1. Introduction

Polycrystalline nickel–zinc (NiZn) ferrites are an important family of soft magnetic materials in modern electromagnetic technology, widely used in high-frequency applications such as transformers, inductors, antennas, and noise suppressors [

1]. Their exceptional magnetic properties, such as low power losses, high magnetic permeability, and sufficient saturation induction, make them ideal materials for devices operating in the megahertz range [

2,

3]. Their relatively high specific resistivity helps minimize eddy currents, further enhancing performance at high frequencies. The growing demand for more compact, efficient, and high-performing electronic devices is driven by the increasing switching frequencies of wide-band semiconductors [

4,

5]. One major limitation to device miniaturization arises from the high power losses of the ferrite materials, which, combined with their high thermal resistance, may lead to excessive heating, and consequently reduced component efficiency.

Research on the development of improved monolithic polycrystalline NiZn ferrite magnetic components for inductors and transformers spans several key directions, focusing on enhancing their properties, expanding their applications, and addressing challenges in high-frequency performance. Regarding property enhancement, primary areas of exploration include: (i) investigating the effects of additions of various substitutional or grain boundary metals ions (such as, i.e., Cu [

6,

7], Co [

2,

8,

9], Sn [

10], V [

11], Mn [

12] or rare earth elements [

13]) to optimize magnetic permeability, coercivity and loss behavior. (ii) Microstructural engineering, which involves studying the impact of grain size on magnetic losses, permeability and saturation magnetization to enhance high-frequency performance [

14,

15]; understanding and controlling lattice defects such as dislocations and vacancies [

16]; and exploring advanced sintering methods like microwave [

17], spark plasma [

18] or hot-pressing [

19] to achieve dense, homogeneous materials with superior properties. Additionally, significant research efforts focused on analyzing and mitigating losses caused by eddy currents, hysteresis, and domain wall dynamics, particularly in the megahertz range [

20,

21].

Cobalt-doped NiZn ferrites have been extensively investigated, and the mechanisms through which cobalt influences magnetic performance have been the subject of several studies [

20,

22,

23,

24,

25]. The materials exhibit ferrimagnetic ordering, which is characteristic of spinel ferrites, in general. The magnetic moments on A and B sites are antiparallel, but unequal in magnitude, resulting in a net magnetization. The cation site occupancy in NiZn ferrites and Co-doped NiZn ferrites has been extensively reported in the literature [

26,

27]. These materials typically adopt a mixed spinel structure with a certain degree of inversity. For example, in (Ni

0.5Zn

0.5)Fe

2O

4 annealed at 1100 °C, Zn

2+ ions show a strong preference for tetrahedral (A) sites, while Ni

2+ ions exhibit an even stronger preference for octahedral (B) sites, resulting in an inversion degree of approximately 0.5. Co

2+ ions also show a strong site preference. When Co

2+ is introduced into the lattice—either by partially substituting Ni

2+ or as an additional dopant—it significantly alters the cation distribution, and consequently, the magnetic behavior. Co

2+ ions prefer octahedral sites, primarily due to their larger crystal field stabilization energy (CFSE). This site selectivity also causes a redistribution of Fe

3+ ions toward the A-sites to maintain charge neutrality and site balance. It is important to note that, although the general trends in site preferences remain consistent, the exact cation site occupation fractions are influenced by the synthesis method and processing conditions, such as annealing temperature and particle or grain size [

28]. Most research on Co-doped NiZn ferrites has focused on particles and structures in the submicron range [

29], primarily in the context of developing materials for microwave, non-reciprocal devices or antenna applications. In such cases, dielectric losses and permittivity are properties of significant importance. For power applications, even at frequencies of 10 MHz, the key performance parameters are power losses, initial permeability, and the frequency stability of the permeability. This distinction also explains the lower cobalt content used in this study, which is significantly less than that reported in most previous works [

22,

23,

24]. Higher cobalt concentrations, while increasing coercivity, also raise hysteresis losses and reduce initial permeability to levels unsuitable for power applications.

In addition, most investigations into power losses have not extended the frequency range beyond 5 MHz. To the authors’ knowledge, data on NiZn ferrite power losses (expressed as mW cm−3) at 10 MHz is scarcely available in the scientific literature. In this article, the magnetic performance of Co-doped NiZn ferrites at 10 MHz is investigated under fields ranging from 3 to 10 mT and at temperatures from 20 to 120 °C. The dependence on compositional and operational parameters is discussed. Emphasis is placed on high-temperature (>80 °C) losses, and certain strategies for mitigating these losses are proposed.

2. Materials and Methods

Polycrystalline NiZn ferrites were synthesized using the conventional mixed oxide method. Oxide precursors of the cations (NiO, ZnO, Co

3O

4, Fe

2O

3, all Merck analytical grade) were proportioned for a synthesis batch of approximately 500 g and subsequently wet-mixed for 3 h in a ball mill containing 500 mL double-distilled water and approximately 3.6 kg of steel milling balls with a nominal diameter of 12 mm. The mixed product was dried and pre-fired at 750 °C for 3 h in air. The pre-fired powder was then ball-milled under the same conditions as the wet-mixing step. The milled powder was roll-granulated with the addition of 10 wt.% of a binder solution, consisting of 2 wt.% aqueous Tylose solution (Tylose MH 300 P2 Shin Etsu, Venlo, the Netherlands). The granulated powder was subsequently uniaxially compacted at a pressure of 100 MPa, to form ring-shaped specimens with an outer diameter of 23 mm and an inner diameter of 15 mm. These specimens were finally sintered in air at temperature ranging between 1125 and 1225 °C. The sintered specimens had a nominal outer diameter of 20 mm, an inner diameter of 12.5 mm and a height of 8 mm. The synthesized ferrite compositions, divided into three groups (A, B and C) are listed in

Table 1.

In the synthesis experiments of group A, the effect of varying iron content was studied while keeping the cobalt, nickel and zinc contents constant. The Ni/Zn molar ratio was maintained at 1 to achieve high saturation induction and magnetic permeability [

2]. Additionally, a cobalt content of 0.02 atoms per formula unit was introduced because, as reported, this content significantly increases the specific resistivity of NiZn ferrites [

12] and retards domain wall or ferromagnetic resonance [

20,

30]. In group B experiments, the cobalt content was varied at a constant iron content (equal to 1.95 iron atoms per formula unit) and Ni/Zn ratio (equal to 1). The cobalt was increased in steps of 2000 ppm (wt.) CoO (or approximately 0.06 cobalt atoms per formula unit) from 0.02 up to 0.052 cobalt atoms per formula unit. Higher cobalt contents resulted to an unacceptable increase in the high-frequency power losses and are, therefore, not studied further. Finally, in group C, the effect of the Ni/Zn molar ratio was investigated while maintaining constant iron (equal to 1.95 iron atoms per formula unit) and cobalt (equal to 0.040 cobalt atoms per formula unit) contents. Specimens A195/B020 and B040/C100 have a double code name since they can be encountered as members of two experimental series.

The microstructure of the sintered polycrystalline specimens was examined using a scanning electron microscope (SEM, JEOL JSM-IT500, Tokyo, Japan) on thermally etched and gold-sputtered cross sections. Particle size analyses and specific surface area measurements of pre-fired and milled powders were performed using laser scattering (Mastersizer S, Malvern, UK) and nitrogen adsorption–desorption (Autosorb 1, Quantachrome, Boynton Beach, FL, USA), respectively. X-ray diffraction (XRD) was conducted for structural determination using CuKa radiation (Bruker D8 Advance, Munich, Germany). The final densities of the sintered specimens were measured geometrically. Based on repeated measurements, the absolute error was estimated to be ±0.05 g cm−3.

The magnetic properties of the specimens were measured using an automated programmable unit consisting of: an impedance-gain analyzer (E4991A, Agilent Technologies Inc., Kobe, Japan), an oscilloscope (MDO4034C, Tektronix Inc., Beaverton, OR, USA), a power amplifier (2200L, Electronics and Innovation, Rochester, NY, USA), a frequency generator (33500B, Keysight, Santa Rosa, CA, USA) and a programmable oven. The measurements were performed on toroidal specimens wound with copper wires to form inductors. The power losses were measured directly from the alternating voltage across the winding, the in-phase component of the current (complex permeability) and the specimen volume. Sinusoidal magnetic field is applied to the ferrite material, and the resulting voltage and current waveforms are measured. The waveforms are then multiplied together to obtain the instantaneous power loss at each point in the cycle. The average power loss is then calculated by integrating the instantaneous power over a complete cycle. For each sintering trial, four identical specimens were stacked and sintered simultaneously. The two specimens in the middle were used for magnetic performance characterization. The results were very reproducible, with a relative error of less than 5%, even under the heaviest conditions of 10 MHz and 10 mT.

