Comparison of Different Temperature Control Systems in Tropical-Adapted Greenhouses for Green Romaine Lettuce Production

Abstract

1. Introduction

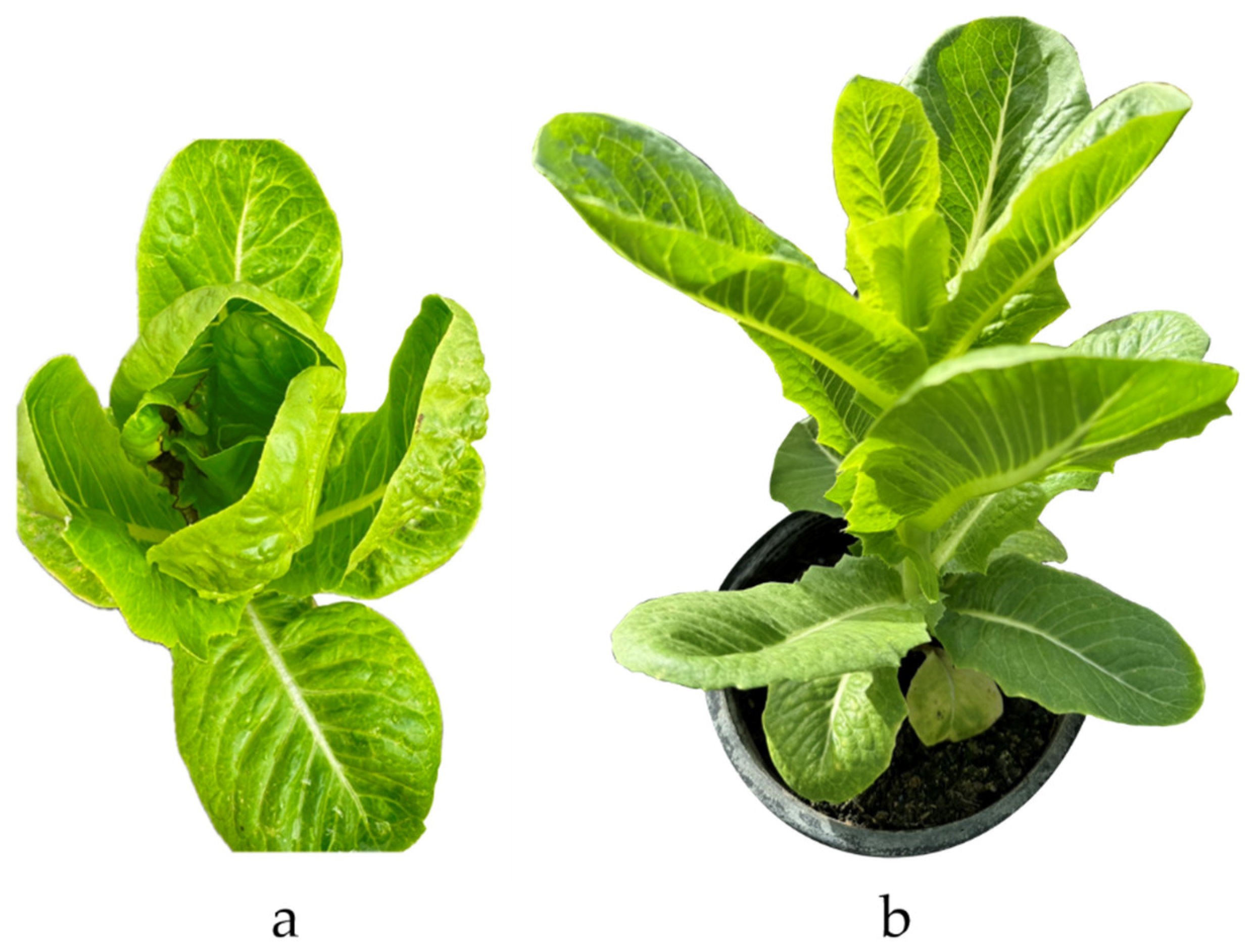

2. Materials and Methods

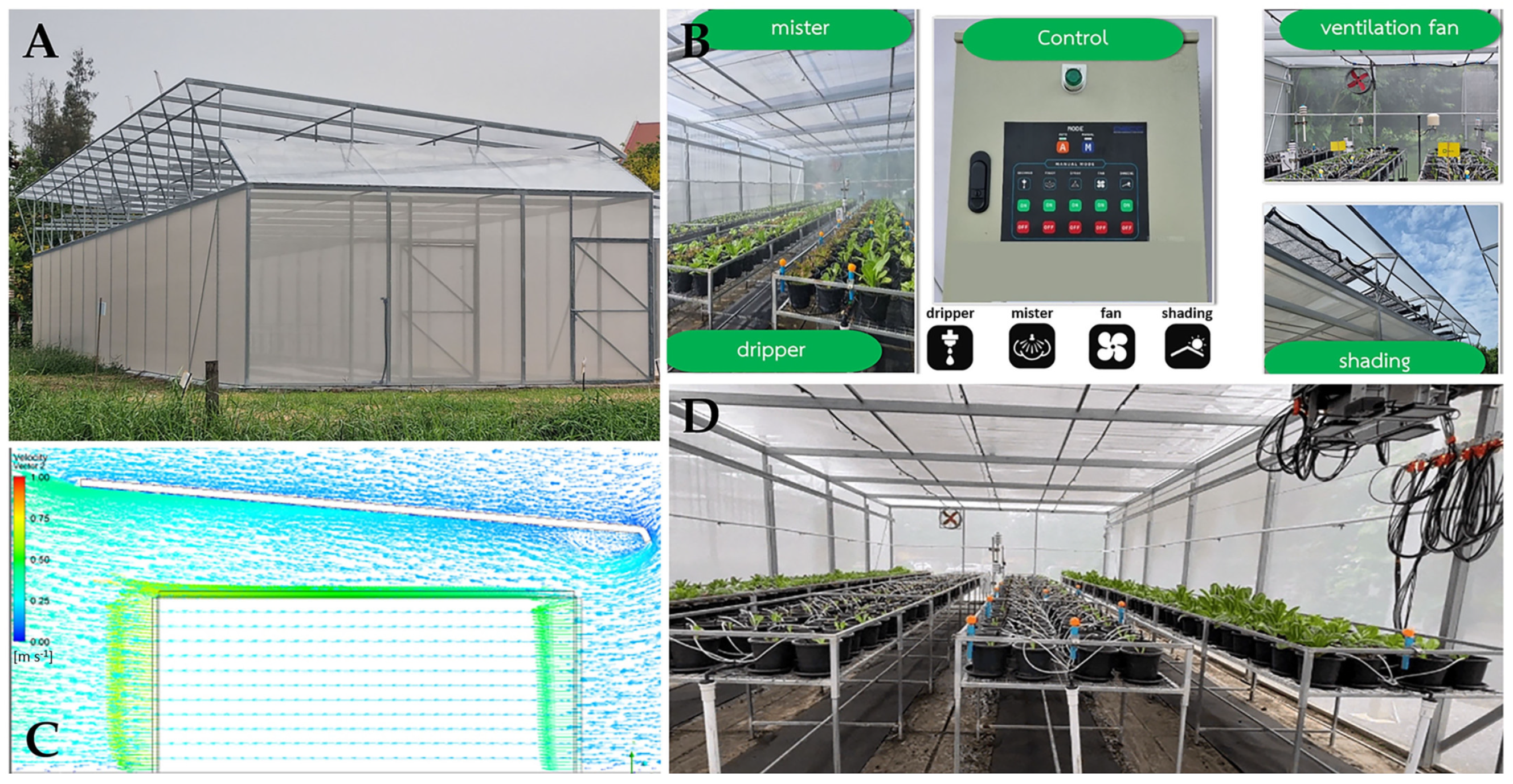

2.1. Experimental Designs and Management of Temperature Control System

2.2. IoT System for Environmental Data Acquisition

2.3. Growth Conditions

2.4. Plant Growth and Biomass Accumulation

2.5. Physiological Evaluations

2.6. Phytochemical Analysis

2.6.1. Chlorophyll Content

2.6.2. Total Phenolics Content

2.6.3. DPPH Radical Scavenging Activity

2.7. Nutrient Accumulation in Plant Tissues

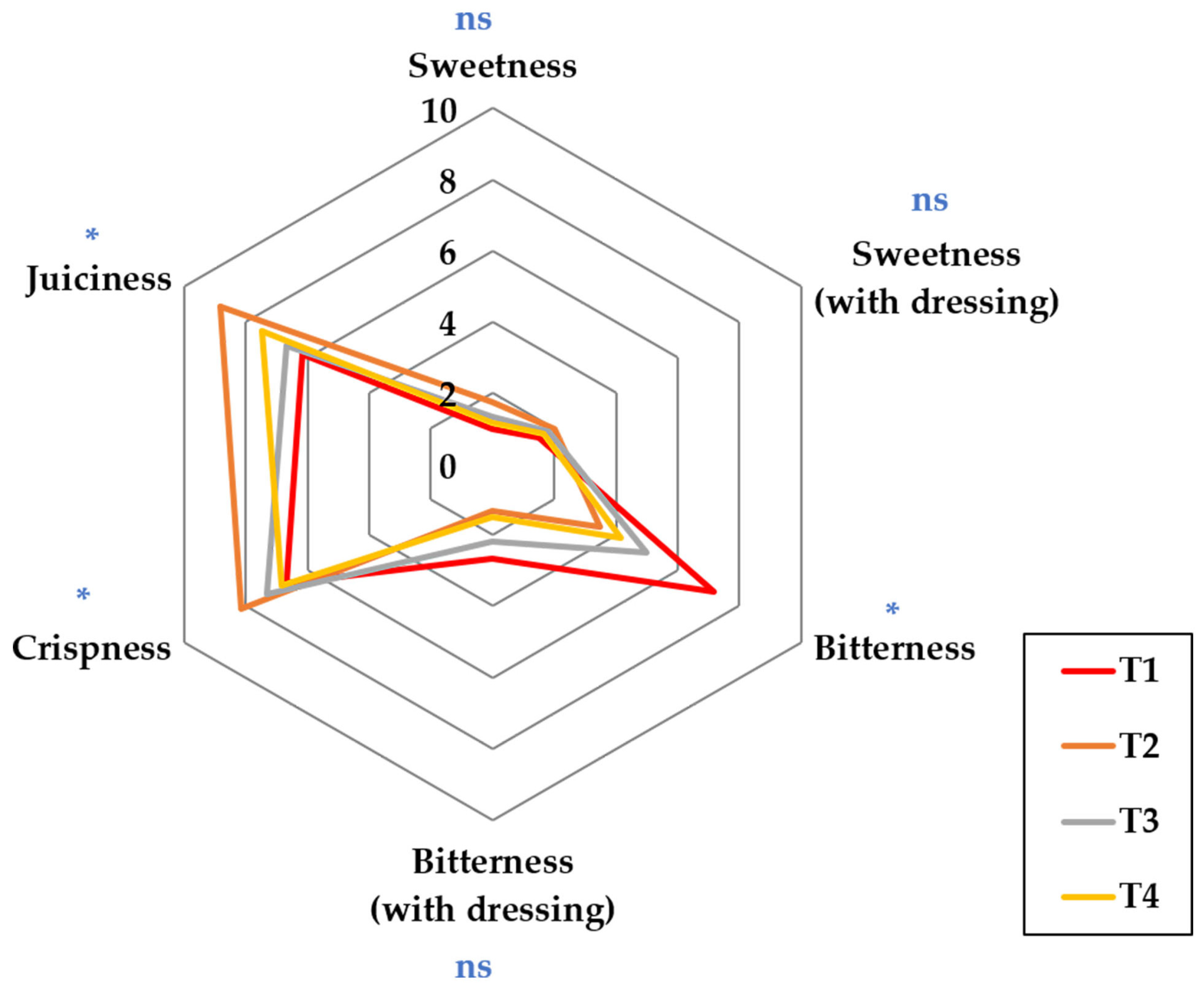

2.8. Sensory Test

2.9. Statistical Analysis

3. Results

3.1. Environmental Conditions in the Greenhouse

3.2. Plant Growth Characteristics

3.3. Physiological Responses

3.4. Phytochemical Contents

3.5. Nutrient Concentrations in Plant Tissues

