Enhancing Magnetic Performance of FeNi50 Soft Magnetic Composites with Double-Layer Insulating Coating for High-Frequency Applications

Abstract

1. Introduction

2. Experimental

2.1. Materials and Chemicals

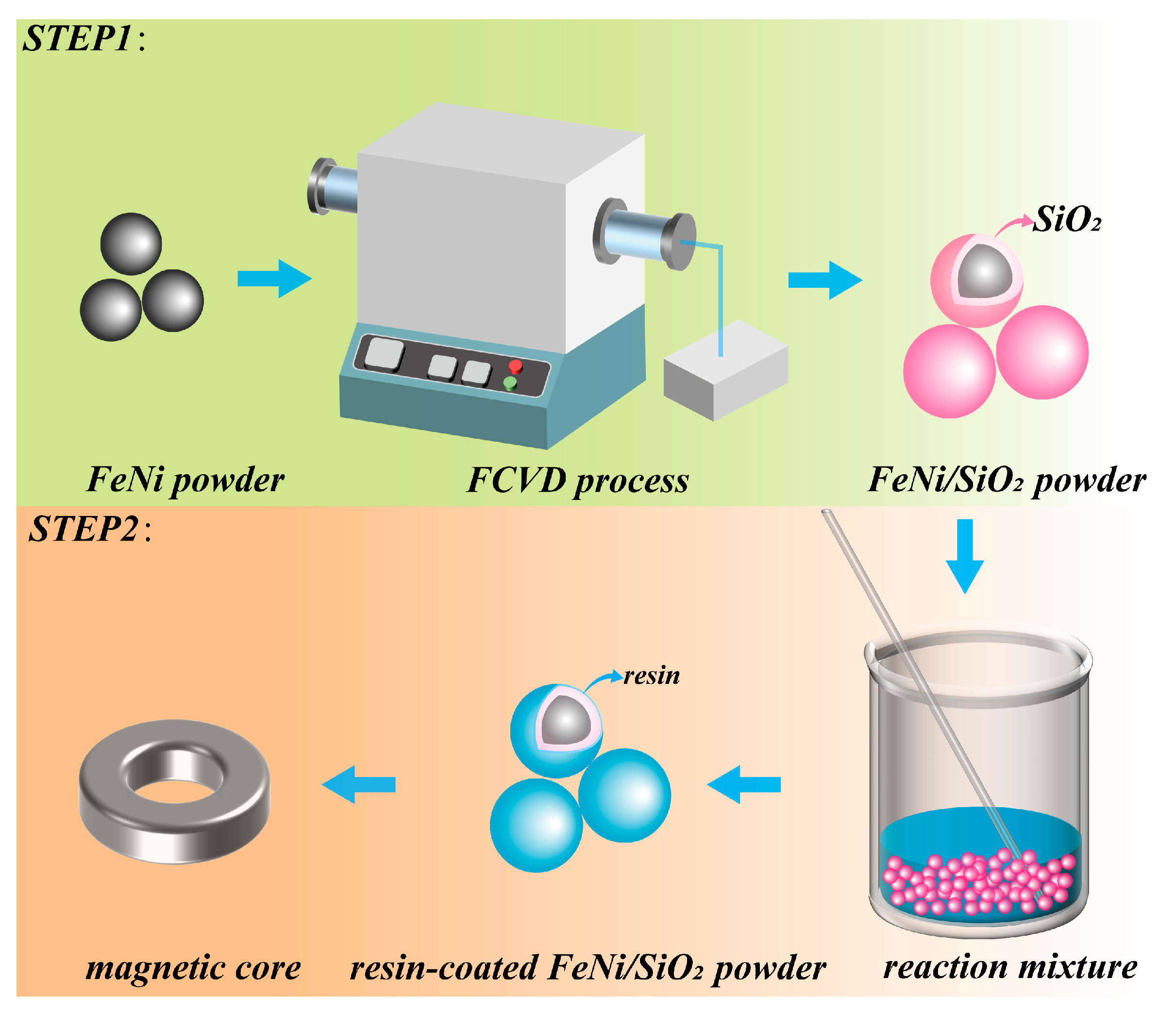

2.2. Synthesis of FeNi50 SMCs with Composite Insulation Layers

2.3. Characterization

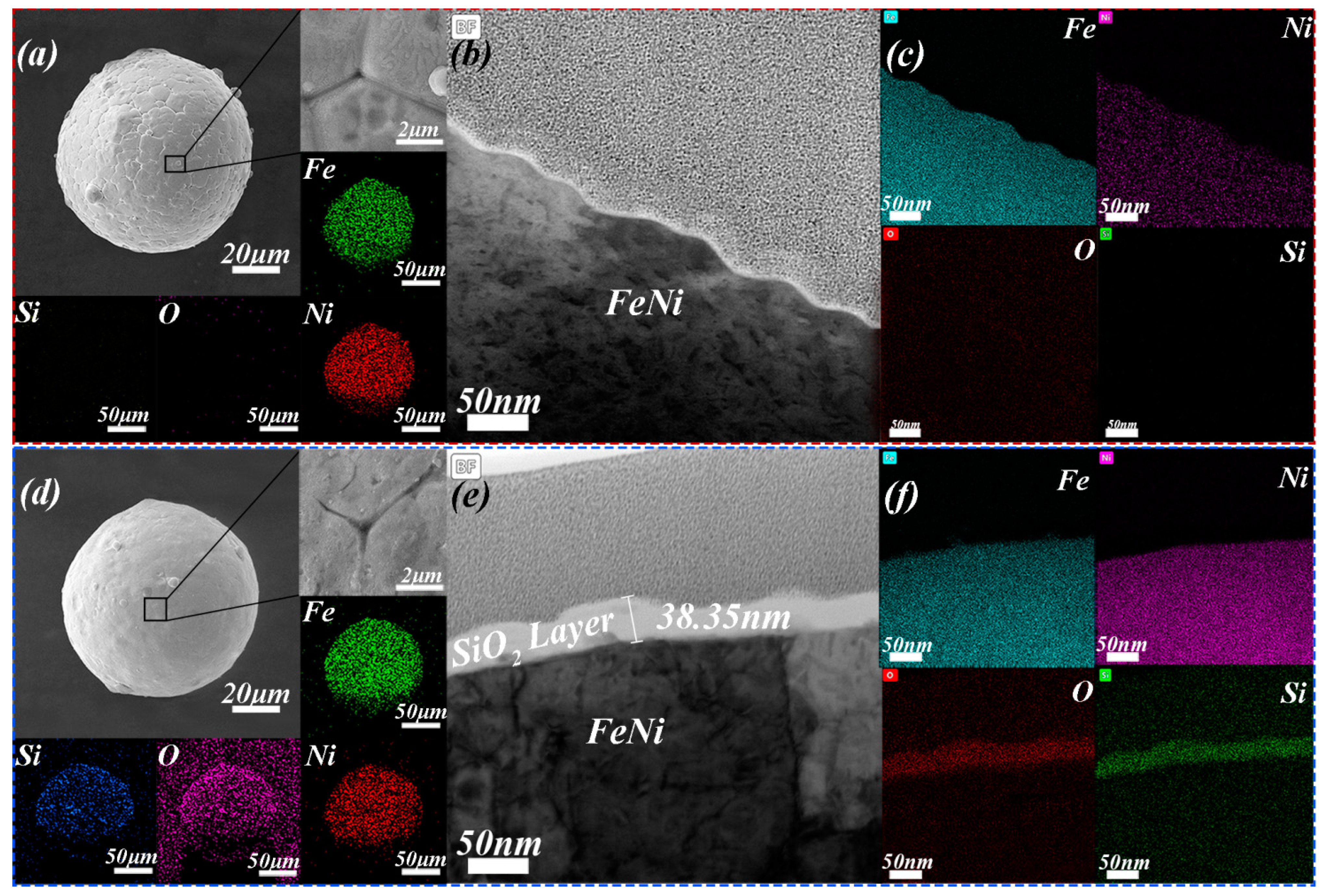

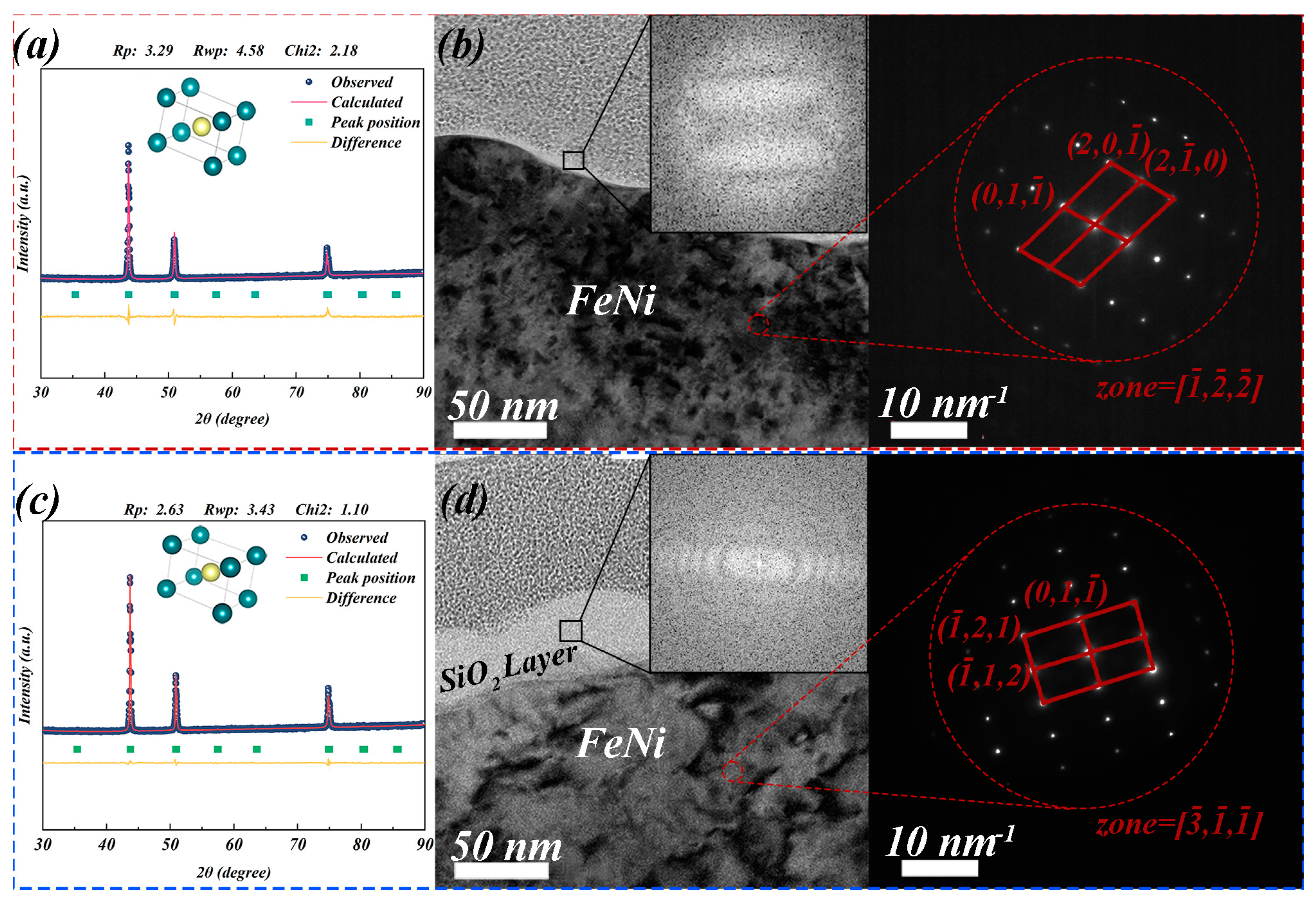