3. Results and Discussion

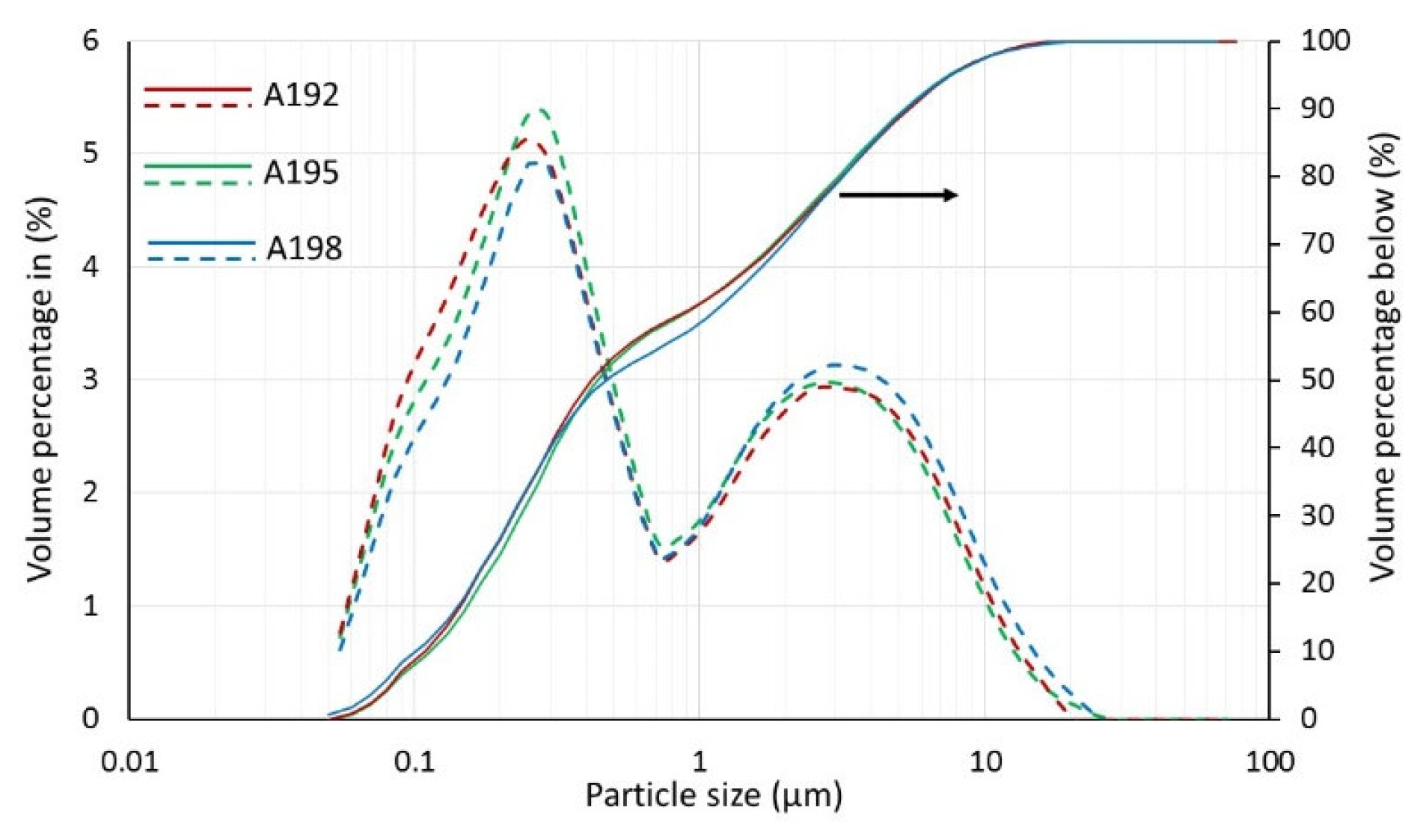

All prefired and milled powders of group A syntheses were characterized to ensure identical structure, providing a common starting point for the sintering and microstructure development steps without the influence of factors other than chemical composition. Indicative particle size analysis results for prefired and -milled powders A192, A195 and A198 are presented in

Figure 1. In all cases, a bimodal particle size distribution was observed, with an average particle size d50 ranging between 0.4 and 0.5 μm. The differences between the powders are considered negligible and within the experimental uncertainties. The BET specific surface areas of all group A syntheses range from 3.0 to 3.5 m

2 g

−1.

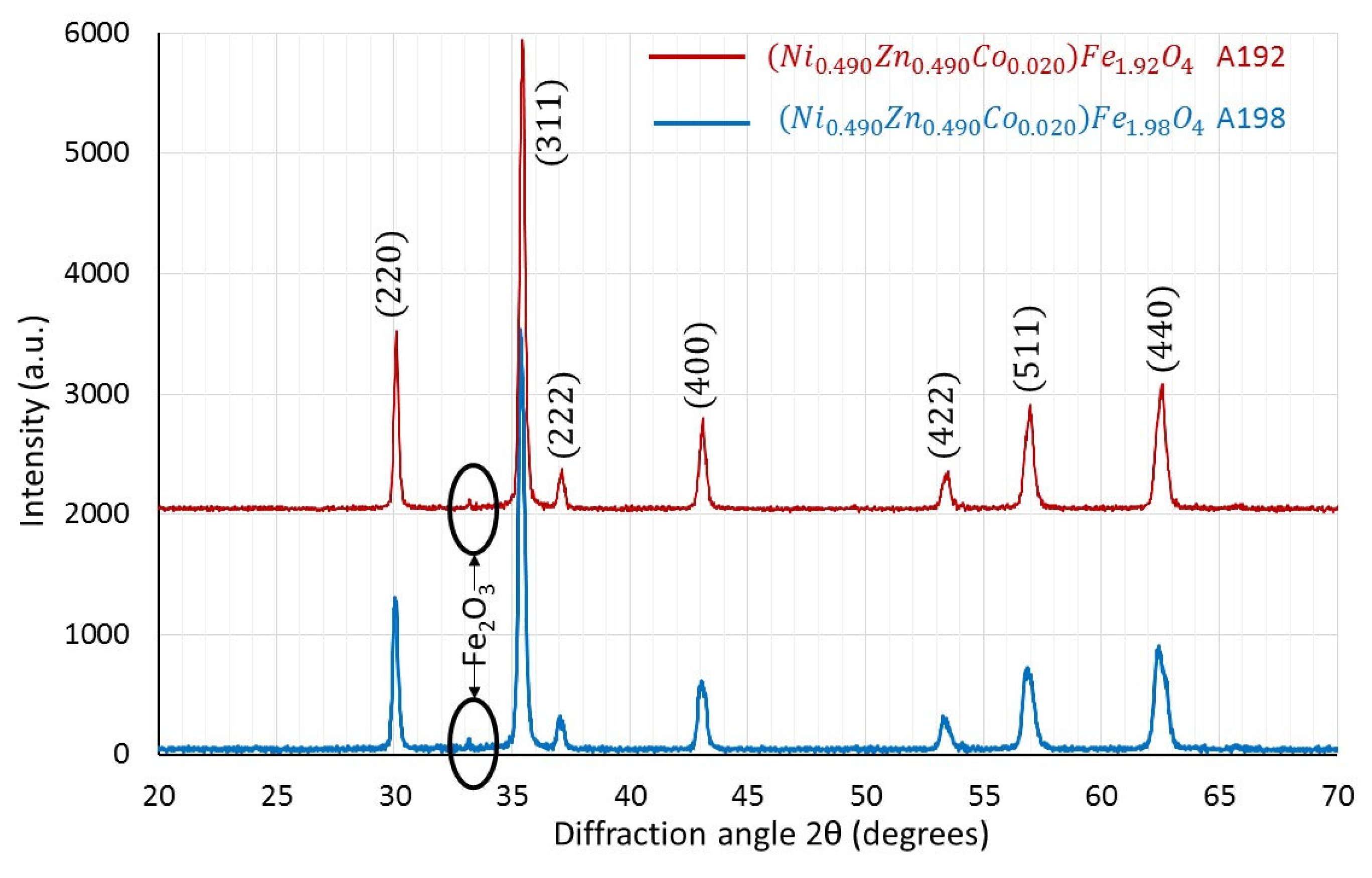

XRD analysis revealed that all prefired and milled powders consisted of a single spinel phase. Representative results for powder samples A192 and A198 are shown in

Figure 2.

The prefiring temperature of 750 °C appears sufficient to drive the ferrite formation reaction almost to completion. Minor, barely detectable traces of Fe

2O

3 (marked with black cycles in

Figure 2) are not considered significant and are unlikely to influence the subsequent microstructure development or magnetic performance. It is therefore concluded that all prefired powders in group A are structurally nearly identical.

