A Comparative Analysis of the Grafting Efficiency of Watermelon with a Grafting Machine

Abstract

1. Introduction

2. Materials and Methods

2.1. Seedling Production

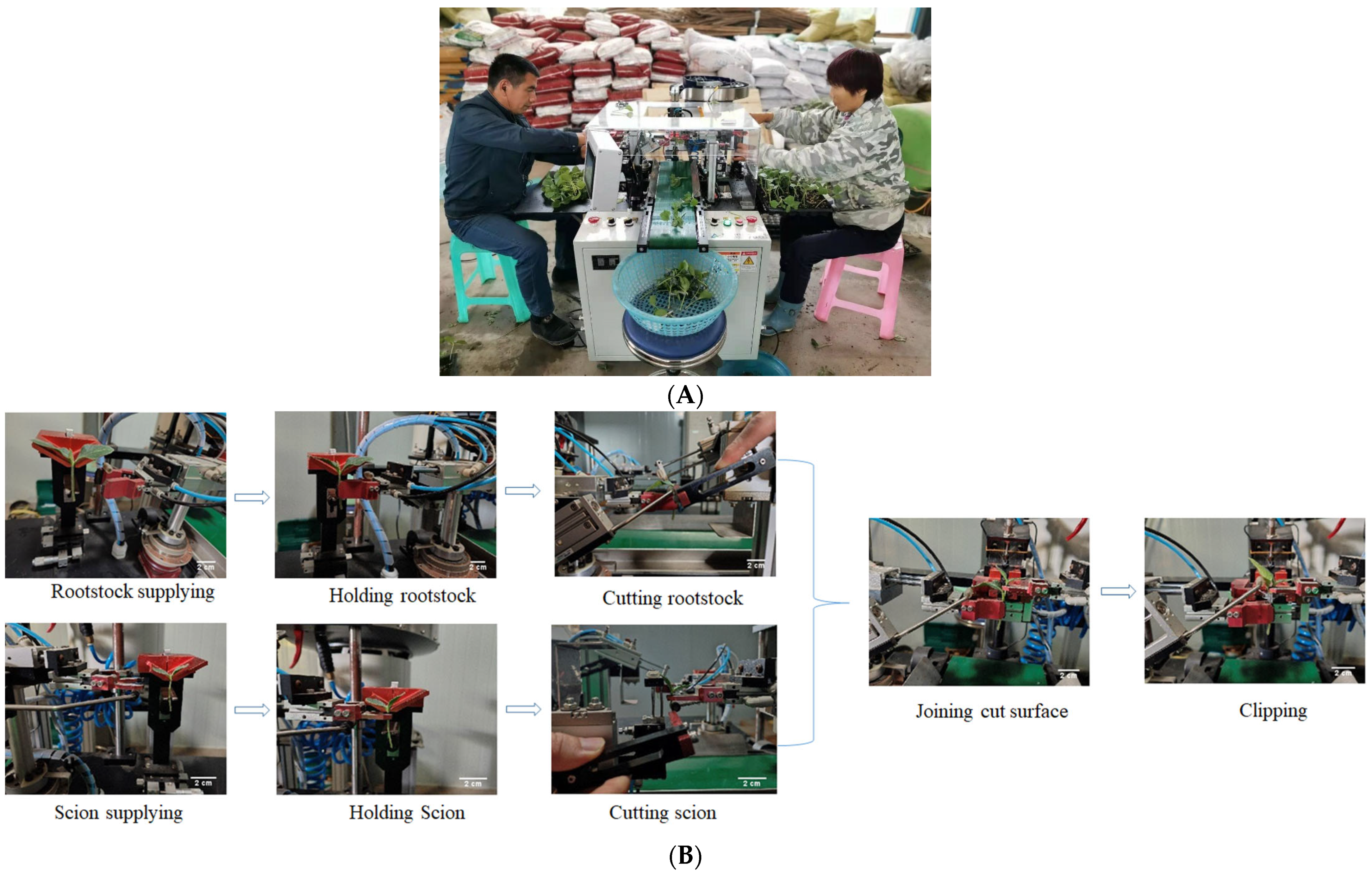

2.2. Device Description and Productive Process

2.3. Experimental Design

