Abstract

Biofuel consists of non-fossil fuel derived from the organic biomass of renewable resources, including plants, animals, microorganisms, and waste. Energy derived from biofuel is known as bioenergy. The reserve of fossil fuels is now limited and continuing to decrease, while at the same time demand for energy is increasing. In order to overcome this scarcity, it is vital for human beings to transfer their dependency on fossil fuels to alternative types of fuel, including biofuels, which are effective methods of fulfilling present and future demands. The current review therefore focusses on second-generation lignocellulosic biofuels obtained from non-edible plant biomass (i.e., cellulose, lignin, hemi-celluloses, non-food material) in a more sustainable manner. The conversion of lignocellulosic feedstock is an important step during biofuel production. It is, however, important to note that, as a result of various technical restrictions, biofuel production is not presently cost efficient, thus leading to the need for improvement in the methods employed. There remain a number of challenges for the process of biofuel production, including cost effectiveness and the limitations of various technologies employed. This leads to a vital need for ongoing and enhanced research and development, to ensure market level availability of lignocellulosic biofuel.

1. Introduction

The term ‘biofuel’ is applied to fuel derived from renewable, living materials, e.g., plants and animals. Biofuels are energy carriers and non-fossil fuels that store the energy derived from the organic biomass of plants, animals, microorganisms, and waste. Energy derived from biofuels is known as bioenergy [1,2,3,4,5].

The development of renewable energy from biomass, solar, wind, water, and nuclear energy has now become an urgent issue as a result of the continued increase in demand for fossil fuel based petroleum products, along with their established role in global warming and climate change [1,6]. In addition, petroleum products have a limited reserve stock, leading to increased global attention being focused on studies of biomass based energy (i.e., biofuels) [5,7,8,9,10,11,12,13,14,15,16,17,18,19,20].

Biofuels can take the following forms: (1) liquid (i.e., ethanol and biodiesel); (2) solid (i.e., charcoal, wood pellets and fuelwood; and (3) gas (i.e., biogas). Biofuels have a renewable origin through the photosynthetic solar energy conversion to chemical energy, while petroleum products are derivatives of crude fossil fuel, obtained following its processing in oil refineries.

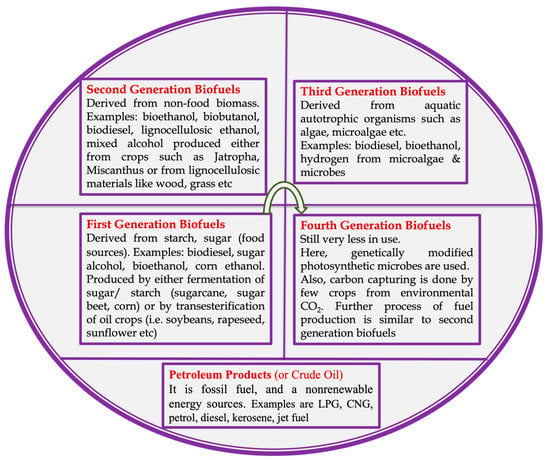

Based on its origin (i.e., biomass feedstock) and the technology used in biofuel production, biofuels are categorized between first- and fourth-generation biofuels [7,11,12,13,21,22,23,24,25] (Figure 1).

Figure 1.

Comparison of first-, second-, third-, and fourth-generation biofuels, and petroleum fuels (adopted and modified from Naik et al. [13] and Dragone et al. [25]).

- (i)

- First-generation biofuel is primarily derived from parts of edible plants (i.e., grains and oilseeds). These types of fuel have derived from sugar, starch, vegetable oil, and fats. Examples of most popular first-generation biofuels are biodiesel, ethanol, biofuel gasoline, biogas, etc. [7,13,24,26]. Presently, first-generation biofuel (biodiesel and bioethanol) is mainly produced by using agricultural feedstock such as sugarcane, corn, sugar beets, etc. [23]. Economic feasibility of biofuel production using crops (such as oilseed crops) as feedstock is not cost effective presently, therefore, a more efficient approach is needed to enhance the biofuel production and convert it to an economically feasible stage. Additionally, more research work is needed to increase the biodiesel production using first-generation feedstock such as oil [23].

- (ii)

- Second-generation biofuel is a comparatively advanced biofuel which is derived from various non-food biomass of plant/or animal. Second-generation (lignocellulosic) biofuel is derived from non-edible plants or non-edible parts of the plants. It is well known that non-edible lignocellulosic biomass (such as vegetable grasses, forest residues, agricultural waste, etc.) is present abundantly in the natural ecosystem, therefore, it could be used as a feedstock for biofuel production. Examples of second-generation biofuels are lignocellulosic ethanol, butanol, mixed alcohols, etc. [4,13,24,27].

- (iii)

- Third-generation biofuel is derived from photosynthetic microbes, e.g., microalgae. They derived from autotrophic organism. Here, carbon dioxide, light, and other nutrient sources are used in the synthesis of feedstock (biomass) which is further used in biofuel production [8,24,25,28]. Biofuels obtained from third-generation sources (such as microalgae) might be a better energy substitute as compared to previous generation biofuels, due to their short life cycle and less requirement of valuable agricultural land and resources for their growth [25]. Algae have rapid growth and higher rate of the photosynthesis compared to terrestrial plants used in first- and second-generation biofuel production. Due to their use in biofuel production, photosynthetic microbes (such as algae/microalgae) have recently received more attention from researchers worldwide [12].

- (iv)

- Fourth-generation biofuel is not common and at an under developmental stage since a few years ago. Here, genetically altered photosynthetic microbes (such as cyanobacteria, algae, fungi) are used as feedstock. Photosynthetic microbes have the ability to convert atmospheric CO2 to biofuel [24]. Some studies reported that carbon capturing is undertaken by some crops, taken from the atmosphere and further stored in their leaves, stems, etc., which is further converted into fuel using second-generation techniques [12]. Alalwan et al. [24] reported that, in the fourth-generation biofuels, genetically modified microorganisms are used to obtain more carbon (HC) yield and reduced carbon emissions [24].

Impact of Environmental Factors on Biofuel Production

Environmental factors also play a major role in the production of biofuels because growth of various crops and microbes employed in the biofuel production are directly influenced by environmental factors. The impacts of environmental factors on biofuel have been studied and discussed by several researchers [29,30,31]. Hosseinzadeh-Bandbafha et al. [30] described in detail the environmental impacts related to biodiesel. They used life cycle assessment method to discuss the biodiesel additives and their environmental impacts [30]. Sharma et al. [31] recently focused on the biofuel technologies used for sustainable environmental management. They explained, in detail, issues related to biofuel and its criteria of sustainability [31].

