Optimization of Spontaneous Fermentation Conditions of Kohlrabi by Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

2.1. Spontaneous Fermentation of Kohlrabi

2.2. Chemical Property Analyses

2.2.1. Determination of Total Phenolic Content

2.2.2. Determination of Total Antioxidant

2.2.3. Physicochemical Analyses

2.3. Microbiological Property Analyses

2.4. Statistical Analyses

3. Results and Discussions

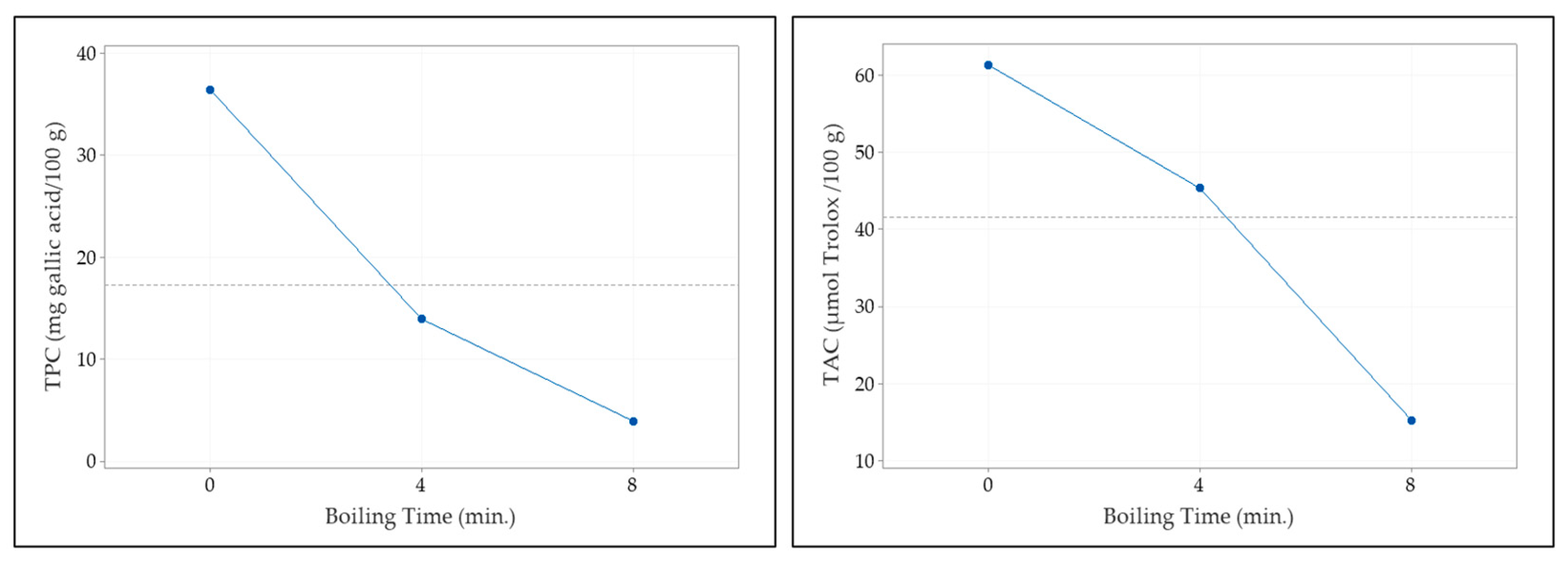

3.1. Chemical Properties of Fermented Kohlrabi

3.2. Microbiological Properties of Fermented Kohlrabi

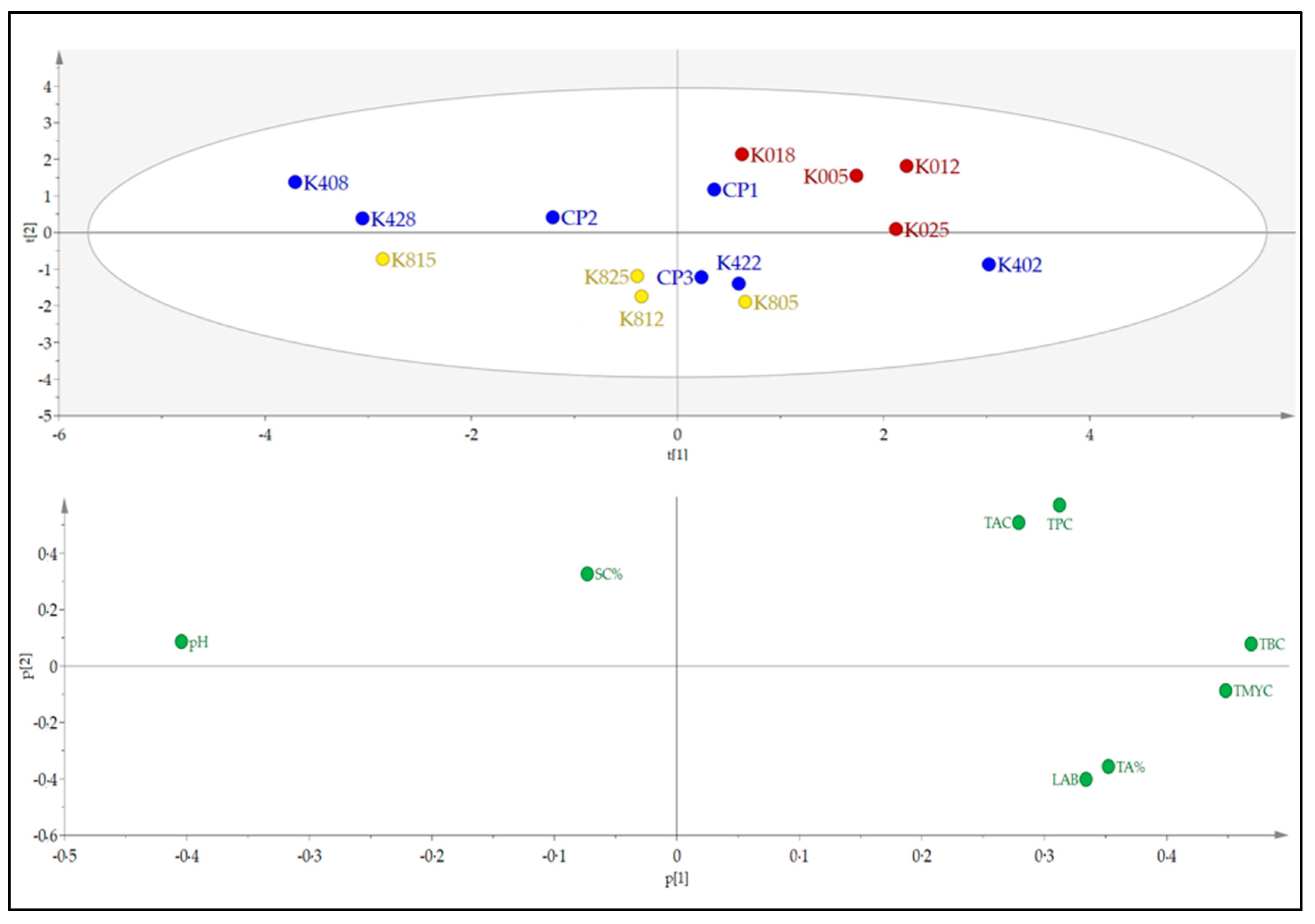

3.3. Principal Component Analysis of Fermented Kohlrabi Samples

3.4. Optimization of Spontaneous Fermentation of Kohlrabi

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Paśko, P.; Galanty, A.; Tyszka-Czochara, M.; Żmudzki, P.; Zagrodzki, P.; Gdula-Argasińska, J.; Prochownik, E.; Gorinstein, S. Health Promoting vs Anti-nutritive Aspects of Kohlrabi Sprouts, a Promising Candidate for Novel Functional Food. Plant Foods Hum. Nutr. 2021, 76, 76–82. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Z.; Zhu, M.; Zhu, Z.; Wang, Z.; Tian, S.; Chen, G. Anthocyanin accumulation and molecular analysis of correlated genes in purple kohlrabi (Brassica oleracea var. gongylodes L.). J. Agric. Food Chem. 2015, 63, 4160–4169. [Google Scholar] [CrossRef] [PubMed]

