Flavour Characteristics of Fermented Meat Products in China: A Review

Abstract

:1. Introduction

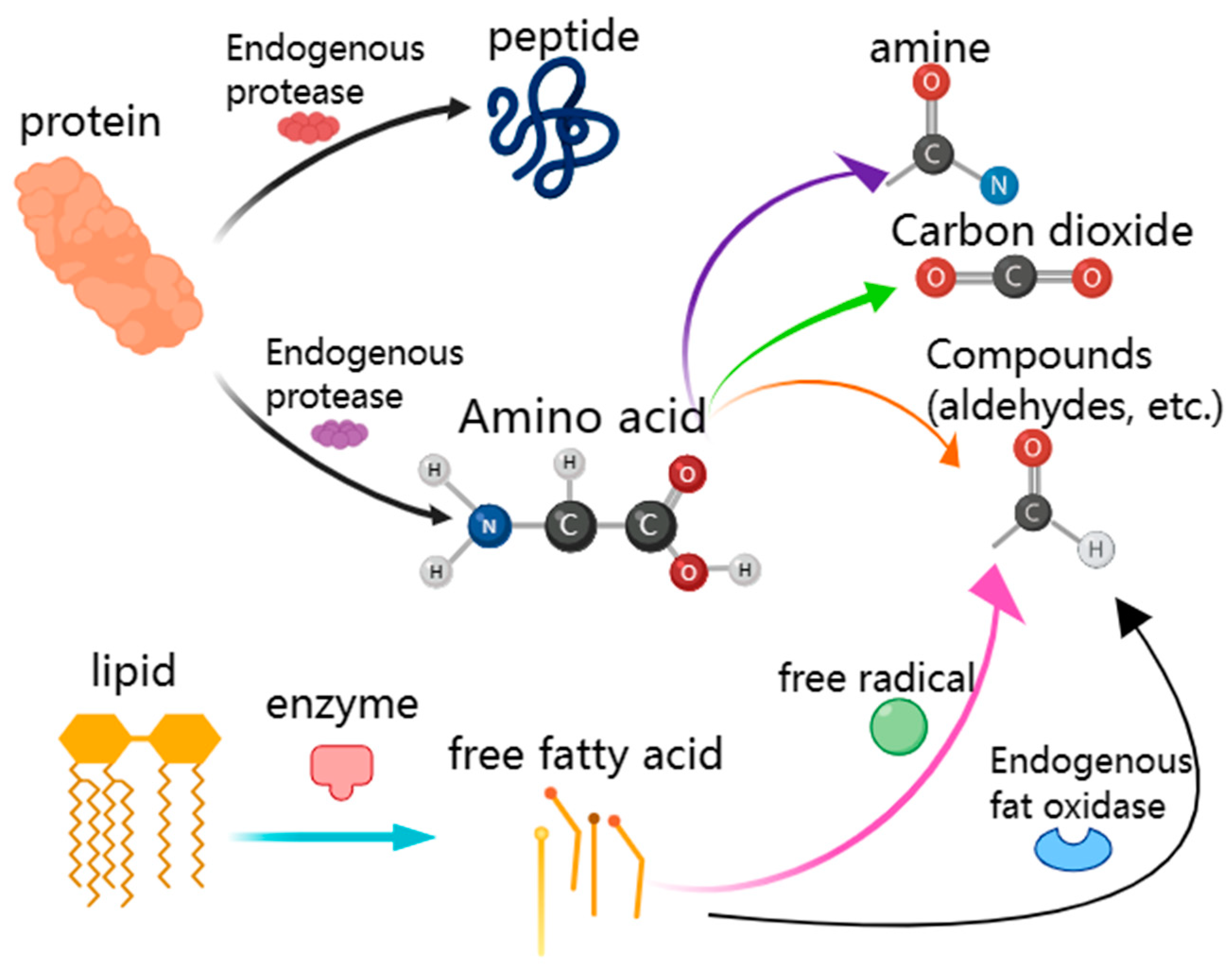

2. Formation of Flavour Substances in Fermented Meat Products

| Type | Flavour Precursors |

|---|---|

| Free amino acids [19,20] | Alanine, glycine, lysine, aspartic acid, valine, leucine, isoleucine, serine, aspartic acid, asparagine, glutamic acid, histidine, tyrosine, arginine, tryptophan, proline, threonine, phenylalanine |

| Lipids [19,21] | Triglycerides, phospholipids, oleic acid, linoleic acid |

| Reducing sugars [19] | Starch, glucose, ribose |

| Nucleotides and peptides [19,22] | Inosine, inosine, inosinic acid, guanylic acid, glutathione |

