1. Introduction

Crop load management is undertaken in modern apple (

Malus x domestica Borkh.) production to ensure regular bearing and good fruit quality, and according to Looney [

1], fruit thinning is considered one of the most important orchard management practices. Thinning early in the season, before cell division is complete, enables maximisation of carbohydrate availability, optimising yield and fruit quality and reducing the risk of biennial bearing [

2]. The standard industry practice for crop load management in many countries is based on chemical thinning (CT), with thinning chemicals applied during the bloom and post-bloom periods, followed up with hand thinning. However, the response to chemical thinning is very weather-dependent and there is considerable variation between cultivars in sensitivity to thinning chemicals [

3].

This lack of predictability, combined with an increasing awareness of the environmental impact of many chemicals and the loss of registration of some chemicals, points to a need to find alternate environmentally acceptable methods for managing crop load [

4]. Several different methods of crop manipulation have been described by Costa et al. [

5], including mechanical thinning, flower thinning by hand, and bud extinction during the dormant winter period. Kirstein [

6] also reports on the use of mechanical thinning as an alternative to chemical thinning.

Mechanical thinning has advantages in that the thinning result is immediately visible and environmental conditions do not affect efficacy [

5]. However, there are also disadvantages such as damage to trees, lack of selectivity, and the risk of spreading disease [

7]. For mechanical thinning to be effective, Kirstein [

6] concluded that tree architecture needs to be suited to the particular machine and the orchard floor needs to be clean and level and recommended that, for future adoption of mechanical thinning, new orchards should be established with mechanisation in mind.

It was noted by Lauri et al. [

8,

9] that in cultivars expressing high natural spur extinction, defined as natural abortion of a proportion of growing buds, the remaining floral structures bear fruit and produce bourse shoots that flower the following season, known as the bourse-over-bourse phenomenon. Cultivars characterised by alternate bearing can be encouraged to produce more regularly by reducing the number of axillary shoots along the branches [

10]. This is the basis of artificial bud extinction (ABE), which imitates natural bud extinction by reducing bud density through manual removal of floral buds during late winter or early spring. Buds are preferentially removed from the underside of limbs and shaded areas of the canopy. This allows for precision crop load management as it precisely defines not only how much fruit is set on each limb of the tree, but also where it is positioned.

Because the bulk of the thinning is completed prior to flowering, there is minimal resource wastage in ABE-managed trees. Hence, fruit size is greater than in conventionally-managed trees [

11,

12]. There is also a positive response in fruit set of individual buds with the proportion of buds failing to set fruit being reduced and an increased proportion of buds setting multiple fruit [

11,

13]. Higher yields have also been demonstrated on ABE trees over unmodified trees [

14]. Lauri et al. [

15] concluded that the elimination of shaded laterals and improved light distribution within the tree canopy that results from bud extinction not only improves fruit quality, but also promotes bud organogenesis, resulting in higher return bloom and reducing the risk of biennial bearing.

Several studies examining ABE have postulated that crop load management through ABE was preferable to conventional thinning programs [

13,

16,

17,

18], but these studies have used hand-thinning rather than CT for their conventional management practice, and do not provide evidence that ABE can outperform CT. As well as a lack of comparison of ABE with best practice CT programs, there is no information about the economics of ABE management. As growers are relatively comfortable with the use of CT as a crop load management tool, and ABE is a new tool requiring a paradigm shift, a comparison with CT is required. Several trials were established to determine how ABE technology compares with best practice CT programs in terms of yield, fruit quality, and cost.

2. Materials and Methods

Three small plot field trials (Trials 1–3) and one demonstration trial (Trial 4) were undertaken from 2013 to 2017 in commercial orchards in the Huon Valley in Tasmania to compare the effect of ABE and CT on yields and fruit quality. An economic analysis was undertaken on Trial 4. ‘Gala’ was selected in Trials 1, 2 and 4 as it is a cultivar that is widely grown in Australia. ‘Fuji’ was selected in Trial 3 as it has a strong propensity for biennial bearing.

All trees were on M26 rootstocks and trained to a central leader system. Row orientation was east/west and tree spacing was 4 m between rows and 1 m within the rows. Other trial details are shown in

Table 1.

2.1. Treatment Design

Trial 1 was in a ‘Royal Gala’ trial block that was originally established in 2010 [

19]. Crop management in this block was either by ABE or conventional in which trees received the same winter pruning as ABE trees but no bud extinction and crop load was manipulated by hand-thinning. To ascertain the effect of chemical thinning and time of hand-thinning on ABE trained trees, the following treatments were applied to both ABE and conventionally-managed trees within the orchard block with three different crop loads: [3, 4 or 5 fruit cm

−2 limb cross-sectional area (LCSA)], three thinning methods [chemical thin (CT), hand-thin 5 weeks after full bloom (wAFB) (early HT), or hand-thin after final fruit drop at 9 wAFB (late HT)]. Treatment structure was a 2 (crop management regime) × 3 (crop load) × 3 (thinning method) factorial layout set out in a randomised complete block design.