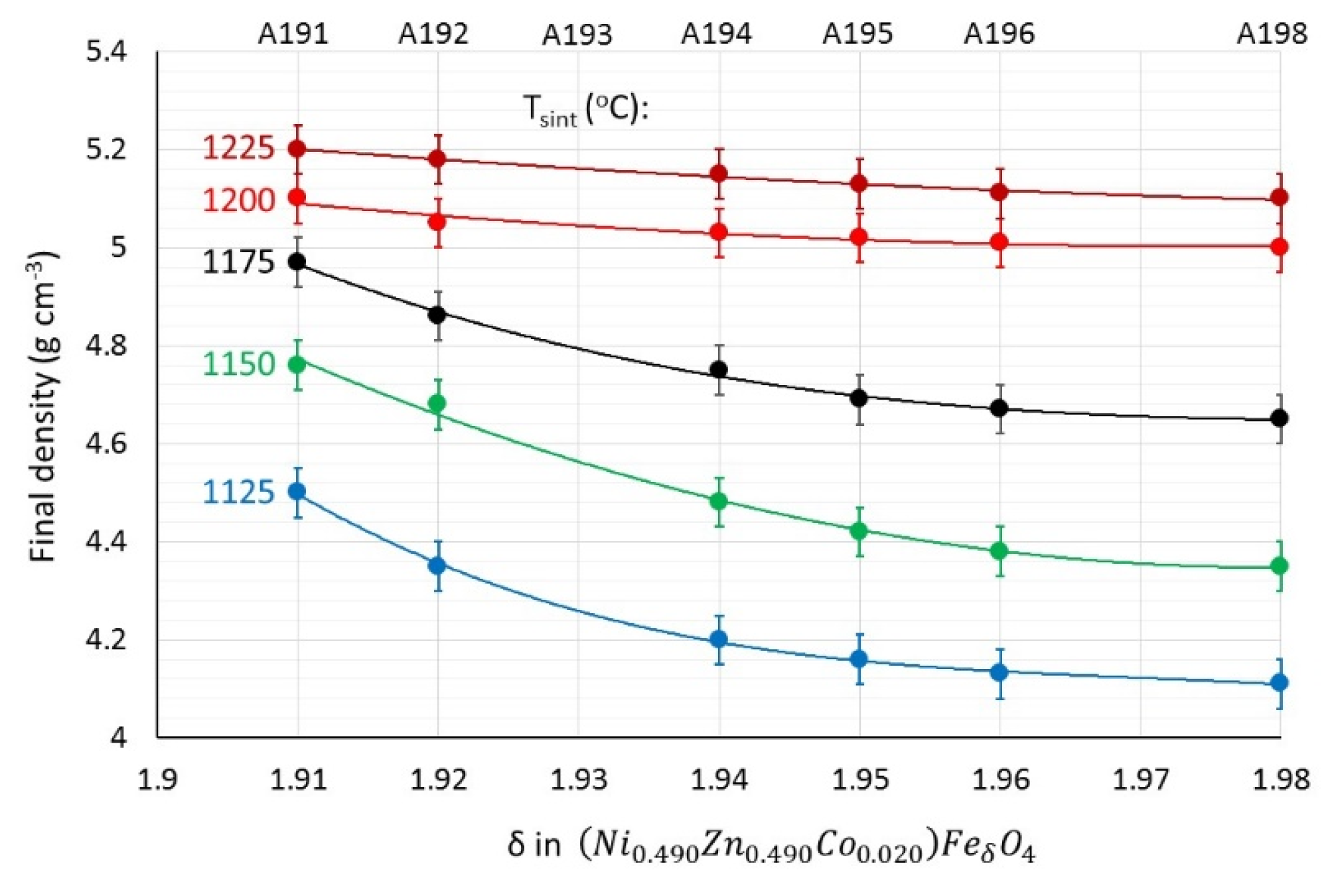

In

Figure 3 the final densities of all group A syntheses sintered at different temperatures (from 1125 to 1225 °C) are presented. As expected, the final density increases with higher sintering temperatures. Furthermore, at a constant sintering temperature, the final density decreases with increasing iron content. Iron deficiency introduces oxygen vacancies in the structure which, in turn, facilitate the diffusion of oxygen anions. In ionic solids, the diffusion of the slowest-moving oxygen ions is generally regarded as the rate-controlling step for densification [

31,

32]. Most commercially available NiZn ferrites are iron-deficient to enhance densification.

For optimal high-frequency magnetic performance, both density and grain size are critical factors. In polycrystalline materials, grain size significantly affects both domain wall and spin rotational resonance [

33,

34]. During sintering, densification and grain growth occur simultaneously [

35], and the microstructure for optimal high-frequency magnetic performance should exhibit sufficiently high density and sufficiently low grain size.

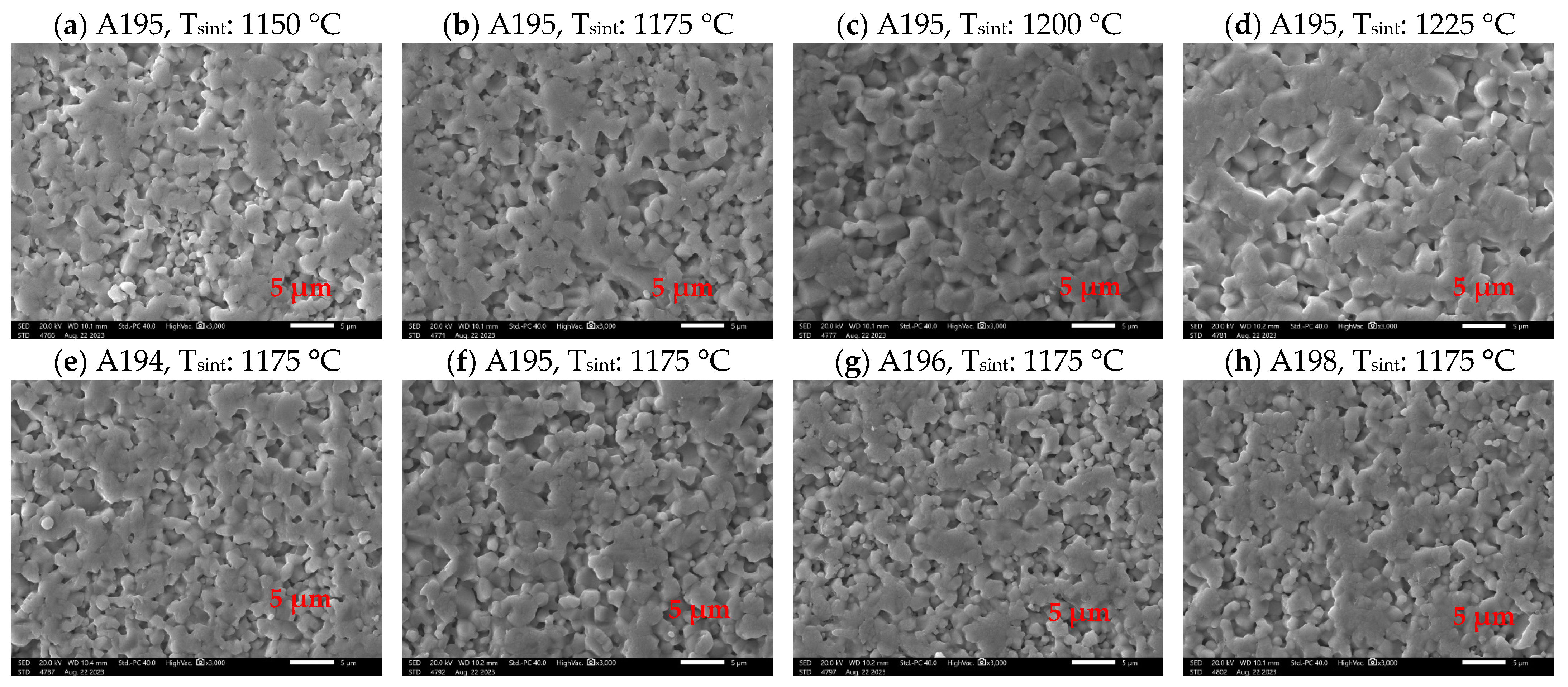

Figure 4 shows typical SEM images.

Figure 4a–d correspond to a constant composition (A195) at different sintering temperatures, while

Figure 4e–h correspond to a constant sintering temperature (1175 °C) with varying compositions.

Although the effect of sintering temperature on the microstructure is evident in the SEM images (

Figure 4a–d), the influence of iron content on the density and microstructure is not clearly visible. The same is true also for specimens of group B, where at an identical sintering temperature of 1150 °C, the microstructure did not seem to be affected by the cobalt content. The obtained SEM micrographs were similar to those presented in

Figure 4e–h, and are therefore not presented. In general, at sintering temperatures below 1200 °C the average grain size is estimated to be below 3 μm, which lies within the monodomain region [

14,

36].

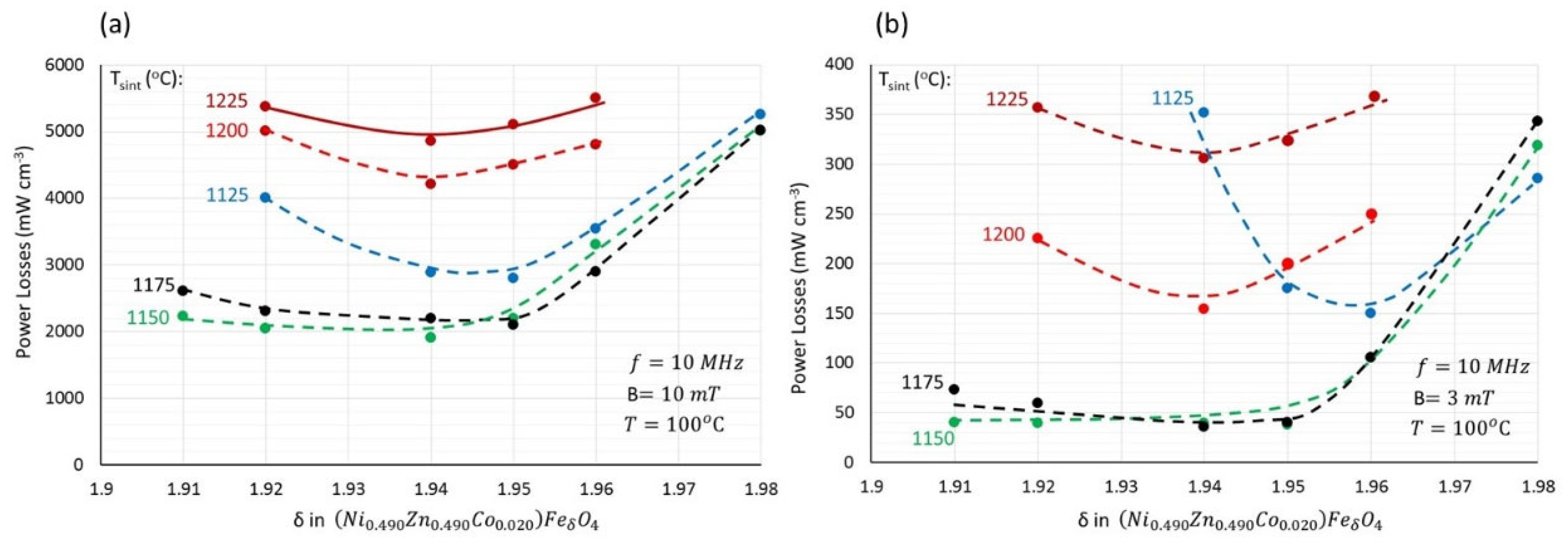

The power losses at 10 MHz and 100 °C for relatively high (10 mT) and low (3 mT) fields are shown in

Figure 5.

As shown, the lowest power losses are achieved with iron contents lower than 1.95 and sintering temperatures between 1150 and 1175 °C. Lower sintering temperatures result in higher losses due to insufficient densification, while at higher sintering temperatures, the 10 MHz losses increase due to larger grain sizes. Power losses also increase with iron contents higher than 1.95. This could be explained either by the fact that high iron contents are associated with lower densities (

Figure 3) or by the fact that higher iron contents lead to higher magnetic permeabilities, which in turn lower the resonance frequency, as described by the law of Snoek [

37]. In particular, specimen A195 ((Ni

0.49Zn

0.49Co

0.02)Fe

1.95O

4) sintered at 1175 °C exhibited power losses of 40 mW cm

−3 (10 MHz, 3 mT, 100 °C) and 2100 mW cm

−3 (10 MHz, 10 mT, 100 °C). Based on this superior high-frequency high-temperature performance, and its relatively high iron content, further optimization was conducted based on this composition at sintering temperatures of 1150 °C and 1175 °C.

