1. Introduction

The American cranberry (

Vaccinium macrocarpon Ait.) is a native North American fruit crop with growing popularity due to its nutraceutical potential [

1,

2,

3,

4]. Cranberry phytochemicals have been associated with a wide variety of health benefits including improvement of digestive and urinary tract health, cancer prevention as well as reduction of cardiometabolic risk factors [

5,

6,

7,

8]. The dissemination of these attributes of this super fruit has led to a steady increase in cranberry production in the US over the past two decades, and as a result, current production is almost double what it was in 1990 [

9]. As the cranberry supply has often exceeded demand, cranberry breeders have begun to shift their focus from improving yield to improving fruit quality, which has become increasingly important for the cranberry industry in recent decades [

10]. In particular, texture is one of the most critical attributes of cranberry fruit, especially due to growing popularity and production of sweetened dried cranberries (SDC), which is one of the most profitable products in the industry [

11,

12]. Although texture is currently one of the priority traits in cranberry, the progress of research and breeding efforts in this regard have been limited due to the lack of a consensus methodology for evaluating this trait.

As has been reported in other species [

13,

14,

15,

16], setting up texture measurement procedures is challenging due to the great variety of factors that can affect the performance of the tests. These factors include those related to fruit characteristics such as shape, size, uniformity, as well as handling and other preparation before measurements. For instance, the firmness of an apple can vary by 0.5% for every degree in temperature change at the time of the measurement, while the firmness of a raspberry can change by more than 2.5% per degree [

17]. On the other hand, there are several instruments and accessories that operate on different principles, but that need to be optimized and calibrated to provide reliable measurements. Maury et al., demonstrated that combinations of speed and strain can influence the accuracy of grape texture measurement when monitoring their ripening process using a double compression test [

14]. In other species such as strawberry, it has even been reported that the methods and firmness traits can be affected differently by the size of the fruit, which can lead to biased measurements [

16]. Thus, the selection of the appropriate measurement methods, traits, parameters, and conditions is crucial to obtain accurate and reproducible results during texture analysis.

Some studies have explored the firmness attributes of raw and processed cranberry fruits, which have been based primarily on compression, as well as puncturing and cutting to a lesser extent [

12,

18,

19,

20,

21,

22,

23,

24]. However, these studies have not used optimized or consensus methodologies, and have employed different conditions and criteria to evaluate the firmness. For example, Foney [

18] performed the measurements using a FirmTech1 instrument (Bio-Works, Stillwater, OK, USA), on the other hand, while Jamaly et al. [

19], Diaz-Garcia et al. [

20], Zielinska et al. [

21], Liu et al. [

22] y shamaei et al. [

23] used different versions of texture analyzers, while Gorzelany et al. [

24] used a Zwick/Roell 2010 testing machine (ZwickRoell GmbH & Co., KG, Ulm, Germany). Additionally, each study made measurements using different settings for parameters such as force, strain, and speed of the probe. Although these studies have provided valuable information on the texture of this crop, the feasibility of these evaluations as a phenotyping method for breeding purposes as in other species [

16,

25,

26,

27,

28] has not been explored. While modern texture analyzers can provide accurate measurements on cranberry, their application and potential remain limited as long as measurements are not taken under consistent, optimal conditions.

In this study, we analyze the key methods, traits, parameters, and conditions for measuring texture in cranberry in order to contribute to the development of a consensus methodology for this crop. We evaluated previously used methods (compression, puncture and shearing) and those used for the first time in cranberry (Kramer shear cell) by testing three different cranberry cultivars with varying levels of fruit firmness (soft, medium, and hard). Our analysis of the different factors that affect the performance of the texture measurement provided valuable insights about the appropriate conditions to obtain accurate and reproducible results. Additionally, our results indicated that the compression (non-destructive) and puncture (destructive) methods are the most promising candidates for use as a standard method and should be further evaluated in future studies based on the information reported in this study. These findings represent an important reference for optimizing current firmness measurement protocols and for developing a standard methodology for cranberry, especially for phenotyping purposes in the breeding programs.

