Single-Chamber Electrofermentation of Rumen Fluid Increases Microbial Biomass and Volatile Fatty Acid Production without Major Changes in Diversity

Abstract

1. Introduction

2. Materials and Methods

2.1. Ruminal Fluid Collection

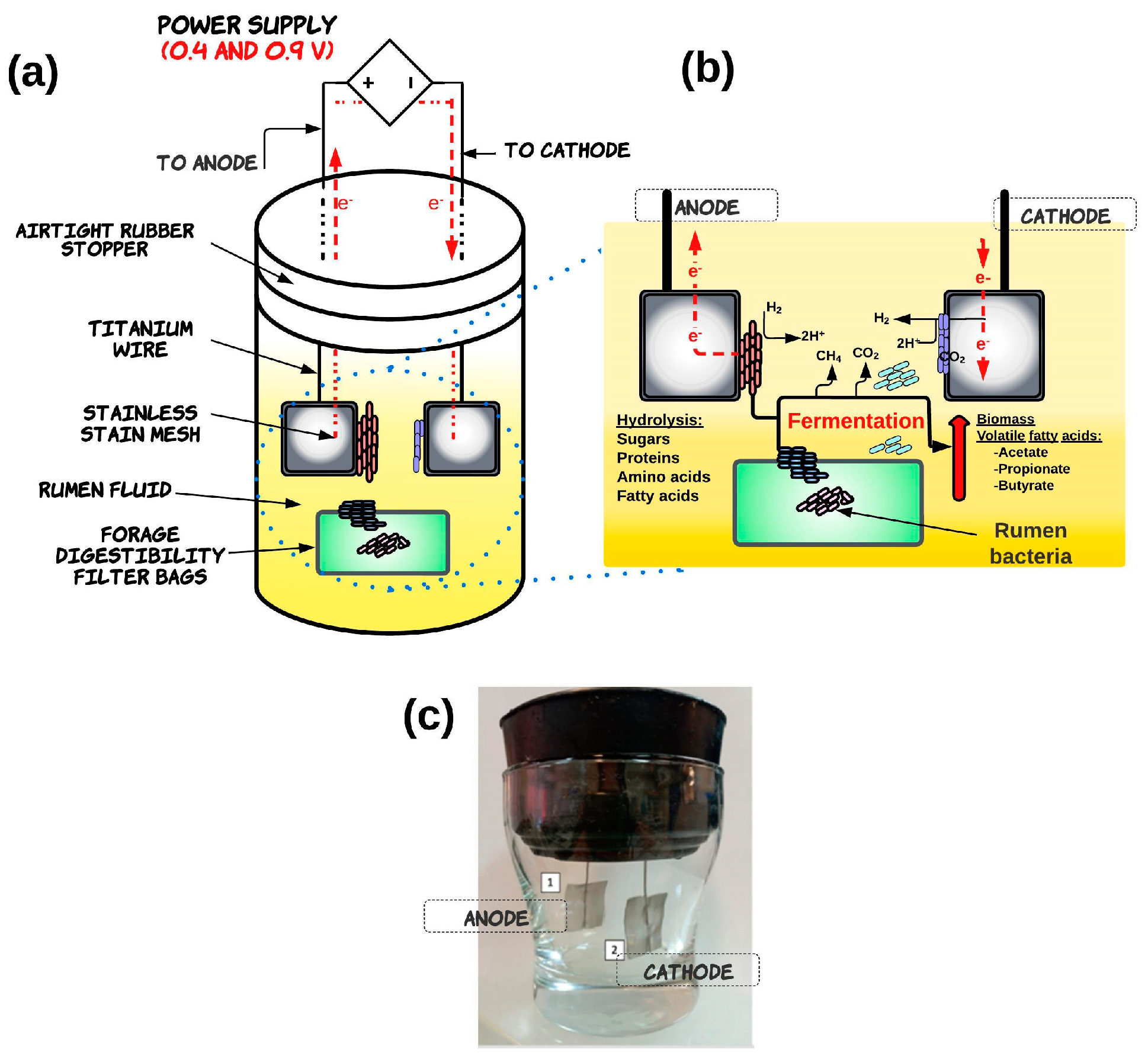

2.2. Electrofermentation System Design and Operation

2.3. Biomass Determination

2.4. Dry Matter Digestibility

2.5. Volatile Fatty Acid Quantification Using Gas Chromatography

2.6. NADH/NAD Ratio Assay

2.7. DNA Extraction and Illumina Sequencing

2.8. Statistical Analysis

3. Results

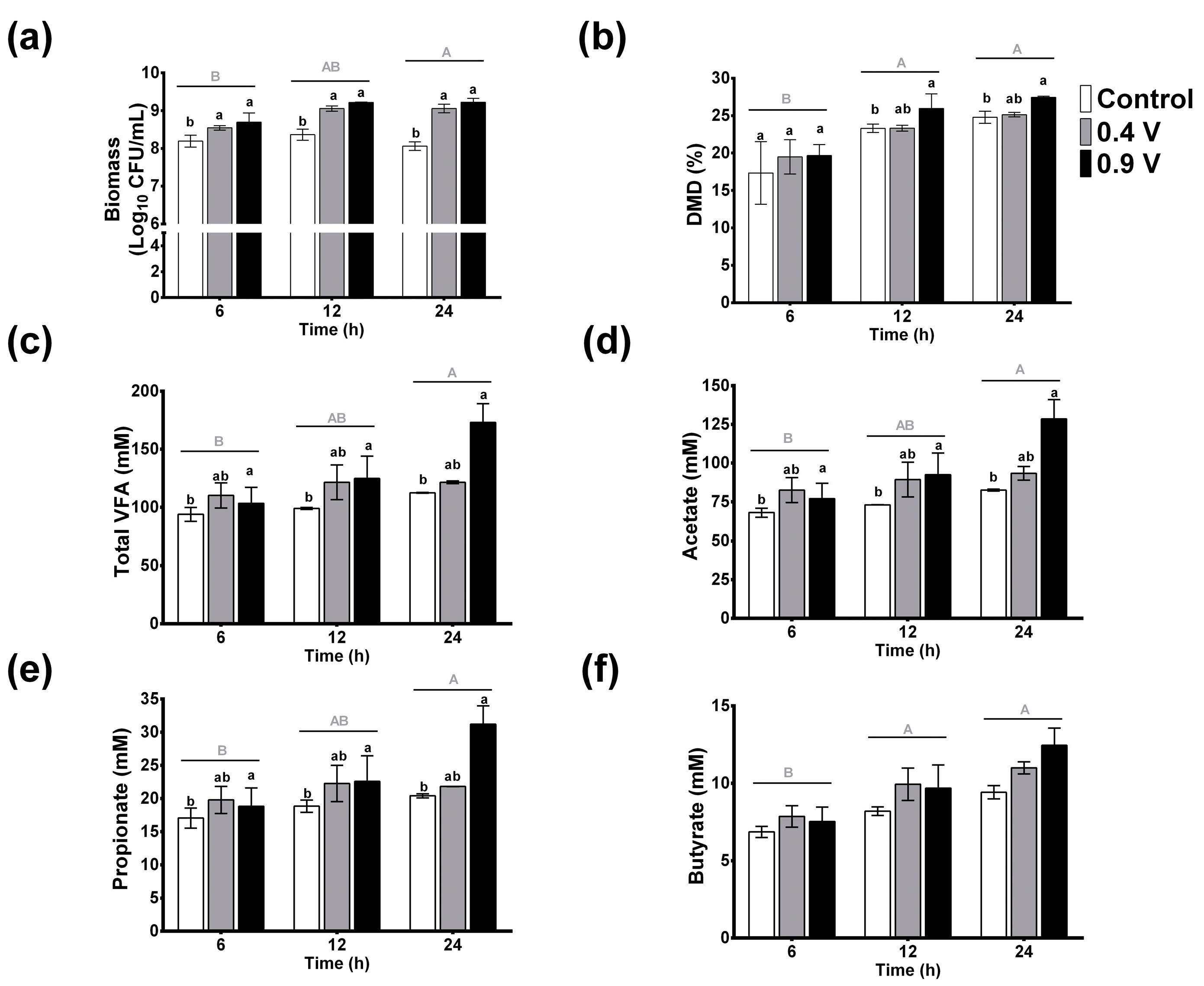