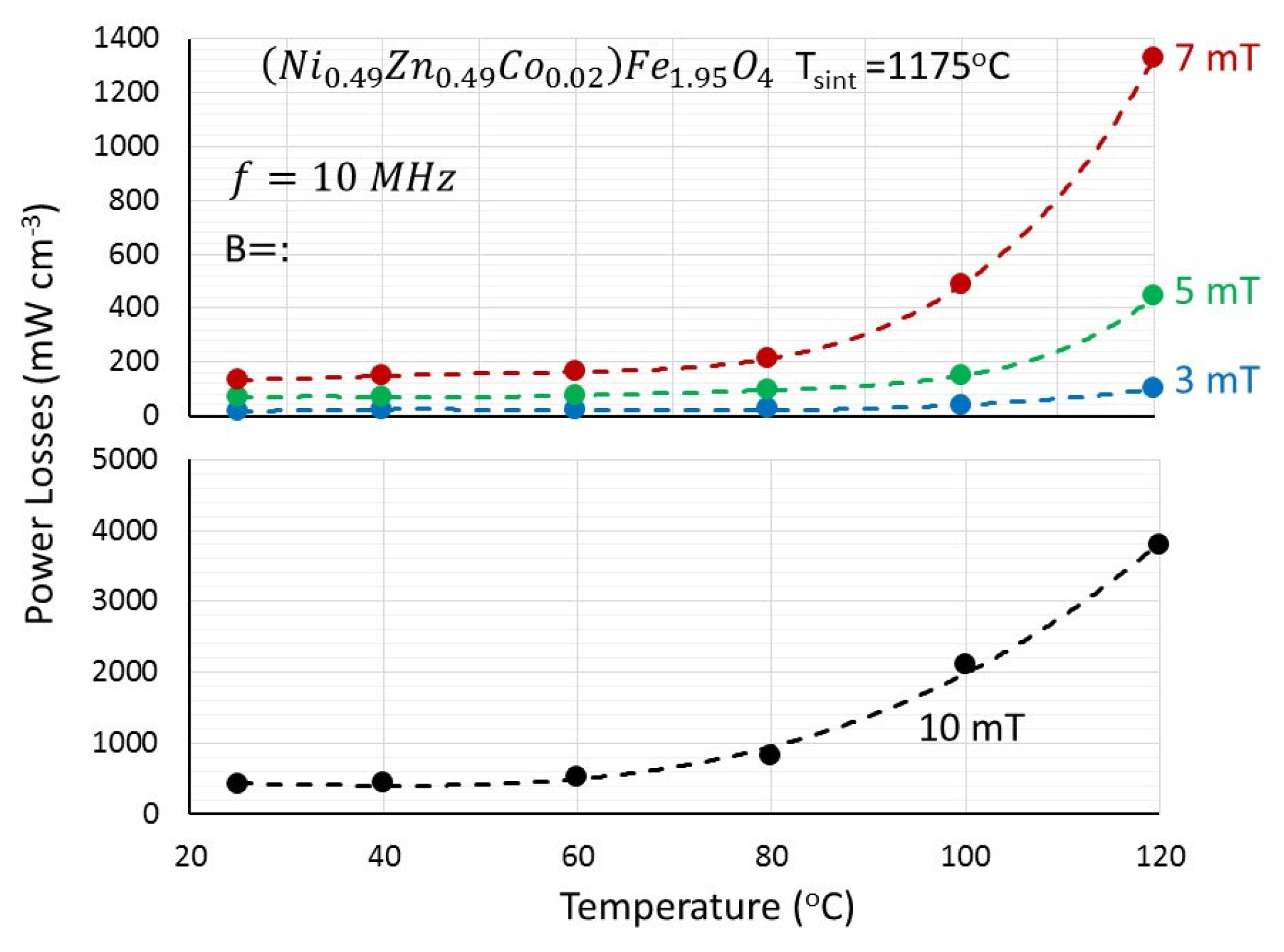

In

Figure 6, the 10 MHz power losses of specimen A195 (sintered at 1175 °C) are shown as a function of temperature, for different induction levels. At low temperatures, the power losses are initially independent of temperature. Beyond a certain temperature, however, a sharp increase in losses with temperature is observed. It is believed that in the temperature-independent region, hysteresis losses dominate. The sharp increase in losses at higher temperatures is most likely dominated due to resonance phenomena, as it is unlikely that eddy currents play a significant role in NiZn ferrites. The DC-specific resistivity of specimen A195 was found to be ~10

5 Ω m at 25 °C, which is considered quite high in order to induce appreciable amounts of eddy current losses. Additionally, the temperature at which power losses begin to increase depends on the applied field. At 3 mT, the losses remain constant up to 100 °C, whereas at 10 mT, the losses start to increase at approximately 60 °C.

The previous considerations suggest that any further reduction in high-temperature losses should focus on increasing the resonance frequency. Cobalt is a well-known ion with a relatively high positive contribution to the magnetocrystalline anisotropy of the host lattice [

2]. Additionally, cobalt has been reported to enhance domain wall pinning, thereby hindering their movement [

8,

20].

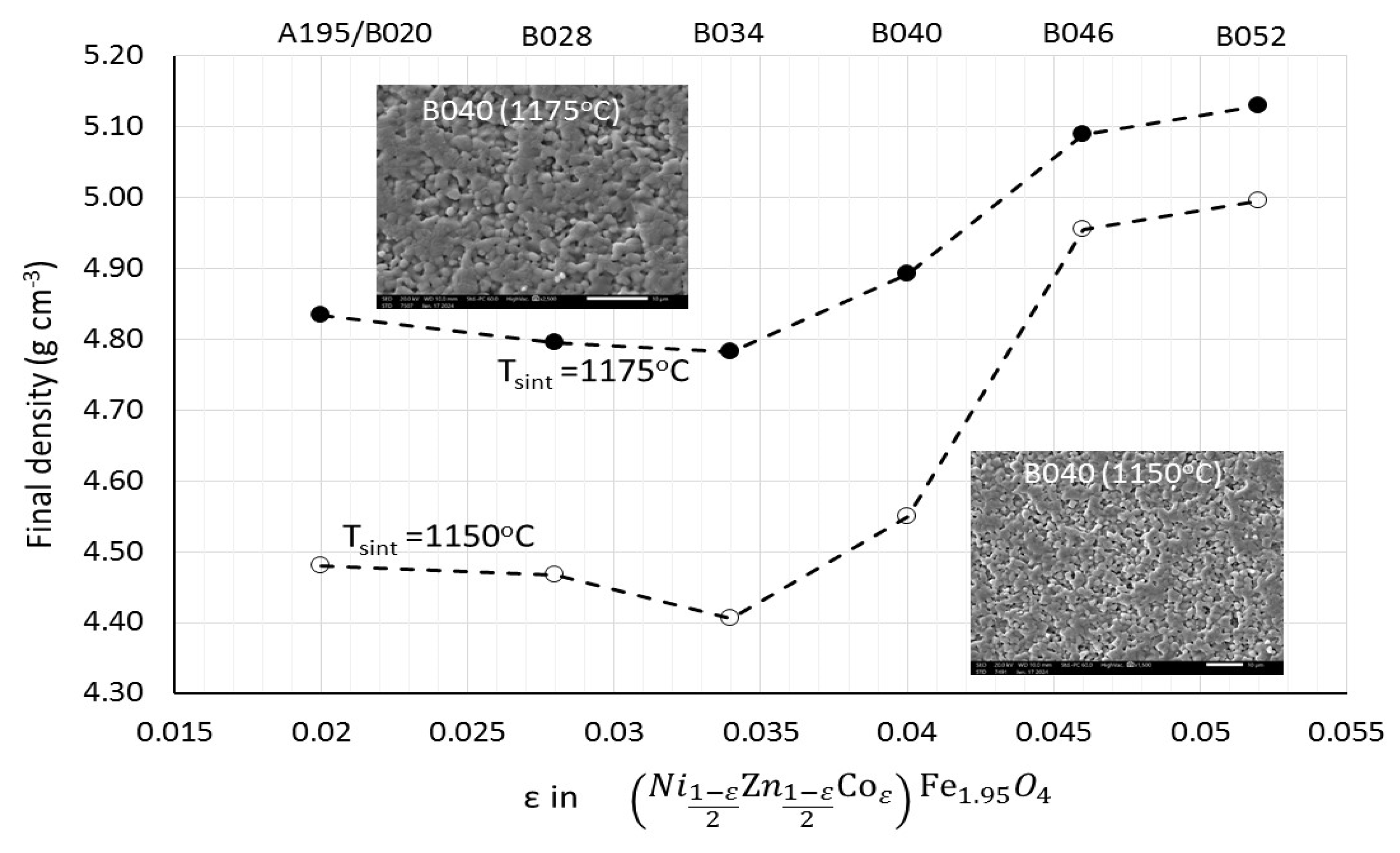

In

Figure 7, the final densities of group B samples are shown for the two sintering temperatures tested in the laboratory, 1150 and 1175 °C. The observed pattern is identical for both sintering temperatures. At cobalt contents up to 0.034 ions per formula unit, the densification appears to be slightly retarded, whereas at higher cobalt contents, enhanced densification is observed. Representative SEM images for the two sintering temperatures are included as insets in

Figure 7. No microstructural differences were visually detected either between the samples with varying cobalt content or between chemically identical specimens sintered at the two different temperatures. The high-frequency power losses of the samples sintered at 1150 °C were superior to those sintered at 1175 °C. This enhanced densification is likely associated with grain growth, which is not visually detectable, but is sufficient to negatively affect the 10 MHz power losses. Consequently, the results reported in the following paragraphs for group B samples refer exclusively to a sintering temperature of 1150 °C.