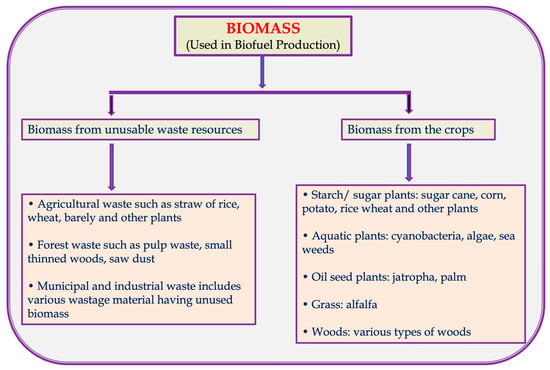

Since first-generation biofuel is obtained from crops such as sugar beet, grains, oil, and seeds, it has a number of limitations preventing it from attaining the targets demanded by the replacement of oil products, i.e., limited production and supply of the raw material. However, second-generation lignocellulosic biofuel is derived from non-edible parts of the biomass, therefore, it is more suitable for future applications. In this review, we are going to focus, in detail, on the second-generation lignocellulosic biofuels (Figure 2).

Figure 2.

Biomass used as a renewable resource for biofuel production (adopted and modified from Naik et al. [13].)

2. Second-Generation Lignocellulosic Biofuels

Researchers and companies have now shifted their attention towards second generation biofuel production, in response to the limitations found in the production and supply of first-generation biofuels. Second-generation lignocellulosic biofuels are produced by employing non-edible biomass (e.g., cellulose, lignin, and hemi-celluloses) in a more sustainable manner rather than first-generation biofuel. Examples of second-generation biofuels are Fischer–Tropsch fuels and cellulosic ethanol. Such fuels are either carbon neutral or negative when it comes to CO2 concentration [13,32,33,34].

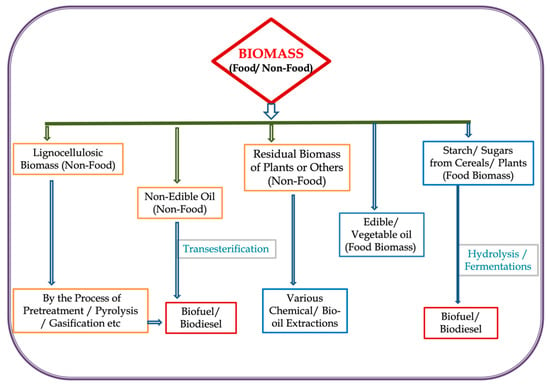

Raw plant biomass material employed in the production of second-generation biofuels are generally referred to as lignocellulosic material and other non-food material of plants [4,20,35,36,37,38]. Such lignocellulosic raw material includes: (1) the by-products of plants (i.e., sugar cane bagasse, forest residues, and cereal straw); (2) the organic constituents of domestic waste; and (3) other forms of feedstock (i.e., crops, grasses, and short duration forests) (Figure 3).

Figure 3.

Schematic representations of second-generation biofuel (adopted and modified from Naik et al. [13]).

Plant biomass is a widely and easily available biological resource for the raw materials for fuel [13,36,39,40]. There is considerable use of plant biomass in liquid biofuel production, due to these comprising cell walls composed largely of polysaccharides [13,40,41]. Badawy et al. [40] aimed to determine the most suitable biodiesel source among various sources such as Jatropha, rice straw, sugarcane, algae, etc. During their study, results showed that Jatropha was the most suitable biodiesel source [40]. Additionally, Arefin et al. [39] described biofuel production by floating aquatic plants, and discussed the methods related to biofuel production by aquatic plants (such as Azolla, duckweed, and water fern). Their observations showed that Azolla and water fern play a much better role in biofuel production as compared to other plants.

In addition to its direct use, second-generation biofuel can also be mixed with petroleum-based fuels in existing engines or used in slightly adapted vehicles with a compatible engine (e.g., vehicles for DME) [33].

It should be noted that the current production of such biofuels is not yet cost effective, due to various technical restrictions that require improvements in the methods employed [42].

3. Feedstock for Second-Generation Lignocellulosic Biofuels

Feedstock for second-generation lignocellulosic biofuels primarily consists of forms of biomass that are unfit for human consumption, hence, it does not compete with the production of food. Potential raw materials for second-generation biofuels consist of: (1) crop residue biomass; (2) non-food energy crops; (3) Jatropha; (4) wood residues; and (5) bacteria [7,22,34,43,44,45,46].

Second-generation biofuels production can also be enhanced by the growth of bio-energy crops in locations unsuitable for the farming of food crops, leading to maximum utilization of marginal land for second-generation biofuel production. Improving current methods will also enable the efficient creation of biofuels from the inedible parts of crops and forest trees. In addition, there is a potential for using waste-products for processing second-generation biofuels.

Firouzi et al. [44] used a hybrid Multi-Criteria Decision Making (MCDM) approach for the screening of biomass for the biofuel production. They noticed that wastes from municipal sewage, forest, and poultry were the most important resources for biofuel production. Narwane et al. [45] also discussed the integrated MCDM approach in the biofuel industry.

4. Lignocellulosic Feedstocks

The lignocellulosic biomass synthesized by photosynthesis on earth reaches more than 100 billion tons every year. However, only a small part is used by human activities, causing a great waste of resources. It is estimated that the lignocellulosic biomass that can be collected and utilized in the United States during a year is around 1.3 billion tons, and China has about 800 million tons [47]. In addition, although the use of fossil resources has brought great convenience to the development of human society, it has also brought a series of problems, such as environmental pollution and an energy crisis. Therefore, countries around the world are stepping up efforts to develop the conversion and utilization of lignocellulose, a renewable resource, to alleviate problems such as energy crises, environmental pollution, and sustainable development [48,49,50,51,52].

The major constituents of lignocellulosic feedstock consist of cellulose and hemicelluloses (i.e., about two thirds of the dry mass of plants), which are converted into sugars by means of thermochemical and biological processes. These lignocellulosic feedstocks are grouped into three types: (1) herbaceous and woody energy crops; (2) agricultural residues; and (3) forest residues. The cellulose present in the cell wall should split to form sugar, which can be further converted either to ethanol [53] or a fuel such as biodiesel or butanol. However, it should be noted that, due to its morphological characteristics, cell walls of the plant obstruct the cellulosic biofuel production.

For the synthesis of improved raw material, such as carbohydrates (which are further processed into biofuel), bioenergy crops should be grown on marginal land, employing the latest genomics and breeding technologies. Growing bioenergy crops on marginal land will lead to the production of sustainable biofuels.

There is a considerable variety of agricultural feedstock, which differ in their structural and chemical composition, leading to the production of a variety of biofuels, as discussed in the following sections.

5. Pretreatment of the Lignocellulosic Biomass

Pretreatment of raw material is an important step during biofuel production. It is applied during the process of biofuel and bioenergy production. It consists of mainly: (i) physical and chemical pretreatment and (ii) biological pretreatment.

- (i)

- Physical and chemical pretreatment is widely used during biofuel production to improve quality of the substrate to be used for further digestion. Methods using heat, pressure, steam, hot water, ultrasonics, etc., are employed during the physical pretreatment process, while the oxidation, ozonization, acid or base pretreatment are used during chemical pretreatment methods [48]. These methods generally used in a combined way to obtain better results.

