Abstract

Lithium–sulfur batteries (LSBs) are favorable candidates for advanced energy storage, boasting a remarkable theoretical energy density of 2600 Wh kg−1. Moreover, several challenges hinder their practical implementation, including sulfur’s intrinsic electrical insulation, the shuttle effect of lithium polysulfides (LiPSs), sluggish redox kinetics of Li2S2/Li2S, and the uncontrolled growth of Li dendrites. These issues pose significant obstacles to the commercialization of LSBs. A viable strategy to address these challenges involves using MXene materials, 2D transition metal carbides, and nitrides (TMCs/TMNs) as hosts, functional separators, or interlayers. MXenes offer exceptional electronic conductivity, adjustable structural properties, and abundant polar functional groups, enabling strong interactions with both S cathodes and Li anodes. Despite their advantages, current MXene synthesis methods predominantly rely on acid etching, which is associated with environmental concerns, low production efficiency, and limited structural versatility, restricting their potential in LSBs. This review provides a comprehensive overview of traditional and environmentally sustainable MXene synthesis techniques, emphasizing their applications in developing S cathodes, Li anodes, and functional separators for LSBs. Additionally, it discusses the challenges and outlines future directions for advancing MXene-based solutions in LSBs technology.

1. Introduction

Conventional lithium-ion batteries (LIBs) face significant challenges owing to their limited energy conversion efficiency and high production costs, making them less capable of meeting the increasing demand for energy storage, especially in the electric vehicle sector [1,2]. In contrast, LSBs offer several advantages, such as an impressive energy density of 2600 Wh kg−1, eco-friendliness, and the low cost of sulfur (S). These features make LSBs highly promising for advancing electric vehicles and smart grid technologies [3,4,5]. However, several inherent challenges hinder the commercialization of LSBs [6]. First, S and its discharge products, such as Li2S, exhibit extremely poor electronic conductivity, significantly impeding redox reactions and reducing S utilization. For instance, the conductivities of S and Li2S are as low as ~5 × 10−30 and ~10−13 S cm−1, respectively [7]. Second, LiPSs are highly soluble in the electrolyte during cycling, leading to the shuttle effect. This phenomenon accelerates capacity decay and lowers the battery’s coulombic efficiency (CE). LiPSs can penetrate the separator and reach the Li anode, where they react with Li, causing corrosion. Third, Li’s spontaneous reaction with the liquid electrolyte forms a fragile solid electrolyte interphase (SEI) on the anode, further reducing the CE. Lastly, uneven Li deposition can result in internal short circuits, posing significant safety risks to the battery.

To overcome these challenges, scientists have developed various approaches to enhance the activity of LSBs. For S cathodes, C-based hosts like porous C [8], CNTs [9], and hollow C spheres [10] have been engineered to entrap polysulfides within their nanopores. Nevertheless, the non-polar nature of C composites limits their ability to effectively immobilize polysulfides. To address this, polar host materials with strong chemisorption characteristics for LiPSs have garnered significant interest. These include heteroatom-doped carbons (for instance, B-doped [11] and N-doped [12]), metal oxides and sulfides [13,14], MXene [15], and GO [16], have gained significant attention. For Li anodes, various strategies have been explored to stabilize the Li/electrolyte interface and adjust Li deposition. These include the use of electrolyte additives, 3D current collectors, protective physical layers, and solid electrolytes [17].

MXenes are a versatile family of 2D TMCs and TMNs. The first discovered MXene, Ti3C2Tx (where Tx signifies surface-terminating groups like O, OH, and F), is synthesized using selectively etching of an A-layer from the parent MAX phase. The MAX phase has the common formula Mn+1AX; here, M is the early transition metals (TMs), A is typically an element from groups IIIA or IVA (e.g., Ti, V, Nb, or Mo), X represents C or N, and n varies from 1 to 3. The derived MXenes follow the formula Mn+1XnTx; here, M denotes the TMs site, X refers to the C or N atoms, n varies from 1 to 4, and Tx indicates the functional groups attached to the surface. Structurally, MXenes preserve a hexagonal close-packed (hcp) arrangement like the basal plane of their MAX phase. In this framework, the TM atoms (M) form a densely packed layer, while the X atoms occupy octahedral sites between these M atom layers.

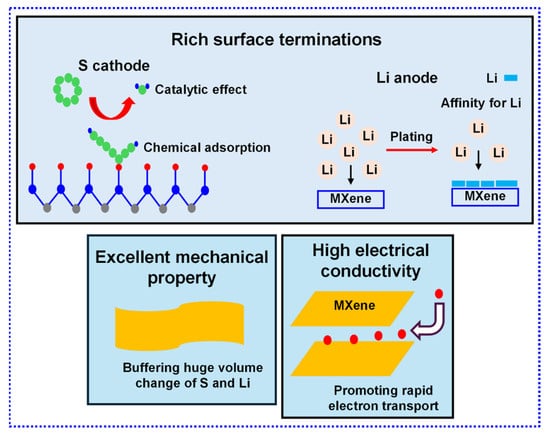

MXene, characterized by outstanding conductivity, remarkable mechanical properties, and adjustable interlayer distance [18,19,20], presents significant promise for advancing LSBs (Figure 1). Its potential is evident in several key respects: (i) MXene’s superior conductivity facilitates efficient reduction of S at the cathode, thereby achieving high S consumption. (ii) The ample polar functional groups on its surface exhibit a robust affinity for LiPSs, efficiently minimizing their dissolution into the electrolyte and enhancing the CE of LSBs. Furthermore, these functional groups act as catalysts, accelerating the conversion of LiPSs into Li2S2 and Li2S, thereby improving reaction kinetics. (iii) The polar functional groups also enable robust chemisorption of Li+, promoting uniform Li nucleation and deposition. (iv) MXene’s exceptional mechanical strength ensures electrode stability during cycling, while its customizable architecture makes it adaptable for various scenarios. Despite these benefits, the practical implementation of MXene in LSBs is constrained by environmentally detrimental preparation processes and suboptimal structural design.

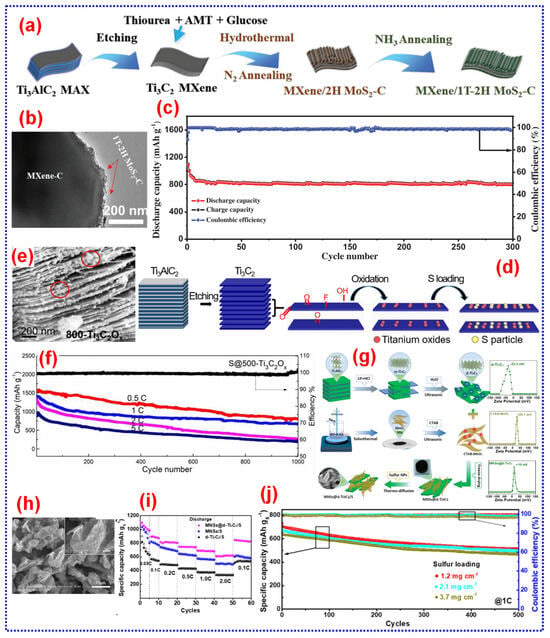

Figure 1.

Distinctive benefits of MXene for LSBs.

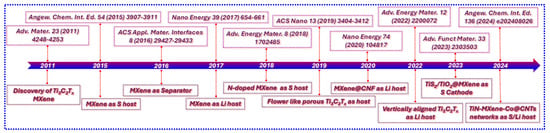

In this work, we first explore the preparation approaches of MXene, transitioning from conventional techniques to eco-friendly alternatives. We thoroughly evaluate how these methods impact the cost, energy efficiency, environmental sustainability, and structural characteristics of the resulting MXene. Subsequently, we review recent progress in the application of MXene as a cathode and anode host, as well as a functional interlayer or separator in LSBs (Figure 2), with a focus on the relationship between MXene’s surface chemistry and the energy storage performance of LSBs. The studies highlighted in Figure 2 collectively showcase the evolution of MXenes in LSBs, beginning with the discovery of Ti3C2Tx MXene in 2011. Early work demonstrated MXene’s potential as a conductive S host (2015) and as a separator coating (2016) to suppress polysulfide shuttling. Subsequent research explored MXene as a Li host (2017) and incorporated N-doping (2018) and porous architecture (2019) to enhance active material utilization and ion transport. Hybrid structures such as MXene@CNF (2020) and vertically aligned MXenes (2022) improved Li plating stability and ionic conductivity. Recent innovations include multifunctional composites like TiS2/TiO2@MXene (2023) and 3D TiN-MXene-Co@CNT networks (2024), which synergistically address conductivity, polysulfide retention, and structural stability. These advancements have progressively established MXenes as versatile and high-performance components for next-generation LSBs. Lastly, we propose future directions for MXene synthesis and discuss its potential for real-world applications in LSBs.

Figure 2.

Key advancements in the MXene for LSBs.

2. Synthesis of MXene

MXene originates from the MAX phase (Mn+1AXn), a ternary layered carbide or nitride, where “A” denotes elements from groups IIIA or IVA, for instance, Al, Si, or Ti. Due to the robust metallic M-A bonds with high bond energy [21], simple mechanical exfoliation cannot separate MXene sheets from the MAX phase. To overcome this, researchers have developed selective etching techniques to eliminate the A-layer from the MAX phase, thereby producing MXene. This etching process generates dangling bonds on the M atomic layer, which accelerates the attachment and coordination of various surface terminations. The synthesis method plays a critical role in determining MXene’s characteristics, including its surface chemistry, sheet size, and structure, as different etching techniques lead to distinct physicochemical characteristics. Traditional etching methods often involve F-containing compounds, which are highly detrimental to the environment and human health. Conversely, green synthesis methods eliminate the use of F, providing a safer and more eco-friendly alternative. This section offers a detailed review of both traditional and green synthesis approaches for MXene. Furthermore, a comparison of the differences between these methods is presented in Table 1.

Table 1.

The differences between traditional and green preparation routes [5].

2.1. Traditional Preparation Routes

2.1.1. HF Etching

In 2011, Gogotsi and colleagues achieved the successful delamination of Ti3AlC2 to synthesize Ti3C2 MXene for the first time using HF etching [22]. This process involves the selective elimination of A-layer from the MAX phase, as outlined below:

Ti3AlC2 + 3HF → AlF3 + 3/2H2 (g)↑ + Ti3C2

Ti3C2 + 2H2O → Ti3C2(OH)2 + H2 (g)↑

Ti3C2 + 2HF → Ti3C2F2 + H2 (g)↑

HF removes Al atoms from Ti3AlC2 through a substitution reaction, releasing H2 as a byproduct. The resulting Ti3C2 reacts further with H2O and HF to yield Ti3C2Tx (Tx: -F, -OH). In 2015, Rosen et al. successfully synthesized Mo2CTx MXene by etching Mo2Ga2C MAX phase, which contains extra A-layer atoms, using HF acid as the etchant [23]. This approach was later applied to produce other MXenes, such as Nb4C3Tx [24] and Hf3C2Tx [25]. Naguib and colleagues immersed the MAX phase in a 50 wt% HF solution for 2 h, followed by washing, etching, and centrifugation, yielding a multi-layered, accordion-type MXene architecture that is difficult to replicate using other etching techniques. This distinctive structure results from the exothermic removal of Al and the release of H2 during the process [26]. Since its introduction, the HF etching route has remained the most widely employed due to its simplicity and rapid effectiveness in etching the MAX phase. Moreover, HF’s extreme corrosiveness poses significant environmental and health hazards and can lead to the over-etching of MXene, adversely affecting its performance. Consequently, there is an urgent need for milder, less toxic, and more eco-friendly alternatives to HF etching technique.