3. Flavour Profiles in Fermented Meat Products

3.1. Dry-Cured Ham

3.2. Sausage

3.3. Preserved Meat

3.4. Cured Fish

3.5. Sour Meat

| Flavour Substance | Flavour |

|---|---|

| Ethyl butyrate [81] | Aroma of apple |

| Ethyl caprate [81,87] | Fruity, aroma of wine |

| Ethyl acetate [81,87,88] | Aroma of grape |

| Ethyl oenanthate [81] | Aroma of pineapple |

| Ethyl caprylate [81] | Aroma of brandy |

| Ethyl lactate [87] | Fruity |

| L- Ethyl lactate [88] | Aroma of wine |

| Ethyl phenylacetate [88] | Aroma of honey |

4. Conclusions and Prospects

Funding

Conflicts of Interest

References

- Liu, Y.; Yu, Q.; Wan, Z.; Li, H.; Liu, J.; Wang, J.; Liu, Y. Research progress on the effect of antioxidant activity of fermentation agents on the quality of fermented meat products. Food Sci. 2021, 42, 302–312. [Google Scholar] [CrossRef]

- Sivamaruthi, B.S.; Kesika, P.; Chaiyasut, C. A Narrative Review on Biogenic Amines in Fermented Fish and Meat Products. J. Food Sci. Technol. 2021, 58, 1623–1639. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhao, J.; Zang, J.; Peng, C. Research progress on the relationship between characteristic flavors and microorganisms in fermented meat products. Food Ind. Sci. Technol. 2023, 45, 1–23. [Google Scholar] [CrossRef]

- Yu, C.; Yao, D.; Man, Y.; Wang, C. The harm of biogenic amines in fermented meat and control. J. Meat Res. 2010, 24, 41–45. [Google Scholar] [CrossRef]

- Pedro, D.; Saldaña, E.; Lorenzo, J.M.; Pateiro, M.; Dominguez, R.; Dos Santos, B.A.; Cichoski, A.J.; Campagnol, P.C.B. Low-Sodium Dry-Cured Rabbit Leg: A Novel Meat Product with Healthier Properties. Meat Sci. 2021, 173, 108372. [Google Scholar] [CrossRef]

- Fan, W.; Zhang, H.; Ding, Y.; Han, S.; Yang, G. Research progress of flavor substances in fermented meat products. Feed Expo 2013, 26, 44–47. [Google Scholar] [CrossRef]

- Munekata, P.E.S.; Pateiro, M.; Tomasevic, I.; Domínguez, R.; Da Silva Barretto, A.C.; Santos, E.M.; Lorenzo, J.M. Functional Fermented Meat Products with Probiotics—A Review. J. Appl. Microbiol. 2022, 133, 91–103. [Google Scholar] [CrossRef]

- Wang, H.; Xu, J.; Liu, Q.; Xia, X.; Sun, F.; Kong, B. Effect of the Protease from Staphylococcus Carnosus on the Proteolysis, Quality Characteristics, and Flavor Development of Harbin Dry Sausage. Meat Sci. 2022, 189, 108827. [Google Scholar] [CrossRef]

- Rizzi, G.P. The Strecker Degradation of Amino Acids: Newer Avenues for Flavor Formation. Food Rev. Int. 2008, 24, 416–435. [Google Scholar] [CrossRef]

- Petrova, I.; Aasen, I.M.; Rustad, T.; Eikevik, T.M. Manufacture of Dry-Cured Ham: A Review. Part 1. Biochemical Changes during the Technological Process. Eur. Food Res. Technol. 2015, 241, 587–599. [Google Scholar] [CrossRef]

