1. Introduction

The invention of the vehicle has made a profound change in human life and transformed human society. Today, this industry forms the main part of the global economy and has the most direct or indirect job creation. On the other hand, a large number of vehicles causes serious problems, such as global warming, pollutant production, and a drastic reduction in energy resources. That is why, in recent years, the idea of electric vehicles has emerged as a replacement for internal combustion vehicles.

To achieve optimum performance, durability, and safety considerations, the battery cell should work within the safe functioning scope of temperature, current, and voltage, as demonstrated by the battery cell manufacturer. These ranges could be different corresponding to the battery manufacturer and cell chemistry [

1,

2].

Several publications have appeared in recent years, documenting different thermal management systems. Mohsen Mousavi and his colleagues [

3] analyzed and optimized the influencing parameters on lithium-ion battery air-cooling which were used in electric vehicles, by considering their practical constraints. In addition, a genetic algorithm procedure was used to optimize the decision variables. Interpreting the outcomes showed that, by enlarging the tube’s diameter on the battery and keeping the air velocity in a specified range, the number of transfer units could be maximized [

3].

Heesung Park [

4] introduced a design of airflow arrangement for cooling the battery system by employing numerical calculations. The cooling efficiency was analyzed by implementing a thermal resistance model. The needed cooling performance was accomplished by using the suggested tapered pressure-relief ventilation and manifold. In addition, the power consumption for the functioning fan was improved, owing to air-pressure relief [

4].

A transient numerical model of a lithium-ion battery pack thermal management system was developed [

5] by employing air-cooling for electric vehicle applications. The effects of module configuration in a battery pack were investigated with various ambient temperature situations. They concluded that the arrangement that more lithium-ion battery cells were located near the airflow inlet is more efficient to decrease the temperature deviation between modules [

5].

Mariani [

6] did an experimental investigation to evaluate the cooling of the batteries for electric car application. The position with maximum temperature was found by employing an infrared camera, together with two thermocouples. The location was found 27 mm under the negative Table Air and water were selected as cooling fluids. They concluded that the water provides a lower temperature, but the employment of air is suggested because of its greater simplicity and safety [

6].

A comprehensive thermal analysis of the investigated lithium-ion battery cell was accomplished [

7,

8,

9,

10]. Notwithstanding, thermal analysis of indirect liquid cooling for the studied lithium-ion battery was not investigated. Thermal management of lithium-ion batteries is an important research area. However, to the authors’ best knowledge, very few publications are available and could be found in the literature that discuss and analyze a thermal management design which provides a homogeneous temperature distribution across the surface of lithium-ion batteries.

An online thermal runaway diagnosis approach for lithium-ion batteries, according to real-world data, was proposed. The outcomes demonstrate that the diagnosis technique, which was instituted by the density-based spatial clustering, accompanied by noise clustering, could efficaciously forecast the potential thermal runaway battery cells. Through evaluating a large quantity of real-world data, the stability, feasibility, necessity, robustness, and reliability of the technique were acknowledged and discussed. Moreover, comparison with another diagnosis approach was accomplished, and the outcomes demonstrate the advantage of the suggested technique [

11].

A procedure to guarantee the influence safety of the battery was studied. In particular, the characteristics which could guarantee the safety of the pouch-type lithium-ion battery cell utilized to the embedded battery cell were investigated. The rate of influence failure was calculated based on the material of the pouch neighboring the battery, and the outcomes varied based on the elongation tensile, thickness, and strength [

12].

Hybrid solid polymer electrolytes, which were achieved by a fast, truly solvent-free, consequently obtainable procurement process, were reported. Unlike numerous other super ionic conductors which were employed for composite electrolytes, Li

1.5Al

0.5Ge

1.5(PO4)

3 is comparatively stable in atmosphere and could be analyzed in a dry room, which is more scalable, cheap, and favorable than an air-filled dry box for manufacturing safe lithium batteries [

13].

A new chamber temperature ionic liquid-based electrolyte, which could be employed with big-energy cathode lithium-rich nickel manganese cobalt oxide in lithium-ion batteries, was reported. The electrochemical and physical features of the recently improved materials were completely specified, additionally through post-cycling electrochemical impedance spectroscopy investigation of the consequential lab-scale lithium-ion battery cells upon constant-current and long-term cycling. Moreover, an ingenious polymer electrolyte was established, which is studied in connection with its electrochemical behavior and ion transport features, through constant-current cycling, cyclic voltammetry, and electrochemical impedance spectroscopy [

14].

A thermal management system was designed for the cooling of electric vehicle battery modules by using nano fluids [

15]. To enhance the working effectiveness of the lithium-ion battery according to the fluid dynamics and energy conservation, the battery module accompanied by phase-change water/material cooling-plate was numerically analyzed and designed [

16]. A double-objective cooling plate for prismatic lithium-ion batteries was proposed. The main purpose was to raise the battery pack safety and life for utilizations in aircraft, vehicles, and stationary electric storage for renewables and grid applications [

17].

There are many papers about thermal management of lithium-ion cells, but none of them used a precise procedure for the determination of the heat generation of batteries. Other investigations estimate the amount of heat generation for their batteries. In this investigation, the isothermal battery calorimeter was used for the determination of heat generation. The novelty and originality of the results are that, for the first time, isothermal battery calorimeter was used for the thermal analysis and management of lithium-ion cells because the isothermal battery calorimeter is the most precise method for determination of heat generation of lithium-ion batteries. In addition, the effect of important parameters such as entrance temperature of coolant fluid, entrance velocity of coolant fluid, ambient temperature, current rate, and plate material on the cooling performance of cooling plates were not investigated.

