1. Introduction

A number of Fe-based and Co-based rare earth (R) intermetallic compounds have been studied systematically in terms of their structure and magnetic properties [

1,

2,

3,

4]. However, studies on Mn-based rare earth intermetallic alloys are limited. Although some scattered studies on R-Mn intermetallic systems can be traced back to the middle of the last century, the magnetic properties of R-Mn alloys remain unclear due to their high complexity in crystallographic and magnetic structures. Binary Sm

6Mn

23 crystallizes in a face-centered Th

6Mn

23-type cubic structure in which there are five crystallographically non-equivalent positions (24e, 4b, 24d, 32f1 and 32f2) [

5]. The Sm atoms occupy the 24e positions while the Mn atoms occupy the four remaining non-equivalent positions. The interactions between the localized magnetic moments of the R atoms, originating from the 4f shell, and the magnetic moments of the Mn atoms, due to the 3d shell, are very complex [

5]. A net antiparallel coupling of Sm moments and Mn moments is found to exist in the Sm

6Mn

23 alloys, which arises from a non-collinear rare earth magnetic structure and a ferrimagnetic Mn magnetic structure [

6]. Moreover, Sm in Sm

6Mn

23 was found to have about the same crystal field parameter as that in SmCo

5, about −200 K, which could lead to high magnetic anisotropy and thus the development of the large coercivity needed for permanent magnet materials [

6].

Although the Sm

6Mn

23 phase is a thermal stable phase, there is no thermally stable La-Mn binary alloyed phase according to the La-Mn binary phase diagram [

7]. It is known that elemental substitution usually has substantial effects on the structure and magnetic properties of a compound. The effect of the substitution of Mn with Fe on the magnetic properties of Sm

6Mn

23 has been studied previously [

8,

9], while the studies on the substitution of Sm in Sm

6Mn

23 with other rare earth elements are relatively rare. It should be noted that the effects of La-substitution on the magnetic properties of Nd-Fe-B have been studied systematically [

10,

11]. After La-substitution, melt-spun (Nd

1−xLa

x)

13Fe

81B

6 (0 ≤

x ≤ 0.5) alloys and the alloy containing 40 at. % La have more uniform and refined microstructures, resulting in enhanced magnetic properties and thermal stability [

11]. An enhanced coercivity in a sample of Sm

5LaMn

23 induction-melted ingots was observed in our previous work but no systematic studies of La-substitution have been conducted [

12]. The investigations of Sm

6−xLa

xMn

23 compounds with an extended composition range and a different preparation method in this work provide us a deeper understanding of the effect of La-substitution on the structure and magnetic properties of the ternary alloys of Sm

6−xLa

xMn

23.