- Monforte, A.R.; Martins, S.I.F.S.; Silva Ferreira, A.C. Impact of Phenolic Compounds in Strecker Aldehyde Formation in Wine Model Systems: Target and Untargeted Analysis. J. Agric. Food Chem. 2020, 68, 10281–10286. [Google Scholar] [CrossRef]

- Nashalian, O.; Yaylayan, V.A. Thermally Induced Oxidative Decarboxylation of Copper Complexes of Amino Acids and Formation of Strecker Aldehyde. J. Agric. Food Chem. 2014, 62, 8518–8523. [Google Scholar] [CrossRef]

- Andrade, M.J.; Córdoba, J.J.; Casado, E.M.; Córdoba, M.G.; Rodríguez, M. Effect of Selected Strains of Debaryomyces Hansenii on the Volatile Compound Production of Dry Fermented Sausage “Salchichón”. Meat Sci. 2010, 85, 256–264. [Google Scholar] [CrossRef] [PubMed]

- Beck, H.C.; Hansen, A.M.; Lauritsen, F.R. Catabolism of Leucine to Branched-Chain Fatty Acids in Staphylococcus Xylosus. J. Appl. Microbiol. 2004, 96, 1185–1193. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, W.; Wang, X. Origin and formation of flavor substances in fermented sausage. Food Sci. Technol. 2015, 40, 160–165. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Lipid Oxidation in Meat and Meat Products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xie, J.; Zhang, C.; Xu, Y.; Yang, X. Effect of Lipid on Formation of Maillard and LIPID-MAILLARD Meaty Flavour Compounds in Heated Cysteine-xylose-methyl Linoleate System. Flavour Fragr. J. 2022, 37, 274–284. [Google Scholar] [CrossRef]

- Bork, L.V.; Haase, P.T.; Rohn, S.; Kanzler, C. Formation of Melanoidins—Aldol Reactions of Heterocyclic and Short-Chain Maillard Intermediates. Food Chem. 2022, 380, 131852. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yang, Y.; Zhao, Q.; Tang, C.; Qin, Y. Research progress on the relationship between flavor precursors and flavor quality meat. Chin. J. Anim. Sci. 2019, 55, 1–7. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, C.; Wang, C.; Zheng, Y.; Ye, K.; Tang, C. Application of Zhou Guanghong ultrasonic technology in meat processing and its influence on meat flavor precursors. Food Ind. Sci. Technol. 2019, 40, 320–323+335. [Google Scholar] [CrossRef]

- Chen, X.; Fan, S. Study on flavor of cured meat of Fan Suqin. Meat Ind. 2010, 31, 31–34. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.; Liu, X.; Tian, H.; Meng, Y. Study on flavor nucleotides and volatile flavor substances of triploid rainbow trout cultured in Ma Rui Qinghai Province. Food Ind. Sci. Technol. 2022, 43, 310–318. [Google Scholar] [CrossRef]

- Liu, R.; Ma, Y.; Chen, L.; Lu, C.; Ge, Q.; Wu, M.; Xi, J.; Yu, H. Effects of the Addition of Leucine on Flavor and Quality of Sausage Fermented by Lactobacillus Fermentum YZU-06 and Staphylococcus Saprophyticus CGMCC 3475. Front. Microbiol. 2023, 13, 1118907. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Zhou, Y.; Wang, G.; Zhu, R.; Ge, C.; Liao, G. Changes in the Physicochemical Properties and Volatile Flavor Compounds of Dry-cured Chinese Laowo Ham during Processing. J. Food Process. Preserv. 2020, 44, e14593. [Google Scholar] [CrossRef]

- Xu, H.; Deng, J.; Li, X.; Wu, Y.; Li, P. Differences and correlation analysis of bacterial community structure and flavor in three kinds of Xu Baocai dry-cured ham. Food Res. Dev. 2022, 43, 14–22. [Google Scholar] [CrossRef]