3.6. Sensory Test Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amitrano, C.; Rouphael, Y.; De Pascale, S.; De Micco, V. Modulating vapor pressure deficit in the plant micro-environment may enhance the bioactive value of lettuce. Horticulturae 2021, 7, 32. [Google Scholar] [CrossRef]

- Nicholson, C.F.; Eaton, M.; Gomez, M.I.; Mattson, N.S. Economic and environmental performance of controlled-environment supply chains for leaf lettuce. Eur. Rev. Agric. Econ. 2023, 50, 1547–1582. [Google Scholar] [CrossRef]

- Houghton, J.T.; Ding, Y.; Griggs, D.J.; Noguer, M.; van der Linden, P.J.; Dai, X.; Maskell, K.; Johnson, C.A. Climate Change 2001: The Scientific Basis; Cambridge University Press: Cambridge, UK, 2001; p. 881. [Google Scholar]

- Jung, W.; Kim, H. Evaluation of heat stress levels inside greenhouses during summer in Korea. Int. J. Environ. Res. Public Health 2022, 19, 12497. [Google Scholar] [CrossRef]

- Ghoulem, M.; Moueddeb, K.E.; Nehdi, E.; Boukhanouf, R.; Calautit, J.K. Greenhouse design and cooling technologies for sustainable food cultivation in hot climates: Review of current practice and future status. Biosyst. Eng. 2019, 183, 121–150. [Google Scholar] [CrossRef]

- Soussi, M.; Chaibi, M.T.; Buchholz, M.; Saghrouni, Z. Comprehensive review on climate control and cooling systems in greenhouses under hot and arid conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- He, J.; Lee, S.K.; Dodd, I.C. Limitations to photosynthesis of lettuce grown under tropical conditions: Alleviation by root-zone cooling. J. Exp. Bot. 2001, 52, 1323–1330. [Google Scholar] [CrossRef]

- He, J.; Qin, L.; Chong, E.L.C.; Choong, T.W.; Lee, S.K. Plant growth and photosynthetic characteristics of Mesembryanthemum crystallinum grown aeroponically under different blue- and red-LEDs. Front. Plant Sci. 2017, 8, 361. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, H.A.; Yu-Xin, T.; Qi-Chang, Y. Optimal control of environmental conditions affecting lettuce plant growth in a controlled environment with artificial lighting: A review. S. Afr. J. Bot. 2020, 130, 75–89. [Google Scholar] [CrossRef]

- Jishi, T.; Ishii, T.; Shoji, K. Cultivation of cos lettuce using blue LED and quantum dot wavelength conversion sheets. Sci. Hortic. 2022, 295, 110772. [Google Scholar] [CrossRef]

