Effects of Solid-State Fermentation Pretreatment with Single or Dual Culture White Rot Fungi on White Tea Residue Nutrients and In Vitro Rumen Fermentation Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. Fungal Source

2.2. Millet Spawn Preparation

2.3. Tea Residue Source

2.4. Fermentation Method

2.5. Chemical Index and Fiber Carbohydrates Analysis

2.6. Morphological Observation

2.7. In Vitro Fermentation

2.8. Statistical Analysis

3. Results

3.1. Changes in Chemical Index and Fiber Carbohydrates

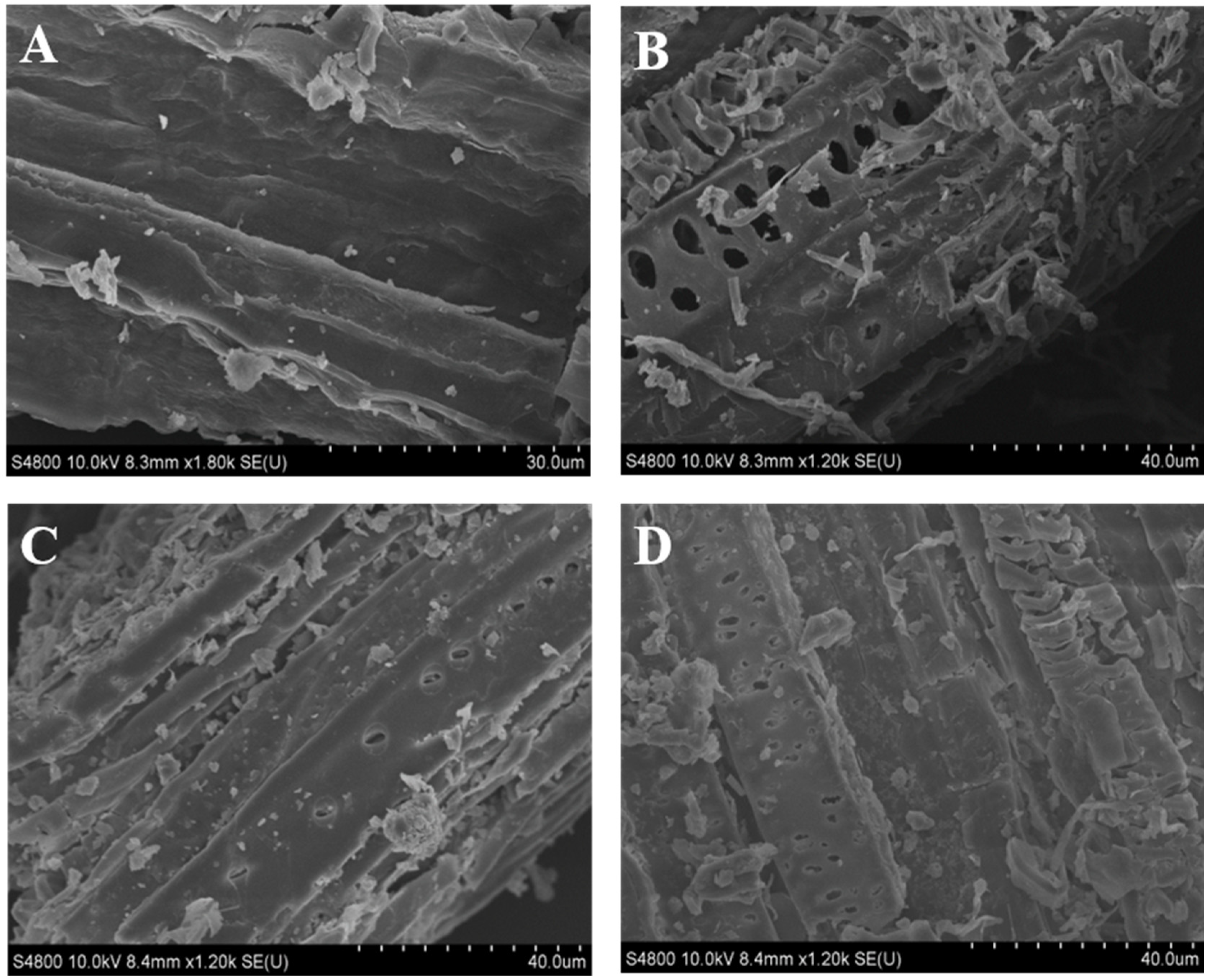

3.2. Morphological Observation

3.3. In Vitro Fermentation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manhongo, T.T.; Chimphango, A.; Thornley, P.; Roder, M. An economic viability and environmental impact assessment of mango processing waste-based biorefineries for co-producing bioenergy and bioactive compounds. Renew. Sustain. Energy Rev. 2021, 148, 15. [Google Scholar] [CrossRef]

- Zou, C.N.; Xiong, B.; Xue, H.Q.; Zheng, D.W.; Ge, Z.X.; Wang, Y.; Jiang, L.Y.; Pan, S.Q.; Wu, S.T. The role of new energy in carbon neutral. Pet. Explor. Dev. 2021, 48, 480–491. [Google Scholar] [CrossRef]

- Li, J.F.; Wu, Y.J.; Zhao, J.; Wang, S.R.; Dong, Z.H.; Shao, T. Bioaugmented degradation of rice straw combining two novel microbial consortia and lactic acid bacteria for enhancing the methane production. Bioresour. Technol. 2022, 344, 10. [Google Scholar] [CrossRef] [PubMed]

- Vethathirri, R.S.; Santillan, E.; Wuertz, S. Microbial community-based protein production from wastewater for animal feed applications. Bioresour. Technol. 2021, 341, 12. [Google Scholar] [CrossRef]