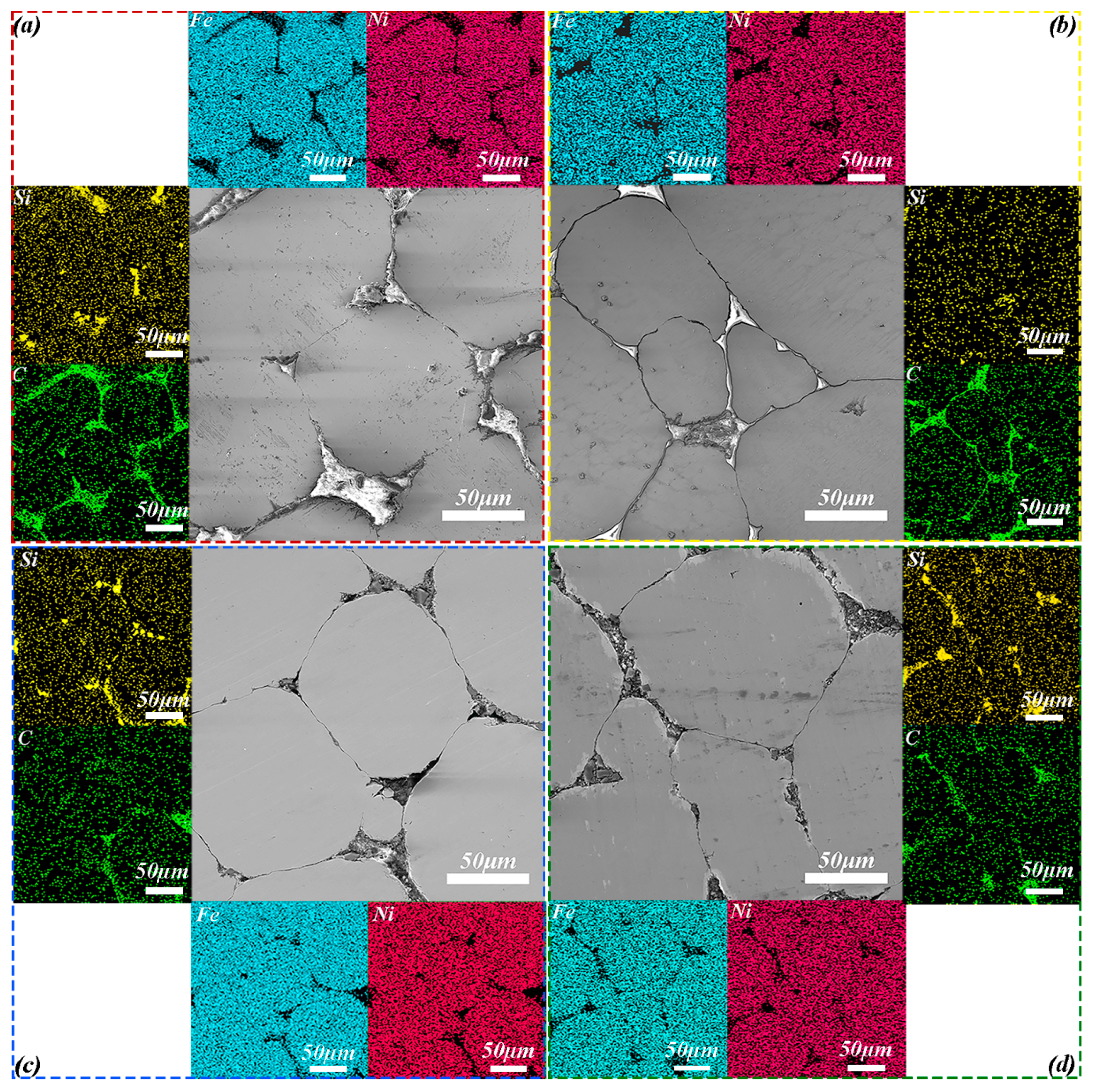

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Périgo, E.A.; Weidenfeller, B.; Kollár, P.; Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 031301. [Google Scholar] [CrossRef]

