Bio-Electrochemical Performance of a Ceramic Microbial Fuel Cell Treating Kitchen Waste Leachate: Effect of Organic Loading Rate and Anode Electrode Surface Area

Abstract

1. Introduction

2. Material and Methods

2.1. Microbial Fuel Cell Fabrication

2.2. Analytical Methods

2.2.1. Leachate

2.2.2. Electrical Performance of MFC

2.3. Experimental Setting

3. Results and Discussion

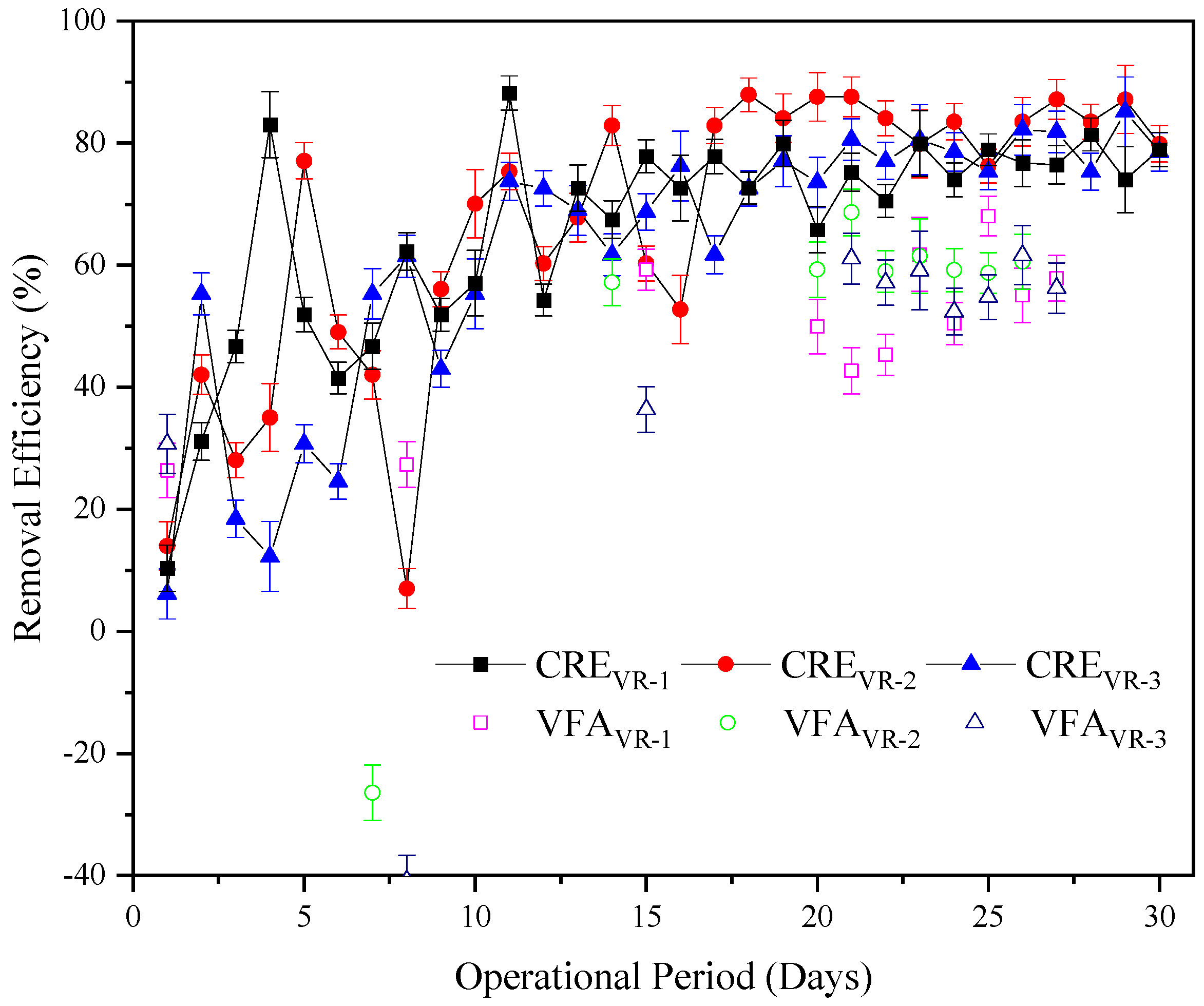

3.1. COD Removal in Earthen MFC

3.1.1. Effect of Leachate Strength

3.1.2. Effect of HRT

3.1.3. Effect of Anode Electrode Surface Area

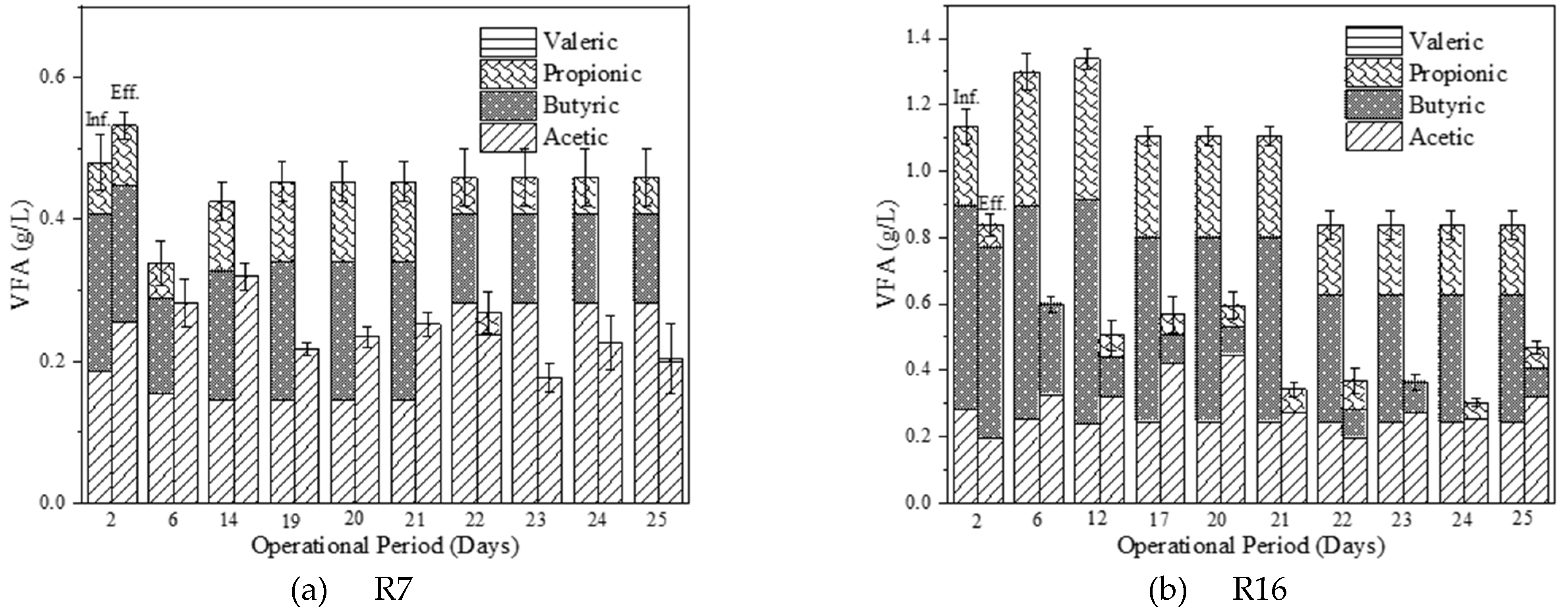

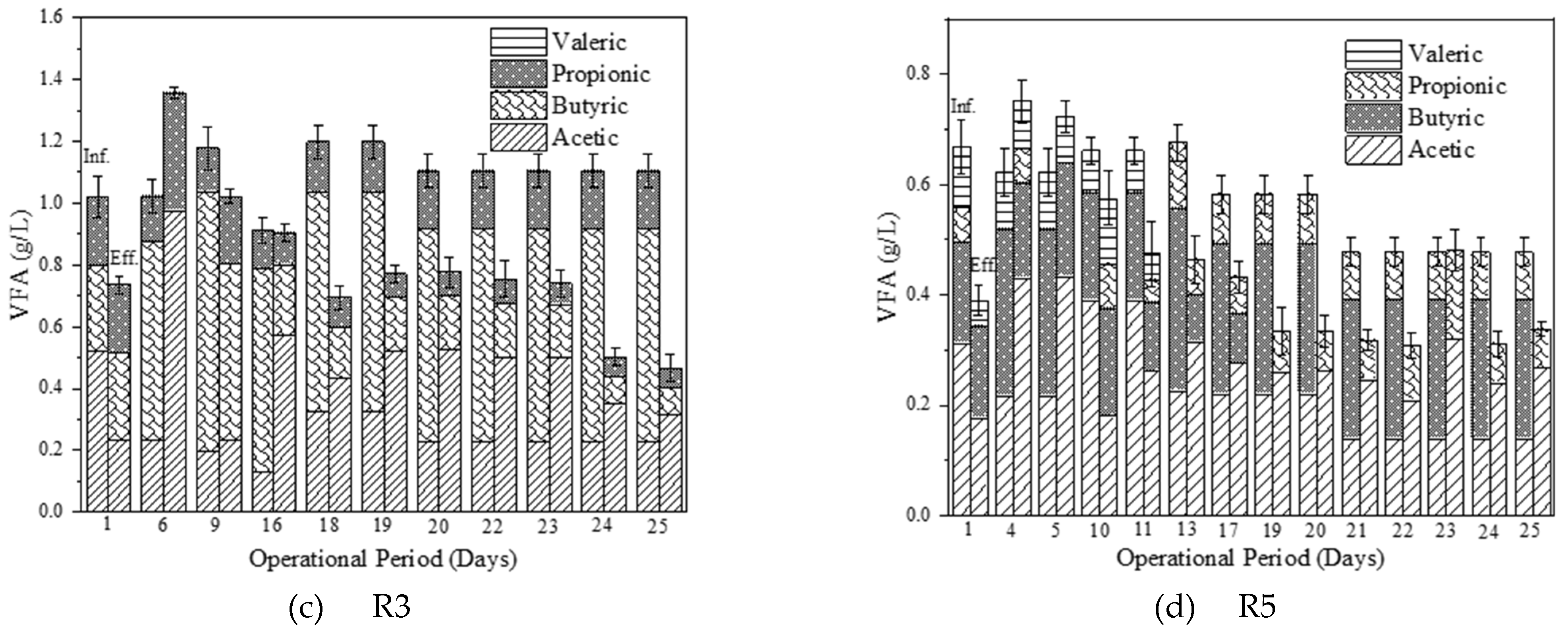

