Simulation and Performance Analysis of Integrated Gasification–Syngas Fermentation Plant for Lignocellulosic Ethanol Production

Abstract

1. Introduction

2. Material and Methods

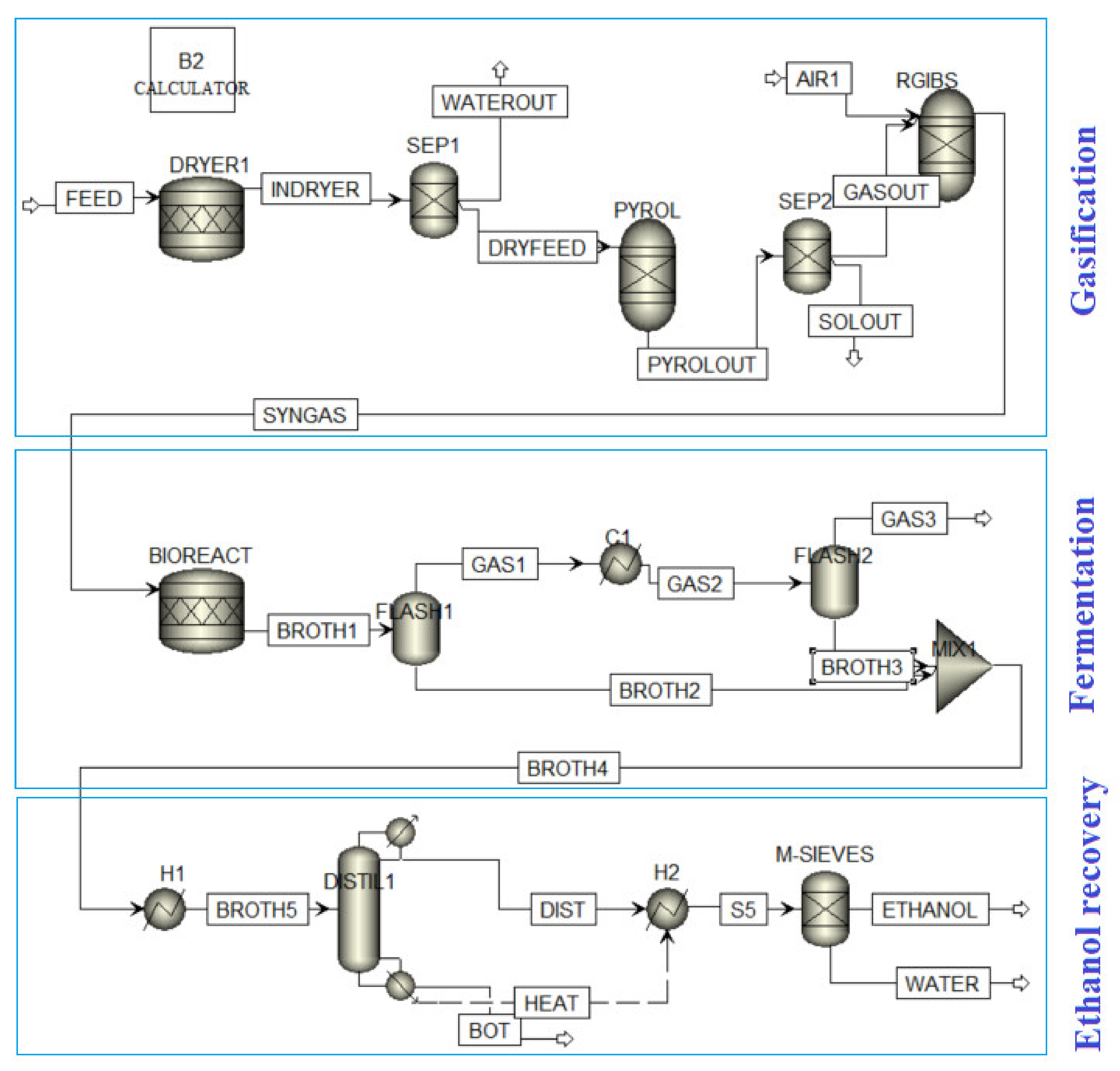

2.1. System Description

2.2. Simulation Model

2.2.1. Gasification Module

2.2.2. Fermentation Module