- Trompetter, B.; Leveneur, J.; Goddard-Winchester, M.; Rumsey, B.; Turner, J.; Weir, G.; Kennedy, J.; Chong, S.; Long, N. Ferrite based soft magnetic composite development intended for inroad charging application. J. Magn. Magn. Mater. 2023, 570, 170530. [Google Scholar] [CrossRef]

- Taghvaei, A.; Shokrollahi, H.; Ebrahimi, A.; Janghorban, K. Soft magnetic composites of iron-phenolic and the influence of silane coupling agent on the magnetic properties. Mater. Chem. Phys. 2009, 116, 247–253. [Google Scholar] [CrossRef]

- Liu, M.; Huang, K.; Liu, L.; Li, T.; Cai, P.; Dong, Y.; Wang, X.-M. Fabrication and magnetic properties of novel Fe-based amorphous powder and corresponding powder cores. J. Mater. Sci. Mater. Electron. 2018, 29, 6092–6097. [Google Scholar] [CrossRef]

- Li, W.; Su, G.; Li, W.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Li, J.; Che, S. Monomolecular cross-linked highly dense cubic FeCo nanocomposite for high-frequency application. J. Mater. Sci. 2022, 57, 13481–13495. [Google Scholar] [CrossRef]

- Gao, Z.; Jia, J.; Zhao, Q.; Kong, H.; Wu, Z.; Li, J. Determination of a quantitative relationship between deposition duration and magnetic performance of soft ferromagnetic composites via data-analysis and theoretical models. J. Magn. Magn. Mater. 2022, 549, 168891. [Google Scholar] [CrossRef]

- Lei, J.; Zheng, J.; Zheng, H.; Qiao, L.; Ying, Y.; Cai, W.; Li, W.; Yu, J.; Lin, M.; Che, S. Effects of heat treatment and lubricant on magnetic properties of iron-based soft magnetic composites with Al2O3 insulating layer by one-pot synthesis method. J. Magn. Magn. Mater. 2019, 472, 7–13. [Google Scholar] [CrossRef]

- Qian, L.; Peng, J.; Xiang, Z.; Pan, Y.; Lu, W. Effect of annealing on magnetic properties of Fe/Fe3O4 soft magnetic composites prepared by in-situ oxidation and hydrogen reduction methods. J. Alloys Compd. 2019, 778, 712–720. [Google Scholar] [CrossRef]

- Ni, J.L.; Hu, F.; Feng, S.J.; Kan, X.C.; Liu, X.S. Magnetic properties of FeSiAl soft magnetic composites under transverse magnetic field. J. Supercond. Nov. Magn. 2021, 34, 883–887. [Google Scholar] [CrossRef]

- Zhou, B.; Dong, Y.; Liu, L.; Chang, L.; Bi, F.; Wang, X. Enhanced soft magnetic properties of the Fe-based amorphous powder cores with novel TiO2 insulation coating layer. J. Magn. Magn. Mater. 2019, 474, 1–8. [Google Scholar] [CrossRef]

- Hu, W.; Fan, X.; Luo, Z.; Luo, F.; Li, G.; Wang, J. Prepared novel Fe soft magnetic composites coated with ZnO by Zn(CH3COO)2 pyrolysis. J. Magn. Magn. Mater. 2020, 505, 166744. [Google Scholar] [CrossRef]

- Luo, Z.; Feng, B.; Chen, D.; Yang, Z.; Jiang, S.; Wang, J.; Wu, Z.; Li, G.; Li, Y.; Fan, X. Preparation and magnetic performance optimization of FeSiAl/Al2O3–MnO–Al2O3 soft magnetic composites with particle size adjustment. J. Mater. Sci. Mater. Electron. 2021, 33, 850–860. [Google Scholar] [CrossRef]

- Guan, W.; Shi, X.; Xu, T.; Wan, K.; Zhang, B.; Liu, W.; Su, H.; Zou, Z.; Du, Y. Synthesis of well-insulated Fe–Si–Al soft magnetic composites via a silane-assisted organic/inorganic composite coating route. J. Phys. Chem. Solids 2021, 150, 109841. [Google Scholar] [CrossRef]

- Wang, J.; Qiu, Z.; Xu, J.; Zheng, Z.; Liu, X.; Zeng, D. Evolution of coating layers during high-temperature annealing and their effects on magnetic behavior of Fe(Si) soft magnetic composites. Adv. Powder Technol. 2022, 33, 103876. [Google Scholar] [CrossRef]

