Transformation of Brewer’s Spent Grain Through Solid-State Fermentation: Implications for Nutrition and Health

Abstract

1. Introduction

2. Valorization of Brewer’s Spent Grain: A Sustainable Approach to Food, Feed, and Biotechnology

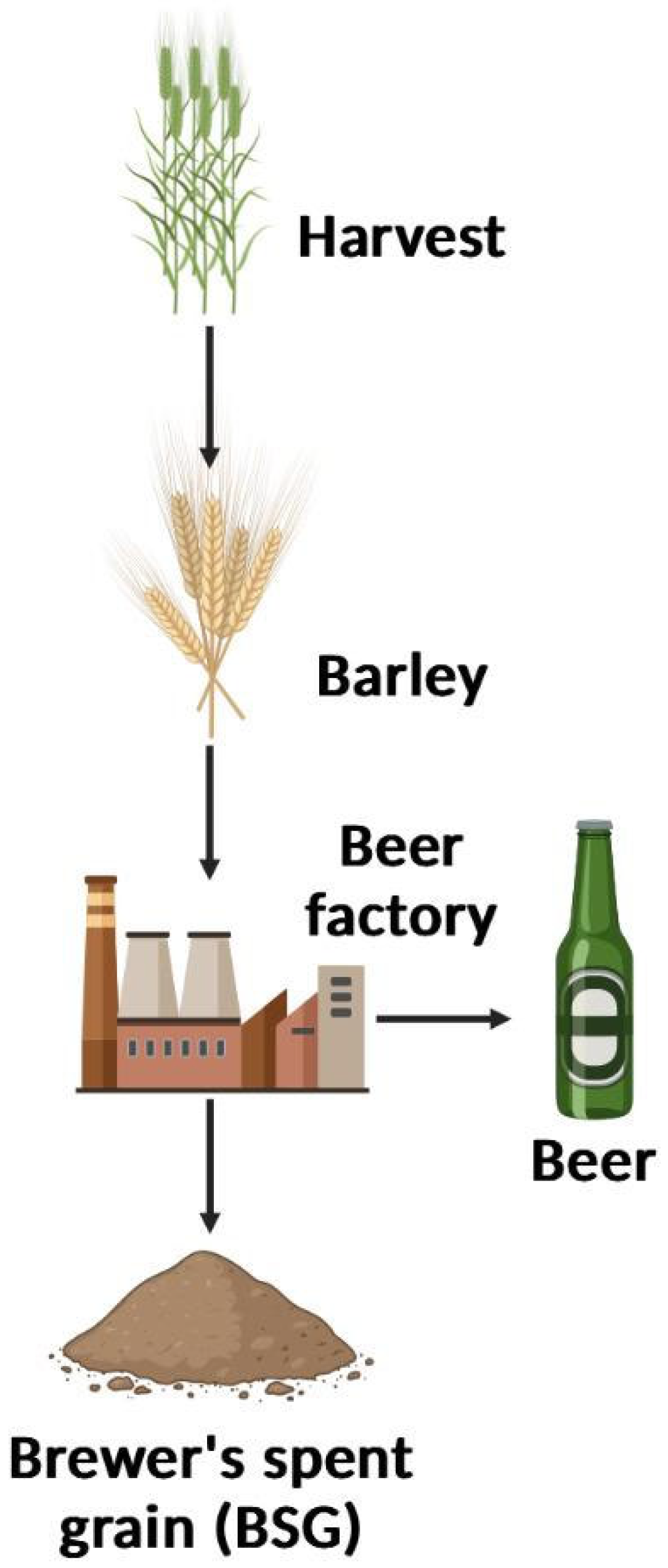

3. The Brewing Process: From Malted Barley to Brewer’s Spent Grain

4. Nutritional Composition of Brewer’s Spent Grain

5. Health Benefits of Brewer’s Spent Grain

6. Strategies to Improve the Bioavailability of Nutrients in Brewer’s Spent Grain

7. Physical Processing to Enhance BSG Nutrient Bioavailability

7.1. Thermal Processing to Enhance BSG Nutrient Bioavailability

7.2. Milling to Enhance BSG Nutrient Bioavailability

7.3. Extrusion Processing to Enhance BSG Nutrient Bioavailability

8. Fermentation and Enzymatic Hydrolysis to Enhance BSG Nutrient Bioavailability

9. Solid-State Fermentation of Brewer’s Spent Grain: Advancing Nutritional and Functional Applications

10. Valorization of BSG Through Solid-State Fermentation

11. Key Factors Influencing Solid-State Fermentation

12. Microbial Diversity in Solid-State Fermentation: Role of Fungi and Bacteria and Their Impact on Brewer’s Spent Grain

13. Hindrance Factors and Technical Challenges in Brewery Spent Grain Upcycling

14. Economic and Regulatory Dimensions of BSG Upcycling

15. Food Applications and Future Perspectives of Brewer’s Spent Grain Fermentation

16. Limitations of Current Knowledge

17. Final Recommendations

Funding

Conflicts of Interest

References

- Mussatto, S.I. Brewer’s spent grain: A valuable feedstock for industrial applications: Brewer’s spent grain and its potential applications. J. Sci. Food Agric. 2014, 94, 1264–1275. [Google Scholar] [CrossRef] [PubMed]

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ spent grain: A review with an emphasis on food and health. J. Inst. Brew. 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Patel, A.; Mikes, F.; Bühler, S.; Matsakas, L. Valorization of Brewers’ Spent Grain for the Production of Lipids by Oleaginous Yeast. Molecules 2018, 23, 3052. [Google Scholar] [CrossRef] [PubMed]

- Cooray, S.T.; Chen, W.N. Valorization of brewer’s spent grain using fungi solid-state fermentation to enhance nutritional value. J. Funct. Foods 2018, 42, 85–94. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Brewer’s Spent Grains: Possibilities of Valorization, a Review. Appl. Sci. 2020, 10, 5619. [Google Scholar] [CrossRef]