- (ii)

- Biological pretreatment is mainly used for breaking lignin coatings and disrupting the cellulose structure so that it would be more susceptible for enzymatic or microbial digestion. During biological pretreatment methods, microorganisms play an important role and useful by-products are also produced [48].

Several researchers around the globe have discussed the importance of the pretreatment process used during biofuel production [2,48,49,50,51,52,54,55,56,57,58,59,60]. Wagner et al. [48] described the pretreatment methods to increase the production of biogas employing lignocellulosic biomass. Galbe and Wallberg [49] also described the common efficient pretreatment methods for lignocellulosic feedstock. Similarly, Sivamani et al. [54] studied acid pretreatment for the production of bioethanol.

Recently, Ab Rasid et al. [51] presented and discussed the lignocellulosic biomass pretreatment. They presented and focused on the green pretreatment strategies such as ionic liquids, ozonolysis, deep eutectic solvents, etc., for biomass pretreatment. Afolalu et al. [2] and Beig et al. [52] also discussed the different challenges related to the pretreatment of lignocellulosic biomass. Afolalu et al. [2] described the chemical, physical, and biological pretreatment processes.

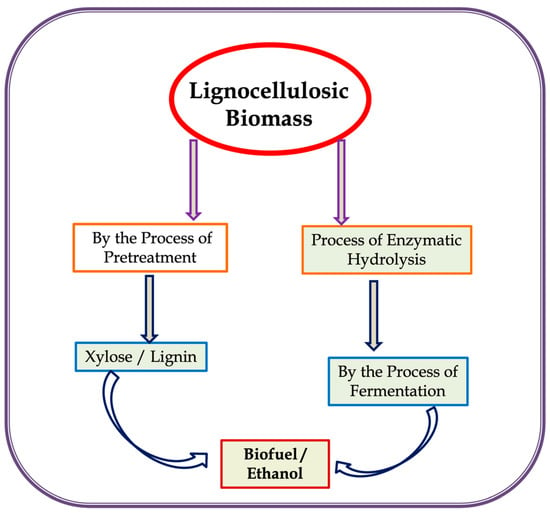

Dionísio et al. [55] used dilute sulfuric acid for the pretreatment, which leads to 89.5% of hemicellulose solubilization. Lima et al. [56] discussed the ozone pretreatment of sugarcane for the ethanol and biogas integrated production. Morales-Martínez et al. [57] described the chemical pretreatment for ethanol production employing coffee husk waste. Mund et al. [58] discussed enzymatic hydrolysis and pretreatment of the leaf waste for biofuel production (Figure 4).

Figure 4.

Lignocellulosic biomass conversion. A schematic view (adopted and modified from Naik et al. [13].

6. Conversion of Feedstock into Biofuels

Conversion of feedstock is an important step. There are primarily two processing routes followed for biofuel production from lignocellulosic raw materials:

- (i)

- Biochemical route,

- (ii)

- Thermochemical route.

6.1. Biochemical Route

Microorganisms and different enzymes are employed to convert various components of feedstocks (i.e., cellulose and hemicellulose) to sugars, followed by fermentation for ethanol production [27]. Generally, the reaction conditions of biochemical methods are relatively mild where pretreatment temperature is 60–220 °C, enzyme hydrolysis temperature is about 50 °C, and fermentation temperature is 20–60 °C [61].

This route employs various enzymes during conversion of feedstocks to biofuels, although it still requires a considerable amount of work to improve the characteristics of feedstocks and their cost effectiveness, i.e., lowering the production cost, and other related features, such as the efficacy of the enzymes and an improvement in the complete process of conversion [27,59,62,63,64,65,66,67,68,69,70].

It should be noted that, before the enzymatic hydrolysis, pre-treatment of the cellulosic and related feedstocks is a highly decisive step, which can be undertaken in either a physical manner, or chemically or biologically [71]. This reduces the cost of the overall process.

6.2. Thermochemical Route

Biomass changes into liquid fuel, employing gasification technologies and a number of different biofuels, i.e., ethanol, synthetic diesel, and aviation fuel. The Fischer–Tropsch conversion techniques may be used. Thermochemical methods include pyrolysis, liquefaction and gasification.

Pyrolysis is one of the important processes for biofuel production. The pyrolysis takes place at 300–1000 °C under oxygen-free conditions [72]. The pyrolysis products are synthesis gas (CO, CO2, CH4, and H2, etc.), bio-oil, and bio-char. According to different conditions, the major rapid pyrolysis product is bio-oil, and bio-carbon is a major yield of slow pyrolysis. Various researchers around the globe have discussed and reported on the pyrolysis in biofuel production [60,72,73,74]. Djandja et al. [73] reported on the pyrolysis process and its use in the sewage sludge conversion in biofuel. They described the sewage sludge pyrolysis methods. Fombu and Ochonogor [74] designed a semi-batch pyrolysis reactor for enhanced biofuel production.

High temperature liquefaction is the biomass conversion into bio-oil at 250–370 °C under conditions containing more moisture [75].

Gasification is the conversion of biomass to CO, CO2, H2O, H2, CH4, etc., at 900–1200 °C, as well as the formation of by-products tar and coke [76].

This technique is also referred to as the biomass-to-liquids method. In this method, gasification/pyrolysis produces a gas (CO + H2) that enables a broad range of carbon biofuels (i.e., aviation fuel and synthetic diesel) to be synthesized, employing the Fischer–Tropsch conversion. Recently, Cai et al. [77] studied the co-gasification methods for biomass and solid waste in the gasifier.

A comparison of both conversation methods reveals differing yields in terms of feedstock, while demonstrating a similarity in terms of energy. A comparison with different feedstocks reveals a complex picture. One major difference in biochemical and thermochemical methods is ethanol production in the biochemical method, while a range of higher hydrocarbons are synthesized by the thermochemical route (example: jet fuel). Doliente et al. [78] described in detail about the supply chain components of the bio-aviation fuel.

The biofuel costs of both pathways are not fixed, and vary between companies, thus leading to the potential for an alternative process to benefit the industry.

7. Other Approaches for Enhanced Biofuel Production

A change in the composition of cell walls may improve biofuel production. This may lead to improvement in biofuel production from lignocellulosic biomass through the employment of modern approaches of molecular biology, along with synthetic and systemic biology, to improve plant cell wall digestibility [31,79,80].

7.1. Synthetic Biology and System Biology

In recent years, vast development of synthetic and systems biology technology has provided a new perspective and tools for the research of lignocellulose biorefinery. The metagenomic, transcriptome, and metagenomics technologies developed in recent years can skip microbial pure-breeding and directly read the genome, transcriptome, and proteome information of the microbial community in the original environment to identify cellulase genes. Research related to expression level and mechanism of enzymes laid the foundation for the subsequent study of new cellulase gene extraction, heterologous protein expression, purification, and degradation mechanisms [81,82]. A number of research institutions such as the US Department of Energy directly extracted total DNA and total RNA from termite intestines and established a metagene library. By employing sequencing techniques, it become evident that there are a large variety of cellulose, hemicellulose hydrolysis related genes, which further enhances people’s understanding of the richness of cellulase [83,84].