- Luo, D.; Wu, C.; Yan, M. Incorporation of the Fe3O4 and SiO2 nanoparticles in epoxy-modified silicone resin as the coating for soft magnetic composites with enhanced performance. J. Magn. Magn. Mater. 2018, 452, 5–9. [Google Scholar] [CrossRef]

- Wu, Z.; Xian, C.; Jia, J.; Liao, X.; Kong, H.; Xu, K. Formation process of the integrated core(Fe-6.5wt.%Si)@shell(SiO2) structure obtained via fluidized bed chemical vapor deposition. Metals 2020, 10, 520. [Google Scholar] [CrossRef]

- Torrero, J.; Montiel, M.; Peña, M.A.; Ocón, P.; Rojas, S. Insights on the electrooxidation of ethanol with Pd-based catalysts in alkaline electrolyte. Int. J. Hydrog. Energy 2019, 44, 31995–32002. [Google Scholar] [CrossRef]

- Vidya, V.G.; Sadasivan, V.; Meena, S.S.; Bhatt, P. Synthesis, spectral and biological studies of complexes with bidentate azodye ligand derived from resorcinol and 1-amino-2-naphthol-4-sulphonic acid. Orient. J. Chem. 2018, 34, 45–54. [Google Scholar] [CrossRef]

- Barbosa, I.A.; Filho, P.C.d.S.; da Silva, D.L.; Zanardi, F.B.; Zanatta, L.D.; de Oliveira, A.J.; Serra, O.A.; Iamamoto, Y. Metalloporphyrins immobilized in Fe3O4@SiO2 mesoporous submicrospheres: Reusable biomimetic catalysts for hydrocarbon oxidation. J. Colloid Interface Sci. 2016, 469, 296–309. [Google Scholar] [CrossRef]

- Maruko, Y.; Galindo, T.G.P.; Tagaya, M. Modification of poly (dimethylsiloxane) by mesostructured siliceous films for constructing protein-interactive surfaces. E-J. Surf. Sci. Nanotechnol. 2018, 16, 41–48. [Google Scholar] [CrossRef]

- Bo, X.; Zhang, Q.; Li, X.; Zhao, Y. Multifunctional porous silica nanoparticles for dual responsive drug release. J. Sol-Gel Sci. Technol. 2020, 93, 324–331. [Google Scholar] [CrossRef]

- Odenwald, C.; Kickelbick, G. Additive-free continuous synthesis of silica and ORMOSIL micro- and nanoparticles applying a microjet reactor. J. Sol-Gel Sci. Technol. 2019, 89, 343–353. [Google Scholar] [CrossRef]

- Wu, Z.; Xian, C.; Jia, J.; Liao, X.; Kong, H.; Wang, X.; Xu, K. Silica coating of Fe-6.5 wt%Si particles using fluidized bed CVD: Effect of precursor concentration on core–shell structure. J. Phys. Chem. Solids 2020, 146, 109626. [Google Scholar] [CrossRef]

- Temuujin, J.; Okada, K.; MacKenzie, K.; Jadambaa, T. Characterization of porous silica prepared from mechanically amorphized kaolinite by selective leaching. Powder Technol. 2001, 121, 259–262. [Google Scholar] [CrossRef]

- Gemeay, A.H.; Keshta, B.E.; El-Sharkawy, R.G.; Zaki, A.B. Chemical insight into the adsorption of reactive wool dyes onto amine-functionalized magnetite/silica core-shell from industrial wastewaters. Environ. Sci. Pollut. Res. 2020, 27, 32341–32358. [Google Scholar] [CrossRef] [PubMed]

- de Moura, S.G.; Ramalho, T.C.; de Oliveira, L.C.A.; Dauzakier, L.C.L.; Magalhães, F. Photocatalytic degradation of methylene blue dye by TiO2 supported on magnetic core shell (Si@Fe) surface. J. Iran. Chem. Soc. 2022, 19, 921–935. [Google Scholar] [CrossRef]

- Fitzer, E.; Schaefer, W.; Yamada, S. The formation of glasslike carbon by pyrolysis of polyfurfuryl alcohol and phenolic resin. Carbon 1969, 7, 643–648. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Yang, H.; Li, H.; Liu, X. Soft magnetic properties of gas-atomized FeSiAl microparticles with a triple phosphoric acid-sodium silicate-silicone resin insulation treatment. J. Electron. Mater. 2022, 51, 2142–2155. [Google Scholar] [CrossRef]

- Bolshakov, V.; Vaganov, V.; Bier, T.; Ie, A.B.; Matiushenko, I.; Ozhyshchenko, O.; Popov, M.; Sopilniak, A. The usage of smart materials for skin-diagnostics of building structures while their monitoring. Procedia Eng. 2017, 172, 119–126. [Google Scholar] [CrossRef]

- Wan, J.; Li, C.; Bu, Z.-Y.; Xu, C.-J.; Li, B.-G.; Fan, H. A comparative study of epoxy resin cured with a linear diamine and a branched polyamine. Chem. Eng. J. 2012, 188, 160–172. [Google Scholar] [CrossRef]