Trials 2 & 3 consisted of four treatments in a 2 (crop management regime) × 2 (thinning method) factorial on two cultivars, ‘Alvina Gala’ and ‘Fiero Fuji’. Crop management was either conventional as described above or ABE, and the thinning method was either chemical thin or hand-thin only; trees receiving CT were also hand-thinned after final fruit drop to mimic normal commercial practice. Crop load was set at 5 buds cm−2 LCSA in 2015/16 and 6 buds in 2016/17 in the Gala and 6 buds/cm−2 LCSA in both years in the Fuji.

Trial 4 was established as a demonstration site to verify the results of Trials 1 to 3 on a larger semi-commercial scale and to determine comparative costs between ABE and CT. Treatments consisted of two pruning levels (standard ABE pruning vs. grower pruning (GP)) with or without CT. The grower pruning was included as most growers retain more limbs in a tree than is recommended for ABE management, and this allowed a comparison of the difference between ABE and the level of pruning that would be undertaken by most growers. An additional treatment was included to compare GP + CT as this was the standard crop load management in the orchard. A full row was dedicated to each treatment. Rows consisted of 67 trees and every 10th tree in each row was tagged and used for assessments.

The same assessments were undertaken for all trials, as discussed below.

2.2. Pruning and Tree Setup for ABE

All trees were pruned in late winter; unbalanced limbs were removed, limb numbers were reduced to a maximum of 6–7 limbs per metre of tree height, and spurs and small twiggy branches removed from the main trunk. Upright limbs were tied down to a more horizontal position.

On the ABE trees, floral bud density was set on the assumption of carrying one fruit per bud after hand thinning. Spur selection and spatial arrangement was achieved by removing weak, shaded and downward facing buds and shoots, leaving the strongest well positioned buds on each limb. Setting bud numbers before bud burst meant that trees commenced spring growth with reduced numbers of floral buds. Bud removal was performed in late winter immediately after pruning. Axillary floral buds were removed from one-year-old wood after bud burst. The number of flower clusters were recorded for each tree.

In Trial 4, the grower pruning regime had 9–10 limbs per m of tree height and the main trunk was left untouched. This meant that these treatments had more wood, allowing less light into trees.

2.3. Chemical Thinning

Trial 1—The program undertaken on trees tagged for chemical thinning consisted of the bloom thinner NAA (40 g L

−1 naphthalene acetic acid, Gro-Chem, Melbourne, Australia) followed by the post-bloom thinner MaxCel

® (20 g L

−1 6-benzyladenine, Valent BioSciences, Epping, Australia).

Table 2 details rates and application times.

Trials 2 & 3—The bloom thinners Ethrel

® (720 g L

−1 ethephon, Bayer CropScience Australia, Sydney, Australia) and NAA, and post-bloom thinner MaxCel

® were applied as described in

Table 2.

All sprays in Trials 1, 2 and 3 were applied using a backpack sprayer. Ethrel and NAA were applied to runoff and MaxCel applied to point of drip. The wetter Kendeen (Kendon Chemical & MNFG Co. Pty. Ltd., Melbourne, Australia) was included at the label rate for all applications.

Trial 4—The chemical thinning program consisted of bloom applications of Ethrel and NAA and a post-bloom tank mix application of MaxCel and carbaryl. All chemicals were applied using an airblast sprayer at 1000 L ha−1 water volume.

2.4. Flowering, Fruit Set and Hand-Thinning

In all trials, three representative mid-canopy limbs were tagged in each tree for assessment of flower number and fruit set. The number of blossom clusters was counted on each tagged limb just prior to bloom. Limb cross-sectional area was measured 2 cm from the base of each limb, and floral cluster density calculated for each limb; a tree mean was calculated using the individual limb densities.

Total fruit set was measured on all treatment trees prior to hand-thinning by recording the number of fruit within each cluster. Both ABE and conventional trees were hand-thinned to their final crop load after fruit set. The number of flower clusters that had set fruit were recorded on each tree. If fewer than the required number of buds bore fruit, two fruit per spur were retained on the strongest buds to achieve the required crop density per limb. In the conventionally-managed trees, fruit were thinned to one fruit per bud and then further reduced to achieve the required fruit densities. In Trial 1 the early HT treatments were thinned on 18 November (5 wAFB) and the late HT treatments on 17 December (9 wAFB) following the natural December drop. In Trials 2, 3 and 4, hand-thinning was completed on all treatments by 7 wAFB.

The flowering period in the first season for Trials 2 and 3 was extremely short, with flowering commencing on 2nd October and 100% bloom reached by 8th October; full bloom occurred on 6th October. In Trial 3, several of the ‘Fuji’ trees were experiencing an off-year in the first year of the study with low floral bud numbers.

2.5. Fruit Quality Assessments

All trees were harvested at normal commercial fruit maturity in March of the respective seasons and yield and fruit quality parameters measured. All fruits from each tree were counted and weighed and yield (kg per tree) calculated. After harvesting, a random sample of 50 fruit from each tree was selected. Fruit were returned to the laboratory and a subsample of 30 defect-free fruit taken for laboratory analysis of fruit quality and maturity. Fruit quality assessments undertaken were: weight, diameter (D), length (L), background colour (BGC), red blush coverage, flesh firmness, total soluble solids (TSS) content, malic acid (MA) content, starch pattern index (SPI) and percentage of dry matter content (DMC).