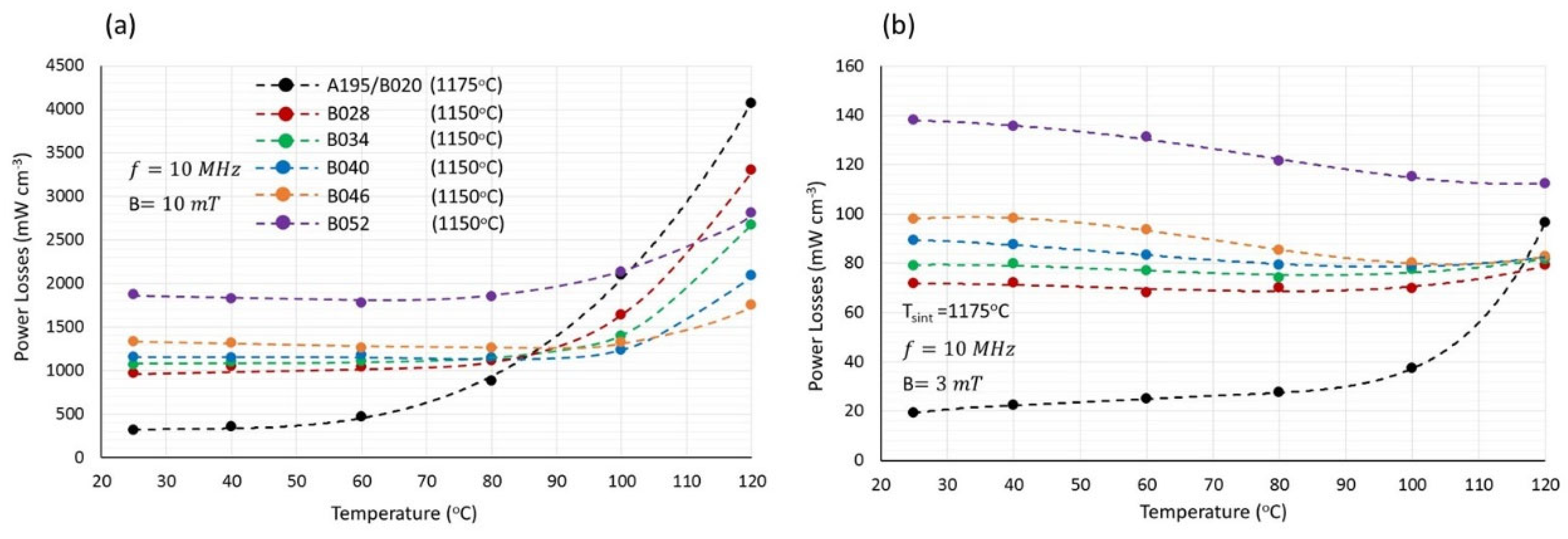

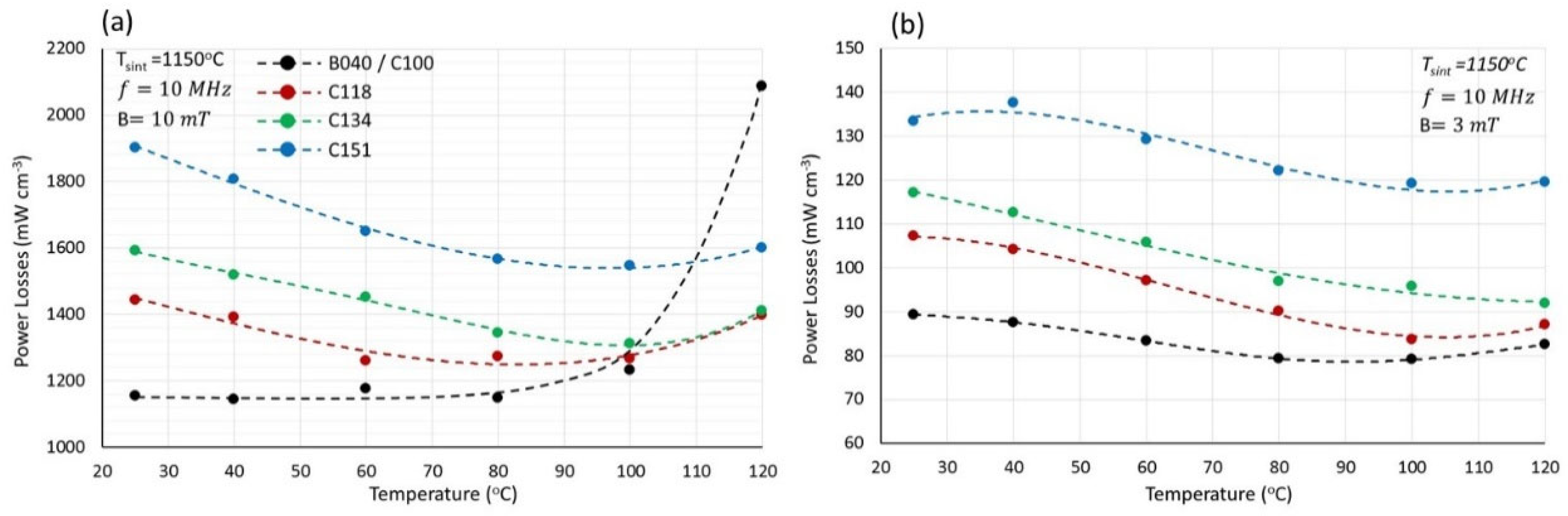

Figure 8 shows the 10 MHz power losses as a function of temperature for group B specimens with gradually increasing cobalt content.

In general, cobalt stabilizes the temperature dependence of the power losses. This is likely due to shift in resonance to higher frequencies, as will be described in a subsequent paragraph. At an induction field of 10 mT (

Figure 8a), the low-temperature losses, attributed to hysteresis, increase with increasing cobalt content, while the losses at temperatures above 80 °C decrease significantly. For instance, at 10 MHz, 10 mT and 100 °C, specimen A195/B020 exhibited power losses of 2100 mW cm

−3, while specimen B040 1233 mW cm

−3 exhibited an approximate decrease of 41%. A similar reduction is observed at 120 °C, where losses decrease by 57% between specimens A195/B020 (4072 mW cm

−3) and B046 (1751 mW cm

−3). As shown in

Figure 8b, the beneficial effect of cobalt on reducing high-frequency, high-temperatures losses weakens at lower fields. This is because at lower fields, the temperature range over which hysteresis losses dominate is broader (

Figure 6), and these losses increase with higher cobalt content.

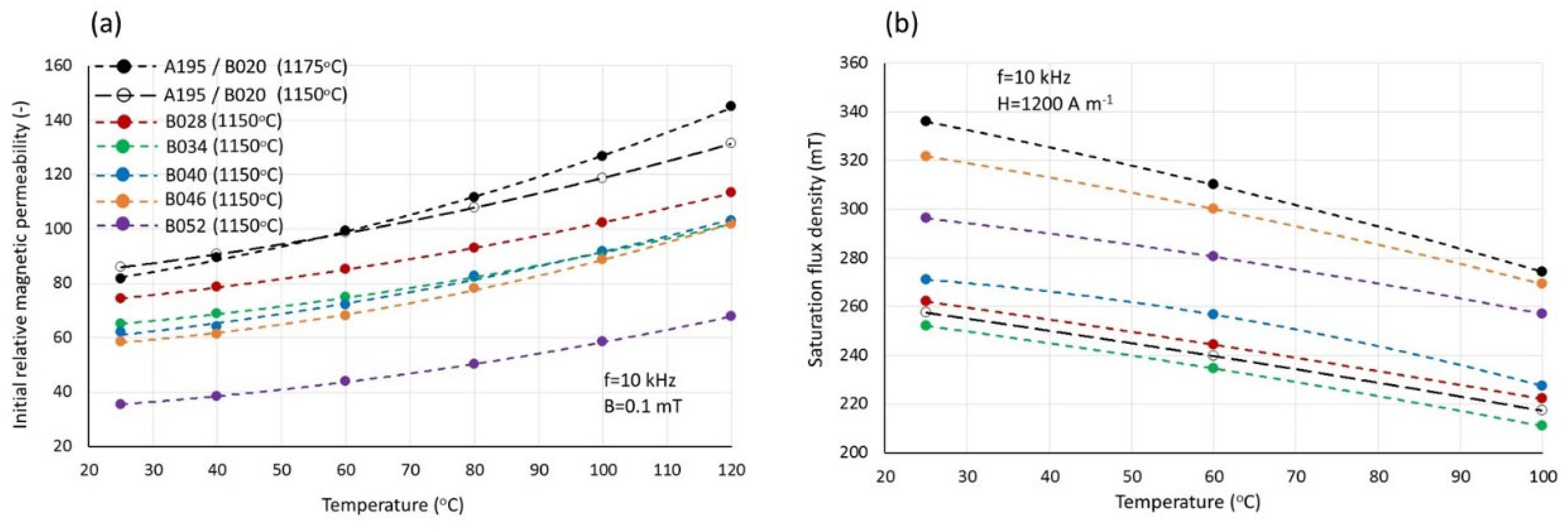

The initial magnetic permeabilities and the saturation magnetic flux densities are shown in

Figure 9.

The permeabilities, in all cases, increased with increasing temperature. Furthermore, it appears that permeability decreases with increasing cobalt content. However, it is challenging to attribute this effect solely to the presence of cobalt since the counteracting effect of density is also included in these results. On the other hand, the saturation flux density seems to increase with cobalt content up to a level of 0.046 cobalt ions per formula unit, beyond which it decreases. As reported in the literature [

26,

27,

28], the strong preference of Co

2+ ions for octahedral (B) sites leads to a broader cation redistribution, including the migration of Fe

3+ ions from octahedral to tetrahedral (A) sites. At higher levels of redistribution, the Fe

3+ distribution becomes the dominant factor influencing the magnetic properties. As the Co

2+ doping concentration increases, the occupancy of Fe

3+ ions on the A-sites also increases. At a certain Co

2+ concentration, the magnetic moment of the A-sublattice becomes sufficiently large to reduce the net magnetic moment of the material. This behavior explains the observed trend in the saturation induction of the group B specimens, as shown in

Figure 9b.

