1. Introduction

Concrete has been one of the most widely used materials in the construction industry since it was invented by ancient Romans [

1]. The need for the construction of infrastructure requires large amounts of investment and natural resources, and yields a huge amount of negative environmental impacts [

2]. Romans were the first civilization that showed interest in producing lightweight concrete [

3]. They investigated the properties of volcanic minerals for the first time to use them in construction [

4] and, therefore, produced a concrete mixture with reduced weight [

3,

4,

5,

6,

7]. The objective was to enhance construction techniques and subsequently, to succeed in achieving a more efficient construction work.

A vast amount of waste ends up in junkyards; hence, waste management systems are currently being put in place to cope with this environmental issue [

8,

9]. Over the last decades, environmental concerns related to climate change have been forcing every industrial sector to review their industrial processes to reduce the waste they produce [

8]. The need for a more sustainable construction industry is now of general concern and the industry is being urged to work towards this objective. The improvements in this area are being supported by research into new systems of managing waste in a more sustainable way [

10]. These facts indicate that numerous research studies have been required over the last few years and are currently being implemented to find out new ways of producing more efficient and modern construction materials [

10,

11,

12]. Applications of concrete, wood and rubber materials in machine foundations have extensively been discussed in the literature recently.

Wooden materials are extensively used within construction and in many other industries. These processes imply the rejection of a significant amount of timber and the production of considerable surplus of wood. The rejected timber and the surplus end up being waste in different forms including wood shavings, wood dust or spare cuts amongst others.

The renowned acoustic and thermal properties of wood make it a suitable material to incorporate into new sustainable construction materials [

13]. The low density and high porosity of wood also make it an ideal material to develop lightweight construction products. The authors in [

14] focused on the development of new lightweight materials, finding recycled timber waste to be an appropriate material to incorporate within the composition of construction materials. Its light nature is an important property of the wood to study in relation to the development of new lightweight construction products.

Wood waste may be manipulated to meet the requirements of a certain material such as concrete. Given the versatility of wood waste, it may be used for a large range of different purposes. The above means that, depending on the forms that it is presented, sawdust, wood chips or pellets or others, timber may be used as coarse or fine aggregate when used within the composition of concrete products [

15].

In summary, the previous work confirms that, in general, the characteristic of wood makes it a feasible material to be combined into sustainable construction products, and specifically, an excellent candidate to be incorporated into lightweight concrete [

13,

15].

The possibility of making stronger concretes, introducing rubber as an aggregate, has also been extensively investigated [

16,

17,

18,

19,

20]. Different types of tires have been utilized for partially replacing the natural aggregates in the concrete mixes. For instance, scrap tires obtained by simple grinding with no further purifications (containing steel and textile fibers in their composition); crumb rubber produced by the cryogenic process; milled tire rubber treated with sodium hydroxide solution to accomplish better adhesion of the rubber with the cement paste; and scrap truck tire rubber have also been investigated [

16].

Previous research obtained rubberized concrete that showed a behavior that generally did not achieve a suitable compressive strength for structural applications. However, these attempts were not satisfactory because the technology used to traditionally produce these concretes was deficient [

16]. Nevertheless, the authors in [

16] detailed a pattern showing that the compressive strength of the mixtures decreased as the amount of rubber in the mixture increased. Nowadays, tire rubber waste is being used in paving materials, for example. However, this use only allows a certain portion of the waste generated to be recycled [

19].

Most of the available literature showed the impacts of improving the mechanical (strength, stiffness, and natural frequency) characteristics of concrete by using additions such as wood or rubber. Not much research, however, pointed to the impacts on natural frequencies in applications related to machinery foundations. Natural frequency has a great impact on the potential applications of the recycled concrete. The natural frequency of the recycled concrete is less tested in the literature.

In this paper, we investigate the mechanical properties of two different types of recycled concrete (that use wood and rubber) relative to those characteristics of pure concrete, in terms of maximum load and natural frequencies of the two products.

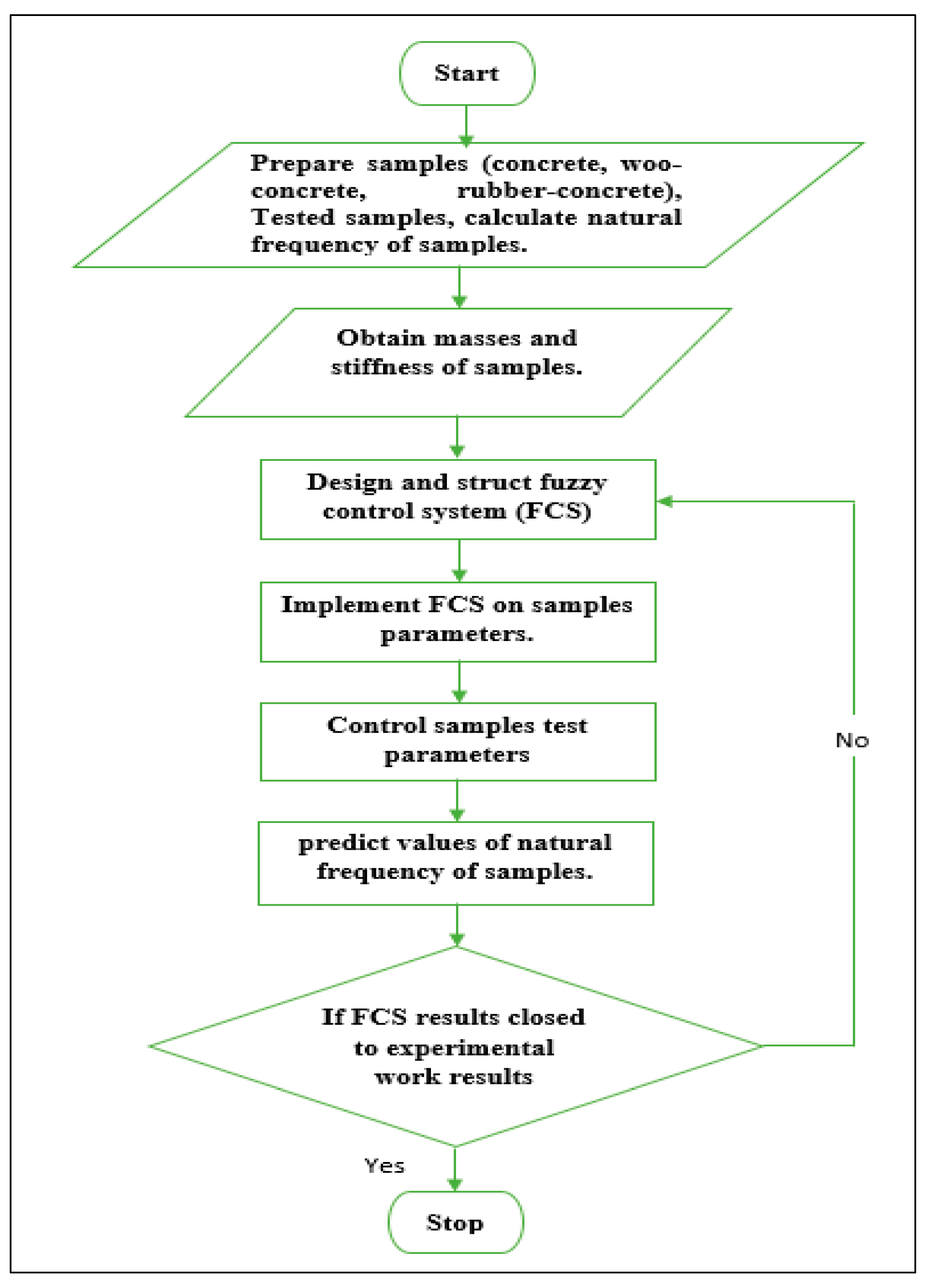

The paper is structured as follows.

Section 2 presents the methodology adopted in the paper to compare the two types of composite concrete mixtures. Experimental lab testing procedures and results are presented in

Section 3. A fuzzy logic control system was designed and implemented using the sample’s data to determine and predict the natural frequency values of the samples, as is presented in

Section 4. Discussion of the results is presented in

Section 5, while conclusions and recommendations are presented in

Section 6.