7.2. Microbial Community-Based Approaches

The genome, metabolome, flux group, and computational simulation techniques of systems biology and synthetic biology also provide rich tools for microbial community research [85]. At present, screening of microbial communities that degrade cellulose efficiently from nature, identifying their community structure, studying the fermentation kinetics, analyzing the mechanism of their efficient degradation and transformation, and then simulating the construction of similar systems or further strengthening their functions through transformation will provide us with new ideas for the establishment of a new cellulose degradation system [86,87,88].

Lipase producing or lipolytic bacteria are also our future hope since lipases used in the transesterification reaction further lead to biodiesel production [17]. Al Makishah et al. [17] isolated a bacterial stain (Micrococcus luteus) which has novel lipolytic transesterification activity.

7.3. Metabolic Engineering Techniques

Due to the complexity of sugar utilization and stress resistance traits, which involve multiple levels of genes, proteins, regulatory factors, and stress behaviors, it is difficult to achieve the desired result through simple genetic or metabolic engineering [89]. Adaptive evolutionary engineering based on metabolic engineering can allow microorganisms to quickly obtain excellent phenotypes, but there are problems such as unclear gene targets and negative mutation interference [90,91]. The multi-omics technology development has opened up a new perspective for evolutionary engineering, and also provided a reliable target for reverse metabolic engineering [92].

Systems and synthetic biology have improved people’s knowledge about microbial physiology and metabolic processes, along with the complexity of interactions between metabolic pathways and their regulatory networks. Using accurate computer simulations of complex metabolic networks, the ability to optimize growth or produce a product under specific conditions can be obtained with minimal changes and printing [93].

7.4. Nanotechnology-Based Approaches

Nanotechnology has a very vast scope for the industries related to biofuel production. Nanotechnology along with its nanomaterials have emerged as an effective solution for the biofuel field in achieving cost-effective and efficient approaches to enhance biofuel production [94]. Worldwide, several researchers have reported and discussed the use of nanotechnology in the enhanced biofuel production [40,94,95,96]. Nizami and Rehan [94] discussed the use of nanotechnology and its tremendous ability to develop a cost-effective and efficient biofuel industry. Similarly, Sekoai et al. [95] discussed use of nanoparticles in the biofuel processes (such as biogas, biodiesel, bioethanol production), towards improving its process yields.

7.5. Integration of Various Approaches

A new strategy to systematically integrate microbiome data, gene expression profiling, proteomics, and metabolomics has enabled researchers to study cell metabolism in depth, so that they can know that they are rationally designing strains. Now, new tools provided by synthetic biology could introduce a wide range of genetic diversity into a microbial host. Combined together with breeding, higher throughput technology, and adaptive evolution, a series of genetic transformations can be completed to optimize biological process project objectives [60,97,98,99,100]. Recently, Patel and Shah [100] discussed the integrated lignocellulosic biorefinery to obtain biofuel as well as more than 200 value added products. Sarkar and Sarkar [99] discussed the multi-stage smart system for the sustainable biofuel production, especially to generate purified biofuel using less energy and less carbon emissions. During their study, waste and consumed energy was reduced [99].

Advanced bio-refineries may prove beneficial for reducing second-generation biofuel costs, while the efficiency of the processing methods will be improved by using the entire biomass in advanced biorefineries. An additional significant method would be second-generation biofuel production from wood industries and pulp.

Apart from the above approaches, Rosson et al. [101] described the use of raw waste animal fats as bioliquids. It is also opening a new area for renewable energy. Al Hatrooshi et al. [102] used waste shark liver oil (WSLO) for making biodiesel as cost effective as possible, which is also a non-edible feedstock.

8. Challenges to Be Overcome

There are several constraints faced during biofuel production including production cost, environmental factors (loss of soil and land area), and others. Here, a number of challenges are presented.

The first major challenge is the production cost, i.e., high cost of the biofuel (bioethanol) production and its economic feasibility compared to the price of crude oil [29,38,42,59].

Mizik et al. [38] recently discussed the various constraints, specifically on the economical aspect, in detail. The authors raised various concerns associated to biofuel production and stated that higher generation biofuels are not price competitive due to their production costs and technology limitations [38].

The second major challenge is technology-based limitations, which need to improve in order to achieve cost effective and commercially suitable second-generation biofuels. The advancement in new techniques is proving a challenging task, in particular, when it comes to addressing the cost barriers linked with biofuel production [15,42].

Another major challenge may be the source of funding for continuous and enhanced research and development to raise the biofuel to a market level. This includes: (1) specific and enhanced support for higher yields of energy crops; (2) sustainable biomass production; (3) lowering the cost of the supply chain; and (4) improving the process of conversion.

9. Conclusions

During the present study we discussed the various aspects related to biofuels (especially second-generation lignocellulosic biofuels), concepts surrounding biofuels, and the challenges. Previously, the main focus was on the first-generation biofuels which have direct consequences/effects on various products obtained from agricultural resources, therefore, food prices might be affected. Additionally, poorer countries showed their resistance towards biofuels due to the lower cost effectiveness. Various research around the globe is going now to obtain solutions in the form of sustainable energy sources, i.e., second-generation lignocellulosic biofuels, which would be environmentally friendly and cost effective. Additionally, to avoid the negative impact of first-generation biofuel production on food supplies, use of agricultural waste residues and lignocellulosic feedstock (i.e., second-generation biofuel) might be a better option in a possible short-term period.

However, as first-generation biofuels include various challenges in their production and use, shifting to next generation lignocellulosic biofuel might become more economically feasible.

Current processes for production of these alternative fuels are still in development. It is expected that bio-refining plants based on derivatives of lignocellulose would be able to use a broader range of raw organic materials. This may lead to incorporation of the operational procedure and catalytic design, in order to increase the efficiency of biofuel production in a specific biofuel process. The prime objectives of any bio-refinery are to generate a variety of products using different biomass combinations. Finally, organic chemistry commitment requires the concepts of biological products and bioprospecting systems, thus forcing technological combination and chemical biological transformation of the materials.