Another approach to increasing the resonance frequency involves varying the Ni/Zn molar ratio, which was maintained equal to 1 in all group A and B specimens. It is known that increasing the Ni/Zn ratio raises the magnetocrystalline anisotropy constant while reducing the saturation flux density and initial magnetic permeability [

2]. Consequently, the resonance frequency is expected to shift to higher frequencies, leading to reduced high-frequency losses. The decision to vary the Ni/Zn ratio from 1 to higher values was made for specimen B040/C100. This specimen was selected because it exhibited the lowest losses at 100 °C, sufficiently low losses at 120 °C and acceptable magnetic permeabilities and saturation flux densities. Based on this rationale, group C syntheses were developed.

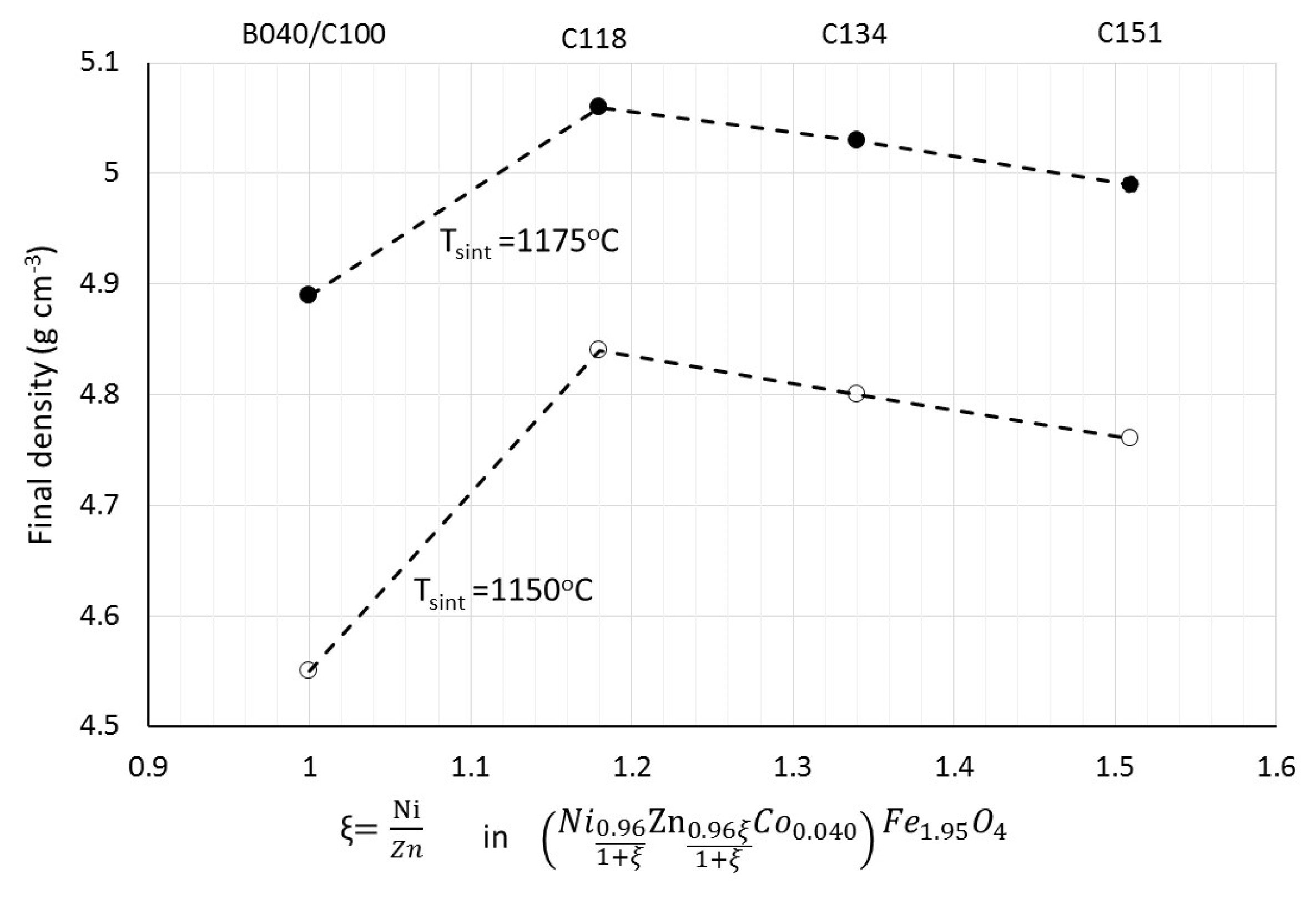

The final sintered densities of group C specimens are shown in

Figure 10. The initial increase in the Ni/Zn ratio to 1.18 results in higher densities, while a further increase shows a tendency toward lower densities. SEM investigations did not reveal any clearly distinguishable differences in the microstructures.

The 10 MHz power losses as a function of temperature are shown in

Figure 11. The advantage of a higher Ni/Zn ratio becomes evident only at the relatively high field of 10 mT. Achieved power losses at 120 °C with specimen C118 were 1400 mW cm

−3, which are lower than the corresponding values of all group B specimens reported earlier (

Figure 8). Under low fields of 3 mT (

Figure 11b), the specimen B040 remains superior in terms of power losses.

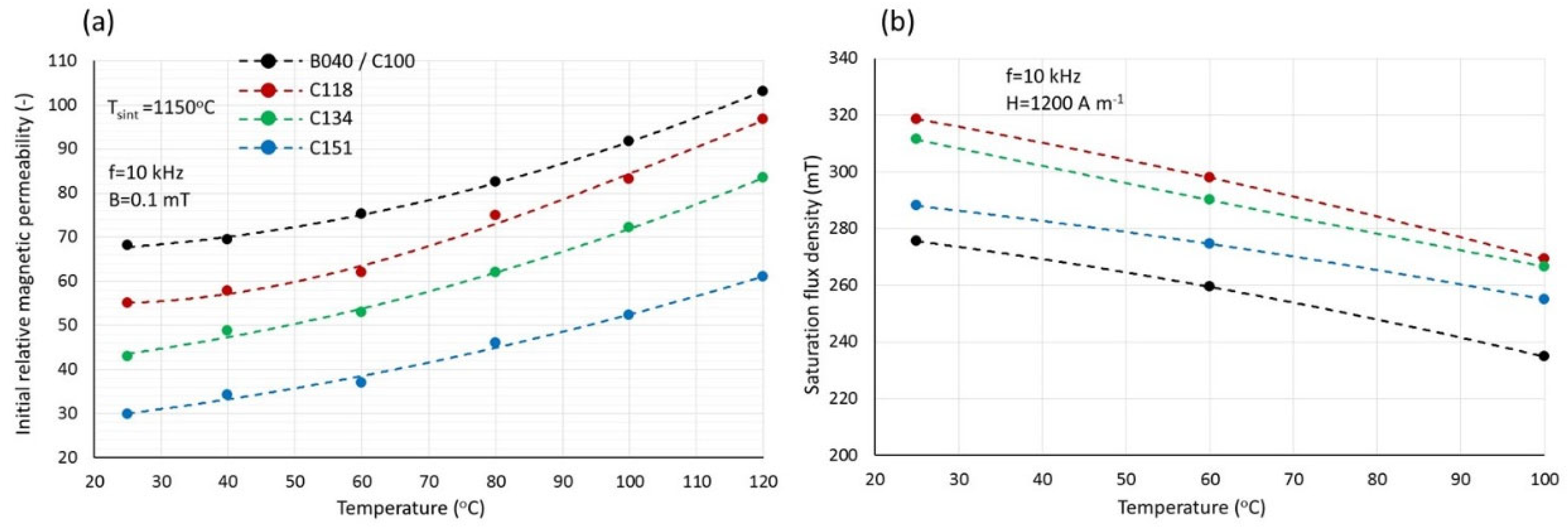

The initial magnetic permeabilities and saturation flux densities of group C specimens are shown in

Figure 12.

The magnetic permeabilities clearly decrease with increasing Ni/Zn ratio, as predicted by the theory of antiferromagnetism [

2]. However, this trend is not entirely followed by the saturation flux density, which increases significantly when the Ni/Zn ratio varies from 1 to 1.18, beyond which it decreases, as expected. The saturation flux density that physically represents the resultant magnetic moment per unit volume, appears to be influenced by the density more than the initial permeability. Despite the higher Ni/Zn ratio, the permeability of specimen C118 is higher than that of specimen B040 due to its higher density (

Figure 10). At comparable densities, however, the permeability decreases, as the Ni/Zn ratio becomes the determining factor.

Power losses in ferrites are generally categorized into hysteresis losses (P

h), eddy current losses (P

e) and residual losses (P

r). The identification of loss sources relies on their distinct frequency dependencies: per cycle, hysteresis losses remain independent of frequency, eddy current losses increase linearly with frequency, and residual losses exhibit an even stronger frequency-dependent growth [

38].