- Park, W.T.; Kim, J.K.; Park, S.; Lee, S.W.; Li, X.; Kim, Y.B.; Uddin, M.R.; Park, N.; Kim, S.J.; Park, S.U. Metabolic profiling of glucosinolates, anthocyanins, carotenoids, and other secondary metabolites in kohlrabi (Brassica oleracea var. gongylodes). J. Agric. Food Chem. 2012, 60, 8111–8116. [Google Scholar] [CrossRef] [PubMed]

- Zagrodzki, P.; Paśko, P.; Galanty, A.; Tyszka-Czochara, M.; Wietecha-Posłuszny, R.; Rubió, P.S.; Barton, H.; Prochownik, E.; Muszyńska, B.; Sułkowska-Ziaja, K.; et al. Does selenium fortification of kale and kohlrabi sprouts change significantly their biochemical and cytotoxic properties? J. Trace Elem. Miner. 2020, 59, 126466. [Google Scholar] [CrossRef] [PubMed]

- Kosewski, G.; Górna, I.; Bolesławska, I.; Kowalówka, M.; Więckowska, B.; Główka, A.K.; Morawska, A.; Jakubowski, K.; Dobrzyńska, M.; Miszczuk, P.; et al. Comparison of antioxidative properties of raw vegetables and thermally processed ones using the conventional and sous-vide methods. Food Chem. 2018, 240, 1092–1096. [Google Scholar] [CrossRef] [PubMed]

- Park, C.H.; Yeo, H.J.; Kim, N.S.; Eun, P.Y.; Kim, S.J.; Arasu, M.V.; Al-Dhabi, A.N.; Park, S.Y.; Kim, J.K.; Park, S.U. Metabolic profiling of pale green and purple kohlrabi (Brassica oleracea var. gongylodes). Appl. Biol. Chem. 2017, 60, 249–257. [Google Scholar] [CrossRef]

- Yang, Z.; Duan, X.; Yang, J.; Wang, H.; Liu, F.; Xu, X.; Pan, S. Effects of high hydrostatic pressure and thermal treatment on texture properties of pickled kohlrabi. LWT 2022, 157, 113078. [Google Scholar] [CrossRef]

- Salehi, F. Color changes kinetics during deep fat frying of kohlrabi (Brassica oleracea var. gongylodes) slice. Int. J. Food Proper. 2019, 22, 511–519. [Google Scholar] [CrossRef]

- Chen, H.; Nie, X.; Peng, T.; Xiang, L.; Liu, D.; Luo, H.; Zhao, Z. Effects of Low-Temperature and Low-Salt Fermentation on the Physicochemical Properties and Volatile Flavor Substances of Chinese Kohlrabi Using Gas Chromatography–Ion Mobility Spectrometry. Fermentation 2023, 9, 146. [Google Scholar] [CrossRef]

- Yeo, H.J.; Lim, S.-Y.; Park, C.H.; Kim, C.Y.; Sathasivam, R.; Kim, J.K.; Park, S.U. Metabolic Analyses and Evaluation of Antioxidant Activity in Purple Kohlrabi Sprouts after Exposed to UVB Radiation. Antioxidants 2022, 11, 1443. [Google Scholar] [CrossRef]

- Nie, X.; Chen, H.; Xiang, L.; Zhang, Y.; Liu, D.; Zhao, Z. GC-TOF-MS-Based Non-Targeted Metabolomic Analysis of Differential Metabolites in Chinese Ultra-Long-Term Industrially Fermented Kohlrabi and Their Associated Metabolic Pathways. Metabolites 2022, 12, 991. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Banat, F.; Taher, H. A review on the lactic acid fermentation from low-cost renewable materials: Recent developments and challenges. Environ. Technol. Innov. 2020, 20, 101138. [Google Scholar] [CrossRef]

- Rodríguez, L.G.R.; Gasga, V.M.Z.; Pescuma, M.; Van Nieuwenhove, C.; Mozzi, F.; Burgos, J.A.S. Fruits and fruit by-products as sources of bioactive compounds. Benefits and trends of lactic acid fermentation in the development of novel fruit-based functional beverages. Food Res. Int. 2021, 140, 109854. [Google Scholar] [CrossRef] [PubMed]