Author Contributions

Idea/Plan of the manuscript—A.K.R. and N.H.A.M.; written manuscript’s draft—A.K.R., N.H.A.M. and Z.W.; data analysis and critical revision of the manuscript—A.K.R., G.G., S.P. and R.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, Y.; Cruz-Morales, P.; Zargar, A.; Belcher, M.S.; Pang, B.; Englund, E.; Dan, Q.; Yin, K.; Keasling, J.D. Biofuels for a sustainable future. Cell 2021, 184, 1636–1647. [Google Scholar] [CrossRef]

- Afolalu, S.A.; Yusuf, O.O.; Abioye, A.A.; Emetere, M.E.; Ongbali, S.O.; Samuel, O.D. Biofuel, a sustainable renewable source of energy—A review. IOP Conf. Ser. 2021, 665, 012040. [Google Scholar] [CrossRef]

- Khan, M.A.H.; Bonifacio, S.; Clowes, J.; Foulds, A.; Holland, R.; Matthews, J.C.; Percival, C.J.; Shallcross, D.E. Investigation of Biofuel as a Potential Renewable Energy Source. Atmosphere 2021, 12, 1289. [Google Scholar] [CrossRef]

- Perea-Moreno, M.A.; Samerón-Manzano, E.; Perea-Moreno, A.J. Biomass as renewable energy: Worldwide research trends. Sustainability 2019, 11, 863. [Google Scholar] [CrossRef] [Green Version]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status and prespective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Nazari, M.T.; Mazutti, J.; Basso, L.G.; Colla, L.M.; Brandli, L. Biofuels and their connections with the sustainable development goals: A bibliometric and systematic review. Environ. Dev. Sustain. 2021, 23, 11139–11156. [Google Scholar] [CrossRef]

- Aro, E.-M. From first generation biofuels to advanced solar biofuels. Ambio 2016, 45, 24–31. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Nanda, M.; Joshi, H.C.; Singh, A.; Sharma, S.; Verma, M. Production of biodiesel and bioethanol using algal biomass harvested from fresh water river. Renew. Energy 2018, 116, 606–612. [Google Scholar] [CrossRef]

- Muhammad, U.L.; Shamsuddin, I.M.; Danjuma, A.; Musawa, R.S.; Dembo, U.H. Biofuels as the starring substitute to fossil fuels. Pet. Sci. Eng. 2018, 2, 44–49. [Google Scholar] [CrossRef] [Green Version]

- Subramaniam, Y.; Masron, T.A.; Azman, N.H.N. Biofuels, environmental sustainability and food security: A review of 51 countries. Energy Res. Soc. Sci. 2020, 68, 101549. [Google Scholar] [CrossRef]

- Ganguly, P.; Sarkhel, R.; Das, P. The second-and third-generation biofuel technologies: Comparative perspectives. In Sustainable Fuel Technologies Handbook; Academic Press: Cambridge, MA, USA, 2021; pp. 29–50. [Google Scholar] [CrossRef]

- Dutta, K.; Daverey, A.; Lin, J.-G. Evolution retrospective for alternative fuels: First to fourth generation. Renew. Energy 2014, 69, 114–122. [Google Scholar] [CrossRef]

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Pandit, S.; Savla, N.; Sonawane, J.M.; Sani, A.M.; Gupta, P.K.; Mathuriya, A.S.; Rai, A.K.; Jadhav, D.A.; Jung, S.P.; Prasad, R. Agricultural waste and wastewater as feedstock for bioelectricity generation using microbial fuel cells: Recent advances. Fermentation 2021, 7, 169. [Google Scholar] [CrossRef]

- Shahid, M.K.; Batool, A.; Kashif, A.; Nawaz, M.H.; Aslam, M.; Iqbal, N.; Choi, Y. Biofuels and biorefineries: Development, application and future perspectives emphasizing the environmental and economic aspects. J. Environ. Manag. 2021, 297, 113268. [Google Scholar] [CrossRef]

- Sindhu, R.; Binod, P.; Pandey, A.; Ankaram, S.; Duan, Y.; Awasthi, M.K. Biofuel production from biomass: Toward sustainable development. In Current Developments in Biotechnology and Bioengineering; Kumar, S., Kumar, R., Pandey, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 79–92. [Google Scholar] [CrossRef]

- Al Makishah, N.H.; Rai, A.K.; Neamatallah, A.A.; Mabrouk, A.M. Micrococcus luteus 2030: A novel lipolytic bacterial strain isolated from local contaminated soil in Saudi Arabia. Sylwan 2019, 163, 132–152. [Google Scholar]

- Sánchez, Ó.J.; Cardona, C.A. Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresour. Technol. 2008, 99, 5270–5295. [Google Scholar] [CrossRef]

- Escobar, J.C.; Lora, E.S.; Venturini, O.J.; Yánez, E.E.; Castillo, E.F.; Almazan, O. Biofuels: Environment, technology and food security. Renew. Sustain. Energy Rev. 2009, 13, 1275–1287. [Google Scholar] [CrossRef]

- Jusakulvijit, P.; Bezama, A.; Thrän, D. The availability and assessment of potential agricultural residues for the regional development of second-generation bioethanol in Thailand. Waste Biomass Valor. 2021, 12, 6091–6118. [Google Scholar] [CrossRef]

- EASAC. The Current Status of Biofuels in the European Union, Their Environmental Impacts and Future Prospects; German National Academy of Sciences Leopoldina: Haale, Germany, 2012; 47p, ISBN 978-3-8047-3118-9. [Google Scholar]

- Oumer, A.N.; Hasan, M.M.; Baheta, A.T.; Mamat, R.; Abdullah, A.A. Bio-based liquid fuels as a source of renewable energy: A review. Renew. Sust. Energ. Rev. 2018, 88, 82–98. [Google Scholar] [CrossRef]

- Hirani, A.H.; Javed, N.; Asif, M.; Basu, S.K.; Kumar, A. A review on first-and second-generation biofuel productions. In Biofuels: Greenhouse Gas Mitigation and Global Warming; Kumar, A., Ogita, S., Yau, Y.Y., Eds.; Springer: New Delhi, India, 2018; pp. 141–154. [Google Scholar] [CrossRef]

- Alalwan, H.A.; Alminshid, A.H.; Aljaafari, H.A. Promising evolution of biofuel generations. Subject review. Renew. Energy Focus. 2019, 28, 127–139. [Google Scholar] [CrossRef]

- Dragone, G.; Fernandes, B.; Vicente, A.A.; Teixeira, J.A. Third generation biofuels from microalgae. In Current Research, Technology and Education Topics in Applied Microbiology and Microbial Biotechnology; Mendez-Vilas, A., Ed.; FORMATEX: Badajoz, Spain, 2010; pp. 1355–1366. [Google Scholar]

- Gumienna, M.; Szambelan, K.; Jelen, H.; Czarnecki, Z. Evaluation of ethanol fermentation parameters for bioethanol production from sugar beet pulp and juice. J. Inst. Brew. 2014, 120, 543–549. [Google Scholar] [CrossRef]

- Sims, R.E.H.; Mabee, W.; Saddler, J.N.; Taylor, M. An overview of second generation biofuel technologies. Bioresour. Technol. 2010, 101, 1570–1580. [Google Scholar] [CrossRef] [PubMed]