2.1.2. In Situ HF Etching

To address the corrosion challenges associated with HF, Ghidiu and colleagues developed an in situ HF generation etching method. This technique includes the reaction of 6 M HCl with 1.98 g of LiF to produce in situ HF, which specifically removes the Al atomic layer from Ti3AlC2. The process yields a clay-type MXene with exceptional dispersion and hydrophilicity, suitable for direct use as a flexible thin-film electrode using a simple rolling technique [27]. Additionally, this etching process can be modified by substituting LiF and HCl with other fluoride salts (NaF, KF, CsF) and strong acids like H2SO4. Halim’s team suggested that NH4HF2 could serve as an alternative to HF for etching the Al layer from Ti3AlC2 [28]. Feng et al [29]. further elucidated the etching mechanism, presenting it through the following reaction formulae:

Ti3AlC2 + XHF2 → XaAlFb + AlF3 + H2 (g)↑ + Ti3C2

AlF3 + cH2O → AlF3. cH2O

Ti3C2 + XHF2 + H2O → Ti3C2Fx(OH)yXz

In this context, “X” represents cations such as NH4+, K+, and Na+; while a, b, c, x, y, and z denote the numerical values [29]. The equations above highlight that both H+ and F− ions are essential for MXene production, suggesting that this method operates through a reaction process similar to HF etching.

Compared to conventional HF etching, this approach offers several advantages: (i) it involves safer and milder preparation processes; and (ii) cations in the solution, such as Li+ and NH4+, intercalate between MXene layers, increasing interlayer spacing and reducing van der Waals forces, thereby simplifying synthesis, resulting in fewer -F terminations and more -O terminations, which minimizes side reactions. As a result, this method has become a preferred approach among researchers for synthesizing MXene. However, some challenges persist, such as the formation of unetched residual MAX phase biproducts, lower etching efficacy, and the lengthy nature of the process.

2.1.3. Molten Fluorine Salt Etching

Compared to carbide MAX precursors, nitride MAX precursors have stronger bonds between the A and M layer atoms, requiring greater energy to eliminate the A-layer. Furthermore, Tin+1Nn precursors are less stable and can easily dissolve in HF. To overcome these challenges, Urbankowski et al. introduced this etching route in 2016 for synthesizing nitride MXene [30]. In this approach, Ti4AlN3 was etched using a molten fluoride salt mixture (LiF, KF, and NaF in a mass ratio of 29:59:12 wt%) and calcined at 550 °C in an Ar atmosphere to eliminate the Al layer. After etching, fluoride impurities were eliminated with H2SO4, and Ti4N3Tx NSs were obtained through TBAOH intercalation and sonication. This method relies on precise temperature control and the use of an inert atmosphere to selectively etch the Al layer while maintaining the structural integrity of Ti-N bonds in Ti4N3. Nitride MXenes prepared using this method exhibit improved electronic conductivity and a higher DOS. Additionally, non-terminated Ti4N3 displays metallic and magnetic characteristics. Furthermore, Ti4N3Tx MXenes exhibit lower crystallinity compared to those produced by the previously mentioned etching methods, resulting in reduced flexibility.

2.1.4. Water-Free Etching

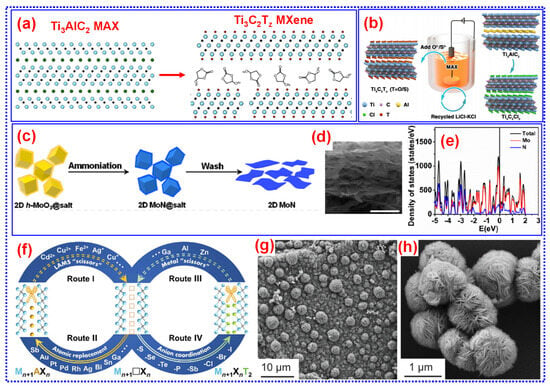

Acid-etching methods typically rely on water as a solvent, which can limit the potential applications of MXene. For instance, certain polymerization reactions cannot proceed in the presence of water, and quantum dot (0D) materials cannot be integrated with MXene under aqueous conditions. Moreover, even trace amounts of water in MXene materials can significantly degrade battery performance. As a result, MXene must undergo vacuum annealing before cell assembly. To address these limitations, Natu and colleagues introduced an innovative method that utilizes organic polar solvents like DMF, NMP, DMSO, and PC in combination with NH4HF2 to etch MAX precursors in the water-free atmosphere. This process produces Ti3C2Tx with a high-content of -F terminations (Figure 3a) [31]. MXene composite electrodes prepared using this approach demonstrated twice the anode capacity in SIBs compared to those etched in water. Moreover, this method requires significantly more time (196 h compared to 48 h for aqueous etching) and necessitates working in a glove box, adding operational complexity for researchers.

Figure 3.

(a) Pictorial demonstration of water-free etching approach. Adapted from [31], Copyright 2020, Elsevier B.V. (b) Preparation of MXene from the MAX phase by molten salt assisted electrochemical etching and the in situ modification of surface terminations. Adapted from [32], Copyright 2021, Wiley-VCH. (c–e) Pictorial demonstration of preparation and DOS of 2D MoN. Adapted from [33], Copyright 2017, American Chemical Society. (f) Pictorial representation of structural editing of MAX phases and MXenes using chemical scissor-mediated intercalation procedure. Adapted from [34], Copyright 2023, The AAAS. SEM micrograph of (g) microspheres developing on carpets, and (h) individual microspheres. Adapted from [35], Copyright 2023, The AAAS.

2.2. Green Synthesis

Traditional MXene synthesis methods suffer from several limitations, including high energy requirements, the use of toxic HF, and the production of hazardous waste, making them less environmentally sustainable and impractical for industrial-scale applications. As a result, there is an urgent demand for green, energy-efficient, controllable, and environmentally friendly synthesis approaches. Furthermore, conventional methods limit MXene surface terminations to -F and -OH, whereas green preparation approaches can create new terminations with stronger affinities for S and Li, enabling improved structural control of MXene. These methods also allow for electronic modulation by creating defect vacancies and single-atom doping, thereby enhancing MXene’s characteristics [36]. Exploring green preparation strategies is therefore essential for achieving greater structural diversity, advanced surface chemistry, precise synthesis, and broader potential advantages of MXene.

2.2.1. Electrochemical Etching

Etching with F-containing agents creates -F terminations on MXene, which can react with residual water to produce HF, potentially causing electrode corrosion. Hence, the development of F-free etching methods for MXene is crucial. Electrochemical etching offers a viable alternative, utilizing a cathode–anode system submerged in an electrolyte. By applying a voltage difference and carefully adjusting the voltage range (etching potential) within the reaction window between the A and M atomic layers, the A-layer in the MAX phase can be precisely removed [37]. In 2017, Sun et al. pioneered the preparation of MXene using an F-free solution through the electrochemical etching approach [38]. Building on this, Yang et al., in 2018, successfully etched Ti3AlC2 using a two-electrode electrochemical system [39]. In this method, a mixture of NH4Cl and TMAOH was used as an electrolyte, with Ti3AlC2 acting as both the cathode and anode. The chemical reactions involved proceeded as below:

Ti3AlC2 − 3e− + 3Cl− → Ti3C2 + AlCl3

Ti3C2 + 2OH− − 2e− → Ti3C2(OH)2

Ti3C2 + 2H2O → Ti3C2(OH)2 + H2 (g)↑

Shen and colleagues initiated a molten salt-assisted electrochemical etching technique. By subjecting the MAX precursor to a 2 V voltage in a LiCl-KCl molten salt environment, they successfully synthesized Ti3C2Cl2 without introducing any metal impurities. To modify the surface terminations, they substituted -Cl with -O or -S by utilizing different salts, streamlining the process of functional group modification and broadening the variety of achievable functional groups (Figure 3b) [32]. This technique significantly accelerates MXene preparation due to the application of an electric field. Moreover, it offers a safer etching atmosphere, and the resulting MXene film features a large lateral size. However, the harsh etching conditions constrain the MXene yield, presenting challenges for scaling up production.

2.2.2. Salt-Templated Approach

Gogotsi and colleagues introduced a salt-templated technique to enable the large-scale synthesis of nitride MXene [33]. The process involved coating NaCl with MoO3, achieved by calcining a Mo precursor deposited NaCl under an Ar atmosphere. This was followed by ammoniation to convert the coating into MoN. Lastly, the NaCl was dissolved through washing, successfully isolating MoN. By adjusting the precursor and synthesis parameters, it is possible to produce a broader range of nitride MXenes. The resulting product exhibits metallic characteristics and exceptional rate capabilities (Figure 3c–e). This approach offers significant promise for producing high-quality nitride MXenes without relying on etching processes.

2.2.3. Alkali Etching Approach

Aluminum’s amphoteric nature allows it to react with acids and bases, making NaOH a viable etchant for synthesizing Ti3C2Tx [40]. In this process, OH− ions react with Al to form Al(OH)4−, which interacts with Ti3C2 to yield Ti3C2Tx. However, the Ti3C2Tx structure is unstable in alkaline environments and prone to corrosion. To address this, Li and colleagues introduced an alkali-assisted hydrothermal technique, carefully controlling the NaOH concentration (27.5 M) and reaction temperature (270 °C) to prevent framework corrosion [41]. Despite its effectiveness, this method requires high temperatures and concentrated alkali, raising safety concerns and limiting scalability. As a safer alternative, Xuan et al. utilized organic bases such as TBAOH as etching agents to intercalate and delaminate Ti3AlC2, facilitating the formation of Al(OH)4− as the surface termination of Ti3C2 [42]. Although the alkali-assisted hydrothermal method yields MXene with great purity (92 wt%), the resulting material is often multilayered and requires additional delamination to achieve few-layer or monolayer MXene for broader applications. On the other hand, the TBAOH method necessitates HF pretreatment to remove surface oxides from Ti3AlC2, introducing safety risks.

2.2.4. Lewis Acidic Molten Salt Etching

Although many MAX phases contain non-Al atomic layers, studies on synthesizing MXene from the MAX phases without Al layers remain scarce. Li’s group demonstrated a process using high-temperature ZnCl2 molten salts to process MAX phases with Al atomic layers. This approach enabled the formation of novel MAX precursors with Zn as the A-layer, such as Ti3ZnC2, V2ZnC, and Ti2ZnN [43]. Building on this work, Huang’s group introduced this approach. In this strategy, Lewis acid cations with greater redox potentials oxidize and selectively etch the A-layers of MAX phases with lesser redox potentials [44]. Using CuCl2 molten salts at elevated temperatures, this method successfully etched MAX phases with A-layers made of elements like Si, Zn, and Ga, resulting in MXene materials rich in -Cl terminations. The details of the etching process are as follows:

Ti3SiC2 + 2CuCl2 → Ti3C2 + SiCl4 (g)↑ + 2Cu

Ti3C2 + CuCl2 → Ti3C2Cl2 + Cu

Huang and colleagues, in 2023, proposed a “chemical scissor” strategy for structural modification of MAX phases and MXene, paving the way for 3D assembly of 2D materials (Figure 3f) [34]. This innovative technique expands the variety of MAX phases that can be utilized and enables precise tuning of MXene’s surface functional groups and structural characteristics. Despite its potential, the application of this approach is restricted by the intrinsic characteristics of traditional Lewis acidic molten salts, such as their low redox potential and instability at high temperatures. Additionally, the chemical mechanisms underlying the intercalation process remain insufficiently understood.

2.2.5. UV Induced Selective Etching

UV irradiation has been reported to increase the surface reactivity of materials, with Mo2Ga2C standing out for its exceptional UV-absorbing characteristics. Mei and colleagues, in 2020, leveraged a UV-sensitive Mo2Ga2C precursor and employed UV irradiation under mild conditions in the presence of phosphoric acid to etch Ga atoms. This process yielded Mo2C MXene NSs, which, after ultrasonic delamination, demonstrated potential as anodes for rechargeable batteries [45]. This approach allows for the synthesis of MXene within just a few hours, significantly dropping fabrication time. Moreover, the Mo2C exhibits mesoporous architecture, making it highly favorable for electrochemical applications. Nevertheless, the technique may require specialized equipment and precise control of the reaction conditions, potentially necessitating advanced technical expertise. In summary, while this etching offers notable benefits in certain applications, its strengths and limitations should be carefully evaluated based on the intended use.