- Qiao, F.; Ma, C. Analysis of volatile flavor compounds in the processing of Ma Changwei Xuanwei ham. Food Res. Dev. 2006, 27, 24–29. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, X.; Huang, L.; Wang, Y.; Wang, B.; Zhang, J.; Zhang, Y.; Wang, Q. Electronic nose and gas chromatography-mass spectrometry were used to analyze the aroma components of mutton ham at different storage times. Food Sci. 2019, 40, 215–221. [Google Scholar] [CrossRef]

- Bai, L. Study on Flavor Grade of Jinhua Ham. Master’s Thesis, Bohai University, Jinzhou, China, 2020. [Google Scholar]

- Ding, X.; Wang, G.; Zou, Y.; Zhao, Y.; Ge, C.; Liao, G. Influence of Partial Replacement of NaCl with KCl on the Volatile Compounds of Xuanwei Ham Investigated by Gas Chromatography-Ion Mobility Spectrometry Combined with Multivariate Statistical Analysis. Food Sci. 2020, 41, 190–198. [Google Scholar]

- Chen, X. Study on Antioxidant Activity and Flavor of Jinhua Ham during Hanging Fermentation Stage; Shanghai Institute of Applied Technology: Shanghai, China, 2015. [Google Scholar]

- Zhang, X. Study on Fatty Oxygenase and Flavor of Rugao Ham; Nanjing Agricultural University: Nanjing, China, 2008. [Google Scholar]

- Xia, F. Comparative Study on the Quality of Jinhua Ham Produced by Traditional Technology and Modern Technology; Zhejiang University: Hangzhou, China, 2016. [Google Scholar]

- Wang, F.; Gao, Y.; Wang, H.; Xi, B.; He, X.; Yang, X.; Li, W. Analysis of Volatile Compounds and Flavor Fingerprint in Jingyuan Lamb of Different Ages Using Gas Chromatography–Ion Mobility Spectrometry (GC–IMS). Meat Sci. 2021, 175, 108449. [Google Scholar] [CrossRef]

- Gao, S.; Song, X.; Chen, L.; Zhang, J.; Liu, Y. Analysis of the Volatile Compounds of Jinhua Ham by Monolithic Material Sorptive Extraction Coupled with Gas Chromatography-Mass Spectrometry. Food Sci. 2015, 36, 113–116. [Google Scholar] [CrossRef]

- El Hadi, M.; Zhang, F.-J.; Wu, F.-F.; Zhou, C.-H.; Tao, J. Advances in Fruit Aroma Volatile Research. Molecules 2013, 18, 8200–8229. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Mou, B.; Ju, M.; CUI, F.; Li, G.; Piao, C.; Cui, M. Characterization of Flavor Components of Dry-Cured Ham with Different Salt Substitute Formulations Using Solid Phase Microextraction-Gas Chromatography-Mass Spectrometry, Electronic Nose and Electronic Tongue. Food Sci. 2022, 43, 246–256. [Google Scholar] [CrossRef]

- Song, X. Study on Flavor Grade of Jinhua Ham and Xuanwei Ham; Shanghai Ocean University: Shanghai, China, 2015. [Google Scholar]

- Guo, X.; Lu, S.; Wang, B.; Wang, Q. Research progress on flavor analysis of Chinese traditional ham. Grain Oil 2019, 32, 18–21. [Google Scholar]

- Dang, Y.; Liu, Z.; Gao, X.; Gao, X.; Cao, J.; Bao, G. Determination of Volatiles in Ham by Gas Chromatography with Olfactory Detection. Int. J. Food Eng. 2016, 12, 323–332. [Google Scholar] [CrossRef]

- Yao, P.; Qiao, F.; Yan, H.; Ma, C. Isolation and Identification of Volatile Compounds of Xuanwei Ham. Food Sci. 2004, 25, 146–150. [Google Scholar] [CrossRef]

- Flores, M.; Grimm, C.C.; Toldrá, F.; Spanier, A.M. Correlations of Sensory and Volatile Compounds of Spanish “Serrano” Dry-Cured Ham as a Function of Two Processing Times. J. Agric. Food Chem. 1997, 45, 2178–2186. [Google Scholar] [CrossRef]