3. Experimental Lab Testing

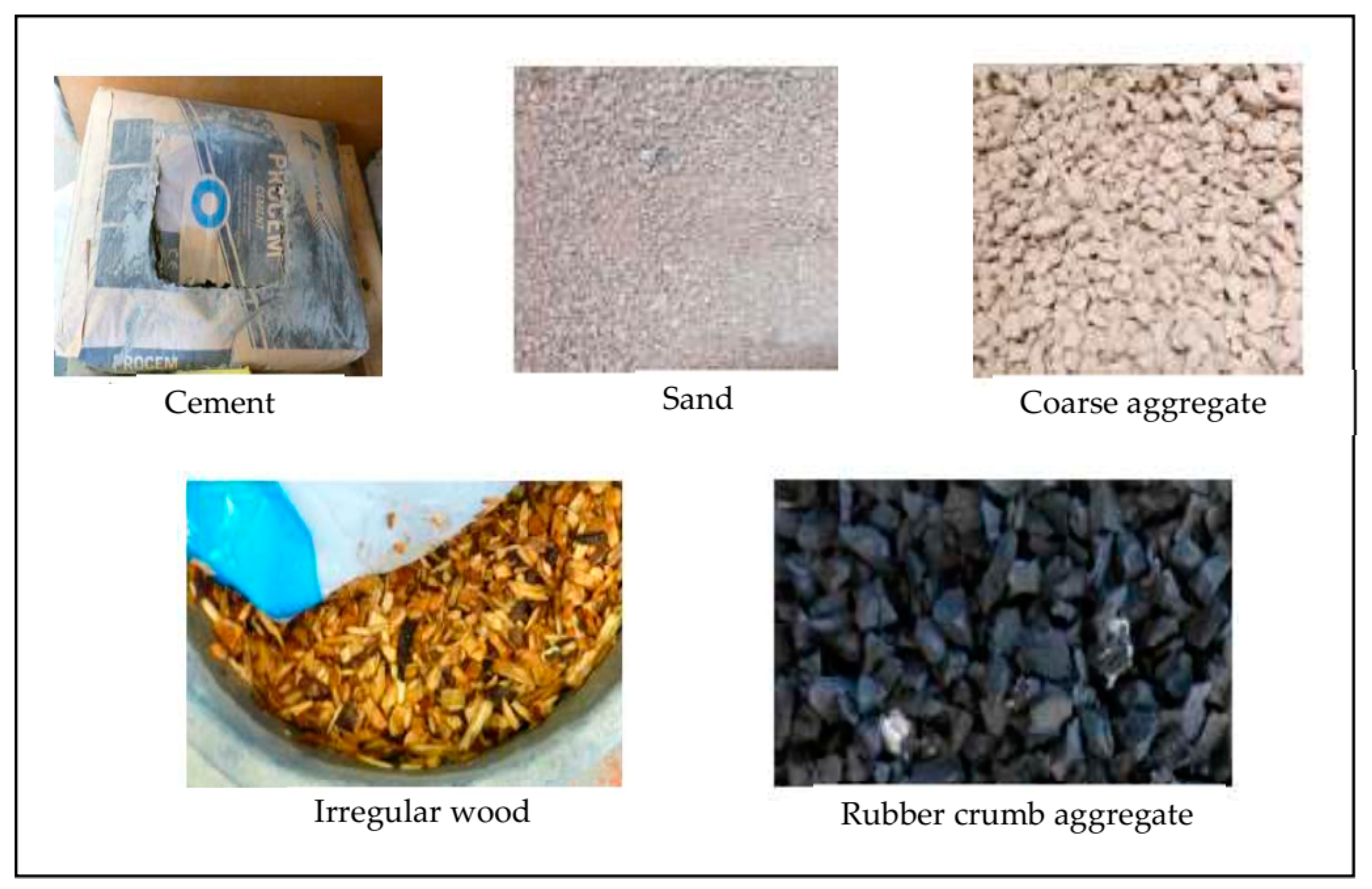

The materials that were used to prepare the concrete samples tested in the present paper were cement, aggregate, wood, and rubber, as shown in

Figure 2. The used cement was CEM I 52.5N compressive strength, medium size sand, coarse aggregate, irregular wood chips, and rubber crumbs.

It should be noted here that most concrete structures present damping; considering that the method discussed in this paper is based on natural frequencies and modes of vibration, there could be an influence of damping. In this case, we have not considered damping as it is quite complex to determine and varies with many factors such as adding any structural material, the temperature and moisture in air. For the structures mentioned in our work, the damping values have been taken to be between 0.2 and 0.7 (under-damped). This is an area for further investigation, however.

3.1. Samples’ Characteristics

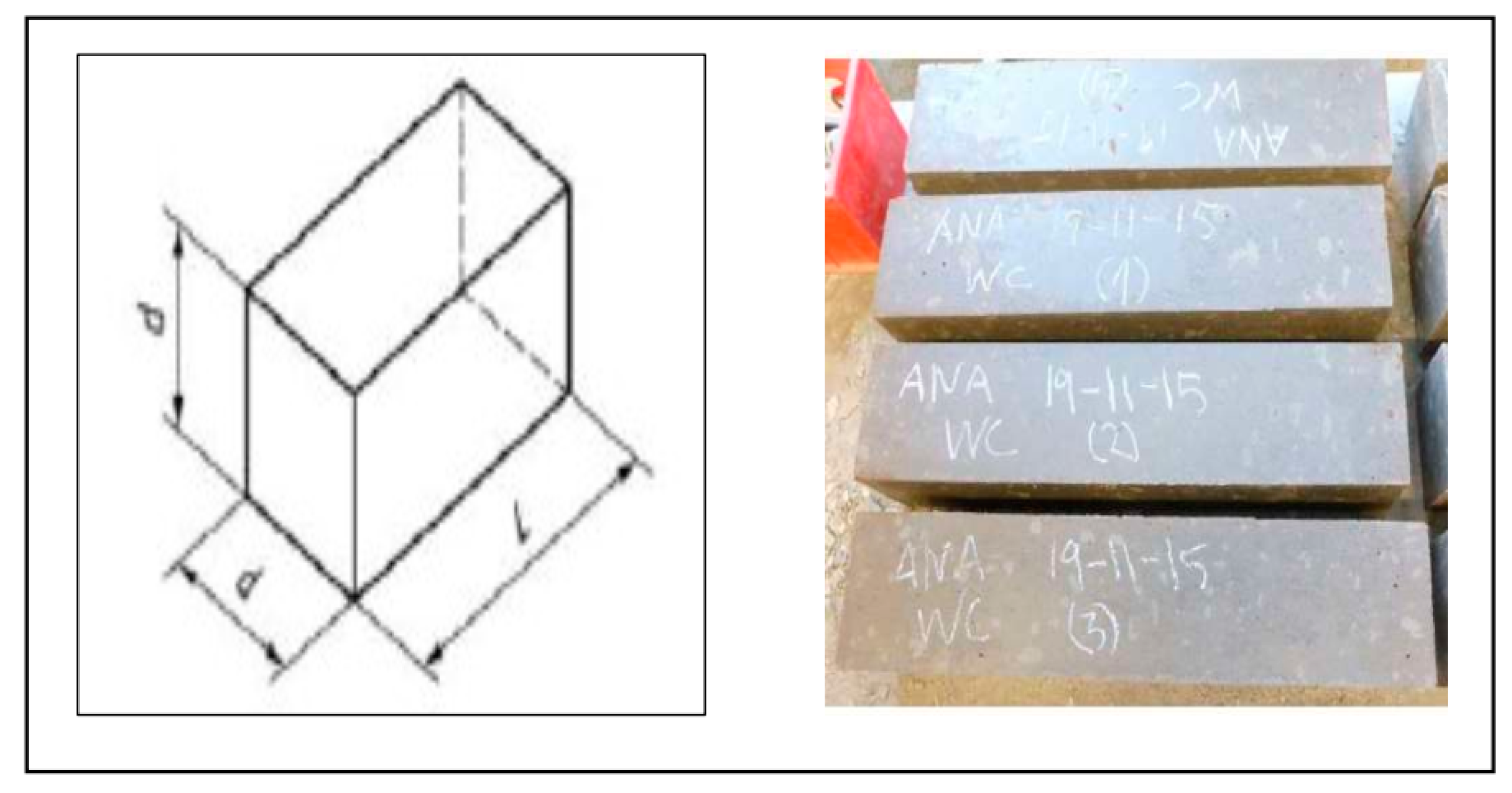

The tested samples were prepared as beam shapes of 100 × 100 × 500 mm dimensions, as shown in

Figure 3. There were three categories of samples: pure concrete (100% concrete mix), concrete with 15% wood mixture, and concrete with 15% rubber mixture. The samples were limited to 15% mixture due to limited lab time availability because of COVID-19 restrictions. Ideally, three or more sample mixes could have been used. However, this is suggested for further future work.

Five samples were prepared for each category. These samples only differed in terms of maximum load applied.

Table 1 shows the implementation of different loads, and the deflection appeared in the beams with each material used.