- Degrain, A.; Manhivi, V.; Remize, F.; Garcia, C.; Sivakumar, D. Effect of Lactic Acid Fermentation on Color, Phenolic Compounds and Antioxidant Activity in African Nightshade. Microorganisms 2020, 8, 1324. [Google Scholar] [CrossRef]

- Karami, Z.; Akbari-Adergani, B. Bioactive food derived peptides: A review on correlation between structure of bioactive peptides and their functional properties. J. Food Sci. Technol. 2019, 56, 535–547. [Google Scholar] [CrossRef] [PubMed]

- Granato, D.; Barba, F.J.; Bursać Kovačević, D.; Lorenzo, J.M.; Cruz, A.G.; Putnik, P. Functional foods: Product development, technological trends, efficacy testing, and safety. Ann. Rev. Food Sci. Technol. 2020, 11, 93–118. [Google Scholar] [CrossRef]

- Aktas, A.B.; Ozen, B.; Tokatli, F.; Sen, I. Phenolics profile of a naturally debittering olive in comparison to regular olive varieties. J. Sci. Food Agric. 2014, 94, 691–698. [Google Scholar] [CrossRef]

- Akbas, E.; Kilercioglu, M.; Onder, O.N.; Koker, A.; Soyler, B.; Oztop, M.H. Wheatgrass juice to wheat grass powder: Encapsulation, physical and chemical characterization. J. Funct. Foods 2017, 28, 19–27. [Google Scholar] [CrossRef]

- Nielsen, S.S. Sodium Determination Using Ion-Selective Electrodes, Mohr Titration, and Test Strips. In Food Analysis Laboratory Manual, 3rd ed.; Nielsen, S.S., Ed.; Springer: New York, NY, USA, 2017; pp. 160–170. [Google Scholar] [CrossRef]

- Cemeroglu, B. Gıda Analizleri Genişletilmiş 2. Baskı, 3rd ed.; Gıda Teknolojisi Derneği Yayınları: Ankara, Türkiye, 2010; pp. 34–44. [Google Scholar]

- Halkman, A.K. Mikroorganizma Analiz Yöntemleri. In Merck Gıda Mikrobiyolojisi Uygulamaları, 1st ed.; Halkman, A.K., Ed.; Başak Matbaacılık Ltd., Şti.: Ankara, Türkiye, 2005; pp. 89–124. [Google Scholar]

- Farahnaky, A.; Kamali, E.; Golmakani, M.T.; Gavahian, M.; Mesbahi, G.; Majzoobi, M. Effect of ohmic and microwave cooking on some bioactive compounds of kohlrabi, turnip, potato, and radish. J. Food Meas. Charact. 2018, 12, 2561–2569. [Google Scholar] [CrossRef]

- Bajkacz, S.; Ligor, M.; Baranowska, I.; Buszewski, B. Separation and Determination of Chemopreventive Phytochemicals of Flavonoids from Brassicaceae Plants. Molecules 2021, 26, 4734. [Google Scholar] [CrossRef]

- Deepa, P.; Sowndhararajan, K.; Park, S.J. Polyphenolic contents and antioxidant activity of brassicaceae sprouts cultivated in the plant factory system. J. Agric. Life Environ. Sci. 2020, 32, 321–331. [Google Scholar] [CrossRef]

- Hien, T.T.; Truc, T.T.; Muoi, N.V. Effect of salt concentration and pH value on the lactic fermentation process of kohlrabi (Brassica oleracea L.). Res. Innov. Food Sci. Technol. 2022, 10, 399–412. [Google Scholar] [CrossRef]

- Kao, C.C.; Wang, H.M.; Tsai, S.J.; Lin, J.Y. Sensory and microbial analyses on naturally lacto-fermented cucumbers. Int. J. Gastron. Food Sci. 2023, 32, 100714. [Google Scholar] [CrossRef]

- Haile, M.; Kang, W.H. Isolation, identification, and characterization of pectinolytic yeasts for starter culture in coffee fermentation. Microorganisms 2017, 7, 401. [Google Scholar] [CrossRef] [PubMed]