3.1. Effects of Ruminal Electrofermentation on Biomass and Dry Matter Digestibility

3.2. Volatile Fatty Acids

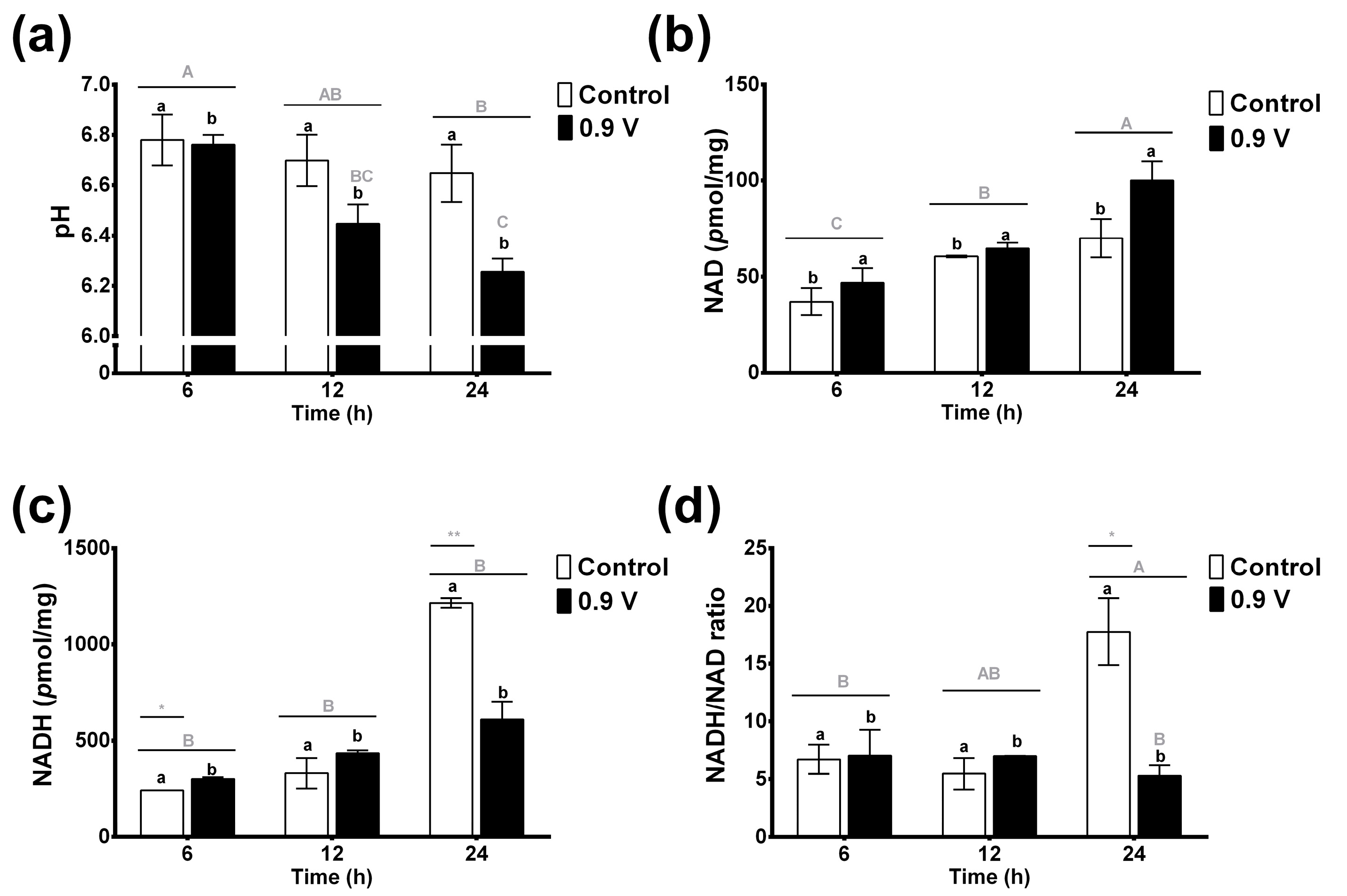

3.3. Effects of Rumen Electrofermentation on pH and NADH/NAD Ratio

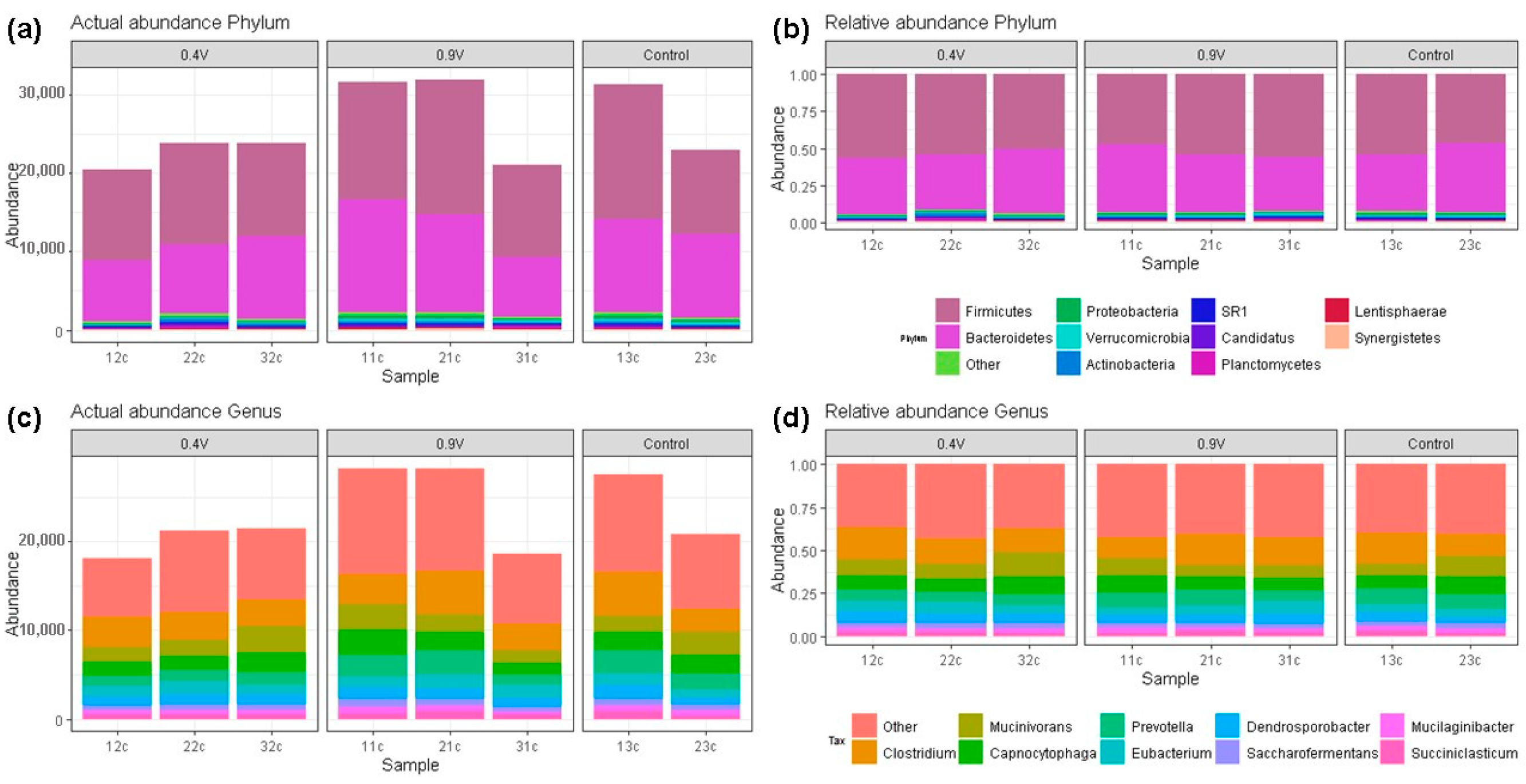

3.4. Rumen Microbial Community Composition across Electrofermentation Systems

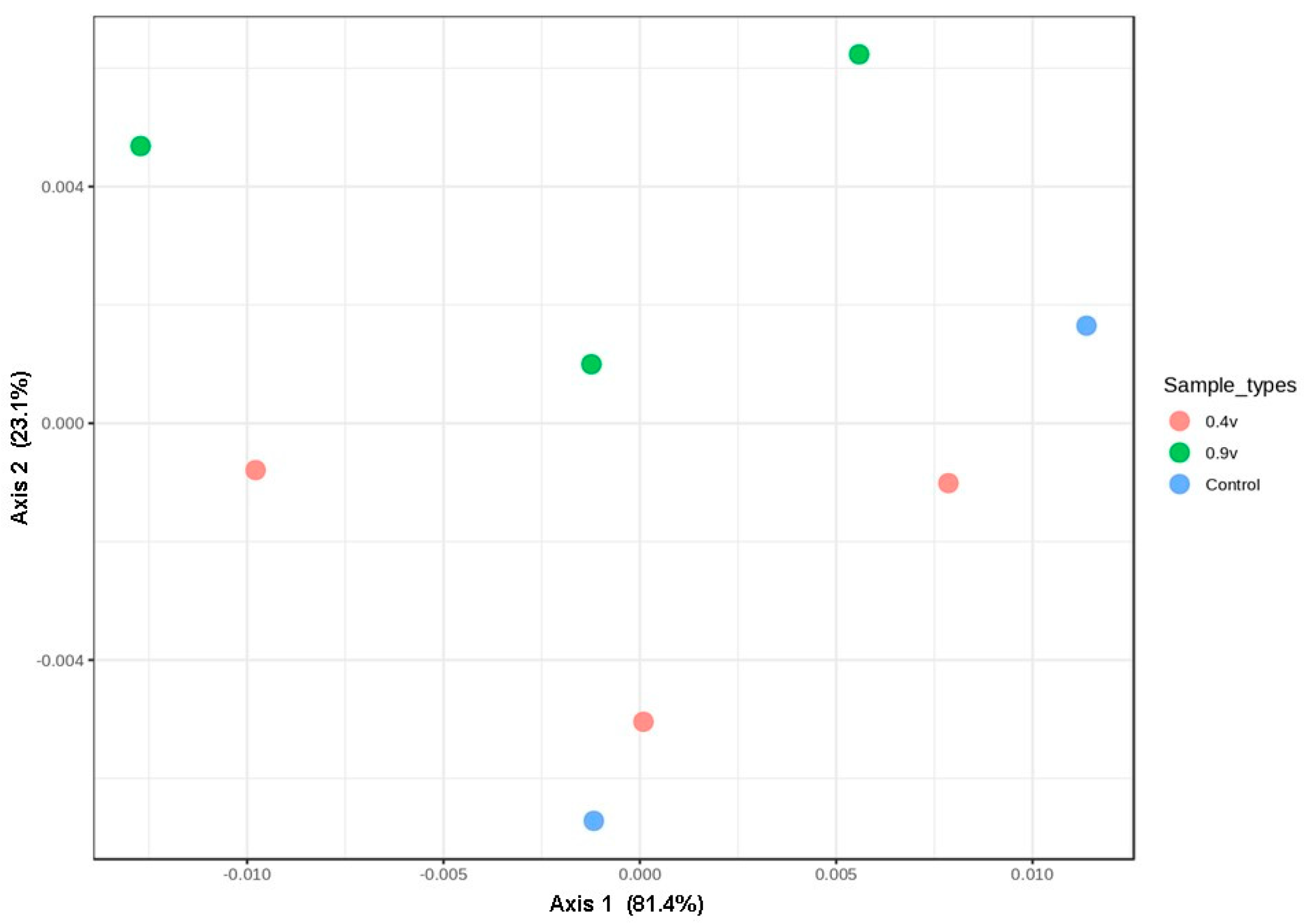

3.5. Rumen Bacterial Diversity and Similarities in the Electrofermentation System

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Owens, F.N.; Basalan, M. Ruminal fermentation. In Rumenology; Millen, D.D., De Beni Arrigoni, M., Pacheco, R.D.L., Eds.; Springer: Cham, Switzerland, 2016; pp. 63–102. [Google Scholar]

