Low-Grade Syngas Biomethanation in Continuous Reactors with Respect to Gas–Liquid Mass Transfer and Reactor Start-Up Strategy

Abstract

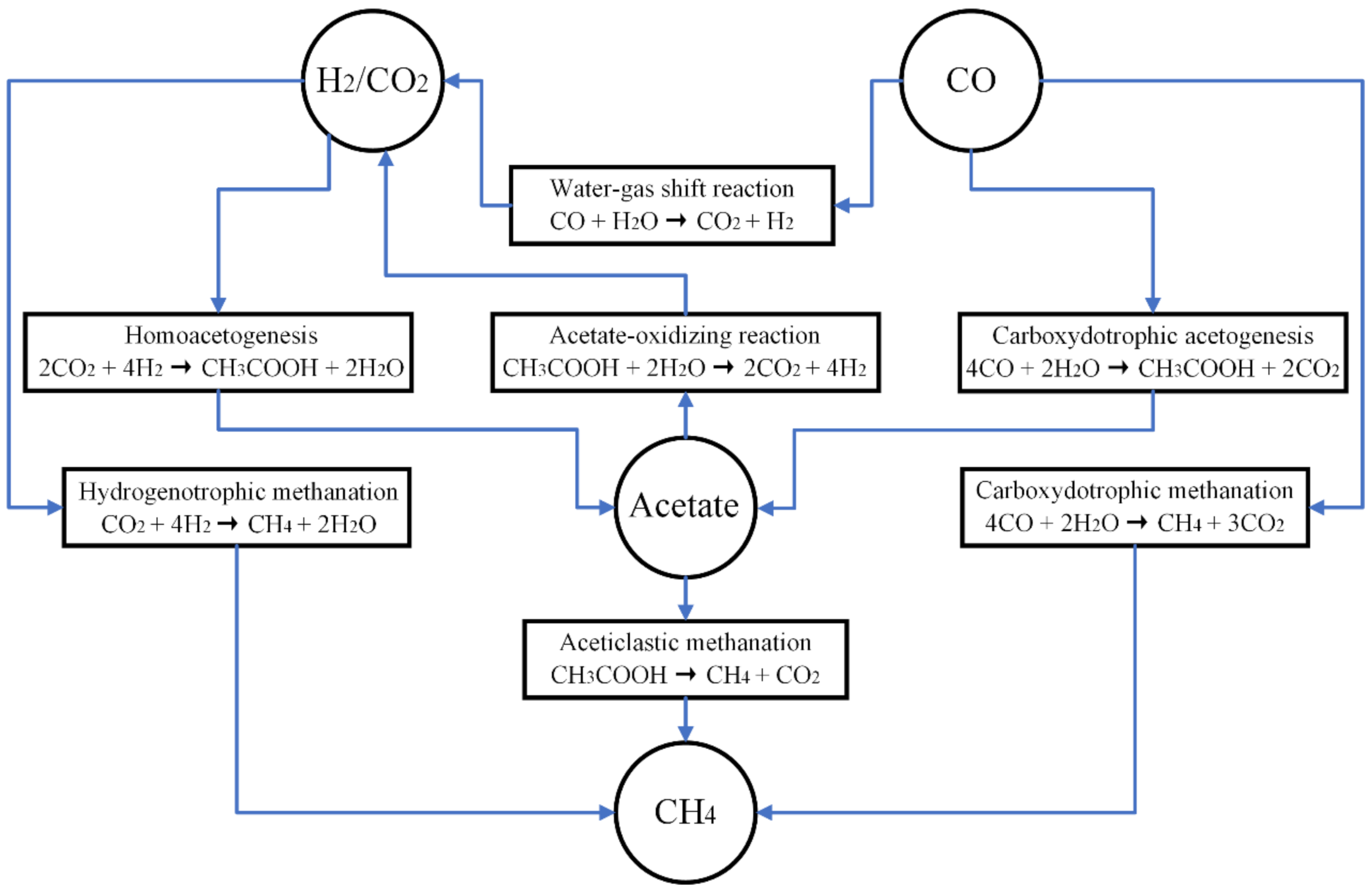

1. Introduction

2. Materials and Methods

2.1. Growth Medium and Inoculum

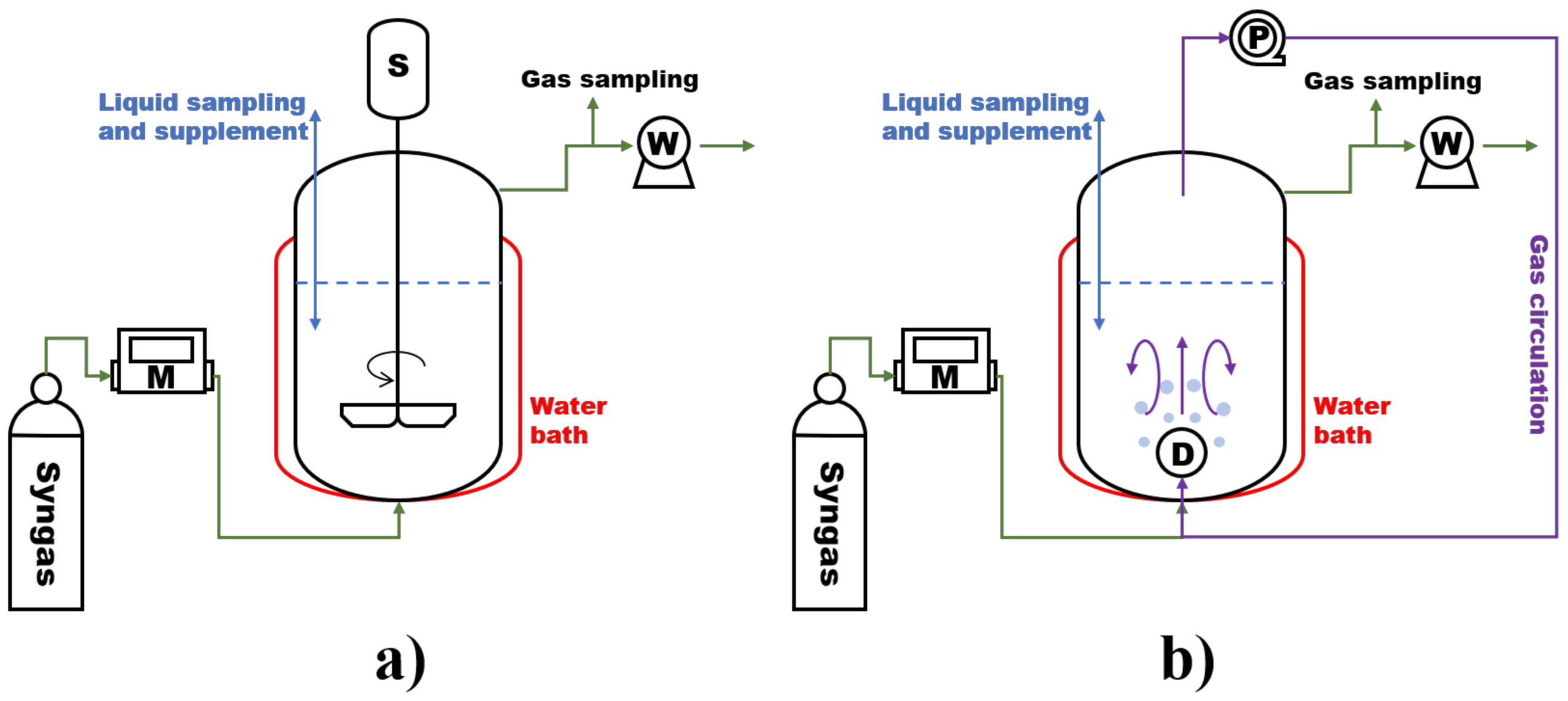

2.2. Reactor Configuration and Operation

2.2.1. Continuous Stirred Tank Reactor