2.2.6. CVD

CVD is a versatile technique that enables gaseous precursors to react and form solid materials, which are then deposited onto substrates for fabricating thin films, and heterostructures. Xu and colleagues employed the CVD method to directly synthesize ultrathin α-Mo2C 2D crystals with lateral dimensions exceeding 100 μm by employing methane as the C source and Cu/Mo foils as substrates at 1085 °C [46]. Later, Geng and colleagues utilized CVD to grow Mo2C on graphene, achieving lateral sizes till the centimeter dimension [47]. Notably, the Mo2C structures synthesized on graphene exhibit greater uniformity and possess hexagonal structures compared to pure Mo2C crystals. Recently, Talapin and colleagues developed a “carpet-like” Ti2CCl2 structure by depositing a gas blend of CH4 and TiCl4 onto a surface of Ti at 950 °C. This MXene featured a unique spherical architecture formed through bending and unfolding, resulting in a highly accessible surface with exposed catalytically active edges, offering exceptional Li+ storage capacity (Figure 3g,h) [35]. CVD offers several advantages: (i) it enables the direct preparation of MXene, free of surface functional groups, enabling a detailed examination of its internal atomic layer structure; (ii) it produces MXene with greater lateral sizes, great surface quality, less defect density, and precise control; (iii) it eliminates the need for MAX phase precursors, significantly reducing preparation time. Despite these advantages, the range of MXenes that can be synthesized through CVD is currently limited. Furthermore, the great production costs and stringent reaction environments, such as extended durations, specific gas requirements, and elevated temperatures, pose significant challenges for large-scale purposes.

2.2.7. Thermal Reduction

In 2020, Sun and colleagues proposed a novel thermal reduction as a straightforward and eco-friendly approach for preparing MXene. This process involved heating the Ti2SC MAX phase in an Ar and H2 atmosphere at 800 °C to precisely remove S atoms. The process was followed by ultrasound-supported treatment, yielding free-standing 2D Ti2C NSs [48]. This straightforward technique shows promise for large-scale industrial production. However, it is crucial to keep the temperature below 700 °C to prevent the nucleation of TiO2, which can adversely impact MXene yield and quality.

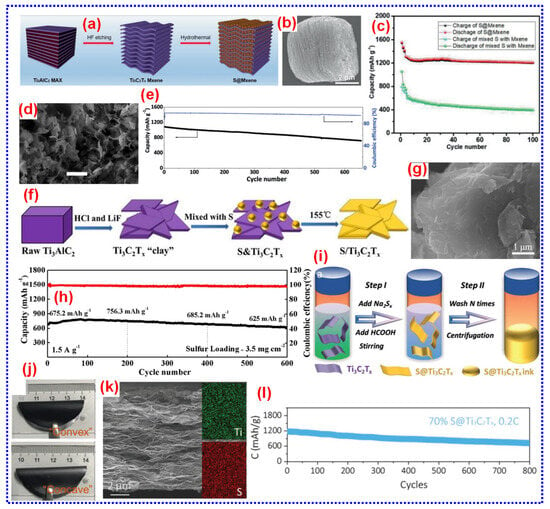

2.2.8. In Situ Hydrothermal Process

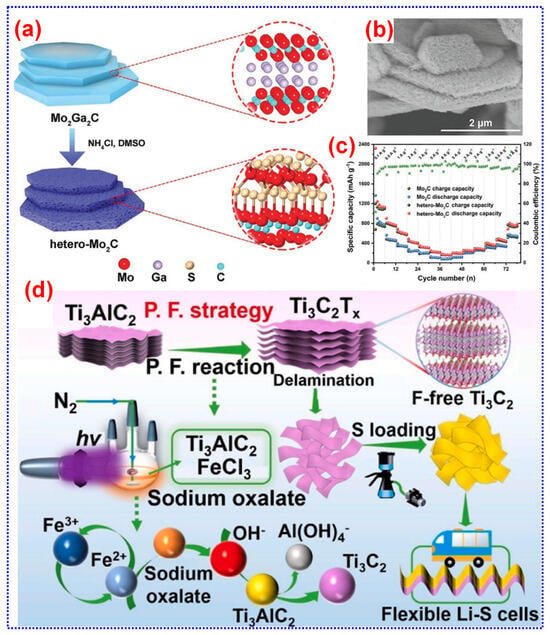

The hydrothermal process involves conducting a reaction within a sealed container, utilizing water as the solvent at a controlled atmosphere inside the reactor [49,50,51]. Song and colleagues employed an in situ hydrothermal process to prepare amorphous MoS2 integrated with F-free Mo2CTx. This was achieved using NH4Cl as the etchant, DMSO as the S source, and Mo2Ga2C as the starting material, under conditions of 180 °C for five days [52]. This study offers fresh perspectives on developing novel heterogeneous MXenes beyond traditional types, broadening the scope of MXene research. Moreover, the incorporation of MoS2 imparts a distinctive morphology and heterojunction structure to the heterogeneous Mo2C, enhancing its structural stability. This modification adjusts the Li+ storage activity and facilitates ion movement. Additionally, the hetero-Mo2C sample demonstrated outstanding cycle stability, retaining a capacity of 683.9 mAh g−1 after 1200 cycles (Figure 4a–c).

Figure 4.

(a–c) Diagram illustrating the preparation and FE-SEM image of hetero-Mo2C and the cycle performance of hetero-Mo2C and Mo2C samples at 1 A g−1. Adapted from [52], Copyright 2022, Wiley-VCH. (d) Pictorial demonstration of P.F. approach for the preparation of Ff-Ti3C2. Adapted from [53], Copyright 2022, American Chemical Society.

2.2.9. Photo-Fenton (P.F.)

The P.F. is among the widely investigated advanced oxidation processes, recognized as a promising approach for pollutant removal through reactive oxygen groups in both homo- and heterogeneous iron-mediated techniques [54,55,56,57]. Xiao and colleagues introduced a low temperature “soft chemistry” technique depending on the P.F. process. In this process, Ti3AlC2 was immersed in a solution of Fe (III) and Na2C2O4 under continuous stirring. H2O2 was then added, and the mixture was exposed to UV illumination while stirring for 10 h. After centrifugal drying, F-free Ti3C2 (Ff-Ti3C2) with a purity of up to 95% was obtained [53]. During the P.F. reaction, reactive oxygen species (HO* and O2*−) are continuously generated, weakening the Ti-Al bond in the MAX phase and promoting the high concentration of OH− formation, which facilitates the topochemical delamination of Al layer. The resulting Ff-Ti3C2 displays exceptional mechanical stability, enhanced wettability of the electrolyte, and robust electrocatalytic action for the decomposition of Li2S, making it an excellent S cathode host for advanced LSBs (Figure 4d). However, the use of light sources and oxidative processes in the P.F. technique may result in extensive synthesis periods compared to further preparation techniques, potentially enhancing experimental complication and costs.

2.2.10. Physical Vacuum Distillation

Feng and colleagues introduced an acid- and F-free physical vacuum distillation technique for the direct synthesis of various MXenes [58]. This method began with the incorporation of low-boiling-point Zn into the MAX phase using ZnCl2 molten salt. Later, the A-layer is removed through this technique, leading to the successful fabrication of a range of F-free MXenes with different TMs. These included Nb2CTx, Ti3C2Tx, Nb4C3Tx, Ta2CTx, and Ti2NTx, where Tx denotes -Cl and -O functional groups. The activity is governed by the following reactions:

Ti3AlC2 (s) + 1.5ZnCl2 (s) → Ti3C2 (s) + 1.5 Zn (s) + AlCl3 (g)↑

Ti3C2 (s) + ZnCl2 (s) → Ti3C2Cl2 (s) + 1.5 Zn (s)

Zn (s) → Zn (g)↑

The structure of MXene and specific surface area (SSA) can be customized by varying the temperature, making them suitable for diverse applications. This synthesis approach eliminates the need for acids or bases, and the metallic Zn can be reclaimed after evaporation, offering an eco-friendly, cost-efficient, and sustainable approach for producing various MXenes. Additionally, this technique shows great promise for large-scale production owing to its affordability, straightforwardness, and precise control. Furthermore, despite its capability for single-step MXene synthesis, the method operates at high temperatures. Therefore, developing alternative preparation techniques that work at room temperature or lower is crucial for enabling the industrial utilization of MXenes.

Therefore, MXenes can be produced through various synthesis techniques, including acid, and electrochemical etching, salt templating, and physical vacuum distillation. Traditional acid etching typically yields MXenes with surface functional groups like -OH, -O, and -F. In contrast, methods like electrochemical etching, salt templating, and vacuum distillation may present alternative functional groups, like S or Cl. These electronegative elements exhibit strong interactions with S and Li, enhancing electrochemical performance. By selecting and optimizing the preparation approach, the surface chemistry of MXenes may be effectively tailored to enhance the performance of LSBs. Table 2 summarizes the preparation approaches, electrochemical performance, and characteristics of MXenes, while Table 3 outlines design recommendations for their application in S cathodes, separators, and Li anodes in LSBs.

Table 2.

The characteristics, benefits, limitations, electrochemical characteristics, and impact on surface terminations associated with various MXene preparation techniques [5].

Table 3.

Guiding principles for utilizing MXene in various applications for LSBs [5].

3. The Characteristics of MXenes

3.1. Structural Characteristics

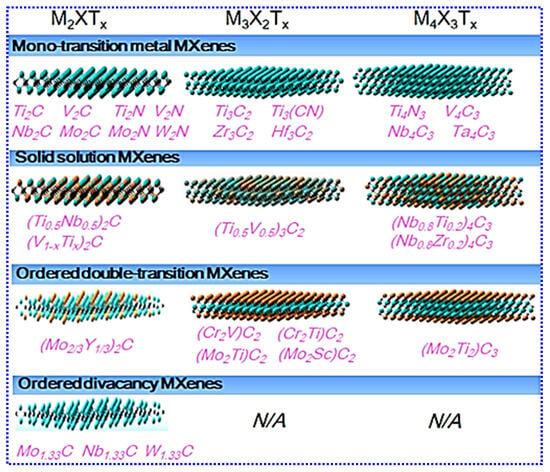

Atomic structure of MXenes is key to investigating their unique properties. As earlier discussed, MAX precursors are layered hexagonal materials classified under the P63/mmc space group, where alternating “MX” and “A” layers stack along the c-axis. When the A-layer is removed, MXenes retain the hexagonal close-packed structure of their parent MAX phases. This structural continuity means that the compositional and structural diversity of MAX precursors clearly translate into a wide range of MXenes. Researchers have identified numerous new MAX precursors to prepare unique MXenes. Depending on the choice of “M,” MXenes can be categorized into four distinct varieties [62], as depicted in Figure 5. The first and most common category is mono-TM MXenes. Examples include Ti2C [63,64,65,66], Ti2N [67,68,69,70], Nb2C [71,72], V2C [71,73], V2N [74,75], Cr2C [76,77], Ta2C [78,79], Mo2C [23,80,81], Ti3C2 [82,83,84], Zr3C2 [85], Hf3C2 [25], Ta4C3 [26,86], Nb4C3 [87,88], V4C3 [89,90], and Ti4N3 [30,91], among others. The second category consists of randomly arranged double-TM (double-M) MXenes, such as (Ti,Nb)2C [26,92], (Cr,V)3C2 [26,93], (Nb,V)2C [94], (Nb,Ti)4C3 [95], (Nb,Zr)4C3 [95], and (Mo,V)4C3 [96], among others. The third category includes ordered double-M MXenes, such as Mo2TiC2 [97], Cr2TiC2 [98], Mo2Ti2C3 [97], and Mo2ScC2 [99]. The final category is ordered divacancy MXenes, for example, Mo1.33C [100] and W1.33C [101]. Newly, some high-entropy MXenes have also been investigated, including Ti1.1V0.7CrxNb1.0Ta0.6C3Tz (Tz = -F, -O, -OH) [102], TiVNbMoC3Tx [103], TiVCrMoC3Tx [103], and (Ti1/3V1/6Zr1/6Nb1/6Ta1/6)CxN1-xTy [104].