- Nagaraja, T.G.; Newbold, C.J.; van Nevel, C.J.; Demeyer, D.I. Manipulation of ruminal fermentation. In The Rumen Microbial Ecosystem; Springer: Dordrecht, The Netherland, 1997; pp. 523–632. Available online: http://link.springer.com/10.1007/978-94-009-1453-7_13 (accessed on 10 January 2023).

- Aguilar-González, M.; Buitrón, G.; Shimada-Miyasaka, A.; Mora, O. State of the art of bioelectrochemical systems: Feasibility for enhancing rumen propionate production. Agrociencia 2016, 50, 149–166. [Google Scholar]

- Castillo-González, A.R.; Burrola-Barraza, M.E.; Domínguez-Viveros, J.; Chávez-Martínez, A. Rumen microorganisms and fermentation. Arch. Med. Vet. 2014, 46, 349–361. [Google Scholar] [CrossRef]

- Azzaz, H.H.; Murad, H.A.; Morsy, T.A. Utility of ionophores for ruminant animals: A review. Asian J. Anim. Sci. 2015, 9, 254–265. [Google Scholar] [CrossRef]

- Zhou, R.; Wu, J.; Lang, X.; Liu, L.; Casper, D.P.; Wang, C.; Zhang, L.; Shen, W. Effects of oregano essential oil on in vitro ruminal fermentation, methane production, and ruminal microbial community. J. Dairy Sci. 2020, 103, 2303–2314. [Google Scholar] [CrossRef]

- Jadhav, R.V.; Kannan, A.; Bhar, R.; Sharma, O.P.; Gulati, A.; Rajkumar, K.; Zhang, L.; Sheng, W. Effect of tea (Camellia sinensis) seed