Technological Trends and Engineering Issues on Vertical Farms: A Review

Abstract

:1. Introduction

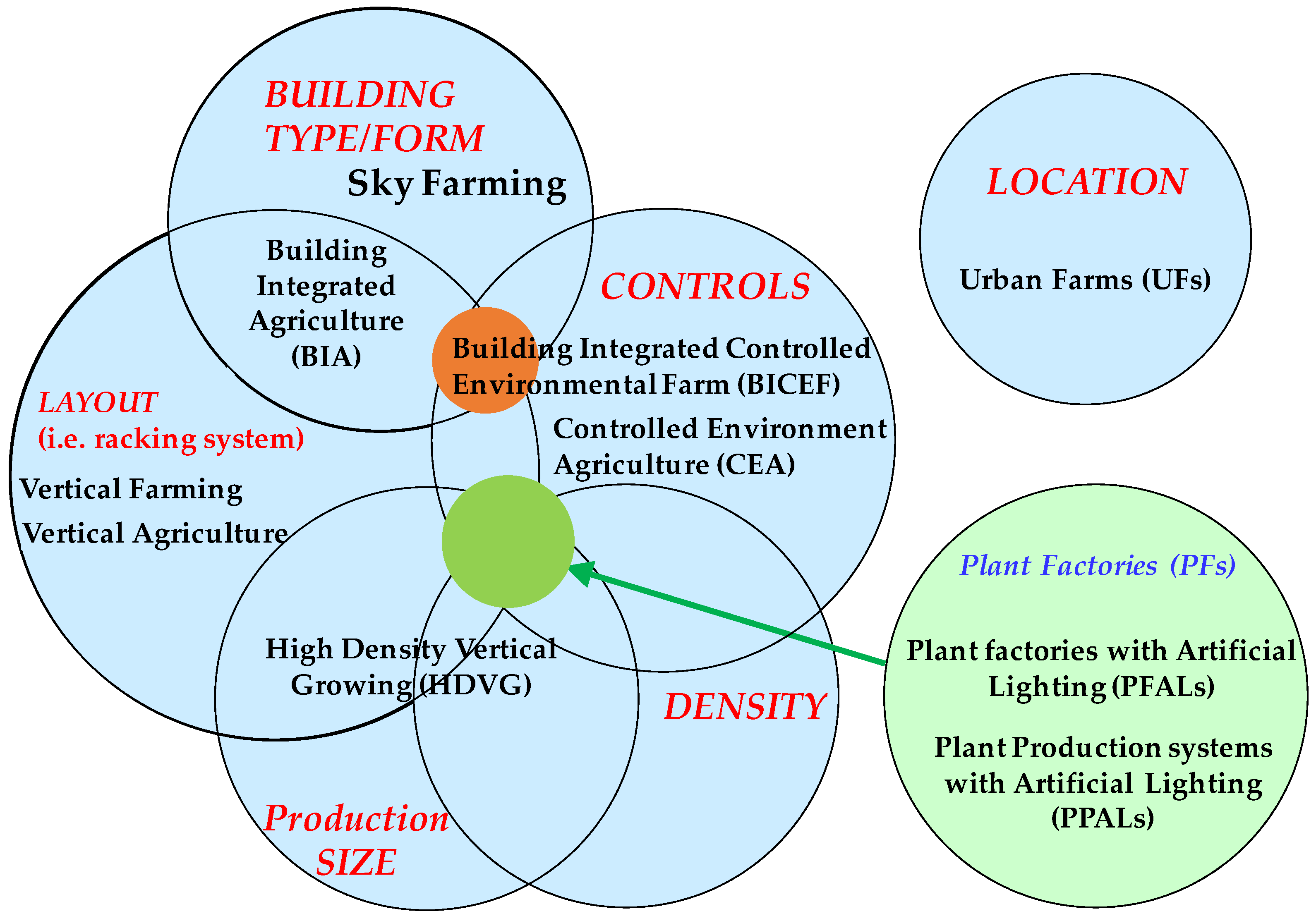

2. Vertical Farming: Concept, Classification, and Key Considerations

2.1. Definition and Types

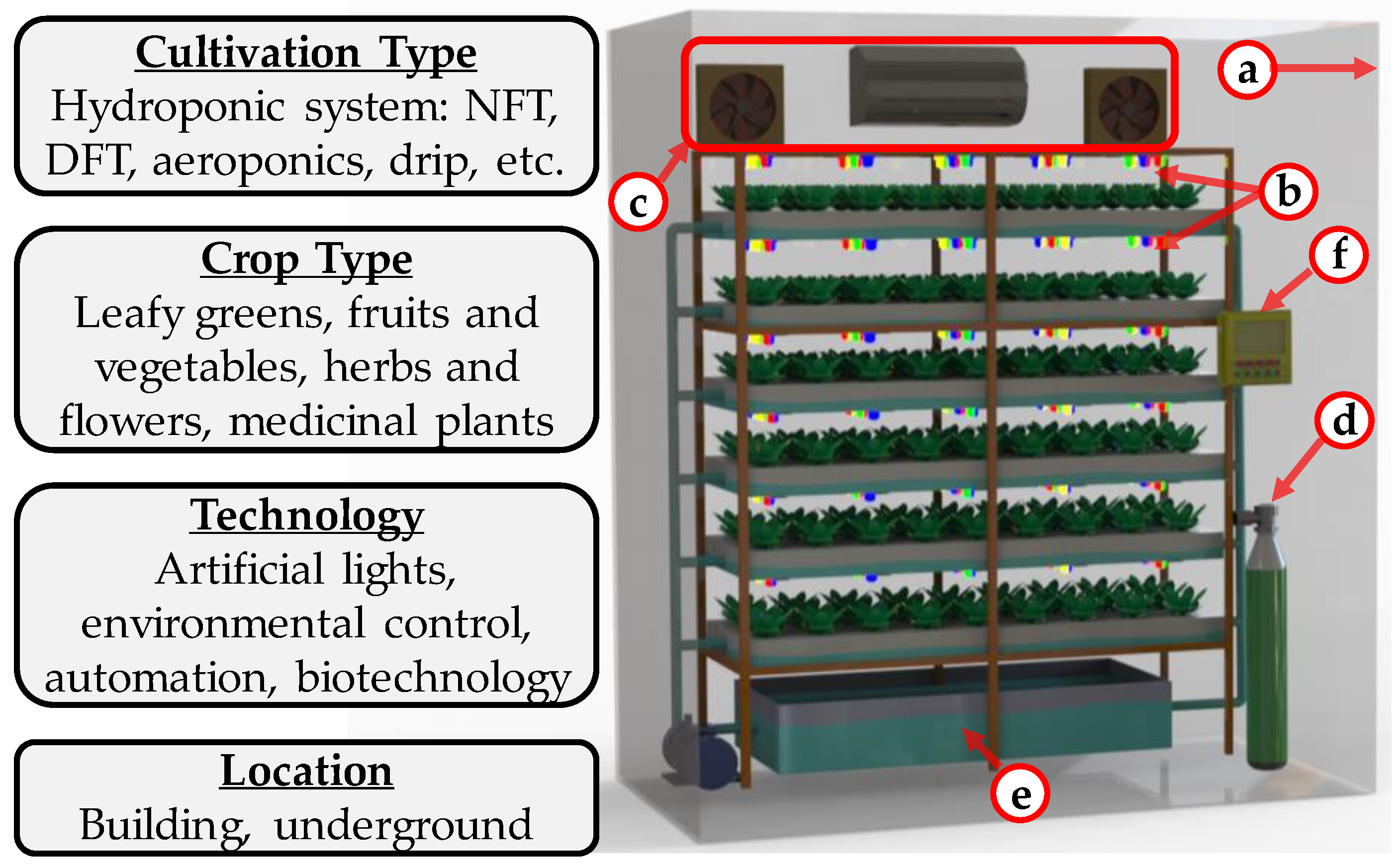

2.2. General Structures and Characteristics

2.3. Key Considerations

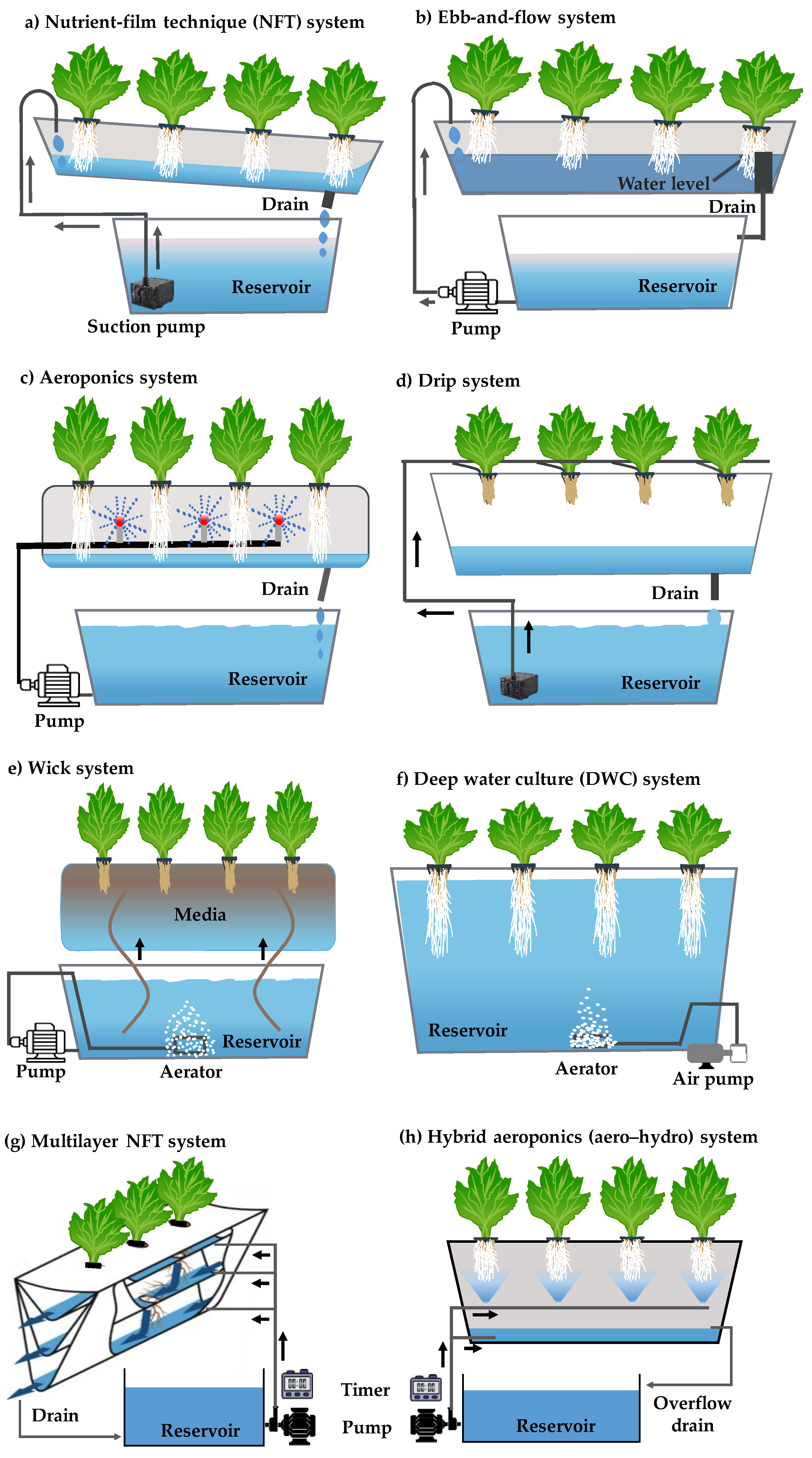

2.3.1. Crop-Cultivation System

2.3.2. Crop Selection

2.3.3. Technological Level

2.3.4. Location

3. Technological Trends

3.1. Sensing Technology

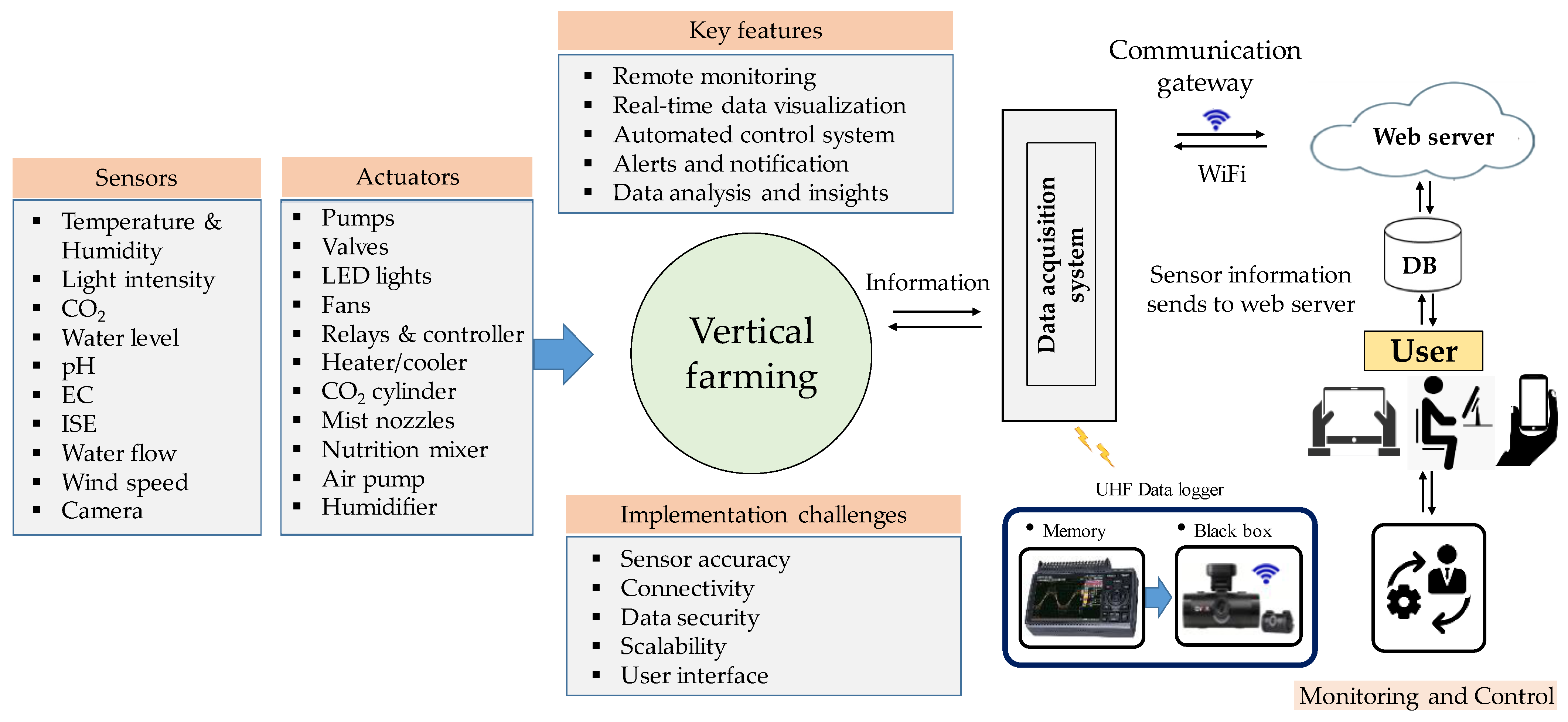

3.1.1. Sensors and Actuators

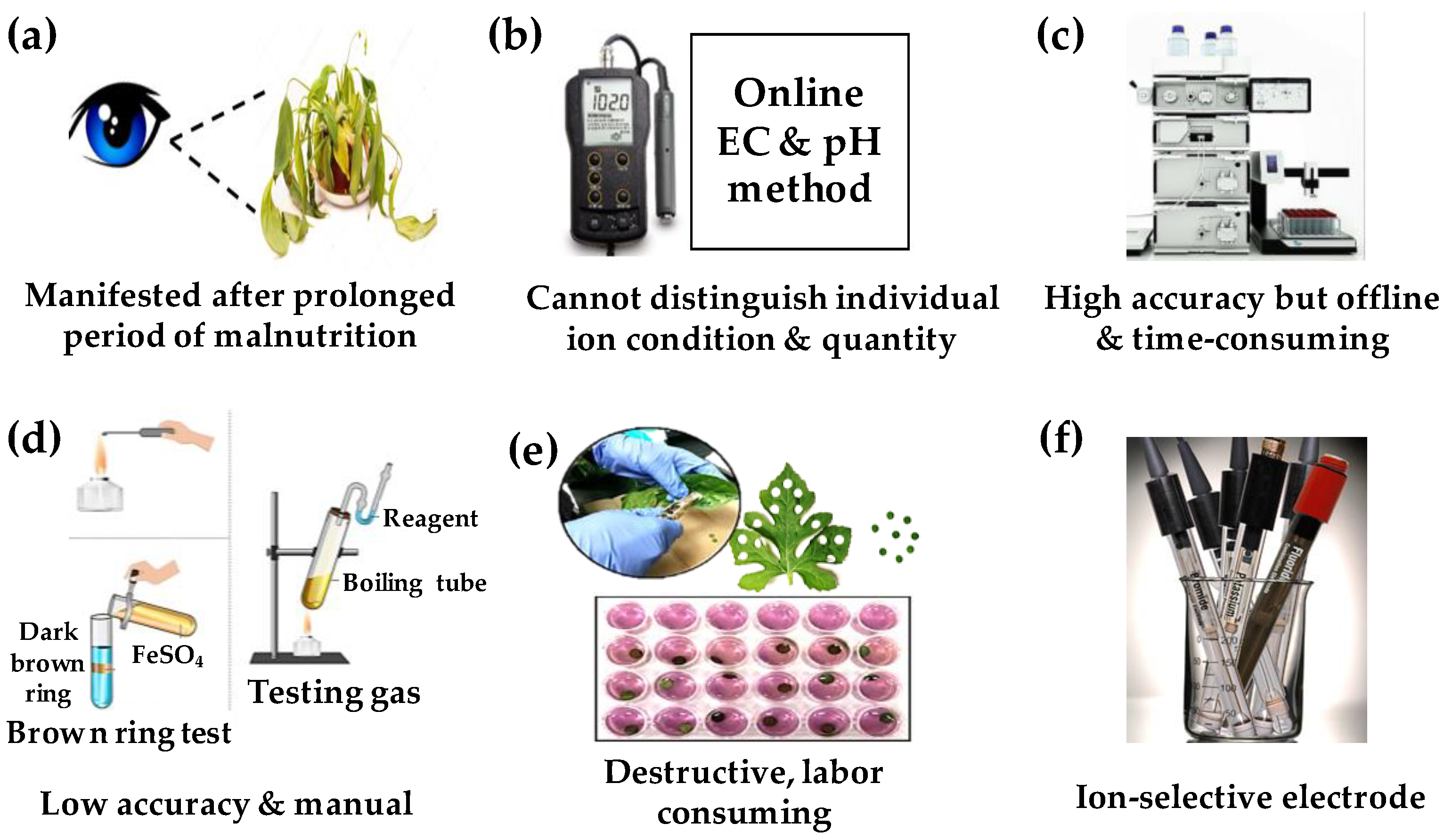

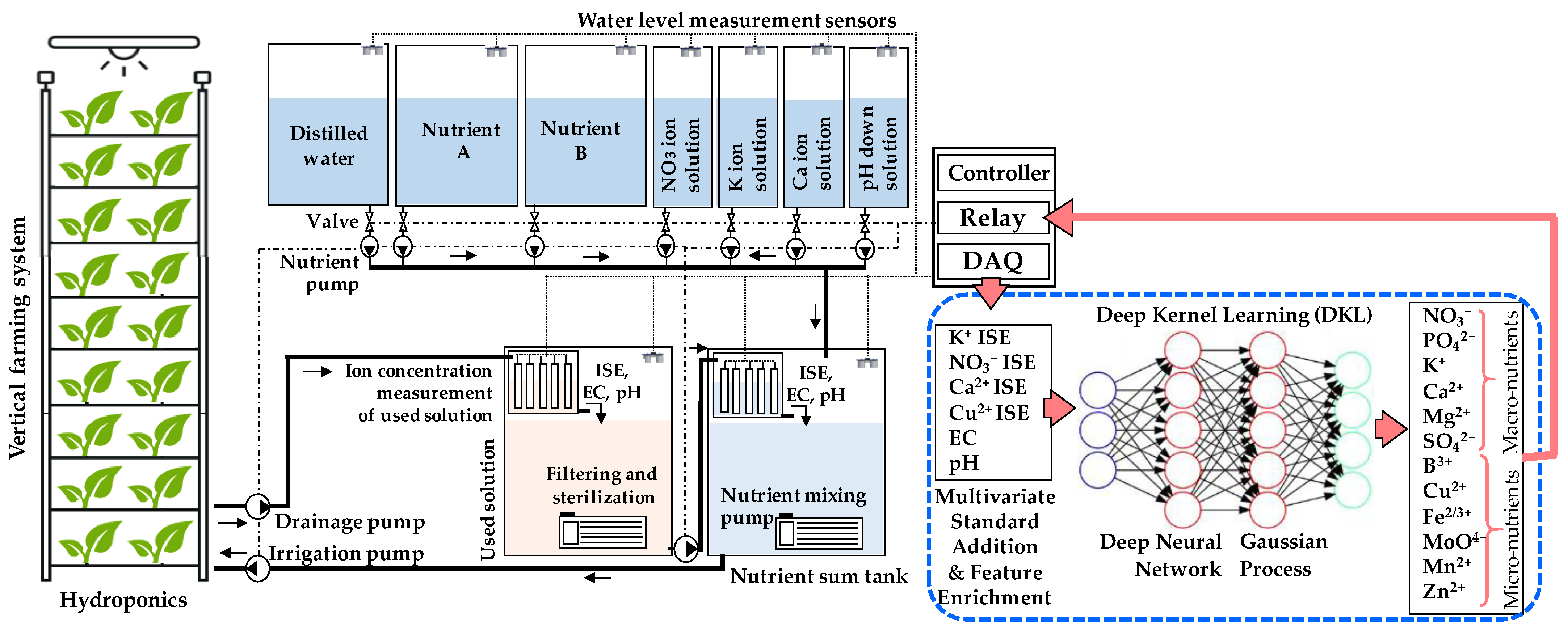

3.1.2. Nutrient-Sensing Systems

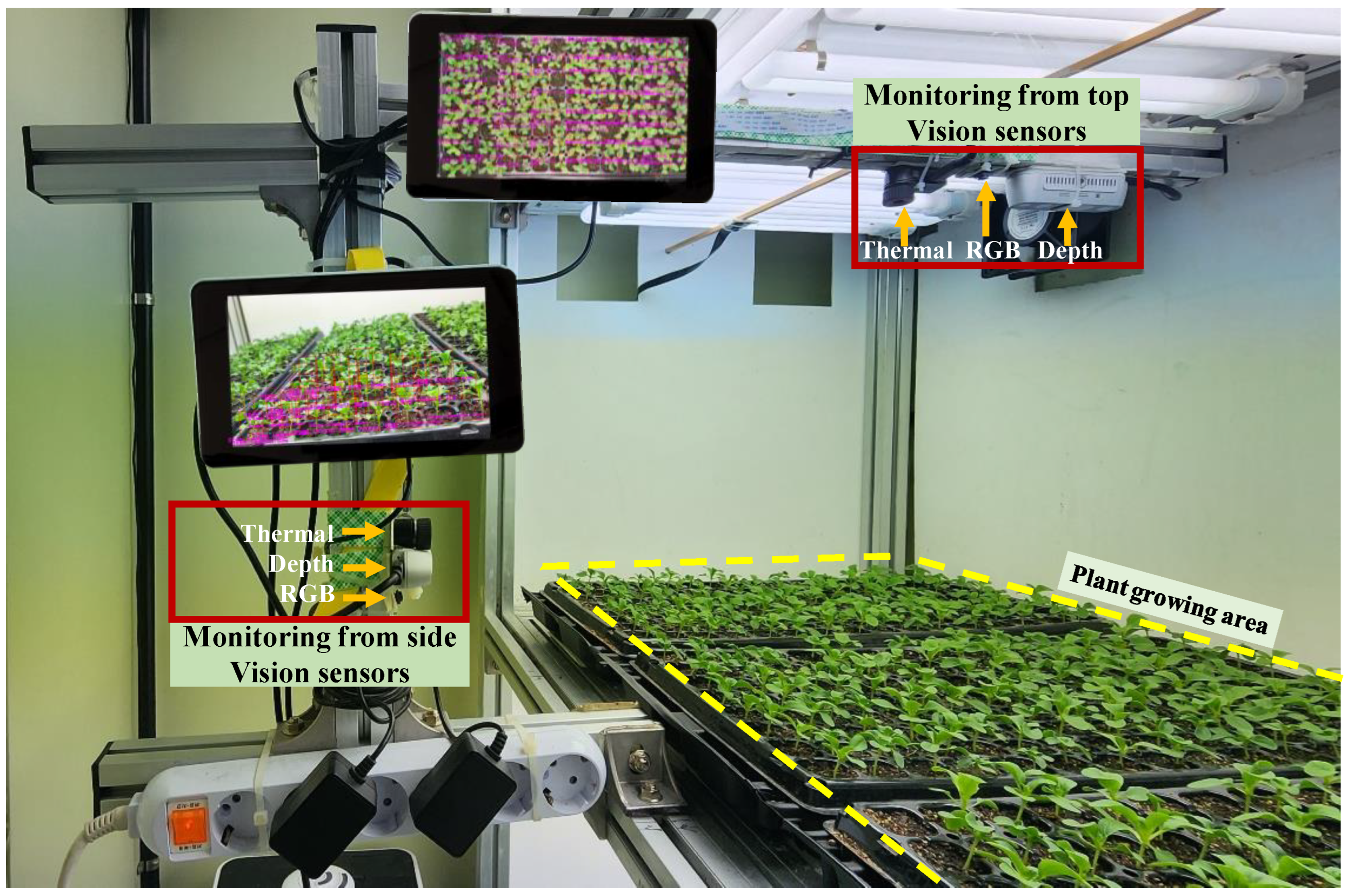

3.1.3. Plant Monitoring and Control Systems

3.2. Unmanned Vertical Farming Systems