- Hooks, T.; Sun, L.; Kong, Y.; Masabni, J.; Niu, G. Effect of nutrient solution cooling in summer and heating in winter on the performance of baby leafy vegetables in deep-water hydroponic systems. Horticulturae 2022, 8, 749. [Google Scholar] [CrossRef]

- Zhuang, Y.; Lu, N.; Shimamura, S.; Maruyama, A.; Kikuchi, M.; Takagaki, M. Economies of scale in constructing plant factories with artificial lighting and the economic viability of crop production. Front. Plant Sci. 2022, 13, 992194. [Google Scholar] [CrossRef] [PubMed]

- Avgoustaki, D.D.; Xydis, G. Indoor vertical farming in the urban nexus context: Business growth and resource savings. Sustainability 2020, 12, 1965. [Google Scholar] [CrossRef]

- Asseng, S.; Guarin, J.R.; Raman, M.; Monje, O.; Kiss, G.; Despommier, D.D.; Meggers, F.M.; Gauthier, P.P.G. Wheat yield potential in controlled-environment vertical farms. Proc. Natl. Acad. Sci. USA 2020, 117, 19131–19135. [Google Scholar] [CrossRef] [PubMed]

- Baumont de Oliveira, F.J.; Ferson, S.; Dyer, R.A.D.; Thomas, J.M.H.; Myers, P.D.; Gray, N.C. How high is high enough? Assessing financial risk for vertical farms using imprecise probability. Sustainability 2022, 14, 5676. [Google Scholar] [CrossRef]

- Stagnari, F.; Galieni, A.; Pisante, M. Shading and nitrogen management affect quality, safety and yield of greenhouse-grown leaf lettuce. Sci. Hortic. 2015, 192, 70–79. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Wang, J. Effects of light intensity and temperature on the photosynthesis characteristics and yield of lettuce. Horticulture 2022, 8, 178. [Google Scholar] [CrossRef]

- Boo, H.O.; Heo, B.G.; Gorinstein, S.; Chon, S.U. Positive effects of temperature and growth conditions on enzymatic and antioxidant status in lettuce plants. Plant Sci. 2011, 181, 479–484. [Google Scholar] [CrossRef]

- Choi, K.Y.; Lee, Y.B. Effect of air temperature on tipburn of butterhead and leaf lettuce in a plant factory. J. Kor. Soc. Hort. Sci. 2003, 44, 805–808. [Google Scholar]

- Simonne, A.; Simonne, E.; Eitenmiller, R.; Coker, C.H. Bitterness and composition of lettuce varieties grown in the southeastern United States. Horttechnology 2002, 12, 721–726. [Google Scholar] [CrossRef]

- Jeong, S.W.; Kim, G.S.; Lee, W.S.; Kim, Y.H.; Kang, N.J.; Jin, J.S.; Lee, G.M.; Kim, S.T.; El-Aty, A.M.A.; Shim, J.H.; et al. The effects of different night-time temperatures and cultivation durations on the polyphenolic contents of lettuce: Application of principal component analysis. J. Adv. Res. 2015, 6, 493–499. [Google Scholar] [CrossRef][Green Version]

- Endo, M.; Fukuda, N.; Yoshida, H.; Fujiuchi, N.; Yano, R.; Kusano, M. Effects of light quality, photoperiod, CO2 concentration, and air temperature on chlorogenic acid and rutin accumulation in young lettuce plants. Plant Physiol. Biochem. 2022, 186, 290–298. [Google Scholar] [CrossRef] [PubMed]

- Jones, J.B., Jr. Hydroponics: A Practical Guide for the Soilless Grower, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2005; pp. 76–83. [Google Scholar]

- Kittas, C.; Karamanis, M.; Katsoulas, N. Air temperature regime in a forced ventilated greenhouse with rose crop. Energy Build. 2005, 37, 807–812. [Google Scholar] [CrossRef]

- Hirai, M.; Yoshikoshi, H.; Kitano, M.; Wakimizu, K.; Sakaida, T.; Yoshioka, T.; Nitabaru, J.; Nakazono, K.; Hayashi, M.; Maki, T. Production of value-added crop of green tea in summer under the shade screen net: Canopy microenvironments. Acta Hortic. 2008, 797, 411–417. [Google Scholar] [CrossRef]

- Ilic, Z.S.; Milenkovic, L.; Stanojevic, L.; Cvetkovic, D.; Fallik, E. Effects of the modification of light intensity by color shade nets on yield and quality of tomato fruits. Sci. Hortic. 2012, 139, 90–95. [Google Scholar] [CrossRef]

- Shaban, N.T.; Tzvetkova, N.; Cherkez, R.; Parvanova, P. Evaluation of response of lettuce (Lactuca sativa L.) to temperature and light stress. Acta Agrobot. 2016, 69, 1664. [Google Scholar] [CrossRef]

- LI-COR. Using the LI-6800 Portable Photosynthesis System; LI-COR: Lincoln, NE, USA, 2011; Version 2. [Google Scholar]