Although the safety improvement of lithium batteries is one of the goals of battery thermal management systems, it was not the purpose of this paper. The main goal of this investigation was to analyze thermal behavior of the battery, which is in direct contact with the cooling plates, by using experimental data from isothermal battery calorimeter. In addition, this investigation demonstrates a computational analysis method to describe the pressure drop and temperature distribution by using internal flowing twisted conduits for cooling of lithium-ion batteries.

The influence of different parameters, such as entrance velocity and temperature of coolant fluid, working temperature, current rate, and plate material on the cooling performance of the cold plate was studied. Notwithstanding, there were no comprehensive investigations on this effect. Consequently, this research paper demonstrates a numerical study on internal flowing cooling plates by considering different influential parameters.

2. Numerical Modeling

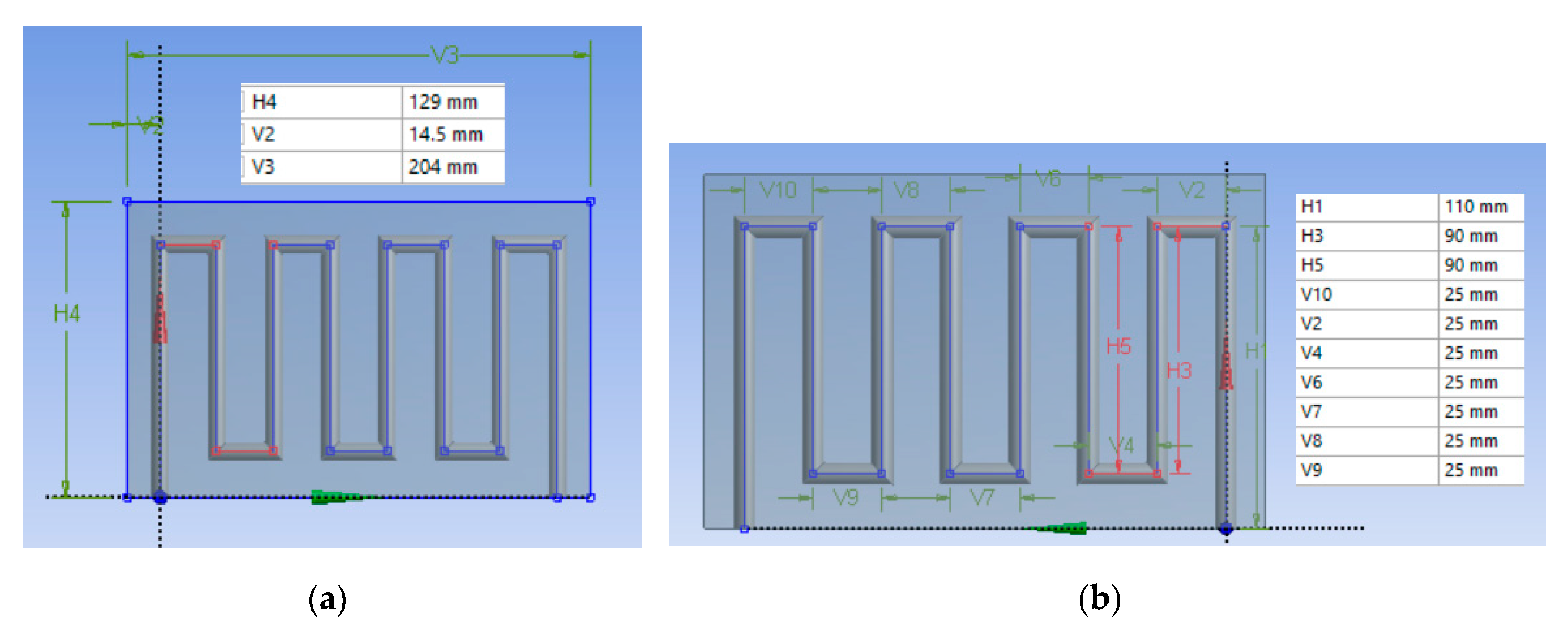

The cold plate with identical dimension as the lithium-ion battery cell was placed between every pair of lithium-ion battery cells. The external dimensions of the cold plate are shown in

Figure 1. Because the investigated cold plate is symmetric, it can be divided in two equal parts. Correspondingly, only a half plate is needed to be considered for each battery cell. This can decrease computation time subject to the same condition. Following implementing symmetry condition on the upper surface of computational fluid dynamics model, the width of cold plate decreases to half of complete plate.

The twisting conduit arrangement was established with a different number of cooling conduits. Finally, one arrangement was selected for further analysis. The fluid direction of channels’ configuration with different direction designs was established, as illustrated in

Figure 1.

In this investigation, the cold plate was supposed to be isotropic and homogenous for simplicity of computation. Incompressible fluids with a constant property were considered to be cooling liquids. The quadrilateral lithium-ion battery cell in this investigation has a nominal voltage of 2.26 V and a capacity of 13 Ah. Copper and aluminum were selected as the cooling plates. Liquid water was employed as the coolant fluid.

An analysis was implemented in ANSYS. The corresponding physical parameters for simulation were supported by the software. Several flow rates were considered for the coolant fluid. Laminar and turbulent model were chosen in simulations, based on the Reynolds number.

