Optimization of Applied Irrigation Water for High Marketable Yield, Fruit Quality and Economic Benefits of Processing Tomato Using a Low-Cost Wireless Sensor

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site

2.2. Cropping Details

2.3. Experimental Design and Treatments

2.4. Growing Degree Days, Production and Fruit Quality

2.5. Economic Analysis

2.6. Statistical Analysis

3. Results

3.1. Weather Data and Growing Degree Days

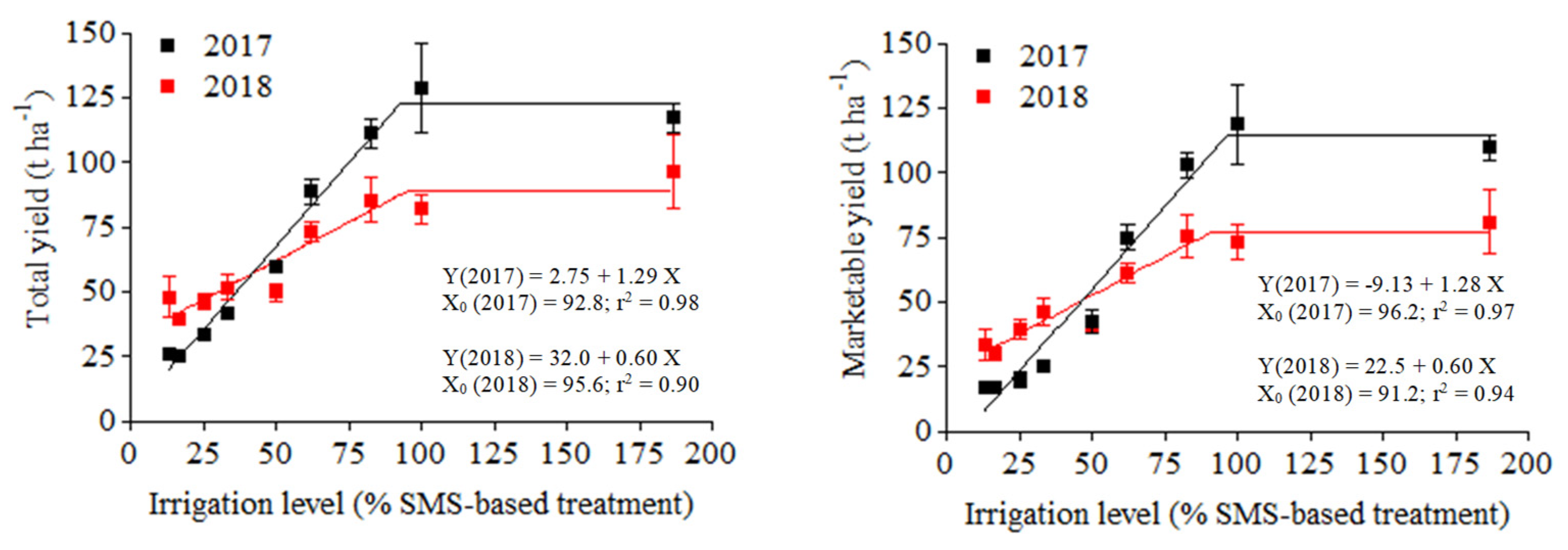

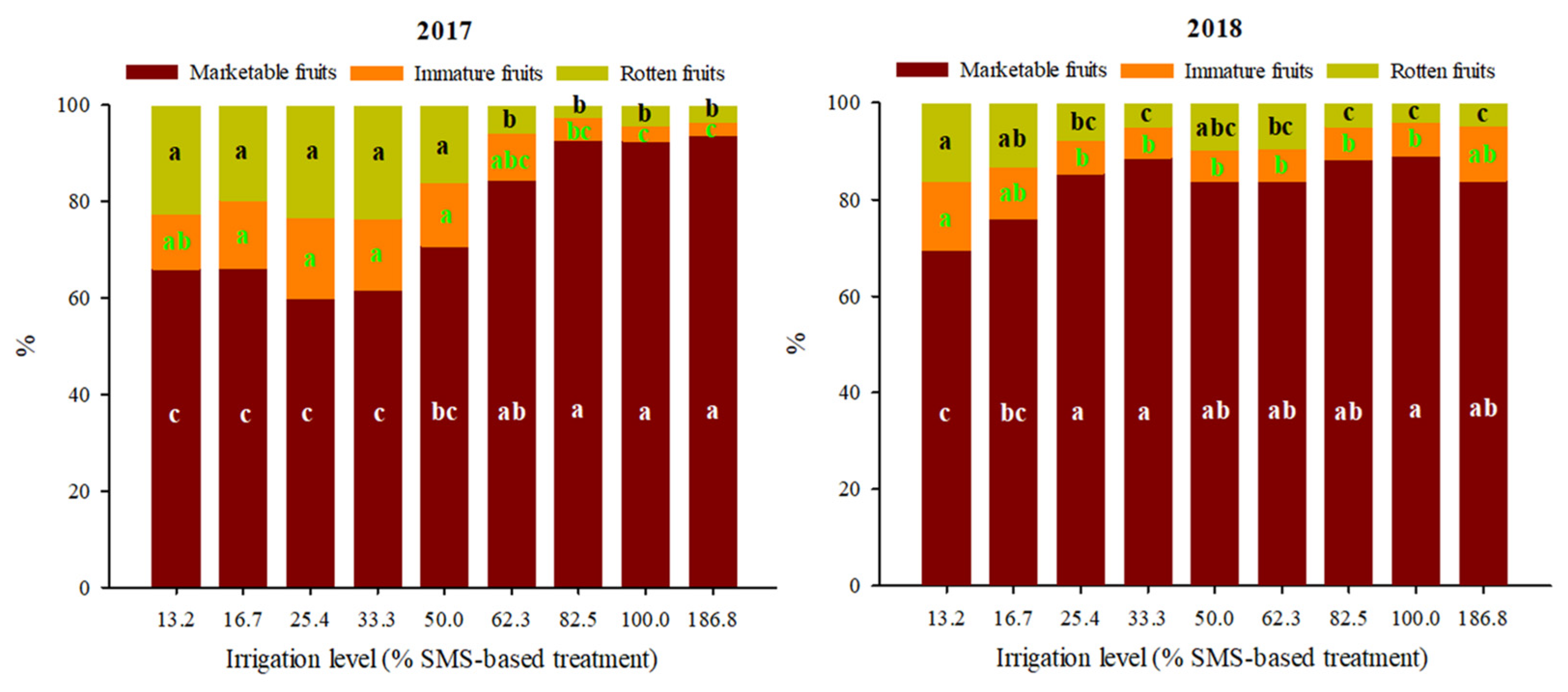

3.2. Yield and Fruit Quality

3.3. Economic Outcomes

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). The Global Framework on Water Scarcity in Agriculture; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2018. [Google Scholar]

- Bos, M.G. Summary of ICID definitions on irrigation efficiency. ICID Bull 1985, 34, 28–31. [Google Scholar]