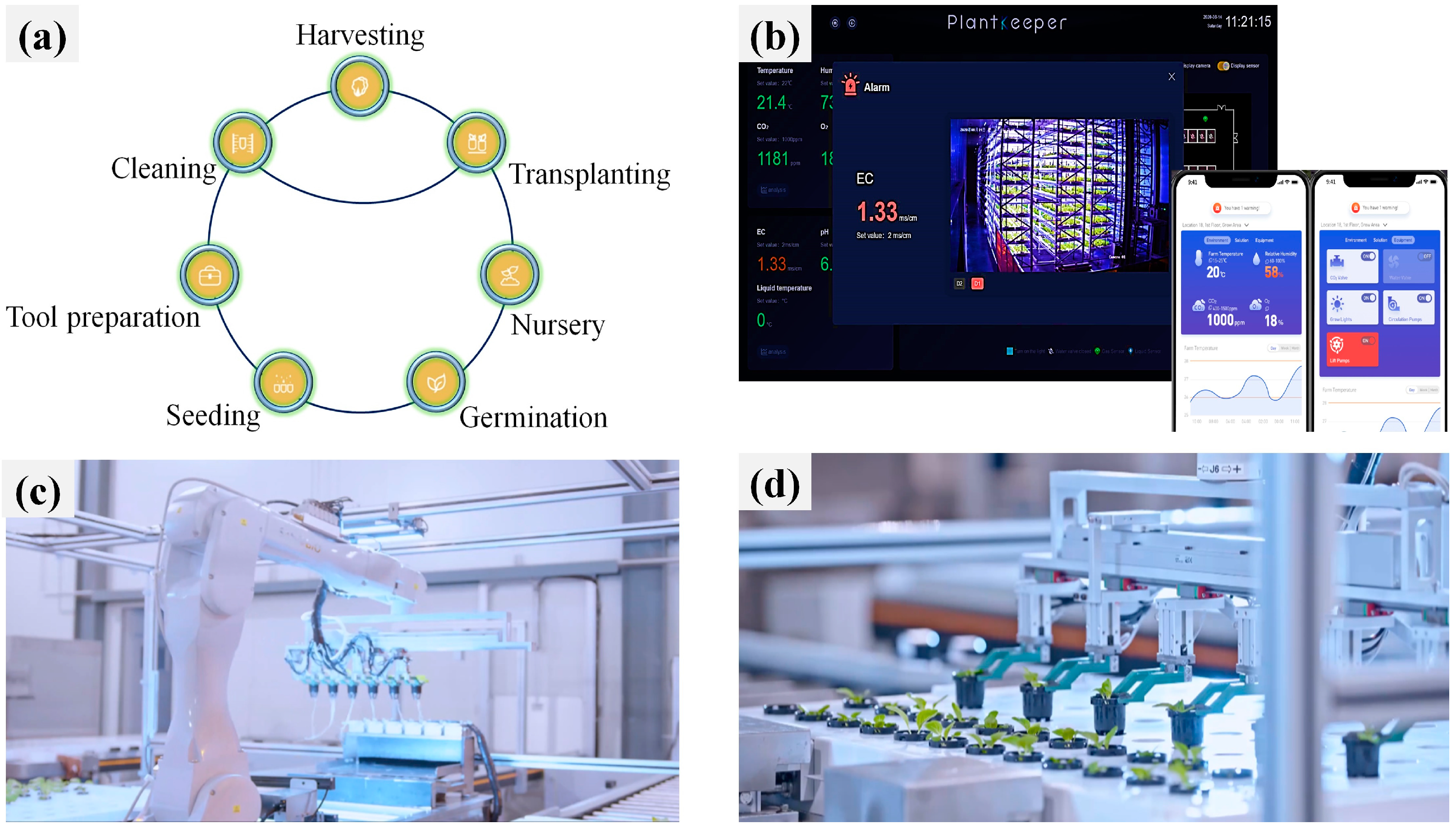

3.2.1. Automated Vertical Farming Systems

3.2.2. Robotic Vertical Farming Systems

3.2.3. Vertical Farming with Drones

3.3. AI-Based Research Trends

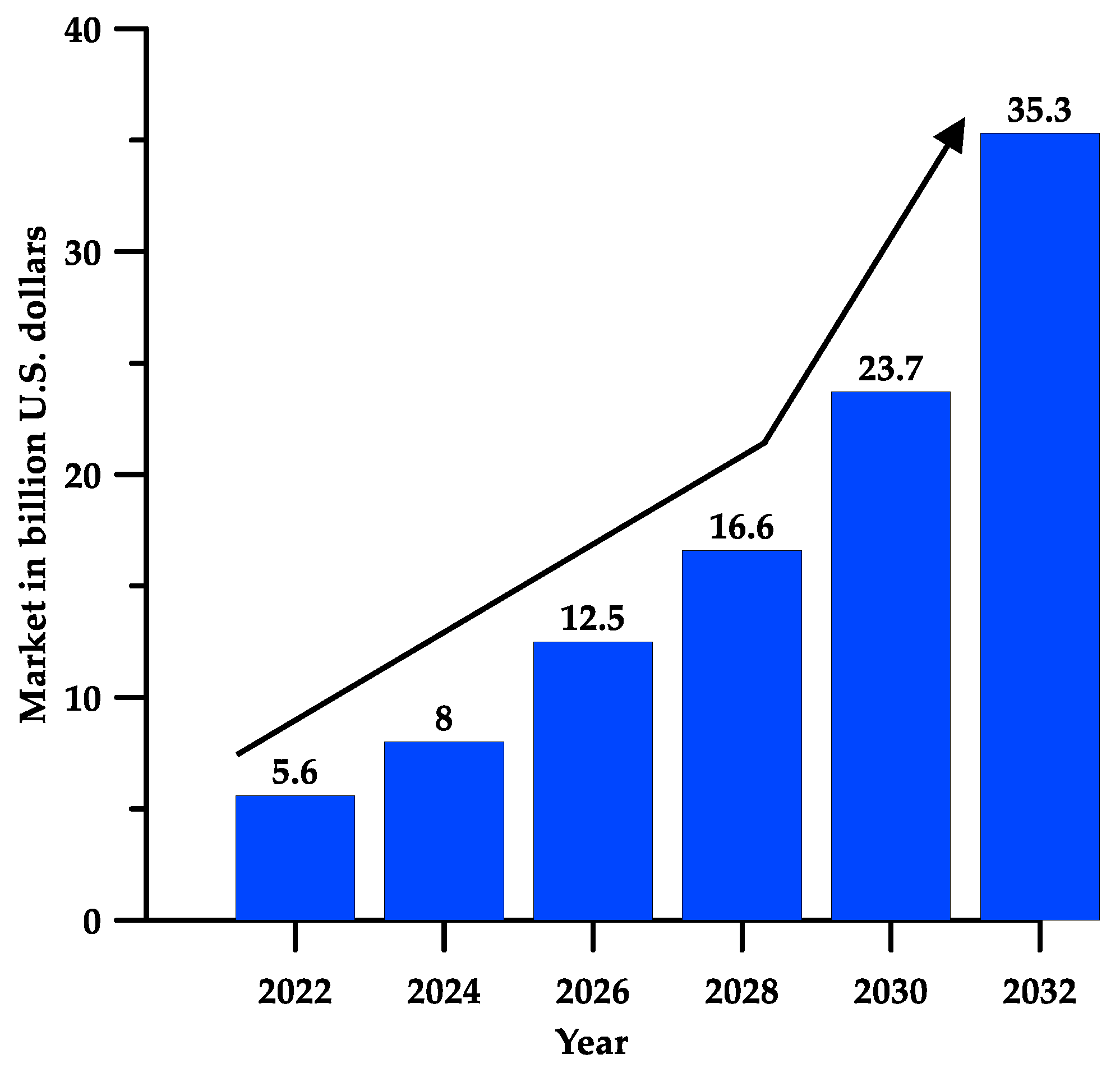

4. Global Industrial and Market Trends

4.1. Global Status

4.2. Industry and Market Trends in Asia

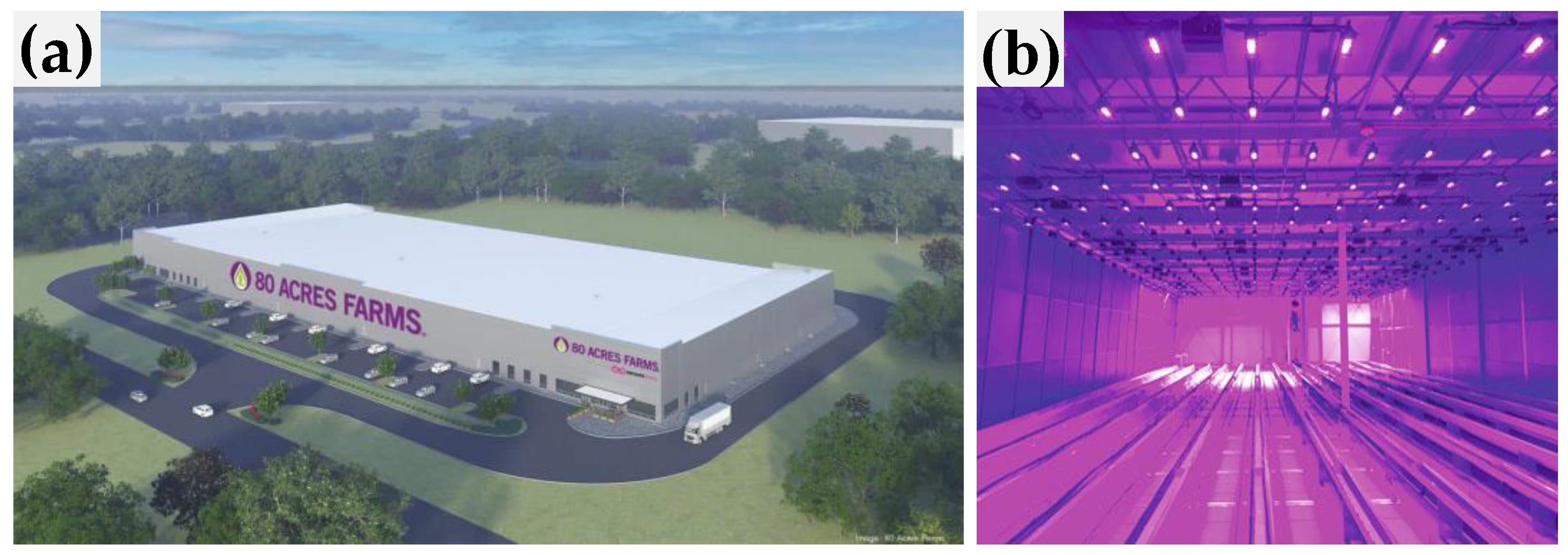

4.3. Industry and Market Trends in the USA

4.4. Industry and Market Trends in Europe

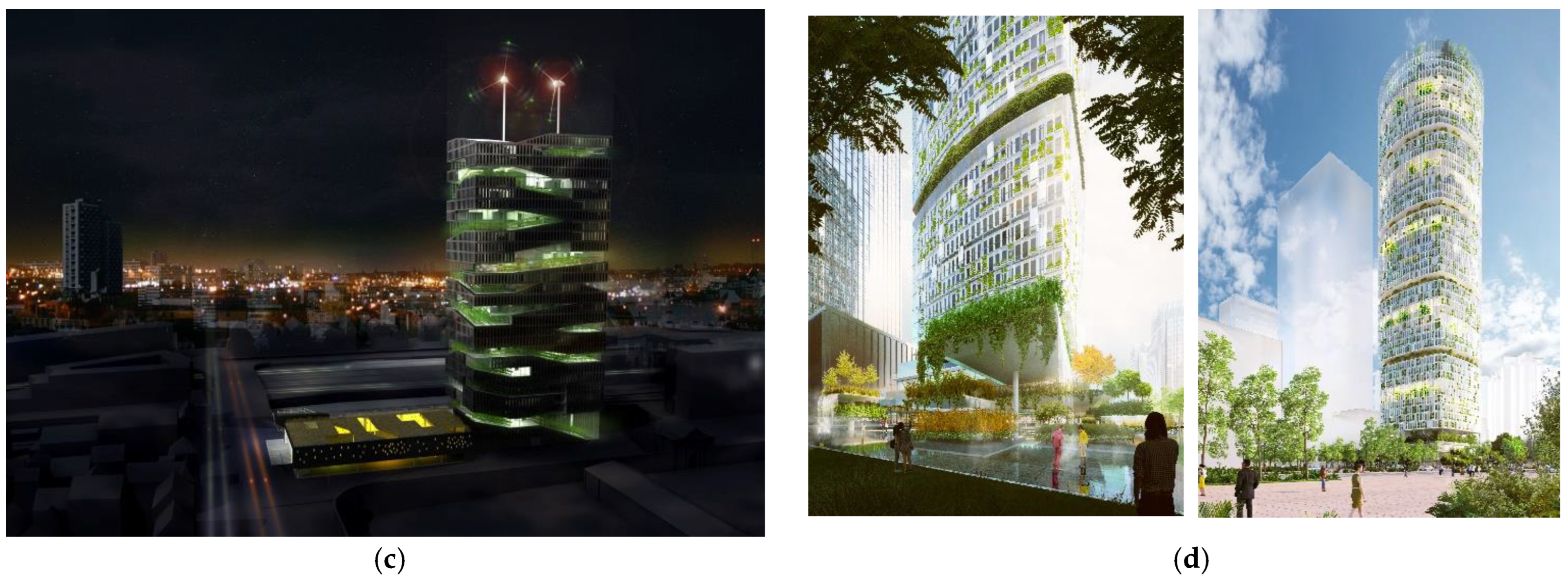

4.5. Innovative Concepts for Upcoming Vertical Farms

| Vertical Farm, Location | Company | Key Features | Reference |

|---|---|---|---|

| Sunqiao Urban Agricultural District, Shanghai, China | Sasaki Architects, Boston, USA |

| [208] |

| La Tour Vivante, Rennes, France, | SOA Architectes, Paris, France |

| [209] |