4. Discussion

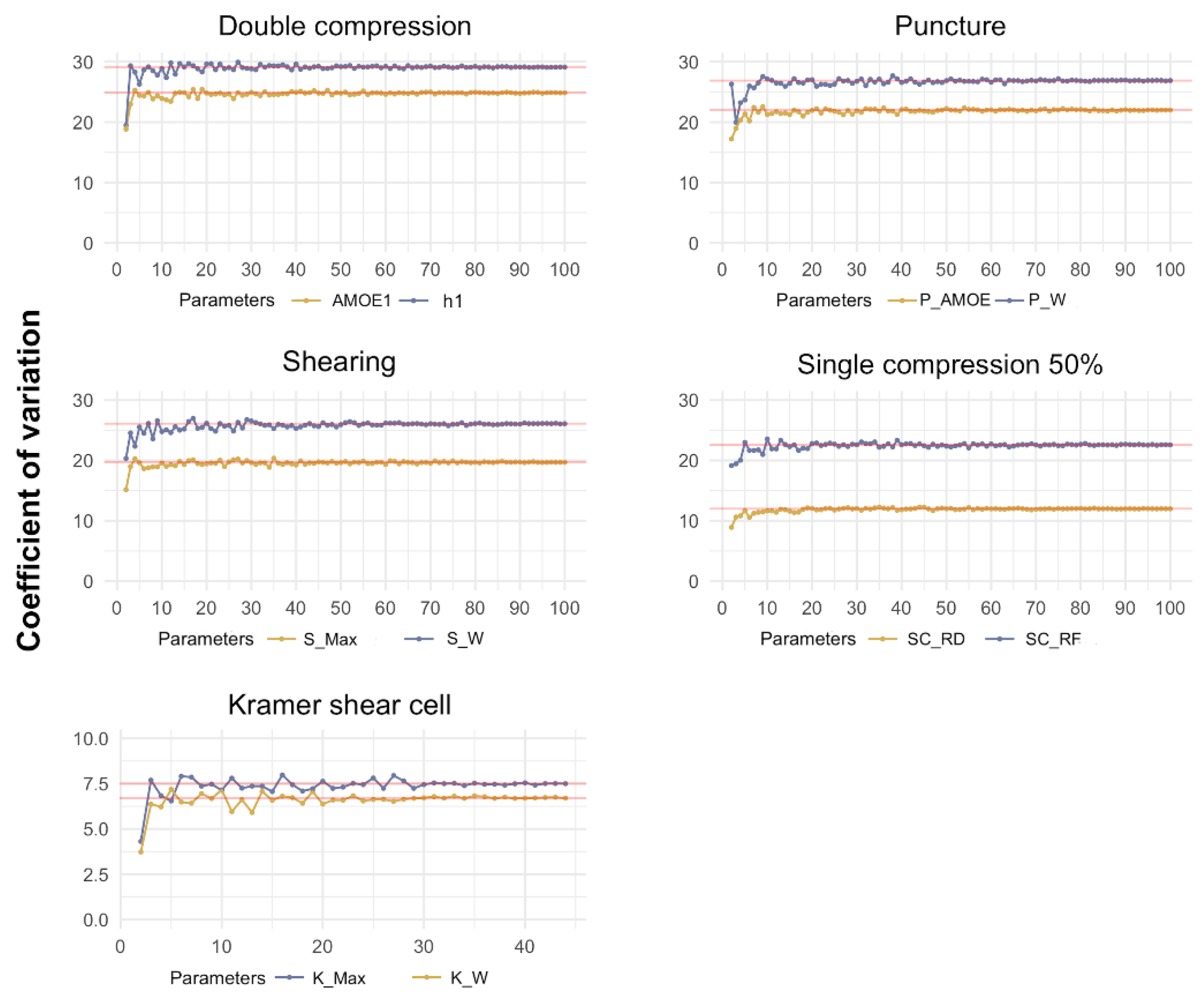

Although fruit firmness is a priority trait for the cranberry industry and breeding programs, no standard methodology has been established to assess texture in cranberry. In this study, we analyze the most relevant factors for a correct evaluation of cranberry fruit texture in methodologies previously used in this crop (compression, puncture, shearing), and those explored for the first time (Kramer shear cell). Our results suggest that a sample size of n ≥ 30 is preferred to achieve good precision of texture measurements for all methodologies considered (