MXenes can also be prepared from non-MAX precursors. For instance, layered carbides like Zr3Al3C5 [85], Hf3(AlSi)4C5 [25], and Mo2Ga2C [23] have been utilized to produce Zr3C2Tx, Hf3C2Tx, and Mo2CTx, respectively. Additionally, surface terminations are critical to the structural diversity and characteristics of MXenes, with their nature strongly influenced by the preparation process. These surface groups can be precisely tailored through post-treatment processes. For example, F terminations can be eliminated through high-temperature vacuum annealing [105] or alkali behavior [106]. O terminations can be introduced by exposing MXenes to O2 [107], CO2 [108], and Li2O treatment [44], or by transforming OH terminations through vacuum annealing [105]. Conversely, O terminations can be eliminated under a H2 atmosphere [105], while halide terminations can be eliminated using LiH [44]. Additionally, terminations of S, Se, and Te can be incorporated by treating MXenes with NaNH2, Li2S, Li2Se, and Li2Te, respectively [44]. However, conventional etching methods often lead to the oxidation and hydrolysis of resulting MXene moieties. Thus, it is crucial to establish a clear structure–property relationship for MXenes to better understand how to prevent their degradation. This will help improve their oxidative and aqueous-phase stability.

Figure 5.

Structures of synthesized MXenes. Adapted from [109], Copyright 2021, Wiley-VCH.

3.2. Electronic Characteristics

Theoretical studies have revealed that MXenes can display diverse electronic properties, ranging from metallic and semiconductor-like to topological insulating behaviors depending on their M and X atoms, as well as T surface terminations [110]. Interestingly, the electronic characteristics of MXenes are more significantly influenced by their external metal atomic layer than the internal metal layer [111]. While most MXenes exhibit a metallic nature, a subset has been predicted to function as semiconductors. Kawazoe and colleagues demonstrated through simulations that Sc2CT2 (T = F, OH, and O), Ti2CO2, Zr2CO2, and Hf2CO2 are semiconductors with band gaps spanning 0.24 to 1.8 eV [112]. The additional valence electrons contributed by N atoms make Mn+1CnTx generally more favorable as semiconductors, whereas Mn+1NnTx tends to exhibit stronger magnetic properties [112]. Surface terminations are also pivotal in shaping MXenes electronic characteristics. For instance, their work functions range widely from 1.6 to 8.0 eV [113] and can be finely tuned by modifying the surface termination groups [113]. Generally, OH terminations typically result in lower work functions owing to their effective surface dipole moment, while terminations of O and F yield greater work functions due to their great electronegativity [114].

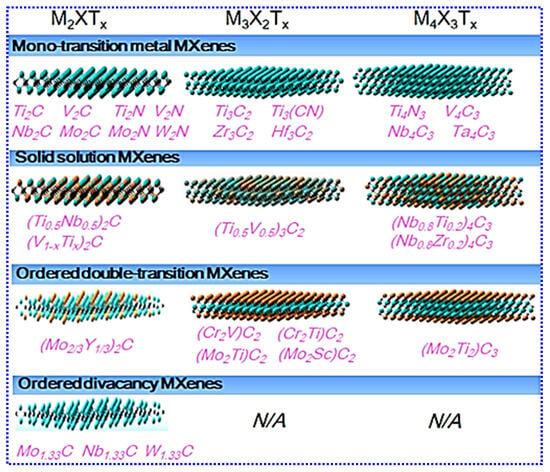

To date, all experimentally synthesized MXenes have exhibited metallic or semi-metallic characteristics, with no semiconducting MXenes realized yet. Studies show that MXene electrical conductivity is significantly affected by factors like the precursor material, its size, etching techniques, and post-treatment processes [115]. For instance, post-annealing treatments can efficiently eliminate water, intercalants, and surface functional groups, resulting in enhanced conductivity (Figure 6a–c) [105]. Recently, Gogotsi and colleagues set a record for MXene conductivity, achieving approximately 20,000 S cm−1 for Ti3C2Tx by optimizing the Ti3AlC2 MAX [115]. Surface terminations of MXenes, typically uncovered by synthesis methods, are often diverse and contribute to their wide-ranging properties [113]. For instance, the commonly studied Ti3C2Tx generally features terminations like -O, -OH, and -F. These surface groups can be modified through vacuum annealing, allowing adjustments in the work function from 4.1 to 4.8 eV (Figure 6d,e) [114]. Additional chemical treatments, for instance, grafting diazonium surface groups [113], or using ammonium hydroxide [116], N2H4, or UV-ozone [117], provide further control over the MXenes work function. Talapin and co-workers in 2020 reported superconducting transitions in Nb2C with terminations such as -Cl2, -S2, -Se, and -NH at temperatures below 10 K [67]. Moreover, the functional groups present on MXenes facilitate their integration with a variety of organic materials and ligands, greatly enhancing their application potential [118].

Figure 6.

(a–c) Electrical response of MXene films to heat treatment. Adapted from [105], Copyright 2019, Springer Nature. (d) Secondary electron cutoff (SECO) spectra of Ti3C2Tx after heat treatment at various temperatures. (e) Work function measurements of Ti3C2Tx with respect to temperature. Adapted from [114], Copyright 2019, American Chemical Society.

3.3. Mechanical Characteristics

MXenes significantly enhance the performance of S cathodes through three main advantages: (1) enabling uniform and efficient interactions with numerous S moieties; (2) maintaining electrocatalytic activity to facilitate the conversion of polysulfides; and (3) accommodating the substantial volume changes of S during charging and discharging. These benefits stem from the exceptional mechanical stability of MXenes, which permits them to endure the significant volume expansions of S without structural degradation. This stability ensures consistent bonding with S, thereby enhancing the cathode’s performance. The mechanical characteristics of MXenes are closely linked to their surface terminations, thickness, and structural attributes. First-principles measurements by Sun and colleagues demonstrated that 2D Ti2C can withstand considerable strain, enduring 9.5, 18, and 17% under bi- and uni-axial tension beside the x- and y-axes [119]. Additionally, functionalizing the surface with oxygen was found to prevent the failure of the Ti layer, allowing the material to stretch further to 20, 28, and 26.5% in the corresponding directions. This highlights the critical role of surface termination in enhancing the mechanical strength of MXenes [119]. Balke’s group investigated the mechanical properties of stacked Ti3C2 NSs with various surface terminations (-F, -O, and -OH) using DFT [120]. Their findings revealed that OH-terminated MXene layers had a minimal gap distance of 0.57 Å, whereas O- and F-terminated layers exhibited a gap distance of approximately 2.5 Å. The improved elastic constants of OH-terminated MXenes were attributed to the formation of hydrogen bonds between their hydroxyl groups. However, the presence of H2O molecules in the interlayer spaces significantly weakens the mechanical strength of MXenes. Structurally, bare Ti2C displayed greater stiffness and strength compared to bare Ti3C2 and Ti4C3. The Young’s modulus values for these materials were calculated using DFT and molecular dynamics (MD) simulations, yielding 597, 502, and 534 GPa, respectively [119]. Under high strain, the first crack in Ti4C3 was observed to originate at its center, whereas failure in Ti3C2 and Ti2C initiated at their edges [119]. Experimentally, the Young’s modulus of Ti3C2Tx and Nb4C3Tx was evaluated at 0.33 [121] and 0.39 TPa [122], respectively. Compared to other 2D materials, MXenes displayed exceptional mechanical performance, underscoring their competitiveness in this regard.

Although monolayer MXenes exhibit excellent mechanical properties, widely used MXene films are typically composed of stacked multilayer NSs, resulting in significantly lower mechanical performance. For instance, Gogotsi et al. reported that pure Ti3C2Tx films exhibit a Young’s modulus of 3.52 GPa and a uniaxial tensile strain of 1%, significantly lower than the predicted values for monolayer NSs [123]. This disparity is primarily due to the inherent properties of Ti3C2Tx NSs, like their size, defects, imperfect edges, and weak interlayer forces. Low-quality MXene NSs can further compromise mechanical performance, as the interlayer forces in MXene films are primarily van der Waals interactions, which do not provide sufficient mechanical strength to bulk films. Strengthening the interlayer interactions has proven to be a highly efficient strategy for improving the MXenes performance. One common strategy involves introducing ionic or bonding agents. For example, incorporating polyvinyl alcohol (PVA) into Ti3C2Tx films significantly improved their strength [123]. Gogotsi and colleagues demonstrated that the Ti3C2Tx/PVA composite films achieved a tensile strength of 91 ± 10 MPa, almost four times greater than that of Ti3C2Tx films. Similarly, Kim and colleagues drew inspiration from mussel adhesive proteins to utilize dopamine for enhancing interlayer interactions and structural organization in Ti3C2Tx films [124]. By polymerizing dopamine in situ on the surfaces of Ti3C2Tx flakes, they created a thin adhesive layer, resulting in a greatly aligned and densely packed architecture. This modification improved the tensile strength by sevenfold and significantly enhanced the films elongation. Cheng and colleagues developed a high-performance Ti3C2Tx film using a two-step bridging strategy [125]. This process involved sequentially bridging Ti3C2Tx NSs with sodium alginate through hydrogen bonding and Ca2+ ions via ionic bonding. The resulting modified Ti3C2Tx film demonstrated exceptional mechanical properties, including an in-plane tensile strength of 436 MPa and a Young’s modulus of 14 GPa, representing approximately 6.9 and 2.5-fold improvements, respectively, compared to pure Ti3C2Tx NSs. Building on this work, the same team recently implemented an effective densification technique that combined sequential bridging with hydrogen and covalent bonding. This method utilized borate ions for hydrogen bonding and sodium carboxymethyl cellulose (CMC) for covalent bonding [126]. The resulting mixed Ti3C2Tx film achieved remarkable mechanical performance, with a tensile strength of 583 ± 16 MPa, a young’s modulus of 27.8 ± 2.8 GPa, and an impressive toughness of 15.9 ± 1.0 MJ m−3.

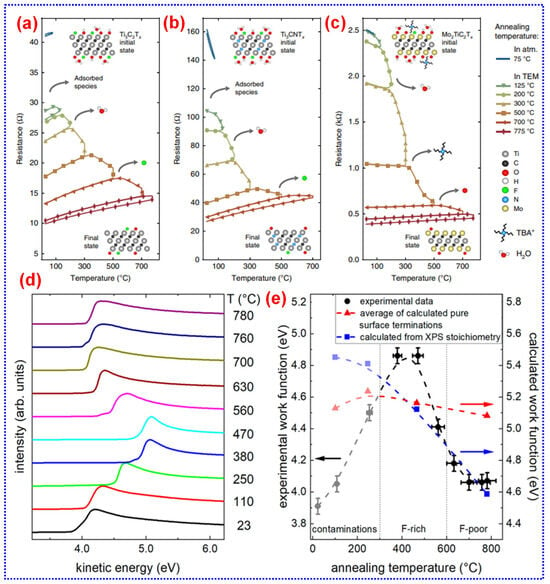

4. Principle of LSBs

As illustrated in Figure 7, LSBs are composed of four main components: the S cathode, metal anode, organic liquid electrolyte, and a porous polymer separator. Unlike conventional LIBs that operate through an “ion intercalation/deintercalation” process, LSBs function based on redox reactions among elemental S and the metal. In LSBs, S acts as the final charge moiety, so the operational cycle typically begins with the discharge activity. During discharge, the metal anode undergoes oxidation, releasing metal cations that migrate toward the cathode in the presence of electric field. At the cathode, these cations react with S to produce metal sulfides. The reverse reactions happen during the charging phase.

