Development and Characterization of Pistachio Yogurt Analog: A Healthy, Sustainable, and Innovative Plant-Based Alternative

Abstract

1. Introduction

2. Material and Methods

2.1. Raw Materials

2.2. Production of Pistachio Milk and Pistachio-Based Yogurt Analog Manufacture

2.3. Fermentation Kinetics

2.4. Microbiological Counts

2.5. Compositional Analysis

2.6. Color Measurements

2.7. Free Amino Acid Content Analysis

2.8. Sensory Evaluation

2.9. Statistical Analysis

3. Results and Discussion

3.1. Fermentation Kinetics

3.2. Microbial Counts

3.3. Compositional Analysis

3.4. Color Measurement

3.5. Free Amino Acid Profile

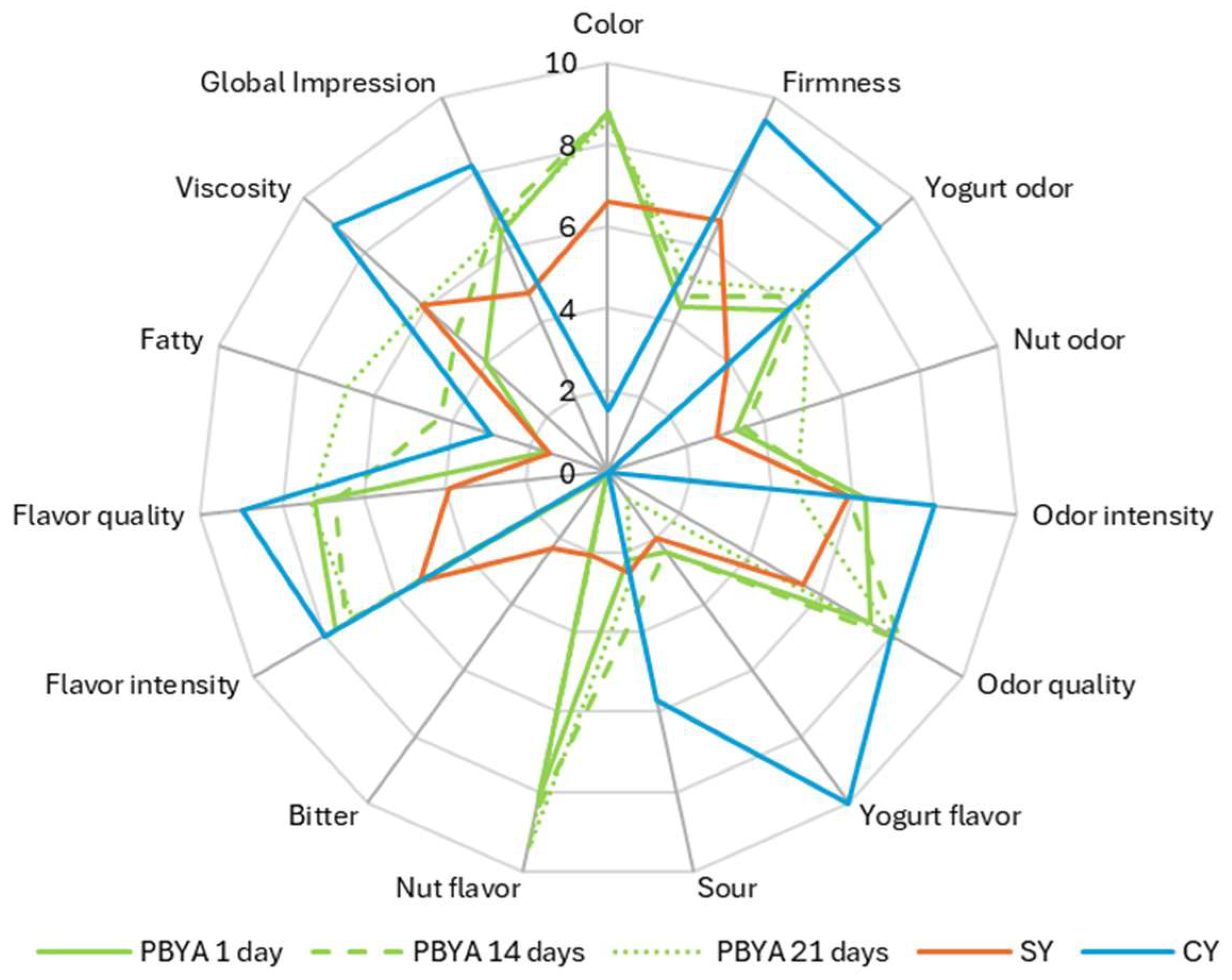

3.6. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pua, A.; Tang, V.C.; Goh, R.M.; Sun, J.; Lassabliere, B.; Liu, S.Q. Ingredients, Processing, and Fermentation: Addressing the Organoleptic Boundaries of Plant-Based Dairy Analogues. Foods 2022, 11, 875. [Google Scholar] [CrossRef] [PubMed]

- Blanco-Gutiérrez, I.; Varela-Ortega, C.; Manners, R. Evaluating Animal-Based Foods and Plant-Based Alternatives Using Multi-Criteria and SWOT Analyses. Int. J. Environ. Res. Public Health 2020, 17, 7969. [Google Scholar] [CrossRef] [PubMed]

- Sá, A.G.A.; Moreno, Y.M.F.; Carciofi, B.A.M. Plant proteins as high-quality nutritional source for human diet. Trends Food Sci. Technol. 2020, 97, 170–184. [Google Scholar] [CrossRef]

- Galindo, A.; Collado-González, J.; Griñán, I.; Corell, M.; Centeno, A.; Martín-Palomo, M.J.; Girón, I.F.; Rodríguez, P.; Cruz, Z.N.; Memmi, H.; et al. Deficit irrigation and emerging fruit crops as a strategy to save water in Mediterranean semiarid agrosystems. Agric. Water Manag. 2018, 202, 311–324. [Google Scholar] [CrossRef]

