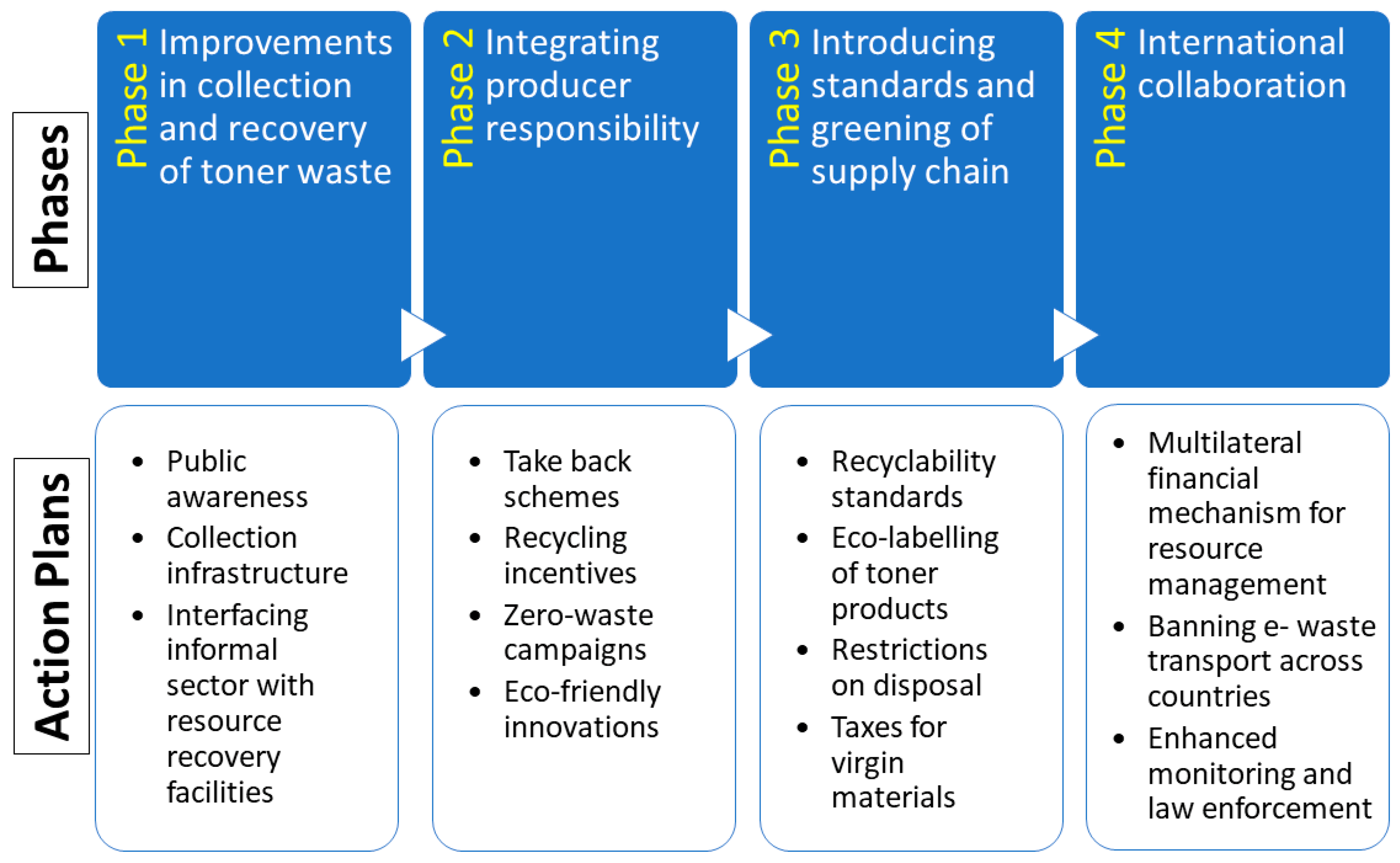

5. Future Directions

5.1. Policies and Legislations

5.2. Standards and Eco-Labelling

5.3. Innovations in Recycling

Funding

Conflicts of Interest

References

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR)–co-hosted SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA): Bonn, Germany; Geneva, Switzerland; Rotterdam, The Netherlands, 2020. [Google Scholar]

- Bhoi, V.N.; Shah, T. E-waste: A new environmental challenge. IJARCSSE 2014, 4, 442–447. [Google Scholar]

- Vucinic, A.A.; Vujevic, D.; Mujkic, K.; Novak, M. Recycling of waste toner in the republic of Croatia—An environmentally friendly approach. Chem. Engg. Trans. 2013, 34, 121–126. [Google Scholar]