3. Results and Discussion

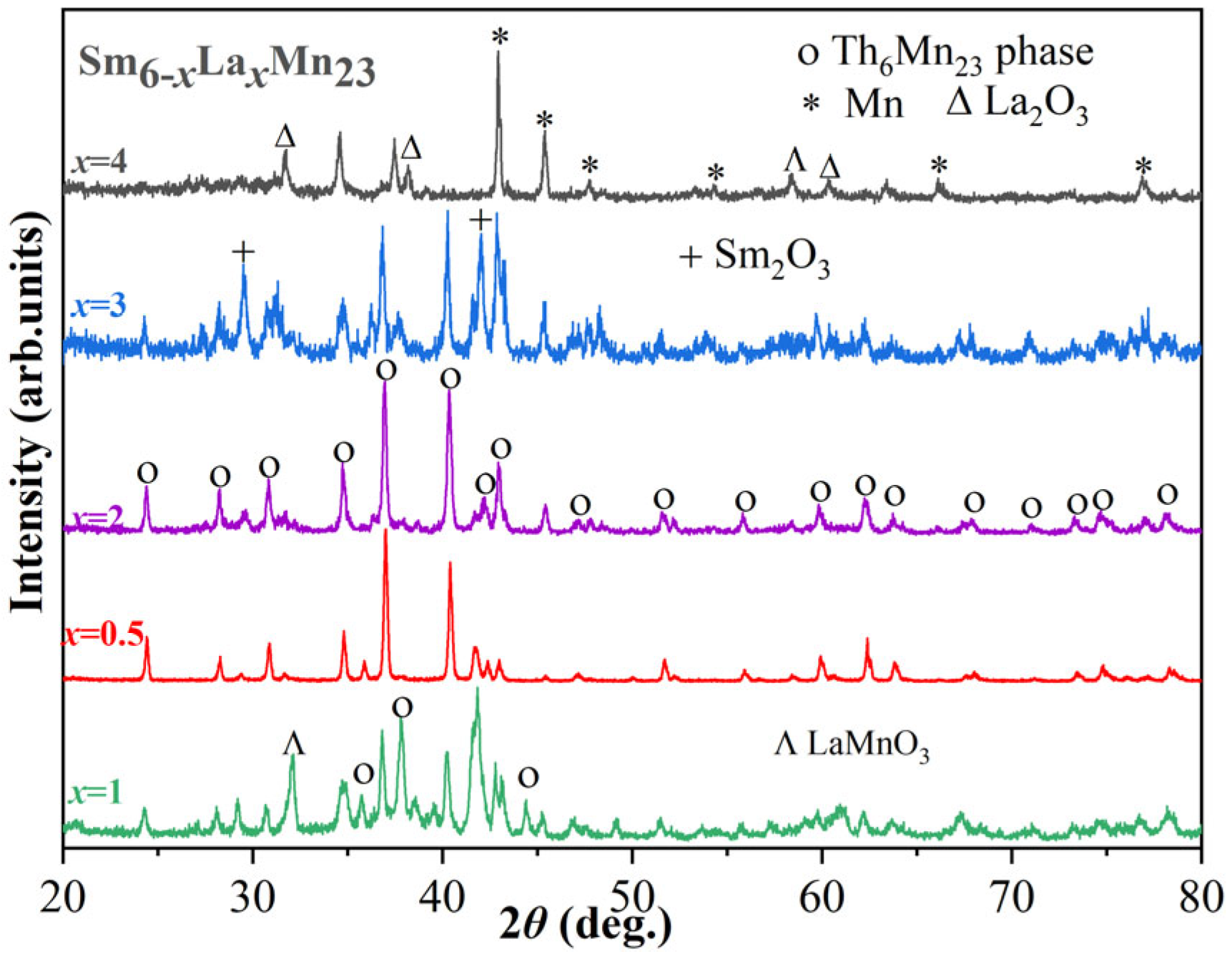

Figure 1 shows the room temperature X-ray power patterns of Sm

6−xLa

xMn

23 (

x = 0.5, 2, 3 and 4) induction-melted ingots and Sm

6−xLa

xMn

23 (

x = 1) melt-spun ribbons after annealing. The main phase of Sm

6−xLa

xMn

23 (

x = 0.5, 2, 3) ingots and the

x = 1 melt-spun ribbons could be indexed with the Th

6Mn

23 cubic structure. It seems that the Th

6Mn

23 phase in the

x = 1 melt-spun ribbons segregates into two phases with two varied lattice parameters due to compositional inhomogeneity. In our previous work, an Sm

5LaMn

23 ingot was synthesized by the induction-melting method, with a mainly cubic Th

6Mn

23 structure and a small presence of α-Mn and Sm

2O

3 [

12]. It is known that the lattice parameters of R

6Mn

23 vary slightly with varying R elements. The presence of two kinds of Th

6Mn

23-phase with varied lattice parameters in the rapidly solidified samples was ascribed to the thermally meta-stable characteristic of the rapidly quenched samples, in which the (Sm, La)

6Mn

23 phase may exhibit a locally varying La/Mn ratio and thus a varied lattice parameter. An annealing process can usually promote the increased growth of the rapidly quenched ribbons, but may also promote phase decomposition of meta-stable phases. In addition, when the melt is cooling down slowly, as in the case of an ingot in [

12], the (Sm, La)

6Mn

23 phase may have enough time to form a relatively homogenous phase. The relative intensity of the peaks of the Th

6Mn

23 phase at 37.5 and 40.4 reverse gradually with an increasing

x substitution, as seen in

x = 0.5, 2, 3. We speculate that such gradual change might be due to the change in the atomic scattering factor of the X-ray after substitution. The high peak at 42.5 of the

x = 3 sample was ascribed to the formation of Mn instead of the Th

6Mn

23 phase.