Fruit length and diameter were measured using Vernier calipers. Fruit flesh firmness was measured on pared flesh with an Effegi 11 mm penetrometer probe fitted to a Güss Model GS-20 Fruit Texture Analyser (Güss, Strand, South Africa). Juice expressed from the apples during firmness measurements was used to assess TSS concentration with an Atago PR-1 digital refractometer (Atago Co. Ltd., Tokyo, Japan). The starch-iodine test for apples was used to determine SPI; each fruit was cut transversely across the equator and the cut surface of the calyx end painted with a solution of 1 g potassium iodide plus 0.25 g iodine per 100 mL of water. The resulting pattern of starch hydrolysis was compared with the ENZA 6-point starch pattern chart (ENZA International Ltd., Hastings, New Zealand) and the pattern most similar to that of the fruit recorded. For DMC, two wedges were removed from opposite sides of each fruit, placed in labelled paper bags, weighed, oven dried at 60 °C to a constant weight, dry weight recorded and DMC calculated from dry weight/fresh weight. Juice pH and titratable acidity (TA) were determined using a Mettler Toledo G20 compact titrator. Malic acid content was calculated from the TA results.

Background colour in Trial 1 was estimated using ‘Royal Gala’ colour swatches (ENZA International Ltd., 10-point chart). In Trials 2, 3 and 4, background colour was assessed with a DA meter (Model FRM01, Sinteleia, Bologna, Italy) to estimate the amount of chlorophyll in the skin using the DA index (Difference of Absorbance between 670 and 720 nm).

Blush colour intensity was assessed using an 11-point colour chart (39CO2, ENZA New Zealand). Blush colour area (%) was measured for each fruit by estimating the percentage of fruit surface with a blush intensity of ≥5. To avoid bias, all assessments were performed by the same observer.

Return bloom was measured in the spring of the year following treatment using the same three tagged limbs in each plot. Limb basal cross-sectional area was measured, and the number of flower clusters recorded and used to calculate return bloom density.

2.6. Data Analysis

Data were subjected to analysis of variance using Genstat release 17.1 (VSN International Ltd., Hertfordshire, UK). Data are presented as mean values for each treatment and/or main effect. Significance was calculated at p = 0.05 and least significant difference (LSD) used for comparison of mean values in the tables and figures. Data was checked for normal distribution, and no data transformations were necessary.

2.7. Determining Costs for Comparison of ASE and Chemical Thinning

To compare the costs of the different regimes, the time taken to prune, complete the ABE setup (bud removal) and hand-thin were recorded and used to calculate the cost per hectare of each activity based on a labour cost of $25 per hour. The chemical thinning cost included the cost of chemicals, labour at $25 per hour and a machinery cost of $25 per hour for the tractor/sprayer.

4. Discussion

The four studies presented here have demonstrated that ABE is a feasible alternative to chemical thinning for crop load management in apple, validating the suggestion by Tustin et al. [