- MAPA. Ministerio de Agricultura; Pesca y Alimentación-Anuario de Estadística: Madrid, Spain, 2023. [Google Scholar]

- FAOSTAT. Food and Agriculture Organization of the United Nations-Crops Statistics; FAOSTAT: Rome, Italy, 2022. [Google Scholar]

- Martínez-Peña, R.; Vélez, S.; Vacas, R.; Martín, H.; Álvarez, S. Remote Sensing for Sustainable Pistachio Cultivation and Improved Quality Traits Evaluation through Thermal and Non-Thermal UAV Vegetation Indices. Appl. Sci. 2023, 13, 7716. [Google Scholar] [CrossRef]

- Pakzadeh, R.; Goli, S.A.H.; Abdollahi, M.; Varshosaz, J. Formulation optimization and impact of environmental and storage conditions on physicochemical stability of pistachio milk. J. Food Meas. Charact. 2021, 15, 4037–4050. [Google Scholar] [CrossRef]

- Erem, E.; Kilic-Akyilmaz, M. Bioactive properties of fermented spreadable product manufactured from pistachio kernels. J. Food Sci. Technol. 2024, 62, 1116–1122. [Google Scholar] [CrossRef]

- Di Renzo, T.; Osimani, A.; Marulo, S.; Cardinali, F.; Mamone, G.; Puppo, C.; Garzón, A.G.; Drago, S.R.; Laurino, C.; Reale, A. Insight into the role of lactic acid bacteria in the development of a novel fermented pistachio (Pistacia vera L.) beverage. Food Biosci. 2023, 53, 102802. [Google Scholar] [CrossRef]

- Reale, A.; Puppo, M.C.; Boscaino, F.; Garzon, A.G.; Drago, S.R.; Marulo, S.; Di Renzo, T. Development and Evaluation of a Fermented Pistachio-Based Beverage Obtained by Colloidal Mill. Foods 2024, 13, 2342. [Google Scholar] [CrossRef]