The minor phases in Sm

6−xLa

xMn

23 (

x = 0.5, 1, 2, and 3) ingots/ribbons could be indexed with Sm

2O

3 and α-Mn, which increases in proportion with an increasing

x, indicating the decreasing stability of the Sm

6−xLa

xMn

23 phase with an increasing

x. Noticeably, the (3, 1, −3) plane at 41.93° of Sm

2O

3 (space group C12/m1) in the

x = 3 ingot seems to overlap with 42.01° of the Th

6Mn

23 phase in the

x = 2 ingot. We ascribe the appearance of α-Mn in Sm

6−xLa

xMn

23 (

x = 0.5, 2) to Sm evaporation and the precipitation of the unreacted Mn when the high temperature melt was cooling down. Since a thermodynamically stable La-Sm binary phase does not exist, an increasing La content would also increase the fraction of the unreacted Mn phase. The formation of Sm

2O

3 was ascribed to the oxidation of the fine powders of the samples during XRD experiments when exposed to air. The lattice parameters of Sm

6−xLa

xMn

23 with

x = 0.5, 2, and 3 are estimated to be 12.616 Å, 12.631 Å, and 12.656 Å, respectively. The lattice parameter of Sm

6Mn

23 was reported to be 12.594 Å in a previous study [

13], indicating increasing lattice parameters of Sm

6−xLa

xMn

23 with increasing La content. We ascribe the increasing lattice parameters of Sm

6−xLa

xMn

23 with an increasing

x to the larger ionic radius of La over that of Sm. The Th

6Mn

23 cubic structured phase almost disappears in Sm

6−xLa

xMn

23 when

x = 4, where α-Mn is the main phase, as shown in

Figure 1. Owing to the increasing La content and the inhomogeneity in Sm

6−xLa

xMn

23 (

x = 1 and 4), a trace amount of La

2O

3 and LaMnO

3 could be found.