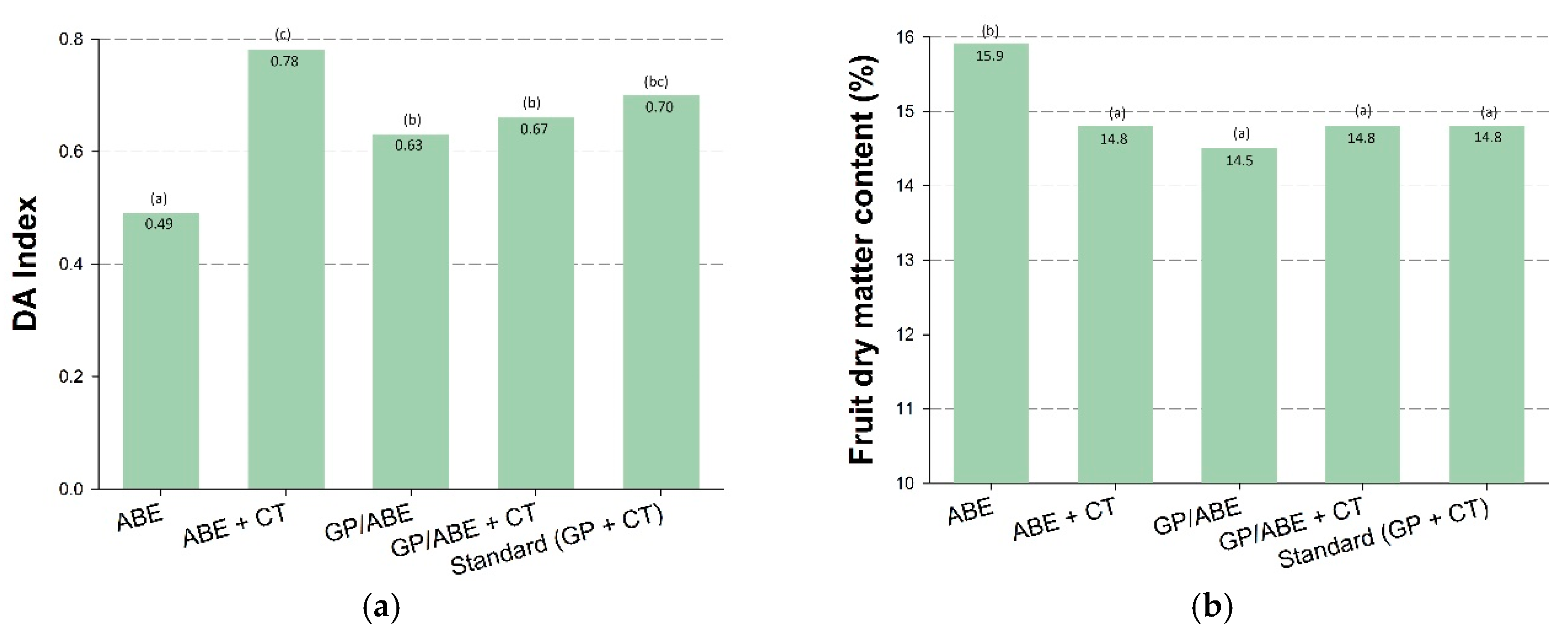

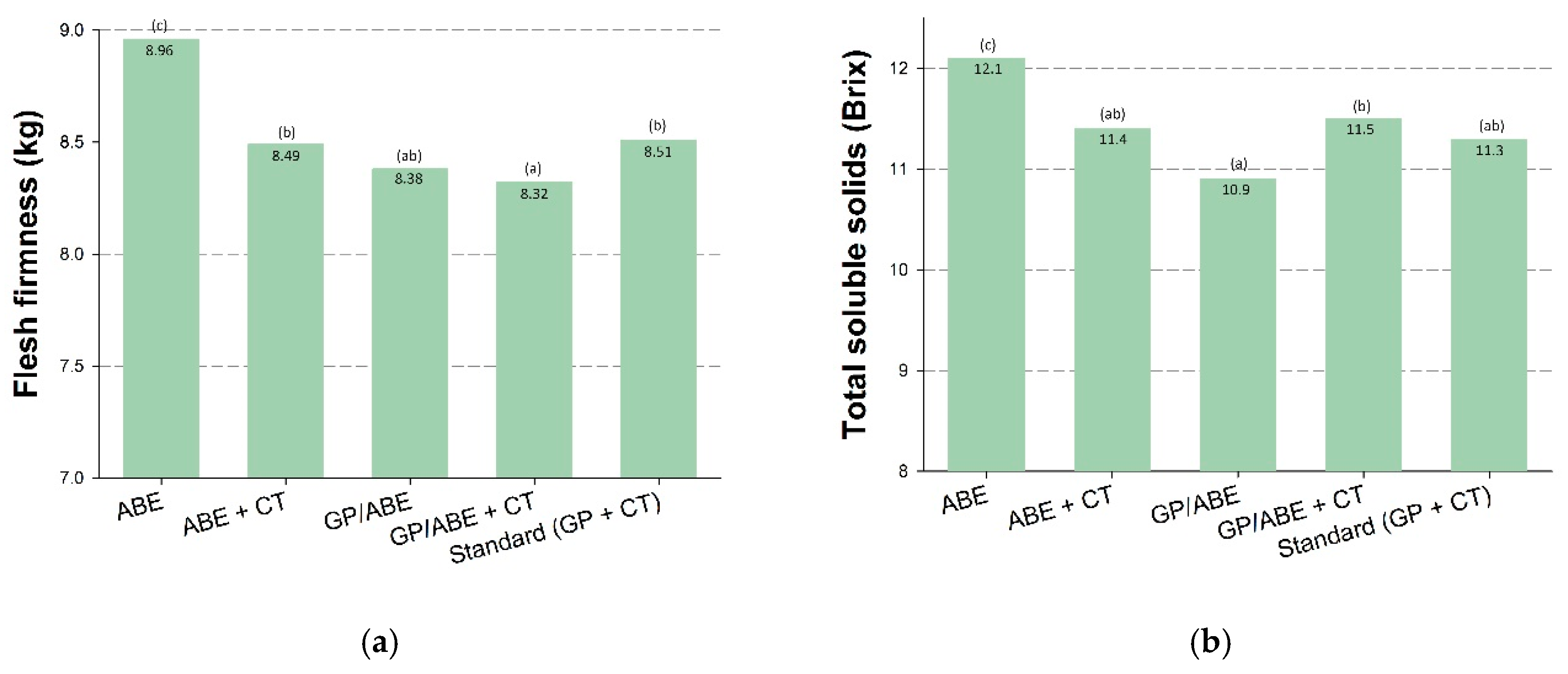

11] that ABE could replace chemical thinning as a crop load management tool. Additionally, there is good evidence to show that applying chemical thinners to ABE-managed trees can result in reduced fruit quality in terms of firmness, TSS and DMC, thus indicating that chemical thinning should not be used to complement ABE.