| Jian Mu Tower, Shenzhen, China | Carlo Ratti Associati, Turin, Italy |

| [210] |

| Urban Skyfarm, Seoul, South Korea | Aprilli Design Studio, Toronto, Canada |

| [213] |

| Hive-Inn™ City Farm, New York, USA | OVA Studio Ltd., Sheung Wan, Hong Kong |

| [216] |

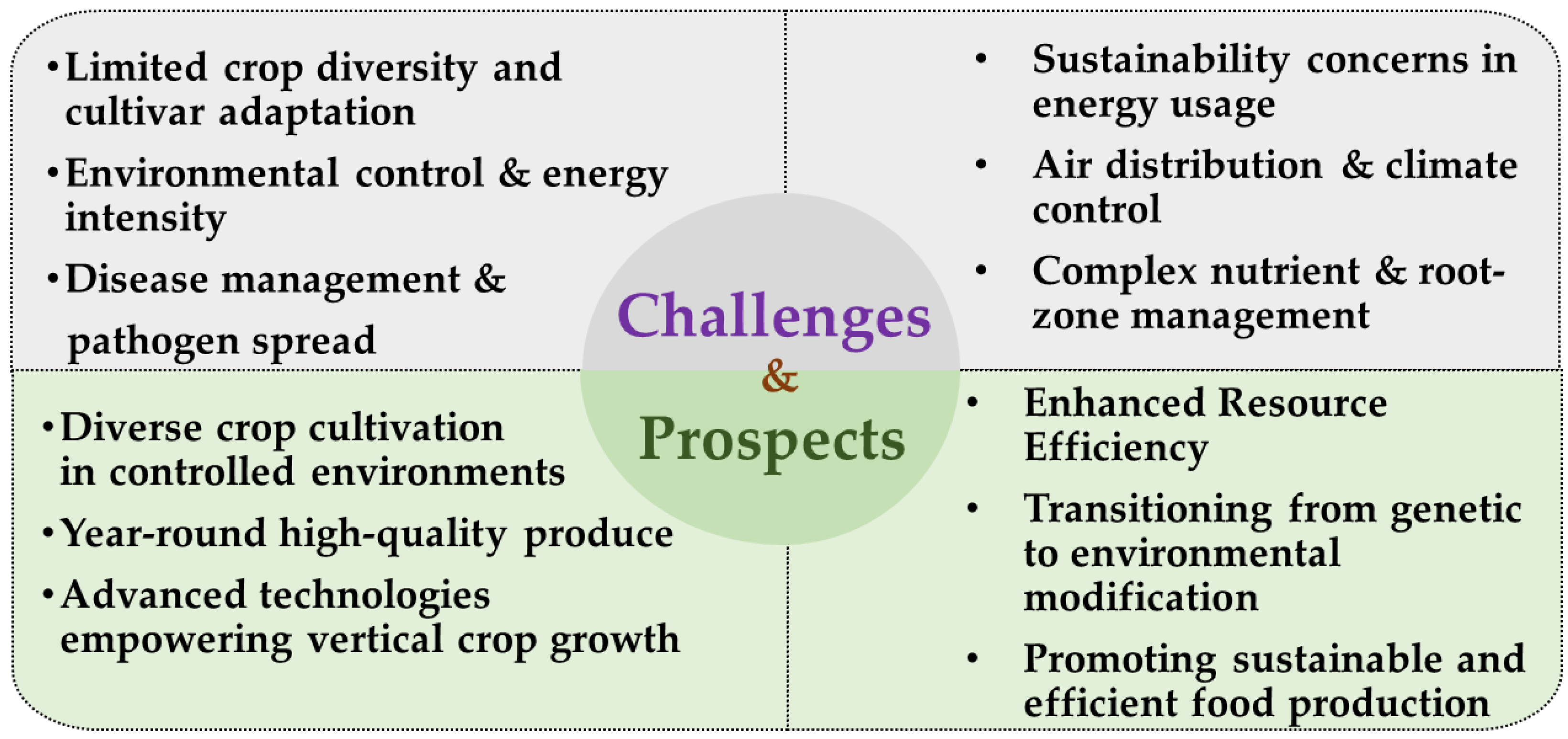

5. Issues and Future Prospects

5.1. Opportunities and Challenges Regarding Crops, the Environment, and Economics

5.1.1. Crop-Production Perspective

5.1.2. Environmental Perspective

5.1.3. Economic Perspective

5.2. Opportunities and Challenges for Global Food Security

5.3. Technological Opportunities and Challenges

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations, Department of Economic and Social Affairs, Population Division. World Population Prospects 2022: Summary of Results (UN DESA/POP/2022/TR/NO.3); United Nations: New York, NY, USA, 2022. [Google Scholar]