With the intention of analyzing the thermal performance of the battery cell, while the battery charges and discharged at different current rates, a steady heat flux (W/m

2) was exerted via the surface of the cooling plate. The meshing design of the cold plate is illustrated in

Figure 2. The tetrahedron mesh grid was adopted.

3. Energy Equations

The heat generation of the lithium-ion battery cell was regarded to be homogeneous. Therefore, heat generation per volume of battery cell could be determined as follows:

where

Q is the volumetric heat generation rate;

Ri is the internal resistance of the battery cell;

Vb is the volume of the battery cell;

I is the battery cell current;

T is the temperature; and

VOCV is the open circuit voltage.

The mathematical statement for energy conservation of the lithium-ion battery cell could be described as follows:

where

is the density of the battery cell;

Cp is the heat capacity of the battery cell;

Kx is the thermal conductivity in the direction of

x;

Ky is the thermal conductivity in direction of

y; and

Kz is the thermal conductivity in the direction of

z.

The convective boundary condition was considered in the external walls of the lithium-ion battery cell. The quantity of heat, which was transferred to environment, could be stated as follows:

where

q is the transferred heat through convection;

h is the convective heat dissipated coefficient of air;

T2 is the wall temperature; and

T1 is the ambient temperature.

ANSYS solver was employed to solve the equations for the conservation of energy, momentum, and mass for the cooling fluid. The governing equations are summarized as follows:

where

V is the velocity;

x is the direction vectors;

is the density;

P is the pressure;

is the fluid viscosity;

Cp is the specific heat capacity;

T is the temperature; and

K is the thermal conductivity.

4. Thermal Characterization

Comprehension of the rate of heat dissipation and generation within the lithium-ion battery cell is essential because the performance of the lithium-ion battery is greatly dependent on the temperature of the battery cells. The heat generation within the lithium-ion battery cell is a complicated process. It corresponds to the electrochemical reaction rates. In addition, it varies with temperature and time. Electrochemical reactions cause entropy variation, and internal resistance causes ohmic heating. These result in heat generation throughout the battery cell working. The generated heat is able to enhance the battery cell temperature because of heat accumulation.

Reversible and irreversible heat, ohmic heat, and reaction heat are the main heat sources accompanying with the working of lithium-ion batteries. The generated heat from lithium-ion batteries should be transferred rapidly; otherwise, it will cause a quick growth in the temperature of the battery cell.