- Salhofer, S.; Tesar, M. Assessment of removal of components containing hazardous substances from small WEEE in Austria. J. Hazard Mater. 2011, 186, 1481–1488. [Google Scholar] [CrossRef]

- Nnorom, I.C.; Osibanjo, O. Overview of electronic waste (e-waste) management practices and legislations, and their poor applications in the developing countries. Resour. Conserv. Recycl. 2008, 52, 843–858. [Google Scholar] [CrossRef]

- Devin, N.; Perkins, B.S.; Marie-Noel Brune Drisse, M.S.; Tapiwa Nxele, M.S.; Peter, D.; Sly, M.D. E-waste: A global hazard. Ann. Glob. Health 2014, 80, 286–295. [Google Scholar]

- Lasaridi, K.; Terzis, E.; Chroni, C.; Kostas, A. World Statistics on E-Scrap Arisings and the Movement of E-Scrap between Countries, 2016–2025; BIR Global Facts & Figures; BIR: Brussels, Belgium, 2016; pp. 1–80. [Google Scholar]

- Babar, S.; Gavade, N.; Shinde, H.; Gore, A.; Mahajan, P.; Lee, K.H.; Bhuse, V.; Garadkar, K. An innovative transformation of waste toner powder into magnetic g-C3N4-Fe2O3 photocatalyst: Sustainable e-waste management. J. Environ. Chem. Eng. 2019, 7, 103041. [Google Scholar] [CrossRef]

- Aydemir, C.; Ozsoy, S.A. Environmental impact of printing ink and printing process. J. Graph. Eng. Des. 2020, 11, 11–17. [Google Scholar] [CrossRef]

- Yordanova, D.; Angelova, S.; Dombalov, I. Utilisation options for waste toner powder. Int. Sci. J. Environ. Sci. 2019, 8, 140–144. [Google Scholar]

- Nakadate, T.; Yamano, Y.; Yamauchi, T.; Okubo, S.; Nagashima, D. Assessing the chronic respiratory health risk associated with inhalation exposure to powdered toner for printing in actual working conditions: A cohort study on occupationally exposed workers over 10 years. BMJ Open 2018, 8, e022049. [Google Scholar] [CrossRef] [Green Version]

- Pirela, S.V.; Martin, J.; Bello, D.; Demokritou, P. Nanoparticle exposures from nano-enabled toner-based printing equipment and human health: State of science and future research needs. Crit. Rev. Toxicol. 2017, 47, 678–704. [Google Scholar] [CrossRef]

- Ahmadi, A.; Williamson, B.H.; Theis, T.L.; Powers, S.E. Life-cycle inventory of toners produced for xerographic processes. J. Clean. Prod. 2003, 11, 573–582. [Google Scholar] [CrossRef]

- Vasudevan, H.; Kalamkar, V.; Terkar, R. Remanufacturing for sustainable development: Key challenges, elements and benefits. Int. J. Innov. Manag. Technol. 2012, 3, 84–89. [Google Scholar]

- Bowe, B.; Xie, Y.; Gibson, A.K.; Cai, M.; van Donkelaar, A.; Martin, R.V.; Burnett, R.; Al-Aly, Z. Ambient fine particulate matter air pollution and risk of hospitalization among COVID-19 positive individuals: Cohort study. Environ. Int. 2021, 154, 106564. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Liu, J.; Li, Y.; Fu, S.; Xu, X.; Li, L.; Zhou, J.; Liu, X.; He, X.; Yan, J.; et al. Airborne particulate matter, population mobility and COVID-19: A multi-city study in China. BMC Public Health 2020, 20, 1585. [Google Scholar] [CrossRef]

- Kojima, M.; Yoshida, A.; Sasaki, S. Difficulties in applying extended producer responsibility policies in developing countries: Case studies in e-waste recycling in China and Thailand. J. Mater. Cycles Waste Manag. 2009, 11, 263–269. [Google Scholar] [CrossRef]

- Akenji, L.; Hotta, Y.; Bengtsson, M.; Hayashi, S. EPR policies for electronics in developing Asia: An adapted phase-in approach. Waste Manag. Res. 2011, 29, 919–930. [Google Scholar] [CrossRef]

- Fink, J.K. Chapter 20—Toners. In Plastics Design Library, Reactive Polymers Fundamentals and Applications, 2nd ed.; William Andrew Publishing: Norwich, NY, USA, 2013; pp. 475–481. [Google Scholar]