- United Nations, Department of Economic and Social Affairs, Population Division. World Urbanization Prospects: The 2018 Revision (ST/ESA/SER.A/420); United Nations: New York, NY, USA, 2019. [Google Scholar]

- Vollset, S.E.; Goren, E.; Yuan, C.-W.; Cao, J.; Smith, A.E.; Hsiao, T.; Bisignano, C.; Azhar, G.S.; Castro, E.; Chalek, J.; et al. Fertility, mortality, migration, and population scenarios for 195 countries and territories from 2017 to 2100: A forecasting analysis for the Global Burden of Disease Study. Lancet 2020, 396, 1285–1306. [Google Scholar] [CrossRef] [PubMed]

- Saad, M.H.M.; Hamdan, N.M.; Sarker, M.R. State of the art of urban smart vertical farming automation system: Advanced topologies, issues and recommendations. Electronics 2021, 10, 1422. [Google Scholar] [CrossRef]

- Beacham, A.M.; Vickers, L.H.; Monaghan, J.M. Vertical farming: A summary of approaches to growing skywards. J. Hortic. Sci. Biotechnol. 2019, 94, 277–283. [Google Scholar] [CrossRef]

- Ragaveena, S.; Shirly Edward, A.; Surendran, U. Smart controlled environment agriculture methods: A holistic review. Rev. Environ. Sci. Biotechnol. 2021, 20, 887–913. [Google Scholar] [CrossRef]

- Gan, C.I.; Soukoutou, R.; Conroy, D.M. Sustainability framing of controlled environment agriculture and consumer perceptions: A review. Sustainability 2023, 15, 304. [Google Scholar] [CrossRef]

- Engler, N.; Krarti, M. Review of energy efficiency in controlled environment agriculture. Renew. Sustain. Energy Rev. 2021, 141, 110786. [Google Scholar] [CrossRef]

- Lee, G.O.; Jang, S.-N.; Kim, M.J.; Cho, D.Y.; Cho, K.M.; Lee, J.H.; Son, K.-H. Comparison of growth patterns and metabolite composition of different ginseng cultivars (Yunpoong and K-1) grown in a vertical farm. Horticulturae 2023, 9, 583. [Google Scholar] [CrossRef]

- Nájera, C.; Gallegos-Cedillo, V.M.; Ros, M.; Pascual, J.A. Role of spectrum-light on productivity, and plant quality over vertical farming systems: Bibliometric analysis. Horticulturae 2023, 9, 63. [Google Scholar] [CrossRef]

- Statista. Global Vertical Farming Market Projection 2022–2032. 2023. Available online: https://www.statista.com/statistics/487666/projection-vertical-farming-market-worldwide/ (accessed on 7 August 2023).

- Li, H.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D. Towards automated greenhouse: A state of the art review on greenhouse monitoring methods and technologies based on internet of things. Comput. Electron. Agric. 2021, 191, 106558. [Google Scholar] [CrossRef]

- Vatistas, C.; Avgoustaki, D.D.; Bartzanas, T. A systematic literature review on controlled-environment agriculture: How vertical farms and greenhouses can influence the sustainability and footprint of urban microclimate with local food production. Atmosphere 2022, 13, 1258. [Google Scholar] [CrossRef]

- Oh, S.; Lu, C. Vertical farming—Smart urban agriculture for enhancing resilience and sustainability in food security. J. Hortic. Sci. Biotechnol. 2023, 98, 133–140. [Google Scholar] [CrossRef]

- Kalantari, F.; Mohd Tahir, O.; Mahmoudi Lahijani, A.; Kalantari, S. A review of vertical farming technology: A guide for implementation of building integrated agriculture in cities. Adv. Eng. Forum 2017, 24, 76–91. [Google Scholar] [CrossRef]

- Al-Kodmany, K. The Vertical Farm: A review of developments and implications for the vertical city. Buildings 2018, 8, 24. [Google Scholar] [CrossRef]

- Sandison, F.; Yeluripati, J.; Stewart, D. Does green vertical farming offer a sustainable alternative to conventional methods of production?: A case study from Scotland. Food Energy Secur. 2023, 12, e438. [Google Scholar] [CrossRef]

- Yuan, G.N.; Marquez, G.P.B.; Deng, H.; Iu, A.; Fabella, M.; Salonga, R.B.; Ashardiono, F.; Cartagena, J.A. A review on urban agriculture: Technology, socio-economy, and policy. Heliyon 2022, 8, e11583. [Google Scholar] [CrossRef]

- Kozai, T. Towards sustainable plant factories with artificial lighting (PFALs) for achieving SDGs. Int. J. Agric. Biol. Eng. 2019, 12, 28–37. [Google Scholar] [CrossRef]

- Kalantari, F.; Tahir, O.T.; Joni, R.A.; Aminuldin, N.A. The importance of the public acceptance theory in determining the success of the vertical farming projects. Manag. Res. Pract. 2018, 10, 5–16. [Google Scholar]

- Despommier, D. Vertical Farms in Horticulture. In Encyclopedia of Food and Agricultural Ethics; Thompson, P.B., Kaplan, D.M., Eds.; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Banerjee, C.; Adenaeuer, L. Up, up and away! The economics of vertical farming. J. Agric. Stud. 2014, 2, 40–60. [Google Scholar] [CrossRef]

- Van Gerrewey, T.; Boon, N.; Geelen, D. Vertical Farming: The only way is up? Agronomy 2022, 12, 2. [Google Scholar] [CrossRef]

- Waldron, D. Evolution of vertical farms and the development of a simulation methodology. WIT Trans. Ecol. Environ. 2018, 217, 975–986. [Google Scholar]

- Despommier, D. The Vertical Farm: Feeding the World in the 21st Century; St. Martin’s Press: New York, NY, USA, 2010; pp. 11–16. [Google Scholar]

- Kozai, T.; Niu, G. Introduction: Overview and concept of closed plant production system (CPPS). In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 3–6. [Google Scholar] [CrossRef]

- Despommier, D. Vertical farms, building a viable indoor farming model for cities. Field Actions Sci. Rep. 2019, 20, 68–73. Available online: http://journals.openedition.org/factsreports/5737 (accessed on 15 January 2023).

- Benke, K.; Tomkins, B. Future food-production systems: Vertical farming and controlledenvironment agriculture. Sustain. Sci. Pract. Policy 2017, 13, 13–16. [Google Scholar] [CrossRef]

- Despommier, D. The rise of vertical farms. Sci. Am. 2009, 301, 80–87. [Google Scholar] [CrossRef]

- Al-Chalabi, M. Vertical farming: Skyscraper sustainability? Sustain. Cities Soc. 2015, 18, 74–77. [Google Scholar] [CrossRef]

- Fischetti, M. Growing vertical: Skyscraper farming. Sci. Am. 2008, 18, 74–79. [Google Scholar] [CrossRef]

- Benis, K.; Reinhart, C.; Ferrão, P. Building-Integrated Agriculture (BIA) in urban contexts: Testing a simulation-based decision support workflow. In Proceedings of the 15th International Building Performance Simulation Association (IBPSA) Conference, San Francisco, CA, USA, 7–9 August 2017. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Kalantari, F.; Ting, K.C.; Thorp, K.R.; Hameed, I.A.; Weltzien, C.; Ahmad, D.; Shad, Z.M. Advances in greenhouse automation and controlled environment agriculture: A transition to plant factories and urban agriculture. Int. J. Agric. Biol. Eng. 2018, 11, 1–22. [Google Scholar] [CrossRef]

- Kozai, T. Resource use efficiency of closed plant production system with artificial light: Concept, estimation and application to plant factory. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 2013, 89, 447–461. [Google Scholar] [CrossRef] [PubMed]

- Butturini, M.; Marcelis, L.F.M. Vertical farming in Europe: Present status and outlook. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 77–91. [Google Scholar] [CrossRef]

- SharathKumar, M.; Heuvelink, E.; Marcelis, L.F.M. Vertical farming: Moving from genetic to environmental modification. Trends Plant Sci. 2020, 25, 724–727. [Google Scholar] [CrossRef]

- Chole, A.S.; Jadhav, A.R.; Shinde, V. Vertical farming: Controlled environment agriculture. Just Agric. 2021, 1, 249–256. Available online: https://justagriculture.in/files/newsletter/2021/jan/055.pdf (accessed on 9 August 2023).

- Chaudhry, A.R.; Mishra, V.P. A comparative analysis of vertical agriculture systems in residential apartments. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019. [Google Scholar] [CrossRef]

- Kozai, T.; Niu, G. Plant factory as a resourceefficient closed plant production system. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 93–115. [Google Scholar] [CrossRef]

- Kozai, T. Current Status of Plant Factories with Artificial Lighting (PFALs) and Smart PFALs. In Smart Plant Factory—The Next Generation Indoor Vertical Farms; Kozai, T., Ed.; Springer: Singapore, 2018; pp. 3–13. [Google Scholar] [CrossRef]

- Wong, C.E.; Teo, Z.W.N.; Shen, L.; Yu, H. Seeing the lights for leafy greens in indoor vertical farming. Trends Food Sci. Technol. 2020, 106, 48–63. [Google Scholar] [CrossRef]

- Son, J.E.; Kim, H.J.; Ahn, T.I. Hydroponic systems. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 273–283. [Google Scholar] [CrossRef]

- van Delden, S.H.; SharathKumar, M.; Butturini, M.; Graamans, L.J.A.; Heuvelink, E.; Kacira, M.; Kaiser, E.; Klamer, R.S.; Klerkx, L.; Kootstra, G.; et al. Current status and future challenges in implementing and upscaling vertical farming systems. Nat. Food 2021, 2, 944–956. [Google Scholar] [CrossRef]

- Maucieri, C.; Nicoletto, C.; Os, E.V.; Anseeuw, D.; Havermaet, R.V.; Junge, R. Hydroponic technologies. In Aquaponics Food Production Systems; Goddek, S., Joyce, A., Kotzen, B., Burnell, G.M., Eds.; Springer: Cham, Switzerland, 2019; pp. 77–110. [Google Scholar] [CrossRef]

- Eldridge, B.M.; Manzoni, L.R.; Graham, C.A.; Rodgers, B.; Farmer, J.R.; Dodd, A.N. Getting to the roots of aeroponic indoor farming. New Phytol. 2020, 228, 1183–1192. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.M.; Syed, T.N.; Chandio, F.A.; Tunio, M.H.; Ahmad, F. Overview of the aeroponic agriculture—An emerging technology for global food security. Int. J. Agric. Biol. Eng. 2020, 13, 1–10. [Google Scholar] [CrossRef]

- Aerofarms. Available online: https://aerofarms.com/ (accessed on 26 August 2023).

- Plenty. Available online: https://www.plenty.ag/ (accessed on 26 August 2023).

- Bowery. Available online: https://bowery.co/ (accessed on 26 August 2023).

- Pala, M.; Mizenko, L.; Mach, M.; Reed, T. Aeroponic greenhouse as an autonomous system using intelligent space for agriculture robotics. In Robot Intelligence Technology and Applications 2: Results from the 2nd International Conference on Robot Intelligence Technology and Applications; Kim, J.H., Matson, E., Myung, H., Xu, P., Karray, F., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 83–93. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Buttar, N.A. Modern plant cultivation technologies in agriculture under controlled environment: A review on aeroponics. J. Plant Interact. 2018, 13, 338–352. [Google Scholar] [CrossRef]

- Chowdhury, M.; Islam, M.N.; Reza, M.N.; Ali, M.; Rasool, K.; Kiraga, S.; Lee, D.L.; Chung, S.O. Sensor-based nutrient recirculation for aeroponic lettuce cultivation. J. Biosyst. Eng. 2021, 46, 81–92. [Google Scholar] [CrossRef]

- Tunio, M.H.; Gao, J.; Shaikh, S.A.; Lakhiar, I.A.; Qureshi, W.A.; Solangi, K.A.; Chandio, F.A. Potato production in aeroponics: An emerging food growing system in sustainable agriculture forfood security. Chil. J. Agric. Res. 2020, 80, 118–132. [Google Scholar] [CrossRef]

- NGS. New Growing System. Available online: https://ngsystem.com (accessed on 8 April 2023).

- Omega Garden™. Hydroponics Design. Available online: https://omegagarden.com/ (accessed on 10 July 2023).

- Farmdominium™. The Farmdominium™ Concept. Available online: https://omegagarden.com/the-farmdominium/ (accessed on 10 July 2023).