3.2. VFA Degradation in CMFC

3.2.1. Effect of Leachate Strength

3.2.2. Effect of HRT

3.2.3. Effect of Anode Electrode Surface Area

3.3. Power Density

3.3.1. Effect of the Leachate Strength

3.3.2. Effect of HRT

3.3.3. Effect of Anode Electrode Surface Area

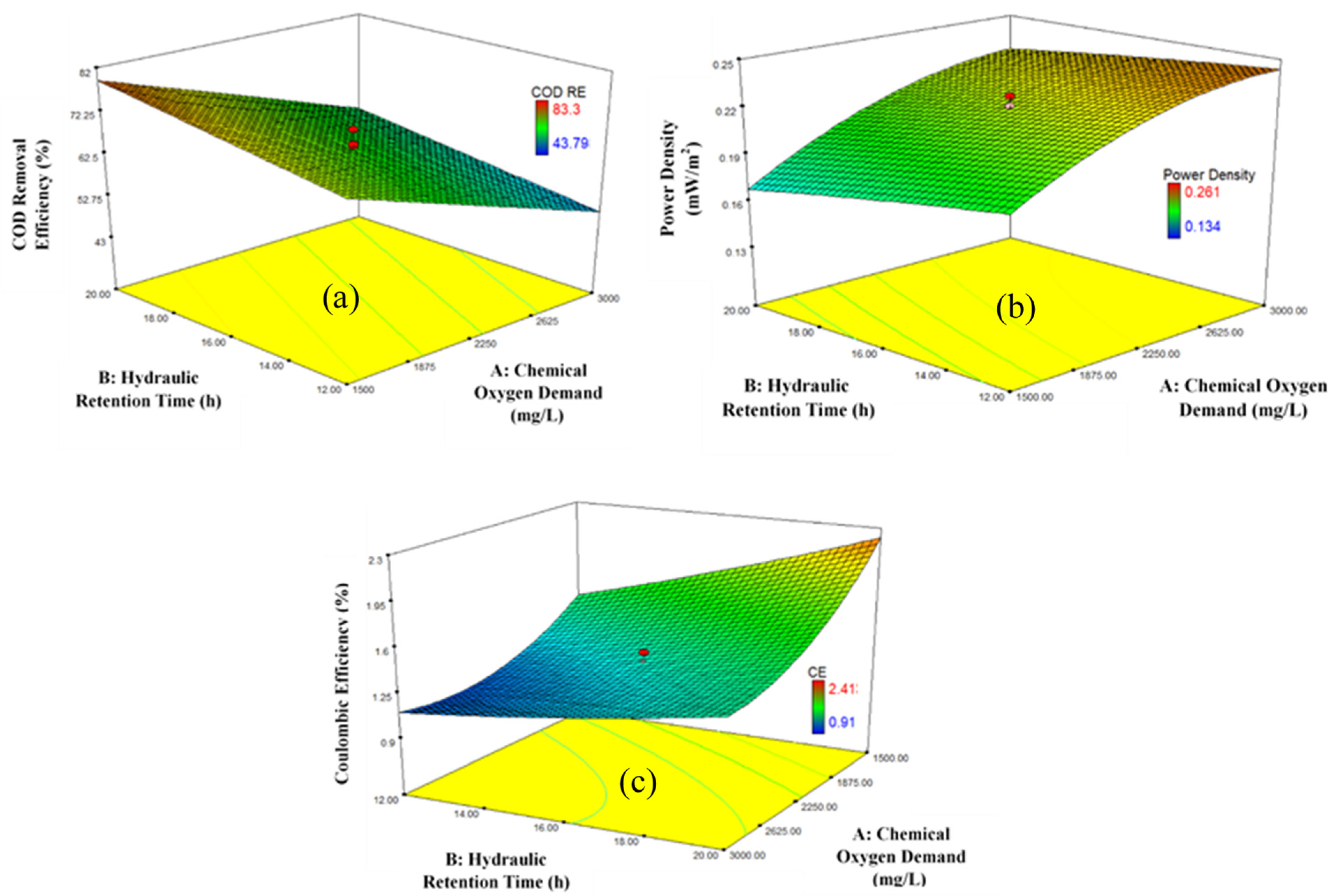

3.4. Coulombic Efficiency