- Mitri, S.; Salameh, S.-J.; Khelfa, A.; Leonard, E.; Maroun, R.G.; Louka, N.; Koubaa, M. Valorization of Brewers’ Spent Grains: Pretreatments and Fermentation, a Review. Fermentation 2022, 8, 50. [Google Scholar] [CrossRef]

- Eliopoulos, C.; Arapoglou, D.; Chorianopoulos, N.; Markou, G.; Haroutounian, S.A. Conversion of brewers’ spent grain into proteinaceous animal feed using solid state fermentation. Environ. Sci. Pollut. Res. 2022, 29, 29562–29569. [Google Scholar] [CrossRef]

- Thai, S.; Avena-Bustillos, R.J.; Alves, P.; Pan, J.; Osorio-Ruiz, A.; Miller, J.; Tam, C.; Rolston, M.R.; Teran-Cabanillas, E.; Yokoyama, W.H.; et al. Influence of drying methods on health indicators of brewers spent grain for potential upcycling into food products. Appl. Food Res. 2022, 2, 100052. [Google Scholar] [CrossRef]

- Inzunza-Soto, M.; Avena-Bustillos, R.-J.; Thai, S.; Roman, V.; Whitehill, L.; Tam, C.; Rolston, M.-R.; Alemán-Hidalgo, D.-M.; Terán-Cabanillas, E.; Yokoyama, W.; et al. Health Benefits of High Protein and Dietary Fiber Dry-Fractioned Brewery Spent Grain Fines. ACS Food Sci. Technol. 2022, 2, 1870–1878. [Google Scholar] [CrossRef]

- Robinson, T.; Singh, D.; Nigam, P. Solid-state fermentation: A promising microbial technology for secondary metabolite production. Appl. Microbiol. Biotechnol. 2001, 55, 284–289. [Google Scholar] [CrossRef]

- Chin, Y.L.; Chai, K.F.; Chen, W.N. Upcycling of brewers’ spent grains via solid-state fermentation for the production of protein hydrolysates with antioxidant and techno-functional properties. Food Chem. X 2022, 13, 100184. [Google Scholar] [CrossRef]

- Nazzaro, F.; Fratianni, F.; Ombra, M.N.; d’Acierno, A.; Coppola, R. Recovery of biomolecules of high benefit from food waste. Curr. Opin. Food Sci. 2018, 22, 43–54. [Google Scholar] [CrossRef]

- Lao, E.J.; Dimoso, N.; Raymond, J.; Mbega, E.R. The prebiotic potential of brewers’ spent grain on livestock’s health: A review. Trop. Anim. Health Prod. 2020, 52, 461–472. [Google Scholar] [CrossRef]

- Santos, D.; Barreiros, L.; Jesus, Â.; Silva, A.L.; Martins, J.P.; Oliveira, A.I.; Pinho, C. Beer with Probiotics: Benefits and Challenges of Their Incorporation. Beverages 2024, 10, 109. [Google Scholar] [CrossRef]

- Wang, S.-M.; Wu, J.-X.; Gunawan, H.; Tu, R.-Q. Application of Life Cycle Assessment in Beer Production: Systematic Review. Beverages 2024, 10, 86. [Google Scholar] [CrossRef]

- Ravanal, M.C.; Doussoulin, J.P.; Mougenot, B. Does sustainability matter in the global beer industry? Bibliometrics trends in recycling and the circular economy. Front. Sustain. Food Syst. 2024, 8, 1437910. [Google Scholar] [CrossRef]

- Shen, Y.; Abeynayake, R.; Sun, X.; Ran, T.; Li, J.; Chen, L.; Yang, W. Feed nutritional value of brewers’ spent grain residue resulting from protease aided protein removal. J. Anim. Sci. Biotechnol. 2019, 10, 78. [Google Scholar] [CrossRef]

- Chu, H.-Y.I.; Miri, T.; Onyeaka, H. Valorization of Bioactive Compounds Extracted from Brewer’s Spent Grain (BSG) for Sustainable Food Waste Recycling. Sustainability 2025, 17, 2477. [Google Scholar] [CrossRef]

- Neylon, E.; Arendt, E.K.; Zannini, E.; Sahin, A.W. Fermentation as a Tool to Revitalise Brewers’ Spent Grain and Elevate Techno-Functional Properties and Nutritional Value in High Fibre Bread. Foods 2021, 10, 1639. [Google Scholar] [CrossRef]

- Hejna, A.; Marć, M.; Kowalkowska-Zedler, D.; Pladzyk, A.; Barczewski, M. Insights into the Thermo-Mechanical Treatment of Brewers’ Spent Grain as a Potential Filler for Polymer Composites. Polymers 2021, 13, 879. [Google Scholar] [CrossRef]

- García, D.C.; Villalba, I.; Savino, N.; Nazareno, M.A. Nutritional and functional characterization of different types of brewer’s spent grain flours. Food Biosci. 2025, 64, 105890. [Google Scholar] [CrossRef]

- Nyhan, L.; Sahin, A.W.; Schmitz, H.H.; Siegel, J.B.; Arendt, E.K. Brewers’ Spent Grain: An Unprecedented Opportunity to Develop Sustainable Plant-Based Nutrition Ingredients Addressing Global Malnutrition Challenges. J. Agric. Food Chem. 2023, 71, 10543–10564. [Google Scholar] [CrossRef]

- Nagy, V.; Diósi, G. Using brewer’s spent grain as a byproduct of the brewing industry in the bakery industry. Élelmiszervizsgálati Közlemények 2021, 67, 3339–3350. [Google Scholar] [CrossRef]

- Verni, M.; Pontonio, E.; Krona, A.; Jacob, S.; Pinto, D.; Rinaldi, F.; Verardo, V.; Díaz-de-Cerio, E.; Coda, R.; Rizzello, C.G. Bioprocessing of Brewers’ Spent Grain Enhances Its Antioxidant Activity: Characterization of Phenolic Compounds and Bioactive Peptides. Front. Microbiol. 2020, 11, 1831. [Google Scholar] [CrossRef]