2.2.2. Bubble Column Reactor with Gas Circulation

2.2.3. Start-Up Strategy

2.3. Analytical Methods

2.4. Calculations

2.5. Gene Sequencing and Functional Analysis

3. Results and Discussion

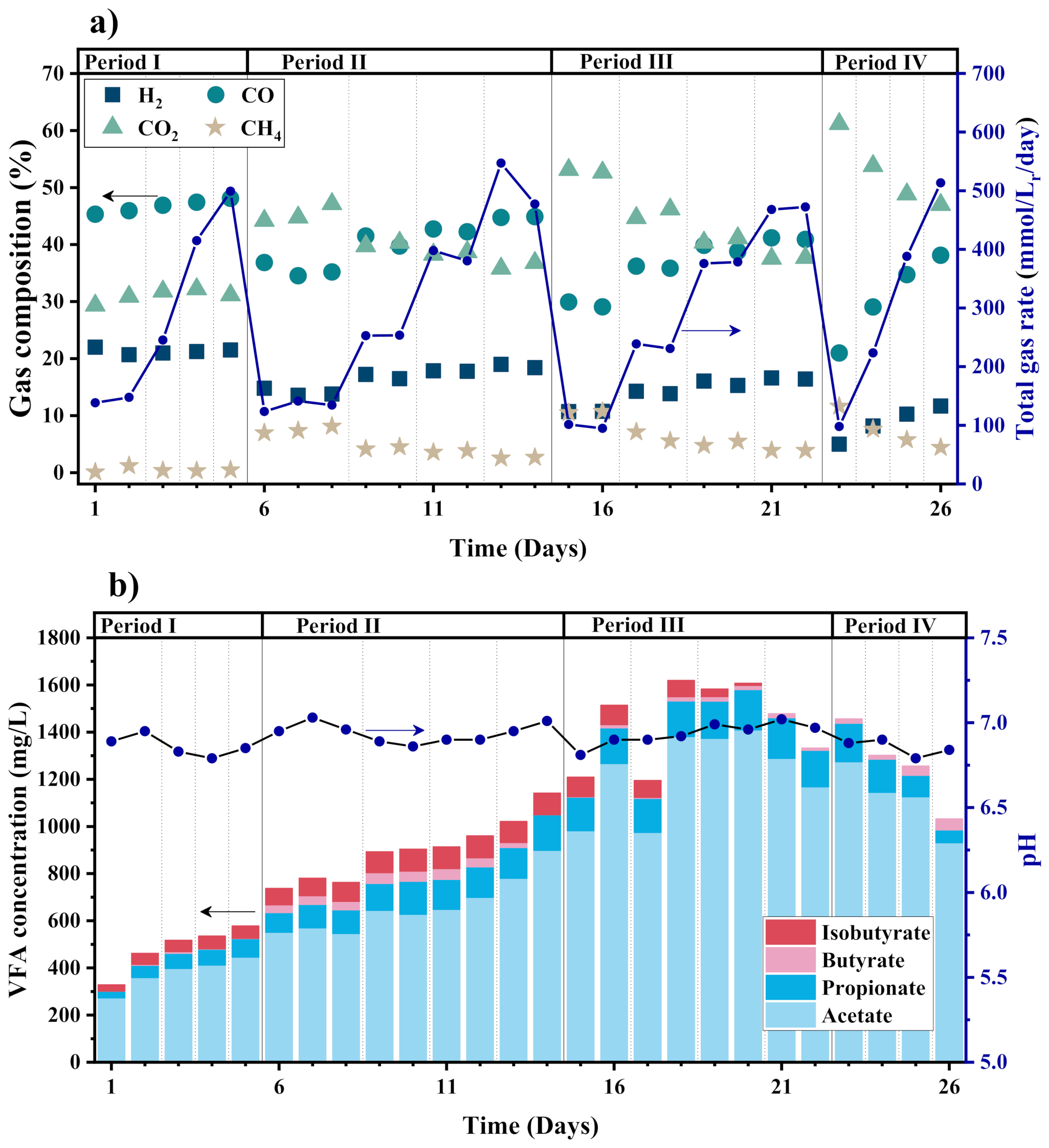

3.1. Performance of the Continuous Stirred Tank Reactor

| Period | Stirring Speed (rpm) | GRT (h) | Day | ηH2 (%) | ηCO (%) | KLa (day−1) | ||