- Mackinney, G. Absorption of light by chlorophyll solutions. J. Biol. Chem. 1941, 140, 315–322. [Google Scholar] [CrossRef]

- Chutimanukul, P.; Wanichananan, P.; Janta, S.; Toojinda, T.; Clive, D.; Kriengkrai, M. The influence of different light spectra on physiological responses, antioxidant capacity and chemical compositions in two holy basil cultivars. Sci. Rep. 2022, 12, 588. [Google Scholar] [CrossRef]

- Noisapung, J.; Hokpanna, A. The Low Heated Greenhouse for Organic Agriculture. In Proceedings of the 36th Conference of Mechanical Engineering Network of Thailand, Udon Thani, Thailand, 2–5 July 2019. [Google Scholar]

- Carotti, L.; Graamans, L.; Puksic, F.; Butturini, M.; Meinen, E.; Heuvelink, E.; Stanghellini, C. Plant factories are heating up: Hunting for the best combination of light intensity, air temperature and root-zone temperature in lettuce production. Front. Plant Sci. 2021, 11, 592171. [Google Scholar] [CrossRef]

- Sanders, D.C. Home Garden Lettuce, Leaflet; North Carolina State University: Raleigh, NC, USA, 2001. [Google Scholar]

- Ha, T.M. Production efficiency and quality of mustard green (Brassica Juncea (L.) Czern) cultivated according to the Vietnamese good agricultural practice (VietGAP) guideline in Thai Nguyen city. Asian J. Agric. Food Sci. 2014, 2, 329–335. [Google Scholar]

- Chen, Z.; Han, Y.; Ning, K.; Ding, Y.; Zhao, W.; Yan, S.; Luo, C.; Jiang, X.; Ge, D.; Liu, R.; et al. Inflorescence development and the role of LsFT in regulating bolting in lettuce (Lactuca sativa L.). Front. Plant Sci. 2017, 8, 2248. [Google Scholar] [CrossRef]

- Ying, Y.J.; Ma, C.; Xu, Y.J.; Wei, Q.; Imtiaz, M.; Lan, H.B.; Gao, S.; Cheng, L.; Wang, M.; Fei, Z.; et al. A zinc finger protein regulates flowering time and abiotic stress tolerance in chrysanthemum by modulating gibberellin biosynthesis. Plant Cell 2014, 26, 2038–2054. [Google Scholar] [CrossRef] [PubMed]

- Zou, L.P.; Pan, C.; Wang, M.X.; Cui, L.; Han, B.Y. Progress on the mechanism of hormones regulating plant flower formation. Hereditas 2020, 42, 739–751. [Google Scholar] [PubMed]

- Zhao, X.; Carey, E.E. Summer production of lettuce, and microclimate in high tunnel and open field plots in Kansas. HortTechnology 2009, 19, 113–119. [Google Scholar] [CrossRef]

- Katsoulas, N.; Kitta, E.; Kittas, C.; Tsirogiannis, I.L.; Stamati, E.; Sayvas, D. Greenhouse cooling by a fog system: Effects on microclimate and on production and quality of a soilless pepper crop. Acta Hortic. 2006, 719, 455–462. [Google Scholar] [CrossRef]

- Ozturk, H.H. Evaporative cooling efficiency of a fogging system in a rose greenhouse. Aust. J. Exp. Agric. 2006, 46, 1231–1237. [Google Scholar] [CrossRef]

- Ahemd, H.A.; Al-Faraj, A.A.; Abdel-Ghany, A.M. Shading greenhouses to improve the microclimate, energy and water saving in hot regions: A review. Sci. Hortic. 2016, 201, 36–45. [Google Scholar] [CrossRef]

- Laur, S.; da Silva, A.L.B.R.; Díaz-Pérez, J.C.; Coolong, T. Impact of shade and fogging on high tunnel production and mineral content of organically grown lettuce, basil, and arugula in Georgia. Agriculture 2021, 11, 625. [Google Scholar] [CrossRef]

- Chansakoo, W.; Jiracheewee, N.; Panthon, S.; Kupanichpong, W.; Ammarok, S.; Konchom, R.; Thongthaksin, W. Development of prototype greenhouse for off-season cultivation of Curcuma alismatifolia Gagnep. Hort for wealth and well-being. In Proceedings of the 10th National Horticultural Congress 2011, Bangkok, Thailand, 18–22 May 2011. [Google Scholar]

- Kittas, C.; Bartzanas, T.; Jaffrin, A. Greenhouse evaporative cooling: Measurement and data analysis. Acta Hortic. 2000, 534, 67–74. [Google Scholar] [CrossRef]

- Júnior, C.O.C.; Queiroga, R.C.F.; Sousa, C.D.S.; Figueiredo, C.C.; Mesquita, E.; Pereira, F.H.F.; Júnior, S.O.M.; Alves, J.M.; Lima, A.S.; Santos, A.P.L. Shading on yield and quality of lettuce cultivars in semiarid conditions. J. Agric. Sci. 2019, 11, 162–171. [Google Scholar] [CrossRef]