- Dhakal, D.; Younas, T.; Bhusal, R.P.; Devkota, L.; Henry, C.J.; Dhital, S. Design rules of plant-based yoghurt-mimic: Formulation, functionality, sensory profile and nutritional value. Food Hydrocoll. 2023, 142, 108786. [Google Scholar] [CrossRef]

- Devnani, B.; Ong, L.; Kentish, S.E.; Scales, P.J.; Gras, S.L. Physicochemical and rheological properties of commercial almond-based yoghurt alternatives to dairy and soy yoghurts. Future Foods 2022, 6, 100185. [Google Scholar] [CrossRef]

- Vashisht, P.; Sharma, A.; Awasti, N.; Wason, S.; Singh, L.; Sharma, S.; Charles, A.P.R.; Sharma, S.; Gill, A.; Khattra, A.K. Comparative review of nutri-functional and sensorial properties, health benefits and environmental impact of dairy (bovine milk) and plant-based milk (soy, almond, and oat milk). Food Humanit. 2024, 2, 100301. [Google Scholar] [CrossRef]

- Fregapane, G.; Guisantes-Batan, E.; Ojeda-Amador, R.M.; Salvador, M.D. Development of functional edible oils enriched with pistachio and walnut phenolic extracts. Food Chem. 2020, 310, 125917. [Google Scholar] [CrossRef]

- Al Zahrani, A.J.; Shori, A.B. Viability of probiotics and antioxidant activity of soy and almond milk fermented with selected strains of probiotic Lactobacillus spp. LWT 2023, 176, 114531. [Google Scholar] [CrossRef]

- ISO 7889:2003; Yogurt—Enumeration of Characteristic Microorganisms—Colony-Count Technique at 37 Degrees C. ISO: Geneva, Switzerland, 2003.

- AOAC. Latimer, G.W., Jr., Latimer, G.W., Jr., Eds.; Official Methods of Analysis: 22nd Edition (2023). In Official Methods of Analysis of AOAC INTERNATIONAL; Oxford University Press: New York, NY, USA, 2023. [Google Scholar]

- Pearce, K.N. The complexometric determination of calcium in dairy products. J. Dairy Sci. Technol. 1977, 12, 113–115. [Google Scholar]

- Ramos, I.M.; Rodríguez-Sánchez, S.; Palop, M.L.; Poveda, J.M. Reduction in the biogenic amine content of raw milk Manchego cheese by using biogenic-amine-degrading lactic acid bacteria. Food Control 2024, 156, 110133. [Google Scholar] [CrossRef]

- Poveda, J.M. Biogenic amines and free amino acids in craft beers from the Spanish market: A statistical approach. Food Control 2019, 96, 227–233. [Google Scholar] [CrossRef]

- ISO 13299:2016; Sensory Analysis—Methodology—General Guidance for Establishing a Sensory Profile. ISO: Geneva, Switzerland, 2016.

- Ramos, I.M.; Poveda, J.M. Fermented sheep’s milk enriched in gamma-amino butyric acid (GABA) by the addition of lactobacilli strains isolated from different food environments. LWT 2022, 163, 113581. [Google Scholar] [CrossRef]

- ISO 8586:2023; Sensory Analysis—Selection and Training of Sensory Assessors. ISO: Geneva, Switzerland, 2023.

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2007.