- Postel, S.L. Water in Crisis: A Guide to the World’s Fresh Water Resources. In Water and Agriculture; Gleick, P.H., Ed.; Oxford University Press: Oxford, UK, 1993; pp. 56–66. [Google Scholar]

- Wallace, J.S. Increasing Agricultural Water Use Efficiency to Meet Future Food Production. Agric. Ecosyst. Environ. 2000, 82, 105–119. [Google Scholar] [CrossRef]

- McCready, M.S.; Dukes, M.D.; Miller, G.L. Water Conservation Potential of Smart Irrigation Controllers on St. Augustinegrass. Agric. Water Manag. 2009, 96, 1623–1632. [Google Scholar] [CrossRef]

- Jones, H.G. Irrigation Scheduling: Advantages and Pitfalls of Plant-Based Methods. J. Exp. Bot. 2004, 55, 2427–2436. [Google Scholar] [CrossRef]

- Cahn, M.; Johnson, L. New Approaches to Irrigation Scheduling of Vegetables. Horticulturae 2017, 3, 28. [Google Scholar] [CrossRef]

- Ferré, P.A.; Topp, G.C. Time-domain Reflectometry Techniques for Soil Water Content and Electrical Conductivity Measurements. Sens. Update 2000, 7, 277–300. [Google Scholar] [CrossRef]