3.2. Testing Procedures

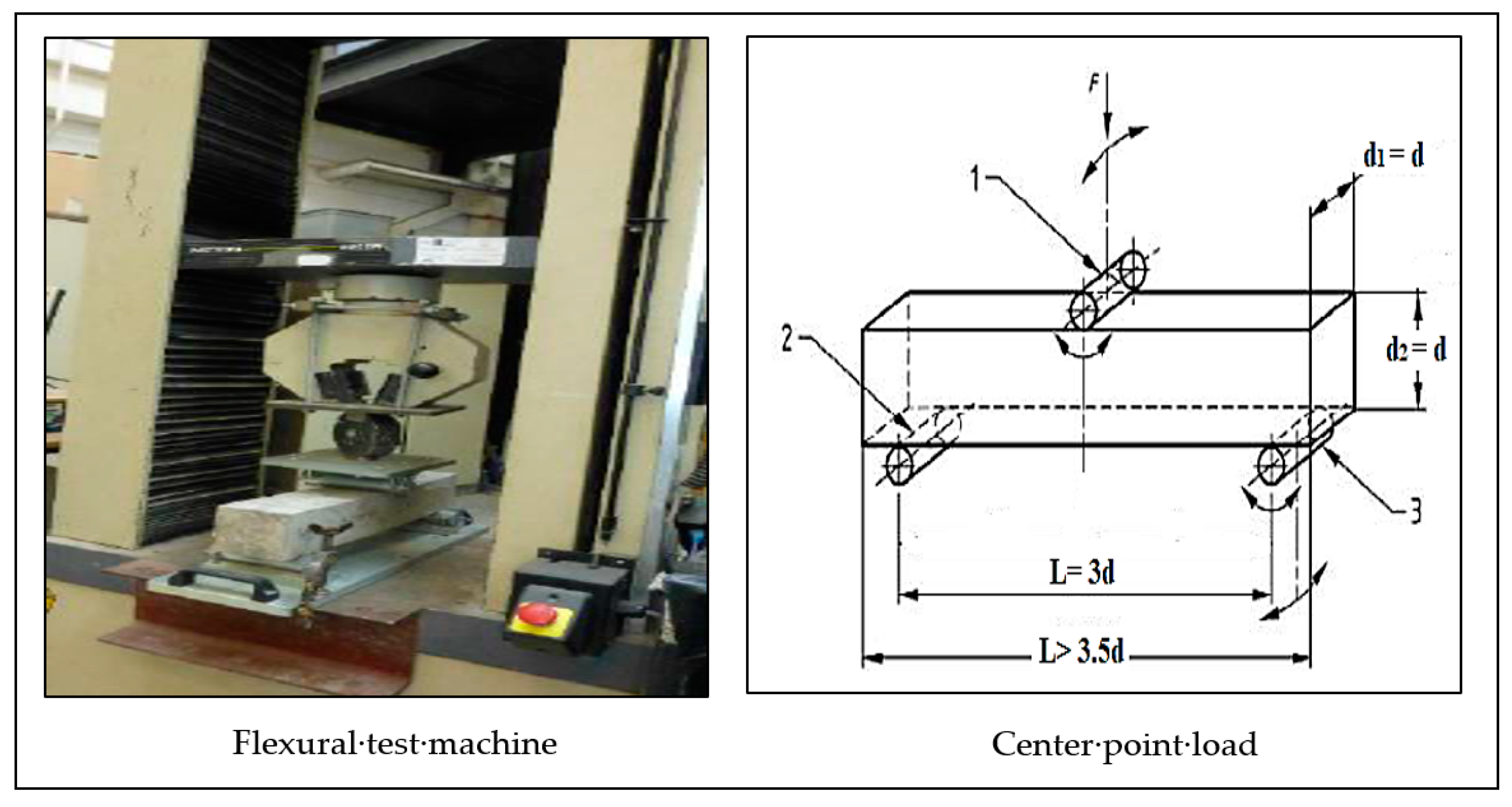

A flexural test machine was used for flexural testing of the prepared concrete samples, as shown in

Figure 4. The samples were pure concrete, concrete with 15% volume of wood mixture, and concrete with 15% volume of rubber mixture. The flexural strength of the samples was obtained from a center-point loading test. The flexural strength

fct was calculated using the formula:

where:

F = maximum load in Newton;

I = distance between the supporting rollers in mm;

d1 and d2 = lateral dimensions of the cross sections in mm.