- Anisha, A.; Kaushik, D.; Kumar, M.; Kumar, A.; Esatbeyoglu, T.; Proestos, C.; Rizwan-Khan, M.; Elobeid, T.; Kaur, J.; Oz, F. Volarisation of Brewer’s spent grain for noodles preparation and its potential assessment against obesity. Int. J. Food Sci. Technol. 2023, 58, 3154–3179. [Google Scholar] [CrossRef]

- Tankem, T.; Ndasi- Ngwasiri, P.; Awganande-Ambindei, W.; Calister-Wingang, M.; Martin-Ngwabie, N.; Benoit-Ngassoum, M.; Richard-Aba, E. Production and Evaluation of the Nutritional and Functional Qualities of “Adakwa” Enriched with Waste Biomass of Traditional Brewer’s Spent Grain as a Functional Staple Food. Adv. Chem. Eng. Sci. 2023, 13, 265–288. [Google Scholar] [CrossRef]

- Gutierrez-Barrutia, M.B.; Cozzano, S.; Arcia, P.; Del Castillo, M.D. In Vitro Digestibility and Bioaccessibility of Nutrients and Non-Nutrients Composing Extruded Brewers’ Spent Grain. Nutrients 2022, 14, 3480. [Google Scholar] [CrossRef] [PubMed]

- Devnani, B.; Moran, G.C.; Grossmann, L. Extraction; Composition; Functionality, and Utilization of Brewer’s Spent Grain Protein in Food Formulations. Foods 2023, 12, 1543. [Google Scholar] [CrossRef]

- Ikram, S.; Huang, L.; Zhang, H.; Wang, J.; Yin, M. Composition and Nutrient Value Proposition of Brewers Spent Grain. J. Food Sci. 2017, 82, 2232–2242. [Google Scholar] [CrossRef]

- Tan, Y.X. Brewers’ Spent Grains as Potential Novel Functional Food Ingredients for Food Security. Ph.D. Thesis, Nanyang Technological University, Singapore, 2020. [Google Scholar] [CrossRef]

- Jaeger, A.; Zannini, E.; Sahin, A.W.; Arendt, E.K. Barley Protein Properties, Extraction and Applications, with a Focus on Brewers’ Spent Grain Protein. Foods 2021, 10, 1389. [Google Scholar] [CrossRef]

- Bianco, A.; Budroni, M.; Zara, S.; Mannazzu, I.; Fancello, F.; Zara, G. The role of microorganisms on biotransformation of brewers’ spent grain. Appl. Microbiol. Biotechnol. 2020, 104, 8661–8678. [Google Scholar] [CrossRef]

- McCarthy, A.L.; O’Callaghan, Y.C.; Piggott, C.O.; FitzGerald, R.J.; O’Brien, N.M. Brewers’ spent grain; bioactivity of phenolic component, its role in animal nutrition and potential for incorporation in functional foods: A review. Proc. Nutr. Soc. 2013, 72, 117–125. [Google Scholar] [CrossRef]

- Liu, L.; Chen, M.; Coldea, T.E.; Yang, H.; Zhao, H. Modified structural and functional properties of arabinoxylan derived from brewers’ spent grain by ultrasound-assisted extraction. Rs.3.rs 2022. [Google Scholar] [CrossRef]

- Ohra-aho, T.; Niemi, P.; Aura, A.-M.; Orlandi, M.; Poutanen, K.; Buchert, J.; Tamminen, T. Structure of Brewer’s Spent Grain Lignin and Its Interactions with Gut Microbiota in Vitro. J. Agric. Food Chem. 2016, 64, 812–820. [Google Scholar] [CrossRef] [PubMed]

- Reis, S.F.; Gullón, B.; Gullón, P.; Ferreira, S.; Maia, C.-J.; Alonso, J.-L.; Domingues, F.-C.; Abu-Ghannam, N. Evaluation of the prebiotic potential of arabinoxylans from brewer’s spent grain. Appl. Microbiol. Biotechnol. 2014, 98, 9365–9373. [Google Scholar] [CrossRef] [PubMed]

- Ullah, H.; Espotio, C.; Piccinochi, R.; De Lellis, L.F.; Santarcangelo, C.; Minno, A.D.; Baldi, A.; Buccato, D.G.; Khan, A.; Piccinocchi, G.; et al. Postprandial Glycemic and Insulinemic Response by a Brewer’s Spent Grain Extract-Based Food Supplement in Subjects with Slightly Impaired Glucose Tolerance: A Monocentric, Randomized, Cross-Over, Double-Blind, Placebo-Controlled Clinical Trial. Nutrients 2022, 14, 3916. [Google Scholar] [CrossRef]

- Niemi, P.; Aura, A.-M.; Maukonen, J.; Smeds, A.-I.; Mattila, I.; Niemela, K.; Tamminen, T.; Faulds, C.-F.; Buchert, J.; Poutanen, K. Interactions of a Lignin-Rich Fraction from Brewer’s Spent Grain with Gut Microbiota in Vitro. J. Agric. Food Chem. 2013, 61, 6754–6762. [Google Scholar] [CrossRef]

- Gupta, M.; Abu-Ghannam, N.; Gallaghar, E. Barley for Brewing: Characteristic Changes during Malting, Brewing and Applications of its By-Products. Compr. Rev. Food Sci. Food Saf. 2010, 9, 318–328. [Google Scholar] [CrossRef]

- Ivanova, K.; Denkova, R.; Kostov, G.; Petrova, T.; Bakalov, I.; Ruscova, M.; Penov, N. Extrusion of brewers’ spent grains and application in the production of functional food. Characteristics of spent grains and optimization of extrusion: Extrusion of brewers’ spent grains and application in the production of functional food. Characteristics of spent grains and optimization of extrusion. J. Inst. Brew. 2017, 123, 544–552. [Google Scholar] [CrossRef]

- Steiner, J.; Procopio, S.; Becker, T. Brewer’s spent grain: Source of value-added polysaccharides for the food industry in reference to the health claims. Eur. Food Res. Technol. 2015, 241, 303–315. [Google Scholar] [CrossRef]