|---|---|---|---|---|---|---|---|---|

| I | 0 | 2.5 | 1–2 | 0.92 ± 0.82 | 8.42 ± 0.13 | 21.57 ± 3.07 | 20.07 ± 18.26 | 63.45 ± 18.13 |

| 1.25 | 3 | 0.83 | 22.81 | 30.93 | 4.99 | 101.24 | ||

| 0.833 | 4 | 1.25 | 11.80 | 21.20 | 7.30 | 89.73 | ||

| 0.625 | 5 | 2.24 | 19.42 | 27.89 | 7.44 | 221.98 | ||

| 9.95 ± 5.92 | ||||||||

| II | 200 | 2.5 | 6–8 | 10.64 ± 0.26 | 43.46 ± 0.90 | 42.28 ± 0.84 | 84.83 ± 0.51 | 128.45 ± 1.33 |

| 1.25 | 9–10 | 10.89 ± 0.49 | 35.97 ± 1.31 | 38.25 ± 1.23 | 49.33 ± 0.18 | 199.68 ± 10.77 | ||

| 0.833 | 11–12 | 14.34 ± 0.20 | 30.61 ± 1.74 | 33.80 ± 1.88 | 49.52 ± 1.95 | 252.94 ± 15.50 | ||

| 0.625 | 13–14 | 13.23 ± 0.58 | 28.05 ± 5.99 | 31.06 ± 4.57 | 38.06 ± 7.92 | 293.49 ± 42.66 | ||

| 55.44 ± 17.60 | ||||||||

| III | 250 | 2.5 | 15–16 | 10.38 ± 0.25 | 68.48 ± 1.01 | 65.24 ± 1.70 | 53.35 ± 2.01 | 234.41 ± 9.55 |

| 1.25 | 17–18 | 14.89 ± 2.08 | 50.47 ± 1.57 | 49.19 ± 1.11 | 46.76 ± 3.61 | 289.30 ± 7.94 | ||

| 0.833 | 19–20 | 19.26 ± 1.48 | 40.89 ± 1.21 | 40.60 ± 0.58 | 52.80 ± 3.50 | 328.14 ± 9.05 | ||

| 0.625 | 21–22 | 18.15 ± 0.07 | 41.77 ± 0.10 | 42.04 ± 0.07 | 34.62 ± 0.01 | 433.91 ± 0.71 | ||