- Starr, J.L.; Paltineanu, I.C. Capacitance devices. In Methods of Soil Analysis. Part 4. Physical Methods; Dane, J.H., Topp, G.C., Eds.; Soil Science Society of America, Inc.: Madison, WI, USA, 2002; pp. 463–474. [Google Scholar]

- Lim, S.J.; Shin, M.N.; Son, J.K.; Song, J.D.; Cho, K.H.; Lee, S.H.; Ryu, J.H.; Cho, J.Y. Evaluation of Soil Pore-Water Salinity Using a Decagon GS3 Sensor in Saline-Alkali Reclaimed Tidal Lands. Comput. Electron. Agric. 2017, 132, 49–55. [Google Scholar] [CrossRef]

- Thompson, R.B.; Gallardo, M.; Agüera, T.; Valdez, L.C.; Fernández, M.D. Evaluation of the Watermark Sensor for Use with Drip Irrigated Vegetable Crops. Irrig. Sci. 2006, 24, 185–202. [Google Scholar] [CrossRef]

- Albergel, C.; de Rosnay, P.; Gruhier, C.; Muñoz-Sabater, J.; Hasenauer, S.; Isaksen, L.; Kerr, Y.; Wagner, W. Evaluation of Remotely Sensed and Modelled Soil Moisture Products Using Global Ground-Based in Situ Observations. Remote Sens. Environ. 2012, 118, 215–226. [Google Scholar] [CrossRef]

- Jaria, F.; Madramootoo, C.A. Thresholds for Irrigation Management of Processing Tomatoes Using Soil Moisture Sensors in Southwestern Ontario. Trans. ASABE 2013, 56, 155–166. [Google Scholar] [CrossRef]

- Patanè, C.; Tringali, S.; Sortino, O. Effects of Deficit Irrigation on Biomass, Yield, Water Productivity and Fruit Quality of Processing Tomato under Semi-Arid Mediterranean Climate Conditions. Sci. Hortic. 2011, 129, 590–596. [Google Scholar] [CrossRef]

- Giuliani, M.M.; Nardella, E.; Gatta, G.; De Caro, A.; Quitadamo, M. Processing Tomato Cultivated under Water Deficit Conditions: The Effect of Azoxystrobin. Acta Hortic. 2011, 914, 287–294. [Google Scholar] [CrossRef]

- Rinaldi, M.; Rana, G. Water use of processing tomato in the Capitanata region (Southern Italy). Riv. Ital. Di Agrometeorol. 2004, 1, 31–35. [Google Scholar]

- Rudich, J.; Kalmar, D.; Geizenberg, C.; Harel, S. Low Water Tensions in Defined Growth Stages of Processing Tomato Plants and Their Effects on Yield and Quality. J. Hortic. Sci. 1977, 52, 391–399. [Google Scholar] [CrossRef]

- Cahn, M.D.; Herrero, E.V.; Snyder, R.L.; Hanson, B.R. Water Management Strategies for Improving Fruit Quality of Drip-Irrigated Processing Tomatoes. Acta Hortic. 2001, 542, 111–116. [Google Scholar] [CrossRef]

- Lovelli, S.; Potenza, G.; Castronuovo, D.; Perniola, M.; Candido, V. Yield, Quality and Water Use Efficiency of Processing Tomatoes Produced under Different Irrigation Regimes in Mediterranean Environment. Ital. J. Agron. 2017, 12, 17–24. [Google Scholar] [CrossRef]

- Dumas, Y.; Dadomo, M.; Di Lucca, G.; Grolier, P. Effects of Environmental Factors and Agricultural Techniques on Antioxidantcontent of Tomatoes. J. Sci. Food Agric. 2003, 83, 369–382. [Google Scholar] [CrossRef]

- Fereres, E.; Soriano, M.A. Deficit Irrigation for Reducing Agricultural Water Use. J. Exp. Bot. 2006, 58, 147–159. [Google Scholar] [CrossRef]

- Kuşçu, H.; Turhan, A.; Demir, A.O. The Response of Processing Tomato to Deficit Irrigation at Various Phenological Stages in a Sub-Humid Environment. Agric. Water Manag. 2014, 133, 92–103. [Google Scholar] [CrossRef]