- Xu, Y. Effect of Microorganisms on Flavor of Dry-Cured Ham and Its Application; Hefei University of Technology: Hefei, China, 2022. [Google Scholar]

- Niu, X. Screening of Staphylococcus Intermedius in Fermented Ham and Its Application in Fermented Sausage; Harbin University of Commerce: Harbin, China, 2020. [Google Scholar]

- Wang, B.; Zhou, C.; Li, T.; Lu, L.; Chen, C.; Du, G.; Fang, F. Tetracococcus halophilus and its application in fermented food. Food Ferment. Ind. 2017, 43, 267–272. [Google Scholar] [CrossRef]

- Xing, B.; Zhou, T.; Gao, H.; Wu, L.; Zhao, D.; Wu, J.; Li, C. Flavor Evolution of Normal- and Low-Fat Chinese Sausage during Natural Fermentation. Food Res. Int. 2023, 169, 112937. [Google Scholar] [CrossRef]

- Ordóñez, J.A.; Hierro, E.M.; Bruna, J.M.; Hoz, L.D.L. Changes in the Components of Dry-Fermented Sausages during Ripening. Crit. Rev. Food Sci. Nutr. 1999, 39, 329–367. [Google Scholar] [CrossRef]

- Duan, W.; Tang, X.; Xiong, Y.; Chen, J. Comparative study on volatile components of Salami sausage. Food Ind. Sci. Technol. 2010, 31, 89–93. [Google Scholar] [CrossRef]

- Li, G.; Gao, Y.; Liu, W. Study on Aroma Compounds of the Black Piper. Food Sci. 2003, 24, 128–131. [Google Scholar] [CrossRef]

- Costa, R.M.; Liu, L.; Nicolelis, M.A.L.; Simon, S.A. Gustatory Effects of Capsaicin That Are Independent of TRPV1 Receptors. Chem. Senses 2005, 30, i198–i200. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Zhou, G.; Xu, X. A Novel Analytical Method for Key Odor Compounds of Chinese Sausage. Meat Res. 2011, 25, 15–20. [Google Scholar] [CrossRef]

- Zeng, X.; Bai, W.; Chen, H.; Huang, B. At the same time, the volatile components of Cantonese sausage were analyzed by distillation extraction/gas-mass spectrometry. Food Ferment. Ind. 2010, 36, 139–143. [Google Scholar] [CrossRef]

- Chen, Y. Study on volatile flavor of Cantonese sausage in different regions of Guangdong Province. Agric. Prod. Process. 2015, 14, 61–64. [Google Scholar]

- Li, H.; Chen, Y.; Li, M.; Cao, L. Optimization and flavor analysis of Sichuan sausage seasoning formula. Food Ind. Sci. Technol. 2017, 38, 221–225+249. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, H.; Ye, C.; Pei, Z.; Yan, H. Effects of different starter cultures on bacterial phase, volatile flavor components and quality of fermented sausage. J. Northeast Agric. Univ. 2021, 52, 45–53. [Google Scholar] [CrossRef]

- Tong, G. Research on Making Craft of Mount Qingcheng Bacon. Chin. Seas. 2014, 39, 98–101+110. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Q.; Chen, C.; Yu, H.; Xu, B. Effects of Different Smoking Methods on Sensory Properties, Free Amino Acids and Volatile Compounds in Bacon. J. Sci. Food Agric. 2021, 101, 2984–2993. [Google Scholar] [CrossRef]

- Mao, Y.; Li, Y.; Yun, J.; He, K.; Wang, R.; Wu, S. Analysis on the changes of volatile flavor substances in the production of traditional Longxi cured meat. Food Ferment. Ind. 2021, 47, 144–152. [Google Scholar] [CrossRef]