- Hussain, F.; Shah, S.Z.; Ahmad, H.; Abubshait, S.A.; Abubshait, H.A.; Laref, A.; Manikandan, A.; Kusuma, H.S.; Iqbal, M. Microalgae an ecofriendly and sustainable wastewater treatment option: Biomass application in biofuel and bio-fertilizer production. A review. Renew. Sust. Energ. Rev. 2021, 137, 110603. [Google Scholar] [CrossRef]

- Popp, J.; Harangi-Rakos, M.; Gabnai, Z.; Balogh, P.; Antal, G.; Bai, A. Biofuels and their co-products as livestock feed: Global economic and environmental implications. Molecules 2016, 21, 285. [Google Scholar] [CrossRef] [Green Version]

- Hosseinzadeh-Bandbafha, H.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Demirbas, A. A comprehensive review on the environmental impacts of diesel/biodiesel additives. Energy Convers. Manag. 2018, 174, 579–614. [Google Scholar] [CrossRef]

- Sharma, S.; Kundu, A.; Basu, S.; Shetti, N.P.; Aminabhavi, T.M. Sustainable environmental management and related biofuel technologies. J. Environ. Manag. 2020, 273, 111096. [Google Scholar] [CrossRef]

- Schenk, P.M.; Thomas-Hall, S.R.; Stephens, E.; Marx, U.C.; Mussgnug, J.H.; Posten, C.; Kruse, O.; Hankamer, B. Second Generation Biofuels: High-Efficiency Microalgae for Biodiesel Production. Bioenerg. Res. 2008, 1, 20–43. [Google Scholar] [CrossRef]

- Eisentraut, A. Sustainable Production of Second-Generation Biofuels: Potential and Perspectives in Major Economies and Developing Countries; IEA Energy Papers, No. 2010/01; OECD Publishing: Paris, France, 2010; 221p. [Google Scholar] [CrossRef]

- Scully, S.M.; Orlygsson, J. Recent advances in second generation ethanol production by thermophilic bacteria. Energies 2015, 8, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Gomez, L.D.; Clare, G.S.; McQueen-Mason, J. Sustainable liquid biofuels from biomass: The writing’s on the walls. New Phytol. 2008, 178, 473–485. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Ioannidou, O.; Skoulou, V. Rapeseed residues utilization for energy and 2nd generation biofuels. Fuel 2008, 87, 1492–1502. [Google Scholar] [CrossRef]

- Dhiman, S.; Mukherjee, G. Present scenario and future scope of food waste to biofuel production. J. Food Process Eng. 2021, 44, e13594. [Google Scholar] [CrossRef]

- Mizik, T.; Gyarmati, G. Economic and sustainability of biodiesel production- A systematic literature review. Clean Technol. 2021, 3, 19–36. [Google Scholar] [CrossRef]

- Arefin, M.A.; Rashid, F.; Islam, A. A review of biofuel production from floating aquatic plants: An emerging source of bio-renewable energy. Biofuel. Bioprod. Biorefin. 2021, 15, 574–591. [Google Scholar] [CrossRef]

- Badawy, T.; Mansour, M.S.; Daabo, A.M.; Aziz, M.M.A.; Othman, A.A.; Barsoum, F.; Basouni, M.; Hussien, M.; Ghareeb, M.; Hamza, M.; et al. Selection of second-generation crop for biodiesel extraction and testing its impact with nano additives on diesel engine performance and emissions. Energy 2021, 237, 121605. [Google Scholar] [CrossRef]

- Pauly, M.; Keegstra, K. Cell-wall carbohydrates and their modification as a resource for biofuels. Plant J. 2008, 54, 559–568. [Google Scholar] [CrossRef] [PubMed]

- Raud, M.; Kikas, T.; Sippula, O.; Shurpali, N.J. Potentials and challenges in lignocellulosic biofuel production technology. Renew. Sust. Energ. Rev. 2019, 111, 44–56. [Google Scholar] [CrossRef]

- Aderibigbe, F.A.; Shiru, S.; Saka, H.B.; Amosa, M.K.; Mustapha, S.I.; Alhassan, M.I.; Adejumo, A.L.; Abdulraheem, M.; Owolabi, R.U. Heterogeneous catalysis of second generation oil for biodiesel production: A review. ChemBioEng Rev. 2021, 8, 78–89. [Google Scholar] [CrossRef]

- Firouzi, S.; Allahyari, M.S.; Isazadeh, M.; Nikkhah, A.; van Haute, S. Hybrid multi-criteria decision-making approach to select appropriate biomass resources for biofuel production. Sci. Total Environ. 2021, 770, 144449. [Google Scholar] [CrossRef]

- Narwane, V.S.; Yadav, V.S.; Raut, R.D.; Narkhede, B.E.; Gardas, B.B. Sustainable development challenges of the biofuel industry in India based on integrated MCDM approach. Renew. Energy 2021, 164, 298–309. [Google Scholar] [CrossRef]

- Sarangi, P.K.; Nayak, M.M. Agro-Waste for Second-Generation Biofuels. In Liquid Biofuels: Fundamentals, Characterization, and Applications; Shadangi, K.P., Ed.; Scrivener Publishing LLC: Beverly, MA, USA, 2021; pp. 697–709. [Google Scholar] [CrossRef]

- Shi, Y. China’s resources of biomass feedstock. Eng. Sci. 2011, 13, 16–23. [Google Scholar]

- Wagner, A.O.; Lackner, N.; Mutschlechner, M.; Prem, E.M.; Markt, R.; Illmer, P. Biological pretreatment strategies for second-generation lignocellulosic resources to enhance biogas production. Energies 2018, 11, 1797. [Google Scholar] [CrossRef] [Green Version]

- Galbe, M.; Wallberg, O. Pretreatment for biorefineries: A review of common methods for efficient utilisation of lignocellulosic materials. Biotechnol. Biofuels 2019, 12, 294. [Google Scholar] [CrossRef] [Green Version]

- Machineni, L. Lignocellulosic biofuel production: Review of alternatives. Biomass Convers. Biorefin. 2020, 10, 779–791. [Google Scholar] [CrossRef]

- Ab Rasid, N.S.; Shamjuddin, A.; Rahman, A.Z.A.; Amin, N.A.S. Recent advances in green pre-treatment methods of lignocellulosic biomass for enhanced biofuel production. J. Clean. Prod. 2021, 321, 129038. [Google Scholar] [CrossRef]

- Beig, B.; Riaz, M.; Naqvi, S.R.; Hassan, M.; Zheng, Z.; Karimi, K.; Pugazhendhi, A.; Atabani, A.E.; Chi, N.T.L. Current challenges and innovative developments in pretreatment of lignocellulosic residues for biofuel production: A review. Fuel 2021, 287, 119670. [Google Scholar] [CrossRef]

- Gnansounou, E.; Dauriat, A. Techno-economic analysis of lignocellulosic ethanol: A review. Bioresour. Technol. 2010, 101, 4980–4991. [Google Scholar] [CrossRef] [PubMed]