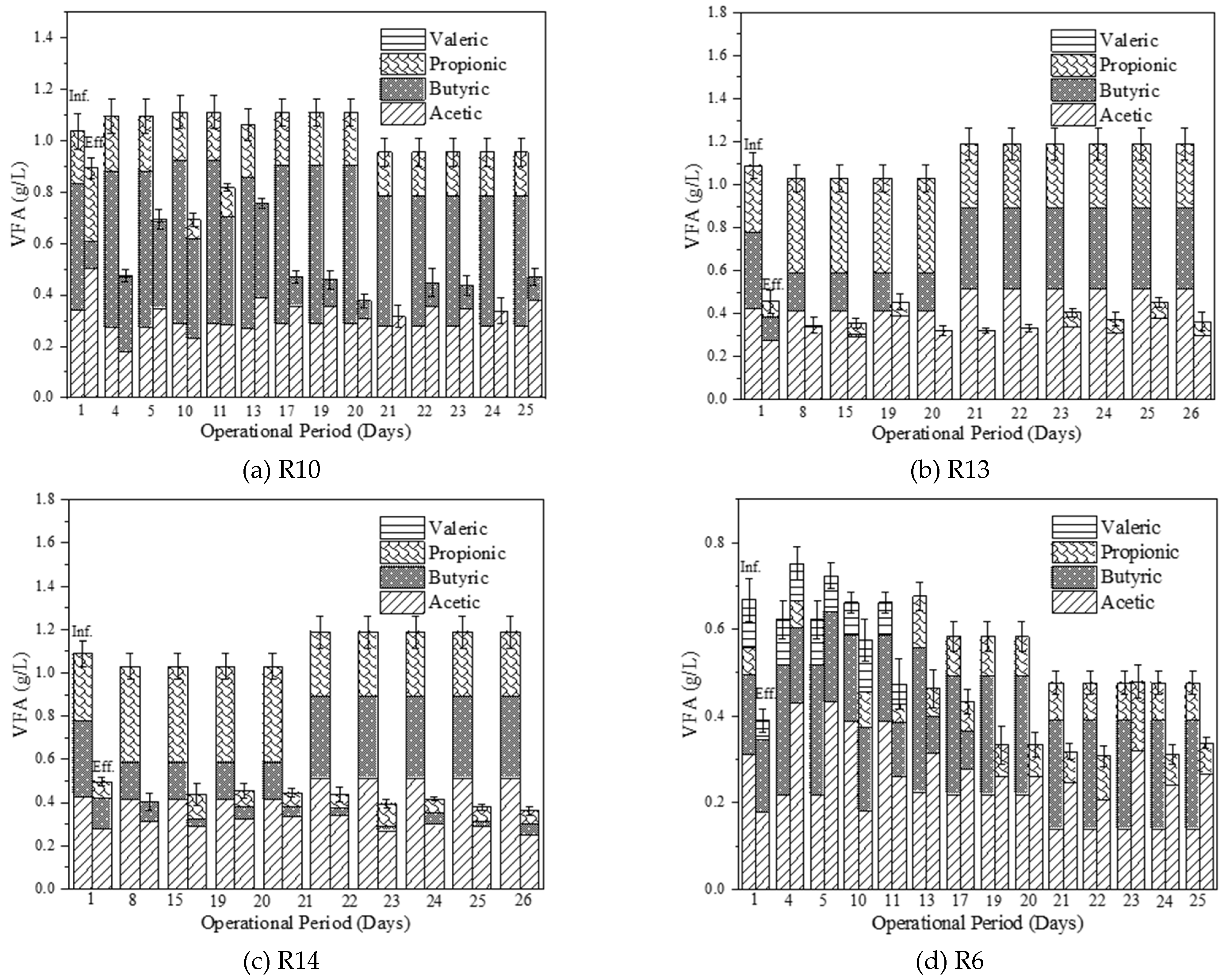

3.5. Cyclic Voltammetry

3.6. Impedance

3.7. ANOVA Analysis

3.8. Validation Runs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Dhar, H.; Kumar, S.; Kumar, R. A Review on Organic Waste to Energy Systems in India. Bioresour. Technol. 2017, 245, 1229–1237. [Google Scholar] [CrossRef] [PubMed]