saponins on in vitro rumen fermentation, methane production and true digestibility at different forage to concentrate ratios. J. Appl. Anim. Res. 2018, 46, 118–144. [Google Scholar] [CrossRef]

- Arowolo, M.A.; He, J. Use of probiotics and botanical extracts to improve ruminant production in the tropics. Anim. Nutr. J. 2018, 4, 241–249. [Google Scholar] [CrossRef]

- Yamada, S.; Takamatsu, Y.; Ikeda, S.; Kouzuma, A.; Watanabe, K. Towards application of electro-fermentation for the production of value-added chemicals from biomass feedstocks. Front. Chem. 2022, 9, 1–7. [Google Scholar] [CrossRef]

- Moscoviz, R.; Toledo-Alarcón, J.; Trably, E.; Bernet, N. Electro-fermentation: How to drive fermentation using electrochemical systems. Trends Biotechnol. 2016, 34, 856–865. [Google Scholar] [CrossRef]

- Bhagchandanii, D.D.; Babu, R.P.; Sonawane, J.M.; Khanna, N.; Pandit, S.; Jadhav, D.A.; Khilari, S.; Prassad, R. A comprehensive uderstanding of electro-fermentation. Fermentation 2020, 6, 92. [Google Scholar] [CrossRef]

- Schievano, A.; Sciarria, T.P.; Vanbroekhoven, K.; De Wever, H.; Puig, S.; Andersen, S.J.; Rabaey, K.; Pant, D. Electro-fermentation-merging electrochemistry with fermentation in industrial applications. Trends Biotechnol. 2016, 34, 866–878. [Google Scholar] [CrossRef]