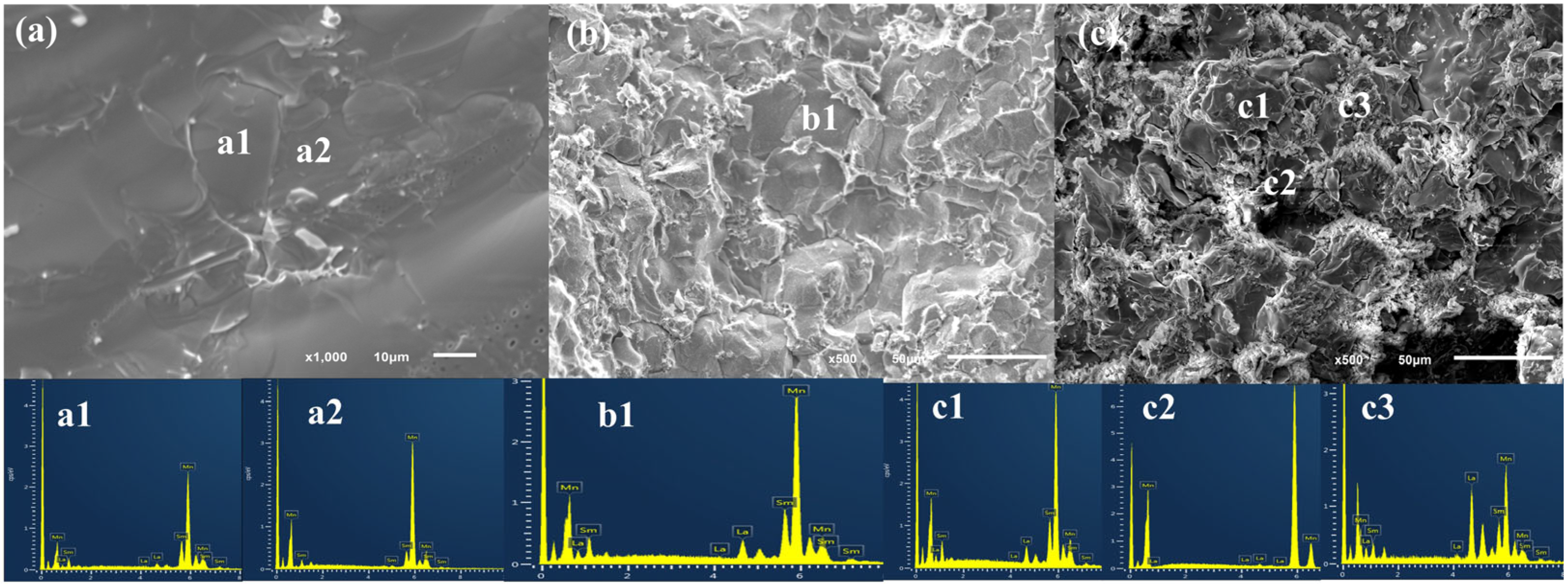

Figure 2 shows the typical morphological microstructure of the fractured surface of Sm

6−xLa

xMn

23 (

x = 0.5, 2, and 3) alloys. The homogeneity of Sm

5.5La

0.5Mn

23 and Sm

4La

2Mn

23 seem better than that of Sm

3La

3Mn

23, in agreement with the XRD results that showing less stable Th

6Mn

23 structure and more impurities in the samples with an increasing

x. The grain size of the melt-spun ribbons with

x = 1 is much smaller than that of the other samples, as manifested by a broadening of the XRD peaks, owing to the rapid solidification process of the melt-spun ribbons.

A detailed compositional analysis was conducted by using the energy-dispersive X-ray spectrum. The atomic ratio of La:Sm:Mn was estimated to be ~0.575:5.75:23 (a1), in good agreement with the nominal composition in La

0.5Sm

5.5Mn

23 within the experimental uncertainties. It should be noted that a Mn-rich region (a2) was also observed by EDX and the atomic percentage of Mn was estimated to be 90.46% while no La element was observed. We ascribe the slight compositional deviation of Sm

5.5La

0.5Mn

23 to the evaporation of the constituents during melting and the inhomogeneity of the samples during the cooling process. The Sm

4La

2Mn

23 showed an atomic ratio of 1.53:5.5:23 at b1. The Sm

3La

3Mn

23 showed a presence of matrix regions (c1) with a composition close to the nominal composition, Mn-rich regions (c2) and rare-earth-rich region (c3), as shown in

Figure 2b. The atomic ratio of the rare-earth-rich region c3 was estimated to be La: Sm: Mn ~10.7:8.2:23, while the atomic percentage of Mn in Mn-rich region was almost 100 % Mn at c2, corresponding to the minor phase of the α-Mn phase, as confirmed by XRD.