4. Testing Results

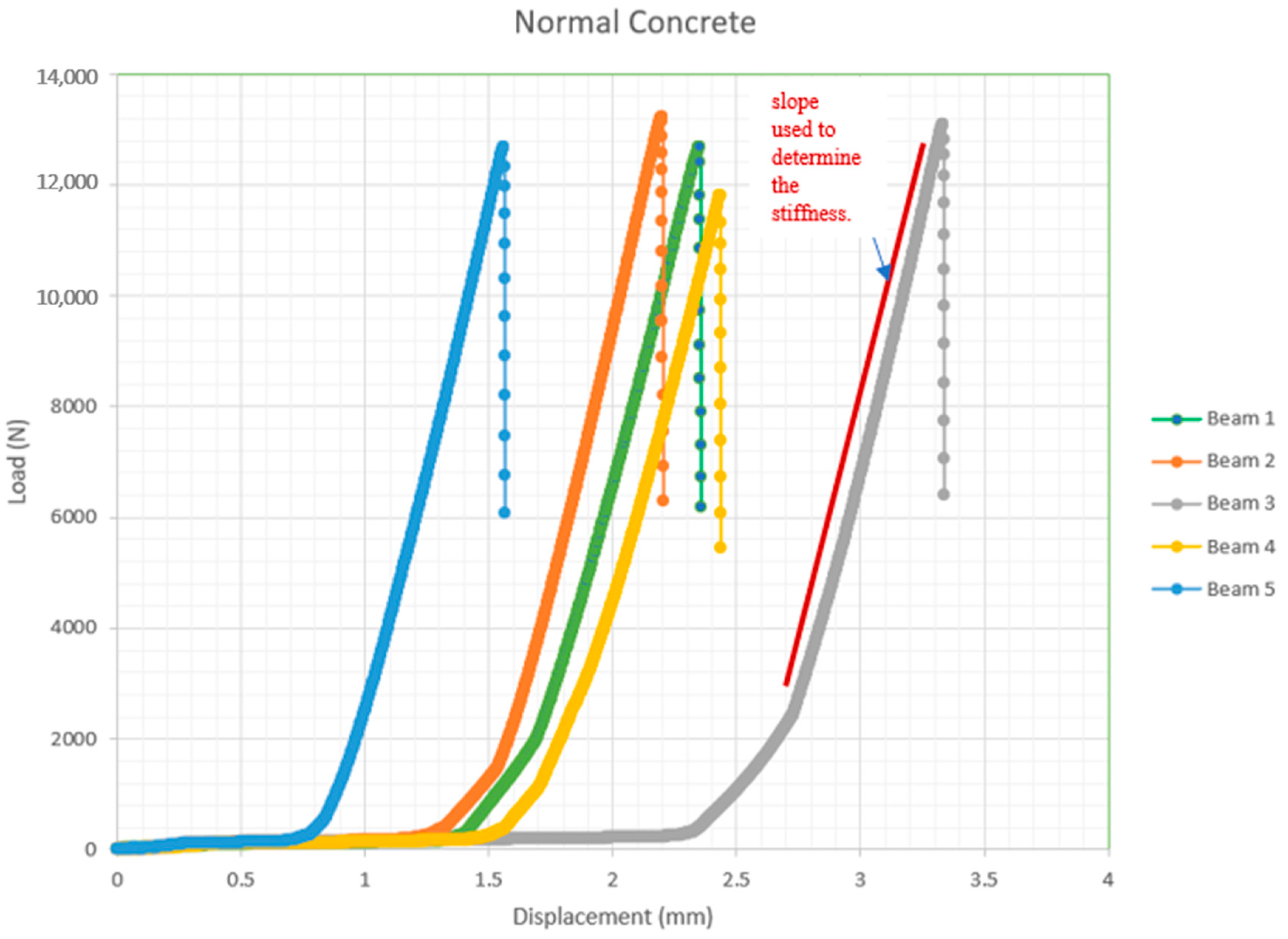

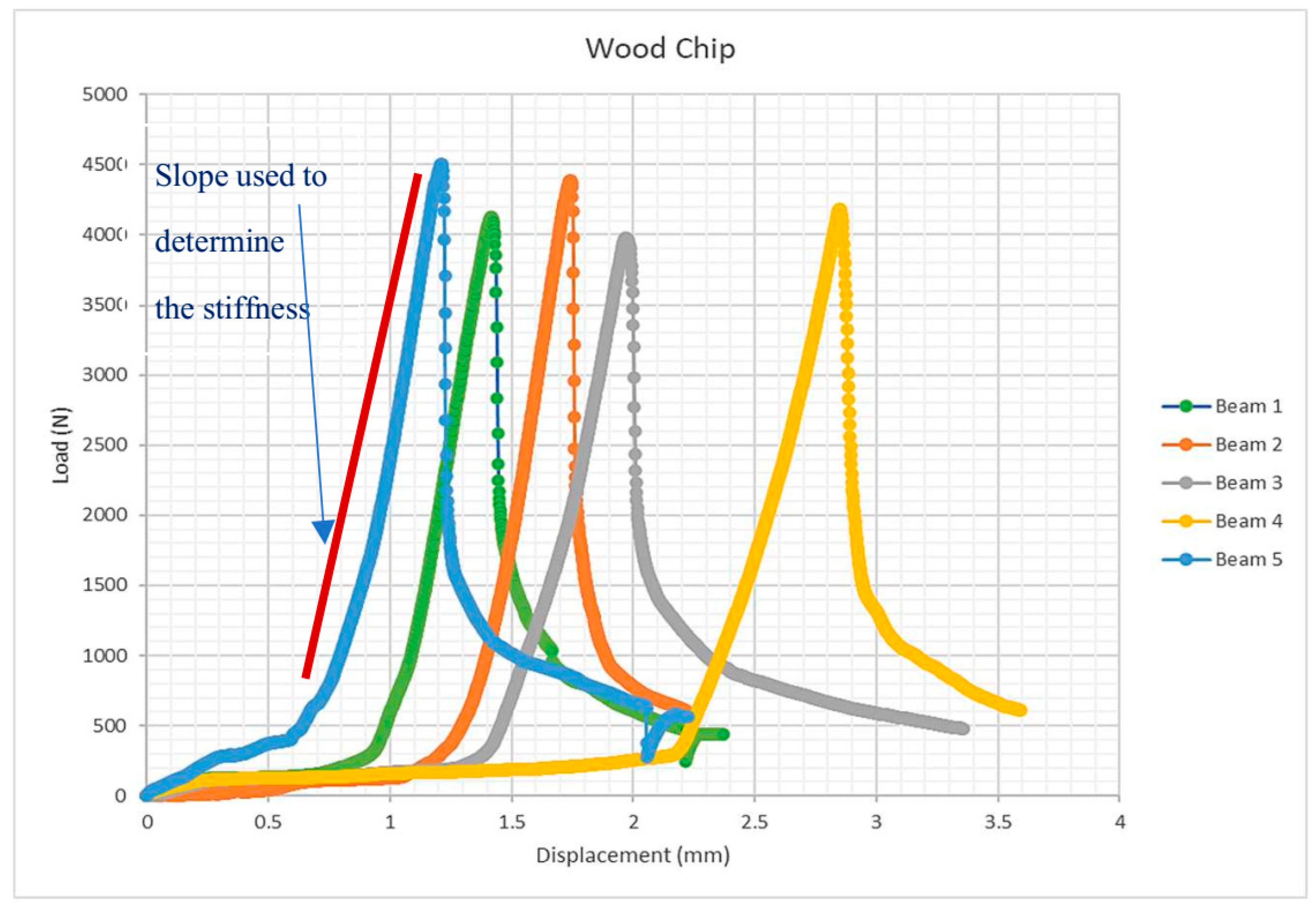

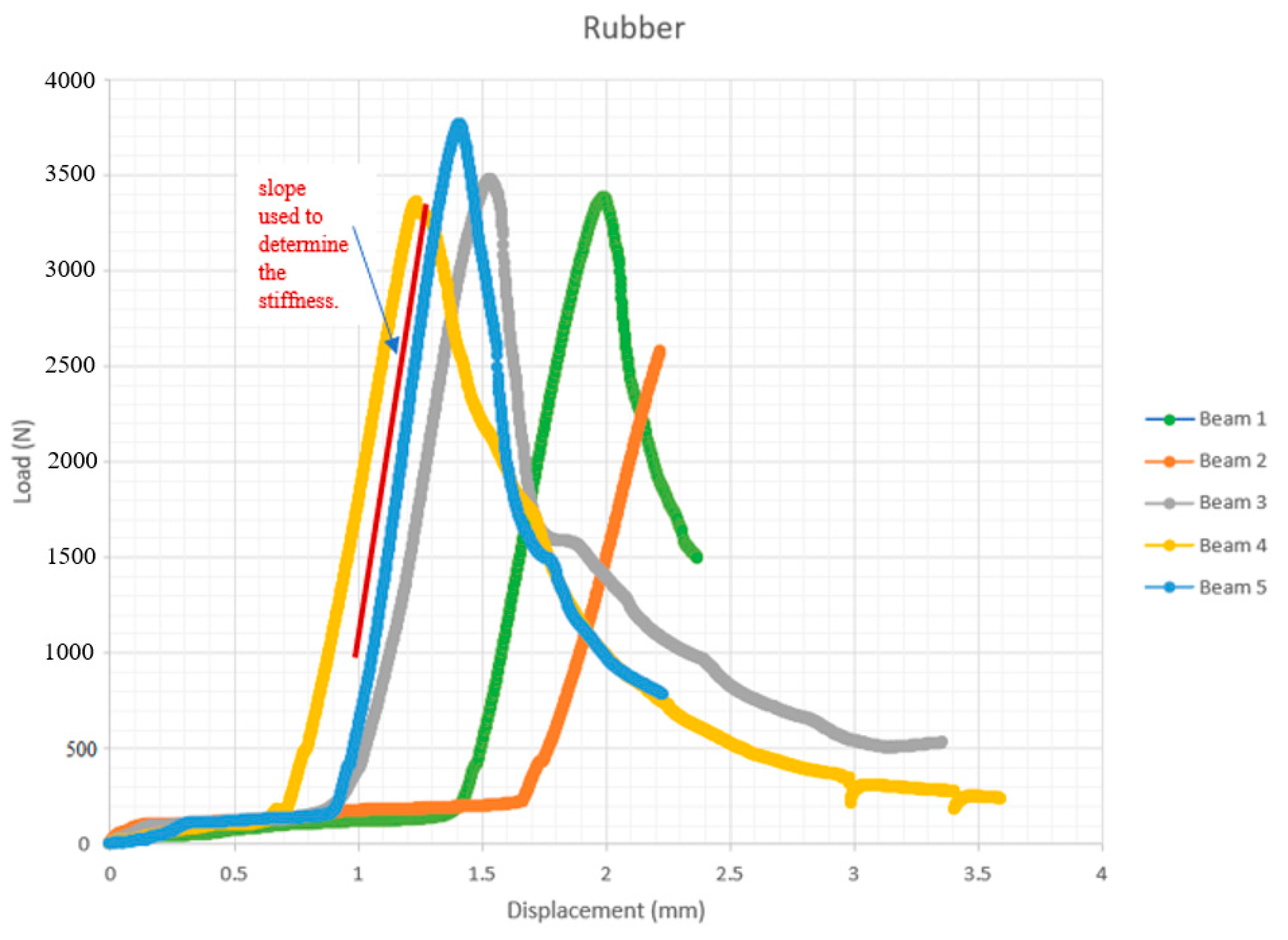

The data of the center-point flexural tests were used to plot graphs that represent the characteristics of the samples. A load–displacement graph for the pure concrete samples is presented in

Figure 5. Graphs for samples of concrete with 15% wood mixture and concrete with 15% rubber mixture are presented in

Figure 6 and

Figure 7, respectively. There is no specific standard method that is available to determine the stiffness. The method employed in this work is based on the linear behavior of the material. An analysis was conducted between the applied load and relative displacement within the linear elasticity of the material. A regression analysis was carried out to determine the stiffness of the material.

Stiffness

K of the samples was calculated using the load–displacement graphs. The samples were also weighted before testing them to obtain the mass

M. The values of the natural frequencies (

f) were calculated using the formula:

The mass, stiffness, and natural frequencies for normal concrete, concrete with 15% wood mixture, and concrete 15% rubber mixture samples are presented in

Table 2,

Table 3 and

Table 4, respectively.