Figure 1). The sample size suggested in this study is higher than that previously used for raw cranberry fruits by Forney [

18], Diaz-Garcia et al. [

20], Zielinska et al. [

21] and Liu et al. [

23] (from 15 to 25 fruits) but less than sample size used by Jamaly et al. (n = 50) [

19]. In addition, the suggested sample size is different from that used in the industry which can be as low as n = 5 or as high as n = 50 per batch. It should be noted that the coefficients of variation reported were calculated using a sample of soft, medium, and firm cultivars, which represent a wide range of firmness and accurately reflect the heterogeneous conditions of the samples processed in the industry. While coefficients of variation varied considerably between methodologies and texture traits, most were around 20%, which is common in native foods and ensures reliable and reproducible results for most traits [

13] (

Table S1). In particular, the traits of the Kramer shear cell methodology showed the lowest coefficient of variation (6.71 and 7.50) most likely because dozens of fruits were subjected to a single measurement. However, the number of fruits needed (30 loads) to achieve good repeatability makes it an unfeasible method. Therefore, the Kramer shear cell test was discarded for the following analyses.

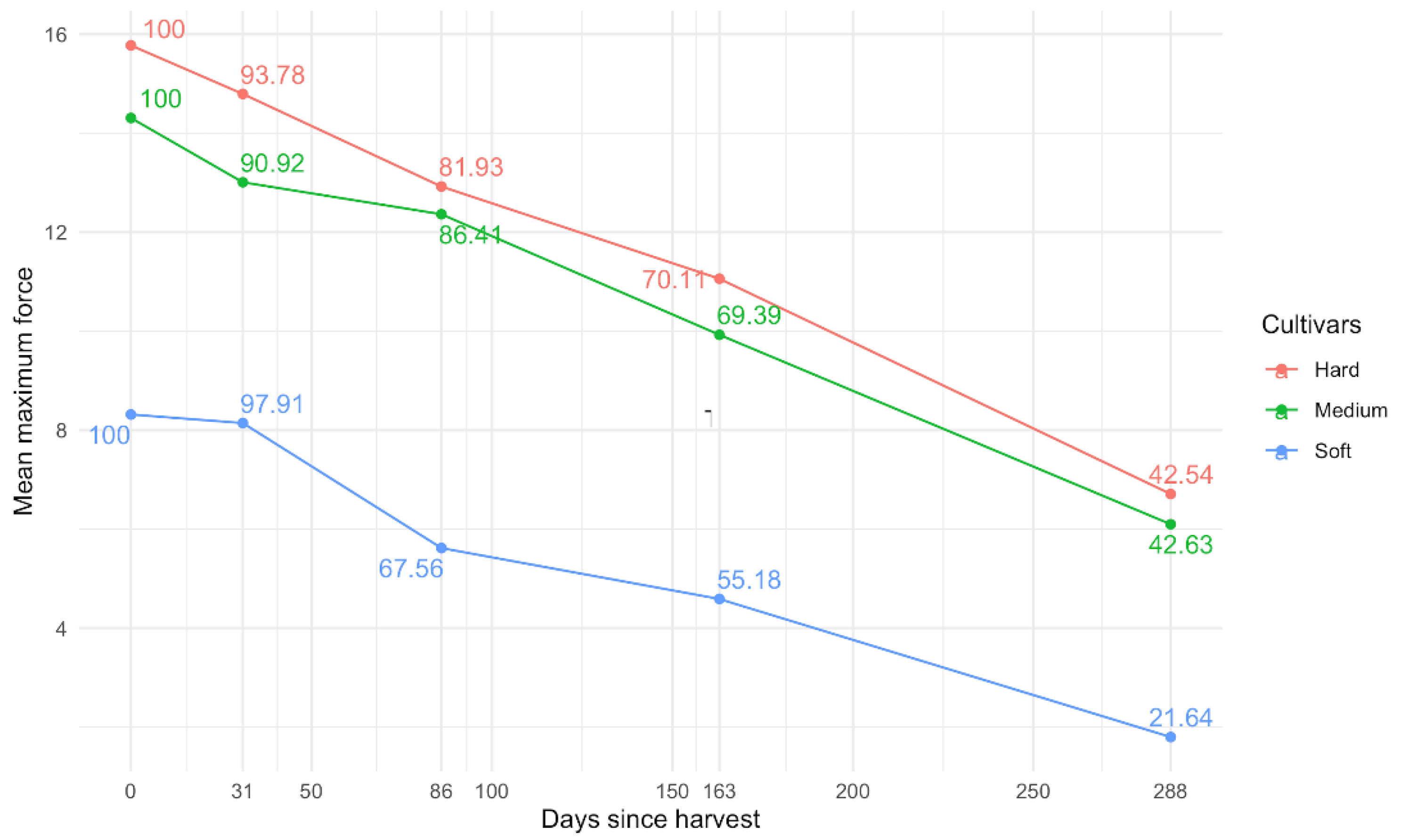

The change in firmness during storage has important implications for industry as well as for research, especially in the breeding process where scalability is key. As shown in

Figure 2, the first month offers a good time frame to measure fruit firmness, as firmness decline remains relatively low. These results are consistent with previous reports [

18,

21], although other studies based on parameters related to elasticity and deformation showed more dramatic changes [

24]. In order to process a large number of samples, we suggest recording the measurement dates and process the samples based on an experimental design in order to take into account the storage time and loss of firmness through modeling. Remarkably, our results show that the trend of firmness during storage depends considerably on the cultivar as has been shown for other attributes of fruit quality and marketability, which has implications for management during storage and decision making for fruit evaluation [

36].