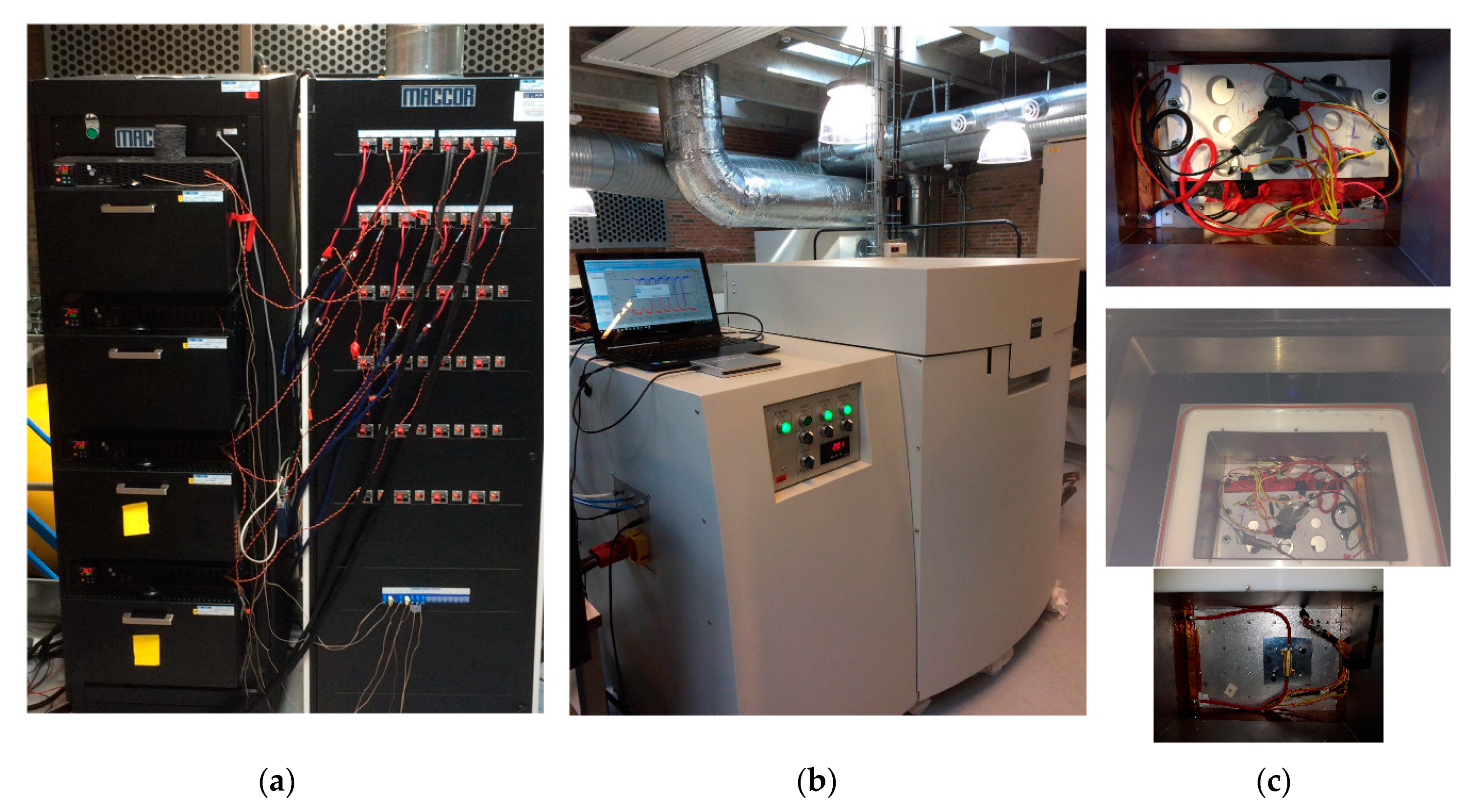

A commercial 13 Ah lithium-ion pouch cell was employed for the thermal characterization experimentations. The discharging and charging of the lithium-ion pouch cell were accomplished by using a Maccor Instrument battery cycler. The experimental setup is shown in

Figure 3. Isothermal battery calorimeter assembly, which was used for measurement of heat generation, is illustrated in

Figure 4.

The current that was used in the constant current charging and discharging tests started from 13 A (1C) to 104 A (8C). The cutoff voltage for constant current charging experiments was 2.8 V, whereas for constant current discharging experiments, it was 1.6 V.

The measurement of the heat flux of the battery cell during the course of charging and discharging at different current rates was accomplished at isothermal condition by using an isothermal battery calorimeter.

Figure 5 demonstrates the generated heat in a 13 Ah lithium-ion pouch cell, which was measured by using an isothermal battery calorimeter. The charging and discharging current rates were selected from 1 to 8C.

5. Result and Discussion

A heat-transfer analysis is required for a battery pack to transmit the heat uniformly, which is dissipated from the battery pack to keep its reliability, efficiency, durability, life cycle, and safety. In this investigation, the numerical outcomes of the internal flowing twisted conduits for cooling of lithium-ion batteries were presented. The present method from this investigation could be used to analyze the battery thermal management system for electric vehicle applications with a suitable temperature scope.

The effectiveness of the designed cooling plates was assessed by computer simulation and modeling. In the simulation, the lithium-ion battery cell was regarded as a heat generation source throughout its working. The input data for simulation of the cooling plate were derived from the experimentation, which was accomplished to measure the heat generation in the lithium-ion battery cell.

In the simulation section, four different entrance temperatures (283, 293, 303, and 313 K) and four different entrance velocity (0.1, 0.5, 1, and 2 m/s) were designated for the water cooling. In addition, two different current rates (4 and 8 C), two different ambient temperatures (303 and 313 K), and two different plate materials (copper and aluminum) were designated for the system.

The model is able to simulate the evolution of operating situation from low to high temperatures for the coolant. In the following sections, the effect of different parameters on the cooling performance of thermal management arrangement is described.

5.1. Influence of Entrance Temperature of Coolant Fluid

The entrance flow rate of 0.5 m/s was assigned, to investigate the impact of entrance temperature on cooling effectiveness of the cold plate. Aluminum was selected as the material of the cooling plate. Ambient temperature and discharge-current rate of the battery cell were chosen to be 323 K and 8 C, correspondingly.