- Volman, J.J.; Ramakers, J.D.; Plat, J. Dietary modulation of immune function by β-glucans. Physiol. Behav. 2008, 94, 276–284. [Google Scholar] [CrossRef]

- Crowley, D.; O’Callaghan, Y.; McCarthy, A.; Connolly, A.; Piggott, A. FitzGerald, R.; O’Brien, N.-M. Immunomodulatory potential of a brewers’ spent grain protein hydrolysate incorporated into low-fat milk following in vitro gastrointestinal digestion. Int. J. Food Sci. Nutr. 2015, 66, 672–676. [Google Scholar] [CrossRef]

- Oh, D.-R.; Kim, M.J.; Choi, E.J.; Kim, Y.; Lee, H.S.; Bae, D.; Choi, C. Protective Effects of p-Coumaric Acid Isolated from Vaccinium bracteatum Thunb. Leaf Extract on Corticosterone-Induced Neurotoxicity in SH-SY5Y Cells and Primary Rat Cortical Neurons. Processes 2021, 9, 869. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Y.; Teo, S.-Q.; Heng, C.-W.; Shan-Lee, D.-P.; Gan, A.-X.; Kim, J.-E. Impact of solid-state fermented Brewer’s spent grains incorporation in biscuits on nutritional, physical and sensorial properties. LWT 2023, 182, 114840. [Google Scholar] [CrossRef]

- Cao, H.; Saroglu, O.; Karadag, A.; Diaconeasa, Z.; Zoccatelli, G.; Conte-Junior, C.-A.; Gonzalez-Aguilar, G.-A.; Ou, J.; Bai, W.; Zamarioli, C.M.; et al. Available technologies on improving the stability of polyphenols in food processing. Food Front. 2021, 2, 109–139. [Google Scholar] [CrossRef]

- Zeko-Pivač, A.; Tisma, M.; Znidarsic-Plazl, P.; Kulisic, B.; Sakellaris, G.; Hao, J.; Planinic, M. The Potential of Brewer’s Spent Grain in the Circular Bioeconomy: State of the Art and Future Perspectives. Front. Bioeng. Biotechnol. 2022, 10, 870744. [Google Scholar] [CrossRef]

- Korzeniowska, J.N.Y.M. Brewers’ spent grain in food systems: Processing and final products quality as a function of fiber modification treatment. J. Food Sci. 2021, 86, 1532–1551. [Google Scholar] [CrossRef]

- Makowska, A.; Mildner-Szkudlarz, S.; Obuchowski, W. Effect of Brewer’s Spent Grain Addition on Properties of Corn Extrudates with an Increased Dietary Fibre Content. Pol. J. Food Nutr. Sci. 2013, 63, 19–24. [Google Scholar] [CrossRef]

- Olawoye, B.T.; Gbadamosi, S.O.; Yildiz, F. Effect of different treatments on in vitro protein digestibility, antinutrients, antioxidant properties and mineral composition of Amaranthus viridis seed. Cogent Food Agric. 2017, 3, 1296402. [Google Scholar] [CrossRef]

- Onofre, S.B.; Bertoldo, I.C.; Abatti, D.; Refosco, D. Chemical Composition of the Biomass of Saccharomyces cerevisiae-(Meyen ex E. C. Hansen, 1883) Yeast obtained from the Beer Manufacturing Process. Int. J. Adv. Eng. Res. Sci. 2018, 5, 351–355. [Google Scholar] [CrossRef]

- Sganzerla, W.G.; Viganó, J.; Nochi-Castro, L.-E.; Maciel-Silva, F.-W.; Rostagno, M.-A.; Mussatto, S.-I.; Forster-Carneiro, T. Recovery of sugars and amino acids from brewers’ spent grains using subcritical water hydrolysis in a single and two sequential semi-continuous flow-through reactors. Food Res. Int. 2022, 157, 111470. [Google Scholar] [CrossRef]

- Gómez, B.; Míguez, B.; Veiga, A.; Parajó, J.C.; Alonso, J.L. Production, Purification, and in Vitro Evaluation of the Prebiotic Potential of Arabinoxylooligosaccharides from Brewer’s Spent Grain. J. Agric. Food Chem. 2015, 63, 8429–8438. [Google Scholar] [CrossRef]

- Behera, S.S.; Ray, R.C.; Das, U.; Panda, S.K.; Saranraj, P. Microorganisms in Fermentation. In Essentials in Fermentation Technology; Berenjian, A., Ed.; Learning Materials in Biosciences; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Couto, S.R.; Sanromán, M.Á. Application of solid-state fermentation to food industry—A review. J. Food Eng. 2006, 76, 291–302. [Google Scholar] [CrossRef]

- Martín-García, B.; Tylewicz, U.; Verardo, V.; Pasini, F.; Gómez-Caravaca, A.-M.; Caboni, M.-F.; Dalla Rosa, M. Pulsed electric field (PEF) as pre-treatment to improve the phenolic compounds recovery from brewers’ spent grains. Innov. Food Sci. Emerg. Technol. 2020, 64, 102402. [Google Scholar] [CrossRef]

- Czubaszek, A.; Wojciechowicz-Budzisz, A.; Spychaj, R.; Kawa-Rygielska, J. Effect of Added Brewer’s Spent Grain on the Baking Value of Flour and the Quality of Wheat Bread. Molecules 2022, 27, 1624. [Google Scholar] [CrossRef]

- Oiza, N.; Moral-Vico, J.; Sánchez, A.; Oviedo, E.R.; Gea, T. Solid-State Fermentation from Organic Wastes: A New Generation of Bioproducts. Processes 2022, 10, 2675. [Google Scholar] [CrossRef]

- Li, Q.; Li, W.; Li, L.; Zong, X.; Coldea, T.E.; Yang, H.; Zhao, H. Enhancing the foaming properties of brewer’s spent grain protein by ultrasound treatment and glycation reaction. Food Funct. 2023, 14, 2781–2792. [Google Scholar] [CrossRef] [PubMed]