- Gong, Z.; Yu, H.; Zhang, J.; Li, F.; Song, H. Microbial electro-fermentation for synthesis of chemicals and biofuels driven by bi-directional extracellular electron transfer. Synth. Syst. Biotechnol. 2020, 5, 304–313. [Google Scholar] [CrossRef] [PubMed]

- Rismani-Yazdi, H.; Christy, A.D.; Dehority, B.A.; Morrison, M.; Yu, Z.; Tuovinen, O.H. Electricity generation from cellulose by rumen microorganisms in microbial fuel cells. Biotechnol. Bioeng. 2007, 97, 1398–1407. [Google Scholar] [CrossRef]

- Zang, G.L.; Sheng, G.P.; Tong, Z.H.; Liu, X.W.; Teng, S.X.; Li, W.W.; Yu, H.Q. Direct electricity recovery from canna indica by an air-cathode microbial fuel cell inoculated with rumen microorganisms. Environ. Sci. Technol. 2010, 44, 2715–2720. [Google Scholar] [CrossRef] [PubMed]

- Rismani-Yazdi, H.; Carver, S.M.; Christy, A.D.; Yu, Z.; Bibby, K.; Peccia, J.; Touvinen, O.H. Suppression of methanogenesis in cellulose-fed microbial fuel cells in relation to performance, metabolite formation, and microbial population. Bioresour. Technol. 2013, 129, 281–288. [Google Scholar] [CrossRef] [PubMed]

- Chung, R.; Kang, E.Y.; Shin, Y.J.; Park, J.J.; Park, P.S.; Han, C.H.; Kim, B.; Moon, S.I.; Park, J.; Chung, P.S. Development of a consolidated anaerobic digester and microbial fuel cell to produce biomethane and electricity from cellulosic biomass using bovine rumen microorganisms. J. Sustain. Bioenergy Syst. 2019, 9, 17–28. [Google Scholar] [CrossRef]

- Tsan, W.C.; Ming, Y.C.; Sheng, C.Z.; Shuai, T. Effect of biometric flow channel on the power generation at different Reynolds numbers in the single chamber of rumen microbial fuel cells (RMFCs). Int. J. Hydrogen Energy 2011, 36, 9242–9251. [Google Scholar] [CrossRef]

- Wang, C.T.; Yang, C.M.J.; Chen, Z.S. Rumen microbial volatile fatty acids in relation to oxidation reduction potential and electricity generation from straw in microbial fuel cells. Biomass Bioenergy 2012, 37, 318–329. [Google Scholar] [CrossRef]

- Aguilar-González, M.; Buitrón, G.; Shimada, A.; Ayala-Sumuano, J.; González-Dávalos, L.; Varela-Echavarría, A.; Mora, O. Study on manipulation of ruminal fermentation using a bioelectrochemical system. J. Anim. Physiol. Anim. Nutr. 2022, 107, 357–366. [Google Scholar] [CrossRef]

- Norma Oficial Mexicana nom-062-zoo-1999, Especificaciones Tecnicas Para la Produccion, Cuidado y Uso de Los Animales de Laboratorio. Diario Oficial de la Federación. 2001. Available online: https://www.gob.mx/cms/uploads/attachment/file/203498/NOM-062-ZOO-1999_220801.pdf. (accessed on 15 November 2022).

- Rodríguez-González, S.; González-Dávalos, L.; Robles-Rodríguez, C.; Lozano-Flores, C.; Varela-Echavarría, A.; Shimada-Miyasaka, A.; Mora, O. Isolation of bacterial consortia with probiotic potential from the rumen of tropical calves. J. Anim. Physiol. Anim. Nutr. 2023, 107, 2–7. [Google Scholar] [CrossRef]

- Yu, Z.; Morrison, M. Improved extraction of PCR-quality community DNA from digesta and fecal samples. Bio Tech. 2004, 36, 808–812. [Google Scholar] [CrossRef]

- Edgar, R.C. Search and clustering orders of magnitude faster than BLAST. Bioinformatics 2010, 26, 2460–2461. [Google Scholar] [CrossRef] [PubMed]