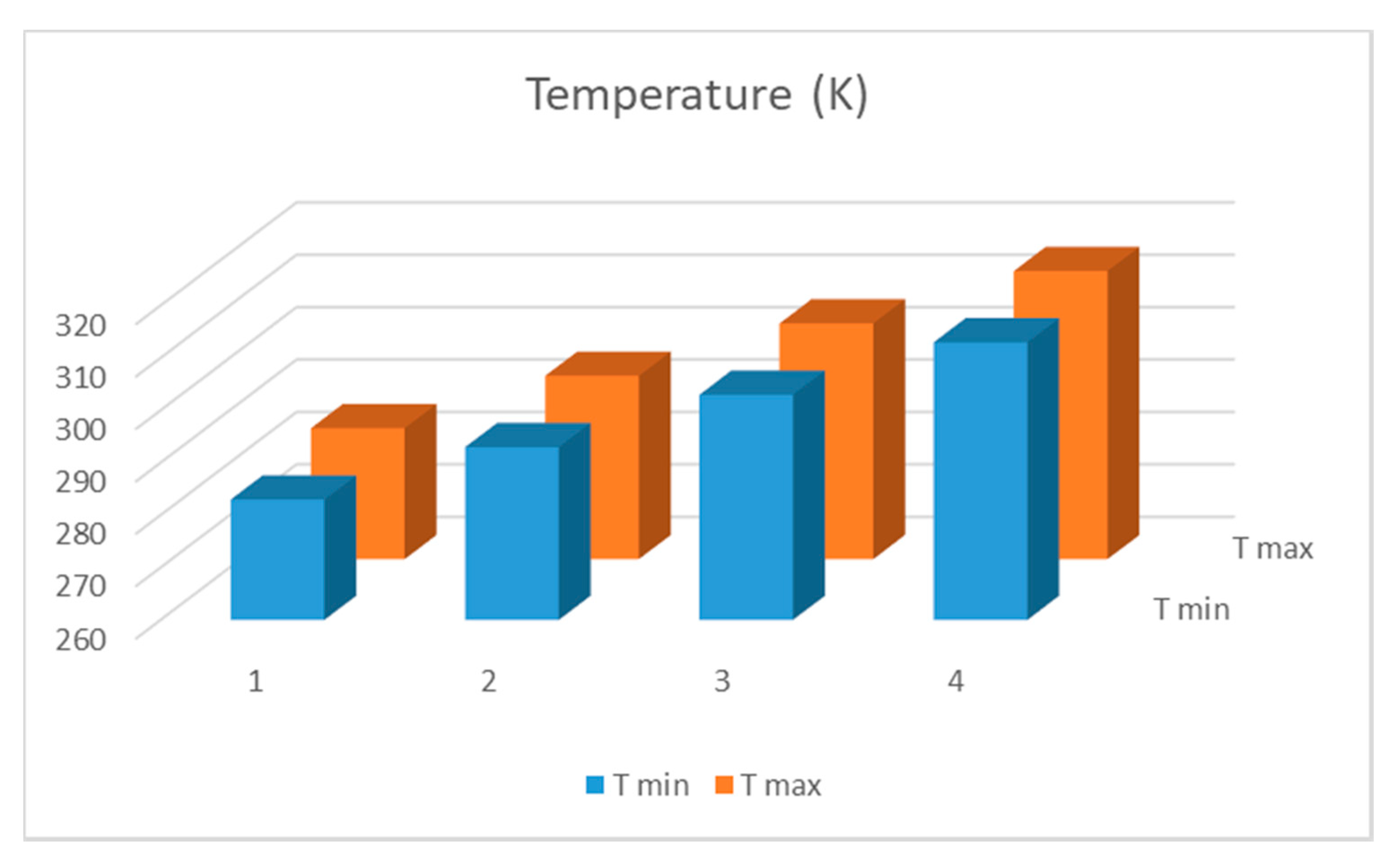

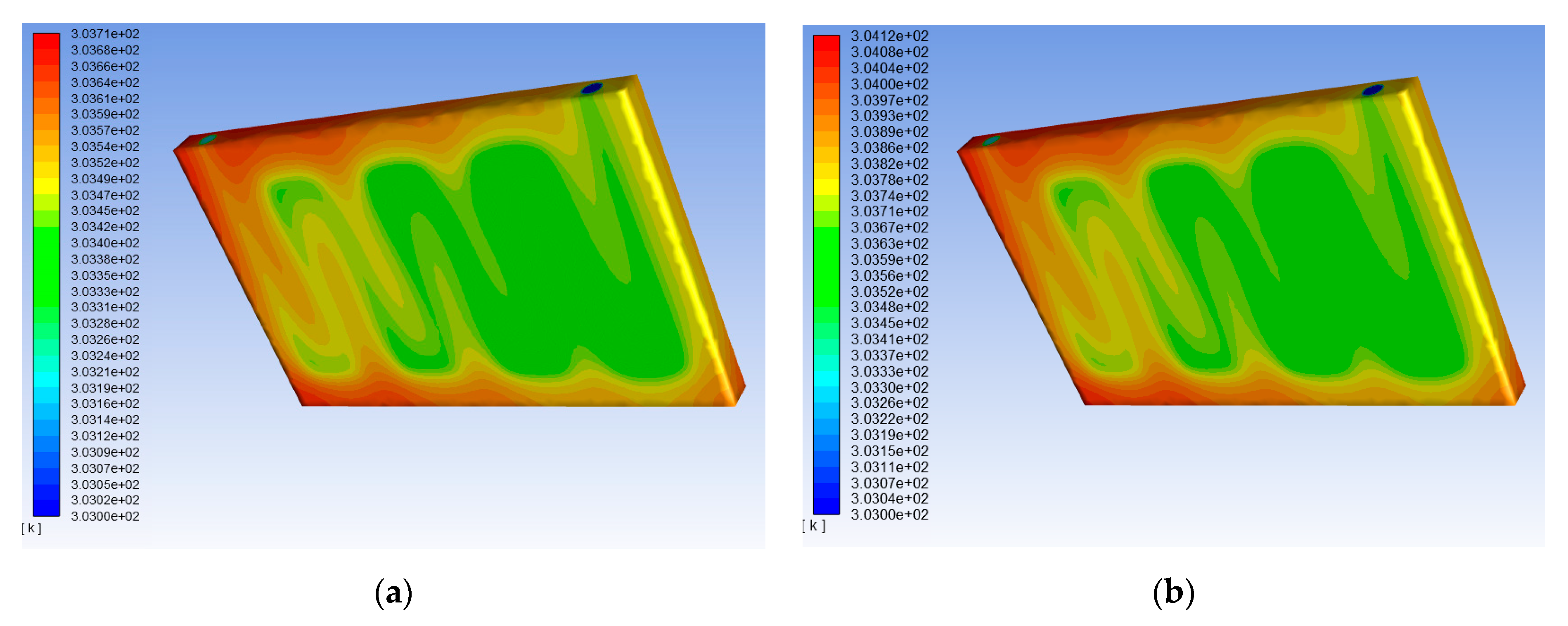

Figure 6 shows that the maximum temperature elevated by 3.5% as the entrance coolant temperature elevated from 283 to 293 K at the entrance coolant flow rate of 0.5 m/s.

Four different values were considered for the entrance temperature of the coolant fluid.

Figure 6 demonstrates the temperature profile of conduits’ configuration along width orientation for different entrance temperatures of coolant fluid. It demonstrates approximately the identical propensity of temperature discrepancy with the configuration of width orientation. It could be noticed that the lesser amount of temperature emerges in the area which is near fluid region.