- Ibarruri, J.; Cebrián, M.; Hernández, I. Solid State Fermentation of Brewer’s Spent Grain Using Rhizopus sp. to Enhance Nutritional Value. Waste Biomass Valor. 2019, 10, 3687–3700. [Google Scholar] [CrossRef]

- Cerda-Cejudo, N.D.; Buenrostro-Figueroa, J.J.; Sepúlveda-Torre, L.; Torres-León, C.; Chávez-González, M.L.; Ascacio-Valdés, J.; Aguilar, C.N. Solid-State Fermentation for the Recovery of Phenolic Compounds from Agro-Wastes. Resources 2023, 12, 36. [Google Scholar] [CrossRef]

- Vong, W.C.; Hua, X.Y.; Liu, S.-Q. Solid-state fermentation with Rhizopus oligosporus and Yarrowia lipolytica improved nutritional and flavour properties of okara. LWT 2018, 90, 316–322. [Google Scholar] [CrossRef]

- Caldera, S.; Jayasinghe, R.; Desha, C.; Dawes, L.; Ferguson, S. Evaluating Barriers, Enablers and Opportunities for Closing the Loop through ‘Waste Upcycling’: A Systematic Literature Review. J. Sustain. Dev. Energy Water Environ. Syst. 2022, 10, 1–20. [Google Scholar] [CrossRef]

- Lock, T.J.; Mah, S.H.; Lai, Z.W. Versatile applications of brewer’s spent grain: Solid-state fermentation and nutritional added value. Appl. Biochem. Biotechnol. 2024, 196, 5508–5532. [Google Scholar] [CrossRef]

- Ogunjobi, A.A.; Mejeha, O.K.; Fagade, O.E. Protein enrichment of brewery spent grains using Aspergillus oryzae. AU J. Technol. 2011, 15, 53–56. [Google Scholar]

- Sousa, D.; Venâncio, A.; Belo, I.; Salgado, J.M. Mediterranean agro-industrial wastes as valuable substrates for lignocellulolytic enzymes and protein production by solid-state fermentation. J. Sci. Food Agric. 2018, 98, 5248–5256. [Google Scholar] [CrossRef]

- Zeng, J.; Huang, W.; Tian, X.; Hu, X.; Wu, Z. Brewer’s spent grain fermentation improves its soluble sugar and protein as well as enzymatic activities using Bacillus velezensis. Process Biochem. 2021, 111, 12–20. [Google Scholar] [CrossRef]

- Tan, Y.X.; Mok, W.K.; Lee, J.; Kim, J.; Chen, W.N. Solid state fermentation of brewers’ spent grains for improved nutritional profile using Bacillus subtilis WX-17. Fermentation 2019, 5, 52. [Google Scholar] [CrossRef]

- Zeng, J.; Sheng, F.; Hu, X.; Huang, Z.; Tian, X.; Wu, Z. Nutrition promotion of brewer’s spent grain by symbiotic fermentation adding Bacillus velezensis and Levilactobacillus brevis. Food Biosci. 2022, 49, 101941. [Google Scholar] [CrossRef]

- Canedo, M.S.; De Paula, F.G.; Da Silva, F.A.; Vendruscolo, F. Protein enrichment of brewery spent grain from Rhizopus oligosporus by solid-state fermentation. Bioprocess Biosyst. Eng. 2016, 39, 1105–1113. [Google Scholar] [CrossRef]

- Leite, P.; Belo, I.; Salgado, J.M. Co-management of agro-industrial wastes by solid-state fermentation for the production of bioactive compounds. Ind. Crops Prod. 2021, 172, 113990. [Google Scholar] [CrossRef]

- Goh, L.L.; Chi Lik Lee, K. Biovalorisation of brewer’s spent grain (BSG) and sensory evaluation of BSG bread. ChemRxiv 2021. [Google Scholar] [CrossRef]

- Ong, A.; Chi Lik Lee, K. Synergistic effect of a mixed culture in solid-state fermentation. ChemRxiv 2021. [Google Scholar] [CrossRef]

- Da Costa Maia, I.; Dos Thomaz Dalmeida, S.C.; Guimarães Freire, D.; Avila Costa Cavalcanti, E.; Cameron, L.; Furtado Dias, J.; Ferreira, M. Effect of solid-state fermentation over the release of phenolic compounds from brewer’s spent grain revealed by UPLC MSE. LWT 2020, 133, 110136. [Google Scholar] [CrossRef]

- Leite, P.; Silva, C.; Salgado, J.M.; Belo, I. Simultaneous production of lignocellulolytic enzymes and extraction of antioxidant compounds by solid-state fermentation of agro-industrial wastes. Ind. Crops Prod. 2019, 137, 315–322. [Google Scholar] [CrossRef]

- Tišma, M.; Jurić, A.; Bucić-Kojić, A.; Panjičko, M.; Planinić, M. Biovalorization of brewers’ spent grain for the production of laccase and polyphenols: Biovalorization of brewers’ spent grain. J. Inst. Brew. 2018, 124, 182–186. [Google Scholar] [CrossRef]

- Fernandes, H.; Castro, C.; Salgado, J.M.; Filipe, D.; Moyano, F.; Ferreira, P.; Peres, H. Application of fermented brewer’s spent grain extract in plant-based diets for European seabass juveniles. Aquaculture 2022, 552, 738013. [Google Scholar] [CrossRef]

- Gmoser, R.; Fristedt, R.; Larsson, K.; Undeland, I.; Taherzadeh, M.J.; Lennartsson, P.R. From stale bread and brewers spent grain to a new food source using edible filamentous fungi. Bioengineered 2020, 11, 582–598. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Wang, Y.; Zhang, B.; Xu, G.; Ai, L. Effect of cultural conditions on antrodin C production by basidiomycete Antrodia camphorata in solid-state fermentation. Biotechnol. Appl. Biochem. 2014, 61, 724–732. [Google Scholar] [CrossRef]