- Khan, N.; Mukhtar, H. Tea Polyphenols in Promotion of Human Health. Nutrients 2019, 11, 39. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations Search Page. Available online: http://www.fao.org/faostat/zh/#search (accessed on 20 September 2022).

- Mahmoud, D.A.R.; Allam, M.A.; Farag, M.M. Tea Wastes as An Alternative Sustainable Raw Material for Ethanol Production. Egypt. J. Chem. 2020, 63, 2683–2697. [Google Scholar] [CrossRef]

- Debnath, B.; Haldar, D.; Purkait, M.K. Potential and sustainable utilization of tea waste: A review on present status and future trends. J. Environ. Chem. Eng. 2021, 9, 14. [Google Scholar] [CrossRef]

- Barathi, M.; Kumar, A.S.K.; Kodali, J.; Mittal, S.; Samhith, G.D.; Rajesh, N. Probing the Interaction between Fluoride and the Polysaccharides in Al(III)- and Zr (IV)-Modified Tea Waste by Using Diverse Analytical Characterization Techniques. Chemistryselect 2017, 2, 10123–10135. [Google Scholar] [CrossRef]

- Schmitz, E.; Leontakianakou, S.; Norlander, S.; Karlsson, E.N.; Adlercreutz, P. Lignocellulose degradation for the bioeconomy: The potential of enzyme synergies between xylanases, ferulic acid esterase and laccase for the production of arabinoxylo-oligosaccharides. Bioresour. Technol. 2022, 343, 10. [Google Scholar] [CrossRef]

- Zhang, W.J.; Pan, K.; Liu, C.J.; Qu, M.R.; OuYang, K.H.; Song, X.Z.; Zhao, X.H. Recombinant Lentinula edodes xylanase improved the hydrolysis and in vitro ruminal fermentation of soybean straw by changing its fiber structure. Int. J. Biol. Macromol. 2020, 151, 286–292. [Google Scholar] [CrossRef]

- Atuhaire, A.M.; Kabi, F.; Okello, S.; Mugerwa, S.; Ebong, C. Optimizing bio-physical conditions and pre-treatment options for breaking lignin barrier of maize stover feed using white rot fungi. Anim. Nutr. Zhongguo Xu Mu Shou Yi Xue Hui 2016, 2, 361–369. [Google Scholar] [CrossRef] [PubMed]