- Guan, Q.; Zheng, W.; Huang, T.; Xiao, Y.; Liu, Z.; Peng, Z.; Gong, D.; Xie, M.; Xiong, T. Comparison of microbial communities and physiochemical characteristics of two traditionally fermented vegetables. Food Res. Int. 2019, 128, 108755. [Google Scholar] [CrossRef]

- Viander, B.; Mäki, M.; Palva, A. Impact of low salt concentration, salt quality on natural large-scale sauerkraut fermentation. Food Microbiol. 2003, 20, 391–395. [Google Scholar] [CrossRef]

- Liong, M.T.; Shah, N.P. Acid and bile tolerance and cholesterol removal ability of lactobacilli strains. J. Dairy Sci. 2005, 88, 55–66. [Google Scholar] [CrossRef]

- Ahmed, S.; Ashraf, F.; Tariq, M.; Zaidi, A. Aggrandizement of fermented cucumber through the action of autochthonous probiotic cum starter strains of Lactiplantibacillus plantarum and Pediococcus pentosaceus. Ann. Microbiol. 2021, 71, 33. [Google Scholar] [CrossRef]

| Experiment No | Boiling Time (min.) | Vinegar Concentration (%) | Salt Concentration (%) | Sample Code | pH | Salt Content (%) | Total Acidity (%) | TPC (mg Gallic Acid/100 g) | TAC (µmol Trolox/100 g) | TMYC (log CFU/mL) | TBC (log CFU/mL) | Total LAB (log CFU/mL) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 4 | 0 | 8 | K408 | 3.84 | 5.00 | 0.85 | 11.57 | 42.39 | 6.20 | 6.13 | 6.07 |

| 2 | 4 | 0 | 2 | K402 | 3.16 | 1.65 | 1.67 | 16.00 | 47.28 | 7.98 | 7.28 | 8.26 |

| 3 | 4 | 25 | 5 | CP1 | 3.14 | 3.43 | 1.31 | 26.91 | 46.47 | 6.73 | 6.82 | 6.39 |

| 4 | 4 | 25 | 5 | CP2 | 3.23 | 3.47 | 1.42 | 24.82 | 43.60 | 5.73 | 6.13 | 6.07 |

| 5 | 0 | 50 | 5 | K025 | 3.18 | 3.17 | 1.49 | 31.52 | 47.33 | 6.92 | 7.19 | 7.40 |

| 6 | 0 | 25 | 2 | K012 | 3.19 | 1.64 | 1.43 | 39.88 | 75.75 | 7.19 | 7.08 | 7.09 |

| 7 | 0 | 0 | 5 | K005 | 3.08 | 3.89 | 1.27 | 38.25 | 65.34 | 7.09 | 6.83 | 7.83 |

| 8 | 0 | 25 | 8 | K018 | 3.11 | 5.03 | 1.13 | 35.98 | 56.56 | 6.42 | 7.17 | 6.62 |

| 9 | 8 | 50 | 5 | K825 | 3.14 | 3.77 | 1.39 | 4.71 | 11.91 | 6.42 | 6.70 | 6.53 |

| 10 | 4 | 25 | 5 | CP3 | 3.30 | 3.49 | 1.42 | 5.15 | 45.82 | 6.79 | 6.84 | 7.86 |

| 11 | 8 | 0 | 5 | K805 | 3.08 | 3.12 | 1.28 | 3.83 | 17.48 | 7.09 | 6.83 | 7.83 |

| 12 | 8 | 25 | 8 | K815 | 3.80 | 5.57 | 1.30 | 2.75 | 15.30 | 6.42 | 6.42 | 6.25 |

| 13 | 4 | 50 | 8 | K428 | 3.46 | 5.40 | 1.12 | 7.57 | 46.47 | 5.26 | 6.19 | 6.20 |

| 14 | 8 | 25 | 2 | K812 | 3.16 | 1.82 | 1.28 | 4.35 | 16.16 | 6.09 | 6.19 | 8.26 |

| 15 | 4 | 50 | 2 | K422 | 3.16 | 1.61 | 1.65 | 5.30 | 44.86 | 6.09 | 6.19 | 8.26 |

| pH | Salt Content (%) | Total Acidity (%) | TPC (mg Gallic Acid/100 g) | TAC (µmol Trolox/100 g) | TMYC (log CFU/mL) | TBC (log CFU/mL) | LAB (log CFU/mL) | |