- Krishna, D.; Kalamdhad, A.S. Pre-Treatment and Anaerobic Digestion of Food Waste for High Rate Methane Production—A Review. J. Environ. Chem. Eng. 2014, 2, 1821–1830. [Google Scholar] [CrossRef]

- Yap, H.Y.; Nixon, J.D. A Multi-Criteria Analysis of Options for Energy Recovery from Municipal Solid Waste in India and the UK. Waste Manag. 2015, 46, 265–271. [Google Scholar] [CrossRef] [PubMed]

- Ntaikou, I.; Kourmentza, C.; Koutrouli, E.C.; Stamatelatou, K.; Zampraka, A.; Kornaros, M.; Lyberatos, G. Exploitation of Olive Oil Mill Wastewater for Combined Biohydrogen and Biopolymers Production. Bioresour. Technol. 2009, 100, 3724–3730. [Google Scholar] [CrossRef]

- Harnisch, F.; Schro¨der, U.S. From MFC to MXC: Chemical and Biological Cathodes and Their Potential for Microbial Bioelectrochemical Systems. Chem. Soc. Rev 2010, 39, 4433. [Google Scholar] [CrossRef]

- Dogan, E.; Dunaev, T.; Erguder, T.H.; Demirer, G.N. Performance of Leaching Bed Reactor Converting the Organic Fraction of Municipal Solid Waste to Organic Acids and Alcohols. Chemosphere 2008, 74, 797–803. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Lam, C.H.; Subramanian, K.; Qin, Z.H.; Mou, J.H.; Jin, M.; Chopra, S.S.; Singh, V.; Ok, Y.S.; et al. Emerging Waste Valorisation Techniques to Moderate the Hazardous Impacts, and Their Path towards Sustainability. J. Hazard. Mater. 2022, 423, 127023. [Google Scholar] [CrossRef]

- Selvasembian, R.; Mal, J.; Rani, R.; Sinha, R.; Agrahari, R.; Joshua, I.; Santhiagu, A.; Pradhan, N. Recent Progress in Microbial Fuel Cells for Industrial Effluent Treatment and Energy Generation: Fundamentals to Scale-up Application and Challenges. Bioresour. Technol. 2022, 346, 126462. [Google Scholar] [CrossRef]

- Sriram, S.; Wong, J.W.C.; Pradhan, N. Recent Advances in Electro-Fermentation Technology: A Novel Approach towards Balanced Fermentation. Bioresour. Technol. 2022, 360, 127637. [Google Scholar] [CrossRef]

- Ma, C.; Liu, J.; Ye, M.; Zou, L.; Qian, G.; Li, Y.Y. Towards Utmost Bioenergy Conversion Efficiency of Food Waste: Pretreatment, Co-Digestion, and Reactor Type. Renew. Sustain. Energy Rev. 2018, 90, 700–709. [Google Scholar] [CrossRef]

- El-Chakhtoura, J.; El-Fadel, M.; Rao, H.A.; Li, D.; Ghanimeh, S.; Saikaly, P.E. Electricity Generation and Microbial Community Structure of Air-Cathode Microbial Fuel Cells Powered with the Organic Fraction of Municipal Solid Waste and Inoculated with Different Seeds. Biomass Bioenergy 2014, 67, 24–31. [Google Scholar] [CrossRef]

- Gurjar, R.; Behera, M. Treatment of Organic Fraction of Municipal Solid Waste in Bioelectrochemical Systems: A Review. J.Hazard. Toxic Radioact. Waste 2020, 24, 04020018. [Google Scholar] [CrossRef]

- Bridier, A.; Desmond-Le Quemener, E.; Bureau, C.; Champigneux, P.; Renvoise, L.; Audic, J.M.; Blanchet, E.; Bergel, A.; Bouchez, T. Successive Bioanode Regenerations to Maintain Efficient Current Production from Biowaste. Bioelectrochemistry 2015, 106, 133–140. [Google Scholar] [CrossRef]