- Sananbio. Indoor Vertical Hydroponic Vegetation Cultivation Module. Available online: https://www.sananbiofarm.com/product/indoor-vertical-hydroponic-vegetation-cultivation-module (accessed on 10 July 2023).

- Alkhalidi, A.; Jarah, H.; Khawaja, M.K. Innovative design for a portable hybrid system of hydroponic and microalgae to produce food and biofuels. Clean Energy 2022, 6, 412–423. [Google Scholar] [CrossRef]

- Lambert, A. Plant Experience (PX) for Vertical Farming 2.0. Liberty Produce. 28 March 2022. Available online: https://www.liberty-produce.com/post/px-for-vertical-farming (accessed on 9 May 2023).

- Pocock, T. Light-emitting diodes and the modulation of specialty crops: Light sensing and signaling networks in plants. HortScience 2015, 50, 1281–1284. [Google Scholar] [CrossRef]

- Pattison, P.; Tsao, J.; Brainard, G.; Bugbee, B. LEDs for photons, physiology and food. Nature 2018, 563, 493–500. [Google Scholar] [CrossRef] [PubMed]

- Bantis, F.; Smirnakou, S.; Ouzounis, T.; Koukounaras, A.; Ntagkas, N.; Radoglou, K. Current status and recent achievements in the field of horticulture with the use of light-emitting diodes (LEDs). Sci. Hortic. 2018, 235, 437–451. [Google Scholar] [CrossRef]

- Nwoba, E.G.; Parlevliet, D.A.; Laird, D.W.; Alameh, K.; Moheimani, N.R. Light management technologies for increasing algal photobioreactor efficiency. Algal Res. 2019, 39, 101433. [Google Scholar] [CrossRef]

- Rehman, A.-U.; Abbasi, A.Z.; Islam, N.; Shaikh, Z.A. A review of wireless sensors and networks’ applications in agriculture. Comput. Stand. Interfaces 2014, 36, 263–270. [Google Scholar] [CrossRef]

- Singh, N.; Singh, A.N. Odysseys of agriculture sensors: Current challenges and forthcoming prospects. Comput. Electron. Agric. 2020, 171, 105328. [Google Scholar] [CrossRef]

- Sivamani, S.; Bae, N.; Cho, Y. A smart service model based on ubiquitous sensor networks using vertical farm ontology. Int. J. Distrib. Sens. Netw. 2013, 9, 161495. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Jianmin, G.; Syed, T.N.; Chandio, F.A.; Buttar, N.A.; Qureshi, W.A. Monitoring and control systems in agriculture using intelligent sensor techniques: A review of the aeroponic system. J. Sens. 2018, 2018, 8672769. [Google Scholar] [CrossRef]

- Dhanaraju, M.; Chenniappan, P.; Ramalingam, K.; Pazhanivelan, S.; Kaliaperumal, R. Smart farming: Internet of things (IoT)-based sustainable agriculture. Agriculture 2022, 12, 1745. [Google Scholar] [CrossRef]

- Kato, K.; Yoshida, R.; Kikuzaki, A.; Hirai, T.; Kuroda, H.; Hiwasa-Tanase, K.; Takane, K.; Ezura, H.; Mizoguchi, T. Molecular breeding of tomato lines for mass production of miraculin in a plant factory. J. Agric. Food Chem. 2010, 58, 9505–9510. [Google Scholar] [CrossRef]

- Borgognone, D.; Colla, G.; Rouphael, Y.; Cardarelli, M.; Rea, E.; Schwarz, D. Effect of nitrogen form and nutrient solution pH on growth and mineral composition of self-grafted and grafted tomatoes. Sci. Hortic. 2013, 149, 61–69. [Google Scholar] [CrossRef]

- Trejo-Téllez, L.I.; Gómez-Merino, F.C. Nutrient solutions for hydroponic systems. In Hydroponics—A Standard Methodology for Plant Biological Researches; Toshiki, A., Ed.; IntechOpen: Rijeka, Croatia, 2012; pp. 1–22. [Google Scholar]

- Bamsey, M.; Graham, T.; Thompson, C.; Berinstain, A.; Scott, A.; Dixon, M. Ion-specific nutrient management in closed systems: The necessity for ion-selective sensors in terrestrial and space-based agriculture and water management systems. Sensors 2012, 12, 13349–13392. [Google Scholar] [CrossRef]

- Kim, H.J.; Kim, W.K.; Roh, M.Y.; Kang, C.I.; Park, J.M.; Sudduth, K.A. Automated sensing of hydroponic macronutrients using a computer-controlled system with an array of ion-selective electrodes. Comput. Electron. Agric. 2013, 93, 46–54. [Google Scholar] [CrossRef]

- Chowdhury, M.; Jang, B.E.; Kabir, M.S.N.; Kim, Y.J.; Na, K.D.; Park, S.B.; Chung, S.O. Factors affecting the accuracy and precision of ion-selective electrodes for hydroponic nutrient supply systems. Acta Hortic. 2020, 1296, 997–1004. [Google Scholar] [CrossRef]

- Chowdhury, M.; Jang, B.E.; Kabir, M.S.N.; Lee, D.H.; Kim, H.T.; Park, T.S.; Chung, S.O. Performance evaluation of commercial ion-selective electrodes for hydroponic cultivation system. Acta Hortic. 2020, 1296, 831–838. [Google Scholar] [CrossRef]

- Jung, D.H.; Kim, H.J.; Choi, G.L.; Ahn, T.I.; Son, J.E.; Sudduth, K.A. Automated lettuce nutrient solution management using an array of ion-selective electrodes. Trans. ASABE 2015, 58, 1309–1319. [Google Scholar] [CrossRef]

- Asaduzzaman, M.; Asao, T. Autotoxicity in strawberry under recycled hydroponics and its mitigation methods. Hortic. J. 2020, 89, 124–137. [Google Scholar] [CrossRef]

- Gutiérrez, M.; Alegret, S.; Caceres, R.; Casadesús, J.; Marfa, O.; Del Valle, M. Application of a potentiometric electronic tongue to fertigation strategy in greenhouse cultivation. Comput. Electron. Agric. 2007, 57, 12–22. [Google Scholar] [CrossRef]

- Jung, D.-H.; Kim, H.-J.; Kim, H.S.; Choi, J.; Kim, J.D.; Park, S.H. Fusion of Spectroscopy and Cobalt Electrochemistry Data for Estimating Phosphate Concentration in Hydroponic Solution. Sensors 2019, 19, 2596. [Google Scholar] [CrossRef] [PubMed]

- Jung, D.H.; Kim, H.J.; Cho, W.J.; Park, S.H.; Yang, S.H. Validation testing of an ion-specific sensing and control system for precision hydroponic macronutrient management. Comput. Electron. Agric. 2019, 156, 660–668. [Google Scholar] [CrossRef]

- Tuan, V.N.; Khattak, A.M.; Zhu, H.; Gao, W.; Wang, M. Combination of multivariate standard addition technique and deep kernel learning model for determining multi-ion in hydroponic nutrient solution. Sensors 2020, 20, 5314. [Google Scholar] [CrossRef]

- Tuan, V.N.; Dinh, T.D.; Khattak, A.M.; Zheng, L.; Chu, X.; Gao, W.; Wang, M. Multivariate standard addition cobalt electrochemistry data fusion for determining phosphate concentration in hydroponic solution. IEEE Access 2020, 8, 28289–28300. [Google Scholar] [CrossRef]

- Zheng, S.; Liu, K.; Xu, Y.; Chen, H.; Zhang, X.; Liu, Y. Robust soft sensor with deep kernel learning for quality prediction in rubber mixing processes. Sensors 2020, 20, 695. [Google Scholar] [CrossRef]

- Cho, W.-J.; Kim, H.-J.; Jung, D.-H.; Han, H.-J.; Cho, Y.-Y. Hybrid signal-processing method based on neural network for prediction of NO3, K, Ca, and Mg ions in hydroponic solutions using an array of ion-selective electrodes. Sensors 2019, 19, 5508. [Google Scholar] [CrossRef] [PubMed]

- Rousseau, C.R.; Bühlmann, P. Calibration-free potentiometric sensing with solid-contact ion-selective electrodes. TrAC Trends Anal. Chem. 2021, 140, 116277. [Google Scholar] [CrossRef]

- Qi, L.; Liang, R.; Jiang, T.; Qin, W. Anti-fouling polymeric membrane ion-selective electrodes. TrAC Trends Anal. Chem. 2022, 150, 116572. [Google Scholar] [CrossRef]

- Popkova, E.G. Vertical farms based on hydroponics, deep learning, and AI as smart innovation in agriculture. In Smart Innovation in Agriculture; Popkova, E.G., Sergi, B.S., Eds.; Springer: Singapore, 2022; pp. 257–262. [Google Scholar] [CrossRef]

- de Abreu, C.L.; van Deventer, J.P. The application of artificial intelligence (AI) and internet of things (IoT) in Agriculture: A systematic literature review. In Artificial Intelligence Research; Communications in Computer and Information Science; Jembere, E., Gerber, A.J., Viriri, S., Pillay, A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; Volume 1551, pp. 32–46. [Google Scholar] [CrossRef]

- Ramakrishnam Raju, S.V.S.; Dappuri, B.; Ravi Kiran Varma, P.; Yachamaneni, M.; Verghese, D.M.G.; Mishra, M.K. Design and implementation of smart hydroponics farming using IoT-based AI controller with mobile application system. J. Nanomater. 2022, 2022, 4435591. [Google Scholar] [CrossRef]

- Lowe, M.; Qin, R.; Mao, X. A review on machine learning, artificial intelligence, and smart technology in water treatment and monitoring. Water 2022, 14, 1384. [Google Scholar] [CrossRef]

- Qazi, S.; Khawaja, B.A.; Farooq, Q.U. IoT-equipped and AI-enabled next generation smart agriculture: A critical review, current challenges and future trends. IEEE Access 2022, 10, 21219–21235. [Google Scholar] [CrossRef]

- Crisnapati, P.N.; Wardana, I.N.K.; Aryanto, I.K.A.A.; Hermawan, A. Hommons: Hydroponic management and moni-toring system for an IOT based NFT farm using web technology. In Proceedings of the 2017 5th International Conference on Cyber and IT Service Management (CITSM), Denpasar, Indonesia, 8–10 August 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Ullah, R.; Asghar, I.; Griffiths, M.G.; Stacey, C.; Stiles, W.; Whitelaw, C. Internet of things based sensor system for vertical farming and controlled environment agriculture. In Proceedings of the 2023 6th Conference on Cloud and Internet of Things (CIoT), Lisbon, Portugal, 20–22 March 2023; pp. 136–140. [Google Scholar] [CrossRef]

- Kaur, G.; Upadhyaya, P.; Chawla, P. Comparative analysis of IoT-based controlled environment and uncontrolled environment plant growth monitoring system for hydroponic indoor vertical farm. Environ. Res. 2023, 222, 115313. [Google Scholar] [CrossRef]

- Morella, P.; Lambán, M.P.; Royo, J.; Sánchez, J.C. Vertical farming monitoring: How does it work and how much does it cost? Sensors 2023, 23, 3502. [Google Scholar] [CrossRef]

- Chowdhury, M.E.H.; Khandakar, A.; Ahmed, S.; Al-Khuzaei, F.; Hamdalla, J.; Haque, F.; Reaz, M.B.I.; Al Shafei, A.; Al-Emadi, N. Design, construction and testing of IoT based automated indoor vertical hydroponics farming test-bed in Qatar. Sensors 2020, 20, 5637. [Google Scholar] [CrossRef]

- Quy, V.K.; Hau, N.V.; Anh, D.V.; Quy, N.M.; Ban, N.T.; Lanza, S.; Randazzo, G.; Muzirafuti, A. IoT-enabled smart agriculture: Architecture, applications, and challenges. Appl. Sci. 2022, 12, 3396. [Google Scholar] [CrossRef]

- Dutta, M.; Gupta, D.; Sahu, S.; Limkar, S.; Singh, P.; Mishra, A.; Kumar, M.; Mutlu, R. Evaluation of growth responses of lettuce and energy efficiency of the substrate and smart hydroponics cropping system. Sensors 2023, 23, 1875. [Google Scholar] [CrossRef]

- Rezk, N.G.; Hemdan, E.E.-D.; Attia, A.-F.; El-Sayed, A.; El-Rashidy, M.A. An efficient IoT based smart farming system using machine learning algorithms. Multimed. Tools Appl. 2021, 80, 773–797. [Google Scholar] [CrossRef]

- Grinblat, G.L.; Uzal, L.C.; Larese, M.G.; Granitto, P.M. Deep learning for plant identification using vein morphological patterns. Comput. Electron. Agric. 2016, 127, 418–424. [Google Scholar] [CrossRef]

- Mehra, M.; Saxena, S.; Sankaranarayanan, S.; Tom, R.J.; Veeramanikandan, M. IoT based hydroponics system using deep neural networks. Comput. Electron. Agric. 2018, 155, 473–486. [Google Scholar] [CrossRef]

- Franchetti, B.; Ntouskos, V.; Giuliani, P.; Herman, T.; Barnes, L.; Pirri, F. Vision based modeling of plants phenotyping in vertical farming under artificial lighting. Sensors 2019, 19, 4378. [Google Scholar] [CrossRef] [PubMed]

- Schima, R.; Mollenhauer, H.; Grenzdörffer, G.; Merbach, I.; Lausch, A.; Dietrich, P.; Bumberger, J. Imagine all the plants: Evaluation of a light-field camera for on-site crop growth monitoring. Remote Sens. 2016, 8, 823. [Google Scholar] [CrossRef]

- Paulus, S.; Behmann, J.; Mahlein, A.-K.; Plümer, L.; Kuhlmann, H. Low-cost 3D systems: Suitable tools for plant phenotyping. Sensors 2014, 14, 3001–3018. [Google Scholar] [CrossRef]

- Mavridou, E.; Vrochidou, E.; Papakostas, G.A.; Pachidis, T.; Kaburlasos, V.G. Machine vision systems in precision agriculture for crop farming. J. Imaging 2019, 5, 89. [Google Scholar] [CrossRef]

- Jiang, G.Q.; Zhao, C.J.; Si, Y.S. A machine vision based crop rows detection for agricultural robots. In Proceedings of the 2010 International Conference on Wavelet Analysis and Pattern Recognition, Qingdao, China, 11–14 July 2010; pp. 114–118. [Google Scholar] [CrossRef]