Figure 7.

Pictorial demonstration showing the configuration of LSBs. Adapted from [127], Copyright 2023, Wiley-VCH.

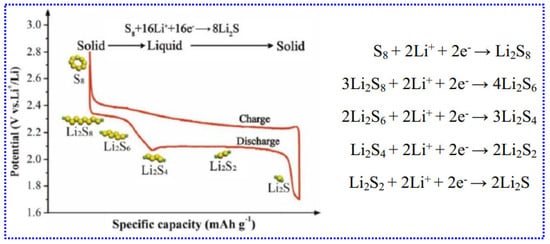

Figure 8 depicts the typical charge and discharge processes of LSBs in ether-related electrolytes. The entire reaction between Li and S is expressed as 2Li + S → Li2S. However, the actual conversion process between S and metal sulfides is more complex. At room temperature, elemental S exists as crown-shaped S8 rings, and the charge/discharge process implies the breaking and reforming of these S8 molecules. During this process, multi-stage LiPSs (Li2Sx, 1 ≤ x ≤ 8) are formed as intermediates [128]. Out of these intermediates, long-chain polysulfides (Li2Sx, 4 ≤ x ≤ 8) are greatly soluble in ether-related electrolytes. This high solubility has both advantages and disadvantages. On the positive side, it enables faster reaction kinetics due to liquid-phase reactions. However, it also leads to the undesirable shuttle effect, where dissolved polysulfides migrate between the electrodes, causing premature battery degradation. In contrast, short-chain polysulfides (Li2Sx, 1 ≤ x < 4) exhibit moderate solubility, reducing dissolution and shuttle-related issues. Nevertheless, their poor conductivity and slower kinetics, resulting from solid-phase reactions, hinder complete charge/discharge cycles. This limitation leads to reduced battery capacity, higher polarization, and diminished performance.

Figure 8.

Typical charge/discharge curves of a LSBs. Adapted from [129], Copyright 2022, Springer Nature.

5. Challenges and Solutions of LSBs

5.1. Challenges of LSBs

The charge storage activity in LSBs is governed by the reversible redox process between S8 and Li2S, expressed as follows:

S8 + 16Li+ + 16e− ↔ 8Li2S

During the discharge activity of LSBs, multiple intermediate reactions occur, forming various LiPSs (Li2Sx, 1 ≤ x ≤ 8), as illustrated in Figure 8. Discharge curve features two distinct voltage plateaus. The first plateau, observed between 2.4 and 2.1 V, corresponds to the decrease in S8 into long-chain LiPSs, providing a theoretical capacity of 418 mAh g−1, which involves the transfer of 0.5 electrons/S atom. The second plateau, from 2.1 to 1.7 V, reflects the conversion of LiPSs into Li2S2/Li2S, with a theoretical capacity of 1254 mAh g−1, representing 1.5 electron transfers/S atom. Due to the great solubility of LiPSs in the electrolyte, the discharge method includes phase transitions: solid (S8) → liquid (LiPSs) → solid (Li2S2/Li2S). During charging, the reverse reaction takes place, where Li2S2/Li2S is oxidized to LiPSs and eventually back to S8 [8]. However, the charge activity is significantly influenced by electric fields and LiPSs concentration gradients. Some LiPSs dissolve in the electrolyte, diffuse across the separator to an anode, and are degraded to short-chain polysulfides Li2Sn (2 ≤ n ≤ 4). These short-chain polysulfides then migrate back to the cathode where they are reoxidized to LiPSs. This repetitive cycle, called as the “shuttle effect,” causes active S loss, anode passivation, and several issues, including rapid capacity decay, reduced cycle life, minimal CE, and severe self-discharge [130]. Another challenge is the extremely low electrical conductivity of S (5 × 10−30 S cm−1 at 25 °C) and Li2S (10−30 S cm−1 at 25 °C), which limits S utilization and reduces capacity. Furthermore, the substantial volume expansion (80%) during the conversion of S8 (2.03 g cm−3) to Li2S (1.66 g cm−3) can also damage the cathode’s structural integrity [131]. For the Li anode, dendrite formation poses a critical safety risk by potentially causing short circuits. Compared to LIBs, the LSBs are more complex due to direct interactions between LiPSs and the Li anode, leading to “dead Li” formation and material loss [132]. Moreover, volume changes during plating and stripping of Li can compromise the anode’s structural stability, eventually causing its failure [133].

5.2. Solutions of LSBs

For the commercial viability of LSBs, it is crucial to enhance their practical capacity and extend cycle life. Achieving these goals primarily relies on mitigating the shuttle effect, improving electrical conductivity, reducing volume changes, and preventing Li dendrite formation. Key approaches involve the strategic design of the cathode, incorporating an interlayer between the cathode and the separator, and optimizing anode structure.

5.2.1. Rational Construction of S Cathode

Since Nazar and colleagues presented the utilization of greatly ordered mesoporous C (CMK-3) for fabricating CMK-3/S composite cathodes in 2009 [134], the design of S cathodes has become a primary strategy for enhancing the electrochemical activity of LSBs. The conductive mesoporous C structure physically traps the S, improves its utilization, and accommodates the volume changes during the charge–discharge cycles, thereby significantly boosting capacity and cycle stability [135]. Since then, extensive research has been conducted on developing composite materials to encapsulate S, leading to notable advancements in the field [136]. Broadly, the materials used to host S in composite cathodes can be classified to three main categories.

The first category includes conductive C materials, including graphene [137], CNTs [138], C nanofibers (CNFs) [139], various porous C structures [140], and their hybrids [141,142]. These C materials form a conductive framework that facilitates rapid electron transport, enabling efficient utilization of S. Additionally, their porous architecture physically confines S and LiPSs, helping to mitigate the shuttle effect and assist significant volume changes during cycling. Moreover, the nonpolar conjugated C planes offer limited ability to strongly bind polar LiPSs, resulting in capacity declining in S/C composite cathodes. To address this issue, incorporating polar sites into the C matrix through heteroatom doping [143,144,145] introduces additional anchoring points that chemically bind LiPSs, further improving the cycle stability of LSBs [146].

The second category consists of polar inorganic compounds [147], including TM oxides (TMOs) (e.g., TiO2 [148] and MnO2 [149]), TM sulfides (e.g., TiS2 [144] and MoS2 [150]), TMNs (e.g., TiN [151] and VN [152]), and TMCs (e.g., Ti3C2Tx [153] and V2CTx [154]). These materials can chemically trap LiPSs within their frameworks, exhibiting significantly stronger binding energies (B.Es) with LiPSs compared to C materials. As a result, they more effectively prevent the shuttle effect and improve the cycling performance of LSBs. However, most inorganic compounds suffer from low conductivity. To address this, they are often combined with C materials to create S hosts, which concurrently suppress the shuttle effect, enhance conductivity, and accommodate the volume variations of LSBs [155]. This confinement can lead to the accumulation of LiPSs, slowing their redox kinetics, particularly in electrodes with great S loading or during prolonged cycling. Therefore, it is essential not only to adsorb LiPSs but also to enhance the reaction kinetics among LiPSs and Li2S. This strategy helps minimize their accumulation, establish a dynamic balance of adsorption and conversion, and further mitigate the shuttle effect while improving S utilization [156]. Consequently, the third major category of S host materials centers on catalytic materials designed to accelerate the conversion between LiPSs and Li2S. These include metals (e.g., Pt [157], Pt@Ni [158]), metal compounds (Fe3O4 [159], CoP [160], MoS2 [161]), metal-free inorganic compounds (black phosphorous [162], C3N4 [163]), and their composites. To improve electrical conductivity further, these catalytic materials are often integrated with conductive C frameworks, including graphene [161] and porous C [158].

5.2.2. Rational Construction of Interlayer Between Cathode and Separator

Adding an interlayer among the cathode and separator offers an additional mechanism to mitigate the shuttle effect of LiPSs by providing physical confinement and/or chemical adsorption. Research on interlayers has primarily focused on the following categories: (i) C materials with porous architecture and high conductivity, enabling them to physically trap LiPSs while also acting as the upper current collector to enable electron transport and improve LiPSs utilization [164]; (ii) polar metal compounds [165] or heteroatom-doped C [166], which chemically bind LiPSs to prevent their shuttle; (iii) negatively charged materials for instance Nafion [167], which prevent LiPSs through electrostatic repulsion; and (iv) catalytic materials, including metal compounds [168] and metals [169], which accelerate redox kinetics by promoting the conversion of adsorbed LiPSs [170]. Interlayer materials can be applied as coatings or vacuum-filtered layers on the separator or exist as independent components. An ideal interlayer should demonstrate strong LiPSs adsorption, high catalytic activity for LiPSs conversion, and possess properties such as being thin, lightweight, and highly conductive to minimize its impact on the overall cell design.

5.2.3. Rational Construction of Li Anode

To enhance the structural stability of Li anodes in LSBs, several approaches have been exploited. These include designing suitable Li hosts [171], applying protective coatings [172], modifying electrolytes to improve the stability of the SEI [173], and transitioning from liquid to solid-state electrolytes [174]. Among these, the advanced preparation of Li hosts has proven particularly effective in suppressing Li dendrite growth and accommodating the volume variations of Li anodes. A novel Li host should possess the following characteristics: (i) light, durable, and porous to effectively accommodate Li; (ii) electrochemical stability during Li plating and stripping processes; (iii) high conductivity and a narrow Li+ diffusion energy barrier to facilitate fast electrochemical kinetics; and (iv) lithophilic properties to ensure efficient interaction with Li and promote uniform Li nucleation [175].

6. Possibility of MXenes for LSBs

Thanks to their outstanding characteristics, 2D MXenes have been widely investigated and utilized in LSBs, playing critical roles in the cathode, as an interlayer between the cathode and separator, and in the Li anode [176]. Their metallic conductivity promotes efficient electron transport, thereby improving S utilization [177]. The 2D structure offers abundant reaction sites for S conversion and can be engineered into 3D porous frameworks to support high S loading and accommodate volume expansion during cycling [178]. Additionally, MXenes exhibit strong B.E with LiPSs through the formation of metal-S bonds [179] and demonstrate catalytic mechanism to speed up the redox reaction kinetics between LiPSs and Li2S [180]. Consequently, MXenes are considered promising candidates for constructing high-performance cathodes and interlayers in LSBs. In addition to their applications in cathodes and interlayers, MXenes also serve as excellent Li hosts. Their metallic conductivity, coupled with a minimal Li+ diffusion energy barrier, enables rapid Li+/electron transfer and supports fast electrochemical kinetics [181]. Additionally, the abundant surface terminations on MXenes promote homogeneous Li nucleation and growth [182], while their 2D structure offers significant opportunities to design advanced MXene/Li composite structures that effectively inhibit Li dendrite formation [183]. Although other 2D materials, such as graphene, TMOs, and layered double hydroxides (LDHs), have also been explored for LSBs, none of them combine all the advantages offered by MXenes. Graphene, for instance, exhibits excellent conductivity, structural stability, and adjustable surface functionality, making it a favorable S host. However, it lacks catalytic activity to accelerate LiPSs conversion, and its actual conductivity is often reduced due to the incomplete reduction of GO [184]. Similarly, some 2D TMOs and LDHs can adsorb LiPSs and catalyze their conversion, but their limited conductivity restricts S employment [185]. Therefore, MXenes stand out as highly promising materials for constructing high-performance LSBs, offering a unique combination of properties that address key challenges in battery design.