- Boulard, T.; Fatnassi, H.; Roy, J.C.; Lagier, J.; Fargues, J.; Smits, N.; Rougier, M.; Jeannequin, B. Effect of greenhouse ventilation on humidity of inside air and in leaf boundary-layer. Agric. For. Meteorol. 2004, 125, 225–239. [Google Scholar] [CrossRef]

- Xue, Y.S.; Zhao, G.Y. Biological characteristics and cultivation techniques of Pleurotus nebrodensis. J. Mudanjiang Norm. Univ. Nat. Sci. Ed. 2006, 4, 7–8. [Google Scholar]

- Li, R.; He, Y.; Chen, J.; Zheng, S.; Zhuang, C. Research progress in improving photosynthetic efficiency. Int. J. Mol. Sci. 2023, 24, 9286. [Google Scholar] [CrossRef] [PubMed]

- Galieni, A.; Mattia, C.D.; Gregorio, M.D.; Speca, S.; Mastrocola, D.; Pisante, M.; Stagnari, F. Effects of nutrient deficiency and abiotic environmental stresses on yield, phenolic compounds and antiradical activity in lettuce (Lactuca sativa L.). Sci. Hortic. 2015, 187, 93–101. [Google Scholar] [CrossRef]

- Kumari, R.; Singh, S.; Agrawal, S.B. Effects of supplemental ultraviolet-b radiation on growth and physiology of Acorus calamus L. (sweet flag). Acta Biol. Cracoviensia Ser. Bot. 2009, 51, 19–27. [Google Scholar]

- Perone, C.; Orsino, M.; Fianza, G.L.; Giametta, F.; Catalano, C. Study of a mechanical ventilation system with heat recovery to control temperature in a monitored agricultural environment under Summer conditions. J. Build. Eng. 2021, 43, 102745. [Google Scholar] [CrossRef]

- Inoue, T.; Sunaga, M.; Ito, M.; Yuchen, Q.; Matsushima, Y.; Sakoda, K.; Yamori, W. Minimizing VPD fluctuations maintains higher stomatal conductance and photosynthesis, resulting in improvement of plant growth in lettuce. Front. Plant Sci. 2021, 12, 646144. [Google Scholar] [CrossRef] [PubMed]

- Bakker, J.C. Analysis of humidity effects on growth and production of glasshouse fruit vegetables. Ph.D. Thesis, Agricultural University, Wageningen, The Netherlands, 1991. [Google Scholar]

- Zhang, D.; Zhang, Z.; Li, J.; Chang, Y.; Du, Q.; Pan, T. Regulation of vapor pressure deficit by greenhouse micro-fog systems improved growth and productivity of tomato via enhancing photosynthesis during summer season. PLoS ONE 2015, 10, e0133919. [Google Scholar] [CrossRef]

- Hoffman, G.J. Humidity. In Controlled Environment Guidelines for Plant Research; Tibbits, W., Kozlowski, T.T., Eds.; Academic Press: London, UK, 1979; pp. 141–172. [Google Scholar]

- Barrett, D.M.; Beaulieu, J.C.; Shewfelt, R. Color, flavor, texture, and nutritional quality of fresh-cut fruits and vegetables: Desirable levels, instrumental and sensory measurement, and the effects of processing. Crit. Rev. Food Sci. Nutr. 2010, 50, 369–389. [Google Scholar] [CrossRef]

- Holmes, S.C.; Wells, D.E.; Pickens, J.M.; Kemble, J.M. Selection of heat tolerant lettuce (Lactuca sativa L.) cultivars grown in deep water culture and their marketability. Horticulturae 2019, 5, 50. [Google Scholar] [CrossRef]

| Treatment | Greenhouse Temperature (°C) | Relative Humidity (%) | Photosynthetically Active Radiation (PAR, μmol m−2 s−1) | VPD (kPa) | ||||