- Abdelbasir, S.M.; Hassan, S.S.M.; Kamel, A.H.; El-Nasr, R.S. Status of electronic waste recycling techniques: A review. Environ. Sci. Pollut. Res. 2018, 25, 16533–16547. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Fan, L.; Xie, H.; Wang, J. A study on explosion characteristics of toner powder. Adv. Mat. Res. 2012, 508, 122–126. [Google Scholar] [CrossRef]

- Tsatsis, D.E.; Valta, K.A.; Vlyssides, A.G.; Economides, D.G. Assessment of the impact of toner composition, printing processes and pulping conditions on the deinking of office waste paper. J. Environ. Chem. Eng. 2019, 7, 103258. [Google Scholar] [CrossRef]

- Ceballos, D.M.; Dong, Z. The formal electronic recycling industry: Challenges and opportunities in occupational and environmental health research. Environ. Int. 2016, 95, 157–166. [Google Scholar] [CrossRef] [Green Version]

- Ruan, J.; Qin, B.; Huang, J. Controlling measures of micro-plastic and nano pollutants: A short review of disposing waste toners. Environ. Int. 2018, 118, 92–96. [Google Scholar] [CrossRef]

- Chi, X.; Porte, M.-S.; Wang, M.Y.L.; Reuter, M.A. Informal electronic waste recycling: A sector review with special focus on China. Waste Manag. 2011, 31, 731–742. [Google Scholar] [CrossRef] [PubMed]

- Park, J.K.; Hoerning, L.; Watry, S.; Burgett, T.; Matthias, S. Effects of electronic waste on developing countries. Adv. Recycl. Waste Manag. 2017, 2, 1000128. [Google Scholar]

- Dijk, P. Can small countries benefit from the e-waste global value chain? Int. J. Waste Resour. 2016, 6, e110. [Google Scholar]

- Huo, X.; Peng, L.; Xu, X.; Zheng, L.; Qiu, B.; Qi, Z.; Zhang, B.; Han, D.; Piao, Z. Elevated blood lead levels of children in Guiyu, an electronic waste recycling town in China. Environ. Health Perspect. 2007, 115, 1113–1117. [Google Scholar] [CrossRef] [PubMed]

- Nakadate, T.; Yamano, Y.; Adachi, C.; Kikuchi, Y.; Nishiwaki, Y.; Nohara, M.; Satoh, T.; Omae, K. A cross sectional study of the respiratory health of workers handling printing toner dust. Occup. Environ. Med. 2006, 63, 244–249. [Google Scholar] [CrossRef] [PubMed]

- Konczol, M.; Weib, A.; Gminski, R.; Merfort, I.; Sundermann, V.-M. Oxidative stress and inflammatory response to printer toner particles in human epithelial A549 lung cells. Toxicol. Lett. 2013, 216, 171–180. [Google Scholar] [CrossRef] [PubMed]

- Leung, A.O.W. Environmental contamination and health effects due to e-waste recycling. In Electronic Waste Management and Treatment Technologies; Elsevier: Amsterdam, The Netherlands, 2019; Volume 15, pp. 335–362. [Google Scholar]

- Rajiv Ranjan, S.; Pathak, P. Policy issues for efficient management of e-waste in developing countries. In Handbook of Electronic Waste Management; Varaprasad, M.N., Vithanage, M., Borthakur, A., Eds.; Butterwoth-Heinemann: Oxford, UK, 2020; pp. 81–99. [Google Scholar]

- Pariatamby, A.; Fauziah, S.H. Sustainable 3R Practice in the Asia and Pacific Regions: The Challenges and Issues. In Municipal Solid Waste Management in Asia and the Pacific Islands, Environmental Science and Engineering; Pariatamby, A., Tanaka, M., Eds.; Springer: Singapore, 2014; pp. 15–40. [Google Scholar]

- Ramalingam, V.V. Synthesis of hybrid black toner from waste toner using nanotechnology-optimization technique. Int. J. Eng. Adv. Technol. 2014, 13, 204–213. [Google Scholar]

- Closed-Loop Recycling Makes Old Printer Cartridges New Again|Plastics Technology (ptonline.com). Available online: https://www8.hp.com/in/en/hp-information/recycling/ink-toner.html (accessed on 1 April 2021).