- Paul, K.; Chatterjee, S.S.; Pai, P.; Varshney, A.; Juikar, S.; Prasad, V.; Bhadra, B.; Dasgupta, S. Viable smart sensors and their application in data driven agriculture. Comput. Electron. Agric. 2022, 198, 107096. [Google Scholar] [CrossRef]

- Pérez-Bueno, M.L.; Pineda, M.; Barón, M. Phenotyping plant responses to biotic stress by chlorophyll fluorescence imaging. Front. Plant Sci. 2019, 10, 1135. [Google Scholar] [CrossRef] [PubMed]

- Zahir, S.A.D.M.; Omar, A.F.; Jamlos, M.F.; Azmi, M.A.M.; Muncan, J. A review of visible and near-infrared (Vis-NIR) spectroscopy application in plant stress detection. Sens. Actuator A Phys. 2022, 338, 113468. [Google Scholar] [CrossRef]

- Brzychczyk, B.; Hebda, T.; Fitas, J.; Giełżecki, J. The follow-up photobioreactor illumination system for the cultivation of photosynthetic microorganisms. Energies 2020, 13, 1143. [Google Scholar] [CrossRef]

- Bagha, H.; Yavari, A.; Georgakopoulos, D. IoT-based plant health analysis using optical sensors in precision agriculture. In Proceedings of the 2021 Digital Image Computing: Techniques and Applications (DICTA), Gold Coast, Australia, 29 November–1 December 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Qu, C.C.; Sun, X.Y.; Sun, W.X.; Cao, L.X.; Wang, X.Q.; He, Z.Z. Flexible wearables for plants. Small 2021, 17, 2104482. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Huang, C.H.; Singh, G.P.; Park, B.S.; Chua, N.H.; Ram, R.J. Portable Raman leaf-clip sensor for rapid detection of plant stress. Sci. Rep. 2020, 10, 20206. [Google Scholar] [CrossRef]

- Wang, T.; Xu, X.; Wang, C.; Li, Z.; Li, D. From smart farming towards unmanned farms: A new mode of agricultural production. Agriculture 2021, 11, 145. [Google Scholar] [CrossRef]

- Avgoustaki, D.D.; Avgoustakis, I.; Miralles, C.C.; Sohn, J.; Xydis, G. Autonomous mobile robot with attached multispectral camera to monitor the development of crops and detect nutrient and water deficiencies in vertical farms. Agronomy 2022, 12, 2691. [Google Scholar] [CrossRef]

- Blom, T.; Jenkins, A.; Pulselli, R.M.; Van den Dobbelsteen, A.A.J.F. The embodied carbon emissions of lettuce production in vertical farming, greenhouse horticulture, and open-field farming in the Netherlands. J. Clean. Prod. 2022, 377, 134443. [Google Scholar] [CrossRef]

- Kozai, T.; Niu, G. Role of the plant factory with artificial lighting (PFAL) in urban areas. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 7–34. [Google Scholar] [CrossRef]

- Eagle Technologies. Use Cases of Factory Automation in Vertical Farming. Factory Automation Food Processing. 2020. Available online: https://eagletechnologies.com/2020/08/03/6-use-cases-of-factory-automation-in-vertical-farming/ (accessed on 12 January 2023).

- CityCrop. Automated Indoor Farming. Available online: https://citycrop.io/ (accessed on 13 February 2023).

- Eponic Agriculture Co. Ltd. A Fully Automated Three-Dimensional Vertical Farm Comes into Operation. Available online: https://www.igrowpreowned.com/igrownews/a-fully-automated-three-dimensional-vertical-farm-comes-into-operation (accessed on 16 June 2023).

- GreenCUBE. Automated Vertical Farming System. Available online: https://tytcorp.com.sg/vertical-cultivation-system/automated-vertical-farming-system (accessed on 18 July 2023).

- iFarm. iFarm StackGrow Vertical Farming Automation Technology. Available online: https://ifarm.fi/technologies/stack-grow (accessed on 16 July 2023).

- Seasony. Making the Future of Vertical Farming Profitable, Scaleable, & Sustainable. Available online: https://seasony.io/ (accessed on 12 May 2023).

- Organifarms. Strawberry Harvesting Robot. 2022. Available online: https://www.organifarms.de/product (accessed on 12 December 2022).

- IGS. Intelligent Growth Solutions (IGS) Ltd. Growth Towers for Indoor Farming: Fully Automated Year Round Growing. Available online: https://www.intelligentgrowthsolutions.com/product/growth-towers (accessed on 15 June 2023).

- Badia Farms. The Farm Of The Future, Today. 2018. Available online: https://www.badiafarms.com/ (accessed on 12 May 2023).

- Techno Farm. Innovation: Vegetable Factory. 2023. Available online: https://www.technofarm.com/en/innovation/ (accessed on 16 March 2023).

- A-Plus. Farm & Factory TAMURA Plant Factory, Fukushima, Japan. 2021. Available online: https://www.a-plus-tamura.com/farm-factory (accessed on 18 April 2023).

- Hornayek, T. Chiba Sees Farming Revolution Budding Underground. 2019. Available online: https://shingetsunewsagency.com/2019/02/26/chiba-sees-farming-revolution-budding-underground/ (accessed on 12 February 2023).

- SANANBIO. Available online: https://www.sananbio.com/ (accessed on 26 February 2023).

- Allinson, M. Future of Agriculture: What Does Automated Vertical Farming Look Like? 2023. Available online: https://roboticsandautomationnews.com/2023/03/10/future-of-agriculture-what-does-automated-vertical-farming-look-like/64840/ (accessed on 16 July 2023).

- iFarm. Available online: https://ifarm.fi/ (accessed on 2 March 2023).

- Iron Ox. Available online: http://ironox.com/ (accessed on 5 March 2023).

- IGS. Intelligent Growth Solutions (IGS). Available online: https://www.intelligentgrowthsolutions.com/ (accessed on 10 March 2023).

- Urban Crop Solution. Available online: https://urbancropsolutions.com/ (accessed on 7 March 2023).

- Lardinois, F. Iron Ox Opens Its First Fully Autonomous Farm. 4 October 2018. Available online: https://techcrunch.com/2018/10/03/iron-ox-opens-its-first-fully-autonomous-farm/ (accessed on 18 August 2023).

- Marchant, W.; Tosunoglu, S. Robotic implementation to automate a vertical farm system. In Proceedings of the 30st Florida Conference on Recent Advances in Robotics, Florida Atlantic University, Boca Raton, FL, USA, 11–12 May 2107; Available online: https://public.eng.fau.edu/design/fcrar2017/papers/RoboticImplementation.pdf (accessed on 12 February 2023).

- AgritechTomorrow, Future Crops Brings Vertical Farming Closer to the Land. 2021. Available online: https://www.agritechtomorrow.com/story/2021/12/future-crops-brings-vertical-farming-closer-to-the-land/13356/ (accessed on 10 January 2023).

- AgriTech. Top 10 Agriculture Trends, Technologies & Innovations for 2023. 2023. Available online: https://www.startus-insights.com/innovators-guide/agriculture-trends-innovation/ (accessed on 16 July 2023).

- Nokia Bell Labs. Available online: https://www.bell-labs.com/ (accessed on 28 February 2023).

- ChemistryViews. Vertical Farming with Drones. Wiley-VCH GmbH. 11 August 2021. Available online: https://www.chemistryviews.org/details/news/11313637/Vertical_Farming_With_Drones/ (accessed on 2 March 2023).

- iFarm. Autonomous Drones Will Help to Observe Plants. Available online: https://ifarm.fi/dron_on_farm (accessed on 18 August 2023).

- Corvus Drones. Available online: https://www.corvusdrones.com/ (accessed on 20 May 2023).

- Arugga—AI Farming. Available online: https://www.arugga.com/ (accessed on 20 May 2023).

- Glick, M. Robotic Bees Could Support Vertical Farms Today and Astronauts Tomorrow. Sci. Am. 17 July 2023. Available online: https://www.scientificamerican.com/article/robotic-bees-could-support-vertical-farms-today-and-astronauts-tomorrow/ (accessed on 21 May 2023).

- Siropyan, M.; Celikel, O.; Pinarer, O. Artificial Intelligence Driven Vertical Farming Management System. In Proceedings of the World Congress on Engineering, London, UK, 6–8 July 2022; Available online: https://www.iaeng.org/publication/WCE2022/WCE2022_pp108-113.pdf (accessed on 15 April 2023).

- Talaviya, T.; Shah, D.; Patel, N.; Yagnik, H.; Shah, M. Implementation of artificial intelligence in agriculture for optimisation of irrigation and application of pesticides and herbicides. Artif. Intell. Agric. 2020, 4, 58–73. [Google Scholar] [CrossRef]

- Hwang, Y.; Lee, S.; Kim, T.; Baik, K.; Choi, Y. Crop growth monitoring system in vertical farms based on region-of-interest prediction. Agriculture 2022, 12, 656. [Google Scholar] [CrossRef]

- Vorapatratorn, S. Development of Automatic Plant Factory Control Systems with AI-Based Artificial Lighting. In Proceedings of the 2021 13th International Conference on Information Technology and Electrical Engineering (ICITEE), Chiang Mai, Thailand, 14–15 October 2021; pp. 69–73. [Google Scholar] [CrossRef]

- Rizkiana, A.; Nugroho, A.P.; Salma, N.M.; Afif, S.; Masithoh, R.E.; Sutiarso, L.; Okayasu, T. Plant growth prediction model for lettuce (Lactuca sativa.) in plant factories using artificial neural network. IOP Conf. Ser. Earth Environ. Sci. 2021, 733, 012027. [Google Scholar] [CrossRef]

- Story, D.; Kacira, M.; Kubota, C.; Akoglu, A.; An, L. Lettuce calcium deficiency detection with machine vision computed plant features in controlled environments. Comput. Electron. Agric. 2010, 74, 238–243. [Google Scholar] [CrossRef]

- Hao, X.; Jia, J.; Gao, W.; Guo, X.; Zhang, W.; Zheng, L.; Wang, M. MFC-CNN: An automatic grading scheme for light stress levels of lettuce (Lactuca sativa L.) leaves. Comput. Electron. Agric. 2020, 179, 105847. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Wang, G.; Zhang, H. Deep learning for plant identification in natural environment. Comput. Intell. Neurosci. 2017, 2017, 7361042. [Google Scholar] [CrossRef]

- Gozzovelli, R.; Franchetti, B.; Bekmurat, M.; Pirri, F. Tip-burn stress detection of lettuce canopy grown in Plant Factories. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Montreal, BC, Canada, 11–17 October 2021; pp. 1259–1268. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, R.; Gao, F.; Wang, W.; Fu, L.; Li, R. Segmentation of abnormal leaves of hydroponic lettuce based on DeepLabV3+ for robotic sorting. Comput. Electron. Agric. 2021, 190, 106443. [Google Scholar] [CrossRef]

- Hendrawan, Y.; Damayanti, R.; Al Riza, D.F.; Hermanto, M.B. Classification of water stress in cultured Sunagoke moss using deep learning. TELKOMNIKA Telecommun. Comput. Electron. Control 2021, 19, 1594–1604. [Google Scholar] [CrossRef]

- Lee, U.; Chang, S.; Putra, G.A.; Kim, H.; Kim, D.H. An automated, high-throughput plant phenotyping system using machine learning-based plant segmentation and image analysis. PLoS ONE 2018, 13, e0196615. [Google Scholar] [CrossRef] [PubMed]

- Lauguico, S.; Concepcion, R.; Tobias, R.R.; Alejandrino, J.; Guia, J.D.; Guillermo, M.; Sybingco, E.; Dadios, E. Machine Vision-Based Prediction of Lettuce Phytomorphological Descriptors using Deep Learning Networks. In Proceedings of the IEEE 12th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Manila, Philippines, 3–7 December 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Moshou, D.; Pantazi, X.E.; Kateris, D.; Gravalos, I. Water stress detection based on optical multisensor fusion with a least squares support vector machine classifier. Biosyst. Eng. 2014, 117, 15–22. [Google Scholar] [CrossRef]

- Kim, S.; Lee, M.; Shin, C. IoT-based strawberry disease prediction system for smart farming. Sensors 2018, 18, 4051. [Google Scholar] [CrossRef]

- Anubhove, M.S.T.; Ashrafi, N.; Saleque, A.M.; Akter, M.; Saif, S.U. Machine learning algorithm based disease detection in tomato with automated image telemetry for vertical farming. In Proceedings of the International Conference on Computational Performance Evaluation (ComPE), Shillong, India, 2–4 July 2020; pp. 250–254. [Google Scholar] [CrossRef]

- Alejandrino, J.; Concepcion, R.; Lauguico, S.; Tobias, R.R.; Almero, V.J.; Puno, J.C.; Bandala, A.; Dadios, E.; Flores, R. Visual classification of lettuce growth stage based on morphological attributes using unsupervised machine learning models. In Proceedings of the IEEE Region 10 Conference (TENCON), Osaka, Japan, 16–19 November 2020; pp. 438–443. [Google Scholar] [CrossRef]

- Gowtham, R.; Jebakumar, R. Analysis and prediction of lettuce crop yield in aeroponic vertical farming using logistic regression method. In Proceedings of the 2023 International Conference on Sustainable Computing and Data Communication Systems (ICSCDS), Erode, India, 23–25 March 2023; pp. 759–764. [Google Scholar] [CrossRef]

- Mamatha, V.; Kavitha, J.C. Machine learning based crop growth management in greenhouse environment using hydroponics farming techniques. Meas. Sens. 2023, 25, 100665. [Google Scholar] [CrossRef]

- Obu, U.; Sarkarkar, G.; Ambekar, Y. Computer Vision for Monitor and Control of Vertical Farms Using Machine Learning Methods. In Proceedings of the International Conference on Computational Intelligence and Computing Applications (ICCICA), Nagpur, India, 26–27 November 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Jayasekara, C.; Banneka, S.; Pasindu, G.; Udawaththa, Y.; Wellalage, S.; Abeygunawardhane, P.K.W. Automated crop harvesting, growth monitoring and disease detection system for vertical farming greenhouse. In Proceedings of the 3rd International Conference on Advancements in Computing (ICAC), Colombo, Sri Lanka, 9–11 December 2021; pp. 228–233. [Google Scholar] [CrossRef]