| 46.88 ± 7.54 | ||||||||

| IV | 300 | 2.5 | 23 | 11.35 | 85.41 | 75.36 | 49.82 | 380.66 |

| 1.25 | 24 | 16.94 | 72.63 | 61.02 | 41.55 | 445.16 | ||

| 0.833 | 25 | 22.20 | 60.26 | 46.06 | 49.01 | 421.68 | ||

| 0.625 | 26 | 22.55 | 55.04 | 41.22 | 38.96 | 458.09 | ||

| 44.84 ± 4.68 |

3.1.1. Effect of Gas Retention Time

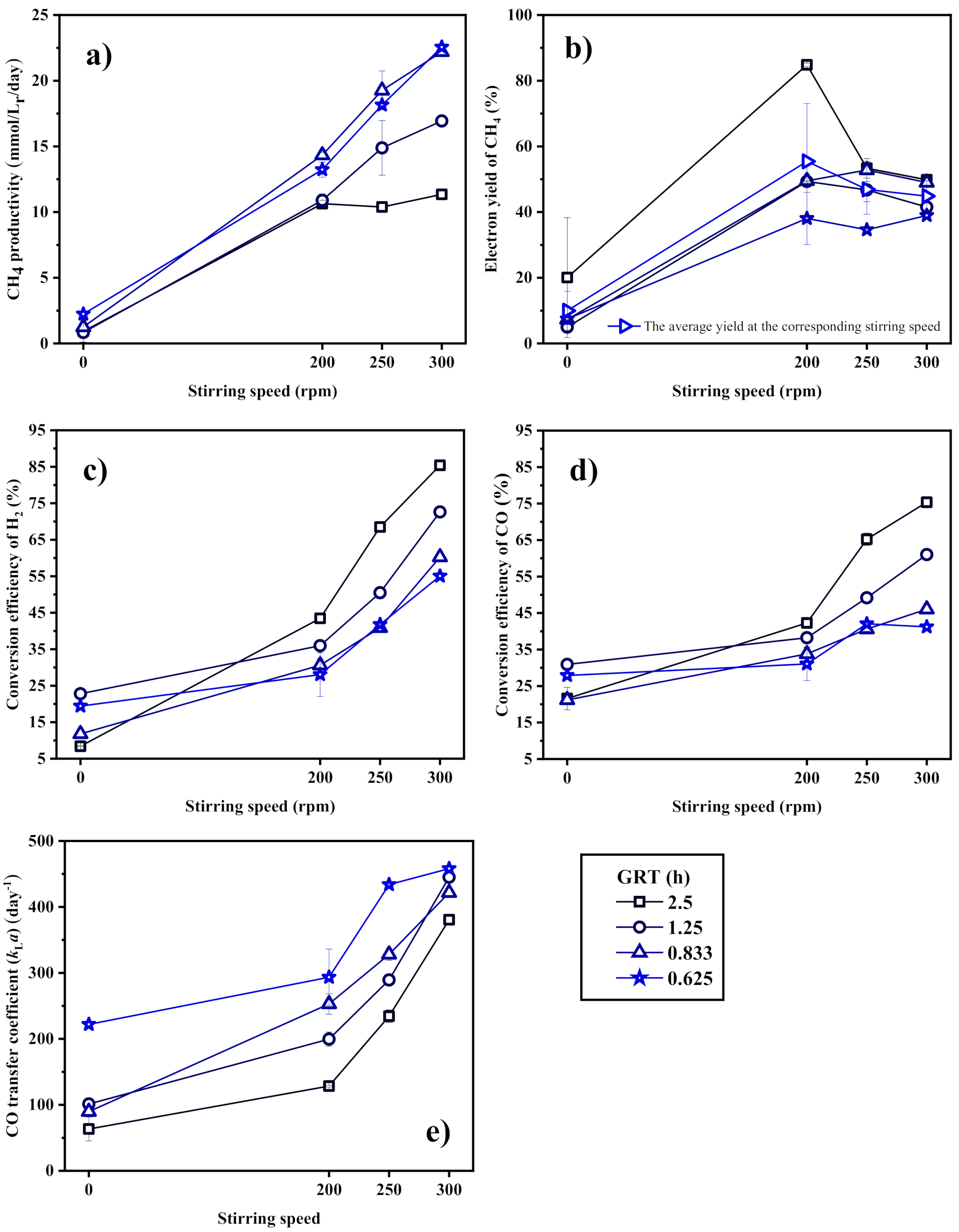

3.1.2. Effect of Stirring Speed

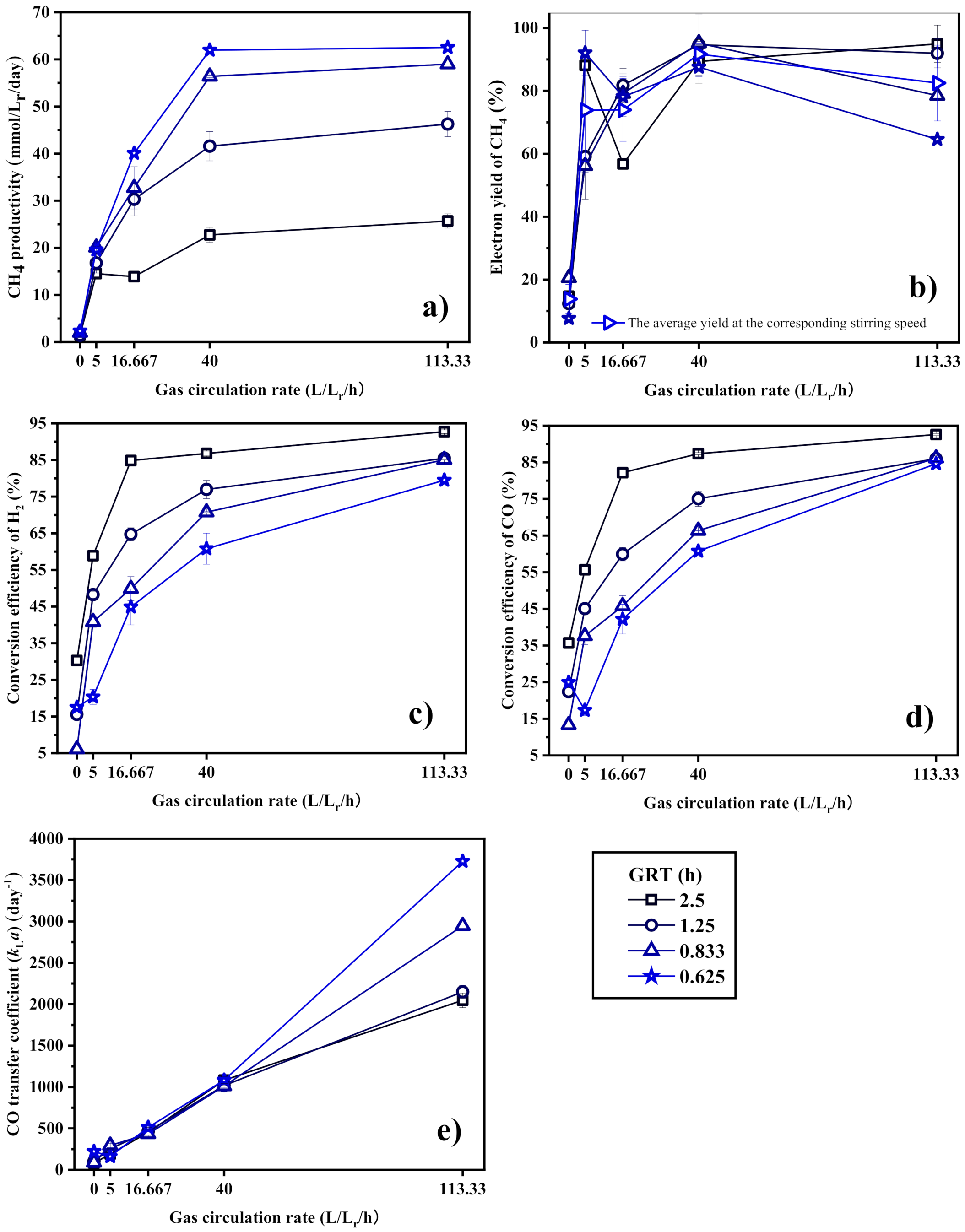

3.2. Performance of the Bubble Column Reactor

| Period | Rc (L·Lr−1·h−1) | GRT (h) | Day | ηH2 (%) | ηCO (%) | KLa (day−1) | ||

|---|---|---|---|---|---|---|---|---|

| I | 0 | 2.5 | 1–2 | 1.46 | 30.28 | 35.70 | 14.72 | 81.57 |

| 1.25 | 3 | 1.47 | 15.56 | 22.39 | 12.37 | 101.24 | ||

| 0.833 | 4 | 2.02 | 6.11 | 13.33 | 20.55 | 89.73 | ||

| 0.625 | 5 | 2.33 | 17.50 | 24.94 | 7.66 | 221.98 | ||

| 13.82 ± 4.64 | ||||||||

| II | 5 | 2.5 | 6–8 | 14.52 | 58.88 | 55.68 | 88.08 | 190.55 |

| 1.25 | 9–10 | 16.78 ± 2.13 | 48.27 ± 0.92 | 45.06 ± 1.45 | 59.12 ± 13.55 | 254.08 ± 4.77 | ||

| 0.833 | 11–12 | 20.09 ± 0.20 | 40.85 ± 1.49 | 37.62 ± 2.43 | 56.18 ± 2.14 | 293.99 ± 23.18 | ||

| 0.625 | 13–14 | 19.55 ± 0.32 | 20.34 ± 2.02 | 17.33 ± 1.48 | 92.06 ± 7.21 | 160.62 ± 15.82 | ||

| 73.86 ± 16.31 | ||||||||

| III | 16.67 | 2.5 | 15–16 | 13.88 | 84.85 | 82.15 | 56.79 | 452.41 |

| 1.25 | 17–18 | 30.30 ± 3.50 | 64.75 ± 1.79 | 59.93 ± 1.81 | 81.77 ± 5.33 | 464.77 ± 47.84 | ||