2.4. Grafting Seedling Healing and Cultivation

2.5. Grafting Efficiency

2.6. Calculation of Hypocotyl Height, Incision Length of Scion and Rootstock

2.7. Grafted Survival and Rootstock Regrowth Rate Measurement

2.8. Statistical Analysis

3. Results

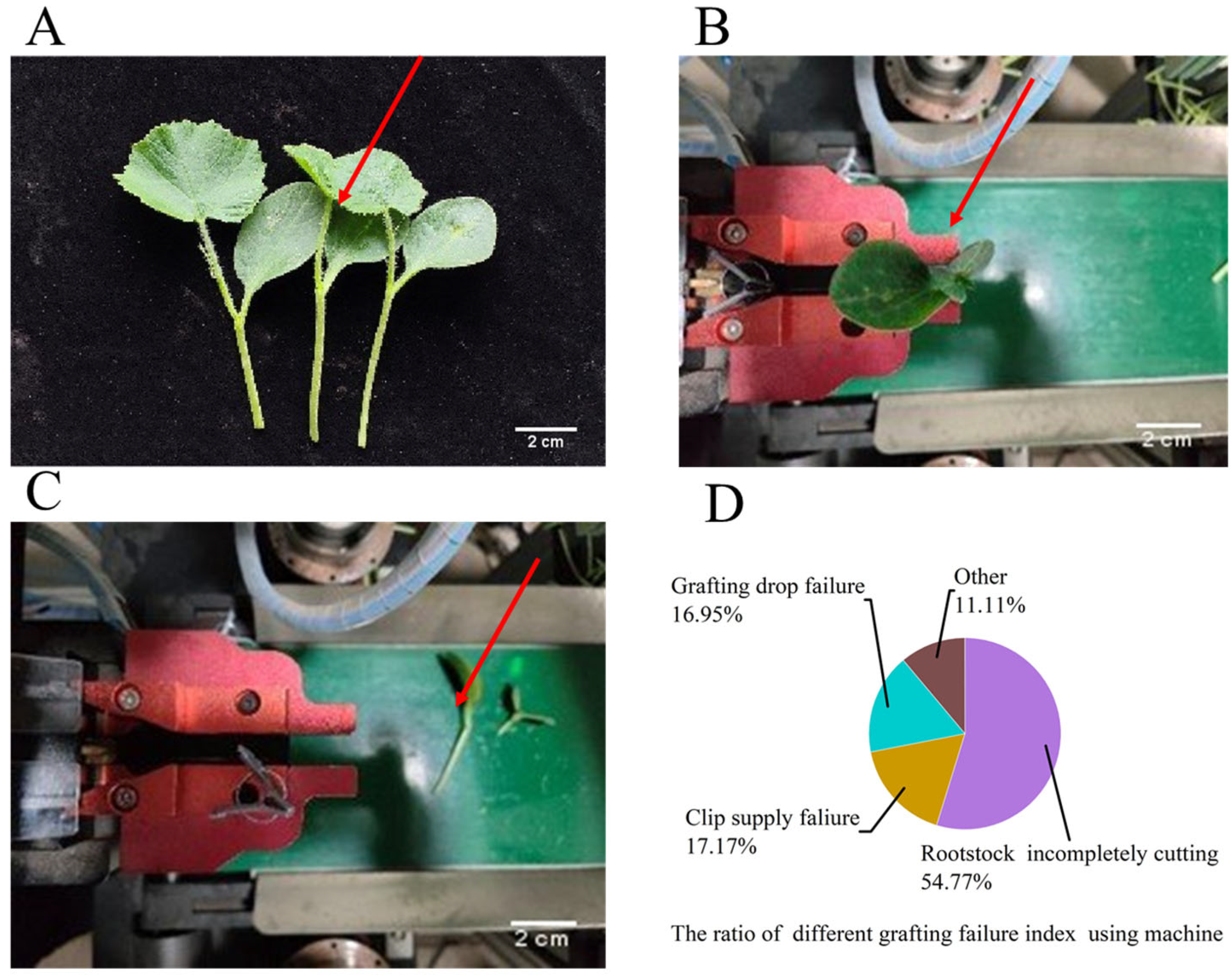

3.1. Grafting Efficiency

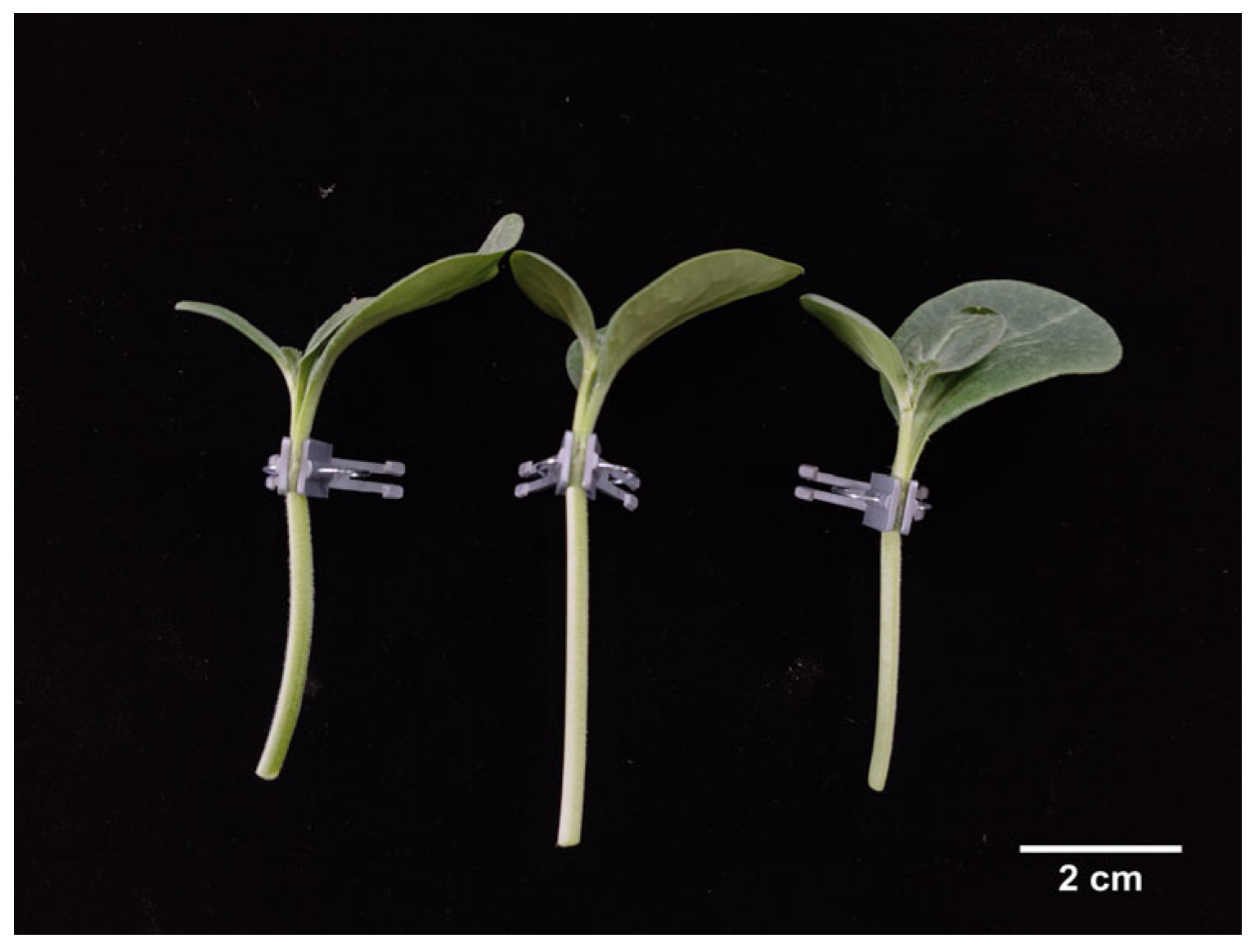

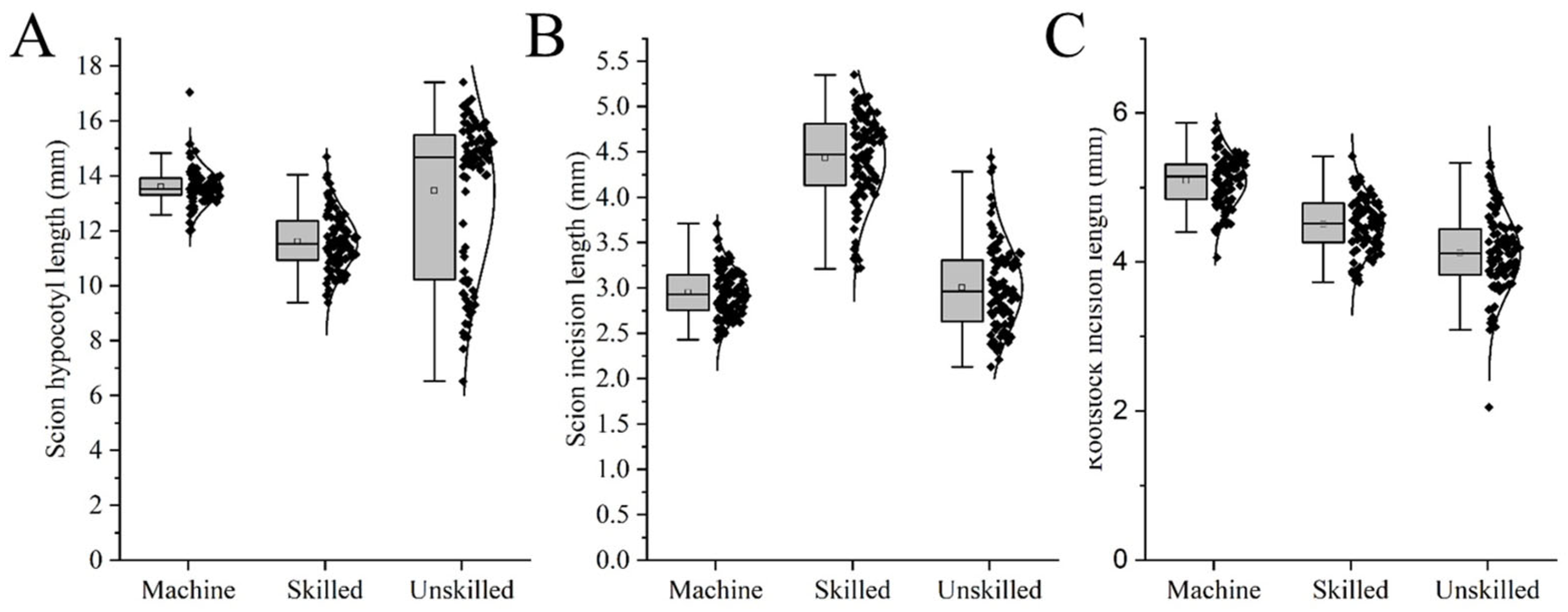

3.2. Measurement of the Scion Hypocotyl Height, Scion Incision Length, and Rootstock Incision Length at Grafting

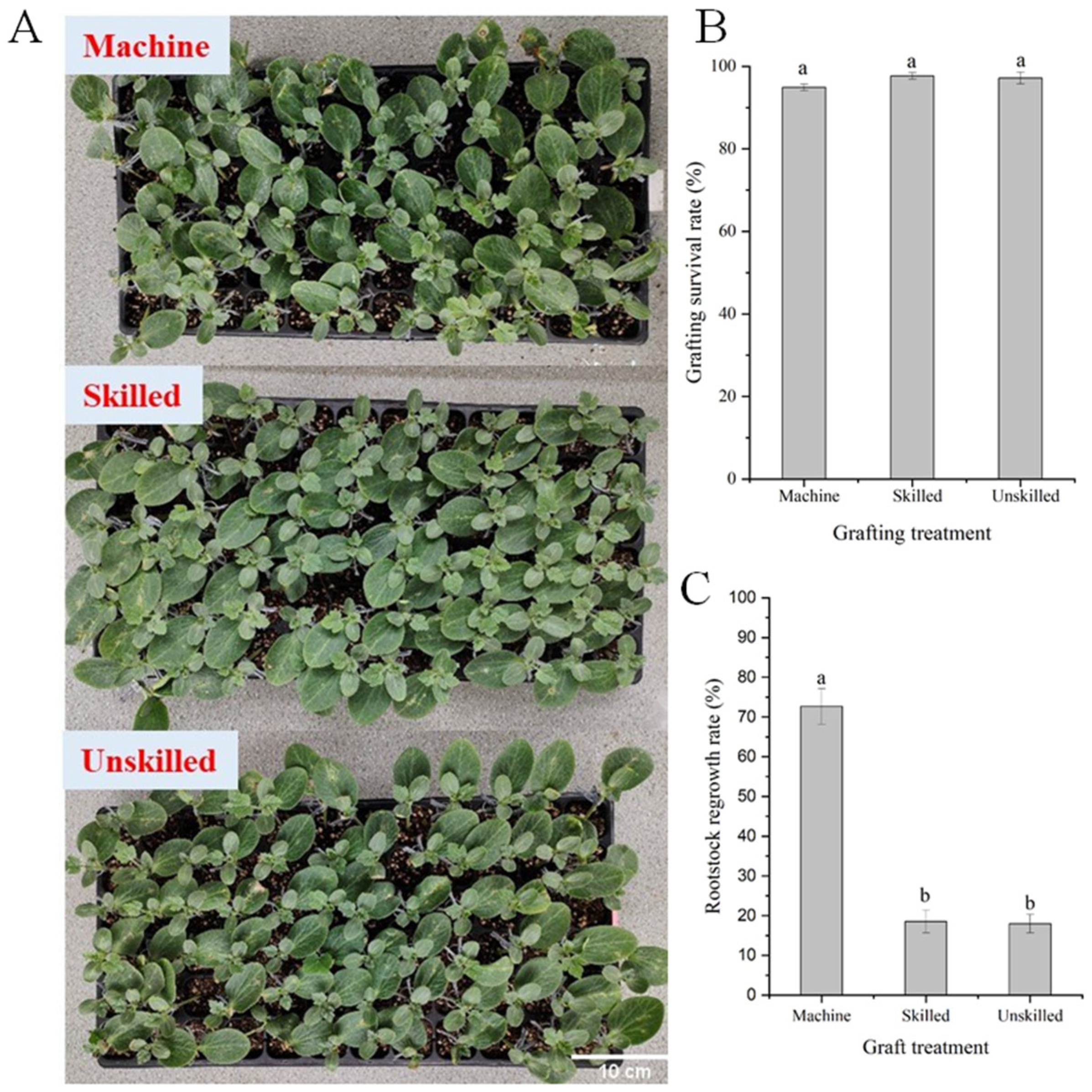

3.3. The Grafted Survival and Rootstock Regrowth Rate

4. Discussion

4.1. Comparison of the Grafting Speed

4.2. Comparison of the Grafted Quality

4.3. Comparison of the Grafting Success Rate and the Grafting Survival Rate

4.4. Performance Comparison of Similar Grafting Machines

4.5. Estimation of Operation Cost

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guan, W.; Zhao, X.; Hassell, R.; Thies, J. Defense mechanisms involved in disease resistance of grafted vegetables. Horticulture 2012, 47, 164–170. [Google Scholar] [CrossRef]