- Xin, X.; Ma, Y.; Liu, Y. Electric Energy Production from Food Waste: Microbial Fuel Cells versus Anaerobic Digestion. Bioresour. Technol. 2018, 255, 281–287. [Google Scholar] [CrossRef]

- Yang, Z.; Nie, C.; Hou, Q.; Zhang, L.; Zhang, S.; Yu, Z.; Pei, H. Coupling a Photosynthetic Microbial Fuel Cell (PMFC) with Photobioreactors (PBRs) for Pollutant Removal and Bioenergy Recovery from Anaerobically Digested Effluent. Chem. Eng. J. 2019, 359, 402–408. [Google Scholar] [CrossRef]

- Tremouli, A.; Karydogiannis, I.; Pandis, P.K.; Papadopoulou, K.; Argirusis, C.; Stathopoulos, V.N.; Lyberatos, G. Bioelectricity Production from Fermentable Household Waste Extract Using a Single Chamber Microbial Fuel Cell. Energy Procedia 2019, 161, 2–9. [Google Scholar] [CrossRef]

- Swiatkiewicz, J.; Slezak, R.; Krzystek, L.; Ledakowicz, S. Production of Volatile Fatty Acids in a Semi-Continuous Dark Fermentation of Kitchen Waste: Impact of Organic Loading Rate and Hydraulic Retention Time. Energies 2021, 14, 2993. [Google Scholar] [CrossRef]

- Jung, S.; Regan, J.M. Comparison of Anode Bacterial Communities and Performance in Microbial Fuel Cells with Different Electron Donors. Appl. Microbiol. Biotechnol. 2007, 77, 393–402. [Google Scholar] [CrossRef]

- Gurjar, R.; Behera, M. Exploring necessity to pre-treat organic fraction of waste prior to use in an earthen MFC modified with bentonite. Water Sci. Technol. 2022, 86, 656–671. [Google Scholar] [CrossRef]

- Cavdar, P.; Yilmaz, E.; Tugtas, A.E.; Calli, B. Acidogenic Fermentation of Municipal Solid Waste and Its Application to Bio-Electricity Production via Microbial Fuel Cells ( MFCs ). Water Sci. Technol. 2011, 64, 789–796. [Google Scholar] [CrossRef]

- Li, X.M.; Cheng, K.Y.; Selvam, A.; Wong, J.W.C. Bioelectricity Production from Acidic Food Waste Leachate Using Microbial Fuel Cells: Effect of Microbial Inocula. Process Biochem. 2013, 48, 283–288. [Google Scholar] [CrossRef]

- Hussain, A.; Filiatrault, M.; Guiot, S.R. Acidogenic Digestion of Food Waste in a Thermophilic Leach Bed Reactor: Effect of PH and Leachate Recirculation Rate on Hydrolysis and Volatile Fatty Acid Production. Bioresour. Technol. 2017, 245, 1–9. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Ghoreyshi, A.A.; Najafpour, G.; Jafary, T. Power Generation from Organic Substrate in Batch and Continuous Flow Microbial Fuel Cell Operations. Appl. Energy 2011, 88, 3999–4004. [Google Scholar] [CrossRef]

- American Public Health Association. Standard Methods for Examination of Water and Wastewater; Eaton, A.D., Clesceri, L.S., Franson, M.A.H., Rice, E.W., Greenberg, A.E., Eds.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Xu, S.Y.; Lam, H.P.; Karthikeyan, O.P.; Wong, J.W.C. Optimization of Food Waste Hydrolysis in Leach Bed Coupled with Methanogenic Reactor: Effect of PH and Bulking Agent. Bioresour. Technol. 2011, 102, 3702–3708. [Google Scholar] [CrossRef]

- Logan, B.E. Microbial Fuel Cells; John Wiley & Sons: Hoboken, NJ, USA, 2008; ISBN 9780470239483. [Google Scholar]

- Behera, M.; Jana, P.S.; Ghangrekar, M.M. Performance Evaluation of Low Cost Microbial Fuel Cell Fabricated Using Earthen Pot with Biotic and Abiotic Cathode. Bioresour. Technol. 2010, 101, 1183–1189. [Google Scholar] [CrossRef]

- Özkaya, B.; Cetinkaya, A.Y.; Cakmakci, M.; Karadaǧ, D.; Sahinkaya, E. Electricity Generation from Young Landfill Leachate in a Microbial Fuel Cell with a New Electrode Material. Bioprocess Biosyst. Eng. 2013, 36, 399–405. [Google Scholar] [CrossRef]

- Choi, J.; Ahn, Y. Enhanced Bioelectricity Harvesting in Microbial Fuel Cells Treating Food Waste Leachate Produced from Biohydrogen Fermentation. Bioresour. Technol. 2015, 183, 53–60. [Google Scholar] [CrossRef]