- Sivamani, S.; Baskar, R.; Chandrasekaran, A.P. Response surface optimization of acid pretreatment of cassava stem for bioethanol production. Environ. Prog. Sustain. Energy 2020, 39, e13335. [Google Scholar] [CrossRef]

- Dionísio, S.R.; Santoro, D.C.J.; Bonan, C.I.D.G.; Soares, L.B.; Biazi, L.E.; Rabelo, S.C.; Ienczak, J.L. Second-generation ethanol process for integral use of hemicellulosic and cellulosic hydrolysates from diluted sulfuric acid pretreatment of sugarcane bagasse. Fuel 2021, 304, 121290. [Google Scholar] [CrossRef]

- Lima, D.R.S.; de Oliveira Paranhos, A.G.; Adarme, O.F.H.; Baêta, B.E.L.; Gurgel, L.V.A.; dos Santos, A.S.; de Queiroz Silva, S.; de Aquino, S.F. Integrated production of second-generation ethanol and biogas from sugarcane bagasse pretreated with ozone. Biomass Convers. Biorefin. 2022, 12, 809–825. [Google Scholar] [CrossRef]

- Morales-Martínez, J.L.; Aguilar-Uscanga, M.G.; Bolaños-Reynoso, E.; López-Zamora, L. Optimization of chemical pretreatments using response surface methodology for second-generation ethanol production from coffee husk waste. BioEnergy Res. 2021, 14, 815–827. [Google Scholar] [CrossRef]

- Mund, N.K.; Dash, D.; Mishra, P.; Nayak, N.R. Cellulose solvent–based pretreatment and enzymatic hydrolysis of pineapple leaf waste biomass for efficient release of glucose towards biofuel production. Biomass Convers. Biorefin. 2021, 1–10. [Google Scholar] [CrossRef]

- Sinitsyn, A.P.; Sinitsyna, O.A. Bioconversion of renewable plant biomass. Second-generation biofuels: Raw materials, biomass pretreatment, enzymes, processes, and cost analysis. Biochemistry 2021, 86, S166–S195. [Google Scholar] [CrossRef] [PubMed]

- Talmadge, M.; Kinchin, C.; Chum, H.L.; de Rezende Pinho, A.; Biddy, M.; de Almeida, M.B.; Casavechia, L.C. Techno-economic analysis for co-processing fast pyrolysis liquid with vacuum gasoil in FCC units for second-generation biofuel production. Fuel 2021, 293, 119960. [Google Scholar] [CrossRef]

- Lynd, L.R.; Weimer, P.J.; van Zyl, W.H.; Pretorius, I.S. Microbial Cellulose Utilization: Fundamental and Biotechnology. Microbiol. Mol. Bio. Rev. 2002, 66, 506–577. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gregg, D.J.; Boussaid, A.; Saddler, J.N. Techno-economic evaluations of a generic wood-to-ethanol process: Effect of increased cellulose yields and enzyme recycle. Bioresour. Technol. 1998, 63, 7–12. [Google Scholar] [CrossRef]

- Weil, J.R.; Dien, B.; Bothast, R.; Hendrickson, R.; Mosier, N.S.; Ladisch, M.R. Removal of fermentation inhibitors formed during pretreatment of biomass by polymeric adsorbents. Indust. Eng. Chem. Res. 2002, 41, 6132–6138. [Google Scholar] [CrossRef]

- Sheehan, J.; Aden, A.; Paustian, K.; Killian, K.; Brenner, J.; Walsh, M.; Nelson, R. Energy and environmental aspects of using corn stover for fuel ethanol. J. Indust. Ecol. 2004, 7, 117–146. [Google Scholar] [CrossRef]

- Eggeman, T.; Elander, R.T. Process and economic analysis of pretreatment technologies. Bioresour. Technol. 2005, 96, 2019–2025. [Google Scholar] [CrossRef]

- Galbe, M.; Liden, G.; Zacchi, G. Production of ethanol from biomass-research in Sweden. J. Sci. Ind. Res. 2005, 64, 905–919. [Google Scholar]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of Promising Technologies for Pretreatment of Lignocellulosic Biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef]

- Rocha–Meneses, L.; Raud, M.; Orupõld, K.; Kikas, T. Second-generation bioethanol production: A review of strategies for waste valorization. Agron. Res. 2016, 15, 830–847. [Google Scholar]

- Jutakridsada, P.; Saengprachatanarug, K.; Kasemsiri, P.; Hiziroglu, S.; Kamwilaisak, K.; Chindaprasirt, P. Bioconversion of Saccharum officinarum leaves for ethanol production using separate hydrolysis and fermentation processes. Waste Biomass Valor. 2019, 10, 817–825. [Google Scholar] [CrossRef]

- Azam, M.; Jahromy, S.S.; Raza, W.; Raza, N.; Lee, S.S.; Kim, K.-H.; Winter, F. Status, characterization and potential utilization of municipal solid waste as renewable energy source: Lahore case study in Pakistan. Environ. Int. 2020, 134, 105291. [Google Scholar] [CrossRef]

- Yang, B.; Wyman, C.E. Pre-treatment: The key to unlocking low cost cellulosic ethanol. Biofuel Bioprod. Biorefin. 2008, 2, 26–40. [Google Scholar] [CrossRef]

- Roy, P.; Dias, G. Prospects for pyrolysis technologies in the bioenergy sector: A review. Renew. Sustain. Energy Rev. 2017, 77, 59–69. [Google Scholar] [CrossRef]

- Djandja, O.S.; Wang, Z.C.; Wang, F.; Xu, Y.P.; Duan, P.G. Pyrolysis of municipal sewage sludge for biofuel production: A review. Ind. Eng. Chem. Res. 2020, 59, 16939–16956. [Google Scholar] [CrossRef]

- Fombu, A.H.; Ochonogor, A.E. Design and Construction of a Semi-batch Pyrolysis Reactor for the Production of Biofuel. In IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Bristol, UK, 2021; p. 012041. [Google Scholar] [CrossRef]

- Li, C.; Aston, J.E.; Lacey, J.A.; Thompson, V.S.; Thompson, D.N. Impact of feedstock quality and variation on biochemical and thermochemical conversion. Renew. Sustain. Energy Rev. 2016, 65, 525–536. [Google Scholar] [CrossRef] [Green Version]

- Richardson, Y.; Joël, B.; Julbe, A. A short overview on purification and conditioning of syngas produced by biomass gasification: Catalytic strategies, process intensification and new concepts. Prog. Energy Combust. Sci. 2012, 38, 765–781. [Google Scholar] [CrossRef]

- Cai, J.; Zeng, R.; Zheng, W.; Wang, S.; Han, J.; Li, K.; Luo, M.; Tang, X. Synergistic Effects of Co-Gasification of Municipal Solid Waste and Biomass in Fixed-Bed Gasifier. Process. Saf. Environ. Prot. 2021, 148, 1–12. [Google Scholar] [CrossRef]