- Khaliq, A.; Rhamdhani, M.A.; Brooks, G.; Masood, S. Metal extraction processes for electronic waste and existing industrial routes: A review and Australian perspective. Resources 2014, 3, 152–179. [Google Scholar] [CrossRef] [Green Version]

- Gaikwad, V.; Kumar, U.; Pahlevani, F.; Piadasa, A.; Sahajwalla, V. Thermal transformation of waste toner powder into a value-added ferrous resource. ACS Sustain. Chem. Eng. 2017, 5, 11543–11550. [Google Scholar] [CrossRef]

- Kumar, U.; Gaikwad, V.; Sahajwalla, V. Transformation of waste toner to iron using E-waste plastics as a carbon resource. J. Clean. Prod. 2018, 192, 244–251. [Google Scholar] [CrossRef]

- Ruan, J.; Dong, L.; Huang, J.; Huang, Z.; Huang, K.; Dong, H.; Zhang, T.; Qiu, R. Vacuum-Gasification-Condensation of Waste Toner to Produce Industrial Chemicals and Nanomaterials. ACS Sustain. Chem. Eng. 2017, 5, 4923–4929. [Google Scholar] [CrossRef]

- Parthasarathy, M. Novel Carbon Material for Highly Efficient Waste Water Treatment and Procedures Thereof. Indian Patent #343663, 2 September 2013. [Google Scholar]

- Zhu, H.; Zhou, Y.; Wang, S.; Wu, X.; Hou, J.; Yin, W.; Feng, K.; Wang, X.; Yang, J. Preparation and application synthesis of magnetic nanocomposite using waste toner for the removal of Cr(VI). RSC Adv. 2018, 8, 27654. [Google Scholar] [CrossRef] [Green Version]

- Hammani, S.; Barhoum, A.; Nagarajan, S.; Bechelany, M. Toner waste powder (TWP) as a filler for polymer blends (LDPE/HIPS) for enhanced electrical conductivity. Materials 2019, 12, 3062. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Mao, J.; Xie, H.; Li, J. Heat-treatment recycling of waste toner and its applications in lithium ion batteries. J. Mater. Cycles Waste Manag. 2018, 20, 361–368. [Google Scholar] [CrossRef]

- Kaipannan, S.; Govindarajan, K.; Sundaramoorthy, S.; Marappan, S. Waste toner-derived carbon/Fe3O4 nanocomposite for high-performance supercapacitor. ACS Omega 2019, 4, 15798–15805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Notani, M.A.; Nejad, F.M.; Fini, E.H.; Asce, M.; Hajikarimi, P. Low-temperature performance of toner-modified asphalt binder. J. Trans. Eng. Part B Pavements 2019, 145, 04019022. [Google Scholar] [CrossRef]

- APM Paves Parking Lot Using Mix with Toner Additive. The Tris and ITRD Database. 2016. Available online: https://trid.trb.org/view/1441988 (accessed on 31 March 2021).

- Notani, M.A.; Hajikarimi, P.; Nejad, F.M.; Khodaii, A. Performance evaluation of waste toner in bituminous material by focusing on aging and moisture susceptibility. J. Mater. Civ. Eng. 2021, 33, 040200405. [Google Scholar] [CrossRef]

- Melnjak, I.; Vicinic, A.A.; Radetic, L.; Grcic, I. Waste toner powder in concrete industry: An approach towards circular economy. Environ. Eng. Manag. J. 2019, 9, 1897–1906. [Google Scholar] [CrossRef]

- Habib, H.; Atassi, Y.; Salloum, A. An eco-friendly, cost-effective, lightweight microwave absorber based on waste toner. J. Electron Mater. 2021, 50, 2049–2056. [Google Scholar] [CrossRef]

- Bhongade, T.; Deepak, M.; Gautam, G.; Vijayakumar, R.P. Synthesis of MWCNTs using waste toner powder as carbon source by chemical vapor deposition method. Fuller. Nanotub. Carbon Nanostruct. 2019, 27, 864–872. [Google Scholar] [CrossRef]

- Xu, Q.; Gong, Y.; Zhang, Z.; Miao, Y.; Li, D.; Yan, G. Preparation of graphene oxide quantum dots from waste toner, and their application to a fluorometric DNA hybridization assay. Microchim. Acta 2019, 186, 483. [Google Scholar] [CrossRef] [PubMed]

- Alabi, O.A.; Bakare, A.A. Electronic waste induced DNA damage: A review. In Landfills: Environmental Impacts, Assessment and Management; Chandler, N., Ed.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2017. [Google Scholar]

- Arjunan, P.; Kouthaman, M.; Kannan, K.; Diwakar, K.; Priyanka, V.; Subadevi, R.; Sivakumar, M. Study on efficient electrode from electronic waste renewed carbon material for sodium battery applications. J. Environ. Chem. Eng. 2021, 9, 105024. [Google Scholar] [CrossRef]