- Xie, P.J.; Fan, L.L.; Huang, L.X.; Zhang, C.H. An innovative co-fungal treatment to poplar bark sawdust for delignification and polyphenol enrichment. Ind. Crops Prod. 2020, 157, 11. [Google Scholar] [CrossRef]

- Sun, H.; Cui, X.; Li, R.L.; Guo, J.B.; Dong, R.J. Ensiling process for efficient biogas production from lignocellulosic substrates: Methods, mechanisms, and measures. Bioresour. Technol. 2021, 342, 10. [Google Scholar] [CrossRef]

- Nayan, N.; Sonnenberg, A.S.M.; Hendriks, W.H.; Cone, J.W. Differences between two strains of Ceriporiopsis subvermispora on improving the nutritive value of wheat straw for ruminants. J. Appl. Microbiol. 2017, 123, 352–361. [Google Scholar] [CrossRef] [PubMed]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists. Official Methods of Analysis of the Association of Official Analytical Chemists, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1995. [Google Scholar]

- Jiang, M.C.; Datsomor, O.; Cheng, Z.Q.; Meng, Z.T.; Zhan, K.; Yang, T.Y.; Huang, Y.H.; Yan, Q.; Zhao, G.Q. Partial Substitution of Alfalfa Hay by Stevia (Stevia rebaudiana) Hay Can Improve Lactation Performance, Rumen Fermentation, and Nitrogen Utilization of Dairy Cows. Front. Vet. Sci. 2022, 9, 8. [Google Scholar] [CrossRef] [PubMed]

- Royer, M.; Diouf, P.N.; Stevanovic, T. Polyphenol contents and radical scavenging capacities of red maple (Acer rubrum L.) extracts. Food Chem. Toxicol. 2011, 49, 2180–2188. [Google Scholar] [CrossRef] [PubMed]

- Menke, K.; Raab, L.; Salewski, A.; Steingass, H.; Fritz, D.; Schneider, W. The estimation of the digestibility and metabolizable energy content of ruminant feedingstuffs from the gas production when they are incubated with rumen liquor in vitro. J. Agric. Sci. 1979, 93, 217–222. [Google Scholar] [CrossRef]

- Lin, M.; Feng, L.M.; Cheng, Z.Q.; Wang, K.P. Effect of ethanol or lactic acid on volatile fatty acid profile and microbial community in short-term sequentially transfers by ruminal fermented with wheat straw in vitro. Process Biochem. 2021, 102, 369–375. [Google Scholar] [CrossRef]

- Yasar, S.; Tosun, R. Improving Nutritional Qualities of Tomato Pomace by Pleurotus ostreatus and Phanerochaete chrysosporium Fermentation. KSU Tarim Doga Derg. 2020, 23, 527–534. [Google Scholar] [CrossRef]

- Yang, C.L.; Chen, Z.F.; Wu, Y.L.; Wang, J.K. Nutrient and ruminal fermentation profiles of Camellia seed residues with fungal pretreatment. Asian-Australas. J. Anim. Sci. 2019, 3, 357–365. [Google Scholar] [CrossRef]

- Nayan, N.; Sonnenberg, A.S.M.; Hendriks, W.H.; Cone, J.W. Variation in the solubilization of crude protein in wheat straw by different white-rot fungi. Anim. Feed. Sci. Technol. 2018, 242, 135–143. [Google Scholar] [CrossRef]

- Arora, D.S.; Sharma, R.K. Comparative ligninolytic potential of Phlebia species and their role in improvement of in vitro digestibility of wheat straw. J. Anim. Feed. Sci. 2009, 18, 151–161. [Google Scholar] [CrossRef]

- Beccaccioli, M.; Reverberi, M.; Scala, V. Fungal lipids: Biosynthesis and signalling during plant-pathogen interaction. Front. Biosci. 2019, 24, 172–185. [Google Scholar] [CrossRef]