- Bonifácio-Lopes, T.; Teixeira, J.A.; Pintado, M. Current extraction techniques towards bioactive compounds from brewer’s spent grain—A review. Crit. Rev. Food Sci. Nutr. 2020, 60, 2730–2741. [Google Scholar] [CrossRef]

- Kumar, V.; Ahluwalia, V.; Saran, S.; Kumar, J.; Patel, A.K.; Singhania, R.R. Recent developments on solid-state fermentation for production of microbial secondary metabolites: Challenges and solutions. Bioresour. Technol. 2021, 323, 124566. [Google Scholar] [CrossRef]

- Marcus, A.; Fox, G. Fungal Biovalorization of a Brewing Industry Byproduct, Brewer’s Spent Grain: A Review. Foods 2021, 10, 2159. [Google Scholar] [CrossRef]

- Cervantes-Ramirez, J.G.; Vasquez-Lara, F.; Sanchez-Estrada, A.; Troncoso-Rojas, R.; Heredia-Olea, E.; Islas-Rubio, A.R. Arabinoxylans Release from Brewers’ Spent Grain Using Extrusion and Solid-State Fermentation with Fusarium oxysporum and the Antioxidant Capacity of the Extracts. Foods 2022, 11, 1415. [Google Scholar] [CrossRef]

- Fernandes, H.; Moyano, F.; Castro, C.; Salgado, J.; Martínez, F.; Aznar, M.; Fernandes, N.; Ferreira, P.; Goncalves, M.; Belo, I.; et al. Solid-state fermented brewer’s spent grain enzymatic extract increases in vitro and in vivo feed digestibility in European seabass. Sci. Rep. 2021, 11, 22946. [Google Scholar] [CrossRef]

- Liguori, R.; Pennacchio, A.; Vandenberghe, L.P.d.S.; De Chiaro, A.; Birolo, L.; Soccol, C.R.; Faraco, V. Screening of Fungal Strains for Cellulolytic and Xylanolytic Activities Production and Evaluation of Brewers’ Spent Grain as Substrate for Enzyme Production by Selected Fungi. Energies 2021, 14, 4443. [Google Scholar] [CrossRef]

- Llimós, J.; Martínez-Avila, O.; Marti, E.; Corchado-Lopo, C.; Llenas, L.; Gea, T.; Ponsá, S. Brewer’s spent grain biotransformation to produce lignocellulolytic enzymes and polyhydroxyalkanoates in a two-stage valorization scheme. Biomass-Convers. Biorefin. 2022, 12, 3921–3932. [Google Scholar] [CrossRef]

- Pejin, J.; Radosavljević, M.; Kocić-Tanackov, S.; Marković, R.; Djukić-Vuković, A.; Mojović, L. Use of spent brewer’s yeast in L-(+) lactic acid fermentation: Use of spent brewer’s yeast in L-(+) lactic acid fermentation. J. Inst. Brew. 2019, 125, 357–363. [Google Scholar] [CrossRef]

- Assunção, I.L.; Morais-Gonzalez, G.-M.; Marques da Silva, V.; Viana da Carvalho, C.-S.; Matos-Machado, A.-G.; Martins dos Santos, V.; Pascoal, G.; Oliveria-Forest, G.; Ferreira de Sousa, J.-C.; Ramos-Fonseca, I.-A.; et al. Fármacos agonistas de receptores GLP-1 como fator de proteção da doença renal crônica em pacientes portadores de diabetes mellitus tipo 2. Res. Soc. Dev. 2021, 10, e134101623517. [Google Scholar] [CrossRef]

- Ogidi, C.O.; George, O.H.; Aladejana, O.M.; Malomo, O.; Famurewa, O. Fruit preservation with bioethanol obtained from the fermentation of brewer’s spent grain with Saccharomyces carlsbergensis. Rev. Fac. Nac. Agron. Medellín 2020, 73, 9321–9331. [Google Scholar] [CrossRef]

- Jackowski, M.; Niedźwiecki, Ł.; Jagiełło, K.; Uchańska, O.; Trusek, A. Brewer’s Spent Grains—Valuable Beer Industry By-Product. Biomolecules 2020, 10, 1669. [Google Scholar] [CrossRef]

- Terfa, R.D.; Patel, P.N.; Kim, H.D.; Gacura, M.D.; Vanderlaan, G.; Chen, L.; Ji, X.; Piovesan, D. Harnessing Brewery Spent Grain for Polyhydroxyalkanoate Production. Macromol 2024, 4, 448–461. [Google Scholar] [CrossRef]

- Terefe, G.; Walelgne, M.; Fekadu, D.; Kitaw, G.; Dejene, M.; Kehaliu, A.; Mekonnen, B.; Habteyesus, Y. Effect of sun dry brewer spent yeast on chemical composition, in vitro digestibility, and ruminal degradation kinetics of wheat straw. CABI Agric. Biosci. 2023, 4, 20. [Google Scholar] [CrossRef]

- Kitaw, G.; Faji, M.; Terefe, G. Nutritional and fungal load dynamics of fresh brewers’ grain stored under aerobic conditions. AMB Express 2022, 12, 10. [Google Scholar] [CrossRef]

- Del Río, J.C.; Prinsen, P.; Gutiérrez, A. Chemical composition of lipids in brewer’s spent grain: A promising source of valuable phytochemicals. J. Cereal Sci. 2013, 58, 248–254. [Google Scholar] [CrossRef]

- Nnadi, M.O.; Bingle, L.; Thomas, K. Bacterial community dynamics and associated genes in hydrocarbon contaminated soil during bioremediation using brewery spent grain. Access Microbiol. 2023, 5, 000519.v3. [Google Scholar] [CrossRef] [PubMed]

- Carrasco, K.H.; Hofgen, E.G.; Brunner, D.; Borchert, K.B.L.; Reis, B.; Steinbach, C.; Mayer, M.; Schwarz, S.; Glas, K.; Schwarz, D. Removal of Iron, Manganese, Cadmium, and Nickel Ions Using Brewers’ Spent Grain. Polysaccharides 2022, 3, 356–379. [Google Scholar] [CrossRef]