- Yildirim, Y.; Hazlett, D.; Davio, R. Toner–modified asphalt demonstration projects. Resour. Conserv. Recycl. 2004, 42, 295–308. [Google Scholar] [CrossRef]

- Huang, J.; Shiva Kumar, G.; Sun, Y. Evaluation of workability and mechanical properties of asphalt binder and mixture modified with waste toner. Constr. Build Mater. 2021, 276, 122230. [Google Scholar] [CrossRef]

- Bousquin, J.; Gambeta, E.; Esterman, M.; Rothenberg, S. Life cycle assessment in the print industry. J. Ind. Ecol. 2012, 16, S195–S205. [Google Scholar] [CrossRef]

- Reinvent Print Sustainability: News of the Day, 19 June 2019. Available online: https://press.hp.com/content/dam/hpi/press/press-kits/2019/anchored-in-sustainable-impact/Reinvent-Print-Sustainability_June-2019.pdf (accessed on 3 April 2021).

- Anastas, P.T.; Warner, J.C. Green Chemistry: Theory and Practice; Oxford University Press: New York, NY, USA, 1998. [Google Scholar]

- Lee, E.; Kmieck-Lawrynowicz, G.; LaMora, K. Emulsion Aggregation Toner Compositions. U.S. Patent US7279261B2, 9 October 2007. [Google Scholar]

- New Eco-Friendly Toner from KYOCERA. Available online: https://www.kyoceradocumentsolutions.com/products/concept/new_toner/pdf/new_toner.pdf (accessed on 4 April 2021).

- Recycling the Rare-Earth Metals of e-Waste. Available online: https://greenchemistry.yale.edu/news/recycling-rare-earth-metals-e-waste (accessed on 4 April 2021).

| Country | Specific or Draft Legislation |

|---|---|

| China | Rules on the administration of the recovery and disposal of discarded electrical and electronic products (promulgated in 2009, effective in 2011) |

| India | E-waste management and handling rules (2016) |

| Indonesia | Specific article on EPR is under preparation under Solid Waste Management Act 2008 |

| Malaysia | Specific article on take-back and deposit refund in Solid Waste and Public Cleansing Management Act 2007. Draft regulation on recycling and disposal of End-of-Life electrical and electronic equipment. |

| Thailand | WEEE Strategic Plan 2007 and Draft Act on Economic Instruments for Environmental Management (under development) |

| Vietnam | Draft regulations on the reclamation and treatment processes for disposal products (under planning; draft released in 2010) |

| Component | Percentage (%) |

|---|---|

| Polymers | 45 |

| Fe3O4 | 25 |

| Carbon black | 20 |

| Additives | 5 |

| Wax | 3 |

| Cellulose/Kaolin | 1 |

| Surfactants | 1 |

| Property of Waste Toner | Emerging Applications | Reference |

|---|---|---|

| Composition | Recovery of pure iron and iron oxides, nanomaterial synthesis | [9,37,39,41] |

| Viscosity | Filler for rubbers | [10] |

| Adsorptive capacity | Wastewater treatment | [40,41] |

| Electrical conductivity | Conducting polymer blends | [42] |

| Charge storage capacity | Power generation/storage devices | [43,44] |

| Mechanical strength | Building construction | [45,46,47,48] |

| Thermal conductivity | Microwave absorbing composites | [49] |

| Waste/Material | Without Recycling (kg/mton) | With Recycling (kg/mton) | Percent Reduction |

|---|---|---|---|

| Solid waste produced in the lifecycle | 1020 | 780 | 24% |

| Virgin materials used in toner lifecycle | 2530 | 1790 | 29% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parthasarathy, M. Challenges and Emerging Trends in Toner Waste Recycling: A Review. Recycling 2021, 6, 57. https://doi.org/10.3390/recycling6030057

Parthasarathy M. Challenges and Emerging Trends in Toner Waste Recycling: A Review. Recycling. 2021; 6(3):57. https://doi.org/10.3390/recycling6030057

Chicago/Turabian StyleParthasarathy, Meera. 2021. "Challenges and Emerging Trends in Toner Waste Recycling: A Review" Recycling 6, no. 3: 57. https://doi.org/10.3390/recycling6030057

APA StyleParthasarathy, M. (2021). Challenges and Emerging Trends in Toner Waste Recycling: A Review. Recycling, 6(3), 57. https://doi.org/10.3390/recycling6030057