It can be seen that the temperature is lower in the vicinity of the inlet zone. Notwithstanding, it becomes greater at the exit area for every configuration. This circumstance could be expressed in such a way that the coolant fluid receives heat throughout the streaming process in the conduit; therefore, the temperature rises alongside the outlet orientation. While the entrance temperature rises, the amount of temperature change demonstrates a negligible variation between different cases. Maximum and minimum temperatures of the cooling plate, for this case, are illustrated in

Figure 7.

Consequently, with the intention of providing the safety of lithium-ion battery cell under a great working temperature, the entrance temperature of the cooling fluid should be decreased. This is an efficacious approach in a specified range of temperature. Evidently, temperature change is approximately constant for different cases. This demonstrates that the homogeneous temperature is independent of entrance temperature of the coolant. Notwithstanding, the increasing trend of entrance temperature is almost similar for all of the cases, as presented in

Figure 6.

5.2. Influence of Entrance Velocity of Coolant Fluid

It was assumed that the cooling liquid streams into the entry of conduit with different flow rates, including 0.1, 0.5, 1, and 2 m/s. The entrance temperature of cooling liquid and ambient temperature were considered 298 and 323 K, correspondingly. In addition, a discharge current equal to 8C was considered for the battery cell. Aluminum was selected as the material of the cooling plate.