- Zhu, L.; Li, C.; Meng, Y.; Wang, B.; Wu, G.; Li, C.; Yao, P.; Ma, X.; Ma, W.; Chen, Y. The changes of volatile flavor components of Zhenbala meat during storage were analyzed by gas chromatography-ion migration spectrometry. J. Food Saf. Qual. Insp. 2022, 13, 4832–4839. [Google Scholar] [CrossRef]

- Carrapiso, A.I.; Noseda, B.; García, C.; Reina, R.; Sánchez Del Pulgar, J.; Devlieghere, F. SIFT-MS Analysis of Iberian Hams from Pigs Reared under Different Conditions. Meat Sci. 2015, 104, 8–13. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.; Peng, R.; Tang, C. Volatile Flavor Compounds of Chongqing Chengkou Bacon. Food Sci. 2016, 37, 120–126. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Zhou, W.; Nie, Q.; Feng, T. Analysis on flavor quality of cured meat with low sodium salt solution and Miaoling traditional cured meat. Packag. Eng. 2021, 42, 93–103. [Google Scholar] [CrossRef]

- Zhang, Y.; Yun, Z.; Zhu, M.; Gou, X.; Huang, Y. Effect of bamboo leaf extract concentrated liquid combined with bamboo rod smoking on flavor quality of cured pork. Food Ferment. Ind. 2022, 48, 123–130. [Google Scholar] [CrossRef]

- Cano-García, L.; Rivera-Jiménez, S.; Belloch, C.; Flores, M. Generation of Aroma Compounds in a Fermented Sausage Meat Model System by Debaryomyces Hansenii Strains. Food Chem. 2014, 151, 364–373. [Google Scholar] [CrossRef]

- Xi, L.; Sun, Y.; Jiang, S.; Wen, C.; Ding, W. Evaluation of Effects of Ultrasound-Assisted Curing on the Flavor of Chinese Bacon. Ultrason. Sonochem. 2023, 96, 106424. [Google Scholar] [CrossRef]

- Du, H.; Chen, Q.; Liu, Q.; Wang, Y.; Kong, B. Evaluation of Flavor Characteristics of Bacon Smoked with Different Woodchips by HS-SPME-GC-MS Combined with an Electronic Tongue and Electronic Nose. Meat Sci. 2021, 182, 108626. [Google Scholar] [CrossRef]

- Li, Z.; Bai, X.; Wei, X.-Y.; Dilixiati, Y.; Fan, Z.-C.; Kong, Q.-Q.; Li, L.; Li, J.-H.; Lu, K.-L.; Zhao, J.; et al. A Solid Acid-Catalyzed Depolymerization of Pine Lignin to Obtain Guaiacol Using a Hydrogen-Free Strategy. Fuel Process. Technol. 2023, 249, 107843. [Google Scholar] [CrossRef]

- Yu, J. Optimization of Traditional Preserved Fish Processing Technology and Its Influence on Product Characteristics; Chengdu University: Chengdu, China, 2019. [Google Scholar]

- Gu, S.; Tang, J.; Zhou, X.; Zheng, H.; Zhou, H.; Ding, T. Quality Change and Aroma Formation in Cured Fish during Traditional Sun Drying Processing. Food Sci. 2019, 40, 36–44. [Google Scholar] [CrossRef]

- Zhang, Q.; Ding, Y.; Gu, S.; Zhu, S.; Zhou, X.; Ding, Y. Identification of Changes in Volatile Compounds in Dry-Cured Fish during Storage Using HS-GC-IMS. Food Res. Int. 2020, 137, 109339. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, J. The relativity analysis between main composition with flavor quality of cured fish. Chin. Seas. 2009, 34, 46–48. [Google Scholar] [CrossRef]

- Wang, W. Nutrient Composition, Physicochemical Properties, Flavor Characteristics and Bacterial Phase Composition of Smelly Mandarin Fish; Hefei University of Technology: Hefei, China, 2015. [Google Scholar]

- Liang, Z.; Huang, N.; Ma, X.; Du, B. Effect of mixed lactic acid bacteria fermentation on flavor characteristics of smelly Mandarin fish. Food Ferment. Ind. 2023, 54, 1–9. [Google Scholar] [CrossRef]