| 0.833 | 19–20 | 32.74 ± 4.50 | 49.91 ± 3.27 | 45.81 ± 2.80 | 79.15 ± 6.27 | 433.43 ± 48.25 | ||

| 0.625 | 21–22 | 40.06 ± 0.44 | 44.91 ± 4.89 | 42.19 ± 4.04 | 78.13 ± 6.32 | 513.24 ± 54.15 | ||

| 73.96 ± 10.00 | ||||||||

| IV | 40 | 2.5 | 23–24 | 22.73 ± 1.61 | 86.80 ± 0.66 | 87.35 ± 0.30 | 89.38 ± 6.94 | 1081.93 ± 40.53 |

| 1.25 | 25–26 | 41.57 ± 3.11 | 76.98 ± 2.47 | 75.06 ± 2.09 | 94.67 ± 9.79 | 1017.45 ± 6.06 | ||

| 0.833 | 27–28 | 56.40 ± 0.23 | 70.78 ± 0.13 | 66.38 ± 0.02 | 95.19 ± 0.50 | 1012.03 ± 23.30 | ||

| 0.625 | 29–30 | 61.96 ± 0.24 | 60.79 ± 4.23 | 60.76 ± 0.91 | 87.57 ± 2.99 | 1081.63 ± 8.28 | ||

| 91.70 ± 3.30 | ||||||||

| V | 113.33 | 2.5 | 31–32 | 25.70 ± 1.51 | 92.73 ± 0.52 | 92.58 ± 0.31 | 94.94 ± 5.96 | 2047.22 ± 87.47 |

| 1.25 | 33–34 | 46.28 ± 2.66 | 85.47 ± 0.42 | 85.98 ± 0.80 | 91.97 ± 4.64 | 2148.88 ± 77.83 | ||

| 0.833 | 35 | 58.98 | 85.09 | 86.11 | 78.50 | 2947.22 | ||

| 0.625 | 36 | 62.54 | 79.48 | 84.62 | 64.57 | 3726.54 | ||

| 82.50 ± 12.06 |

3.2.1. Effect of Gas Retention Time

3.2.2. Effect of Gas Circulation Rate

3.3. Comparison and Discussion of Different Bioreactors

3.4. Effect of Start-Up Strategy

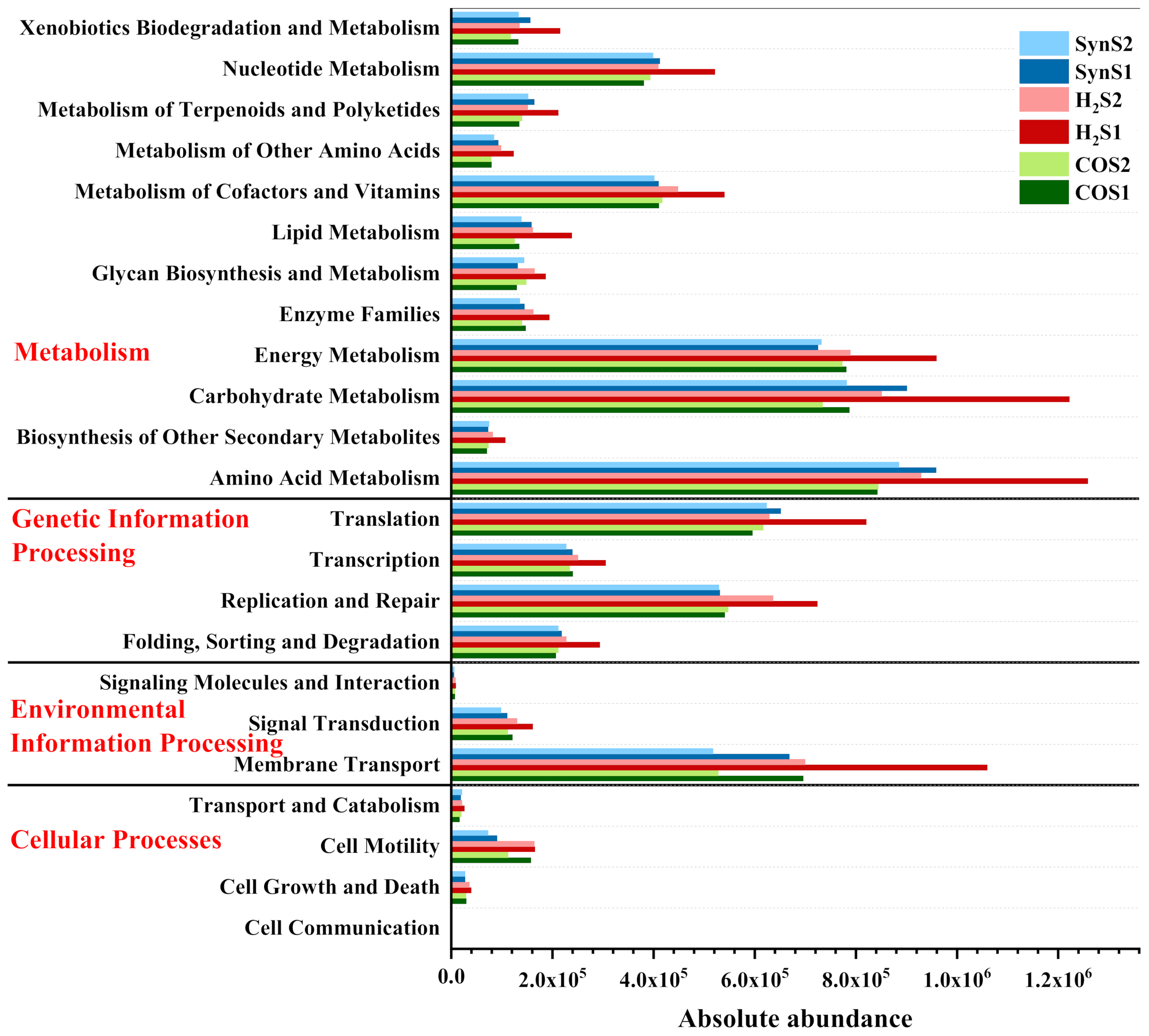

3.5. Analysis of the Microbial Communities

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sorda, G.; Banse, M.; Kemfert, C. An Overview of Biofuel Policies across the World. Energy Policy 2010, 38, 6977–6988. [Google Scholar] [CrossRef]