- Omran, M.; Fabritius, T.; Elmahdy, A.M.; Abdel-Khalek, N.A.; El-Aref, M.; Elmanawi, A.E.-H. Effect of microwave pre-treatment on the magnetic properties of iron ore and its implications on magnetic separation. Sep. Purif. Technol. 2014, 136, 223–232. [Google Scholar] [CrossRef]

- Luo, Z.; Fan, X.; Feng, B.; Yang, Z.; Chen, D.; Jiang, S.; Wang, J.; Wu, Z.; Liu, X.; Li, G.; et al. Highly enhancing electromagnetic properties in Fe-Si/MnO-SiO2 soft magnetic composites by improving coating uniformity. Adv. Powder Technol. 2021, 32, 4846–4856. [Google Scholar] [CrossRef]

- Lv, Q.; Zhu, S.; Zhao, X.; Liu, X.; Feng, S.; Kan, X.; Yujie, Y.; Cheng, Y. Magnetic permeability stability of composite material with nominal composition Ni0.6Fe2.4O4. J. Magn. Magn. Mater. 2022, 553, 169179. [Google Scholar] [CrossRef]

- Zhou, B.; Dong, Y.; Chi, Q.; Zhang, Y.; Chang, L.; Gong, M.; Huang, J.; Pan, Y.; Wang, X. Fe-based amorphous soft magnetic composites with SiO2 insulation coatings: A study on coatings thickness, microstructure and magnetic properties. Ceram. Int. 2020, 46, 13449–13459. [Google Scholar] [CrossRef]

- Kalinin, Y.; Sitnikov, A.; Stognei, O.; Zolotukhin, I.; Neretin, P. Electrical properties and giant magnetoresistance of the CoFeB–SiO2 amorphous granular composites. Mater. Sci. Eng. A 2001, 304–306, 941–945. [Google Scholar] [CrossRef]

- Shi, X.; Chen, X.; Wan, K.; Zhang, B.; Duan, P.; Zhang, H.; Zeng, X.; Liu, W.; Su, H.; Zou, Z.; et al. Enhanced magnetic and mechanical properties of gas atomized Fe-Si-Al soft magnetic composites through adhesive insulation. J. Magn. Magn. Mater. 2021, 534, 168040. [Google Scholar] [CrossRef]

- Nell, M.M.; Schauerte, B.; Brimmers, T.; Hameyer, K. Simulation of iron losses in induction machines using an iron loss model for rotating magnetization loci in no electrical steel. COMPEL–Int. J. Comput. Math. Electr. Electron. Eng. 2022, 41, 600–614. [Google Scholar] [CrossRef]

- Ito, S.; Mifune, T.; Matsuo, T.; Kaido, C.; Takahashi, Y.; Fujiwara, K. Simulation of the stress dependence of hysteresis loss using an energy-based domain model. AIP Adv. 2018, 8, 047501. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Zheng, Z.; Qiu, Z.; Li, K.; Xu, J.; Lu, K.; Zeng, D. Reduction of core loss for FeSi soft magnetic composites prepared using atomic layer deposition-based coating and high-temperature annealing. J. Alloys Compd. 2022, 909, 164655. [Google Scholar] [CrossRef]