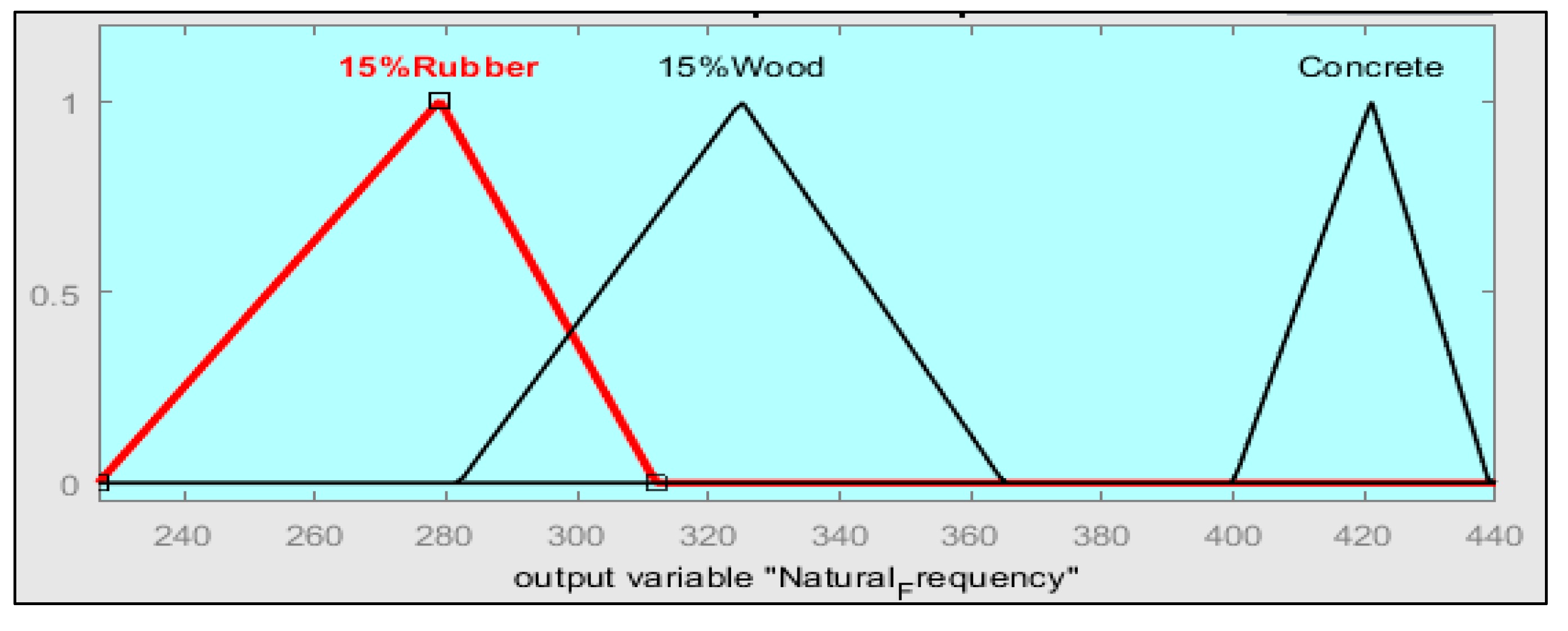

From the above results, it seems that the overall weight of the pure concrete samples was heavier than the weight of the samples with wood and with rubber (2.36 (SD 0.0118), 1.87 (SD 0.037) and 2.24 (SD 0.042)), respectively. The stiffness was also highest for the pure concrete as well as the natural frequency, which was also highest with the pure concrete compared to the other two samples (422 (SD 15.63), 323 (SD 37.3) and 275 (SD 29.78)).

5. Fuzzy Logic Control System (FLCS)

The fuzzy logic control system analyzes analog input values in terms of 1 (true) or 0 (false) distinct values. Fuzzy set group objects are smoothly based on membership to make approximation models useful [

20]. The fuzzy logic scheme is based on the idea of assigning outputs based on the input state’s probability. Following that, If–Then rules are used to build FLCS because they are the most powerful [

21,

22].

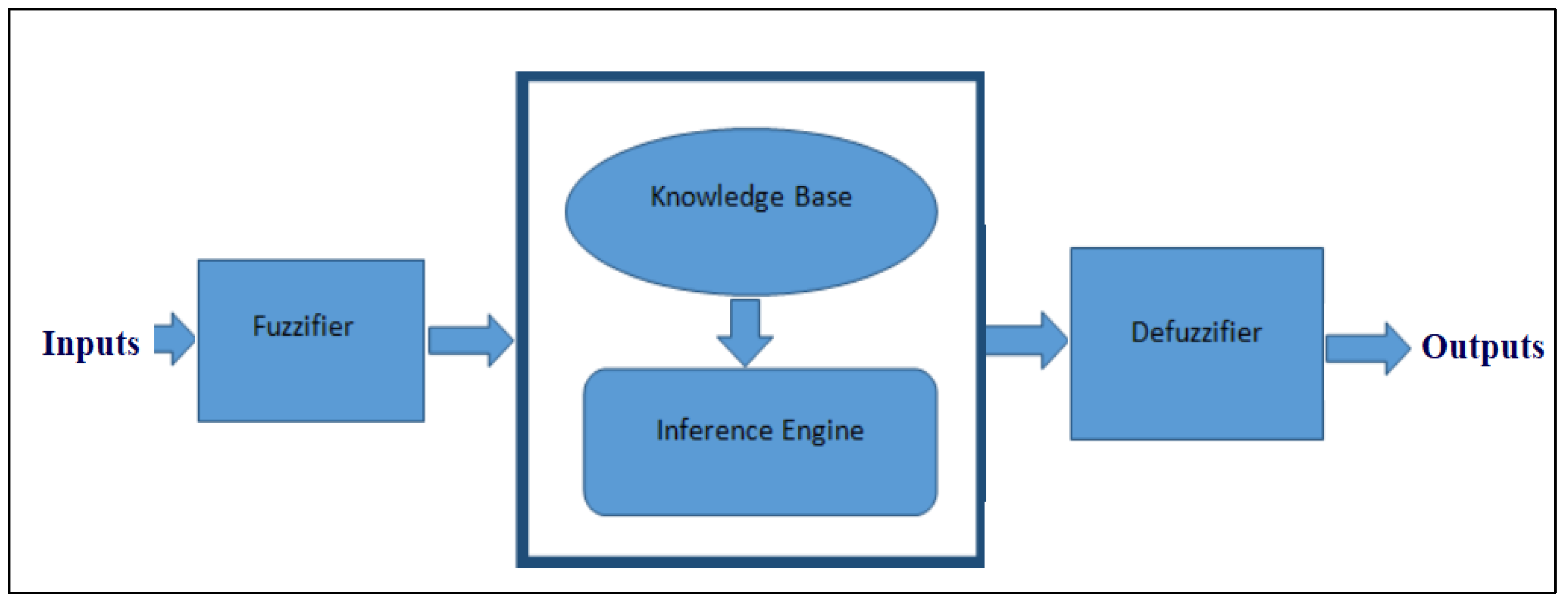

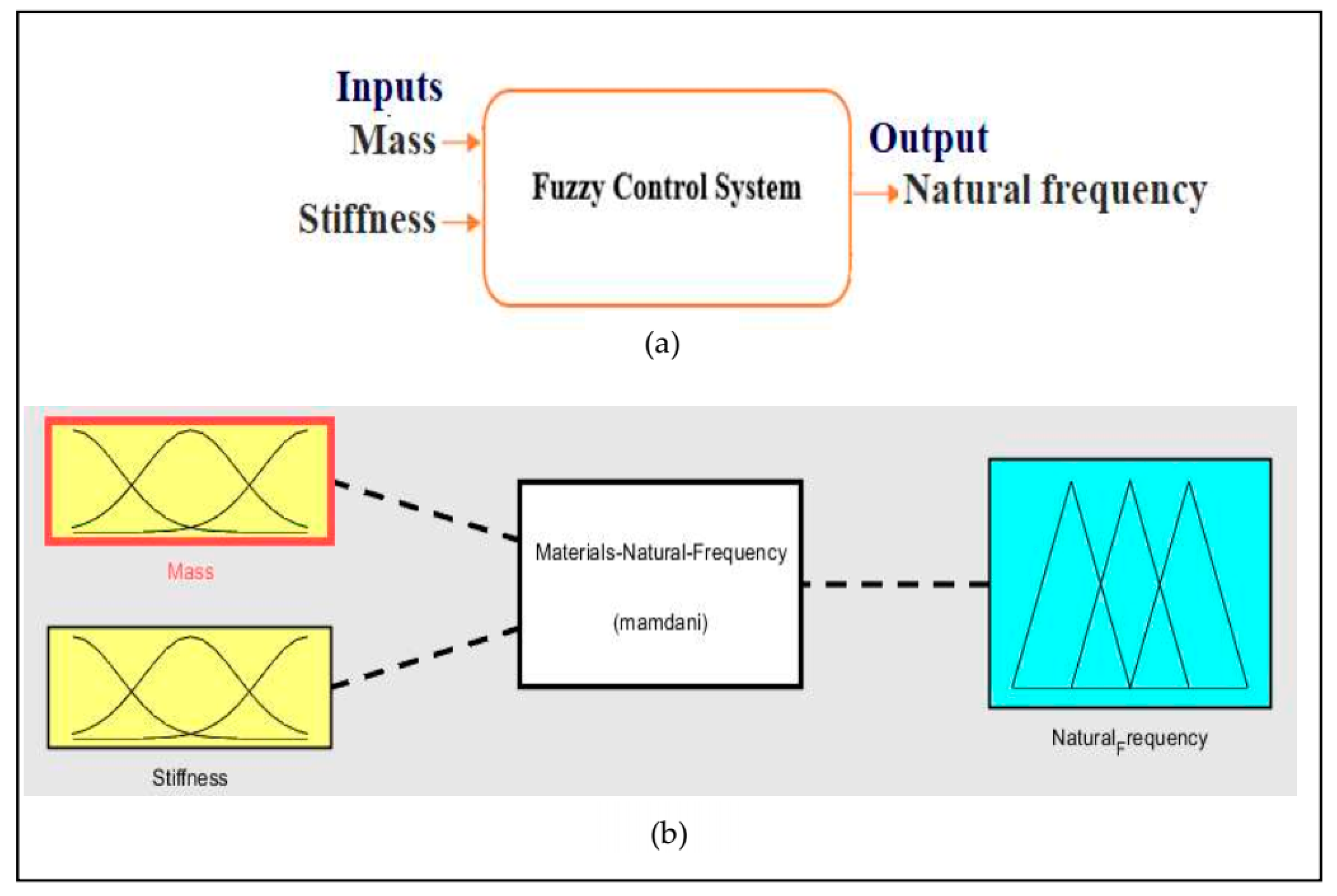

5.1. Structure of Fuzzy Logic Control System

The fuzzifier, knowledge base, fuzzy rule base, and defuzzifier are shown in

Figure 8 as the main components of a fuzzy controller for any managed device.