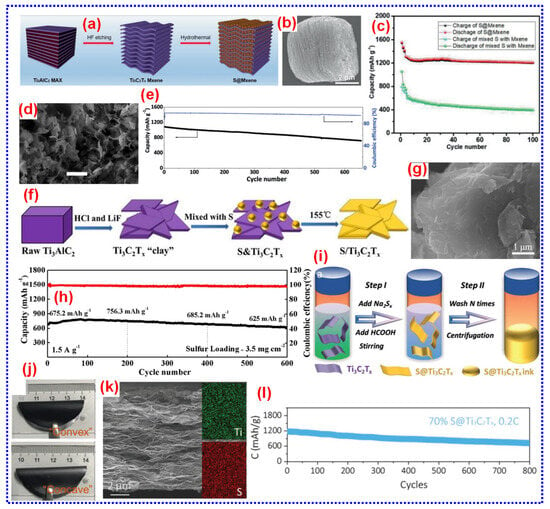

6.1. Conductivity

Since the pioneering discovery of MXene by Gogotsi in 2011 [22], researchers have successfully prepared more than 30 distinct stoichiometric phases of MXenes [62]. These materials are renowned for their exceptional electrical conductivity. For instance, a transparent Ti2CTx film, 100 nm thick and produced via the spin-coating method, exhibits a conductivity of 5.25 × 105 S m−1 [186]. Likewise, a Ti3C2Tx film with a thickness of 214 nm, fabricated through blade coating, achieves a remarkable conductivity of 1.51 × 106 S m−1 [187]. The conductivity of MXenes is primarily governed by interfacial interactions between MXene NSs and can be precisely controlled by altering their composition, structural arrangement, surface terminations, stacking sequence, and intercalants [67]. For example, by controlling the terminations of Nb2C MXene to exclusively include -Cl groups, a remarkable superconductive transition is observed in Nb2CCl2 MXene at 6.3 K [67]. This tunability highlights the versatility and potential of MXenes in applications requiring tailored electrical properties. In LSBs, the metallic conductivity of MXenes enables rapid electron transfer, which supports efficient S utilization and contributes to high capacity and excellent rate performance [177]. Nazar’s group was the first to utilize Ti2CTx MXene NSs as a highly effective S host for LSBs [188]. The resulting S/Ti2CTx cathode, containing 70 wt.% S, achieved an impressive capacity of nearly 1200 mAh g−1 at 0.2 C and 1000 mAh g−1 at a 1 C rate. This demonstrated MXene’s ability to enhance electrical conductivity and electrochemical performance. Furthermore, a Ti3C2Tx interlayer, with a thickness of 522 nm, was vacuum filtrated onto a PP separator. Acting as an upper current collector, this interlayer facilitated electron transfer and enhanced LiPSs utilization. This configuration significantly boosted the capacity of the LSBs, highlighting the advantages of MXenes as interlayer materials for enhancing battery performance [189].

6.2. Structural Variety

The 2D structure of MXenes offers extensive surface contact with S. Moreover, Van der Waals forces and hydrogen bonding cause MXene NSs to stack together, which hinders Li-ion diffusion and limits the maximum utilization [190]. To overcome this, structural modifications can be implemented, such as transforming 2D NSs to 0D nanodots (NDs) or 1D nanoribbons (NRs) or assembling them into 3D porous networks. For instance, 0D Ti3C2Tx NDs were generated in situ and distributed within Ti3C2Tx NSs alongside NRs, which acted as reaction initiators to exfoliate the NSs into smaller NDs. This strategy effectively mitigated the restacking of NSs and self-agglomeration of NDs [191]. Similarly, delaminating 2D Ti3C2 MXenes through a shaking process in KOH solution produced MXene NRs, which facilitated high S loading and rapid Li+ diffusion [192]. Additionally, the abundant surface terminations of 2D MXenes allow their assembly into 3D networks, providing numerous active sites for S use and ample space for great S loading. For instance, a 3D flower type porous MXene structure was synthesized through hydrothermal treatment of Ti3C2Tx MXene in an ethylenediamine solution [193]. This structure exhibited an SSA of 132.8 m2 g−1 and a notable pore volume of 0.262 cm3 g−1. When S was loaded at 61.5 wt.%, the resulting MXene/S cathode achieved an aerial capacity of 10.04 mAh cm−2 with an S loading of 10.5 mg cm−2. These versatile MXene architectures present significant opportunities for developing high-performance LSBs with enhanced S loading.

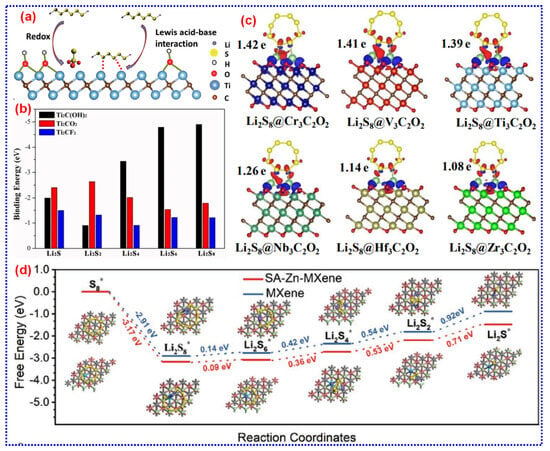

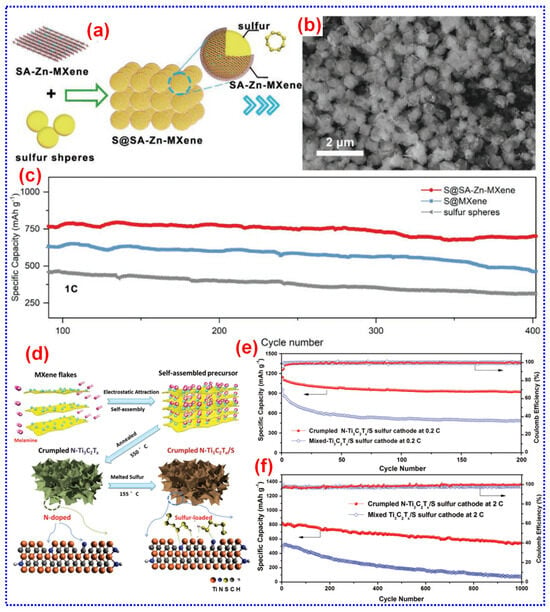

6.3. Adsorption of Soluble Polysulfides Through Chemical Interactions

MXene NSs produced through etching methods are characterized by abundant surface terminations, which play a crucial role in shaping their magnetic [194], electronic [195], and optoelectronic characteristics [196]. These terminations are influenced by the synthesis mechanism [197] or can be customized by post-treatment techniques [67]. Consequently, the characteristics of MXenes may be precisely tuned by modulating their surface terminations. In the context of LSBs, these terminations establish stable chemical interactions with LiPSs, effectively diminishing the shuttle effect and enhancing cycling stability. This functionality makes MXenes highly advantageous as S hosts or as interlayers placed between the cathode and separator [180]. Nazar’s team used XPS analysis to uncover the robust interaction between Ti-based MXenes (for instance Ti2CTx, Ti3C2Tx, and Ti3CNTx) and LiPSs [188]. Their findings suggest that the -OH terminations on MXenes are initially utilized by LiPSs, resulting in the development of thiosulfate and polythionate species. Once the -OH groups are depleted, some Ti atoms with unoccupied orbitals are exposed, allowing these Ti atoms to accept electrons from supplementary LiPSs and form Ti-S bonds through Lewis’s acid–base relations. This dual mechanism, comprising thiosulfate/polythionate transformation and Lewis’s acid–base interactions, enables MXenes to effectively trap LiPSs (Figure 9a). Additionally, DFT measurements validated that Ti-S bond formation is the primary interaction between MXenes and LiPSs [198]. However, the B.E between MXenes and LiPSs must be carefully optimized. Excessively high B.E may cause the breakdown of LiPSs, while too low B.E may fail to securely adsorb them [199]. Achieving an optimal B.E is essential for balancing the binding strength and ensuring the stability of LiPSs. DFT calculations indicate that bare Ti2C free of surface terminations forms excessively strong Ti-S bonds with LiPSs. This interaction disrupts the S-S and Li-S bonds in LiPSs, thereby impeding the reversible reaction among LiPSs and Li2S [198]. As a result, bare Ti2C MXene is not an ideal S host. To address this issue, introducing surface terminations on MXenes is an effective strategy. These terminations facilitate additional reactions with LiPSs and reduce the strength of Ti-S interactions. The B.Es with LiPSs for terminated MXenes follow the order: Ti2CF2 < Ti2CO2 < Ti2C(OH)2 (Figure 9b). On Ti2CO2 and Ti2CF2 surfaces, LiPSs are physically adsorbed, while they bond more strongly to Ti2C(OH)2 surfaces. In this case, the H atoms in Ti2C(OH)2 lower the repulsive forces between negatively charged O and S atoms [198]. Other surface terminations, like -S, -N, and -Cl [200], as well as vacancy defects [201], can also be utilized to adjust MXenes. For instance, S-terminated Ti2C MXene demonstrates a high B.E with LiPSs and a relatively less Li+ diffusion energy barrier, making it an efficient S host with excellent capability to suppress the shuttle effect [200].

Figure 9.

(a) Chemical trapping of LiPSs using MXenes with -OH termination. Adapted from [179], Copyright 2017, Wiley-VCH. (b) B.Es of LiPSs on the terminated Ti2C free of electrolytes. Adapted from [198], Copyright 2017, American Chemical Society. (c) Charge density between Li2S8 and six O-terminated M3C2O2 (M = Cr, V, Ti, Nb, Hf, and Zr). Adapted from [202], Copyright 2019, Royal Society of Chemistry. (d) Gibbs free energy reports of single atom Zn-implanted MXene and MXene interacted with LiPSs. Adapted from [203], Copyright 2020, Wiley-VCH.

In addition to Ti-based MXenes, the interactions of other MXenes with LiPSs have been investigated theoretically [201]. DFT measurements studied six O-terminated M3C2O2 (M = Cr, V, Ti, Nb, Hf, and Zr) MXenes, all of which demonstrated the ability to trap soluble LiPSs (Figure 9c) [202]. Among these, Cr3C2O2 presented the greatest anchoring effect. Furthermore, the study revealed that the anchoring effect for soluble LiPSs increases as the lattice constant of MXenes decreases, offering valuable insights for selecting and designing MXene-based S hosts. The composition, surface terminations, and vacancy defects of MXenes significantly influence their adsorption capabilities with LiPSs. Unlike theoretical MXene models that often assume a single type of termination, actual MXene NSs typically feature a mixture of terminations, leading to more complex interaction mechanisms with LiPSs. Consequently, the theoretical results utilized to predict LiPS adsorption need further refinement to enhance their accuracy. Guided by these theoretical insights, exploring MXenes with novel compositions and diverse terminations remains an essential area of research.

6.4. Catalytic Role in Accelerating the Conversion of Soluble Polysulfides

MXenes exhibit exceptional properties, including metallic conductivity, a high SSA, a tunable bandgap structure, and remarkable carrier anisotropic mobility, making them highly promising electrocatalysts with excellent activity, selectivity, and prolonged loading lifetimes [204]. As a result, MXenes and MXene-based nanocomposites have been successfully utilized in various electrocatalytic applications, such as the HER, OER, N2 RR, O2 RR, and CO2 RR [205]. In the context of LSBs, MXenes have demonstrated their effectiveness as catalysts in facilitating the transformation of LiPSs to Li2S. By lowering the redox reaction barrier and accelerating redox kinetics, MXenes significantly enhances the rate performance of LSBs [154].

The catalytic performance of MXenes was strongly influenced by surface terminations and vacancies. Using the climbing-image nudged elastic band technique, the decomposition barriers of Li2S on functionalized Ti3C2T2 MXenes were calculated in the following order: Ti3C2S2 < Ti3C2O2 < Ti3C2F2 < Ti3C2N2 < Ti3C2Cl2. Notably, all these values are significantly lower than the natural decomposition barrier of Li2S [180]. Among them, Ti3C2S2 and Ti3C2O2 exhibit the lowest decomposition barriers for Li2S6, highlighting their efficiency in accelerating the transformation between LiPSs and Li2S. These two MXenes also have the shortest Li+ diffusion energy barriers, making them excellent candidates for S host materials. Furthermore, introducing suitable vacancies on the MXene can further boost their catalytic activity. For instance, Ti3C2Cl2, with a 1/16 Cl deficiency, exhibits significantly reduced decomposition barriers for Li2S and Li2S6, at 0.316 and 0.537 eV, respectively, compared to 1.625 and 1.532 eV for the non-deficient surface. This demonstrates a substantial improvement in catalytic performance [180].