- Doliente, S.; Narayan, A.; Tapia, F.; Samsatli, N.J.; Zhao, Y.; Samsatli, S. Bio-aviation fuel: A comprehensive review and analysis of the supply chain components. Front. Energy Res. 2020, 8, 110. [Google Scholar] [CrossRef]

- Furtado, A.; Lupo, J.S.; Hoang, N.V.; Healey, A.; Singh, S.; Simmons, B.A.; Henry, R.J. Modifying plants for biofuel and biomaterial production. Plant Biotechnol. J. 2014, 12, 1246–1258. [Google Scholar] [CrossRef] [PubMed]

- Kalluri, U.C.; Yin, H.; Yang, X.; Davison, B.H. Systems and synthetic biology approaches to alter plant cell walls and reduce biomass recalcitrance. Plant Biotechnol. J. 2014, 12, 1207–1216. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ilmberger, N.; Streit, W.R. Screening for cellulase encoding clones in metagenomic libraries. In Metagenomics. Methods in Molecular Biology; Streit, W., Daniel, R., Eds.; Humana Press: New York, NY, USA, 2017; Volume 1539, pp. 205–217. [Google Scholar] [CrossRef]

- Liu, G.; Qin, Y.; Li, Z.; Qu, Y. Development of highly efficient, low-cost lignocellulolytic enzyme systems in the post-genomic era. Biotechnol. Adv. 2013, 31, 962–975. [Google Scholar] [CrossRef] [PubMed]

- Nimchua, T.; Thongaram, T.; Uengwetwanit, T.; Pongpattanakitshote, S.; Eurwilaichitr, L. Metagenomic analysis of novel lignocellulose-degrading enzymes from higher termite guts inhabiting microbes. J. Microbiol. Biotechnol. 2012, 22, 462–469. [Google Scholar] [CrossRef] [Green Version]

- Rashamuse, K.; Tendai, W.S.; Mathiba, K.; Ngcobo, T.; Mtimka, S.; Brady, D. Metagenomic mining of glycoside hydrolases from the hindgut bacterial symbionts of a termite (Trinervitermes trinervoides) and the characterization of a multimodular beta-1,4-xylanase (GH11). Biotechnol. Appl. Biochem. 2017, 64, 174–186. [Google Scholar] [CrossRef]

- Xie, S.; Syrenne, R.; Sun, S.; Yuan, J.S. Exploration of Natural Biomass Utilization Systems (NBUS) for advanced biofuel—From systems biology to synthetic design. Curr. Opin. Biotechnol. 2014, 27, 195–203. [Google Scholar] [CrossRef]

- Liang, J.; Lin, Y.; Li, T.; Mo, F. Microbial consortium OEM1 cultivation for higher lignocellulose degradation and chlorophenol removal. RSC Adv. 2017, 7, 39011–39017. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Dong, D.; Wang, H.; Mueller, K.; Qin, Y.; Wang, H.; Wu, W. Metagenomic analysis of microbial consortia enriched from compost: New insights into the role of Actinobacteria in lignocellulose decomposition. Biotechnol. Biofuels 2016, 9, 22. [Google Scholar] [CrossRef] [Green Version]

- Zhu, N.; Yang, J.; Ji, L.; Liu, J.; Yang, Y.; Yuan, H. Metagenomic and metaproteomic analyses of a corn stover-adapted microbial consortium EMSD5 reveal its taxonomic and enzymatic basis for degrading lignocellulose. Biotechnol. Biofuels 2016, 9, 243. [Google Scholar] [CrossRef] [Green Version]

- Fu, Y.; Chen, L.; Zhang, W. Regulatory mechanisms related to biofuel tolerance in producing microbes. J. Appl. Microbiol. 2016, 121, 320–332. [Google Scholar] [CrossRef] [Green Version]

- Dragosits, M.; Mattanovich, D. Adaptive laboratory evolution—Principles and applications for biotechnology. Microb. Cell Fact. 2013, 12, 64. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farwick, A.; Bruder, S.; Schadeweg, V.; Oreb, M.; Boles, E. Engineering of yeast hexose transporters to transport D-xylose without inhibition by D-glucose. Proc. Natl. Acad. Sci. USA 2014, 111, 5159–5164. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- dos Santos, S.C.; Sá-Correia, I. Yeast toxicogenomics: Lessons from a eukaryotic cell model and cell factory. Curr. Opin. Biotechnol. 2015, 33, 183–191. [Google Scholar] [CrossRef] [PubMed]

- King, Z.A.; Lloyd, C.J.; Feist, A.M.; Palsson, B.O. Next-generation genome-scale models for metabolic engineering. Curr. Opin. Biotechnol. 2015, 35, 23–29. [Google Scholar] [CrossRef]

- Nizami, A.S.; Rehan, M. Towards nanotechnology-based biofuel industry. Biofuel Res. J. 2018, 5, 798–799. [Google Scholar] [CrossRef] [Green Version]

- Sekoai, P.T.; Ouma, C.N.M.; Du Preez, S.P.; Modisha, P.; Engelbrecht, N.; Bessarabov, D.G.; Ghimire, A. Application of nanoparticles in biofuels: An overview. Fuel 2019, 237, 380–397. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Nambiraj, M.; Parthasarathy, M.; Balasubramanian, D.; Hariharan, V.; Jayakar, J. Experimental investigation to reduce environmental pollutants using biofuel nano-water emulsion in thermal barrier coated engine. Fuel 2021, 285, 119200. [Google Scholar] [CrossRef]

- Bassalo, M.C.; Liu, R.; Gill, R.T. Directed evolution and synthetic biology applications to microbial systems. Curr. Opin. Biotechnol. 2016, 39, 126–133. [Google Scholar] [CrossRef] [Green Version]

- Ghim, C.-M.; Kim, T.; Mitchell, R.J.; Lee, S.K. Synthetic biology for biofuels: Building designer microbes from the scratch. Biotechnol. Bioprocess Eng. 2010, 15, 11–21. [Google Scholar] [CrossRef]

- Sarkar, M.; Sarkar, B. How does an industry reduce waste and consumed energy within a multi-stage smart sustainable biofuel production system? J. Clean. Prod. 2020, 262, 121200. [Google Scholar] [CrossRef]

- Patel, A.; Shah, A. Integrated lignocellulosic biorefinery: Gateway for production of second generation ethanol and value added products. J. Bioresour. Bioprod. 2021, 6, 108–128. [Google Scholar] [CrossRef]

- Rosson, E.; Sgarbossa, P.; Pedrielli, F.; Mozzon, M.; Bertani, R. Bioliquids from raw waste animal fats: An alternative renewable energy source. Biomass Convers. Biorefin. 2021, 11, 1475–1490. [Google Scholar] [CrossRef]

- Al Hatrooshi, A.S.; Eze, V.C.; Harvey, A.P. Production of biodiesel from waste shark liver oil for biofuel applications. Renew. Energy 2020, 145, 99–105. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).