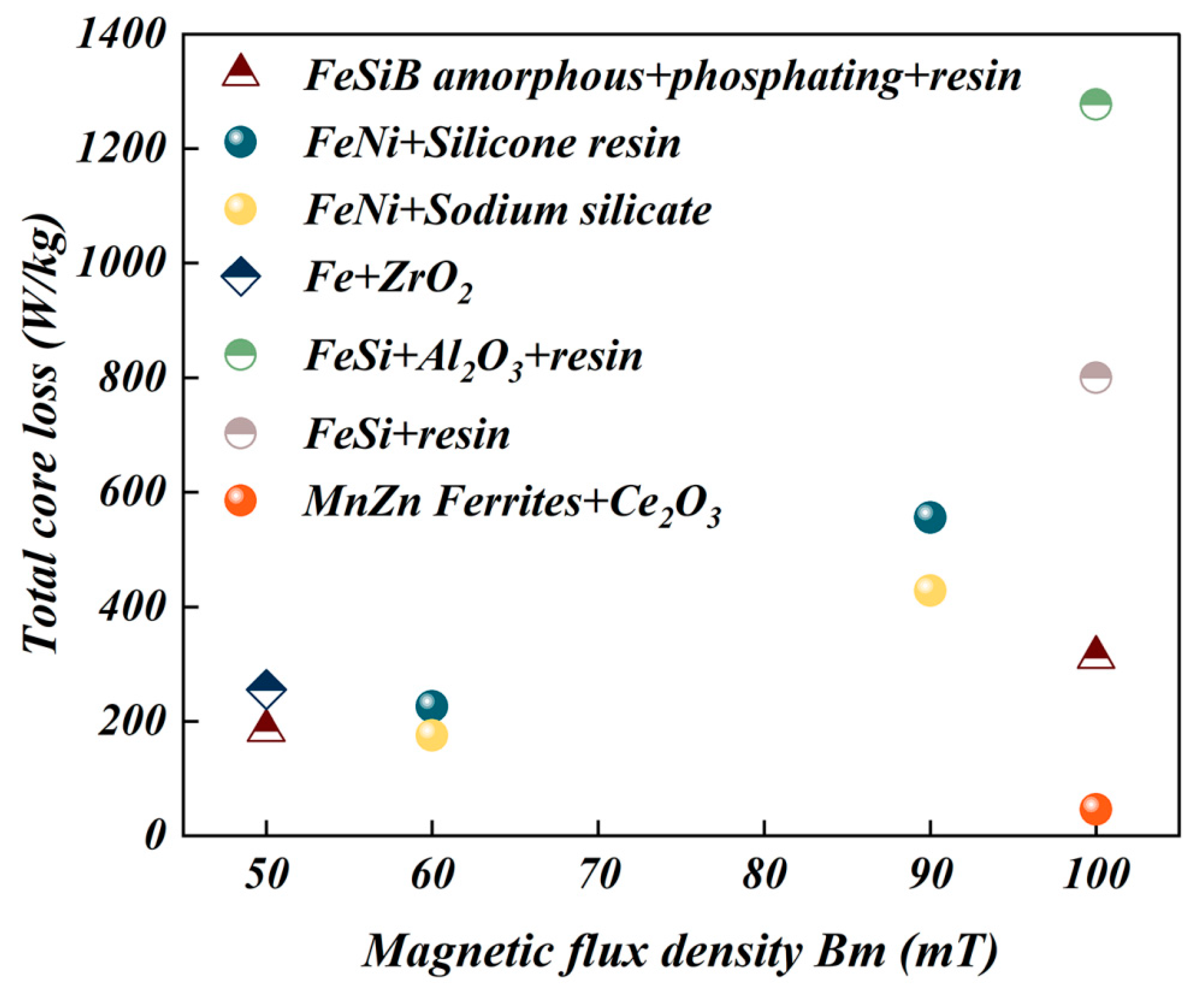

- Strečková, M.; Füzer, J.; Kobera, L.; Brus, J.; Fáberová, M.; Bureš, R.; Kollár, P.; Lauda, M.; Medvecký, Ĺ.; Girman, V.; et al. A comprehensive study of soft magnetic materials based on FeSi spheres and polymeric resin modified by silica nanorods. Mater. Chem. Phys. 2014, 147, 649–660. [Google Scholar] [CrossRef]

- Hu, J.; Li, Z.; Yu, H.; Zhong, X.; Liu, Z.; Long, K.; Li, J. Modifying the Soft Magnetic Properties of Mn-Zn Ferrites by Ce2O3-Doping and Sintering Temperature Optimization. J. Electron. Mater. 2020, 49, 6501–6509. [Google Scholar] [CrossRef]

- Dong, Y.; Li, Z.; Liu, M.; Chang, C.; Li, F.; Wang, X.-M. The effects of field annealing on the magnetic properties of FeSiB amorphous powder cores. Mater. Res. Bull. 2017, 96, 160–163. [Google Scholar] [CrossRef]

- Li, Z.; Dong, Y.; Pauly, S.; Chang, C.; Wei, R.; Li, F.; Wang, X.-M. Enhanced soft magnetic properties of Fe-based amorphous powder cores by longitude magnetic field annealing. J. Alloys Compd. 2017, 706, 1–6. [Google Scholar] [CrossRef]

- Li, W.; Wang, Z.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Che, S. In-situ formation of Fe3O4 and ZrO2 coated Fe-based soft magnetic composites by hydrothermal method. Ceram. Int. 2019, 45, 3864–3870. [Google Scholar] [CrossRef]

| Refinement Parameters | Phase | Cell Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rwp | Rp | Chi2 | a | b | c | α | β | γ | ||

| FeNi50 particles | 3.29 | 4.58 | 2.18 | Fe-Si | 2.535 | 2.535 | 3.583 | 90 | 90 | 90 |

| FeNi50/amorphous SiO2 particles | 2.63 | 3.43 | 1.1 | Fe-Si and amorphous SiO2 | 2.535 | 2.535 | 3.583 | 90 | 90 | 90 |