- Zhang, W. Automotive Fuels from Biomass via Gasification. Fuel Process. Technol. 2010, 91, 866–876. [Google Scholar] [CrossRef]

- He, M.; Sun, Y.; Han, B. Green Carbon Science: Efficient Carbon Resource Processing, Utilization, and Recycling towards Carbon Neutrality. Angew. Chemie Int. Ed. 2022, 61, e202112835. [Google Scholar] [CrossRef]

- Patinvoh, R.J.; Taherzadeh, M.J. Challenges of Biogas Implementation in Developing Countries. Curr. Opin. Environ. Sci. Health 2019, 12, 30–37. [Google Scholar] [CrossRef]

- Grimalt-Alemany, A.; Skiadas, I.V.; Gavala, H.N. Syngas Biomethanation: State-of-the-Art Review and Perspectives. Biofuels, Bioprod. Biorefining 2018, 12, 139–158. [Google Scholar] [CrossRef]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. A Technological Overview of Biogas Production from Biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- König, R.; Cuomo, M.; Pianta, E.; Buetti, A.; Mauri, F.; Tanadini, M.; Principi, P. Addition of Conductive Materials to Support Syntrophic Microorganisms in Anaerobic Digestion. Fermentation 2022, 8, 354. [Google Scholar] [CrossRef]

- Browne, J.; Nizami, A.S.; Thamsiriroj, T.; Murphy, J.D. Assessing the Cost of Biofuel Production with Increasing Penetration of the Transport Fuel Market: A Case Study of Gaseous Biomethane in Ireland. Renew. Sustain. Energy Rev. 2011, 15, 4537–4547. [Google Scholar] [CrossRef]

- Li, C.; Zhu, X.; Angelidaki, I. Syngas Biomethanation: Effect of Biomass-Gas Ratio, Syngas Composition and PH Buffer. Bioresour. Technol. 2021, 342, 125997. [Google Scholar] [CrossRef]

- Ghofrani-Isfahani, P.; Tsapekos, P.; Peprah, M.; Kougias, P.; Zhu, X.; Kovalovszki, A.; Zervas, A.; Zha, X.; Jacobsen, C.S.; Angelidaki, I. Ex-Situ Biogas Upgrading in Thermophilic up-Flow Reactors: The Effect of Different Gas Diffusers and Gas Retention Times. Bioresour. Technol. 2021, 340, 125694. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; He, Z.; Luo, S.; Su, D.; Jiang, H.; Zhou, H.; Xu, Q. Effects of Temperature, Hydrogen/Carbon Monoxide Ratio and Trace Element Addition on Methane Production Performance from Syngas Biomethanation. Bioresour. Technol. 2020, 295, 122296. [Google Scholar] [CrossRef]

- Couto, N.; Rouboa, A.; Silva, V.; Monteiro, E.; Bouziane, K. Influence of the Biomass Gasification Processes on the Final Composition of Syngas. Energy Procedia 2013, 36, 596–606. [Google Scholar] [CrossRef]

- Navarro, S.S.; Cimpoia, R.; Bruant, G.; Guiot, S.R. Biomethanation of Syngas Using Anaerobic Sludge: Shift in the Catabolic Routes with the CO Partial Pressure Increase. Front. Microbiol. 2016, 7, 1188. [Google Scholar] [CrossRef]

- Baleeiro, F.C.F.; Kleinsteuber, S.; Sträuber, H. Recirculation of H2, CO2, and Ethylene Improves Carbon Fixation and Carboxylate Yields in Anaerobic Fermentation. ACS Sustain. Chem. Eng. 2022, 10, 4073–4081. [Google Scholar] [CrossRef]

- Li, T.; Jia, X.; Chen, H.; Chang, Z.; Li, L.; Wang, Y.; Li, J. Tuning the Pore Environment of MOFs toward Efficient CH4/N2Separation under Humid Conditions. ACS Appl. Mater. Interfaces 2022, 14, 15830–15839. [Google Scholar] [CrossRef]

- Xia, A.; Cheng, J.; Murphy, J.D. Innovation in Biological Production and Upgrading of Methane and Hydrogen for Use as Gaseous Transport Biofuel. Biotechnol. Adv. 2016, 34, 451–472. [Google Scholar] [CrossRef]

- Hu, X.; Jiang, B.; Yu, C.; Söderlind, U.; Göransson, K.; Zhang, W. Product Gas Biomethanation with Inoculum Enrichment and Grinding. Biomass Convers. Biorefinery 2022, 1–12. [Google Scholar] [CrossRef]

- Maroufmashat, A.; Fowler, M. Transition of Future Energy System Infrastructure; through Power-to-Gas Pathways. Energies 2017, 10, 1089. [Google Scholar] [CrossRef]

- Lewandowska-Bernat, A.; Desideri, U. Opportunities of Power-to-Gas Technology in Different Energy Systems Architectures. Appl. Energy 2018, 228, 57–67. [Google Scholar] [CrossRef]

- Navarro, S.S.; Cimpoia, R.; Bruant, G.; Guiot, S.R. Specific Inhibitors for Identifying Pathways for Methane Production from Carbon Monoxide by a Nonadapted Anaerobic Mixed Culture. Can. J. Microbiol. 2014, 60, 407–415. [Google Scholar] [CrossRef]

- Bu, F.; Dong, N.; Kumar Khanal, S.; Xie, L.; Zhou, Q. Effects of CO on Hydrogenotrophic Methanogenesis under Thermophilic and Extreme-Thermophilic Conditions: Microbial Community and Biomethanation Pathways. Bioresour. Technol. 2018, 266, 364–373. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Hu, X.; Söderlind, U.; Göransson, K.; Zhang, W.; Yu, C. Identification of the Biomethanation Pathways during Biological CO2 Fixation with Exogenous H2 Addition. Fuel Process. Technol. 2022, 238, 107478. [Google Scholar] [CrossRef]