Berry size can differently affect the calculation of texture traits such that some traits are more prone to biased values. This relationship between size and fruit texture was evaluated with three cultivars that vary in both firmness and size (

Table 5). The texture traits of the compression-based methodology showed stronger positive correlations, especially those related to force. The correlations of the maximum force traits (h1 and h2), which are widely used in cranberry, indicated that the larger the fruit, the firmer it is, as reported by Diaz-Garcia et al. [

20] and contrasting with the findings for similar fruits such as blueberry [

37]. On the other hand, the traits related to elasticity, cohesiveness and stress generally showed lower correlations. In particular, the persistently low correlations between the traits related to cohesiveness and fruit size may indicate that resistance to internal structure damage is largely independent of berry size. The correlations for the puncture and shearing methodologies were varied, and remarkably, the traits involving fruit destruction were negatively correlated with fruit size. To exhaustively evaluate the correlations between texture and fruit size, we subsampled fruits with homogeneous size (no significant difference,

p < 0.05) from each cultivar’s original heterogeneous sample. Although the correlations between size and fruit texture decreased, the previously observed trends were maintained, indicating that these traits depend substantially on the size of the berry.

To evaluate the effect of berry size on the ability of textural traits to discriminate between cultivars, a comparison of the significant differences detected between the homogeneous and heterogeneous samples was made (

Table 5). In general, the number of significant differences detected decreased when using the homogeneous fruit subsample between cultivars, although some traits with high correlations such as maximum force and those related to slope maintained their performance. Interestingly, some traits that are calculated considering the size of the fruit (e.g., apparent modulus of elasticity, maximum contact pressure, and traits associated with stress), and have a low correlation, showed that their ability to detect differences between cultivars depended on the berry size. Similar results were obtained for the texture traits derived from the stress/strain graph in a study carried out on grapes [