Beyond modifying surface terminations, heteroatom doping, such as with N or S, is a powerful strategy to enhance the catalytic activity of MXenes in LSBs. For example, a porous N-doped Ti3C2 with active electrocatalytic properties was synthesized via a melamine-formaldehyde template method [206]. This porous structure, characterized by a high SSA and exceptional conductivity, offered numerous active sites for LiPSs adsorption and facilitated their transformation. The incorporation of N atoms further improved electron transfer and lowered the decomposition barrier of Li2S, thereby accelerating LiPSs conversion and amplifying the catalytic mechanism. Additionally, a single Zn atom implantation into MXenes was explored as an S host, significantly reducing the energy barriers for the conversion of Li2S4 to Li2S2 and Li2S. This improvement is attributed to the great electronegativity of Zn atoms (Figure 9d), enabling the LSBs to achieve outstanding rate performance, delivering a capacity of 640 mAh g−1 at 6 C [203].

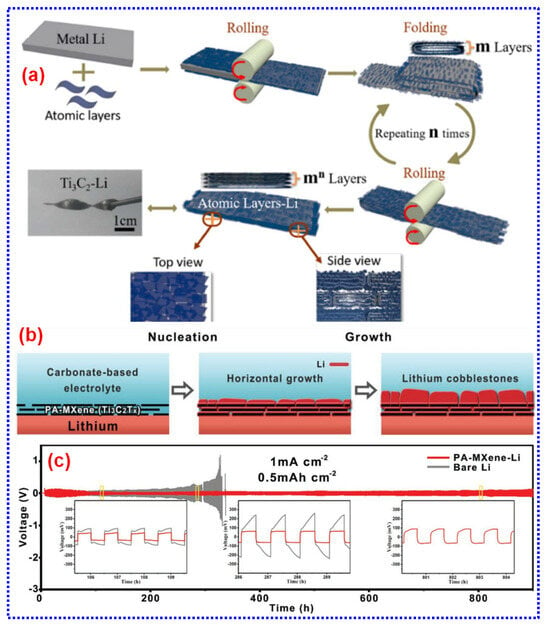

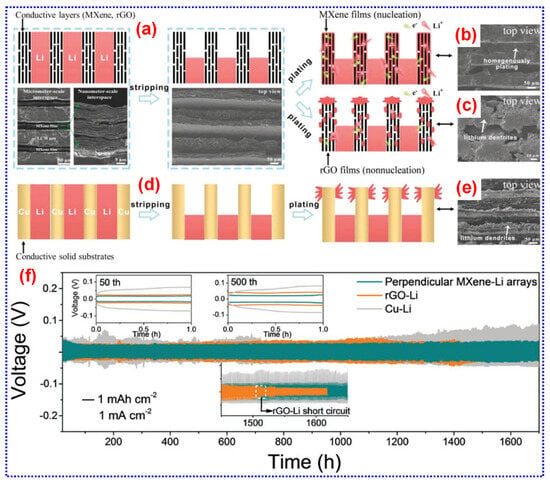

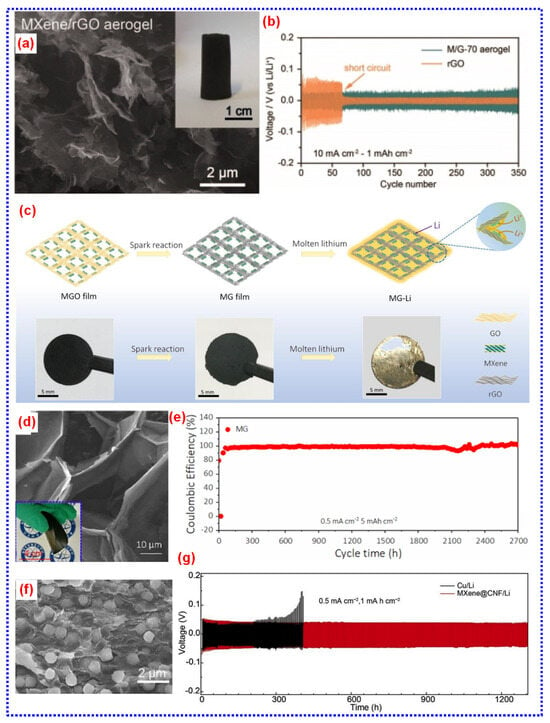

6.5. Prevention of Li Dendrite Growth

MXene NSs feature a distinctive 2D architecture, metallic conductivity, rapid Li+ diffusion, and abundant surface terminations, making them highly effective as Li hosts for suppressing dendrite formation and accommodating volume changes of Li during cycling [207]. First, the structural versatility and exceptional mechanical properties of MXenes offer significant opportunities for designing MXene/Li composite architectures [208]. Second, their metallic conductivity combined with a low Li+ diffusion energy barrier ensures efficient electron and Li+ passage, enabling greater electrochemical kinetics [208]. Third, the surface terminations of MXenes exhibit a strong affinity for Li, offering numerous nucleation sites that promote homogeneous Li deposition and inhibit dendrite formation [182]. For instance, a lamellar Ti3C2Tx-Li metal film was developed using a roll-to-roll process. In this structure, Li was evenly distributed between the MXene sheets, and the conductive Ti3C2Tx framework directed controlled Li dendrite growth within nanoscale gaps. This approach effectively suppressed vertical dendrite development, mitigating the risk of separator piercing [209].

MXenes hold significant potential for enhancing the performance of LSBs by serving as high-performance cathode materials and interlayers between the cathode and separator. Their metallic conductivity, diverse structures, robust chemical adsorption of LiPSs, and catalytic activity for the transformation of LiPSs to Li2S make them ideal candidates for this application. Incorporating MXenes as S hosts or interlayer materials in LSBs can boost S consumption and capacity, mitigate the shuttle effect to improve cycle performance, and accelerate redox reaction kinetics, thereby enhancing rate performance. Additionally, MXenes exhibit a strong affinity for Li, promoting uniform Li nucleation and suppressing dendrite growth, which lowers the risk of short circuits. Consequently, MXenes are widely regarded as promising materials for S hosts in cathodes, effective interlayer components, and reliable matrices in Li anodes for LSBs.

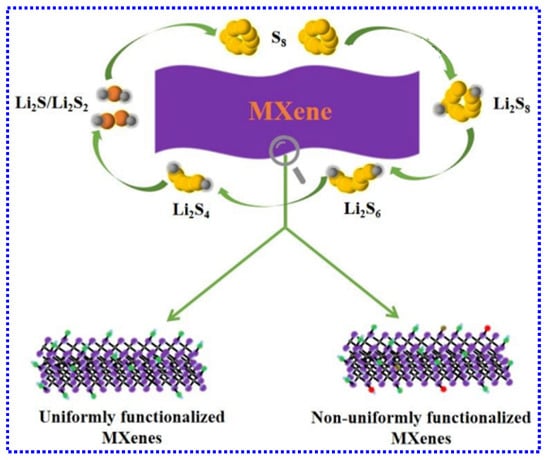

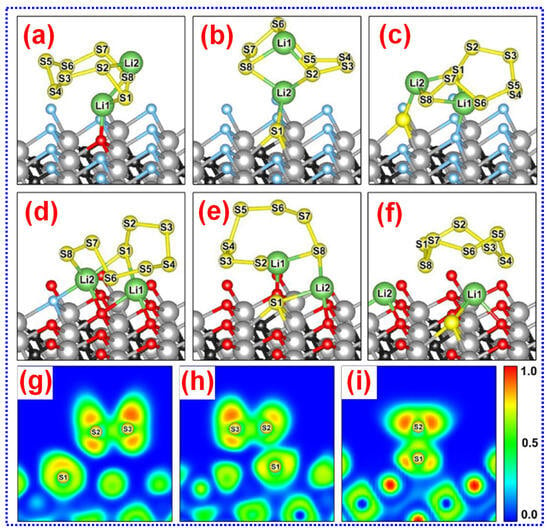

7. Theoretical Investigations on MXene-Based LSBs

Recently, extensive research has focused on designing S hosts with robust chemical interactions with LiPSs and investigating the fundamental mechanisms underlying these materials [210]. With their interactive surfaces and excellent conductivity, MXenes have emerged as highly favorable anchoring materials for S cathodes [211]. Gaining a comprehensive understanding of their fundamental properties and potential applications is crucial for advancing both science and technology in this field. This section provides a concise summary of key theoretical insights into LSBs using MXenes with uniform or non-uniform functionalization (Figure 10).

Figure 10.

Representation of theoretical insights into LSBs utilizing uniformly or non-uniformly functionalized MXenes. Adapted from [212], Copyright 2019, Royal Society of Chemistry.

7.1. MXenes with Uniform Functionalization

7.1.1. MXenes with OH-Functionalization

In 2015, Nazar’s group pioneered the use of the Ti2CTx MXene phase as an S host material [188]. They investigated the surface reactivity of Ti3C2 and Ti3CN MXenes upon interaction with LiPSs through XPS and DFT analyses. Their study revealed that before the formation of Ti-S bonds through Lewis’s acid–base interactions, the terminal -OH groups on Ti3C2 and Ti3CN are steadily utilized by trapped LiPSs, leading to the generation of thiosulfate and polythionate arbitrates. Subsequent research by Rao and collaborators highlighted the strong interactions between S in polysulfide chains and hydrogen in -OH groups, which facilitate the binding of LiPSs to OH-terminated MXenes. This interaction improves the retention of S species within the cathode area of LSBs [198]. Moreover, MXenes are typically prepared from the MAX phases by etching Al or Si using aqueous HF or HCl/LiF solutions, a process that introduces -F, -OH, and -O groups onto the MXene surface [213]. Identifying which specific functional groups dominate or whether they act synergistically remains a challenge. Understanding the anchoring mechanisms of these surface terminations toward LiPSs is therefore critical for advancing experimental research on MXenes.

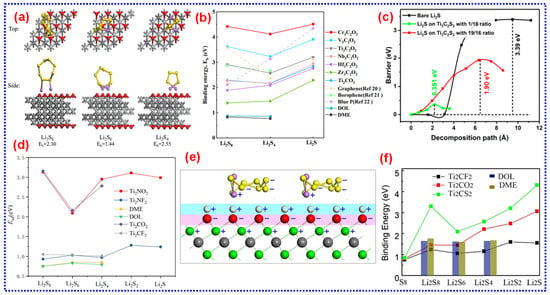

7.1.2. MXenes with O/F-Functionalization

The surface terminations of MXenes are heavily influenced by etching conditions and post-synthetic treatments [213]. While there are discrepancies in quantifying termination group concentrations using characterizations like XPS and NMR, it is generally accepted that -F and -O are the dominant functional groups on MXene surfaces. Recent studies have explored the B.E, bond characteristics, and electron transfer associated with -O and -F uniformly functionalized MXenes [198,201]. Zhao and colleagues provided a detailed analysis of the anchoring mechanisms of O-terminated Ti3C2 and Ti2C MXenes on LiPSs (Figure 11a) [201]. Their findings revealed that interactions between Li+ in LiPSs and O-atoms in Ti2CO2 and Ti3C2O2 monolayers enable O-terminated MXenes to bind LiPSs with control binding strength, stabilizing soluble LiPSs. This behavior demonstrates the amphiphilic nature of MXenes, with lithiophilic properties stemming from Li-O bonding and sulfiphilic characteristics from Ti-S bonding. Fan and collaborators extended this investigation by examining the chemical interactions between LiPSs and six M3C2O2-type MXenes, where M represents Cr, V, Ti, Nb, Hf, and Zr (Figure 11b). Their findings confirmed significant Li-O interactions between these MXenes and LiPSs, akin to the behavior observed with Ti2CO2. Additionally, they identified a correlation between B.Es and lattice constants of M3C2O2 MXenes, where smaller lattice constants resulted in stronger binding with LiPSs [202]. In another work, Wei’s team explored the synergistic effects of LiPSs binding and the catalytic delithiation of Li2S using Ti3C2 MXenes (Figure 11c) [180]. Their results demonstrated that O- and S-terminated Ti3C2 MXenes are highly effective as hosts for S cathodes, corroborating Zhao’s earlier findings [201].