|---|---|---|---|---|---|---|---|---|

| Average | Maximum | Minimum | Average | Maximum | Minimum | |||

| 1st harvesting | ||||||||

| T1 | 35.90 | 37.76 | 32.91 | 61.30 | 67.30 | 57.65 | 886.08 | 2.31 |

| T2 | 33.13 | 34.64 | 31.43 | 68.21 | 73.81 | 62.95 | 592.17 | 1.62 |

| T3 | 33.98 | 36.30 | 32.82 | 66.47 | 70.19 | 61.16 | 506.28 | 1.83 |

| T4 | 33.58 | 35.69 | 31.96 | 67.28 | 70.00 | 63.38 | 499.11 | 1.71 |

| Outside | 32.56 | 34.15 | 30.19 | 68.57 | 76.95 | 62.97 | 1309.53 | 1.55 |

| 2nd harvesting | ||||||||

| T1 | 35.15 | 36.45 | 33.31 | 57.68 | 61.58 | 54.60 | 636.76 | 2.41 |

| T2 | 32.25 | 33.82 | 30.65 | 63.77 | 69.02 | 57.14 | 669.03 | 1.76 |

| T3 | 32.78 | 34.34 | 30.99 | 64.40 | 67.44 | 59.36 | 472.28 | 1.77 |

| T4 | 32.85 | 34.40 | 31.52 | 63.26 | 65.34 | 60.30 | 422.02 | 1.84 |

| Outside | 33.30 | 34.04 | 31.89 | 58.39 | 64.53 | 55.90 | 1429.80 | 2.13 |

| 3rd harvesting | ||||||||

| T1 | 35.85 | 37.11 | 33.01 | 52.14 | 57.41 | 49.94 | 495.91 | 2.83 |

| T2 | 31.33 | 32.27 | 30.20 | 62.21 | 66.70 | 59.35 | 529.90 | 1.73 |

| T3 | 32.66 | 33.82 | 31.29 | 56.07 | 60.53 | 53.16 | 512.38 | 2.17 |

| T4 | 32.32 | 33.90 | 31.62 | 58.09 | 60.67 | 56.10 | 443.04 | 2.15 |

| Outside | 33.33 | 34.40 | 30.95 | 49.29 | 53.97 | 45.42 | 1383.97 | 2.61 |

| Treatment | 1st Harvesting | 2nd Harvesting | 3rd Harvesting |

|---|---|---|---|

| Plant height (cm) | |||

| T1 | 24.70 ± 1.30 | 21.94 ± 1.61 b | 23.32 ± 2.08 b |

| T2 | 25.00 ± 1.92 | 25.82 ± 0.78 a | 26.60 ± 0.42 a |

| T3 | 24.00 ± 1.30 | 18.98 ± 1.05 c | 25.36 ± 0.68 a |

| T4 | 25.00 ± 1.87 | 22.74 ± 0.70 b | 26.20 ± 0.70 a |

| p-value | 0.413 | 0.000 | 0.002 |

| Plant width (cm) | |||

| T1 | 28.34 ± 1.86 bc | 25.26 ± 1.32 | 25.18 ± 0.77 b |

| T2 | 30.80 ± 0.83 a | 25.54 ± 0.38 | 27.88 ± 1.35 a |

| T3 | 26.80 ± 1.79 c | 26.22 ± 2.42 | 24.30 ± 1.21 b |

| T4 | 29.60 ± 1.14 b | 25.88 ± 1.67 | 24.88 ± 0.64 b |

| p-value | 0.004 | 0.804 | 0.000 |

| Leaf number | |||

| T1 | 16.60 ± 1.14 a | 13.20 ± 0.44 c | 15.20 ± 1.30 b |

| T2 | 17.40 ± 2.30 a | 14.80 ± 0.84 ab | 18.40 ± 1.14 a |

| T3 | 12.00 ± 1.00 b | 14.60 ± 0.55 b | 15.00 ± 1.00 b |

| T4 | 17.20 ± 1.48 a | 15.60 ± 0.55 a | 16.40 ± 0.55 b |

| p-value | 0.000 | 0.000 | 0.000 |

| Leaf area (cm2) | |||

| T1 | 795.15 ± 41.73 b | 630.08 ± 23.21 c | 665.72 ± 30.97 b |

| T2 | 984.76 ± 64.91 a | 900.78 ± 58.07 a | 731.53 ± 11.30 a |

| T3 | 556.65 ± 23.61 c | 657.91 ± 71.94 c | 539.79 ± 20.86 c |

| T4 | 766.55 ± 58.82 b | 754.93 ± 43.30 b | 720.13 ± 22.15 a |

| p-value | 0.000 | 0.000 | 0.000 |

| Marketable fresh weight (g plant−1) | |||

| T1 | 75.81 ± 9.51 a | 38.31 ± 6.60 b | 68.41 ± 6.36 b |

| T2 | 80.82 ± 8.42 a | 65.24 ± 7.21 a | 81.90 ± 3.13 a |

| T3 | 49.32 ± 2.54 b | 40.86 ± 2.54 b | 47.35 ± 5.48 c |

| T4 | 77.85 ± 8.06 a | 59.67 ± 5.13 a | 71.83 ± 2.20 b |

| p-value | 0.000 | 0.000 | 0.000 |

| Root fresh weight (g plant−1) | |||

| T1 | 5.29 ± 0.28 a | 3.35 ± 0.63 | 6.33 ± 1.05 a |

| T2 | 4.41 ± 0.36 a | 4.67 ± 0.50 | 5.59 ± 0.61 ab |

| T3 | 3.35 ± 0.81 b | 4.26 ± 0.38 | 4.80 ± 0.52 b |

| T4 | 4.54 ± 0.98 a | 6.55 ± 0.42 | 5.76 ± 0.67 ab |

| p-value | 0.003 | 0.000 | 0.036 |

| Treatment | 1st Harvesting | 2nd Harvesting | 3rd Harvesting |

|---|---|---|---|