- Chang, S.; Lee, U.; Hong, M.J.; Jo, Y.D.; Kim, J.B. Time-series growth prediction model based on U-net and machine learning in Arabidopsis. Front. Plant Sci. 2021, 12, 721512. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Sánchez-Molina, J.A.; Li, M.; Berenguel, M.; Yang, X.T.; Bienvenido, J.F. Leaf area index estimation for a greenhouse transpiration model using external climate conditions based on genetics algorithms, back-propagation neural networks and nonlinear autoregressive exogenous models. Agric. Water Manag. 2017, 183, 107–115. [Google Scholar] [CrossRef]

- Nagano, S.; Moriyuki, S.; Wakamori, K.; Mineno, H.; Fukuda, H. Leaf-movement-based growth prediction model using optical flow analysis and machine learning in plant factory. Front. Plant Sci. 2019, 10, 227. [Google Scholar] [CrossRef]

- Petropoulou, A.S.; van Marrewijk, B.; de Zwart, F.; Elings, A.; Bijlaard, M.; van Daalen, T.; Jansen, G.; Hemming, S. Lettuce production in intelligent greenhouses—3D imaging and computer vision for plant spacing decisions. Sensors 2023, 23, 2929. [Google Scholar] [CrossRef]

- Galaz, V.; Centeno, M.A.; Callahan, P.W.; Causevic, A.; Patterson, T.; Brass, I.; Baum, S.; Farber, D.; Fischer, J.; Garcia, D.; et al. Artificial intelligence, systemic risks, and sustainability. Technol. Soc. 2021, 67, 101741. [Google Scholar] [CrossRef]

- Vela, D.; Sharp, A.; Zhang, R.; Nguyen, T.; Hoang, A.; Pianykh, O.S. Temporal quality degradation in AI models. Sci. Rep. 2022, 12, 11654. [Google Scholar] [CrossRef] [PubMed]

- Avgoustaki, D.D.; Xydis, G. Indoor vertical farming in the urban nexus context: Business growth and resource savings. Sustainability 2020, 12, 1965. [Google Scholar] [CrossRef]

- Mitchell, C.A. History of controlled environment horticulture: Indoor farming and its key technologies. HortScience 2022, 57, 247–256. [Google Scholar] [CrossRef]

- Armanda, D.T.; Guinée, J.B.; Tukker, A. The second green revolution: Innovative urban agriculture’s contribution to food security and sustainability—A review. Glob. Food Sec. 2019, 22, 13–24. [Google Scholar] [CrossRef]

- Hardy, K.; Orridge, T.; Heynes, X.; Gunasena, S.; Grundy, S.; Lu, C. Farming the future: Contemporary innovations enhancing sustainability in the agri-sector. Annu. Plant Rev. 2021, 4, 263–294. [Google Scholar] [CrossRef]

- Piechowiak, M. Countries Using Vertical Farming, Vertical Farming Planet. Available online: https://verticalfarmingplanet.com/countries-using-vertical-farming/#:~:text=There%20are%20currently%20over%20200,that%20focus%20on%20producing%20vegetables (accessed on 2 September 2023).

- Takeshima, H.; Joshi, P.K. Protected Agriculture, Precision Agriculture, and Vertical Farming: Brief Reviews of Issues in the Literature Focusing on the Developing Region in Asia. 2019. Available online: https://www.ifpri.org/publication/protected-agriculture-precision-agriculture-and-vertical-farming-brief-reviews-issues (accessed on 2 September 2023).

- Kalantari, F.; Tahir, O.M.; Joni, R.A.; Fatemi, E. Opportunities and challenges in sustainability of vertical farming: A review. J. Landsc. Ecol. 2018, 11, 35–60. [Google Scholar] [CrossRef]

- Takada, A. As High-Rise Farms Go Global, Japan’s Spread Leads the Way. Available online: https://www.japantimes.co.jp/news/2018/11/01/business/tech/high-rise-farms-go-global-japans-spread-leads-way/ (accessed on 28 January 2023).

- Wen, X. Vertical Farming Reaches New Heights. 13 April 2023. Available online: https://www.chinadaily.com.cn/a/202304/13/WS64373a55a31057c47ebb9cb0_3.html (accessed on 20 February 2023).

- Yan, X. Chinese Startup Gets in on Ground Floor of High-Rise Farms. 17 August 2020. Available online: https://asia.nikkei.com/Business/Startups/Chinese-startup-gets-in-on-ground-floor-of-high-rise-farms (accessed on 20 February 2023).

- Ning, S.; Xydis, G. PEST analysis of the future Chinese vertical farming market: Environmental sustainability and energy savings. AIMS Agric. Food 2023, 8, 496–512. [Google Scholar] [CrossRef]

- Chatterjee, A.; Debnath, S.; Pal, H. Implication of urban agriculture and vertical farming for future sustainability. In Urban Horticulture; Solankey, S.S., Ed.; IntechOpen: Rijeka, Croatia, 2020; pp. 1–11. [Google Scholar] [CrossRef]

- Kollenberg, K.A. Vertical Farming; Can Urban Agriculture Feed a Hungry World? 22 July 2011. Available online: https://cityfarmer.info/south-korean-city-of-suwon-has-a-vertical-farm/ (accessed on 22 December 2022).

- John. The Rise of Smart Vertical Farms in Korea—The Future of Farming. 25 May 2022. Available online: https://www.seoulz.com/the-rise-of-smart-vertical-farms-in-korea-the-future-of-farming/ (accessed on 5 January 2023).

- NextOn. Available online: http://nexton.ag/about/index.php (accessed on 10 February 2023).

- Farm8. Available online: http://en.farm8.co.kr/ (accessed on 10 February 2023).

- N.Thing. Available online: https://nthing.net/TECH (accessed on 10 February 2023).

- ALGA Farmtech. Available online: http://en.algafarmtech.com/index (accessed on 10 February 2023).

- Mordor Intelligence. Vertical Farming Market Size & Share Analysis-Growth Trends & Forecasts (2023–2028). Available online: https://www.mordorintelligence.com/industry-reports/vertical-farming-market (accessed on 2 April 2023).

- 80 Acres Farms. Available online: https://www.80acresfarms.com/ (accessed on 12 April 2023).

- Kozai, T.; Niu, G. Selected PFALs in the United States, the Netherlands, and China. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 419–436. [Google Scholar] [CrossRef]

- American Hydroponics. Available online: https://amhy-dro.com/ (accessed on 31 May 2023).

- Bright Farms. Available online: https://www.brightfarms.com/ (accessed on 31 May 2023).

- Hort Americas. Available online: https://hortameri-cas.com/ (accessed on 31 May 2023).

- The Plant. Available online: https://www.insidetheplant.com/ (accessed on 31 May 2023).

- FarmedHere. Available online: http://www.farmedhere.com/ (accessed on 31 May 2023).

- 80 Acres Farms Layoffs Linked to Industry & Other Collapses. Available online: : https://igrownews.com/80-acres-farms-layoffs-linked-to-industry-other-collapses/ (accessed on 31 May 2023).

- den Besten, J. Vertical farming development; the Dutch approach. In Plant Factory Using Artificial Light; Anpo, M., Fukuda, H., Wada, T., Eds.; Elsevier: Cambridge, MA, USA, 2019; pp. 307–317. [Google Scholar] [CrossRef]

- Benis, K.; Ferrão, P. Commercial farming within the urban built environment–Taking stock of an evolving field in northern countries. Glob. Food Sec. 2018, 17, 30–37. [Google Scholar] [CrossRef]

- PlantLab. Available online: https://plantlab.com/ (accessed on 15 April 2023).

- UrbanFarmers. Available online: http://www.urbanfarmers.nl/ (accessed on 15 April 2023).

- B-Four Agro. Available online: https://b4agro.nl/ (accessed on 15 April 2023).

- Agricool. Available online: https://www.agritec-tu-re.com/agricool/ (accessed on 2 June 2023).

- Infarm. Available online: https://www.infarm.com/ (accessed on 2 June 2023).

- Farmers Cut. Available online: https://farmerscut.com/ (accessed on 2 June 2023).

- Architects, S. A New Model for Urban Farming for the World’s Largest Agricultural Producer and Consumer: China, Sunqiao Urban Agricultural District. Available online: https://www.sasaki.com/projects/sunqiao-urban-agricultural-district/ (accessed on 12 July 2023).

- La Tour Vivante—The Living Tower. SOA Architectes. Available online: https://archello.com/project/la-tour-vivante-the-living-tower (accessed on 10 June 2023).

- Jian Mu Tower. Farmscraper—Tall Building Design Meets Urban Farming. 2021. Available online: https://carloratti.com/project/jian-mu-tower/ (accessed on 9 May 2023).

- Jordana, S. Harvest Green Project/Romses Architects. ArchDaily. 7 May 2009. Available online: https://www.archdaily.com/21555/harvest-green-project-romses-architects (accessed on 18 June 2023).

- Romses Architects. Harvest Green Tower. Available online: http://www.romsesarchitects.com/harvest_green.html (accessed on 18 June 2023).

- Urban Skyfarm. Available online: http://www.aprilli.com/urban-skyfarm/ (accessed on 12 April 2023).

- Peters, A. This Tree-Shaped Farm-On-A-Skyscraper Could Bring Acres of Crops into the City. Available online: https://www.fastcompany.com/3032379/this-tree-shaped-farm-on-a-skyscraper-could-bring-acres-of-crops-into-the-city (accessed on 12 April 2023).

- Spread Co., Ltd. Largest FoodTech Deal in Japan: Vertical Farming Startup Spread Raises $30 Million to Accelerate Its Business. 2 August 2022. Available online: https://spread.co.jp/uploads/news-release_20220802-1.pdf (accessed on 22 May 2023).

- Hive-InnTM City Farm. New York, NY, USA. Available online: https://www.ovastudio.com/work/hive-inn-city-farm-nyc (accessed on 12 December 2022).

- Markham, D. Repurposed Shipping Containers May Be Building Blocks for Modular Vertical Urban Farms. Treehugger News. 11 October 2018. Available online: https://www.treehugger.com/shipping-container-repurposed-vertical-urban-farm-4855558 (accessed on 12 December 2022).

- Orsini, F.; Pennisi, G.; Zulfiqar, F.; Gianquinto, G. Sustainable use of resources in plant factories with artificial lighting (PFALs). Eur. J. Hortic. Sci. 2020, 85, 297–309. [Google Scholar] [CrossRef]

- Roberts, J.M.; Bruce, T.J.A.; Monaghan, J.M.; Pope, T.W.; Leather, S.R.; Beacham, A.M. Vertical farming systems bring new considerations for pest and disease management. Ann. Appl. Biol. 2020, 176, 226–232. [Google Scholar] [CrossRef]

- Hegedűs, C.; Frankó, A.; Varga, P.; Gindl, S.; Tauber, M. Enabling Scalable Smart Vertical Farming with IoT and Machine Learning Technologies. In Proceedings of the NOMS 2023—2023 IEEE/IFIP Network Operations and Management Symposium, Miami, FL, USA, 8–12 May 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Mempel, H.; Jüttner, I.; Wittmann, S. The potentials of indoor farming for plant production. Automatisierungstechnik 2021, 69, 287–296. [Google Scholar] [CrossRef]

- Zhu, X.-G.; Marcelis, L. Vertical farming for crop production. Mod. Agric. 2023, 1, 13–15. [Google Scholar] [CrossRef]

- Naqvi, S.M.Z.A.; Saleem, S.R.; Tahir, M.N.; Hussain, S.; Ul Haq, S.I.; Awais, M.; Qamar, S. Vertical Farming-Current Practices and Its Future. Environ. Sci. Proc. 2022, 23, 4. [Google Scholar] [CrossRef]

- Sarkar, A.; Majumder, M. Opportunities and challenges in sustainability of vertical eco-farming: A review. J. Adv. Agric. Technol. 2015, 2, 98–105. [Google Scholar] [CrossRef]

- Abdullah, M.J.; Zhang, Z.; Matsubae, K. Potential for food self-sufficiency improvements through indoor and vertical farming in the gulf cooperation council: Challenges and opportunities from the case of Kuwait. Sustainability 2021, 13, 12553. [Google Scholar] [CrossRef]

- Csordás, A.; Füzesi, I. The impact of technophobia on vertical farms. Sustainability 2023, 15, 7476. [Google Scholar] [CrossRef]

- Siregar, R.R.A.; Seminar, K.B.; Wahjuni, S.; Santosa, E. Vertical farming perspectives in support of precision agriculture using artificial intelligence: A review. Computers 2022, 11, 135. [Google Scholar] [CrossRef]

- Kim, H.-G.; Park, D.-H.; Chowdhury, O.R.; Shin, C.-S.; Cho, Y.-Y.; Park, J.-W. Location-based intelligent robot management service model using RGPSi with AoA for vertical farm. Lect. Notes Electr. Eng. 2014, 279, 309–314. [Google Scholar] [CrossRef]

- Swain, M. Vertical farming trends and challenges: A new age of agriculture using IoT and machine learning. In Internet of Things for Agriculture 4.0: Impact and Challenges; Sing, R.S., Thakur, A.K., Gehlot, A., Kaviti, A.K., Eds.; Academic Press: Boca Raton, FL, USA, 2022; pp. 1–16. [Google Scholar]

- Shrivastava, A.; Nayak, C.K.; Dilip, R.; Samal, S.R.; Rout, S.; Ashfaque, S.M. Automatic robotic system design and development for vertical hydroponic farming using IoT and big data analysis. Mater. Today Proc. 2023, 80, 3546–3553. [Google Scholar] [CrossRef]

- Larsen, D.H.; Woltering, E.J.; Nicole, C.C.S.; Marcelis, L.F.M. Response of basil growth and morphology to light intensity and spectrum in a vertical farm. Front. Plant Sci. 2020, 11, 597906. [Google Scholar] [CrossRef] [PubMed]