- Gurjar, R.; Shende, A.D.; Pophali, G.R. Treatment of Low Strength Wastewater Using Compact Submerged Aerobic Fixed Film (SAFF) Reactor Filled with High Specific Surface Area Synthetic Media. Water Sci. Technol. 2019, 80, 737–746. [Google Scholar] [CrossRef]

- Mohan, S.V.; Chandrasekhar, K. Self-Induced Bio-Potential and Graphite Electron Accepting Conditions Enhances Petroleum Sludge Degradation in Bio-Electrochemical System with Simultaneous Power Generation. Bioresour. Technol. 2011, 102, 9532–9541. [Google Scholar] [CrossRef]

- Akman, D.; Cirik, K.; Ozdemir, S.; Ozkaya, B.; Cinar, O. Bioelectricity Generation in Continuously-Fed Microbial Fuel Cell: Effects of Anode Electrode Material and Hydraulic Retention Time. Bioresour. Technol. 2013, 149, 459–464. [Google Scholar] [CrossRef]

- Pocaznoi, D.; Calmet, A.; Etcheverry, L.; Erable, B.; Bergel, A. Stainless Steel Is a Promising Electrode Material for Anodes of Microbial Fuel Cells. Energy Environ. Sci. 2012, 5, 9645–9652. [Google Scholar] [CrossRef]

- Muthudineshkumar, R.; Anand, R. Anaerobic Digestion of Various Feedstocks for Second-Generation Biofuel Production. In Advances in Eco-Fuels for a Sustainable Environment; Woodhead Publishing: Sawston, UK, 2019; pp. 157–185. [Google Scholar] [CrossRef]

- Aelterman, P.; Freguia, S.; Keller, J.; Verstraete, W.; Rabaey, K. The Anode Potential Regulates Bacterial Activity in Microbial Fuel Cells. Appl. Microbiol. Biotechnol. 2008, 78, 409–418. [Google Scholar] [CrossRef] [PubMed]

- Aelterman, P.; Rabaey, K.; Pham, H.T.; Boon, N.; Verstraete, W. Continuous Electricity Generation at High Voltages and Currents Using Stacked Microbial Fuel Cells. Environ. Sci. Technol. 2006, 40, 3388–3394. [Google Scholar] [CrossRef]

- Durruty, I.; Bonanni, P.S.; González, J.F.; Busalmen, J.P. Evaluation of Potato-Processing Wastewater Treatment in a Microbial Fuel Cell. Bioresour. Technol. 2011, 105, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Myers, R.; Montgomery, D.C. Response Surface Methodology; John Wiley & Sons: New York, NY, USA, 2002. [Google Scholar]

- You, S.J.; Zhao, Q.L.; Jiang, J.Q.; Zhang, J.N.; Zhao, S.Q. Sustainable Approach for Leachate Treatment: Electricity Generation in Microbial Fuel Cell. J. Environ. Sci. Health Part A 2006, 41, 2721–2734. [Google Scholar] [CrossRef] [PubMed]

- Gurjar, R.; Behera, M. Integrating Operating Conditions to Develop a Neural Network for Predicting Organics Removal and Power Density in an Earthen Microbial Fuel Cell Treating Leachate. Biofuels 2022, 1–10. [Google Scholar] [CrossRef]

- Schröder, U. Anodic Electron Transfer Mechanisms in Microbial Fuel Cells and Their Energy Efficiency. Phys. Chem. Chem. Phys. 2007, 9, 2619–2629. [Google Scholar] [CrossRef]

- Sleutels, T.H.J.A.; Darus, L.; Hamelers, H.V.M.; Buisman, C.J.N. Effect of Operational Parameters on Coulombic Efficiency in Bioelectrochemical Systems. Bioresour. Technol. 2011, 102, 11172–11176. [Google Scholar] [CrossRef]

| Run No | COD (g/L) | HRT (h) | AESA 1 (cm2) | OLR (Kg/m3·d) | CODRE 3 (%) | VFARE 2 (%) | PD (W/m3) | CE (%) |