14], in which it was shown that there was no improvement in the results expressed in stress compared to those expressed in force. The puncture showed good performance to discriminate between cultivars, suggesting that the integration of skin in the evaluation of texture is crucial to obtain more representative measurements, as has been shown in other species [

28,

38]. Therefore, the puncture method is a potential candidate for a standard texture methodology for cranberry. Conversely, the shearing method is not a good candidate since it is not a good cultivar discriminator. These findings show that, even though some traits such as those related to slopes and the maximum force for double compression, show strong correlations, they are able to obtain reliable results. The high correlation shown by texture traits with good performance in detecting differences between cultivars may indicate that there is a genuine correlation between berry size and these texture attributes. It is important to mention that the value of the correlations can be inflated because the cultivars used for this analysis showed a firmness gradient associated with a size gradient in the same direction. Further analysis with cultivars representing greater variation in firmness and size will be required.

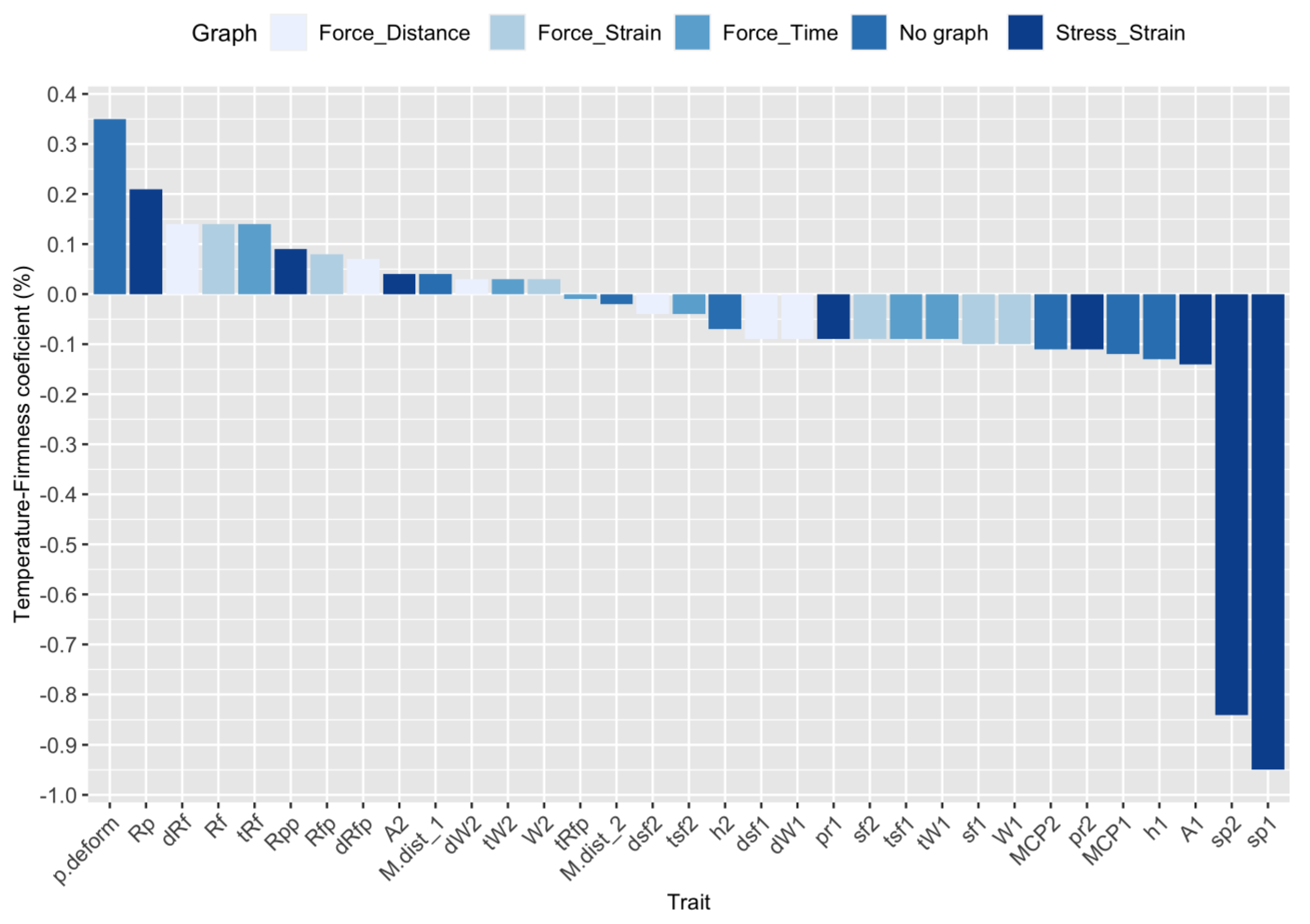

Although the compression method has been widely used in cranberry, the appropriate conditions and parameters for its implementation have not been reported. Some of the most influential factors in the execution of this method were evaluated, such as the fruit temperature and orientation, and the optimal speed/strain combinations. Similar to other raw fruits [

17], cranberry texture parameters decreased as fruit temperature increased and, interestingly, the temperature-firmness coefficient varied widely among parameters ranging from 0.01 to 0.95% for tRfp and sp1, respectively (

Figure 3,

Table S2). These results demonstrate that, depending on the texture trait of interest, temperature control at the time of measurement can be a crucial point to obtain reproducible data. As shown in

Figure 3, measurements related to deformation, cohesiveness, and gumminess increased at higher temperatures, in contrast to the rest of the traits. It is worth mentioning that, due to the nature of the physical characteristics evaluated, the traits related to deformation should be considered as a measure of softness rather than firmness. Although the number of significant differences detected between cultivars for each temperature were very similar, the slight increase in low temperature may be due to a better control of the change in firmness when keeping the fruits in refrigeration (

Table S2).

Because cranberry fruits are traditionally measured on their equatorial side, the firmness values taken on the polar side are unknown and could potentially provide additional information due to the unique internal structure of the fruits (