- Fagone, P.; Jackowski, S. Membrane phospholipid synthesis and endoplasmic reticulum function. J. Lipid Res. 2009, 50, S311–S316. [Google Scholar] [CrossRef]

- Nayan, N.; van Erven, G.; Kabel, M.A.; Sonnenberg, A.S.M.; Hendriks, W.H.; Cone, J.W. Improving ruminal digestibility of various wheat straw types by white-rot fungi. J. Sci. Food Agric. 2019, 99, 957–965. [Google Scholar] [CrossRef]

- Tuyen, V.D.; Cone, J.W.; Baars, J.J.P.; Sonnenberg, A.S.M.; Hendriks, W.H. Fungal strain and incubation period affect chemical composition and nutrient availability of wheat straw for rumen fermentation. Bioresour. Technol. 2012, 111, 336–342. [Google Scholar] [CrossRef]

- Hofrichter, M.; Ullrich, R.; Pecyna, M.J.; Liers, C.; Lundell, T. New and classic families of secreted fungal heme peroxidases. Appl. Microbiol. Biotechnol. 2010, 87, 871–897. [Google Scholar] [CrossRef]

- Shirmohammadli, Y.; Efhamisisi, D.; Pizzi, A. Tannins as a sustainable raw material for green chemistry: A review. Ind. Crops Prod. 2018, 126, 316–332. [Google Scholar] [CrossRef]

- Labuschagne, P.M.; Eicker, A.; Aveling, T.A.S.; de Meillon, S.; Smith, M.F. Influence of wheat cultivars on straw quality and Pleurotus ostreatus cultivation. Bioresour. Technol. 2000, 74, 71–75. [Google Scholar] [CrossRef]

- Membrillo, I.; Sanchez, C.; Meneses, M.; Favela, E.; Loera, O. Effect of substrate particle size and additional nitrogen source on production of lignocellulolytic enzymes by Pleurotus ostreatus strains. Bioresour. Technol. 2008, 99, 7842–7847. [Google Scholar] [CrossRef]

- Reid, I.D. Biological Delignification of Aspen Wood by Solid-State Fermentation with the White-Rot Fungus Merulius tremellosus. Appl. Environ. Microbiol. 1985, 50, 133–139. [Google Scholar] [CrossRef]

- Rüttimann-Johnson, C.; Salas, L.; Vicua, R.; Kirk, T.K. Extracellular Enzyme Production and Synthetic Lignin Mineralization by Ceriporiopsis subvermispora. Appl. Environ. Microbiol. 1993, 59, 1792–1797. [Google Scholar] [CrossRef]

- Niu, D.Z.; Zuo, S.S.; Jiang, D.; Tian, P.J.; Zheng, M.L.; Xu, C.C. Treatment using white rot fungi changed the chemical composition of wheat straw and enhanced digestion by rumen microbiota &ITin vitro&IT. Anim. Feed. Sci. Technol. 2018, 237, 46–54. [Google Scholar] [CrossRef]

- Winquist, E.; Moilanen, U.; Mettala, A.; Leisola, M.; Hatakka, A. Production of lignin modifying enzymes on industrial waste material by solid-state cultivation of fungi. Biochem. Eng. J. 2008, 42, 128–132. [Google Scholar] [CrossRef]

- Sanchez, C. Lignocellulosic residues: Biodegradation and bioconversion by fungi. Biotechnol. Adv. 2009, 27, 185–194. [Google Scholar] [CrossRef]

- Elisashvili, V.; Penninckx, M.; Kachlishvili, E.; Tsiklauri, N.; Metreveli, E.; Kharziani, T.; Kvesitadze, G. Lentinus edodes and Pleurotus species lignocellulolytic enzymes activity in submerged and solid-state fermentation of lignocellulosic wastes of different composition. Bioresour. Technol. 2008, 99, 457–462. [Google Scholar] [CrossRef]