- McMurdie, P.J.; Holmes, S. Phyloseq: An R package for reproducible interactive analysis and graphics of microbiome census data. PLoS ONE 2013, 8, e61217. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, N.; Karthikeyan, M. Study of single chamber and double chamber efficiency and losses of wastewater treatment. Int. Res. J. Eng. Technol. 2018, 5, 1225–1230. [Google Scholar]

- Kracke, F.; Lai, B.; Yu, S.; Krömer, J.O. Balancing cellular redox metabolism in microbial electrosynthesis and electro fermentation–A chance for metabolic engineering. Metab. Eng. 2018, 4, 109–120. [Google Scholar] [CrossRef]

- Chen, B.; Rupani, P.F.; Azman, S.; Dewil, R.; Apples, L. A redox-based strategy to enhance propionic and butyric acid production during anaerobic fermentation. Bioresour Technol. 2022, 361, 127672. [Google Scholar] [CrossRef] [PubMed]

- Choi, O.; Kim, T.; Woo, H.M.; Um, Y. Electricity-driven metabolic shift through direct electron uptake by electroactive heterotroph Clostridium pasteurianum. Sci. Rep. 2014, 4, 6961. [Google Scholar] [CrossRef]

- Niu, D.; Yu, C.; Zheng, M.; Jianjun, R.; Li, C.; Xu, C. Effects of ensiling on Irpex lacteus fermentation in wheat straw: Chemical composition, in vitro rumen digestibility, and fungal community. Anim. Feed. Sci. Technol. 2022, 292, 115433. [Google Scholar] [CrossRef]

| Treatment | Observed OTUs | Chao1 Index | Shannon Index |

|---|---|---|---|

| Control | 1329.0 ± 23.0 | 1395.3 ± 5.4 | 6.12 ± 0.03 |

| 0.4 V | 1317.0 ± 27.0 | 1361.2 ± 22.0 | 6.15 ± 0.00 |

| 0.9 V | 1294.3 ± 11.6 | 1350.8 ± 13.0 | 6.06 ± 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Hernández, R.; Cercado-Quezada, B.; Gómez-Velázquez, H.D.J.; Robles-Rodríguez, C.; González-Dávalos, L.; Varela-Echavarría, A.; Shimada, A.; Mora, O. Single-Chamber Electrofermentation of Rumen Fluid Increases Microbial Biomass and Volatile Fatty Acid Production without Major Changes in Diversity. Fermentation 2023, 9, 502. https://doi.org/10.3390/fermentation9060502

López-Hernández R, Cercado-Quezada B, Gómez-Velázquez HDJ, Robles-Rodríguez C, González-Dávalos L, Varela-Echavarría A, Shimada A, Mora O. Single-Chamber Electrofermentation of Rumen Fluid Increases Microbial Biomass and Volatile Fatty Acid Production without Major Changes in Diversity. Fermentation. 2023; 9(6):502. https://doi.org/10.3390/fermentation9060502

Chicago/Turabian StyleLópez-Hernández, Rocío, Bibiana Cercado-Quezada, Haiku D. J. Gómez-Velázquez, Carolina Robles-Rodríguez, Laura González-Dávalos, Alfredo Varela-Echavarría, Armando Shimada, and Ofelia Mora. 2023. "Single-Chamber Electrofermentation of Rumen Fluid Increases Microbial Biomass and Volatile Fatty Acid Production without Major Changes in Diversity" Fermentation 9, no. 6: 502. https://doi.org/10.3390/fermentation9060502

APA StyleLópez-Hernández, R., Cercado-Quezada, B., Gómez-Velázquez, H. D. J., Robles-Rodríguez, C., González-Dávalos, L., Varela-Echavarría, A., Shimada, A., & Mora, O. (2023). Single-Chamber Electrofermentation of Rumen Fluid Increases Microbial Biomass and Volatile Fatty Acid Production without Major Changes in Diversity. Fermentation, 9(6), 502. https://doi.org/10.3390/fermentation9060502