- Maurya, D.; Pandey, A.K.; Kumar, V.; Dubey, S.; Prakash, V. Grafting techniques in vegetable crops: A review. Int. J. Chem. Stud. 2019, 7, 1664–1672. [Google Scholar]

- Ulas, F.; Aydın, A.; Ulas, A.; Yetisir, H. Grafting for sustainable growth performance of melon (Cucumis melo) under salt stressed hydroponic condition. Eur. J. Sustain. Dev. 2019, 8, 201–210. [Google Scholar] [CrossRef]

- Schwarz, D.; Rouphael, Y.; Colla, G.; Venema, J.H. Grafting as a tool to improve tolerance of vegetables to abiotic stresses. Sci. Hortic. 2010, 127, 162–171. [Google Scholar] [CrossRef]

- Nawaz, M.A.; Imtiaz, M.; Kong, Q.; Fei, C.; Ahmed, W.; Huang, Y.; Bie, Z. Grafting: A technique to modify ion accumulation in horticultural crops. Front. Plant Sci. 2016, 7, 1457. [Google Scholar] [CrossRef]

- Ertle, J.M.; Kubota, C. Watermelon Seedling Quality, Growth, and Development as Affected by Grafting and Chilling Exposure During Simulated Transportation. HortScience 2022, 8, 57. [Google Scholar] [CrossRef]

- Ulas, A. Crossbreeding Rootstocks Improve Nitrogen Efficiency of Grafted Watermelon by Inducing Leaf Physiological and Root Morphological Responses. Horticulturae 2022, 8, 879. [Google Scholar] [CrossRef]

- Sewoong, A.; Jong, H.B.; Ho, C.K.; Yurina, K. Production of Grafted Vegetable Seedlings in the Republic of Korea: Achievements, Challenges and Perspectives. Hortic. Sci. Technol. 2021, 39, 547–559. [Google Scholar]

- Zhang, Y.; Yang, X.; Zhang, L.; Wei, J.; Liu, S.; Xu, L.; Wang, L. The cost analysis of vegetable seedling production in Shandong province. China Veg. 2014, 9, 49–51. [Google Scholar]

- Singh, H.; Kumar, P.; Chaudhari, S.; Edelstein, M. Tomato Grafting: A Global Perspective. HortScience 2017, 52, 1328–1336. [Google Scholar] [CrossRef]

- Djidonou, D.; Gao, Z.; Zhao, X. Economic analysis of grafted tomato production in sandy soils in northern Florida. Horttechnology 2013, 23, 613–621. [Google Scholar] [CrossRef]

- Rysin, O.; Rivard, C.; Louws, F.J. Is vegetable grafting economically viable in the United States: Evidence from four different tomato production systems. Acta Hortic. 2015, 1086, 79–86. [Google Scholar] [CrossRef]

- Pardo-Alonso, J.-L.; Carreño-Ortega, Á.; Martínez-Gaitán, C.-C.; Golasi, I.; Gómez Galán, M. Conventional Industrial Robotics Applied to the Process of Tomato Grafting Using the Splicing Technique. Agronomy 2019, 9, 880. [Google Scholar] [CrossRef]

- Guan, W.; Zhao, X. Effects of Grafting Methods and Root Excision on Growth Characteristics of Grafted Muskmelon Plants. HortTechnology 2015, 25, 706–713. [Google Scholar] [CrossRef]