- Zegbe-Domínguez, J.A.; Behboudian, M.H.; Lang, A.; Clothier, B.E. Deficit Irrigation and Partial Rootzone Drying Maintain Fruit Dry Mass and Enhance Fruit Quality in ‘Petopride’ Processing Tomato (Lycopersicon esculentum, Mill.). Sci. Hortic. 2003, 98, 505–510. [Google Scholar] [CrossRef]

- Colla, G.; Casa, R.; Lo Cascio, B.; Saccardo, F.; Temperini, O.; Leoni, C. Responses of Processing Tomato to Water Regime and Fertilization in Central Italy. Acta Hortic. 1999, 487, 531–536. [Google Scholar] [CrossRef]

- Lowengart-Aycicegi, A.; Manor, H.; Krieger, R.; Gera, G. Effects of Irrigation Scheduling on Drip-Irrigated Processing Tomatoes. Acta Hortic. 1999, 487, 513–518. [Google Scholar] [CrossRef]

- Madramootoo, C.A.; Jaria, F.; Arumugagounder Thangaraju, N.K. Irrigation Scheduling and Requirements of Processing Tomato (Lycopersicon esculentum L.) in Eastern Canada. Irrig. Sci. 2021, 39, 483–491. [Google Scholar] [CrossRef]

- Vázquez, N.; Huete, J.; Pardo, A.; Suso, M.L.; Tobar, V. Use of Soil Moisture Sensors for Automatic High Frequency Drip Irrigation in Processing Tomato. Acta Hortic. 2011, 922, 229–235. [Google Scholar] [CrossRef]

- Serena, M.; Velasco-Cruz, C.; Friell, J.; Schiavon, M.; Sevostianova, E.; Beck, L.; Sallenave, R.; Leinauer, B. Irrigation Scheduling Technologies Reduce Water Use and Maintain Turfgrass Quality. Agron. J. 2020, 112, 3456–3469. [Google Scholar] [CrossRef]

- Dean, T.J.; Bell, J.P.; Baty, A.J.B. Soil Moisture Measurement by an Improved Capacitance Technique, Part I. Sens. Des. Perform. J. Hydrol. 1987, 93, 67–78. [Google Scholar] [CrossRef]

- Fraisse, C.W.; Paula-Moraes, S.V. Degree-Days: Growing, Heating, and Cooling. EDIS 2018, 2018, 1–2. [Google Scholar] [CrossRef]

- Weerakkody, W.A.P.; Peiris, B.C.N. Effect of rainfall during growth stages on vegetative growth and flowering of tomato. In Proceedings of the Fifth Annual Staff Research, Sessions, Galaha, Sri Lanka, 1997; pp. 39–41. [Google Scholar]

- Oladitan, T.O.; Akinseye, F.M. Influence of Weather Elements on Phenological Stages and Yield Components of Tomato Varieties in Rain Forest Ecological Zone, Nigeria. J. Nat. Sci. Res. 2014, 4, 19–23. [Google Scholar]

- Franco, J.A.; Pérez-Saura, P.J.; Ferná Ndez, J.A.; Parra, M.; García, A.L. Effect of Two Irrigation Rates on Yield, Incidence of Blossom-End Rot, Mineral Content and Free Amino Acid Levels in Tomato Cultivated under Drip Irrigation Using Saline Water. J. Hortic. Sci. Biotechnol. 1999, 74, 430–435. [Google Scholar] [CrossRef]

- Suzuki, K.; Sasaki, H.; Nagata, M. Causes and control of blotchy ripening disorder in tomato fruit. Bull. Natl. Inst. Veg. Tea Sci. 2013, 12, 81–88. [Google Scholar]

- Hashem, M.S.; El-Abedin, T.Z.; Al-Ghobari, H.M. Rational Water Use by Applying Regulated Deficit and Partial Root-Zone Drying Irrigation Techniques in Tomato under Arid Conditions. Chil. J. Agric. Res. 2019, 79, 75–88. [Google Scholar] [CrossRef]