2.2.3. Ethanol Recovery Module

3. Results and Discussion

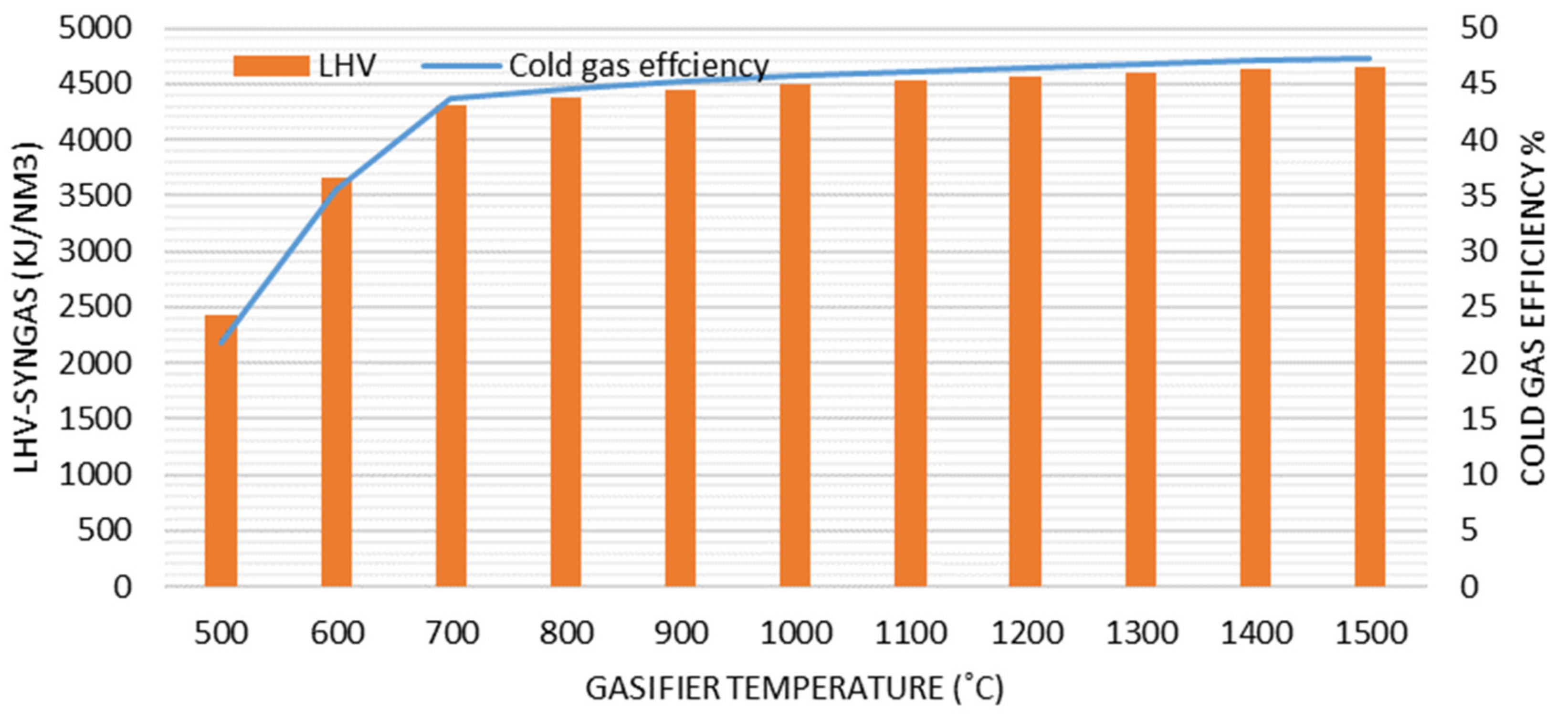

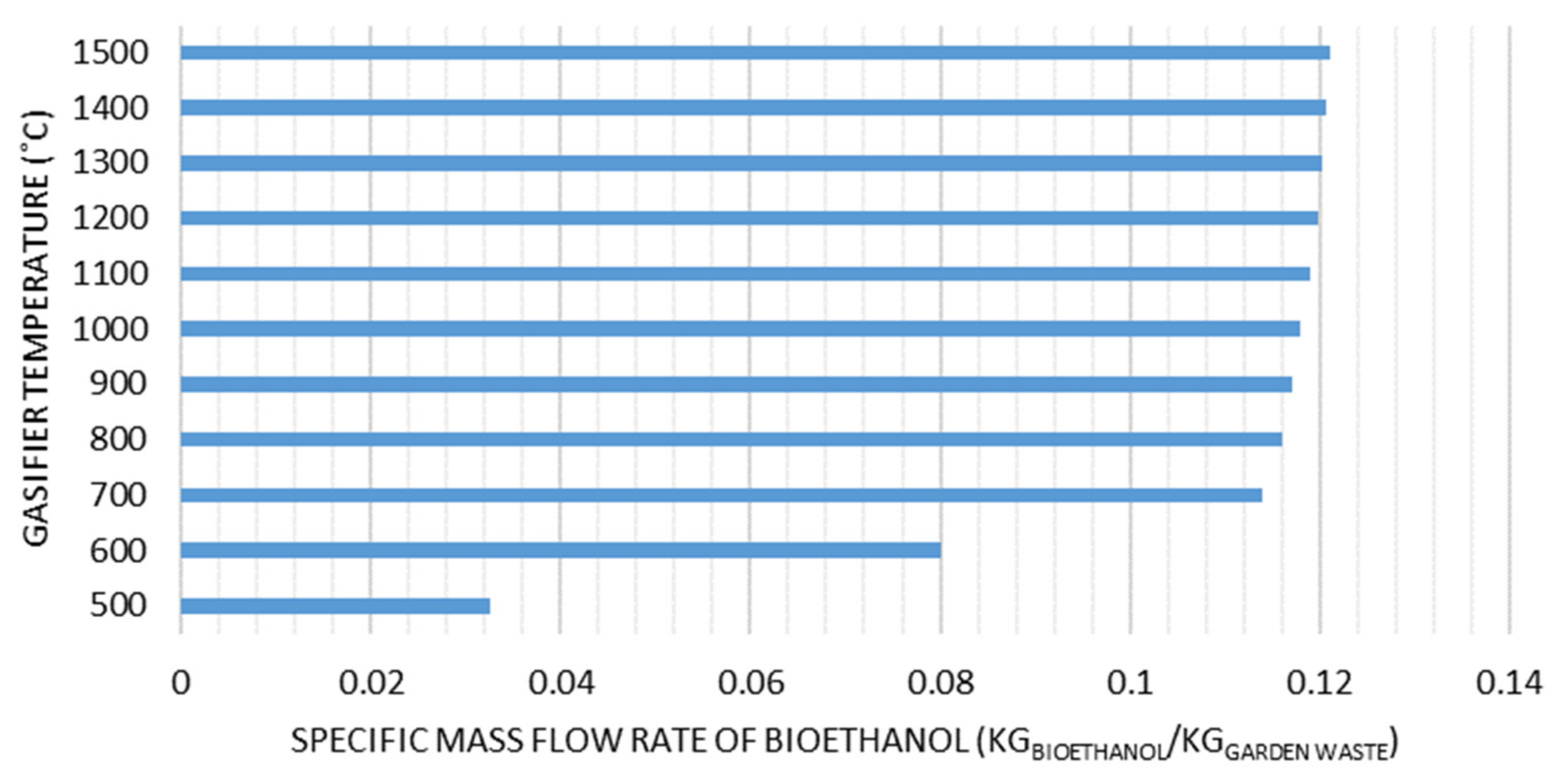

3.1. Effect of Temperature on Gasification Performance and Bioethanol Production

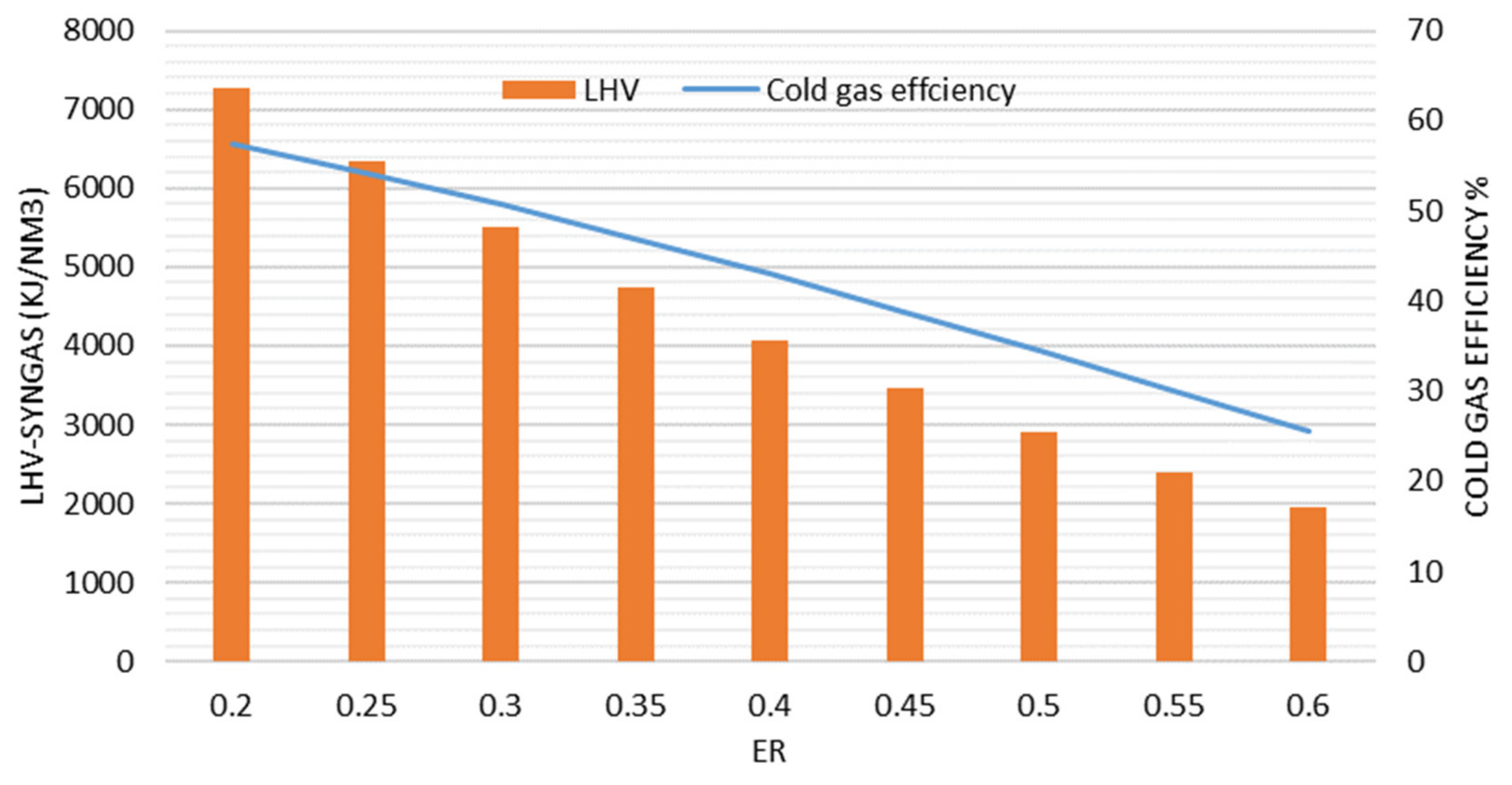

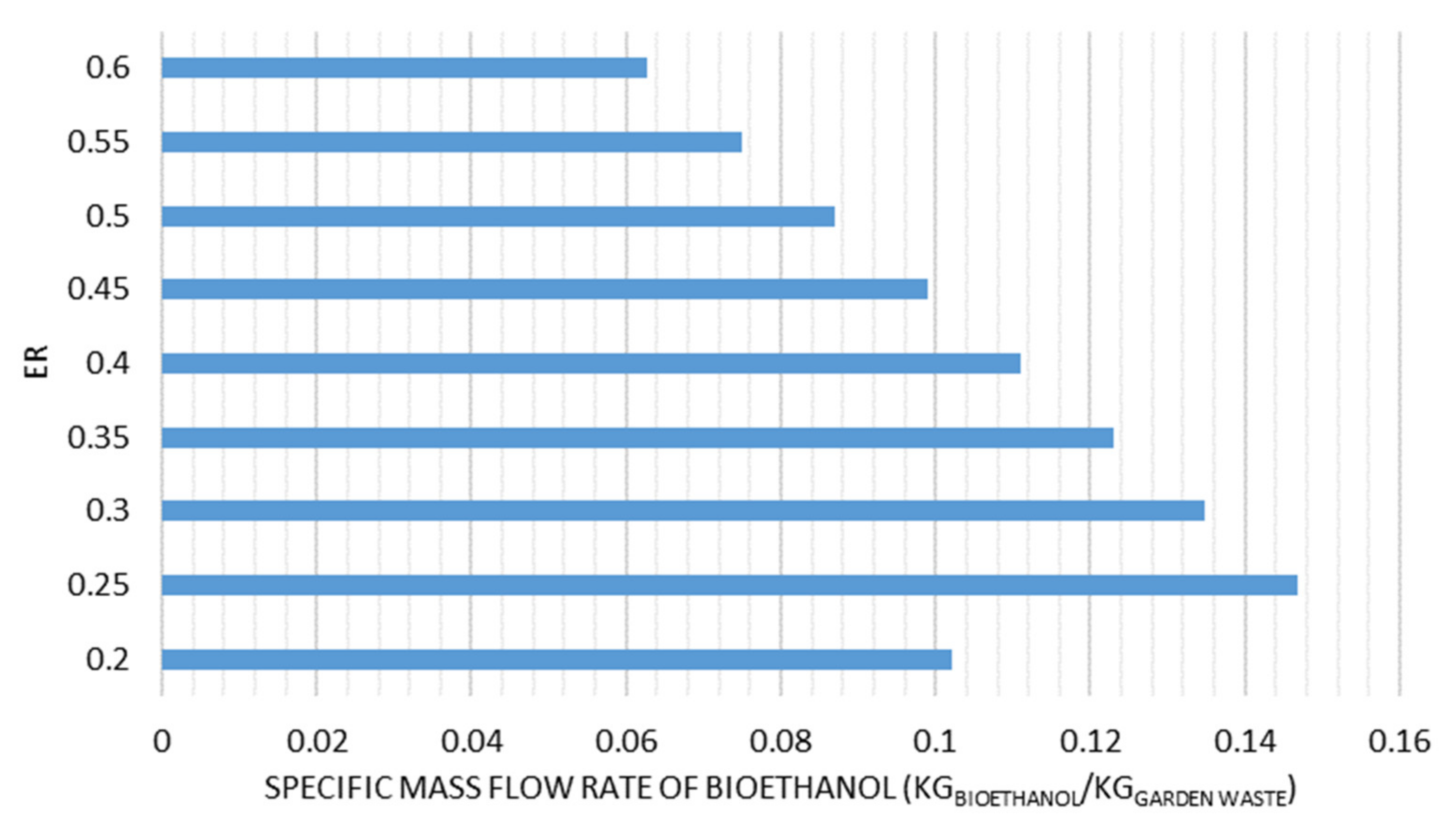

3.2. Effect of ER on Gasification Performance and Bioethanol Production

4. Conclusions

- The maximum value of cold gas efficiency (44.5%) could be achieved around 800 °C, while the lower heating value at this temperature was 4.38 MJ/N·m3. The main reaction controlling the H2 yield is the water-gas reaction because of its endothermic nature.

- CGE and LHV reached the maximum values of 54.2% and 7.28 MJ/N·m3, respectively, at ER = 0.2. These parameters continued to decrease with an increase in ER.

- It is evident that, for efficient gasification and high ethanol yield, the operating temperature range of the reduction zone should be 700–1000 °C, along with an equivalence ratio between 0.2 and 0.4.

- At 700 °C, the bioethanol production yield was 0.114 kg/h per 1 kg/h input garden waste with 50% moisture content. However, under dry-based conditions, this parameter increased to 0.217 kgbioethanol/kggarden waste. Consequently, increasing moisture content strongly degrades the system yield.