- Kholif, A.E.; Gouda, G.A.; Patra, A.K. The sustainable mitigation of in vitro ruminal biogas emissions by ensiling date palm leaves and rice straw with lactic acid bacteria and Pleurotus ostreatus for cleaner livestock production. J. Appl. Microbiol. 2022, 132, 2925–2939. [Google Scholar] [CrossRef]

- Singh, D.; Chen, S.L. The white-rot fungus Phanerochaete chrysosporium: Conditions for the production of lignin-degrading enzymes. Appl. Microbiol. Biotechnol. 2008, 81, 399–417. [Google Scholar] [CrossRef]

- Bentil, J.A.; Thygesen, A.; Mensah, M.; Lange, L.; Meyer, A.S. Cellulase production by white-rot basidiomycetous fungi: Solid-state versus submerged cultivation. Appl. Microbiol. Biotechnol. 2018, 102, 5827–5839. [Google Scholar] [CrossRef]

- Van Kuijk, S.J.A.; Sonnenberg, A.S.M.; Baars, J.J.P.; Hendriks, W.H.; Cone, J.W. Fungal treated lignocellulosic biomass as ruminant feed ingredient: A review. Biotechnol. Adv. 2015, 33, 191–202. [Google Scholar] [CrossRef]

- Zhao, X.B.; Zhang, L.H.; Liu, D.H. Biomass recalcitrance. Part I: The chemical compositions and physical structures affecting the enzymatic hydrolysis of lignocellulose. Biofuels Bioprod. Biorefining-Biofpr 2012, 6, 465–482. [Google Scholar] [CrossRef]

- Rongpipi, S.; Ye, D.; Gomez, E.D.; Gomez, E.W. Progress and Opportunities in the Characterization of Cellulose—An Important Regulator of Cell Wall Growth and Mechanics. Front. Plant Sci. 2019, 9, 28. [Google Scholar] [CrossRef]

- Nayan, N.; Sonnenberg, A.S.M.; Hendriks, W.H.; Cone, J.W. Screening of white-rot fungi for bioprocessing of wheat straw into ruminant feed. J. Appl. Microbiol. 2018, 125, 468–479. [Google Scholar] [CrossRef]

- Ramin, M.; Huhtanen, P. Development of equations for predicting methane emissions from ruminants. J. Dairy Sci. 2013, 96, 2476–2493. [Google Scholar] [CrossRef]

- Abrego-Gacia, A.; Poggi-Varaldo, H.M.; Robles-Gonzalez, V.; Ponce-Noyola, T.; Calva-Calva, G.; Rios-Leal, E.; Estrada-Barcenas, D.; Mendoza-Vargas, A. Lovastatin as a supplement to mitigate rumen methanogenesis: An overview. J. Anim. Sci. Biotechnol. 2021, 12, 12. [Google Scholar] [CrossRef]

- Khonkhaeng, B.; Cherdthong, A. Improving Nutritive Value of Purple Field Corn Residue and Rice Straw by Culturing with White-Rot Fungi. J. Fungi 2020, 6, 69. [Google Scholar] [CrossRef]

- Zhang, T.; Mu, Y.Y.; Zhang, R.Y.; Xue, Y.F.; Guo, C.Z.; Qi, W.P.; Zhang, J.Y.; Mao, S.Y. Responsive changes of rumen microbiome and metabolome in dairy cows with different susceptibility to subacute ruminal acidosis. Anim. Nutr. 2022, 8, 331–340. [Google Scholar] [CrossRef]

- Amin, A.B.; Mao, S.Y. Influence of yeast on rumen fermentation, growth performance and quality of products in ruminants: A review. Anim. Nutr. 2021, 7, 31–41. [Google Scholar] [CrossRef]

- Lam, S.; Munro, J.C.; Zhou, M.; Guan, L.L.; Schenkel, F.S.; Steele, M.A.; Miller, S.P.; Montanholi, Y.R. Associations of rumen parameters with feed efficiency and sampling routine in beef cattle. Animal 2018, 12, 1442–1450. [Google Scholar] [CrossRef]