4.1. Flowering and Fruit Set

Replacing chemical thinning with ABE as a crop load management tool provides the benefit of predictable fruit set and crop load responses, removing the risk of biennial bearing that occurs with current crop load management practices. Tustin et al. [

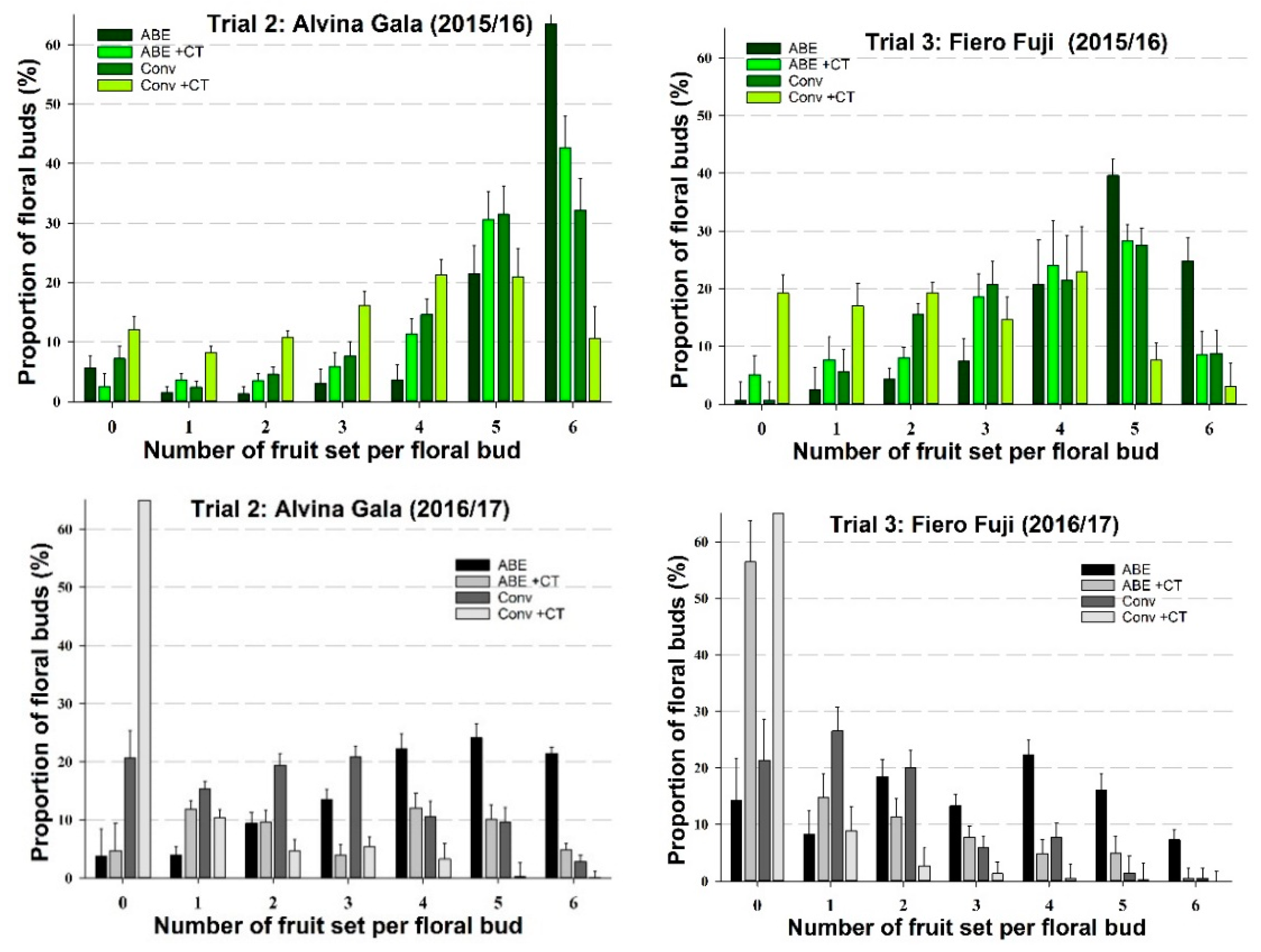

11] describe ABE as differing from conventional thinning by controlling the number of floral sites allowed to develop from the resumption of spring growth. This is clearly demonstrated in this study, with ABE trees carrying approximately 50% fewer floral clusters than conventional trees. The number of floral clusters in the ABE trees was also stable across seasons, with most floral buds setting fruit, compared with the conventionally-managed trees where there was variation, particularly in Fuji which is strongly biennial bearing.

In ABE-managed trees the number of floral buds (clusters) is reduced prior to bud burst, resulting in fewer buds than in conventionally-managed trees. However, the proportion of flower clusters setting fruit is higher than in conventional management, with a greater number of multiple fruit per cluster, consistent with the findings of Tustin et al. [

11], Breen et al. [

13,

17] and Tabing et al. [

18]. Under conventional tree management it is not uncommon to see 30–50% of spur and terminal buds failing to set fruit [

13], while under ABE management the number of buds failing to set is often reduced to less than 5%. ABE produces precise fruit set outcomes despite differences in natural fruit set brought about by normal seasonal differences in environment [

16].