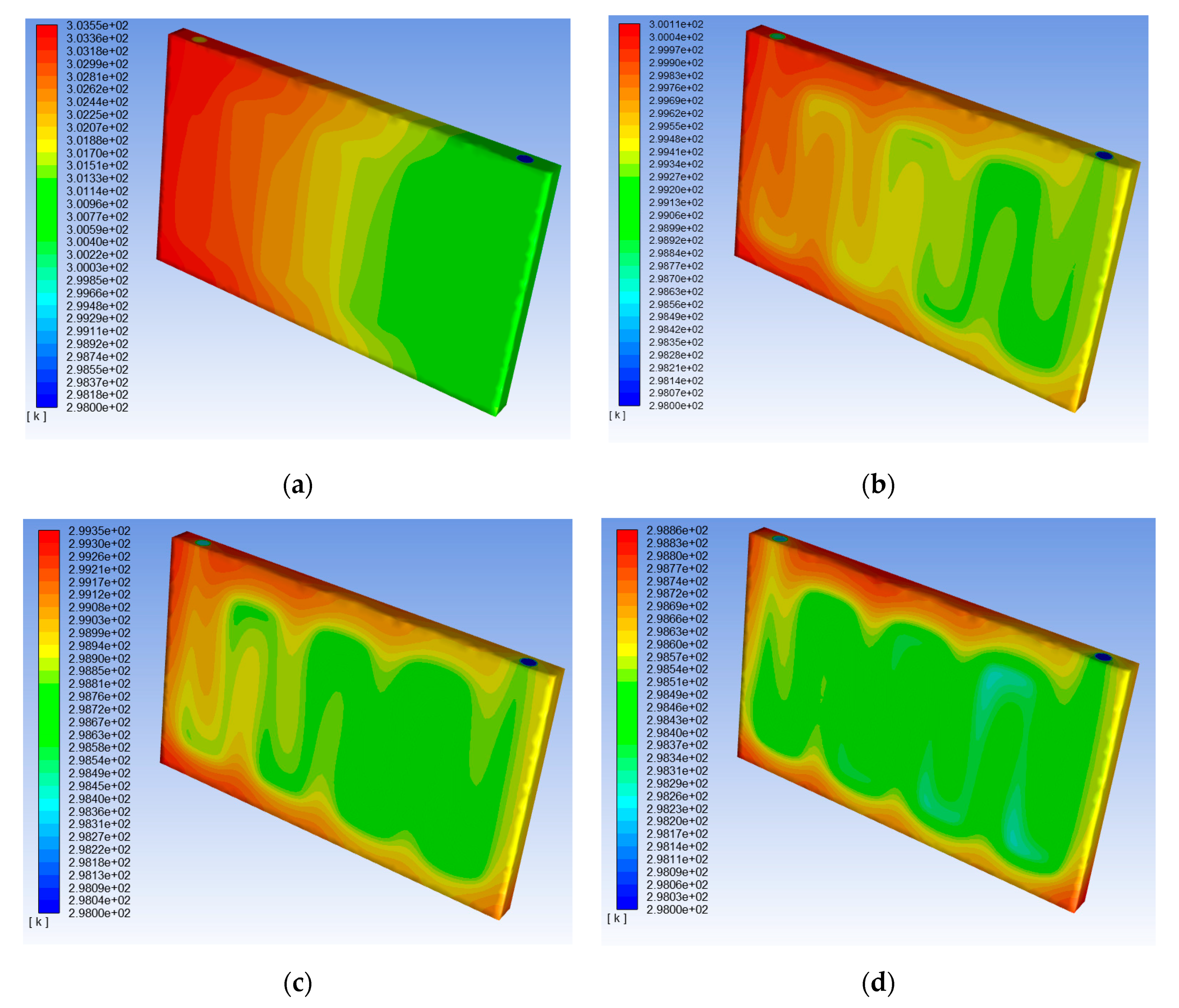

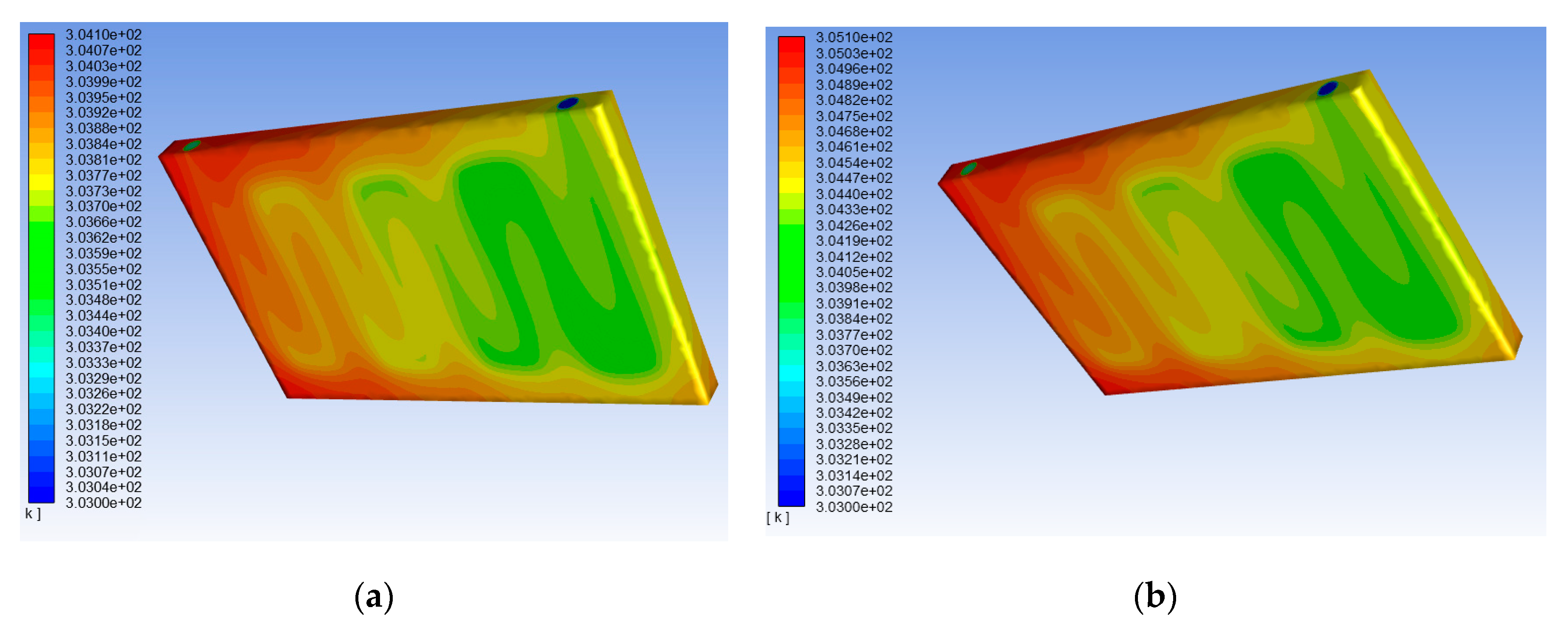

The temperature distribution for different entrance velocities of coolant fluid is illustrated in

Figure 8. A comparison between different cases of entrance velocity of coolant fluid is shown in

Table 1. It can be seen from the figures that, in case d, a more homogeneous temperature distribution could be achieved.

Maximum and minimum temperature of cooling plate in this case is illustrated in

Figure 9. It was seen that there was a big influence of entrance velocity on the performance of cold plates, and it was noticed that, as the entrance velocity enhanced from 0.1 to 2 m/s for a specific discharge rate of 8 C, the maximum temperature quantities were lessened.

An entrance velocity less than 0.1 m/s produces a temperature change of about 6 K, which leads to a lower level of homogeneity in the surface temperature. Therefore, it can be concluded that an entrance velocity lower than this amount is not appropriate for thermal management of the battery cell. An entrance velocity more than 1 m/s produces an acceptable temperature uniformity for the surface temperature. Notwithstanding, applying greater entrance velocities is not recommended because of pump energy consumption. Case d showed the greatest efficacious cooling effectiveness.

5.3. Influence of Ambient Temperature

The temperature of lithium-ion pouch cells is the principal feature that affects the life and performance of the battery pack. The cycle life and energy storage capability of the Lithium-ion pouch cell could be decreased considerably while the lithium-ion pouch cell is working at temperatures below or above specific values. In addition, battery cell temperature and homogeneity have a great effect on the accessibility of the discharging and charging energy and battery cell balancing. A big difference of temperature in a battery pack could cause dissimilar battery cells to discharge and charge at various rates. This phenomenon brings about electrical unbalance in battery cells and consequently decreases the effectiveness of the battery pack.