- Apajalahti, J.; Vienola, K.; Raatikainen, K.; Holder, V.; Moran, C.A. Conversion of Branched-Chain Amino Acids to Corresponding Isoacids—An in vitro Tool for Estimating Ruminal Protein Degradability. Front. Vet. Sci. 2019, 6, 11. [Google Scholar] [CrossRef] [PubMed]

- Nishida, T.; Eruden, B.; Hosoda, K.; Matsuyama, H.; Nakagawa, K.; Miyazawa, T.; Shioya, S. Effects of green tea (Camellia sinensis) waste silage and polyethylene glycol on ruminal fermentation and blood components in cattle. Asian-Australas. J. Anim. Sci. 2006, 19, 1728–1736. [Google Scholar] [CrossRef]

- Kondo, M.; Hirano, Y.; Kita, K.; Jayanegara, A.; Yokota, H. Nutritive evaluation of spent green and black tea leaf silages by in vitro gas production characteristics, ruminal degradability and post-ruminal digestibility assessed with inhibitory activity of their tannins. Anim. Sci. J. 2018, 89, 1656–1662. [Google Scholar] [CrossRef]

- Firkins, J.L.; Yu, Z.; Morrison, M. Ruminal nitrogen metabolism: Perspectives for integration of microbiology and nutrition for dairy. J. Dairy Sci. 2007, 90, E1–E16. [Google Scholar] [CrossRef] [PubMed]

- Bayat, A.R.; Vilkki, J.; Razzaghi, A.; Leskinen, H.; Kettunen, H.; Khurana, R.; Brand, T.; Ahvenjarvi, S. Evaluating the effects of high-oil rapeseed cake or natural additives on methane emissions and performance of dairy cows. J. Dairy Sci. 2022, 105, 1211–1224. [Google Scholar] [CrossRef]

- Noziere, P.; Glasser, F.; Sauvant, D. In vivo production and molar percentages of volatile fatty acids in the rumen: A quantitative review by an empirical approach. Animal 2011, 5, 403–414. [Google Scholar] [CrossRef]

- Giger-Reverdin, S.; Rigalma, K.; Desnoyers, M.; Sauvant, D.; Duvaux-Ponter, C. Effect of concentrate level on feeding behavior and rumen and blood parameters in dairy goats: Relationships between behavioral and physiological parameters and effect of between-animal variability. J. Dairy Sci. 2014, 97, 4367–4378. [Google Scholar] [CrossRef]

- Sutton, J.D.; Dhanoa, M.S.; Morant, S.V.; France, J.; Napper, D.J.; Schuller, E. Rates of production of acetate, propionate, and butyrate in the rumen of lactating dairy cows given normal and low-roughage diets. J. Dairy Sci. 2003, 86, 3620–3633. [Google Scholar] [CrossRef]

- Kristensen, N.B.; Danfaer, A.; Agergaard, N. Absorption and metabolism of short-chain fatty acids in ruminants. Arch. Fur Tierernahr. 1998, 51, 165–175. [Google Scholar] [CrossRef]

| Items | Treatment | Duration of Treatment (Weeks) | SD | p-Value | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | T | W | T × W | |||

| DM | P. chrysosporium | 96.62 a | 91.76 b | 92.94 Bb | 92.99 Bb | 92.54 Bb | 1.816 | <0.01 | <0.00 | 0.14 |

| P. ostreatus | 96.62 a | 91.86 c | 93.84 ABb | 93.43 ABb | 93.48 ABb | |||||

| Dual | 96.62 a | 94.07 b | 93.89 Ab | 94.01 Ab | 94.33 Ab | |||||

| CP | P. chrysosporium | 14.51 c | 14.61 ABc | 16.19 b | 16.18 b | 16.70 a | 1.154 | 0.24 | <0.01 | 0.10 |