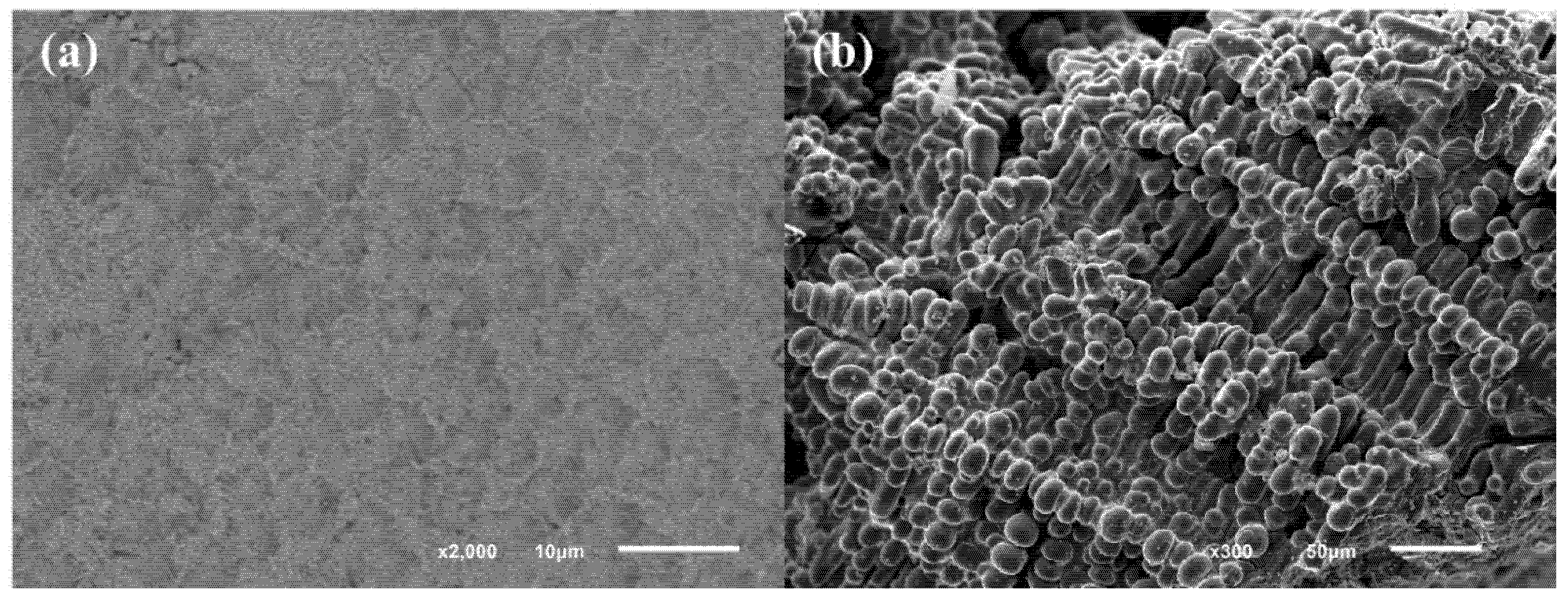

The morphological observations of the Sm

5LaMn

23 melt-spun ribbons and the Sm

2La

4Mn

23 ingot are shown in

Figure 3. A clear phase separation of the main particulate phase separated by the inter-grain phase was observed in the melt spun ribbons, in agreement with the XRD results. The size of a domain which contains many grains with different orientations is around 3 μm or less, resulting in a broadening of the XRD diffraction peaks. It is interesting that the Sm

2La

4Mn

23 ingots show a quite different morphology of well-ordered particles with a smooth surface and spherical dimensions of 15 μm. The formation of the unique shape of the Sm

2La

4Mn

23 alloy is not clear. As mentioned above, the spherical micro-particles are mainly composed of α-Mn, owing to the instability of the Th

6Mn

23 phase at this composition.