- Figueras, J.; Benbelkacem, H.; Dumas, C.; Buffiere, P. Biomethanation of Syngas by Enriched Mixed Anaerobic Consortium in Pressurized Agitated Column. Bioresour. Technol. 2021, 338, 125548. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Jing, Y.; Lin, Y.; Zhang, S.; An, D. A Novel Concept for Syngas Biomethanation by Two-Stage Process: Focusing on the Selective Conversion of Syngas to Acetate. Sci. Total Environ. 2018, 645, 1194–1200. [Google Scholar] [CrossRef] [PubMed]

- Orgill, J.J.; Atiyeh, H.K.; Devarapalli, M.; Phillips, J.R.; Lewis, R.S.; Huhnke, R.L. A Comparison of Mass Transfer Coefficients between Trickle-Bed, Hollow Fiber Membrane and Stirred Tank Reactors. Bioresour. Technol. 2013, 133, 340–346. [Google Scholar] [CrossRef]

- Kougias, P.G.; Tsapekos, P.; Treu, L.; Kostoula, M.; Campanaro, S.; Lyberatos, G.; Angelidaki, I. Biological CO2 Fixation in Up-Flow Reactors via Exogenous H2 Addition. J. Biotechnol. 2020, 319, 1–7. [Google Scholar] [CrossRef]

- Munasinghe, P.C.; Khanal, S.K. Biomass-Derived Syngas Fermentation into Biofuels: Opportunities and Challenges. Bioresour. Technol. 2010, 101, 5013–5022. [Google Scholar] [CrossRef]

- Weber, S.; Schaepe, S.; Freyer, S.; Kopf, M.H.; Dietzsch, C. Impact of Nozzle Operation on Mass Transfer in Jet Aerated Loop Reactors. Characterization and Comparison to an Aerated Stirred Tank Reactor. Eng. Life Sci. 2018, 18, 579–588. [Google Scholar] [CrossRef]

- Asimakopoulos, K.; Łężyk, M.; Grimalt-Alemany, A.; Melas, A.; Wen, Z.; Gavala, H.N.; Skiadas, I.V. Temperature Effects on Syngas Biomethanation Performed in a Trickle Bed Reactor. Chem. Eng. J. 2020, 393, 124739. [Google Scholar] [CrossRef]

- Asimakopoulos, K.; Grimalt-Alemany, A.; Lundholm-Høffner, C.; Gavala, H.N.; Skiadas, I.V. Carbon Sequestration Through Syngas Biomethanation Coupled with H2 Supply for a Clean Production of Natural Gas Grade Biomethane. Waste Biomass Valorization 2021, 12, 6005–6019. [Google Scholar] [CrossRef]

- Oelgeschläger, E.; Rother, M. Carbon Monoxide-Dependent Energy Metabolism in Anaerobic Bacteria and Archaea. Arch. Microbiol. 2008, 190, 257–269. [Google Scholar] [CrossRef]

- Sipma, J.; Henstra, A.M.; Parshina, S.M.; Lens, P.N.; Lettinga, G.; Stams, A.J.M. Microbial CO Conversions with Applications in Synthesis Gas Purification and Bio-Desulfurization. Crit. Rev. Biotechnol. 2006, 26, 41–65. [Google Scholar] [CrossRef]

- Zhang, Z.; Ding, C.; Wang, L.; Jiang, B.; Söderlind, U.; Zhang, W.; Yu, C. CO Biomethanation with Different Anaerobic Granular Sludges. Waste Biomass Valorization 2021, 12, 3913–3925. [Google Scholar] [CrossRef]

- Lide, D. CRC Handbook of Chemistry and Physics. J. Mol. Struct. 1992, 268, 320. [Google Scholar] [CrossRef]

- Esquivel-Elizondo, S.; Delgado, A.G.; Krajmalnik-Brown, R. Evolution of Microbial Communities Growing with Carbon Monoxide, Hydrogen, and Carbon Dioxide. FEMS Microbiol. Ecol. 2017, 93, 1–12. [Google Scholar] [CrossRef]

- Díaz, I.; Fdz-Polanco, F.; Mutsvene, B.; Fdz-Polanco, M. Effect of Operating Pressure on Direct Biomethane Production from Carbon Dioxide and Exogenous Hydrogen in the Anaerobic Digestion of Sewage Sludge. Appl. Energy 2020, 280, 115915. [Google Scholar] [CrossRef]

- Huang, L.; Wang, Q.; Jiang, L.; Zhou, P.; Quan, X.; Logan, B.E. Adaptively Evolving Bacterial Communities for Complete and Selective Reduction of Cr(VI), Cu(II), and Cd(II) in Biocathode Bioelectrochemical Systems. Environ. Sci. Technol. 2015, 49, 9914–9924. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, H.; Zhou, L.; Arhin, S.G.; Papadakis, V.G.; Goula, M.A.; Liu, G.; Zhang, Y.; Wang, W. Bioaugmentation with Well-Constructed Consortia Can Effectively Alleviate Ammonia Inhibition of Practical Manure Anaerobic Digestion. Water Res. 2022, 215, 118244. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.L.; Yang, S.F.; Tay, J.H. Mechanisms and Models for Anaerobic Granulation in Upflow Anaerobic Sludge Blanket Reactor. Water Res. 2003, 37, 661–673. [Google Scholar] [CrossRef]

- Liang, Z.; Tu, Q.; Su, X.; Yang, X.; Chen, J.; Chen, Y.; Liu, C.; Li, H.; He, Q. Formation, Extracellular Polymeric Substances and Microbial Community of Aerobic Granules Enhanced by Microbial Flocculant Compared with Poly-Aluminum Chloride. J. Clean. Prod. 2019, 220, 544–552. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Euverink, G.J.W. Effect of Bioaugmentation Combined with Activated Charcoal on the Mitigation of Volatile Fatty Acids Inhibition during Anaerobic Digestion. Chem. Eng. J. 2022, 428, 131015. [Google Scholar] [CrossRef]

- Ebrahimian, F.; De Bernardini, N.; Tsapekos, P.; Treu, L.; Zhu, X.; Campanaro, S.; Karimi, K.; Angelidaki, I. Effect of Pressure on Biomethanation Process and Spatial Stratification of Microbial Communities in Trickle Bed Reactors under Decreasing Gas Retention Time. Bioresour. Technol. 2022, 361, 127701. [Google Scholar] [CrossRef] [PubMed]