| P. ostreatus | 14.51 c | 14.30 Bc | 16.03 b | 16.70 a | 16.80 a | |||||

| Dual | 14.51 d | 15.30 Acd | 15.94 bc | 16.37 ab | 17.16 a | |||||

| EE | P. chrysosporium | 3.85 c | 6.52 b | 6.56 b | 6.70 b | 8.22 Aa | 2.044 | <0.01 | <0.01 | 0.25 |

| P. ostreatus | 3.85 | 5.55 | 5.76 | 5.70 | 5.25 B | |||||

| Dual | 3.85 b | 4.38 ab | 4.75 ab | 4.80 ab | 5.54 Ba | |||||

| ASH | P. chrysosporium | 4.37 b | 4.43 b | 5.56 ABa | 5.69 a | 5.90 a | 0.828 | <0.05 | <0.01 | 0.23 |

| P. ostreatus | 4.37 e | 4.72 d | 5.30 Bc | 5.72 b | 6.30 a | |||||

| Dual | 4.37 d | 5.48 c | 5.76 Abc | 6.07 ab | 6.29 a | |||||

| TET | P. chrysosporium | 5.73 a | 2.39 Bb | 1.53 c | 1.22 cd | 0.81 d | 1.822 | <0.01 | <0.01 | <0.01 |

| P. ostreatus | 5.73 a | 3.88 Ab | 2.95 bc | 2.35 c | 0.90 d | |||||

| Dual | 5.73 a | 3.57 Ab | 1.60 c | 1.42 c | 1.03 c | |||||

| Items | Treatment | Duration of Treatment (Weeks) | SD | p-Value | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | T | W | T × W | |||

| NDF | P. chrysosporium | 35.84 e | 33.22 Bd | 39.64 Bc | 51.39 Ab | 55.78 Aa | 7.04 | <0.01 | <0.01 | <0.01 |

| P. ostreatus | 35.84 b | 36.76 Ab | 40.23 Ba | 41.45 Ca | 41.76 Ca | |||||

| Dual | 35.84 d | 36.34 Ad | 42.15 Ac | 48.77 Bb | 53.11 Ba | |||||

| ADF | P. chrysosporium | 29.75 b | 26.10 Bc | 30.16 Bb | 39.96 Aa | 42.07 Aa | 5.27 | <0.01 | <0.01 | <0.01 |

| P. ostreatus | 29.75 c | 27.95 Ad | 30.53 Bbc | 32.05 Cb | 34.07 Ba | |||||

| Dual | 29.75 d | 28.01 Ad | 32.26 Ac | 36.59 Bb | 40.87 Aa | |||||

| ADL | P. chrysosporium | 9.05 c | 6.73 Ce | 8.27 Bd | 13.94 Ab | 14.71 Aa | 2.40 | 0.61 | <0.01 | <0.01 |

| P. ostreatus | 9.05 c | 9.19 Ac | 10.77 Ab | 10.90 Bb | 12.06 Ca | |||||

| Dual | 9.05 c | 7.56 Bd | 10.59 Ab | 11.54 Bb | 13.15 Ba | |||||

| HC | P. chrysosporium | 7.29 c | 7.11 Bc | 9.48 bc | 11.43 ab | 13.70 Aa | 2.65 | <0.01 | <0.05 | <0.01 |

| P. ostreatus | 7.29 b | 8.81 Aab | 9.70 a | 9.39 Ba | 7.69 Bb | |||||

| Dual | 7.29 d | 8.32 Ac | 9.89 b | 12.18 Aa | 12.24 Aa | |||||

| CL | P. chrysosporium | 20.70 b | 19.36 ABb | 21.89 Ab | 26.01 Aa | 27.36 Aa | 3.50 | <0.01 | <0.01 | <0.05 |