Breen et al. [

13] reported that as floral bud density is reduced, the proportion of buds failing to set fruit declines and the proportion setting multiple fruit increases. This was demonstrated in this study, even at crop loads as high as 6 fruit cm

−2 LCSA. Flowering and early fruit development is a period of high demand for tree resources. Hence by removing competitive floral carbohydrate sinks before the spring growth period, there is less competition for resources, enabling an improved fruit set. This also carries through to flower initiation for the following season, as this occurs shortly after bloom. Bound et al. [

20] reported a significant depletion in internal carbohydrate reserves in limbs of cherry trees thinned at 8 wAFB compared with trees in which buds were removed prior to bud-break. Costa et al. [

5] states that thinning performed before fruit set may prevent biennial bearing, but fruit thinning performed after fruit set is normally ineffective. In the studies presented here, ABE-managed trees showed no signs of biennial bearing, with sufficient return boom to set a crop load of 6 fruit cm

−2 limb cross-sectional area based on a single fruit per bud, unlike the conventional trees in which bud numbers varied between seasons. This supports the relationship between the extinction of growing points and regularity of bearing described by Lauri et al. [

8,

9,

10].

4.2. Yield and Fruit Quality

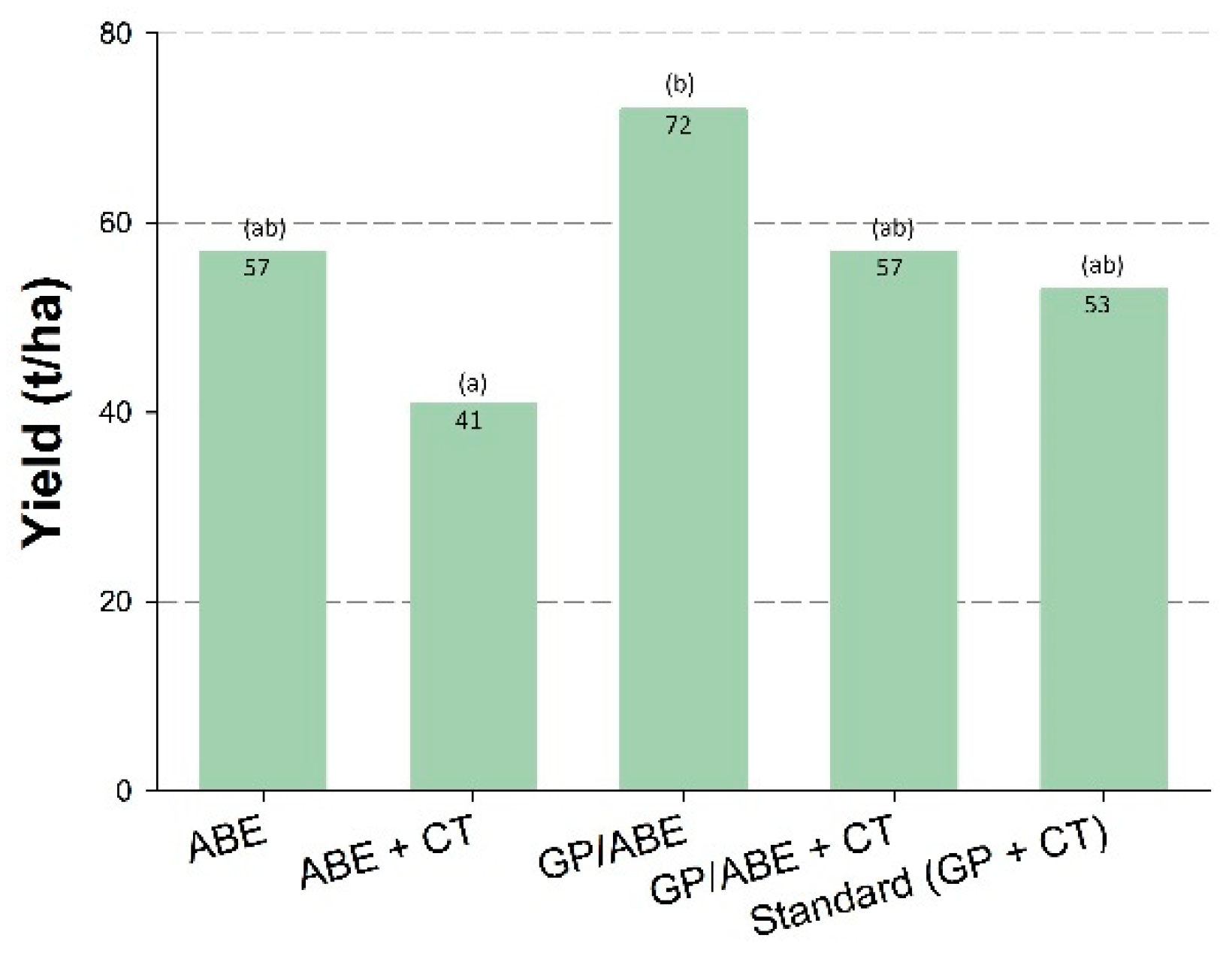

The lack of difference in total yield observed between the ABE and conventional management regimes on the three Gala strains examined is similar to the findings of van Hooijdonk et al. [

12] with ‘Scilate’, Breen et al. [

16] with ‘Royal Gala’ and Tabing et al. [

18] with ‘Kalei’. Tustin et al. [

21] reported a reduction in yield of ‘Scifresh’ in the first year of ABE management. However, increases of 30% and 100% were observed in ‘Fiero Fuji’ yields over the two years of this study. As the ‘Fiero Fuji’ trial was situated 20 m from the ‘Alvina Gala’ trial and conducted in the same years, it is unlikely that other factors played a role in the different impact on yield between these two cultivars. Hence it is feasible that propensity for biennial bearing may influence impact of ABE on yield between cultivars.