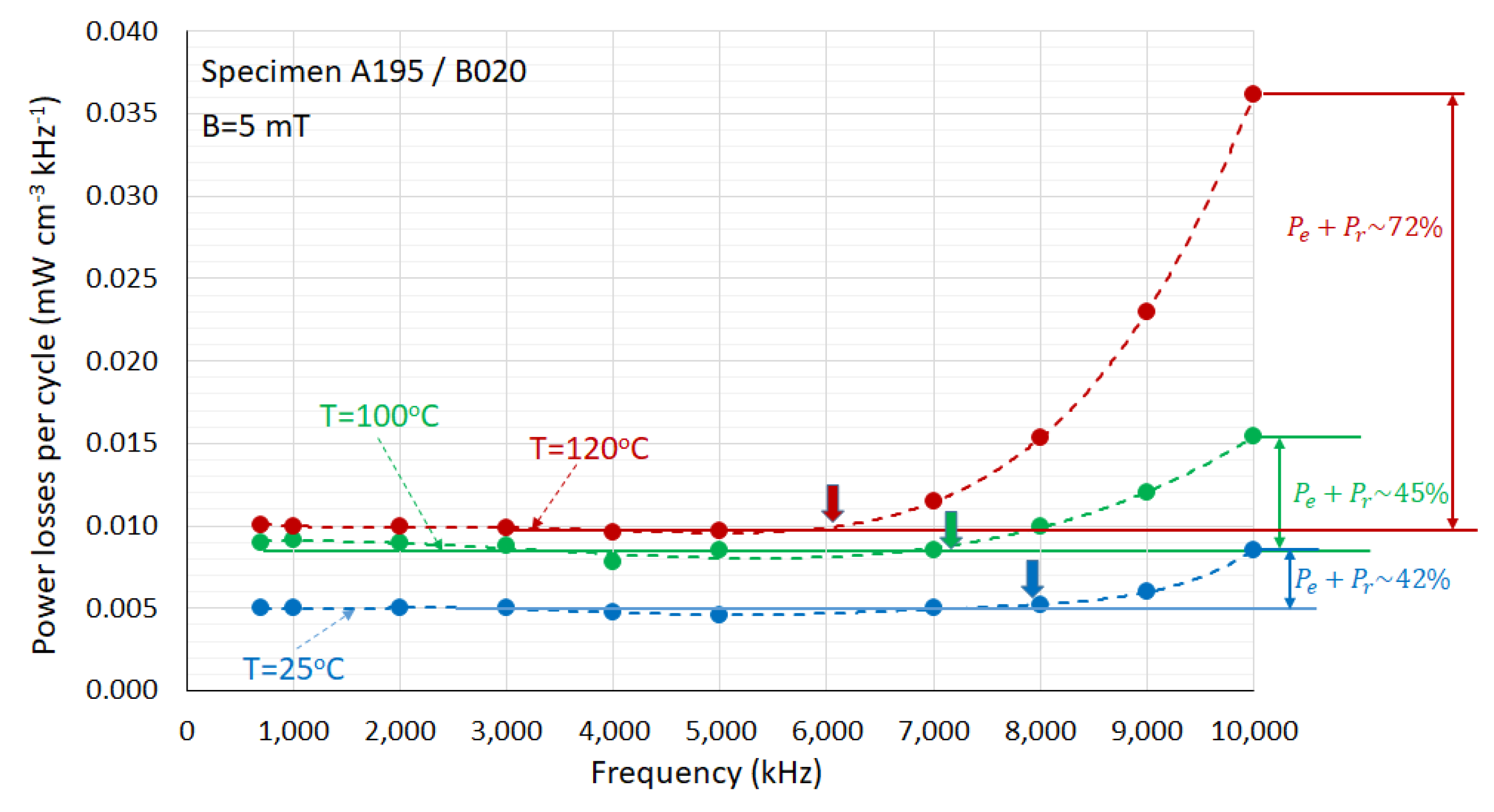

Figure 13 illustrates the power losses per cycle as a function of frequency for specimen A195/B020 across three temperatures, highlighting these trends.

The power losses per cycle remain independent of frequency up to approximately 6 MHz, beyond which they increase significantly. This frequency-independent portion corresponds to hysteresis losses. At higher frequencies, losses exceeding the hysteresis level are attributed to eddy current and residual losses, collectively referred to as Pe + Pr. Differentiating the linear and exponential components graphically is challenging, but it is believed that most of these losses result from resonance effects. Additionally, the threshold frequency at which losses begin to rise decreases with temperature, shifting from approximately 8 MHz at 25 °C to about 6 MHz at 120 °C. Spin rotational resonance is proportional to saturation magnetization, which diminishes as temperature increases [

37]. Furthermore, higher temperatures reduce domain wall stiffness and pinning effects [

38], leading to a decrease in domain wall resonance. At 10 MHz and 120 °C, resonance accounts for over 70% of the observed losses.

Consequently, the sharp increase in 10 MHz losses with temperature, as shown in

Figure 6, is attributed to the same mechanism: resonance effects. The temperature at which losses significantly rise is strongly influenced by the applied field. It is unlikely that the rotational resonance frequency decreases with increasing field strength [

37,

39]. Instead, the primary explanation is that domain wall resonance, the dominant loss-generating mechanism, becomes more pronounced as the applied field reduces the effectiveness of domain wall pinning. Similar effects have been observed in [

8] at 1.5 MHz, where losses were linked to the inefficiency of pinning induced by cobalt.

The introduction of cobalt to NiZn ferrites significantly impacts their magnetic performance, with effects similar to those observed in MnZn ferrites [

8,

20,

40,

41]. At lower frequencies, cobalt compensates for the negative anisotropy of the host lattice, inducing secondary permeability maxima or power loss minima. However, as shown in

Figure 8, these phenomena are absent at 10 MHz. While increasing cobalt content leads to higher hysteresis losses, it also enhances the temperature stability of these losses, likely due to stronger domain wall pinning. This is further evidenced by the decrease in initial permeability with increased cobalt content (

Figure 9a), indicating that magnetization at low frequencies and induction levels relies heavily on domain wall movements. At higher frequencies, such as 10 MHz, the effects of magnetocrystalline anisotropy compensation are overshadowed by resonance losses. The saturation flux density, depicted in

Figure 9b, initially increases with cobalt content due to the higher magnetic moment of Co

2+ ions on B-sites [

23,

42,

43], and subsequently decreases at higher Co

2+ concentrations (e.g., specimen B052) due to the forced migration of Fe

3+ ions to octahedral sites [

23,

26,

27,

28].

Ιn

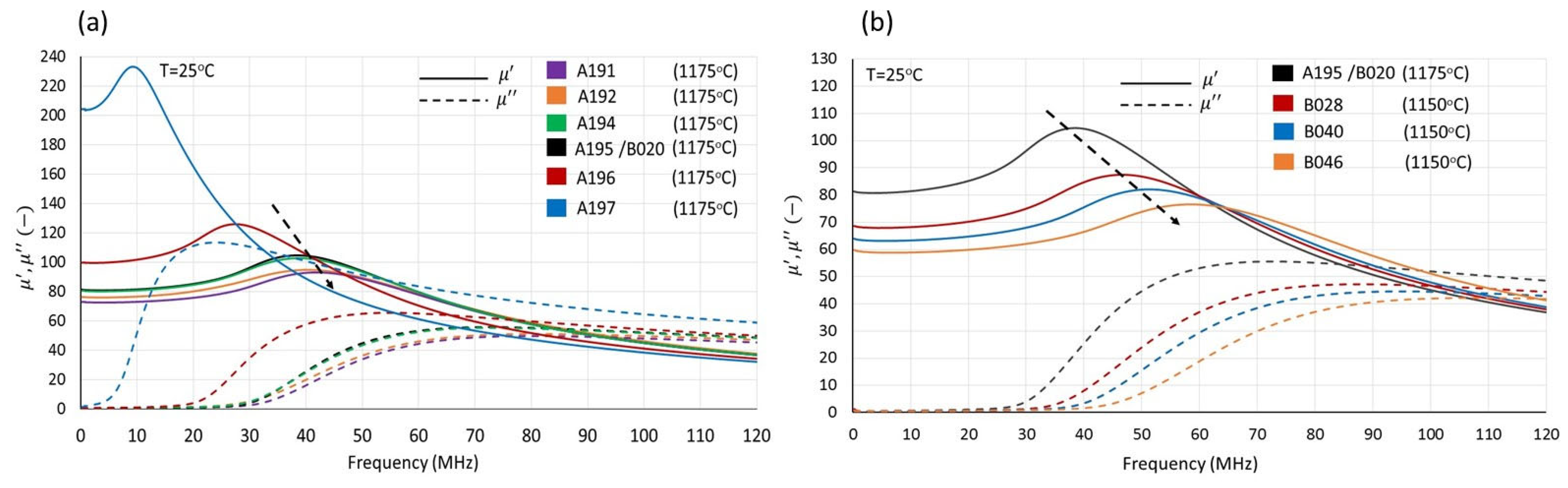

Figure 14, the frequency dependence of the real (μ′) and imaginary (μ′′) components of the complex permeability (μ = μ′ + iμ′′) is presented for specimens of group A and group B. The initial increase in the real part, coinciding with the rise in the imaginary part, is typically attributed to domain wall resonance [

16]. This peak shifts to lower frequencies with increasing iron content (

Figure 14a) and to higher frequencies with increased cobalt content (

Figure 14b). In agreement with the low of Snoek in all cases, the higher resonance frequencies are associated with lower magnetic permeabilities. When the iron content is higher than approximately 1.95 atoms per formula unit (i.e., specimens A196 and A197), a relatively sharp increase in permeability occurs, associated with a decrease in resonance frequency. Taking into account also the lower final densities of these specimens, the sharp increase in the 10 MHz power losses (

Figure 5) can be explained. At iron contents lower than 1.95 atoms per formula unit, the drop in permeability and the increase in resonance frequency become less pronounced. In contrast, as shown in

Figure 14b, the effect of cobalt on the resonance frequency becomes more obvious, indicating enhanced domain wall pinning.