- Izinyon, O.; Nwosu, O.; Akhigbe, L.; Ilaboya, I. Performance evaluation of Fe (III) adsorption onto brewers’ spent grain. Niger. J. Technol. 2016, 35, 970. [Google Scholar] [CrossRef][Green Version]

- Kukic, D.; Vasic, V.-M.; Panic, S.-N.; Radosavljevic, M.-S.; Sciban, M.-B.; Prodanovic, J.-M.; Blagojev, N.-T.; Pejin, J.-D. Adsorption kinetics of Cr(VI) ions onto biochar from brewer’s spent grain. Acta Period. Technol. 2019, 50, 134–142. [Google Scholar] [CrossRef]

- Ness, B. Beyond the Pale (Ale): An Exploration of the Sustainability Priorities and Innovative Measures in the Craft Beer Sector. Sustainability 2018, 10, 4108. [Google Scholar] [CrossRef]

- Pasquet, P.-L.; Villain-Gambier, M.; Trébouet, D. By-Product Valorization as a Means for the Brewing Industry to Move toward a Circular Bioeconomy. Sustainability 2024, 16, 3472. [Google Scholar] [CrossRef]

- Coronado, M.A.; Montero, G.; Montes, D.-G.; Valdez-Salas, B.; Ayala, J.-R.; García, C.; Carrillo, M.; León, J.-A.; Moreno, A. Physicochemical Characterization and SEM-EDX Analysis of Brewer’s Spent Grain from the Craft Brewery Industry. Sustainability 2020, 12, 7744. [Google Scholar] [CrossRef]

- Petit, G.; Korbel, E.; Jury, V.; Aider, M.; Rousseliere, S.; Audebrand, L.-K.; Turgeon, S.-L.; Mikhaylin, S. Environmental Evaluation of New Brewer’s Spent Grain Preservation Pathways for Further Valorization in Human Nutrition. ACS Sustain. Chem. Eng. 2020, 8, 17335–17344. [Google Scholar] [CrossRef]

- Baiano, A.; La Gatta, B.; Rutigliano, M.; Fiore, A. Functional Bread Produced in a Circular Economy Perspective: The Use of Brewers’ Spent Grain. Foods 2023, 12, 834. [Google Scholar] [CrossRef]

- Schettino, R.; Verni, M.; Acin-Albiac, M.; Vicentini, O.; Krona, A.; Knaapila, A.; Cagno, R.D.; Gobbetti, M.; Rizzello, C.G.; Coda, R. Bioprocessed Brewers’ Spent Grain Improves Nutritional and Antioxidant Properties of Pasta. Antioxidants 2021, 10, 742. [Google Scholar] [CrossRef]

| Author’s Last Name | Dietary Fiber | Proteins | Lipids | Ashes | Reference |

|---|---|---|---|---|---|

| Cooray | 45.65 | n.r. | 10.09 | 3.35 | [4] |

| Inzunza-Soto | 46.4 | 19.43 | 8.6 | 5.0 | [15] |

| Neylon | 42.6 | 31.4 | 10.3 | 3.35 | [19] |

| Lynch | 50.0 | 20.0 | n.r. | n.r. | [2] |

| Nyhan | 44.0 | 30.0 | 10.0 | 4.0 | [22] |

| Mussatto and Roberto | 73.0 | 15.3 | 1.4 | 4.6 | [1] |

| Nagy | 19.50 | 23.30 | 7.10 | 4.6 | [23] |

| Component | BSG | Barley |

|---|---|---|

| Essential Amino Acids—EAAs | ||

| Histidine | 2.6 | 2.0 |

| Isoleucine | 4.1 | 3.3 |

| Leucine | 10.0 | 6.0 |

| Lysine | 3.9 | 3.2 |

| Methionine | 2.1 | 1.5 |

| Phenilalanine | 5.9 | 5.2 |

| Threonine | 3.7 | 3.2 |

| Tryptophan | n.r. | 1.7 |

| Valine | 5.2 | 4.5 |

| ΣEAA | 37.5 | 32.7 |

| Non-essential Amino Acids—NEAAs | ||

| Alanine | 6.1 | 3.3 |

| Arginine | 5.2 | 4.5 |

| Asparagine | n.r. | n.r. |

| Aspartic acid | 7.0 | 5.4. |

| Glutamic acid | 21.2 | 22.6 |

| Serine | 4.5 | 4.1 |

| Tyrosine | 3.9 | 2.8 |

| Glycine | 3.6 | 3.2 |

| Glutamine | n.r. | n.r. |

| Proline | 10.2 | 10.0 |

| ΣNEAA | 61.7 | 55.9 |

| Microorganisms | SSF | SmF |

|---|---|---|

| Bacteria | ||

| Bacillus sp. | Composting, Natto, α-amylase | Enzymes (α-amylase, polygalcturonase, phytase, etc.) |

| Clostridium sp. | Ensiling, food | Pesticide degradation |

| Lactic acid bacteria. | Ensiling, food | Fermented foods (yogurt, lacto-pickle, sausage, etc.) |

| Pseudomonas sp. | Composting | Xenobiotic degradation |

| Serratia sp. | Composting | |

| Fungi | ||

| Altemaria sp. | Composting | |

| Penicilum notatum, roquefortii | Cheese | Penicillin |

| Lentinus edodes | Shiitake mushroom | |

| Pleurotus oestreatus, sajor-caju | Mushroom | |

| Amylomyces rouxii | Cassava tape | |

| Beauveria sp., Metharizium sp. | Bioinsecticide | Bioinsecticide |

| Phanerochaete chrysosporium | Composting, lignin degradation | |

| Rhizopus spp. | Composting, food, enzymes, organic acid | Food, enzymes, organic acid |