Figure 11.

(a) The optimized configurations of Li2S8, Li2S6, and Li2S4 adsorbed on a Ti3C2O2 monolayer, along with their respective B.Es. Adapted from [201], Copyright 2017, Elsevier B.V. (b) Graphs showing the calculated B.Es of LiPSs with different M3C2O2 MXenes. Adapted from [202], Copyright 2019, Royal Society of Chemistry. (c) Decomposition barriers of bare Li2S (black) compared to Li2S on a Ti3C2S2 supercell, with Li2S to Ti3C2S2 ratios of 1:16 (green) and 19:16 (red). Adapted from [180], Copyright 2019, American Chemical Society. (d) Adsorption energies of Li2Sx species on different substrates. Adapted from [214], Copyright 2018, Elsevier B.V. (e) Diagram of charged atoms in Li2Sx and MXenes, where “+” denotes electropositive and “-” denotes electronegative atoms. Ti is represented by green spheres, S by yellow spheres, Li by purple spheres, O/F by red spheres within a pink area, and H by white spheres within a light blue area. Adapted from [198], Copyright 2017, American Chemical Society. (f) Comparison of B.Es of Li2Sx with Ti2CS2, Ti2CO2, and Ti2CF2. Adapted from [200], Copyright 2018, Elsevier B.V.

Lin and colleagues investigated the properties of O/F-functionalized Ti2N as substrates, demonstrating that Ti2NO2 and Ti2NF2 exhibit average adsorption energies for LiPSs (Figure 11d) [214]. They found that these MXenes strike an optimal balance between strong adsorption and preserving the structural integrity of LiPSs. Additionally, DOS analysis for S8, Li2S8, Li2S6, Li2S4, Li2S2, and Li2S adsorbed on Ti2NO2 validated that the metallic nature of Ti2NO2 and Ti2NF2 remains intact after adsorption. This retention of metallic properties allows trapped LiPSs species to be readily reduced, with their free electrons facilitating the redox reactions of S species. Similar behavior was observed for F/O-functionalized Ti2C (Ti2CF2 and Ti2CO2) [215]. As a result, Ti2NO2, Ti2NF2, Ti2CF2, and Ti2CO2 are promising candidates for LSBs with improved electrochemical characteristics. Moreover, Rao and collaborators noted that an attraction between Ti and S atoms weakens due to the improved repulsive forces exerted by O/F-termination groups on S atoms [198]. This explains the lower B.Es of LiPSs on functionalized MXenes compared to bare MXenes, with B.E following the order: Ti2CF2 < Ti2CO2 < Ti2C(OH)2. Interestingly, introducing H atoms partially mitigates this repulsive force, as the positively charged H atoms enhance attraction to S atoms. This phenomenon is pictorially illustrated in Figure 11e.

Theoretical calculations reveal that after interacting with long-chain LiPSs, the -O groups on MXenes increase while the -OH groups decrease. This occurs because the protruding H atoms on the MXene surface are more readily replaced by Li, as the dissociation energy required for H removal is lower than that for -OH groups. As a result, the conductivity of MXenes remains largely unaffected by LiPSs adsorption, with their band gaps exhibiting minimal adjustment. Additionally, surface-sulfurized Ti2C (Ti2CS2) have been investigated (Figure 11f) [200]. Compared to Ti2CO2 and Ti2CF2, Ti2CS2 demonstrates the robust affinity for LiPSs, with B.Es following the trend: Ti2CF2 < Ti2CO2 < Ti2CS2. This enhanced binding is attributed to Li’s tendency to interact with negatively charged atoms, for instance, O and F, while being repelled by positively charged Ti atoms. S-terminated MXenes strike a balance between attractive (F-Li) and repulsive (F-Ti) forces because of S’s lower electronegativity (S: 2.58; O: 3.44; F: 3.98), consistent with findings reported by Rao and colleagues [198]. Although S-terminated MXenes have not yet been experimentally synthesized, their robust affinity for polysulfides suggests significant potential for mitigating the LiPSs shuttle effect. Additionally, their metallic properties and low-energy barriers for Li diffusion facilitate the electrochemical reactions of S moieties. These features make S-terminated MXenes promising candidates for designing S host materials for high-performance LSBs.

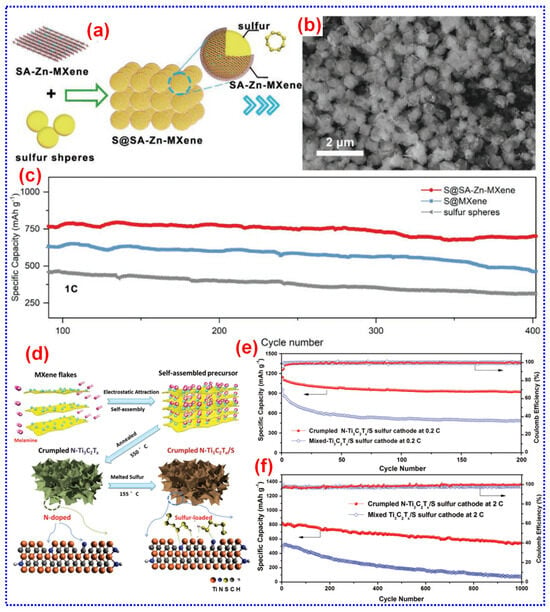

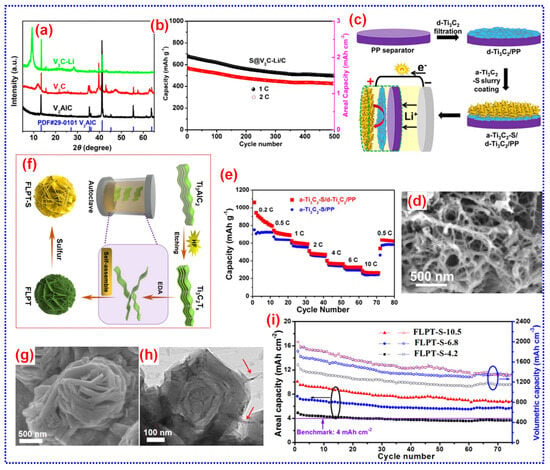

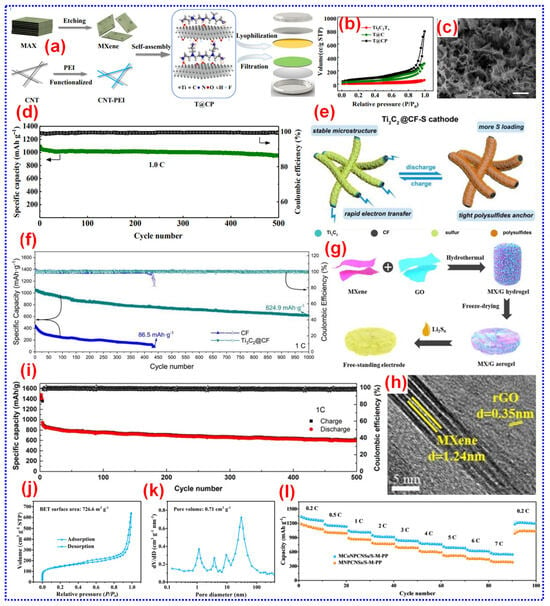

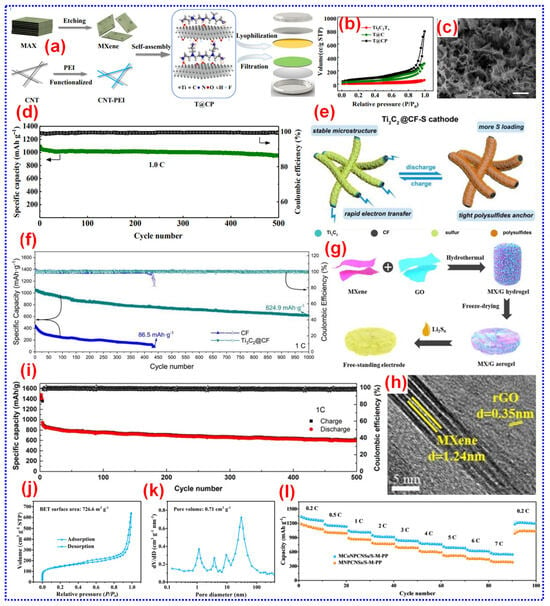

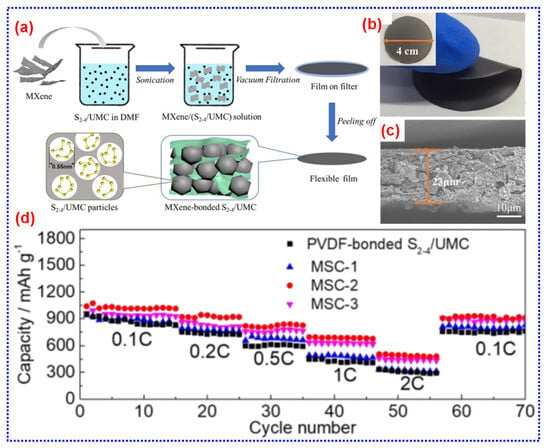

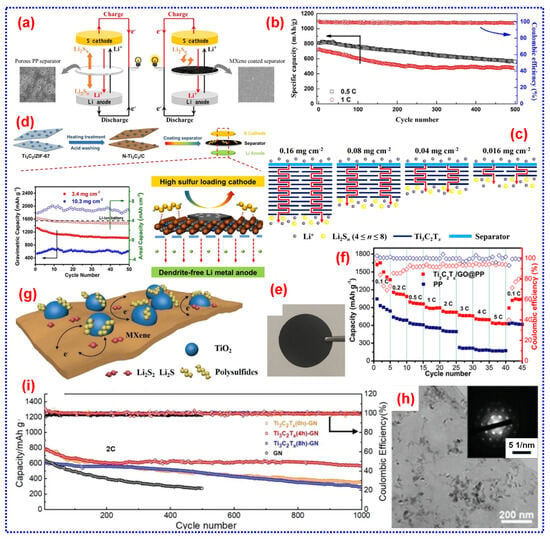

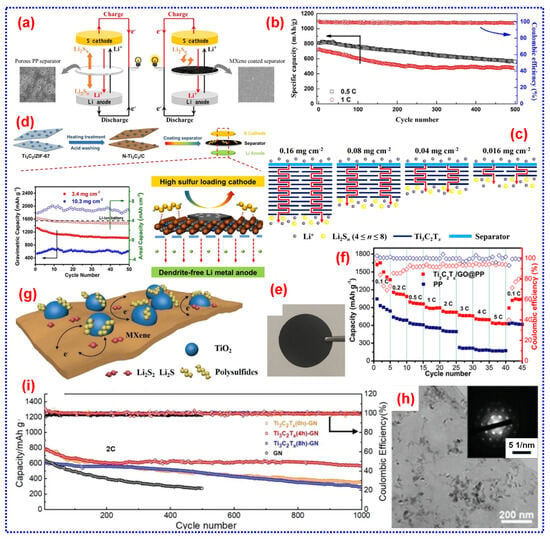

7.2. MXenes with Non-Uniform Functionalization