- Devi, P.; Lukas, S.; Miles, C. Advances in Watermelon Grafting to Increase Efficiency and Automation. Horticulturae 2020, 6, 88. [Google Scholar] [CrossRef]

- Guan, W.; Zhao, X. Techniques for Melon Grafting. Acta Hortic. 2016, 1140, 335–336. [Google Scholar] [CrossRef]

- Liu, C.; Lin, W.; Feng, C.; Wu, X.; Fu, X.; Xiong, M.; Bie, Z.; Huang, Y. A New Grafting Method for Watermelon to Inhibit Rootstock Regrowth and Enhance Scion Growth. Agriculture 2021, 11, 812. [Google Scholar] [CrossRef]

- Daley, S.L.; Hassell, R.L. Fatty alcohol application to control meristematic regrowth in bottle gourd and interspecific hybrid squash rootstocks used for grafting watermelon. HortScience 2014, 49, 60–264. [Google Scholar] [CrossRef]

- Kubota, C.; McClure, M.A.; Kokalis-Burelle, N.; Bausher, M.G.; Rosskopf, E.N. Vegetable grafting: History, use and current technology status in North America. HortScience 2008, 43, 1664–1669. [Google Scholar] [CrossRef]

- Bie, Z.; Nawaz, M.A.; Huang, Y.; Lee, J.M.; Colla, G. Introduction of vegetable grafting. In Vegetable Grafting: Principles and Practices; CABI Publishing: Wallingford, UK, 2017; pp. 1–21. [Google Scholar]

- Zhang, K.; Chu, J.; Zhang, T. Development Status and Analysis of Automatic Grafting Technology for Vegetables. Agric. Mach. J. 2017, 48, 1–13. [Google Scholar]

- Ohkoshi, T.; Kobayashi, K. Development of automatic seedling feeding device for cucurbits grafting robot (Part 1)—Evaluation of stock feeder. J. Jpn. Soc. Agric. Mach. Food Eng. 2013, 75, 100–107. [Google Scholar]

- Kim, H.M.; Hwang, S.J. Comparison of pepper grafting efficiency by grafting robot. Prot. Hortic. Plant Fact. 2015, 24, 57–62. [Google Scholar] [CrossRef]

- Kang, D.H.; Lee, S.Y.; Kim, J.K.; Park, M.J.; Son, J.K.; Yun, S.W. Development of an automatic grafting robot for fruit vegetables using image recognition. Prot. Hortic. Plant Fact. 2019, 28, 322–327. [Google Scholar] [CrossRef]

- Atlantic Group. Available online: http://tech.atlanticgroup.it (accessed on 5 September 2022).

- Lewis, M.; Kubota, C.; Tronstad, R.; Son, Y.J. Scenario-based cost analysis for vegetable grafting nurseries of different technologies and sizes. HortScience 2014, 49, 917–930. [Google Scholar] [CrossRef]

- Yang, L.; Liu, C.; Zhang, T. Design and experiment of vegetable grafting machine with double manipulators. Trans. Chin. Soc. Agric. Mach. 2009, 40, 175–181. [Google Scholar]

- Jiang, K. Study on Mechanism and Experimental Device of Splice Mechanical Grafting of Cucurbit. Ph.D. Thesis, Northeast Agricultural University, Harbin, China, 2019. [Google Scholar]

- Fu, X.; Shi, J.; Huang, Y.; Zhu, E.; Bie, Z.; Lin, W. Design and experiment of full-tray grafting device for grafted melon seedling production. Agriculture 2022, 12, 861. [Google Scholar] [CrossRef]

- Jiang, K.; Zheng, W.G.; Zhang, Q.; Guo, R.; Feng, Q. Development and experiment of vegetable grafting robot. Trans. Chin. Soc. Agric. Eng. 2012, 28, 8–14. [Google Scholar]

- Chen, L.; Jiang, K.; Zhang, Q.; Guo, W.; Zheng, W. Design and experiment on scion cutting mechanism of grafting robot for cucurbit. Int. J. Agric. Biol. Eng. 2020, 13, 99–106. [Google Scholar] [CrossRef]