| Trichoderma sp. | Composting biological control, bioinsecticide | Cellulase |

| Yeasts | ||

| Endomicopsis burtonii, Schwanniomyces castelli | Cassava tape | |

| Saccharomyces cerevisiae | Alcoholic beverages, ethanol | Alcoholic beverages, ethanol |

| Proteins and Amino Acids | |||

|---|---|---|---|

| Microorganisms | SSF Conditions | Product Yield | Reference |

| Aspergillus oryzae | 50 g BSG, 28 °C for 35 days of fermentation | 284 mg/g | [65] |

| Aspergillus niger 01UAs181, Aspergillus uvarum MUM03.49 | 10 g dry BSG, initial moisture content of 75%, C/N ratio of 15, 30 °C for 6 days fermentation | 277 mg/g | [66] |

| Bacillus velezensis K8 | Ultrasound-pre-treatment, initial moisture content of 75%, 30 °C for 6 days of fermentation | 315.9 mg/g | [67] |

| Bacillus subtilis WX-17 | 10 g BSG, 37 °C for 2 days of fermentation | 1.9 mg/g * | [68] |

| Bacillus velezensis K8 and Levilactobacillus brevis LZB2 | Initial moisture level 75%, 30 °C for 6 days of fermentation | 55.6 mg/g and 51.2 mg/g * | [69] |

| Rhizopus oligosporus CCT 4134 | Initial moisture of 70%, 1% of nitrogen supplement (ammonium sulfate, urea, sodium nitrate) per 100 g of dry BSG, 7 days fermentation | 30.6 mg/g | [70] |

| Rhizopus microsporus var. oligosporus DSM 1964 | 10 g BSG, 37 °C for 3 days of fermentation | 7.8 mg/g * | [4] |

| Rhizopus sp. ROR004 | 192 h of fermentation | 47.4 mg/g and 135.8 mg/g * | [60] |

| Phenolic content and Antioxidant capacity | |||

| Aspergillus niger CECT 2088 | 10 g of dry substrate, initial moisture level of 75%, C/N ratio of 15, 25 °C for 7 days of fermentation | 13.3 mg GAE/g 1.5 mg TE/100 g ** | [71] |

| Aspergillus oryzae (EM-2, M-1, SP-05, NJK110, Fuji and Hashimoto) Aspergillus oryzae and Aspergillus sojae (SP-01) Aspergillus luchuensis (Shōchū Black Koji) | 8 g BSG, 22.5 °C and 52% humidity | 9.5 mg GAE/g | [72] |

| Aspergillus oryzae M-1 Bacillus subtilis var. natto | Varies between pure and mixed culture | 11 mg GAE/g | [73] |

| Aspergillus terreus, Aspergillus niger, Aspergillus awamori, Aspergillus oryzae, Rhizopus oryzae | 5 g BSG, 30 °C for 0–7 days of fermentation | 8.2 mg GAE/g 15.1 mg TE/100 g ** | [74] |

| Aspergillus ibericus MUM 03.49, Aspergillus ibericus MUM 04.86, Aspergillus niger CECT 2915, Aspergillus niger CECT 2088, Rhizopus oryzae MUM 10.260 | 2 g dry BSG, initial moisture level of 75%, C/N ratio of 15, 25 °C for 7 days of fermentation | 2.7 mg GAE/g | [75] |

| Rhizopus sp. ROR004 | 192 h of fermentation | 2.0 mg GAE/g | [60] |

| Trametes versicolor | 50 g BSG, 27 °C for 14 days of fermentation | 8.7 mg GAE/g | [76] |

| Soluble sugar | |||

| Aspergillus ibericus MUM 03.49 | 400 g BSG, 25 °C for 7 days of fermentation | 18.9 mg/g | [77] |

| Bacillus velezensis K8 | Ultrasound-pre-treatment, initial moisture content of 75%, 30 °C for 6 days of fermentation | 312.4 mg/g | [67] |

| Bacillus velezensis K8 and Levilactobacillus brevis LZB2 | Initial moisture level 75%, 30 °C for 6 days of fermentation | 73.1 mg/g | [69] |

| Trametes versicolor | 50 g BSG, 27 °C for 14 days of fermentation | 2.4 mg/g | [76] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrera-León, M.; Terán-Cabanillas, E.; Avena-Bustillos, R.d.J.; Cárdenas-Torres, F.I.; Amézquita-López, B.A.; Gómez-Favela, M.A.; Alemán-Hidalgo, D.M.; Arias-Gastélum, M. Transformation of Brewer’s Spent Grain Through Solid-State Fermentation: Implications for Nutrition and Health. Recycling 2025, 10, 170. https://doi.org/10.3390/recycling10050170

Barrera-León M, Terán-Cabanillas E, Avena-Bustillos RdJ, Cárdenas-Torres FI, Amézquita-López BA, Gómez-Favela MA, Alemán-Hidalgo DM, Arias-Gastélum M. Transformation of Brewer’s Spent Grain Through Solid-State Fermentation: Implications for Nutrition and Health. Recycling. 2025; 10(5):170. https://doi.org/10.3390/recycling10050170

Chicago/Turabian StyleBarrera-León, Marcos, Elí Terán-Cabanillas, Roberto de Jesús Avena-Bustillos, Feliznando Isidro Cárdenas-Torres, Bianca Anabel Amézquita-López, Mario Armando Gómez-Favela, David Moroni Alemán-Hidalgo, and Mayra Arias-Gastélum. 2025. "Transformation of Brewer’s Spent Grain Through Solid-State Fermentation: Implications for Nutrition and Health" Recycling 10, no. 5: 170. https://doi.org/10.3390/recycling10050170

APA StyleBarrera-León, M., Terán-Cabanillas, E., Avena-Bustillos, R. d. J., Cárdenas-Torres, F. I., Amézquita-López, B. A., Gómez-Favela, M. A., Alemán-Hidalgo, D. M., & Arias-Gastélum, M. (2025). Transformation of Brewer’s Spent Grain Through Solid-State Fermentation: Implications for Nutrition and Health. Recycling, 10(5), 170. https://doi.org/10.3390/recycling10050170