|---|---|---|---|---|---|---|---|---|

| p-value of model | 0.13 | 0.00 | 0.31 | 0.05 | 0.00 | 0.40 | 0.58 | 0.38 |

| p-value of lack of fit | 0.14 | 1.00 | 0.07 | 0.99 | 0.04 | 0.52 | 0.47 | 0.75 |

| R2 | 0.84 | 1.00 | 0.74 | 0.89 | 0.97 | 0.70 | 0.62 | 0.71 |

| Radj2 | 0.55 | 1.00 | 0.28 | 0.69 | 0.91 | 0.17 | 0.00 | 0.20 |

| Q2 | 0.00 | 0.92 | 0.00 | 0.66 | 0.50 | 0.00 | 0.00 | 0.00 |

| p-value of factors | ||||||||

| Boiling Time (BT) | 0.24 | 0.27 | 0.87 | 0.00 | 0.00 | 0.39 | 0.15 | 0.97 |

| Vinegar Concentration (VC) | 0.65 | 0.54 | 0.30 | 0.40 | 0.23 | 0.09 | 0.54 | 0.50 |

| Salt Concentration (SC) | 0.02 | 0.00 | 0.02 | 0.74 | 0.20 | 0.14 | 0.53 | 0.03 |

| p-value of interactions | ||||||||

| BT*BT | 0.31 | 0.47 | 0.74 | 0.23 | 0.06 | 0.38 | 0.27 | 0.57 |

| VC*VC | 0.94 | 0.69 | 0.97 | 0.27 | 0.39 | 0.64 | 0.96 | 0.38 |

| SC*SC | 0.08 | 0.90 | 0.49 | 0.39 | 0.40 | 0.57 | 0.51 | 0.92 |

| BT*VC | 0.91 | 0.01 | 0.76 | 0.65 | 0.32 | 0.70 | 0.60 | 0.60 |

| BT*SC | 0.08 | 0.31 | 0.42 | 0.89 | 0.16 | 0.41 | 0.88 | 0.37 |

| VC*SC | 0.30 | 0.22 | 0.44 | 0.69 | 0.59 | 0.47 | 0.25 | 0.94 |

| pH | TA (%) | SC (%) | TPC (mg Gallic Acid/100 g) | TAC (µmol Trolox/100 g) | TMYC (log CFU/mL) | TBC (log CFU/mL) | |

|---|---|---|---|---|---|---|---|

| pH | |||||||

| TA% | |||||||

| SC% | 0.6 | −0.72 | |||||

| TPC (mg gallic acid/100 g) | −0.37 | 0.02 | −0.07 | ||||

| TAC (µmol Trolox/100 g) | −0.22 | 0.07 | −0.14 | 0.80 | |||

| TMYC (log CFU/mL) | −0.36 | 0.44 | −0.46 | 0.32 | 0.24 | ||

| TBC (log CFU/mL) | −0.49 | 0.35 | −0.22 | 0.54 | 0.38 | 0.82 | |

| LAB (log CFU/mL) | −0.54 | 0.57 | −0.73 | −0.11 | 0.03 | 0.52 | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karaoglan, H.A.; Aktas, A.B. Optimization of Spontaneous Fermentation Conditions of Kohlrabi by Response Surface Methodology. Fermentation 2023, 9, 550. https://doi.org/10.3390/fermentation9060550

Karaoglan HA, Aktas AB. Optimization of Spontaneous Fermentation Conditions of Kohlrabi by Response Surface Methodology. Fermentation. 2023; 9(6):550. https://doi.org/10.3390/fermentation9060550

Chicago/Turabian StyleKaraoglan, Hatice Aybuke, and Ayse Burcu Aktas. 2023. "Optimization of Spontaneous Fermentation Conditions of Kohlrabi by Response Surface Methodology" Fermentation 9, no. 6: 550. https://doi.org/10.3390/fermentation9060550

APA StyleKaraoglan, H. A., & Aktas, A. B. (2023). Optimization of Spontaneous Fermentation Conditions of Kohlrabi by Response Surface Methodology. Fermentation, 9(6), 550. https://doi.org/10.3390/fermentation9060550