The fuzzy controller’s fuzzification stage includes the knowledge base and the inference engine stages. It transforms crisp input values to fuzzy values. For each of the inputs and outputs, information about fuzzy relationships is stored in the form of membership functions [

23]. The knowledge base component stores information on the membership functions and on the fuzzy rules. This information is typically provided or obtained by knowledge of the system’s operation from the surroundings or the environment. The inference engine accomplishes the process of obtaining information on the membership functions and fuzzy rules. In other words, the inference engine uses linguistic information and accordingly assigns outputs [

24], as it conducts approximate reasoning. The final step in the fuzzy controller method is defuzzification, which entails using a defuzzifier to transform the fuzzy inference engine’s fuzzy values into new values [

25]. The fuzzy logic toolbox in MATLAB [

26] is used to design and implement the Fuzzy System of Human Balancing Test.

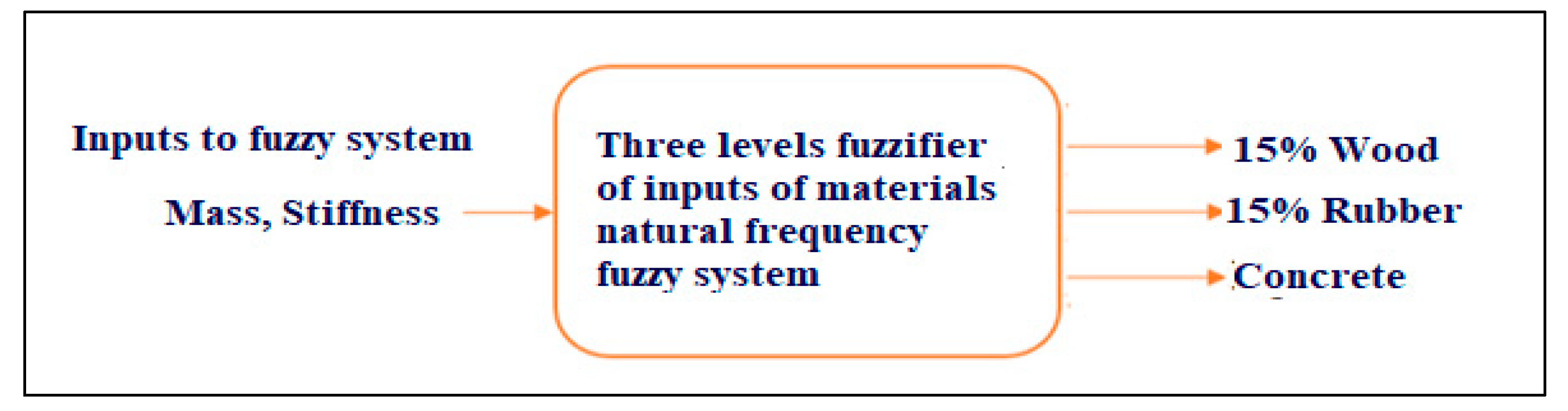

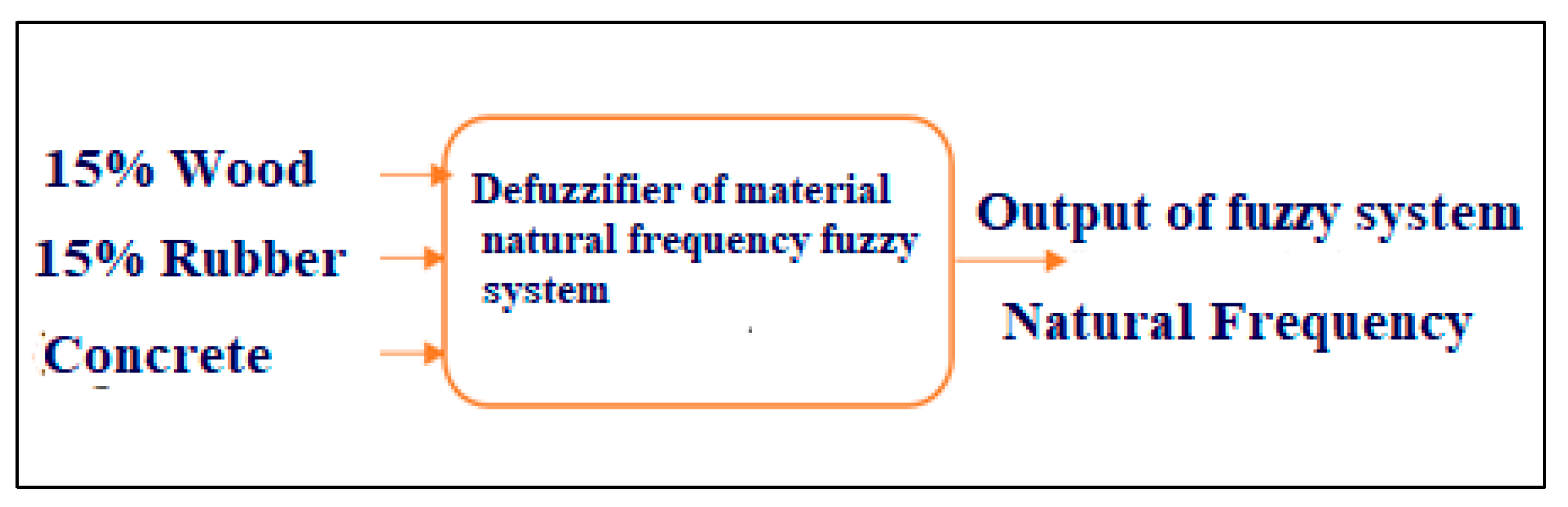

A fuzzy logic control system with two inputs and one output is designed to implement the characteristics of the three samples of concrete (pure concrete, 15% wood–concrete, and 15% rubber–concrete). The system is designed to optimize the values of natural frequency in each sample. The structure of the material’s natural frequency fuzzy system is designed using two inputs and one output. The two inputs are mass and stiffness, and the output is the natural material natural frequency, as shown in

Figure 9. The range values used in this system are: for pure concrete, the mass ranges are 2.29–2.4 Kg; for the concrete with wood, the value ranges are 1.70–1.95 Kg; and finally, for the concrete with rubber, the value ranges are 2–2.27 Kg (as well be further discussed later). Similarly, for the stiffness calculations, the range values that are used are 150–178, 0–79 and 59–90 N/m, respectively, for pure concrete, concrete with wood and concrete with rubber samples; see also Figure 12.

Fuzzy Logic System for Natural Frequency

The fuzzy control system to calculate the natural frequency of the three materials is explained here. The fuzzy system controls the natural frequency of the three types of concrete, taking into account the mass and the stiffness of the samples.

Step 1: The first step would involve defining linguistic variables and terms. For the inputs, the variables are as given below:

Mass of sample: {1.70–1.95, 2.00–2.27, 2.29–2.40};

Stiffness: {00.00–79.00, 59.00–90.00, 150–178}.

The output is the natural frequency of the concrete.

Step 2: The second step involves the construction of membership functions. See discussions in

Section 5.2 below.

Step 3: The third step involves developing a set of rules for the knowledge base. Given below are the set of rules using If–Then Rules:

| Fuzzy Rules (IF-THEN rules)—Relationship Between Inputs and Output |

| If (Mass (Kg) is Concrete) and (Stiffness(N/m) is Concrete) then (Natural-Frequency (Hz) is Concrete) |

| If (Mass (Kg) is 15% Wood) and (Stiffness(N/m) is 15%Wood) then (Natural-Frequency (Hz) is 15%Wood) |

| If (Mass (Kg) is 15% Rubber) and (Stiffness(N/m) is 15%Rubber) then (Natural-Frequency (Hz) is 15%Rubber) |

| If (Mass (Kg) is Concrete) and (Stiffness(N/m) is 15%Rubber) then (Natural-Frequency (Hz) is Concrete |

| If (Mass (Kg) is 15% Rubber) and (Stiffness(N/m) is 15%Rubber) then (Natural-Frequency (Hz) is 15%Rubber) |

| If (Mass (Kg) is Concrete) and (Stiffness(N/m) is 15%Rubber) then (Natural-Frequency (Hz) is Concrete |

Step 4: The fuzzifier, which initially had converted the sensor inputs to these variables, now applies the above rules to perform the fuzzy set operations to determine the output fuzzy functions. Based upon the output fuzzy sets, the membership function is developed.

Step 5: The final step is the defuzzification step where the defuzzifier uses the output membership functions to determine the output; that is the natural frequency.