|---|---|---|---|---|---|---|---|---|

| R1 | 3.0 | 20 | 16 | 3.60 | 56.1 ± 3.1 | 75.5 ± 4.8 | 0.197 ± 0.03 | 1.48 ± 0.18 |

| R2 | 1.5 | 12 | 32 | 3.00 | 69.4 ± 4.9 | 54.7 ± 4.3 | 0.214 ± 0.04 | 1.72 ± 0.27 |

| R3 | 3.0 | 20 | 32 | 3.60 | 59.5 ± 3.4 | 52.4 ± 8.7 | 0.252 ± 0.06 | 1.61 ± 0.26 |

| R4 | 2.3 | 16 | 37.5 | 3.38 | 67.7 ± 3.6 | 63.8 ± 3.6 | 0.232 ± 0.04 | 1.46 ± 0.18 |

| R5 | 1.5 | 20 | 32 | 1.80 | 79.5 ± 3.8 | 68.7 ± 3.5 | 0.169 ± 0.05 | 2.04 ± 0.23 |

| R6 | 1.5 | 12 | 16 | 3.00 | 62.9 ± 4.8 | 50.9 ± 3.1 | 0.181 ± 0.04 | 1.24 ± 0.24 |

| R7 | 1.0 | 16 | 32 | 1.48 | 81.3 ± 4.1 | 44.8 ± 3.2 | 0.134 ± 0.04 | 2.59 ± 0.36 |

| R8 | 3.0 | 12 | 32 | 6.00 | 57.4 ± 4.6 | 74.1 ± 6.3 | 0.251 ± 0.01 | 1.18 ± 0.04 |

| R9 | 1.5 | 20 | 16 | 1.80 | 72.4 ± 4.9 | 66.5 ± 4.3 | 0.210 ± 0.03 | 2.38 ± 0.13 |

| R10 | 3.0 | 12 | 16 | 6.00 | 43.8 ± 4.6 | 68.6 ± 5.7 | 0.178 ± 0.05 | 0.96 ± 0.16 |

| R11 | 2.3 | 16 | 24 | 3.38 | 63.7 ± 3.6 | 75.3 ± 4.6 | 0.217 ± 0.04 | 1.34 ± 0.12 |

| R12 | 2.3 | 16 | 24 | 3.38 | 68.6 ± 3.6 | 77.4 ± 6.4 | 0.227 ± 0.04 | 1.12 ± 0.18 |

| R13 | 2.3 | 22.7 | 24 | 2.38 | 73.3 ± 3.9 | 73.8 ± 4.8 | 0.222 ± 0.03 | 1.79 ± 0.06 |

| R14 | 2.3 | 9.3 | 24 | 5.82 | 69.7 ± 3.2 | 70.0 ± 1.6 | 0.220 ± 0.05 | 0.80 ± 0.15 |

| R15 | 2.3 | 16 | 10.6 | 3.38 | 56.8 ± 2.9 | 74.1 ± 4.5 | 0.202 ± 0.07 | 1.40 ± 0.15 |

| R16 | 3.5 | 16 | 32 | 5.27 | 43.9 ± 4.5 | 65.5 ± 7.1 | 0.246 ± 0.04 | 1.66 ± 0.18 |

| R17 | 2.3 | 16 | 24 | 3.38 | 64.8 ± 2.2 | 71.5 ± 2.1 | 0.206 ± 0.02 | 1.43 ± 0.12 |

| VR1 4 | 1.6 | 22.7 | 37.5 | 1.67 | 75.6 ± 4.3 | 58.6 ± 5.9 | 0.204 ± 0.03 | 2.50 ± 0.26 |

| VR2 | 1.0 | 14.6 | 37.5 | 1.65 | 83.7 ± 3.6 | 60.9 ± 3.3 | 0.196 ± 0.03 | 2.09 ± 0.21 |

| VR3 | 1.2 | 17.7 | 37.5 | 1.67 | 78.8 ± 3.2 | 57.5 ± 3.1 | 0.224 ± 0.02 | 2.62 ± 0.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gurjar, R.; Behera, M. Bio-Electrochemical Performance of a Ceramic Microbial Fuel Cell Treating Kitchen Waste Leachate: Effect of Organic Loading Rate and Anode Electrode Surface Area. Fermentation 2022, 8, 544. https://doi.org/10.3390/fermentation8100544

Gurjar R, Behera M. Bio-Electrochemical Performance of a Ceramic Microbial Fuel Cell Treating Kitchen Waste Leachate: Effect of Organic Loading Rate and Anode Electrode Surface Area. Fermentation. 2022; 8(10):544. https://doi.org/10.3390/fermentation8100544

Chicago/Turabian StyleGurjar, Rishi, and Manaswini Behera. 2022. "Bio-Electrochemical Performance of a Ceramic Microbial Fuel Cell Treating Kitchen Waste Leachate: Effect of Organic Loading Rate and Anode Electrode Surface Area" Fermentation 8, no. 10: 544. https://doi.org/10.3390/fermentation8100544

APA StyleGurjar, R., & Behera, M. (2022). Bio-Electrochemical Performance of a Ceramic Microbial Fuel Cell Treating Kitchen Waste Leachate: Effect of Organic Loading Rate and Anode Electrode Surface Area. Fermentation, 8(10), 544. https://doi.org/10.3390/fermentation8100544