| P. ostreatus | 20.70 ab | 18.75 Bc | 19.76 Bbc | 21.14 Cab | 22.00 Ba | |||||

| Dual | 20.70 c | 20.42 Ac | 21.66 Ac | 25.04 Bb | 27.71 Aa | |||||

| Items | Control | P. chrysosporium | P. ostreatus | Dual | SD | p-Value |

|---|---|---|---|---|---|---|

| GP 2 h | 46.57 | 53.46 | 49.6 | 50.43 | 7.11 | 0.382 |

| GP 4 h | 76.53 a | 71.05 ab | 62.27 c | 68 bc | 7.51 | <0.05 |

| GP 8 h | 97.63 a | 82.51 b | 75.92 b | 82.58 b | 10.41 | <0.05 |

| GP 12 h | 106.26 a | 91.49 b | 88.26 b | 98.07 ab | 10.44 | <0.05 |

| GP 24 h | 116.62 a | 96.04 b | 102.32 b | 107.48 ab | 10.45 | <0.05 |

| GP 36 h | 119.15 a | 97.7 b | 106.77 ab | 113.53 a | 13.71 | <0.05 |

| GP 48 h | 122.88 a | 100.04 b | 109.84 ab | 115.92 a | 15.19 | <0.05 |

| GP 72 h | 131.1 a | 104.32 b | 113.38 b | 118.17 ab | 15.29 | <0.05 |

| Items | Control | P. chrysosporium | P. ostreatus | Dual | SD | p-Value |

|---|---|---|---|---|---|---|

| pH | 6.35 a | 6.28 b | 6.31 ab | 6.29 b | 0.04 | <0.05 |

| NH3-N, mg/dL | 12.61 b | 18.06 a | 20.59 a | 19.74 a | 4.79 | <0.05 |

| TVFA, mmol/L | 114.02 a | 107.31 b | 103.16 b | 104.68 b | 7.36 | <0.05 |

| Individual VFA (mmol/L VFA) | ||||||

| Acetic acid | 74.48 a | 69.10 b | 66.10 b | 66.99 b | 5.77 | <0.05 |

| Propionic acid | 20.27 a | 20.25 a | 16.5 b | 16.85 b | 1.43 | <0.01 |

| A/P | 3.67 b | 3.41 c | 4.00 a | 3.97 a | 0.28 | <0.01 |

| Isobutyric acid | 0.88 b | 0.76 b | 1.40 a | 1.36 a | 0.51 | <0.01 |

| Butyric acid | 12.63 b | 12.07 c | 14.33 a | 14.79 a | 0.98 | <0.01 |

| Isovaleric acid | 3.57 a | 3.20 ab | 3.16 ab | 3.01 b | 0.25 | 0.10 |

| Valeric acid | 2.16 a | 1.92 b | 1.64 c | 1.66 c | 0.29 | <0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Q.; Lin, M.; Huang, Y.; Datsomor, O.; Wang, K.; Zhao, G. Effects of Solid-State Fermentation Pretreatment with Single or Dual Culture White Rot Fungi on White Tea Residue Nutrients and In Vitro Rumen Fermentation Parameters. Fermentation 2022, 8, 557. https://doi.org/10.3390/fermentation8100557

Yan Q, Lin M, Huang Y, Datsomor O, Wang K, Zhao G. Effects of Solid-State Fermentation Pretreatment with Single or Dual Culture White Rot Fungi on White Tea Residue Nutrients and In Vitro Rumen Fermentation Parameters. Fermentation. 2022; 8(10):557. https://doi.org/10.3390/fermentation8100557

Chicago/Turabian StyleYan, Qi, Miao Lin, Yinghao Huang, Osmond Datsomor, Kuopeng Wang, and Guoqi Zhao. 2022. "Effects of Solid-State Fermentation Pretreatment with Single or Dual Culture White Rot Fungi on White Tea Residue Nutrients and In Vitro Rumen Fermentation Parameters" Fermentation 8, no. 10: 557. https://doi.org/10.3390/fermentation8100557

APA StyleYan, Q., Lin, M., Huang, Y., Datsomor, O., Wang, K., & Zhao, G. (2022). Effects of Solid-State Fermentation Pretreatment with Single or Dual Culture White Rot Fungi on White Tea Residue Nutrients and In Vitro Rumen Fermentation Parameters. Fermentation, 8(10), 557. https://doi.org/10.3390/fermentation8100557