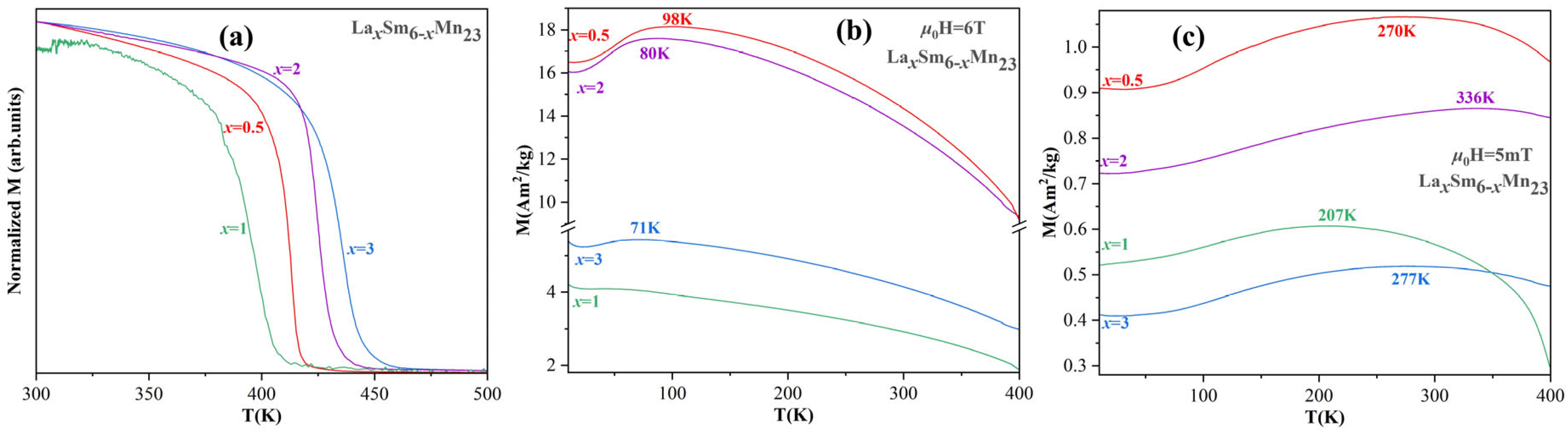

The normalized temperature dependence of magnetization plots of Sm

6−xLa

xMn

23 (

x = 0.5, 1, 2, 3) are shown in

Figure 4a. The Curie temperature (T

C)—defined as the smallest of the d

M/d

T values—of the Sm

6−xLa

xMn

23 ingot/ribbons was measured to be 413 K for

x = 0.5, 398 K for

x = 1 ribbons, 426 K for

x = 2, and 438 K for

x = 3 ingots, respectively. Noticeably, the T

C of Sm

5LaMn

23 and Sm

6Mn

23 alloys prepared by induction melting in our previous work [

12] was measured to be 403 K and 432 K, which agrees well with our results within experimental uncertainties. However, the mechanism of Tc variation with La-substitution remains unclear. It was suggested that the Mn–Mn exchange interactions in R

6Mn

23 may largely dominate the magnetic ordering near T

C with a collinear ferrimagnetic structure and the R–Mn magnetic interactions, positive for light lanthanides, are also non-negligible at high temperatures [

14]. The magnetic parameters of the samples are listed in

Table 1 for comparison.

The temperature dependence of magnetizations of Sm

6−xLa

xMn

23 (

x = 0.5, 1, 2 and 3) measured under an applied magnetic field of 6 T and 5 mT is shown in

Figure 4b,c. Under an applied field of 6 T, the temperature of peak magnetization of La

xSm

6−xMn

23 (

x = 0.5, 2 and 3) ranges from 71 K to 98 K, and that of Sm

6−xLa

xMn

23 (

x = 0.5, 2 and 3) ranges from 207 K to 336 K at 5mT. The temperature shift in peak magnetization under a varied magnetic field may indicate the different M-T behaviors of different magnetic sublattices under varied applied magnetic fields. The maximum magnetization of Sm

5.5La

0.5Mn

23 reaches 18.15 Am

2/kg at 6 T and 98 K. Noticeably, the melt-spun Sm

5LaMn

23 ribbons show no obvious maximum magnetization at 6 T, while it exhibits a peak magnetization at the temperature of 207 K at 5 mT, owing to the field effect.

The magnetic hysteresis loops of Sm

6−xLa

xMn

23 are shown in

Figure 5. The saturation magnetization (Ms, defined as the magnetization value at 6 T) of Sm

6−xLa

xMn

23 at 5 K corresponds to 6.308

μB for

x = 0.5, 1.732

μB for

x = 1, 6.115

μB for

x = 2 and 2.157

μB per unit cell for

x = 3. The coercivity of Sm

6−xLa

xMn

23 at 5 K reached up to 0.44 T for

x = 0.5, 0.53 T for

x = 1, 0.47 for

x = 2 and 0.32 T for

x = 3, respectively. The saturation magnetization of the samples is closely related to the fraction of the Th

6Mn

23 magnetic phase in the samples. The magnetization of Sm

5.5La

0.5Mn

23 and Sm

4La

2Mn

23 was measured to be 11.45 Am

2/kg and 10.6 Am

2/kg, respectively; both are much larger than that of Sm

6−xLa

xMn

23 with

x = 1 and

x = 3.