- Kader, A.A. Effects of Postharvest Handling Procedures on Tomato Quality. Acta Hortic. 1986, 190, 209–222. [Google Scholar] [CrossRef]

- Nangare, D.D.; Singh, Y.; Kumar, P.S.; Minhas, P.S. Growth, Fruit Yield and Quality of Tomato (Lycopersicon esculentum Mill.) as Affected by Deficit Irrigation Regulated on Phenological Basis. Agric. Water Manag. 2016, 171, 73–79. [Google Scholar] [CrossRef]

- Warner, J.; Tan, C.S.; Zhang, T.Q. Water Management Strategies to Enhance Fruit Solids and Yield of Drip Irrigated Processing Tomato. Can. J. Plant Sci. 2007, 87, 345–353. [Google Scholar] [CrossRef]

- Yang, H.; Du, T.; Qiu, R.; Chen, J.; Wang, F.; Li, Y.; Wang, C.; Gao, L.; Kang, S. Improved Water Use Efficiency and Fruit Quality of Greenhouse Crops under Regulated Deficit Irrigation in Northwest China. Agric. Water Manag. 2017, 179, 193–204. [Google Scholar] [CrossRef]

- Chen, J.; Kang, S.; Du, T.; Guo, P.; Qiu, R.; Chen, R.; Gu, F. Modeling Relations of Tomato Yield and Fruit Quality with Water Deficit at Different Growth Stages under Greenhouse Condition. Agric. Water Manag. 2014, 146, 131–148. [Google Scholar] [CrossRef]

- Patanè, C.; Cosentino, S.L. Effects of Soil Water Deficit on Yield and Quality of Processing Tomato under a Mediterranean Climate. Agric. Water Manag. 2010, 97, 131–138. [Google Scholar] [CrossRef]

- Ali, M.B.; Abu-Goukh, A.A. Changes in pectic substances and cell wall degrading enzymes during tomato fruit ripening. Univ. Khartoum J. Agric. Sci. 2005, 13, 202–223. [Google Scholar]

- Ajayi, A.A.; Atolagbe, O.M. Characterisation of Partially Purified Cell Wall-Degrading Enzymes: Polygalacturonase and Cellulase from Tomato Fruits Degraded by Aspergillus Niger. Can. J. Pure Appl. Sci. 2015, 9, 3383–3391. [Google Scholar]

- Schaffer, A.A.; Miron, D.; Petreikov, M.; Fogelman, M.; Spiegelman, M.; Bnei-Moshe, Z.; Shen, S.; Granot, D.; Hadas, R.; Dai, N.; et al. Modification of Carbohydrate Content in Developing Tomato Fruit. HortScience 1999, 34, 1024–1027. [Google Scholar] [CrossRef]

- Agius, C.; von Tucher, S.; Poppenberger, B.; Rozhon, W. Quantification of Sugars and Organic Acids in Tomato Fruits. MethodsX 2018, 5, 537–550. [Google Scholar] [CrossRef]

- Mills, T.M.; Hossein Behboudian, M.; Clothier, B.E. The Diurnal and Seasonal Water Relations, and Composition, of ‘Braeburn’ Apple Fruit under Reduced Plant Water Status. Plant Sci. 1997, 126, 145–154. [Google Scholar] [CrossRef]

- Kramer, P.J. Water Relations of Plants; Academic Press: New York, NY, USA, 1983; p. 489. ISBN 0-12-425040-8. [Google Scholar]

- Khapte, P.S.; Kumar, P.; Burman, U.; Kumar, P. Deficit irrigation in tomato: Agronomical and physio-biochemical implications. Sci. Hortic. 2019, 248, 256–264. [Google Scholar] [CrossRef]