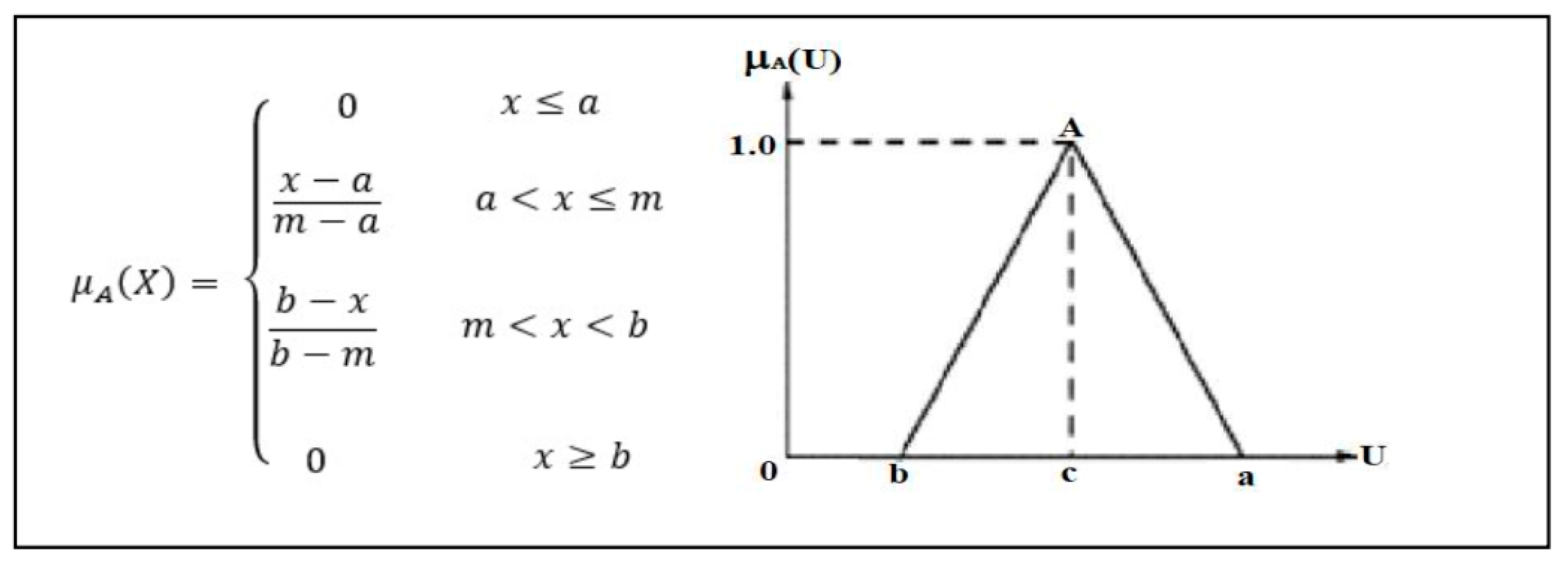

5.2. Inputs and Outputs Membership Function

The membership function of a fuzzy set is a generalization of the classical set’s indicator function. This is a graphically fuzzy set representation (

A) for debate

(X) as a triangular membership function

µA, which is specified by the three parameters a, b and c. These represent the x coordinates of the three vertices in a fuzzy set

A (b—lower boundary, a—upper boundary, where the membership degree is zero; c—the center, where the membership degree is 1), as presented by the equation

µA:X → [0,1], which means the value between 0 and 1 is mapped to (

X). The debate universe is defined by the (

x) axis, and the degree of membership in the [0,1] set is represented by the (

y) axis.

Figure 10 depicts the triangular membership function’s mathematical form, with a and b representing the lower and upper limits, respectively [

27]. Graphs that show the membership functions for the two inputs are presented in

Figure 10,

Figure 11 and

Figure 12.

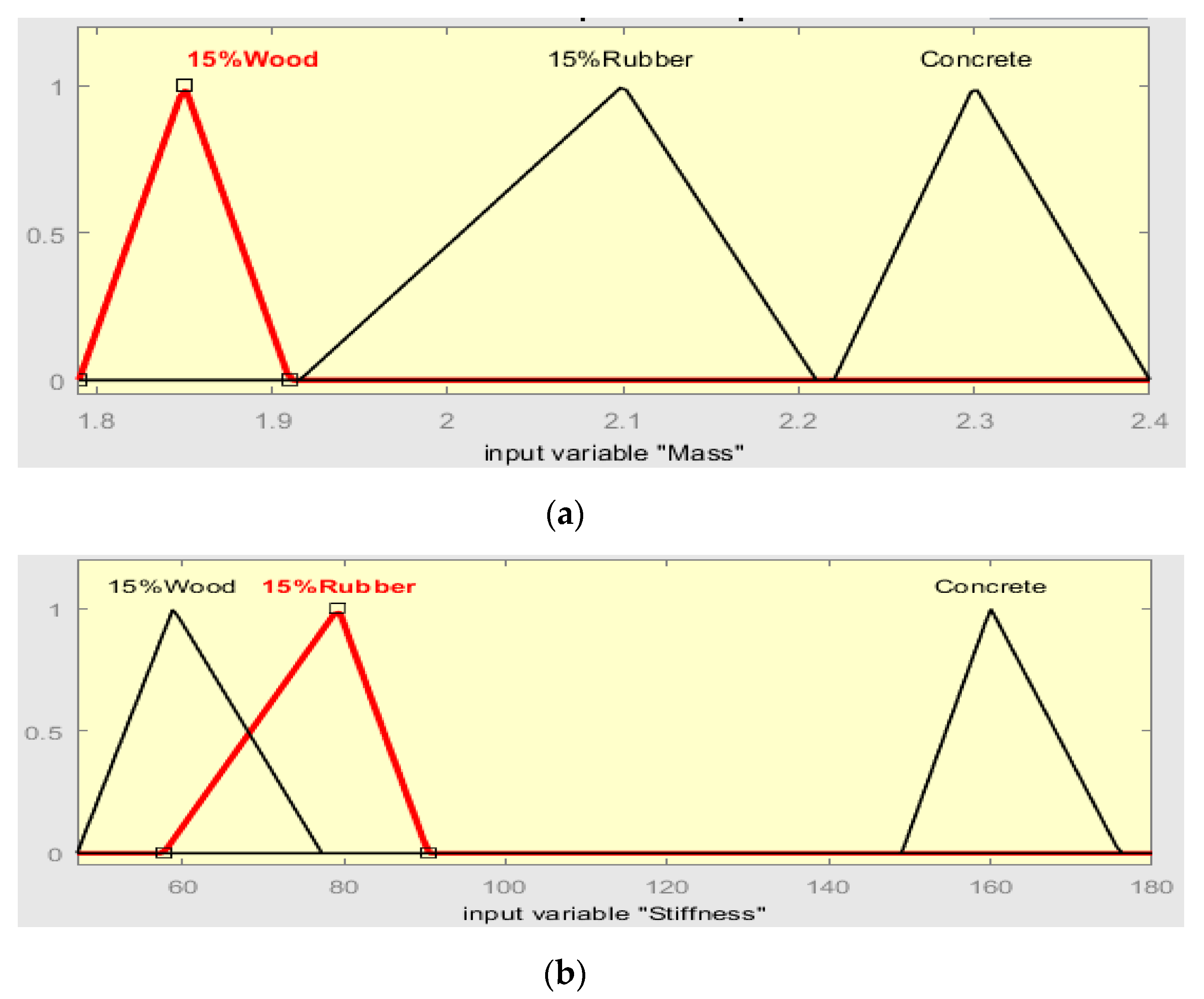

Fuzzification is achieved in a fuzzy scheme by describing deterministic quantities as nondeterministic and transforming a new set of inputs into a fuzzy quantity.

Figure 11 depicts the triangular membership function that was used to fuzzify the input to the constructed fuzzy system (concrete, 15% wood–concrete, 15% rubber–concrete).

A triangular membership function was used to fuzzify the inputs of the fuzzy system, as shown in

Figure 12a,b.

Table 5 shows the values of fuzzy machine inputs

Defuzzification, which is necessary in FLCS, maps a fuzzy set to a new one using a set of rules that transform multiple variables into a fuzzy result for given fuzzy sets and acceptable membership degrees, as shown in

Figure 13.

Figure 14 demonstrates how a triangular membership feature was used in the defuzzification process to obtain values of natural frequency for fuzzy outputs of normal concrete, 15% wood–concrete, and 15% rubber–concrete. Levels of the fuzzy system outputs are shown in

Table 6.