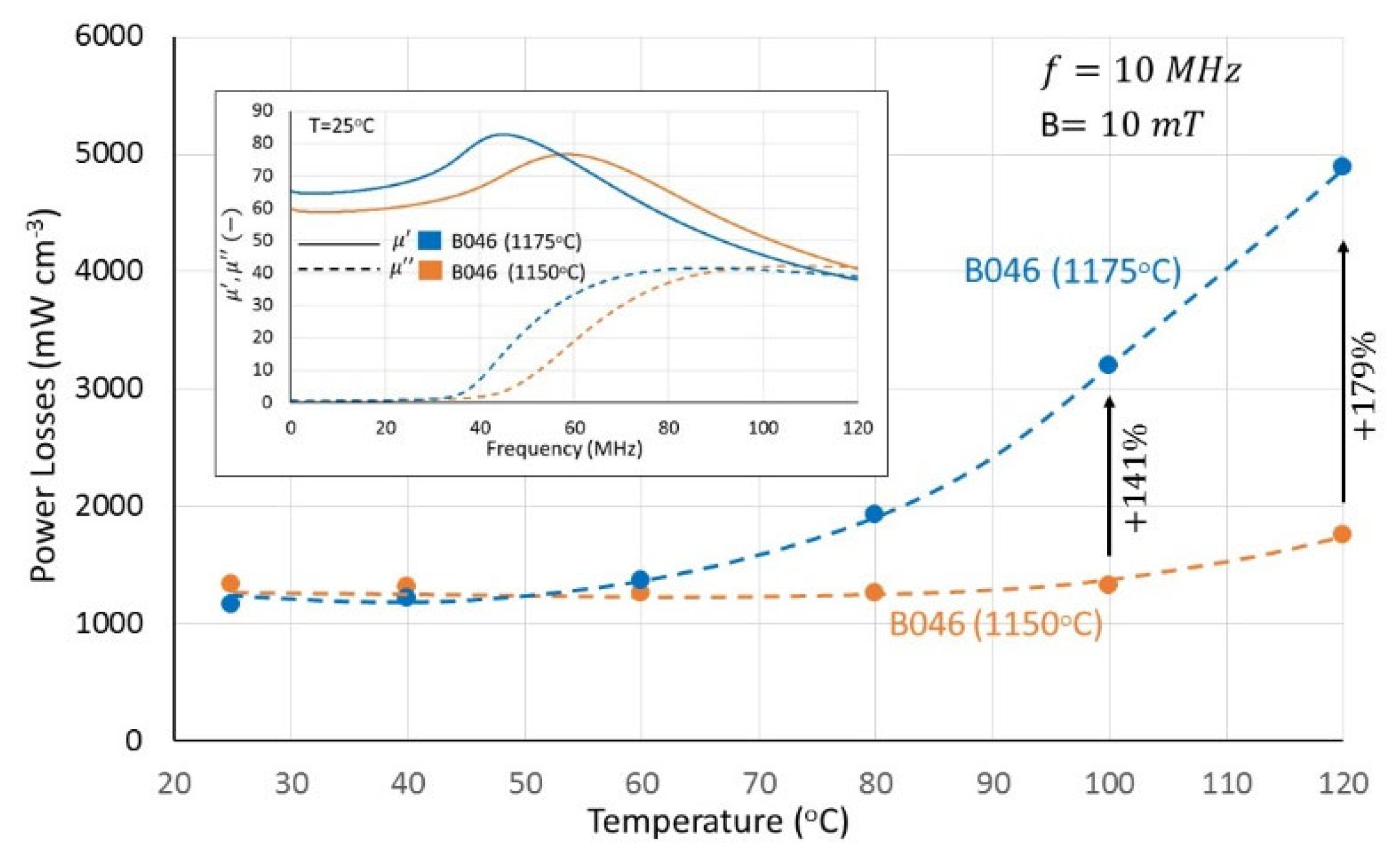

Although cobalt enhances domain wall pinning and facilitates low losses at high temperatures, it also increases the system’s sensitivity to minor variations in operational parameters.

Figure 15 shows the 10 MHz power loss as a function of temperature for specimen B046, sintered at 1150 °C and 1175 °C. While low-temperature losses (up to 60 °C) remain relatively unchanged, and do not seem to be significantly affected, a sharp rise is observed at higher temperatures. As previously noted, no significant differences in the microstructure were detected via SEM analysis. Additionally, the slightly varying densities (shown in

Figure 7) do not account for the substantial differences in power losses.

In the inset of

Figure 15, the real and imaginary components of the magnetic permeability are shown as functions of frequency. The domain wall resonance is clearly shifted to lower frequencies, leading to a sharp increase in power loss at higher temperatures. These results, together with those shown in

Figure 14, provide strong evidence for the co-existence of a domain wall movement magnetization mechanism, even under conditions where the individual particles are considered monodomain, and are consistent with similar phenomena reported in the literature [

21,

22]. The efficiency of cobalt-induced pinning points appears to depend strongly on the sintering temperature, although the underlying mechanism remains unclear. Possible factors include diffusion, segregation and oxidation-reduction reactions during sintering, which may influence the cobalt distribution within the microstructure or its valence. It is worth noting that a 25 °C temperature difference is comparable to the temperature gradients typically observed in industrial production furnaces.

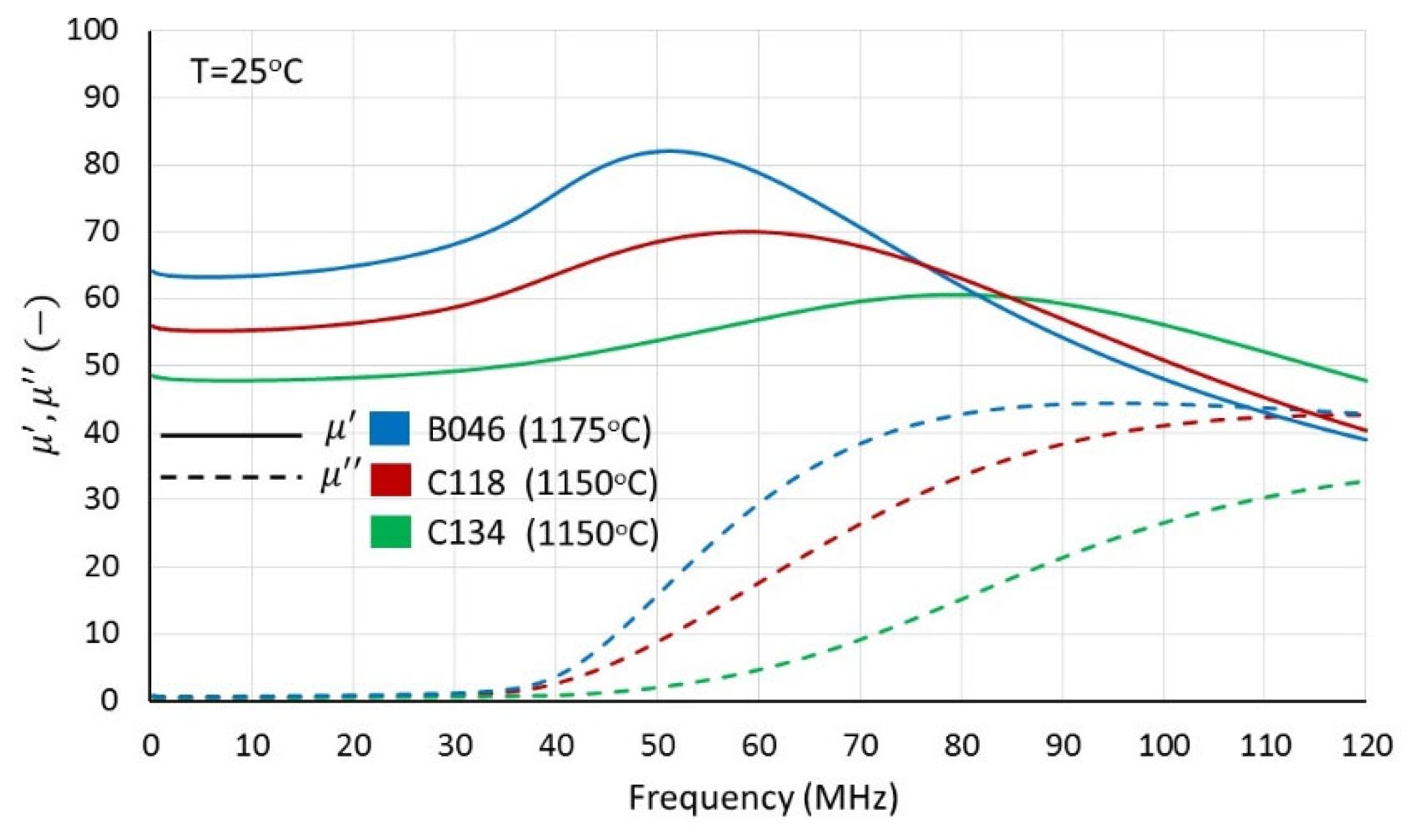

Increasing the Ni/Zn ratio further increases further the hysteresis losses and reduces the permeability, as shown in

Figure 11a and

Figure 12a. The increase in hysteresis losses is primarily attributed to the rise in the magnetocrystalline anisotropy constant [

2], whose contribution to losses becomes more pronounced. At low temperatures, hysteresis losses are no longer independent of temperature, but instead exhibit a decreasing trend (

Figure 9a), reflecting the temperature-dependent reduction of the magnetocrystalline anisotropy constant. Magnetic permeability decreases even further (

Figure 12a), and as shown in

Figure 16, resonance frequencies shift to higher values as a direct consequence of Snoek’s law, which applies to both magnetization mechanisms. Despite the reduced permeability, power losses of 1.4 W cm

−3 were achieved at 10 MHz, 10 mT and 120 °C.

Power loss data at 10 MHz, especially at high temperatures, are scarce or nearly absent in the scientific literature, which hinders comparative discussions. In [

15], power losses of approximately 250 mW cm

−3 were measured at 3 MHz, 10 mT and 25 °C for NiCuZn ferrites. Although this frequency range lies beyond the scope of our study, the power losses of the materials presented in this article (samples A195), under identical conditions, ranged between 100 and 150 mW cm

−3. These values are comparable to those reported in [

44] for NiZn ferrites. However, at 7 MHz, 10 mT and 25 °C, the power losses of about 1000 mW cm

−3 reported in [

15] were significantly higher than the 200–250 mW cm

−3 measured for sample A195/Β020. Additionally, power losses at 10 MHz, 10 mT and 25 °C, reported in [

45], exceed 4 W cm

−3, considerably higher than the corresponding losses presented in

Figure 6. Finally, in [

46], the power losses of NiCuZn ferrites doped with various amounts of V

2O

5 and Bi

2O

3 are reported to be 113 mW cm

−3 at 10 MHz, 5 mT and 25 °C. The corresponding value for the A195/B020 specimen was 60 mW cm

−3, which is approximately 41% lower.