Figure S1). The results showed that higher values are obtained for all the texture traits when measuring the fruits on the polar side as has been reported in other fruit species with marked differences such as apple [

39] and grapefruit [

40] (

Table 6). In addition, the measurements taken on the polar side showed higher coefficients of variation, which could be due in large part to the instability of the fruits at the time of measurement, which makes it an unfeasible procedure. Welch’s two sample t-test showed significant differences for all the traits (except those related to cohesiveness) between both orientations, which suggests that the resistance of the internal structure is similar when the fruit is compressed in both orientations. The change in the number of significant differences detected between cultivars varied for the traits. In particular, the maximum force trait (h1) had a decreased ability to detect differences between cultivars when the fruits were measured on their polar side.

Because current cranberry breeding efforts are focused on fruit firmness, it is desirable that phenotyping methodologies can distinguish firmness gradients between cultivars. The Box-Wilson central composite design revealed that speed/strain couples have an important effect on the ability to discriminate between cultivars according to their texture for each trait (

Table 7,

Table S3). The response of the traits to the speed/strain couples was varied; most force traits perform best with a strain percentage of 5%, while 20% or more strain is better for stress traits. This difference in optimal strain values implies that favoring the conditions for one trait limits the performance of the other, and that this information should therefore be considered, depending on the texture traits that are desired. A similar test carried out on grapes [

14] showed a different relationship between the strain requirements for the force and stress traits, with the force traits being the ones with the highest requirement. Despite the similarities of the cranberry and grape fruits the optimal values of speed and strain for the textural traits were very different, probably due to differences in internal structure and composition of the fruit (e.g., content of water).

A first exploration of the puncture method in cranberry showed that the diameter of the probe did not have an important effect on the performance of this method (

Figure S2). It is worth mentioning that the puncture method showed better results to detect differences between cultivars in the fruit texture-size correlation analysis and that this discrepancy may be due to the use of different cultivars in these tests. It will be necessary to carry out additional tests that include a greater variety of probe diameters as well as consider important factors of the test such as the speed of execution.