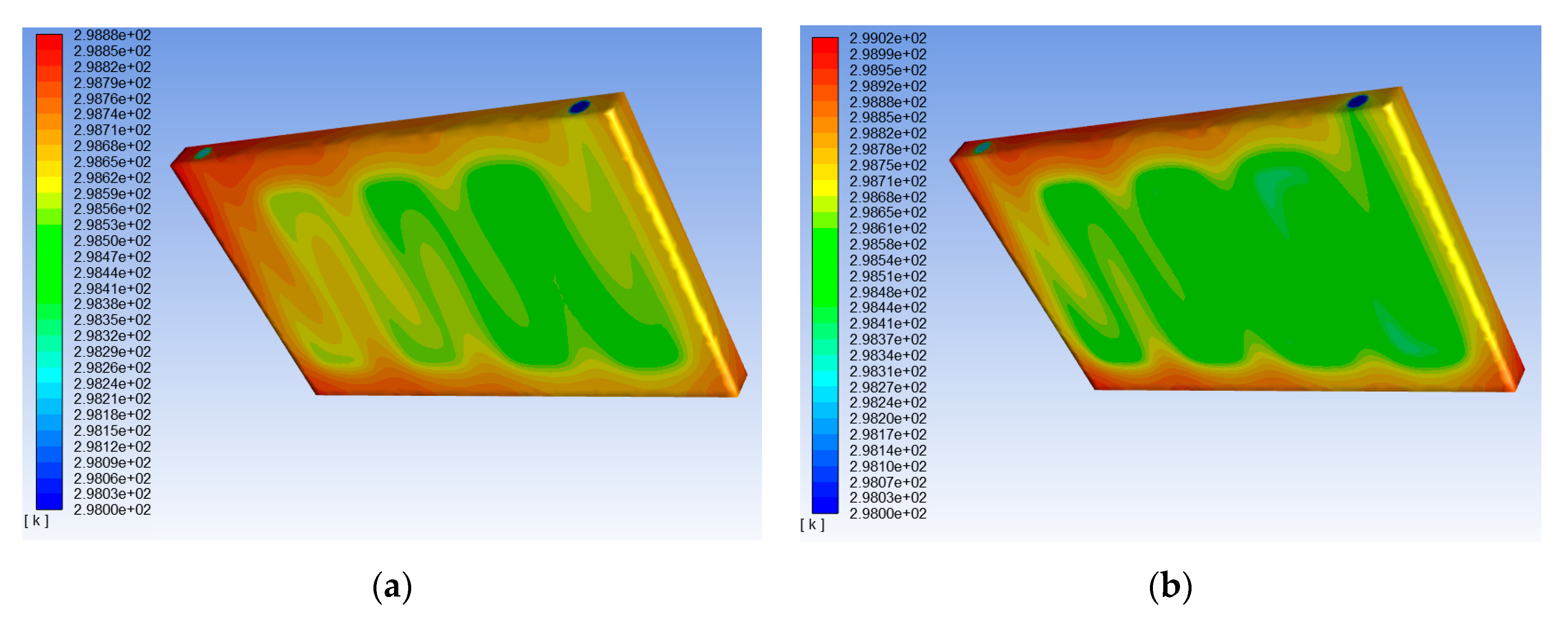

Therefore, it is necessary to keep the temperature of lithium-ion pouch cells in the optimal range, which is defined by the manufacturer. As presented in

Figure 10, the greatest temperature elevated by 0.7 K as ambient temperature elevated from 303 to 313 at an entrance coolant flow rate 1 m/s.

It was assumed that the cooling liquid streams into the entry of conduit with a flow rate of 1 m/s. The entrance temperature of the cooling liquid was considered 303 K. In addition, a discharge current equal to 8 C was considered for the battery cell. Two values were assigned for ambient temperature. Aluminum was selected as the material of cooling plate.

Figure 10 demonstrates the temperature profile of conduits’ arrangement along length orientation for different ambient temperatures, including 303 and 313 K. It can be seen that, by increasing the ambient temperature from 303 to 313 K, a negligible increase was observed for the maximum temperature, and almost no change was seen for uniformity of the surface temperature.

5.4. Influence of Current Rate

To investigate the effect of current rate, the ambient temperature and entrance temperature of cooling liquid were considered 323 and 303 K, correspondingly. In addition, a discharge current equal to 8 C was considered for the battery cell. Copper was selected as the material of cooling plate, and an entrance flow rate of 0.5 m/s was selected.

By increasing the current rate, the amount of heat produced in the battery increases, and as mentioned earlier, one of the major factors in reducing battery life is generating too much heat. This phenomenon causes different problems for electrochemical processes in the battery cell, resulting in decreasing of battery life. As the discharge rate enhanced from 4 to 8C, there was a growth in maximum temperature quantities. The orientation seen was that elevated discharge rates cause raised temperatures in the cold plate.

There are different ways to control this excess heat, which is produced by increasing the current rate. One way is to increase the entrance temperature. The distribution of the temperature within the confines of the plate at the termination of 4 and 8 current-rates constant current discharging cycles, which was acquired by computer simulations, is illustrated in

Figure 11. It can be seen that, by selecting the entrance flow rate equal to 0.5 m/s, only 1 K was seen in the variation of maximum temperature. Therefore, it is possible to dissipate the extra heat, which is generated from 4 to 8C by higher entrance velocity. Notwithstanding, this small temperature variation between cases a and b could be eliminated with an entrance velocity higher than 1 m/s.

5.5. Influence of Plate Material

Copper and aluminum were selected as the materials for the cooling plate. It should be noted that plate material not only influences the temperature profile but it could also influence the pressure reduction and flowing resistance. Temperature distribution for these two cases is shown in

Figure 12. As can be seen in the figures, although a aluminum plate has a higher maximum temperature, it could create more uniform temperature distribution on the surface compared to a copper plate. This is a desired property, more smooth temperature distribution at the cost of higher average temperature.

It was observed that, by changing the plate material, the usual cooling patterns are identical, exhibiting negligible temperature discrepancy at the outlet of the cooling.