- Lahoz, I.; Pérez-de-Castro, A.; Valcárcel, M.; Macua, J.I.; Beltran, J.; Roselló, S.; Cebolla-Cornejo, J. Effect of water deficit on the agronomical performance and quality of processing tomato. Sci. Hortic. 2016, 200, 55–65. [Google Scholar] [CrossRef]

| Cultivation Inputs | Cost (€/ha) | |

|---|---|---|

| 2017 | 2018 | |

| Fertilizers | 641 | 593 |

| Pesticides | 818 | 553 |

| Seedlings | 756 | 795 |

| Irrigation dripline | 460 | 460 |

| Mechanization | 129 | 138 |

| Machine harvesting | 500 | 500 |

| Energy and other costs | 222 | 188 |

| Labour | 1274 | 1103 |

| Total | 4799 | 4329 |

| Irrigation Level (% SMS Treatment) | Cost (€/ha) | |

|---|---|---|

| 2017 | 2018 | |

| 13.2 | 81 | 68 |

| 16.7 | 102 | 86 |

| 25.4 | 156 | 132 |

| 33.3 | 205 | 173 |

| 50.0 | 307 | 259 |

| 62.3 | 382 | 323 |

| 82.5 | 506 | 427 |

| 100.0 | 614 | 518 |

| 186.8 | 1147 | 968 |

| T | TY | MY | UM | PM | PI | PR | MF | FW | FF | TS |

|---|---|---|---|---|---|---|---|---|---|---|

| Y | * | ns | ns | *** | ns | *** | *** | *** | *** | *** |

| I | *** | *** | ns | *** | ** | *** | *** | *** | * | *** |

| Y × I | *** | *** | *** | *** | *** | *** | *** | ns | ns | * |

| Irrigation Level (% of SMS Treatment) | Revenues from Product Sales (€/ha) | Variable Costs (€/ha) | Operating Margins (€/ha) | |||

|---|---|---|---|---|---|---|

| 2017 | 2018 | 2017 | 2018 | 2017 | 2018 | |

| 13.2 | 740 | 2909 | 4880 | 4397 | −4140 | −1488 |

| 16.7 | 1171 | 3110 | 4902 | 4415 | −3731 | −1305 |

| 25.4 | 2247 | 3613 | 4956 | 4461 | −2709 | −848 |

| 33.3 | 3215 | 4065 | 5004 | 4502 | −1789 | −437 |

| 50.0 | 5260 | 5019 | 5106 | 4588 | 154 | 431 |

| 62.3 | 6767 | 5723 | 5182 | 4652 | 1585 | 1071 |

| 82.5 | 9243 | 6879 | 5306 | 4756 | 3937 | 2123 |

| 100.0 | 11,395 | 7884 | 5413 | 4847 | 5981 | 3036 |

| 186.8 | 9323 | 7167 | 5947 | 5297 | 3376 | 1870 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Chami, A.; Cortignani, R.; Dell’Unto, D.; Mariotti, R.; Santelli, P.; Ruggeri, R.; Colla, G.; Cardarelli, M. Optimization of Applied Irrigation Water for High Marketable Yield, Fruit Quality and Economic Benefits of Processing Tomato Using a Low-Cost Wireless Sensor. Horticulturae 2023, 9, 390. https://doi.org/10.3390/horticulturae9030390

El Chami A, Cortignani R, Dell’Unto D, Mariotti R, Santelli P, Ruggeri R, Colla G, Cardarelli M. Optimization of Applied Irrigation Water for High Marketable Yield, Fruit Quality and Economic Benefits of Processing Tomato Using a Low-Cost Wireless Sensor. Horticulturae. 2023; 9(3):390. https://doi.org/10.3390/horticulturae9030390

Chicago/Turabian StyleEl Chami, Antonio, Raffaele Cortignani, Davide Dell’Unto, Roberto Mariotti, Piero Santelli, Roberto Ruggeri, Giuseppe Colla, and Mariateresa Cardarelli. 2023. "Optimization of Applied Irrigation Water for High Marketable Yield, Fruit Quality and Economic Benefits of Processing Tomato Using a Low-Cost Wireless Sensor" Horticulturae 9, no. 3: 390. https://doi.org/10.3390/horticulturae9030390

APA StyleEl Chami, A., Cortignani, R., Dell’Unto, D., Mariotti, R., Santelli, P., Ruggeri, R., Colla, G., & Cardarelli, M. (2023). Optimization of Applied Irrigation Water for High Marketable Yield, Fruit Quality and Economic Benefits of Processing Tomato Using a Low-Cost Wireless Sensor. Horticulturae, 9(3), 390. https://doi.org/10.3390/horticulturae9030390