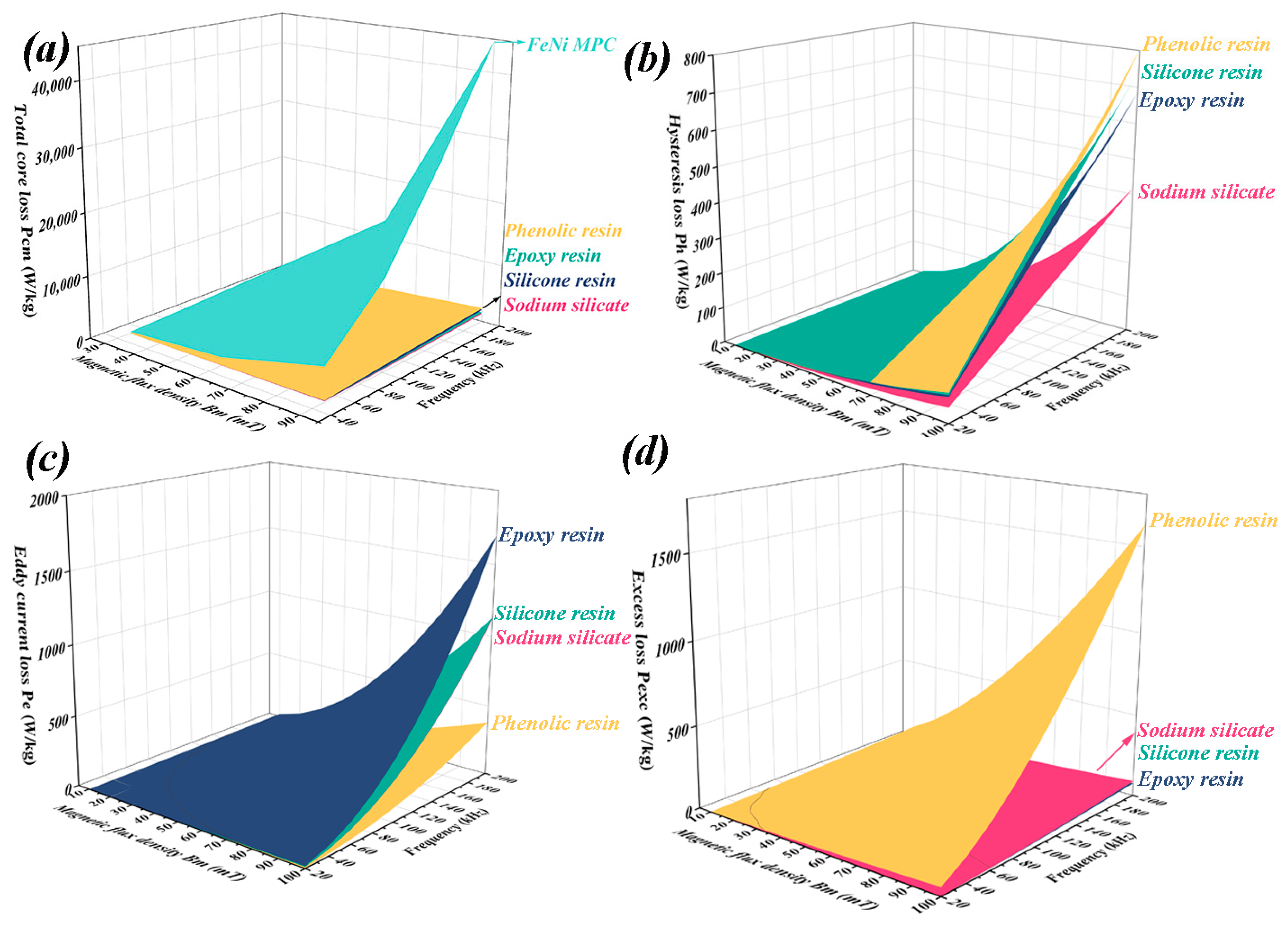

| Hysteresis Component | Eddy-Current Component | Excess Component | R2 | ||

|---|---|---|---|---|---|

| Ch | x | Ce | Cex | ||

| Phenolic resin | 8.42 × 10−5 | 2.33868 | 9.49 × 10−7 | 5.75 × 10−4 | 0.99786 |

| Silicone resin | 2.04 × 10−4 | 2.12966 | 2.83 × 10−6 | 1.77 × 10−5 | 0.99558 |

| Sodium silicate | 2.39 × 10−5 | 2.47016 | 2.81 × 10−6 | 3.18 × 10−5 | 0.99966 |

| Epoxy resin | 6.93 × 10−5 | 2.34721 | 4.24 × 10−6 | 2.71 × 10−5 | 0.99924 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, W.; Zhou, Z.; Zou, R.; Yang, M. Enhancing Magnetic Performance of FeNi50 Soft Magnetic Composites with Double-Layer Insulating Coating for High-Frequency Applications. Magnetochemistry 2024, 10, 45. https://doi.org/10.3390/magnetochemistry10070045

Zheng W, Zhou Z, Zou R, Yang M. Enhancing Magnetic Performance of FeNi50 Soft Magnetic Composites with Double-Layer Insulating Coating for High-Frequency Applications. Magnetochemistry. 2024; 10(7):45. https://doi.org/10.3390/magnetochemistry10070045

Chicago/Turabian StyleZheng, Weizhong, Zixin Zhou, Rongyu Zou, and Minghui Yang. 2024. "Enhancing Magnetic Performance of FeNi50 Soft Magnetic Composites with Double-Layer Insulating Coating for High-Frequency Applications" Magnetochemistry 10, no. 7: 45. https://doi.org/10.3390/magnetochemistry10070045

APA StyleZheng, W., Zhou, Z., Zou, R., & Yang, M. (2024). Enhancing Magnetic Performance of FeNi50 Soft Magnetic Composites with Double-Layer Insulating Coating for High-Frequency Applications. Magnetochemistry, 10(7), 45. https://doi.org/10.3390/magnetochemistry10070045