- Quarton, C.J.; Samsatli, S. Power-to-Gas for Injection into the Gas Grid: What Can We Learn from Real-Life Projects, Economic Assessments and Systems Modelling? Renew. Sustain. Energy Rev. 2018, 98, 302–316. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, K.; Yang, Z.; Guo, H.; Zheng, X.; Zhang, Q.; Xiong, J.; Lu, X. Dynamic Changes of Microbial Community and Moisture Ratio during Bio-Drying of Sludge after Electro-Dewatering. J. Environ. Manage. 2022, 324, 116366. [Google Scholar] [CrossRef]

- Wang, X.; Wang, P.; Meng, X.; Ren, L. Performance and Metagenomics Analysis of Anaerobic Digestion of Food Waste with Adding Biochar Supported Nano Zero-Valent Iron under Mesophilic and Thermophilic Condition. Sci. Total Environ. 2022, 820, 153244. [Google Scholar] [CrossRef]

- Guo, X.; Xia, X.; Tang, R.; Zhou, J.; Zhao, H.; Wang, K. Development of a Real-Time PCR Method for Firmicutes and Bacteroidetes in Faeces and Its Application to Quantify Intestinal Population of Obese and Lean Pigs. Lett. Appl. Microbiol. 2008, 47, 367–373. [Google Scholar] [CrossRef]

- Luo, G.; Wang, W.; Angelidaki, I. Anaerobic Digestion for Simultaneous Sewage Sludge Treatment and CO Biomethanation: Process Performance and Microbial Ecology. Environ. Sci. Technol. 2013, 47, 10685–10693. [Google Scholar] [CrossRef]

| Component | Reagent | Concentration | Unit |

|---|---|---|---|

| A | NH4Cl | 100 | g/L |

| NaCl | 10 | ||

| MgCl2·6H2O | 10 | ||

| CaCl2·2H2O | 5 | ||

| B | K2HPO4·3H2O | 200 | g/L |

| C | FeCl2·4H2O | 2 | g/L |

| H3BO3 | 0.05 | ||

| ZnCl2 | 0.05 | ||

| CuCl2·2H2O | 0.038 | ||

| MnCl2·4H2O | 0.05 | ||

| (NH4)6Mo7O24·4H2O | 0.05 | ||

| AlCl3 | 0.05 | ||

| CoCl2·6H2O | 0.05 | ||

| NiCl2·6H2O | 0.092 | ||

| EDTA | 0.5 | ||

| Concentrated HCl | 1 | ||

| Na2SeO3·5H2O | 0.1 | ||

| D | Biotin | 2 | mg/L |

| Folic acid | 2 | ||

| Pyridoxal HCl | 10 | ||

| Thiamine HCl | 5 | ||

| Riboflavin | 5 | ||

| Nicotinic acid | 5 | ||

| Ca-D-Pantotheinate | 5 | ||

| Cyanocobalamin | 0.1 | ||

| P-aminobenzoic acid | 5 | ||

| Thioctic acid | 5 |

| Outlet Gas Composition in Volume | Lr−1·day−1) | ηH2 (%) | ηCO (%) | YTotal products (%) | pH | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| H2 (%) | CO (%) | CO2 (%) | CH4 (%) | |||||||

| COS2 | 6.29 ± 0.21 | 14.85 ± 0.43 | 62.64 ± 0.70 | 14.64 ± 0.10 | 35.67 ± 0.50 | 76.96 ± 1.12 | 78.24 ± 0.99 | 78.63 ± 2.03 | 78.64 ± 2.04 | 6.78 ± 0.07 |

| H2S2 | 4.02 ± 0.20 | 10.93 ± 0.19 | 67.19 ± 0.81 | 17.07 ± 0.29 | 39.11 ± 1.25 | 86.15 ± 0.84 | 84.96 ± 0.39 | 78.38 ± 2.74 | 78.44 ± 2.73 | 6.75 ± 0.03 |

| SynS2 | 6.43 ± 0.18 | 13.81 ± 0.48 | 62.95 ± 0.49 | 15.02 ± 0.30 | 36.82 ± 0.97 | 76.32 ± 1.24 | 79.64 ± 1.10 | 80.01 ± 3.29 | 80.44 ± 3.60 | 6.66 ± 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, B.; Zhang, D.; Hu, X.; Söderlind, U.; Paladino, G.; Gamage, S.; Hedenström, E.; Zhang, W.; Arrigoni, J.; Lundgren, A.; et al. Low-Grade Syngas Biomethanation in Continuous Reactors with Respect to Gas–Liquid Mass Transfer and Reactor Start-Up Strategy. Fermentation 2023, 9, 38. https://doi.org/10.3390/fermentation9010038

Jiang B, Zhang D, Hu X, Söderlind U, Paladino G, Gamage S, Hedenström E, Zhang W, Arrigoni J, Lundgren A, et al. Low-Grade Syngas Biomethanation in Continuous Reactors with Respect to Gas–Liquid Mass Transfer and Reactor Start-Up Strategy. Fermentation. 2023; 9(1):38. https://doi.org/10.3390/fermentation9010038

Chicago/Turabian StyleJiang, Bingyi, Dongming Zhang, Xiao Hu, Ulf Söderlind, Gabriela Paladino, Shiromini Gamage, Erik Hedenström, Wennan Zhang, Juan Arrigoni, Anders Lundgren, and et al. 2023. "Low-Grade Syngas Biomethanation in Continuous Reactors with Respect to Gas–Liquid Mass Transfer and Reactor Start-Up Strategy" Fermentation 9, no. 1: 38. https://doi.org/10.3390/fermentation9010038

APA StyleJiang, B., Zhang, D., Hu, X., Söderlind, U., Paladino, G., Gamage, S., Hedenström, E., Zhang, W., Arrigoni, J., Lundgren, A., Tuvesson, M., & Yu, C. (2023). Low-Grade Syngas Biomethanation in Continuous Reactors with Respect to Gas–Liquid Mass Transfer and Reactor Start-Up Strategy. Fermentation, 9(1), 38. https://doi.org/10.3390/fermentation9010038