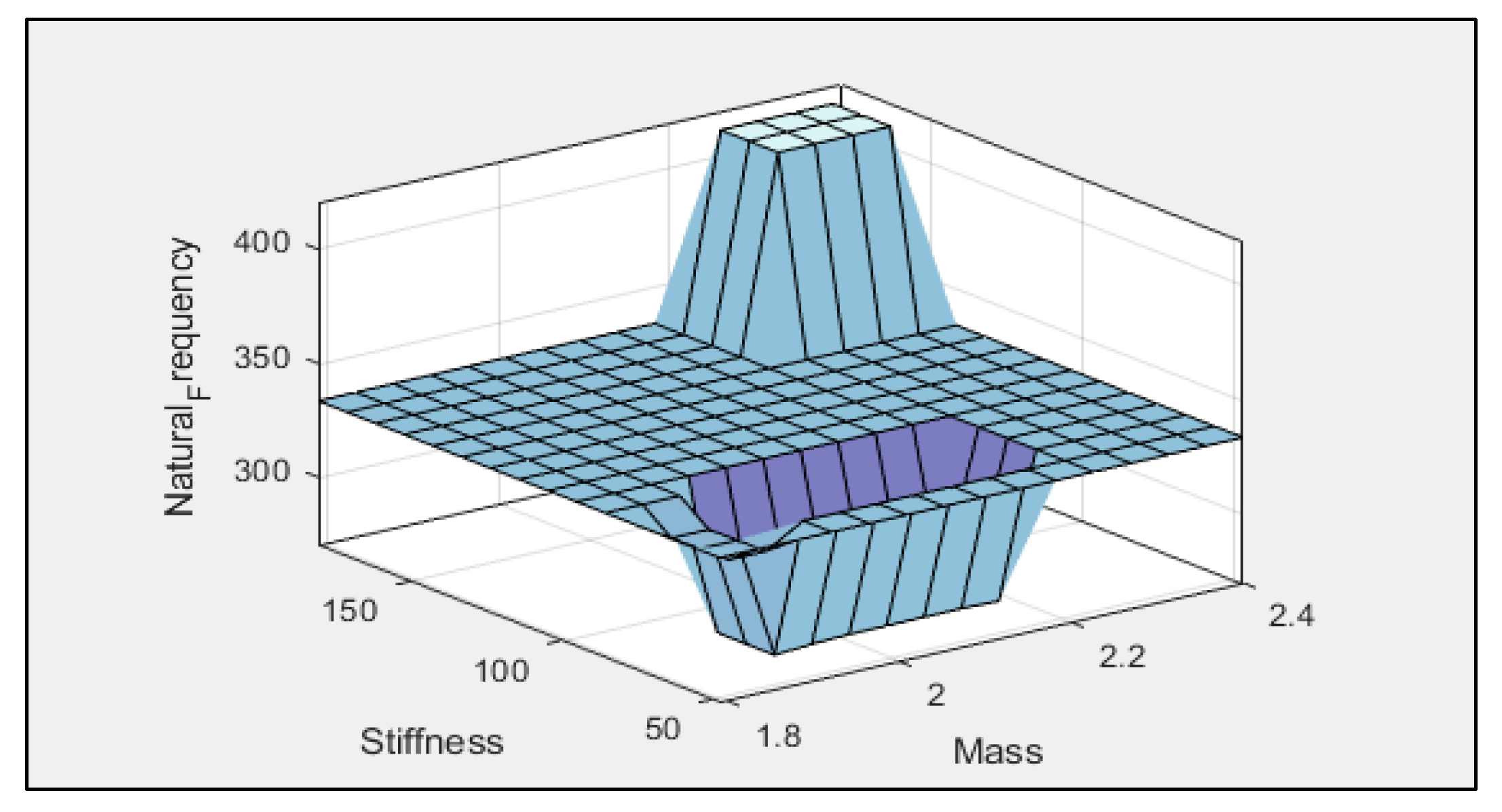

Fuzzy rules based on If–Then rules were used to allocate relationships of change in mass and stiffness of the three materials used as a foundation for the machine (fuzzy system inputs) and the natural frequency of those foundations as fuzzy system outputs, as shown in

Figure 15. The figure shows that the highest values of natural frequencies are observed at the highest values of mass and stiffness (i.e., with natural concrete samples). The lowest values, on the other hand, are observed with the concrete samples with rubber.

Table 2,

Table 3 and

Table 4 present summary statistics of mass, stiffness and natural frequency values for the three sets of samples.

To check the efficiency of the constructed fuzzy system in the optimized values of the natural frequency of the used materials, a comparison was made between the experimental data and the material’s natural frequency fuzzy system, as presented in

Table 7.

The table shows comparable results that were obtained from experimental testing as well as synthesized and analyzed using fuzzy logic modelling. For example, in both sets of analysis, the natural frequencies observed and calculated using the fuzzy logic systems for the pure concrete samples are higher (about 24–36%) than those for samples of concrete mix (wood and rubber, respectively). Concrete mixtures with wood show values of 15% higher natural frequencies than the concrete mixture sample with rubber. The tolerance between the effects of the material natural frequency fuzzy system and the result of the experimental research is approximately 5%, as presented in

Table 7.

These results are specific to the material used in these tests. The results are encouraging. Further research on sampling techniques, material and various percentages of recycled material would provide further evidence and support towards the production of efficient recycled concrete. Different types and characteristics of the material used would impact on the natural characteristics of the samples. It is worthwhile to recommend further future investigations using different types and characteristics of concrete mixes.

To conclude, this work utilizes the natural frequency of two samples of concrete that use recycling material in the mix. The natural frequencies are calculated using samples’ stiffness and mass. A fuzzy logic system was developed to predict the natural frequencies in pure concrete, concrete with wood, and concrete with rubber samples. The experimental and fuzzy method results show comparable results. Results also show that pure concrete had a higher natural frequency than wood concrete and rubber concrete mixes. These results could have useful implications in construction and other engineering applications. Another relevant finding here is that fuzzy logic analysis is a promising tool to investigate the mechanical properties of recycled concrete and other materials. Further investigations of optimum sampling mix and recycling materials are recomended.

The results of the fuzzy logic analysis, show that a fuzzy control system is a simple and inexpensive technique that can be used to predict the natural frequencies of different material through controlling the mass and stiffness of that material sample. The fuzzy control system’s efficacy and adequacy in the material applications of different types of structures could also be investigated.

6. Conclusions

The investigation of the natural frequencies of material is very useful in many fields. For example, concrete foundations are commonly used for absorbing machine vibrations. Machine foundations can increase and optimize machine’s lives by absorbing mechanical vibrations during spinning. To avoid resonance and system malfunction, the natural frequency of the base must not be too close to the natural frequency of the machine. There is a growing body of literature in the field of recycled concrete and mechanical properties of materials. In the present work, an investigation of the mechanical properties of two different types of recycled concrete—one with wood and one with rubber—relative to those characteristics of pure concrete, in terms of maximum load and natural frequencies is presented. The paper contributes to the state of the art in this area in a number of ways. The paper expands the increasing literature in the field of recycled concrete and mechanical properties of materials. The paper investigates the mechanical properties of two different types of recycled concrete by means of studying the natural frequency of the samples, which is a new contribution. In addition, the results from predicting the natural frequencies of concrete using fuzzy logic have been assessed and compared effectively with the analytical results.

The investigation shows that the mixture of concrete with wood chips is superior to the concrete with rubber in terms of their natural frequencies. However, pure concrete is still more superior than both types of recycled concrete. Therefore, further investigation of recycled concrete is still needed.

In this work, natural frequencies are calculated using samples’ stiffness and mass. A fuzzy logic system was developed to predict the natural frequencies in pure concrete, concrete with wood, and concrete with rubber samples. The experimental and fuzzy method results show comparable results. Results also show that pure concrete had a higher natural frequency than wood concrete and rubber concrete mixtures. These results could have useful implications in construction and other engineering applications. Another relevant finding here is that fuzzy logic analysis is a promising tool to investigate the mechanical properties of recycled concrete and other materials. Further investigations of optimum sampling mix, recycling materials, or support of proof of concepts could provide further evidence to demonstrate that the design concepts are feasible.

The results of the fuzzy logic analysis, show that a fuzzy control system is a simple and inexpensive technology that can be used to predict natural frequencies of different materials through controlling the mass and stiffness of that material sample. The fuzzy control system’s efficacy and adequacy in material applications of different types of structures could also be investigated.

7. Limitations

There are several limitations in this work that merit remark. The samples used in testing were all the same size and shape. This is a limitation due to the lack of resources, in particular with the COVID-19 restrictions that were imposed on lab time availability, etc. Two types of composite concrete mixtures—concrete with wood chips mix and concrete with rubber mix—were tested as part of this work, and five samples from each of the two material types were prepared and tested. In ideal situations, more than two types of composite concrete and more than five samples could have been tested. Limitation on lab availability was the main reason for this constraint. The work has also been limited to using 15% volume of rubber and wood in the sample. In future work, it is suggested to test more samples with a variety of sample mixtures in order to enable the investigation of an optimum mix composition that can achieve optimum natural frequencies.

Finally, it should be noted here that there are other factors that can affect the performance of concrete in practice and under lab conditions that were not possible to investigate. For example, most concrete structures present damping problems/issues. In this case, we have not considered damping as it is quite complex to determine and varies with many factors such as adding any structural material and the temperature and moisture in air. For the structures mentioned in our work, the damping values were often considered to be between 0.2 and 0.7 (underdamping conditions). This is an area of imitation that could be suggested for further investigation.