- Bao, R.; Liu, S.; Ji, C.; Liang, H.; Yang, S.; Yan, X.; Zhou, Y.; Lin, X.; Zhu, B. Shortening Fermentation Period and Quality Improvement of Fermented Fish, Chouguiyu, by Co-Inoculation of Lactococcus Lactis M10 and Weissella Cibaria M3. Front. Microbiol. 2018, 9, 3003. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, M.; Yin, J.; Yan, Y.; Lin, X.; Xie, N. Effects of Lactobacillus sake on edible quality and volatile flavor substances of smelly Mandarin fish. Chin. J. Food Sci. 2021, 21, 160–168. [Google Scholar] [CrossRef]

- Li, C.; Wu, J.; Li, Y.; Wang, X.; Zhao, Q.; Xu, K.; Dai, Z.; Gu, T. Analysis of flavor substances and flavor active substances of smelly Mandarin fish. Food Ferment. Ind. 2013, 39, 178–184. [Google Scholar] [CrossRef]

- Wang, W. Study on Protein Degradation and Flavor Formation Mechanism of Sour Fish during Fermentation; Jiangnan University: Wuxi, China, 2017. [Google Scholar]

- Ke, Z. Study on the Identification of Flavor Substances of Smelly Mandarin Fish and the Influence of Selected Strains on Its Flavor; Hebei University of Technology: Tianjin, China, 2021. [Google Scholar]

- Han, J.; Xing, L.; Zhang, W. Screening and identification of high quality fermentation strains in sour meat of Dong people in Guizhou Province. Food Ferment. Ind. 2023, 49, 85–90. [Google Scholar] [CrossRef]

- Yu, B.; Zhou, H.; Li, Z. Application of solid-phase microextraction for analysis of volatile flavors produced by traditional fermented meat. J. Hunan Agric. Univ. (Nat. Sci. Ed.) 2007, 9, 232–234. [Google Scholar] [CrossRef]

- Huang, Q.; Teng, H.; Song, H.; Li, T.; Chen, L. Analysis of volatile components of Xiangxi sour meat by solid phase microextraction combined with GC-MS. Food Ind. 2016, 37, 277–280. [Google Scholar]

- Zhong, Y.; Chen, W.; Duan, Y.; Jiang, J.; Zhu, X.; Li, K.; Wang, Y. Determination of Changes in Key Volatiles during Sour Meat Fermentation by Solid-Phase Microextraction Coupled with Gas Chromatography-Mass Spectrometry. Meat Res. 2021, 35, 20–26. [Google Scholar] [CrossRef]

- Jiang, C.; Shang, W.; Zhang, S.; Liang, H.; Ji, C.; Chen, Y.; Lin, X. Screening and Enzymatic Properties of Lipase-producing Strains and Effects of Their Inoculation on Flavor Compounds of Fermented Sour Meat. Food Sci. 2023, 44, 106–113. [Google Scholar] [CrossRef]

- Fan, X.; Chang, R.; Zhao, Z.; Zhou, C. Changes of volatile flavor substances in sour meat fermentation and their effects on quality. Food Ferment. Ind. 2019, 45, 68–75. [Google Scholar] [CrossRef]

- Li, Z. Effects of different carbon sources on microbial flora and biogenic amines in traditional sour meat. Food Ind. Sci. Technol. 2006, 28, 78–81+84. [Google Scholar] [CrossRef]

- Zhao, X.; Feng, J.; Laghi, L.; Deng, J.; Dao, X.; Tang, J.; Ji, L.; Zhu, C.; Picone, G. Characterization of Flavor Profile of “Nanx Wudl” Sour Meat Fermented from Goose and Pork Using Gas Chromatography–Ion Mobility Spectrometry (GC–IMS) Combined with Electronic Nose and Tongue. Foods 2023, 12, 2194. [Google Scholar] [CrossRef]

- Mi, R.; Chen, X.; Xiong, S.; Qi, B.; Li, J.; Qiao, X.; Wang, S.; Zhang, L. Bacterial Community Diversity and Flavor Characteristics of Traditional Naturally Fermented Sour Meat. Food Sci. 2019, 40, 85–92. [Google Scholar] [CrossRef]