- Lehnert, C.; McCool, C.; Sa, I.; Perez, T. Performance improvements of a sweet pepper harvesting robot in protected cropping environments. J. Field Robot. 2020, 37, 1197–1223. [Google Scholar] [CrossRef]

| Considered Parameters | Hydroponics Techniques | |||||

|---|---|---|---|---|---|---|

| NFT | DWC | Ebb–Flow | Aeroponics | Drip | Wick | |

| Suitability for vertical farming | High | High | High | High | Low | Low |

| Nutrient use efficiency | High | Low | Low | High | Low | Low |

| Aeration requirement | Low | High | Low | Low | Low | Low |

| Salt build-up possibility | Low | High | Low | Low | High | High |

| Root-rot possibility | Low | High | Low | Low | High | High |

| Water saving | High | Low | Low | High | High | High |

| Long growing period | Low | Low | Low | Low | High | Low |

| Energy use | Low | Low | Low | High | Low | Low |

| Pump-failure sensitivity | High | Low | High | High | Low | Low |

| Setup cost | High | Low | Low | High | High | Low |

| Maintenance complexity | Low | Low | Low | High | Low | Low |

| Item | Type | Specification | Applications | Image |

| Sensors | Temperature and humidity | Measuring range: −40–80 °C, 0–100%; Accuracy: ±2%, ±3%; Response time: 5 s; Resolution: 0.1 °C, 0.01%; Power input: 3.3–5.5 V |

|  |

| CO2 | Measuring range: 0–10,000 ppm; Accuracy: ±5% Response time: 10 s; Resolution: 1 ppm; Power input: 3.3–5.5 V |

|  | |

| Light intensity | Measuring range: 0–3000 W/m2; Accuracy: ±1% Response time: 10 µs; Sensitivity: 4 μA per 1000 PPFD in water |

|  | |

| Electrical conductivity (EC) | Meas. Range: 0–20,000 µS/cm; Accuracy: ±4–8% Response time: 5 s; Resolution: 1 ppm; Power input: 5 V |

|  | |

| pH | Measuring range: 0–14; Accuracy: ±0.2%; Response time: 1 s Resolution: 1 ppm; Power input: 5 V |

|  | |

| Ion-selective electrode (ISE) | Measuring range: 1–14,000 ppm; Accuracy: ±10% Response time: 1 s; Resolution: 1 ppm; Power input: 5 V |

|  | |

| Dissolved oxygen (DO) | Measuring range: 0–20 ppm; Accuracy: ±2%; Response time: 40 s; Resolution: 0.006 ppm; Power input: 5 V |

|  | |

| Water level | Measuring range: 0.1–3 m; Accuracy: ±0.2%; Resolution: 0.5 mm Dead band: 0.1 m; Power input: 12–28 V |

|  | |

| Actuators | Heater | Power input: 110, 220 V; Power: 2.8 kW |

|  |

| Cooler | Power input: 110, 220 V; Lowest temp: 0 °C; Coverage: 450 m2 |

|  | |

| Humidifier | Power input: 110, 220 V; Coverage: 2000 m2; Power: 2.2 kW |

|  | |

| Dehumidifier | Power input: 110, 220 V; Humidity removal: 2.5 L/h Air flow rate: 30 m3/h; Coverage: 50–100 m2 |

|  | |

| LEDs | Power input: 110, 220 V; Light intensity: 17,400 flux; Output: 300 W |

|  | |

| Fan | Power input: 110, 220 V; Air flow rate: 4400 m3/h Output: 1.1 kW, 437 rpm |

|  | |

| CO2 regulator | Power input: 110, 220 V; Flow rate: 0.5–15 SCFH Control type: Digital, solenoid |

|  | |

| Nutrient pump | Power input: 110, 220 V; Maximum flow: 100 L/min Maximum head: 24 m; Power: 0.75 HP/0.55 kW |

|  |

| Vertical Farm | Location | Key Technical Features | Reference |

|---|---|---|---|

| GreenCUBE | Singapore |

| [121] |

| iFarm | Helsinki, Finland |

| [122] |

| Seasony | Copenhagen, Denmark |

| [123] |

| Organifarms | Konstanz, Germany |

| [124] |

| Eagle Technologies | Michigan, USA |

| [118] |

| Intelligent Growth Solutions | Edinburgh, Scotland |

| [125] |

| Badia Farms | Dubai, United Arab Emirates |

| [126] |

| Spread (Techno Farm Keihanna) | Kyoto, Japan |

| [127] |

| A-Plus (Farm and Factory TAMURA) | Fukushima, Japan |

| [128] |

| Itoh Denki | Kasai, Japan |

| [129] |

| Model/Algorithm | Observed Features | Accuracy (%) | Plant Type (Application) | Reference |

|---|---|---|---|---|

| CNN, ResNet50 | Plant leaf | 86.0 | Lettuce (disease detection and identification) | [146] |

| 3D plant modeling, deep segmentation | Plant height, leaf area, leaf weight | - | Basil (phenotyping) | [102] |

| Mask-RCNN with pseudo crop mixing | Leaf area | 76.9 | Lettuce (growth monitoring) | [148] |

| ANN algorithm, big data | Plant growth | 98.32 | Lettuce (growth prediction) | [149] |

| ANN, backpropagation | Plant height | 72.8 | Lettuce (growth prediction) | [150] |

| Dual segmented regression | Plant leaf | 97.0 | Lettuce (leaf stress) | [151] |

| MFC-CNN | Plant leaf | 87.95 | Lettuce (leaf stress) | [152] |

| CNN, ResNet26 | Plant leaf | 91.78 | Mix plants (plant stress) | [153] |

| WGAN, deep CNN architectures | Plant leaf | 87.0 | Lettuce (leaf stress) | [154] |

| DeepLabV3+ | Plant leaf | 83.26 | Lettuce (leaf abnormalities) | [155] |

| Deep-learning models | Plant leaf | 94.15 | Moss (water stress) | [156] |

| RF, SVM, MLP | Plant leaf | 95.3, 72.9, 84.4 | Rosette (phenotyping) | [157] |

| InceptionResNetv2, Xception, DarkNet 53 | Plant leaf | 82.0, 75.0, 98.0 | Lettuce (phytomorphological attributes) | [158] |

| LSSVM | Plant leaf | 99.0 | Wheat (water stress) | [159] |

| Neural network, SVM classifier | Plant growth | 80.0 | Strawberry (disease detection) | [160] |

| Viola–Jones algorithm, Haar | Fruit | - | Tomato (disease detection) | [161] |

| Self-organizing map (SOM), hierarchical, K-means | Plant leaf | 91.3, 98.6, 99.1 | Lettuce (growth prediction) | [162] |

| Logistic regression | Plant growth | 97.1 | Lettuce (yield) | [163] |

| KNN algorithm | Plant growth | 93.0 | Leafy vegetables (growth) | [164] |

| Reinforcement learning | Plant leaf | 82.0 | Chili, beans, potatoes, onions (phenotyping) | [165] |

| MobileNetV2 | Plant leaf | 98.4 | Lettuce (growth prediction) | [166] |

| U-Net | Leaf area, fresh weight | 97.0 | Arabidopsis (phenotyping) | [167] |

| Genetics algorithms, back propagation | Leaf area | 99.3 | Tomato (LAI) | [168] |

| DeepFlow, principal-component analysis | Plant area, weight | 74.3 | Lettuce (growth prediction) | [169] |

| Deepabv3+ | Plant height, coverage | 98.2 | Lettuce (plant spacing) | [170] |

| Vertical Farm, Location | Types of Crops | Production Capacity | Cultivation System | Technical Features | Website |

|---|---|---|---|---|---|

| Shinnippo Ltd. 808 Factory, Shizuoka, Japan | Mainly lettuce (frilly, green leaf, silky, and romaine) |

|

|

| https://www.808factory.jp/ (accessed on 7 March 2023) |

| Spread Co., Ltd., Kyoto, Japan | Leafy greens (lettuce), strawberries |

| DFT |

| https://spread.co.jp/en/ (accessed on 7 March 2023) |

| Mirai Co. Ltd., Chiba, Japan | Greenleaf, kale, oakleaf, spinach, basil |

| DFT |

| https://miraigroup.jp/ (accessed on 7 March 2023) |

| N.Thing, Seoul, South Korea | Salad vegetables |

| Modular hydroponics |

| https://nthing.net/ (accessed on 10 February 2023) |

| NextOn, Seoul, South Korea | Special leafy vegetables (caipira, ezatrix, Isabelle), herbs, strawberries, biomaterial |

| Smart hydroponics |

| http://nexton.ag/farm/index.php (accessed on 7 March 2023) |

| Farm8, Gyeonggi-do, South Korea | Salad vegetables, special vegetables (herbs, asparagus, minivegetables, etc.) |

| Hydroponics |

| http://en.farm8.co.kr/ (accessed on 10 February 2023) |

| SANANBIO, Fujian, China | Leafy greens, fruits, microgreens, herbs, medicinal plants, edible flowers, etc. |

| NFT-DWC hybrid irrigation |

| https://www.sananbiofarm.com/ (accessed on 7 March 2023) |

| Vertical Farm, Location | Types of Crops | Production Capacity | Cultivation System | Technical Features | Website |

|---|---|---|---|---|---|

| 80 Acres Urban Agriculture limited liability company (LLC), Ohio, USA | Lettuce, rocket (arugula), kale, basil, microgreens | 90,718.4 kg/year | NFT |

| https://www.80acresfarms.com/ (accessed on 12 April 2023) |

| AeroFarms, New Jersey, USA | Baby bok choy, spinach, and micro arugula, broccoli, and kale | 907,184 kg/year | Aeroponics |

| https://www.aerofarms.com/ (accessed on 7 March 2023) |

| American Hydroponics, California, USA | Leafy greens, herbs, tomatoes, peppers, cucumbers | NFT, Bato bucket, and gutter |

| https://amhydro.com/ (accessed on 7 March 2023) | |

| Bright Farms, New York, USA | Lettuce, butterhead lettuce, baby spinach, basil, chickpeas | Hydroponics |

| https://www.brightfarms.com/ (accessed on 31 May 2023) | |

| Gotham Greens, New York, USA | Lettuces, herbs | 136,000 kg/year | NFT |

| https://www.gothamgreens.com/ (accessed on 7 March 2023) |

| Plenty Unlimited, California, USA | Lettuce | Hydroponics |

| https://www.plenty.ag/ (accessed on 26 August 2023) | |

| Bowery Farming, New York, USA | Leafy greens, lettuce, herbs, tomatoes | Aeroponics |

| https://bowery.co/ (accessed on 26 August 2023) | |

| Altius Farms, Washington, USA | Variety of leafy greens, herbs | Aeroponics |

| https://altiusfarms.com/ (accessed on 7 March 2023) | |

| Green Spirit Farms, Colorado, USA | Variety of leafy greens, herbs | 38,100 kg/year | Aeroponics |

| https://www.greenspiritliving.com/https://altiusfarms.com/ (accessed on 7 March 2023) |

| Vertical Farm, Location | Types of Crops | Production Capacity | Cultivation System | Technical Features | Website |

|---|---|---|---|---|---|

| PlantLab, Hertogenbosch, Netherlands | Lettuce, basil, mint, coriander, fresh-cut herbs, tomatoes | - | Aeroponics |

| https://plantlab.com/ (accessed on 15 April 2023) |

| Jones Food Company, North Lincolnshire, England | Lettuce, cress, komatsuna, hazel, basil, coriander, parsley, mint, dill, rocket, strawberries | 136,078 kg/year | Aeroponics |

| https://www.jonesfoodcompany.co.uk/ (accessed on 7 March 2023) |

| Agricool, Paris, France | Strawberries, basil, arugula | - | Aeroponics |

| https://www.agritecture.com/agricool (accessed on 7 March 2023) |

| Infarm, Berlin, Germany | Lettuce, tomatoes, cucumbers, herbs, microgreens, mushrooms, leafy greens | - | Aeroponics |

| https://www.infarm.com/ (accessed on 2 June 2023) |

| B-Four Agro, Warmenhuizen, Netherlands | Leafy greens, lettuce, kale, spinach | - | Aeroponics |

| https://b4agro.nl/ (accessed on 15 April 2023) |

| Byspire, Oslo, Norway | Lettuce, kale, spinach | 50,000 plants/year | Aeroponics |

| https://www.byspire.no/ (accessed on 7 March 2023) |

| CityFarm, Stockholm, Sweden | Lettuce, arugula, basil | - | Closed-loop aeroponics |

| www.cityfarmer.org (accessed on 7 March 2023) |

| Deliscious, Beesel, Netherlands | Lettuce | - | Aeroponics |

| https://www.deliscious.eu/ (accessed on 7 March 2023) |

| Farmers Cut, Hamburg, Germany | Leafy greens, microgreens, herbs, cress | 400 kg/day | Aeroponics |

| https://farmerscut.com/ (accessed on 2 June 2023) |

| Future Crops, Poeldijk, Netherlands | Herbs, lettuce, baby lettuce, basil, cilantro, parsley | 77,100 kg/year | Aeroponics |

| http://www.future-crops.com/ (accessed on 7 March 2023) |

| BrightBox, Venlo, Netherlands | Lettuce, arugula, basil | - | Aeroponics |

| https://brightbox-venlo.nl/en/ (accessed on 7 March 2023) |

| Urbanika Farms, Kraków, Poland | Lettuce, arugula, basil | - | Hydroponics |

| https://www.urbanikafarms.com/ (accessed on 7 March 2023) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabir, M.S.N.; Reza, M.N.; Chowdhury, M.; Ali, M.; Samsuzzaman; Ali, M.R.; Lee, K.Y.; Chung, S.-O. Technological Trends and Engineering Issues on Vertical Farms: A Review. Horticulturae 2023, 9, 1229. https://doi.org/10.3390/horticulturae9111229

Kabir MSN, Reza MN, Chowdhury M, Ali M, Samsuzzaman, Ali MR, Lee KY, Chung S-O. Technological Trends and Engineering Issues on Vertical Farms: A Review. Horticulturae. 2023; 9(11):1229. https://doi.org/10.3390/horticulturae9111229

Chicago/Turabian StyleKabir, Md Shaha Nur, Md Nasim Reza, Milon Chowdhury, Mohammod Ali, Samsuzzaman, Md Razob Ali, Ka Young Lee, and Sun-Ok Chung. 2023. "Technological Trends and Engineering Issues on Vertical Farms: A Review" Horticulturae 9, no. 11: 1229. https://doi.org/10.3390/horticulturae9111229

APA StyleKabir, M. S. N., Reza, M. N., Chowdhury, M., Ali, M., Samsuzzaman, Ali, M. R., Lee, K. Y., & Chung, S.-O. (2023). Technological Trends and Engineering Issues on Vertical Farms: A Review. Horticulturae, 9(11), 1229. https://doi.org/10.3390/horticulturae9111229