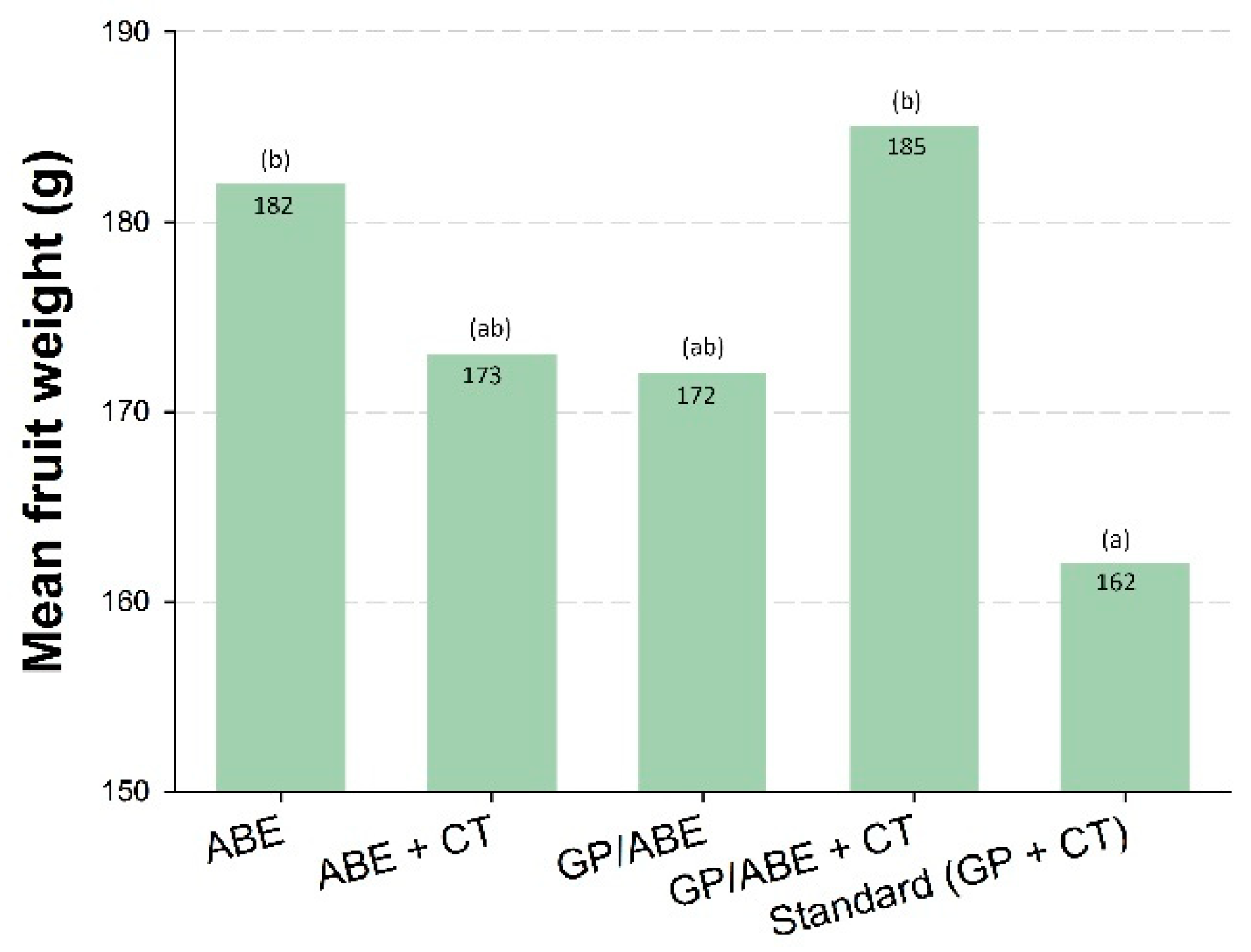

In all four trials reported in this study, fruit weight was increased by 5–38% in all ABE-managed trees. The impact of ABE on fruit weight appears to be consistent across studies, with van Hooijdonk et al. [

12], Breen et al. [

12] and Tabing et al. [

18] all reporting increased fruit weight under ABE management. This beneficial effect can be explained by a combination of increased carbohydrate production, as all buds are in a good light environment, and reduced wastage of resources, with carbohydrate partitioning to fruit that will remain on the tree rather than into non-setting flowers and/or fruit that is later removed. The increase in fruit weight, DMC, firmness and TSS observed with the reduction in crop load in Trial 1 confirms the effect of increased competition for carbohydrate resources on fruit quality. A similar effect of crop load on cherry fruit quality was also reported by Bound et al. [

20]. The reduction in fruit weight and soluble solids content following late hand thinning also suggests that considerable carbohydrate resources are wasted in fruit that is later removed from the tree, confirming the importance of early thinning on fruit quality.