- Mi, R. Effect of Lactobacillus Starter Cultures on the Volatile Flavor Components of Sour Meat. Meat Res. 2018, 32, 48–55. [Google Scholar]

- Li, W.; Bai, Y.; Chen, X.; Mi, R.; Xiong, S.; Wang, S. Effect of Acidic Protease on Microbiota and Flavor Quality of Sour Meat during Fermentation. Food Sci. 2022, 43, 158–167. [Google Scholar] [CrossRef]

| Type of Ham | Flavouring Substances |

|---|---|

| Jinhua Ham [28] | 3-Methylbutyraldehyde, 2-decadienal, 2,4-undecadienal, 5-pentyl-dihydro-2-(3H)-furanone, 5-ethyl-dihydro-2-(3H)-furanone, 6,10,14-trimethyl-2-pentadecanone, 5-methyl-2-isopropyl-cyclohexanone |

| Xuanwei Ham [29] | Furfural, 3-(methylthio)propionaldehyde, (Z)-9,17-octadecadienal, 3-thiophenecarboxaldehyde, 5-ethyl dihydro-2(3H)-furanone, dihydro-5-pentyl-2(3H)-furanone, 6,10-dimethyl-5,9-octadecadienone-2,2-pentylfuran |

| Rugao Ham [31] | 2E,4E-Decadienal, 2Z-heptenal, 2,4-pentadienal, 2Z-heptenal, triethylene glycol, 2-penten-1-ol, 1-penten-3-ol |

| Type | Flavour Substance |

|---|---|

| Identical Flavour Substances [51,52,53] | Cyclohexane, 3-methyl-pentane, limonene, esters ((E)-9-oleic acid methyl ester, ethyl butyrate, ethyl oleate, ethyl palmitate, ethyl caproate, lauric acid, ethyl caproate and ethyl caprylate) |

| Unique Flavouring Substances in Szechuan Sausage [53] | 2-Pentanol, 2-ethylhexanol, propanethiol, diallyl thiosulfinate |

| Unique Flavouring Substances in Cantonese Sausage [51,52] | Ethyl valerate, methyl 8, 11-octadecadienoate, methyl 14-methyl-pentadecanoate, methyl palmitate |

| Type | Flavour Substance |

|---|---|

| Identical Flavour Substances [75,76,77] | phenethyl alcohol, 3-methyl-1-butanol, 4-methyl-1-pentanol, 1-octen-3-ol, octanal, heptanal, ethyl acetate, limonene, terpinene, linalool |

| Unique Flavouring Substances in Anhui stinky Mandarin fish [75,77] | Trans-2-octen-1-ol, (E)-trans-2-octenal, ethyl 3-phenylpropanoate, linalyl acetate, sabinene |

| Unique Flavouring Substances in Guizhou sour fish [76] | 2-Heptanol, benzyl alcohol, cis-4-(isopropyl)-1-methylcyclohex-2-en-1-ol, ethyl 9-hexadecenoate, o-isopropyltoluene terpene |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, M.; Wang, W.; Zhang, J.; Chen, L. Flavour Characteristics of Fermented Meat Products in China: A Review. Fermentation 2023, 9, 830. https://doi.org/10.3390/fermentation9090830

Hao M, Wang W, Zhang J, Chen L. Flavour Characteristics of Fermented Meat Products in China: A Review. Fermentation. 2023; 9(9):830. https://doi.org/10.3390/fermentation9090830

Chicago/Turabian StyleHao, Mai, Wei Wang, Jiamin Zhang, and Lin Chen. 2023. "Flavour Characteristics of Fermented Meat Products in China: A Review" Fermentation 9, no. 9: 830. https://doi.org/10.3390/fermentation9090830

APA StyleHao, M., Wang, W., Zhang, J., & Chen, L. (2023). Flavour Characteristics of Fermented Meat Products in China: A Review. Fermentation, 9(9), 830. https://doi.org/10.3390/fermentation9090830