Author Contributions

Funding

Conflicts of Interest

References

- Safarian, S.; Khodaparast, P.; Kateb, M. Modeling and technical-economic optimization of electricity supply network by three photovoltaic systems. J. Sol. Energy Eng. 2014, 136, 024501. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Akram, A.; Ghobadian, B.; Rafiee, S.; Heijungs, R.; Tabatabaei, M. Environmental impact assessment of olive pomace oil biodiesel production and consumption: A comparative lifecycle assessment. Energy 2016, 106, 87–102. [Google Scholar] [CrossRef]

- Talebnia, F.; Karakashev, D.; Angelidaki, I. Production of bioethanol from wheat straw: An overview on pretreatment, hydrolysis and fermentation. Bioresour. Technol. 2010, 101, 4744–4753. [Google Scholar] [CrossRef] [PubMed]

- Safarian, S.; Unnthorsson, R.; Richter, C. Techno-economic analysis of power production by using waste biomass gasification. J. Power Energy Eng. 2020, 8, 1. [Google Scholar] [CrossRef]

- Safarian, S.; Sattari, S.; Hamidzadeh, Z. Sustainability assessment of biodiesel supply chain from various biomasses and conversion technologies. Biophys. Econ. Resour. Qual. 2018, 3, 6. [Google Scholar] [CrossRef]

- Safarian, S.; Sattari, S.; Unnthorsson, R.; Hamidzadeh, Z. Prioritization of bioethanol production systems from agricultural and waste agricultural biomass using multi-criteria decision making. Biophys. Econ. Resour. Qual. 2019, 4, 4. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R. An assessment of the sustainability of lignocellulosic bioethanol production from wastes in iceland. Energies 2018, 11, 1493. [Google Scholar] [CrossRef]

- Safarian, S.; Unnþórsson, R.; Richter, C. A review of biomass gasification modelling. Renew. Sustain. Energy Rev. 2019, 110, 378–391. [Google Scholar] [CrossRef]

- Datta, B. Socio-economic, environmental, and policy perspectives of advanced biodiesel production. In Advances in Biodiesel Production; Woodhead Publishing: Cambridge, UK, 2012; pp. 32–68. [Google Scholar]

- Liguori, R.; Soccol, C.R.; Porto de Souza Vandenberghe, L.; Woiciechowski, A.L.; Faraco, V. Second generation ethanol production from brewers’ spent grain. Energies 2015, 8, 2575–2586. [Google Scholar] [CrossRef]

- Mu, D.; Seager, T.; Rao, P.S.; Zhao, F. Comparative life cycle assessment of lignocellulosic ethanol production: Biochemical versus thermochemical conversion. Environ. Manag. 2010, 46, 565–578. [Google Scholar] [CrossRef]

- Pardo-Planas, O.; Atiyeh, H.K.; Phillips, J.R.; Aichele, C.P.; Mohammad, S. Process simulation of ethanol production from biomass gasification and syngas fermentation. Bioresour. Technol. 2017, 245, 925–932. [Google Scholar] [CrossRef] [PubMed]

- Safarianbana, S.; Unnthorsson, R.; Richter, C. Development of a new stoichiometric equilibrium-based model for wood chips and mixed paper wastes gasification by aspen plus. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers, Calvin L. Rampton Salt Palace Convention Center: Salt Lake City, UT, USA, 2019. [Google Scholar]

- Safarian, S.; Unnthorsson, R.; Richter, C. Techno-economic and environmental assessment of power supply chain by using waste biomass gasification in iceland. Biophys. Econ. Sustain. 2020, 5, 7. [Google Scholar]

- Safarian, S.; Richter, C.; Unnthorsson, R. Waste biomass gasification simulation using aspen plus: Performance evaluation of wood chips, sawdust and mixed paper wastes. J. Power Energy Eng. 2019, 7, 12–30. [Google Scholar] [CrossRef]

- Ray, R.C.; Ramachandran, S. Bioethanol Production from Food Crops: Sustainable Sources, Interventions, and Challenges; Academic Press: London, UK, 2018. [Google Scholar]

- Safarian, S.; Bararzadeh, M. Exergy analysis of high-performance cycles for gas turbine with air-bottoming. J. Mech. Eng. Res. 2012, 5, 38–49. [Google Scholar]

- Safarian, S.; Unnthorsson, R.; Richter, C. Performance analysis and environmental assessment of small-scale waste biomass gasification integrated chp in iceland. Energy 2020, 197, 117268. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. Simulation of small-scale waste biomass gasification integrated power production: A comparative performance analysis for timber and wood waste. Int. J. Appl. Power Eng. 2020, 9, 147–152. [Google Scholar]