While the impact of ABE on fruit weight was consistent, reports on the impact of ABE on other fruit quality parameters are variable. In a two-year study, Tabing et al. [

18] found no effects on firmness, soluble solids, dry matter content, blush intensity, background colour or starch pattern index on ‘Kalei’. Breen et al. [

16] found no difference in starch pattern index or dry matter content of ‘Royal Gala’ in another two-year study. The effect of ABE on fruit soluble solids, dry matter content, starch pattern index and background colour in the studies reported here was either positive or there was no effect. However, a reduction in fruit firmness was observed in Trial 2, with no effect in Trials 1 and 3 and an increase in Trial 4. It is difficult to explain the reduction in firmness, but several authors have reported variable results on fruit firmness in multiple year studies, with firmness increased in some years, decreased in others or having no effect. It is possible that climatic differences between seasons play a role in these observed variations.

No effects were observed on fruit colour in this study. Tabing et al. [

18] reported an increase in red blush coverage in the second year of a two-year study. A consistent increase of 6–7% in red blush coverage of ‘Scilate’ across all years of a three-year study was reported by van Hooijdonk et al. [

12]. These authors also found increased fruit dry matter content in two of the three years and concluded that the improved canopy and fruit illumination brought about by the reduction in spur density contributed to the improvement in colour and dry matter content. Tabing et al. [

18] also concluded that the increase in colour was due to improved bud positioning and increase in light within the canopy. This is a logical assumption as, under ABE management, buds in shaded areas and on the underside of limbs are removed, hence the buds remaining on the tree are in exposed positions and consequently receive more light. With more exposed fruit, it is not unreasonable to expect an increased risk of sunburn on fruit, although sunburn was not observed in this study, nor has it been reported in other studies. One reason may be that fruit that is exposed to direct sunlight throughout its development is less susceptible to sunburn [

22].

Even though ABE does not always result in an improvement in all fruit quality parameters, it should be noted that it is well recognised that most of the chemicals used as chemical thinning agents can have detrimental impacts on fruit quality. For example, NAA can result in formation of pygmy fruit [

23] and can cause fruit russet under humid conditions [

3], ethephon can depress fruit size, counteracting the benefits gained by early thinning and it also tends to flatten fruit [

3], and application of any chemical after a prolonged cool wet period can induce russet [

2,

3].

Although models have been developed for predicting the response of thinning chemicals [

24], chemical thinning will never be able to provide consistent predictable crop loads. Additionally, apart from the negative impacts of chemicals on fruit quality, other downsides of chemical thinning include the short time frame for chemical application, unpredictable spring weather that makes application difficult and often ineffective and increasing environmental concerns with chemical use.

4.3. Cost Comparison

The cost comparison between ABE and chemical thinning for crop load management has confirmed that implementation of ABE is economically viable for orchardists. The cost in the year of implementation is comparable to conventional crop load management methods with chemical thinning agents, and in subsequent years, when the tree is already ‘set up’, ABE management is more economical than conventional chemical thinning.

Although the first year of ABE implementation is labour intensive as it involves some restructuring of trees, and removing buds across the entire tree, this is compensated by the reduction in hand-thinning. A major advantage of ABE is that spacing, position and number of clusters are already determined during the bud removal process, so all that is required when hand-thinning is to break up bunches and remove fruit with defects. Thus, the hand-thinning process is considerably simplified when compared with conventional management. Even though most flower clusters set fruit, ABE-managed trees do not express late fruitlet drop as there is no excessive fruit set that invokes fruit shedding, so hand thinning to adjust crop load to the final desired numbers can be started within three to four weeks of flowering rather than waiting for fruit drop 8–10 weeks after bloom.

While it should be noted that the cost of implementation of ABE will vary depending on the age and structure of the trees, there is the added benefit that trees can be set up with a pre-determined crop load with reasonable accuracy, thus enabling improved management of fruit size. In addition, bud position is optimised in ABE, fruit is well spaced and light distribution into the canopy is enhanced.

5. Conclusions

The four studies presented here have demonstrated that ABE is a feasible alternative to chemical thinning, improving reliability of crop load management with a move away from chemical use and increasing predictability of fruit size and yield. As bud numbers are set in late winter, trees are significantly thinned before flowering, controlling biennial bearing. In addition, bud position is optimised, fruit is well spaced and light distribution into the canopy is enhanced, ensuring optimal fruit development with respect to size and quality. As well as eliminating the need for chemical thinning, ABE has the added advantages that it is not weather dependent and removes the risk of negative impacts that chemical thinners can have on fruit size, shape and skin finish. ABE is also suitable for use in organic production systems.

In terms of costs, implementation of ABE is comparable to managing crop load through chemical thinning programs, but has the advantage that costs reduce in subsequent years after the initial tree set-up.