| Net photosynthetic rate (μmol m−2 s−1) | |||

| T1 | 8.00 ± 1.60 b | 10.45 ± 0.86 b | 12.00 ± 0.71 bc |

| T2 | 11.31 ± 1.52 a | 16.71 ± 1.65 a | 16.58 ± 1.09 a |

| T3 | 4.32 ± 0.53 c | 9.71 ± 1.66 b | 11.25 ± 0.91 c |

| T4 | 8.90 ± 0.25 b | 11.46 ± 0.60 b | 13.43 ± 0.61 b |

| p-value | 0.001 | 0.001 | 0.000 |

| Stromatal conductance (mol m−2 s−1) | |||

| T1 | 0.22 ± 0.04 ab | 0.38 ± 0.05 a | 0.23 ± 0.01 c |

| T2 | 0.26 ± 0.05 a | 0.42 ± 0.08 a | 0.68 ± 0.16 a |

| T3 | 0.11 ± 0.02 c | 0.23 ± 0.06 b | 0.34 ± 0.07 b |

| T4 | 0.16 ± 0.03 bc | 0.25 ± 0.03 b | 0.25 ± 0.02 c |

| p-value | 0.004 | 0.000 | 0.001 |

| Transpiration rate (mmol m−2 s−1) | |||

| T1 | 7.69 ± 0.27 b | 8.76 ± 1.34 b | 7.24 ± 1.31 ab |

| T2 | 10.36 ± 0.91 a | 11.91 ± 0.50 a | 9.00 ± 0.37a |

| T3 | 6.96 ± 0.27 b | 7.41 ± 1.87 b | 4.31 ± 1.44 c |

| T4 | 7.81 ± 1.47 b | 8.51 ± 0.53 b | 5.88 ± 0.95 bc |

| p-value | 0.007 | 0.010 | 0.005 |

| Treatment | Total Chlorophyll (μg cm−2) | Total Phenolic (mg GAE g−1 DW) | DPPH Radical Scavenging (%) |

|---|---|---|---|

| T1 | 86.06 ± 5.58 b | 60.78 ± 0.27 b | 61.07 ± 1.45 a |

| T2 | 95.10 ± 5.45 a | 67.93 ± 2.66 a | 60.53 ± 3.36 a |

| T3 | 55.21 ± 1.73 c | 38.07 ± 1.21 c | 23.36 ± 3.03 b |

| T4 | 56.47 ± 1.78 c | 41.35 ± 4.25 c | 61.78 ± 1.24 a |

| p-value | 0.000 | 0.000 | 0.000 |

| Treatment | N (%) | P (%) | K (%) |

|---|---|---|---|

| T1 | 3.06 ± 0.13 | 1.16 ± 0.05 b | 3.82 ± 0.10 b |

| T2 | 3.19 ± 0.04 | 1.70 ± 0.07 a | 5.39 ± 0.14 a |

| T3 | 3.08 ± 0.03 | 1.23 ± 0.08 b | 2.64 ± 0.39 c |

| T4 | 3.20 ± 0.10 | 1.69 ± 0.18 a | 5.32 ± 0.04 a |

| p-value | 0.191 | 0.000 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumsong, N.; Thepsilvisut, O.; Imorachorn, P.; Chutimanukul, P.; Pimpha, N.; Toojinda, T.; Trithaveesak, O.; Ratanaudomphisut, E.; Poyai, A.; Hruanun, C.; et al. Comparison of Different Temperature Control Systems in Tropical-Adapted Greenhouses for Green Romaine Lettuce Production. Horticulturae 2023, 9, 1255. https://doi.org/10.3390/horticulturae9121255

Kumsong N, Thepsilvisut O, Imorachorn P, Chutimanukul P, Pimpha N, Toojinda T, Trithaveesak O, Ratanaudomphisut E, Poyai A, Hruanun C, et al. Comparison of Different Temperature Control Systems in Tropical-Adapted Greenhouses for Green Romaine Lettuce Production. Horticulturae. 2023; 9(12):1255. https://doi.org/10.3390/horticulturae9121255

Chicago/Turabian StyleKumsong, Niracha, Ornprapa Thepsilvisut, Phanawan Imorachorn, Preuk Chutimanukul, Nuttaporn Pimpha, Theerayut Toojinda, Opas Trithaveesak, Eakkarach Ratanaudomphisut, Amporn Poyai, Charndet Hruanun, and et al. 2023. "Comparison of Different Temperature Control Systems in Tropical-Adapted Greenhouses for Green Romaine Lettuce Production" Horticulturae 9, no. 12: 1255. https://doi.org/10.3390/horticulturae9121255

APA StyleKumsong, N., Thepsilvisut, O., Imorachorn, P., Chutimanukul, P., Pimpha, N., Toojinda, T., Trithaveesak, O., Ratanaudomphisut, E., Poyai, A., Hruanun, C., Yanuwong, S., Pakhamin, W., Kayoontammarong, C., Janpeng, M., & Ehara, H. (2023). Comparison of Different Temperature Control Systems in Tropical-Adapted Greenhouses for Green Romaine Lettuce Production. Horticulturae, 9(12), 1255. https://doi.org/10.3390/horticulturae9121255