- Williams, P.T. Waste Treatment and Disposal; John Wiley & Sons: Chichester, UK, 2005. [Google Scholar]

- Damartzis, T.; Michailos, S.; Zabaniotou, A. Energetic assessment of a combined heat and power integrated biomass gasification–internal combustion engine system by using aspen plus®. Fuel Process. Technol. 2012, 95, 37–44. [Google Scholar] [CrossRef]

- Tauqir, W.; Zubair, M.; Nazir, H. Parametric analysis of a steady state equilibrium-based biomass gasification model for syngas and biochar production and heat generation. Energy Convers. Manag. 2019, 199, 111954. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. The equivalence of stoichiometric and non-stoichiometric methods for modeling gasification and other reaction equilibria. Renew. Sustain. Energy Rev. 2020, 131, 109982. [Google Scholar] [CrossRef]

- Teo, W.K.; Ruthven, D.M. Adsorption of water from aqueous ethanol using 3-. Ang. molecular sieves. Ind. Eng. Chem. Process Des. Dev. 1986, 25, 17–21. [Google Scholar] [CrossRef]

- Kuo, P.-C.; Wu, W.; Chen, W.-H. Gasification performances of raw and torrefied biomass in a downdraft fixed bed gasifier using thermodynamic analysis. Fuel 2014, 117, 1231–1241. [Google Scholar] [CrossRef]

- Lv, P.; Xiong, Z.; Chang, J.; Wu, C.; Chen, Y.; Zhu, J. An experimental study on biomass air–steam gasification in a fluidized bed. Bioresour. Technol. 2004, 95, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Gai, C.; Dong, Y. Experimental study on non-woody biomass gasification in a downdraft gasifier. Int. J. Hydrog. Energy 2012, 37, 4935–4944. [Google Scholar] [CrossRef]

- Demirbaş, A. Calculation of higher heating values of biomass fuels. Fuel 1997, 76, 431–434. [Google Scholar] [CrossRef]

| Heterogeneous reactions | ||

| Complete combustion | R1 | |

| Partial combustion | R2 | |

| Boudouard | R3 | |

| Water-gas | R4 | |

| Methanation | R5 | |

| Homogeneous reactions | ||

| CO partial combustion | R6 | |

| H2 combustion | R7 | |

| Water-gas shift (WGS) | R8 | |

| Reforming | R9 | |

| H2S and NH3 formation reactions | ||

| H2S formation | R10 | |

| NH3 formation | R11 | |

| Garden Waste | |

|---|---|

| Proximate analysis | |

| Proximate analysis (wt.%) | |

| Moisture | 50 |

| Volatile matter (VM) | 84.5 |

| Fixed carbon (FC) | 14.5 |

| Ash | 1 |

| Ultimate analysis | |

| Elemental analysis (wt.% dry basis) | |

| C | 50.12 |

| H | 6.40 |

| N | 0.14 |

| Cl | 0 |

| S | 0.08 |

| O | 42.26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safarian, S.; Unnthorsson, R.; Richter, C. Simulation and Performance Analysis of Integrated Gasification–Syngas Fermentation Plant for Lignocellulosic Ethanol Production. Fermentation 2020, 6, 68. https://doi.org/10.3390/fermentation6030068

Safarian S, Unnthorsson R, Richter C. Simulation and Performance Analysis of Integrated Gasification–Syngas Fermentation Plant for Lignocellulosic Ethanol Production. Fermentation. 2020; 6(3):68. https://doi.org/10.3390/fermentation6030068

Chicago/Turabian StyleSafarian, Sahar, Runar Unnthorsson, and Christiaan Richter. 2020. "Simulation and Performance Analysis of Integrated Gasification–Syngas Fermentation Plant for Lignocellulosic Ethanol Production" Fermentation 6, no. 3: 68. https://doi.org/10.3390/fermentation6030068

APA StyleSafarian, S., Unnthorsson, R., & Richter, C. (2020). Simulation and Performance Analysis of Integrated Gasification–Syngas Fermentation Plant for Lignocellulosic Ethanol Production. Fermentation, 6(3), 68. https://doi.org/10.3390/fermentation6030068