- Jiang, K.; Zhang, Q.; Chen, L.; Guo, W.; Zheng, W. Design and optimization on rootstock cutting mechanism of grafting robot for cucurbit. Int. J. Agric. Biol. Eng. 2020, 13, 117–124. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, T.; Chen, L.; Huang, W.; Jiang, K. Study on the Method of Matched Splice Grafting for Melon Seedlings Based on Visual Image. Agriculture 2022, 12, 929. [Google Scholar] [CrossRef]

- Jiang, K.; Guo, W.; Chen, L.; Huang, W.; Ge, Y.; Wei, X. Design and Experiment of Automatic Clip-Feeding Mechanism for Vegetable-Grafting Robot. Agriculture 2022, 12, 346. [Google Scholar] [CrossRef]

- Yan, G.; Feng, M.; Lin, W.; Huang, Y.; Tong, R.; Cheng, Y. Review and Prospect for Vegetable Grafting Robot and Relevant Key Technologies. Agriculture 2022, 12, 1578. [Google Scholar] [CrossRef]

- Davis, A.R.; Perkins-Veazie, P.; Sakata, Y.; López-Galarza, S.; Maroto, J.V.; Lee, S.-G.; Huh, Y.-C.; Sun, Z.; Miguel, Z.; Stephen, R.; et al. Cucurbit Grafting. Crit. Rev. Plant Sci. 2008, 27, 50–74. [Google Scholar] [CrossRef]

- Traka-Mavrona, E.; Koutsika-Sotiriou, M.; Pritsa, T. Response of squash (Cucurbita spp.) as rootstock for melon (Cucumis melo L.). Sci. Hortic. 2000, 83, 353–362. [Google Scholar] [CrossRef]

- Hassell, R.L.; Memmott, F.; Liere, D.G. Grafting methods for watermelon production. HortScience 2008, 43, 1677–1679. [Google Scholar] [CrossRef]

- Liang, H.; Jiang, K.; Shi, X.; Zhu, J.; Liu, J.; Wang, D.; Ge, M.; Zhou, M.; Shan, F. An Experimental Study on the Effect of Cutting Angle on the Growth of Grafted Watermelon Seedlings Using the One-Cotyledon Grafting Method. Agronomy 2023, 13, 250. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, H.; Zhu, J.; Ge, M.; Wang, D.; Liu, K.; Zhou, M.; Sun, Y.; Zhang, Q.; Jiang, K.; Shi, X. A Comparative Analysis of the Grafting Efficiency of Watermelon with a Grafting Machine. Horticulturae 2023, 9, 600. https://doi.org/10.3390/horticulturae9050600

Liang H, Zhu J, Ge M, Wang D, Liu K, Zhou M, Sun Y, Zhang Q, Jiang K, Shi X. A Comparative Analysis of the Grafting Efficiency of Watermelon with a Grafting Machine. Horticulturae. 2023; 9(5):600. https://doi.org/10.3390/horticulturae9050600

Chicago/Turabian StyleLiang, Huan, Juhong Zhu, Mihong Ge, Dehuan Wang, Ke Liu, Mobing Zhou, Yuhong Sun, Qian Zhang, Kai Jiang, and Xianfeng Shi. 2023. "A Comparative Analysis of the Grafting Efficiency of Watermelon with a Grafting Machine" Horticulturae 9, no. 5: 600. https://doi.org/10.3390/horticulturae9050600

APA StyleLiang, H., Zhu, J., Ge, M., Wang, D., Liu, K., Zhou, M., Sun, Y., Zhang, Q., Jiang, K., & Shi, X. (2023). A Comparative Analysis of the Grafting Efficiency of Watermelon with a Grafting Machine. Horticulturae, 9(5), 600. https://doi.org/10.3390/horticulturae9050600