- Ning, X.; Luo, Z.; Chen, Z.; Zhou, C.; Xie, C.; Du, W.; Wang, L. Fortification of set yogurt with passion fruit juice: Effects on fermentation kinetics, physicochemical properties, and functionality. J. Dairy Sci. 2021, 104, 4084–4093. [Google Scholar] [CrossRef]

- Łopusiewicz, Ł. Comparison of Homemade and Commercial Plant-Based Drinks (Almond, Oat, Soy) Fermented with Yogurt Starter Culture for Fresh Consumption. Fermentation 2024, 10, 35. [Google Scholar] [CrossRef]

- Pereira, W.A.; Piazentin, A.C.M.; da Silva, T.M.S.; Mendonça, C.M.N.; Figueroa Villalobos, E.; Converti, A.; Oliveira, R.P.S. Alternative Fermented Soy-Based Beverage: Impact of Inulin on the Growth of Probiotic Strains and Starter Culture. Fermentation 2023, 9, 961. [Google Scholar] [CrossRef]

- Ramos, I.M.; Seseña, S.; Poveda, J.M.; Palop, M.L. Screening of Lactic Acid Bacteria Strains to Improve the Properties of Non-fat Set Yogurt by in situ EPS Production. Food Bioprocess. Technol. 2023, 16, 2541–2558. [Google Scholar] [CrossRef]

- Baygut, H.; Cais-Sokolińska, D.; Bielska, P.; Teichert, J. Fermentation Kinetics, Microbiological and Physical Properties of Fermented Soy Beverage with Acai Powder. Fermentation 2023, 9, 324. [Google Scholar] [CrossRef]

- Atik, D.S.; Öztürk, H.İ.; Akın, N.; Özer, B. Textural and rheological characterisation of yoghurts produced with cultures isolated from traditional back-slopped yoghurts. Int. Dairy J. 2023, 138, 105557. [Google Scholar] [CrossRef]

- CODEX STAN 243–2003; Codex Standard for Fermented Milks. Codex-Alimentarius Commission: Rome, Italy, 2003.

- Alsaleem, K.A.; Hamouda, M.E.A. Optimizing Probiotic Low-Fat Yogurt: The Benefits of Incorporating Defatted Rice Bran for Enhanced Quality and Functionality. Food Sci. Nutr. 2024, 12, 10242–10254. [Google Scholar] [CrossRef] [PubMed]

- Soumya, M.P.; Suresh, A.; Parameswaran, R.; Nampoothiri, K.M. Physico-chemical and organoleptic evaluation of probiotic plant-milk yogurt-type beverages as a functional alternative to dairy yogurts. Biocatal. Agric. Biotechnol. 2024, 57, 103060. [Google Scholar] [CrossRef]

- Martin, F.; Cachon, R.; Pernin, K.; De Coninck, J.; Gervais, P.; Guichard, E.; Cayot, N. Effect of oxidoreduction potential on aroma biosynthesis by lactic acid bacteria in nonfat yogurt. J. Dairy Sci. 2011, 94, 614–622. [Google Scholar] [CrossRef] [PubMed]

- Grasso, N.; Alonso-Miravalles, L.; O’Mahony, J.A. Composition, Physicochemical and Sensorial Properties of Commercial Plant-Based Yogurts. Foods 2020, 9, 252. [Google Scholar] [CrossRef]

- Paul, S.K.K.; Islam, M.N.; Dewan, M.F.; Alim, M.A.; Ahmmed, R. Functional yogurt: An approach to enhance yogurt quality with peanut polyphenols. Food Biosci. 2024, 60, 104398. [Google Scholar] [CrossRef]

- Ahmad, I.; Khalique, A.; Shahid, M.Q.; Ahid Rashid, A.; Faiz, F.; Ikram, M.A.; Ahmed, S.; Imran, M.; Khan, M.A.; Nadeem, M.; et al. Studying the Influence of Apple Peel Polyphenol Extract Fortification on the Characteristics of Probiotic Yoghurt. Plants 2020, 9, 77. [Google Scholar] [CrossRef]

- Zhai, J.; Zheng, J.; Jia, Q.; Zhuang, Y.; Gu, Y.; Fan, X.; Ding, Y. Comparative nutritional and physicochemical analysis of plant-based walnut yogurt and commercially available animal yogurt. LWT 2024, 212, 116959. [Google Scholar] [CrossRef]

- Gamli, Ö.F.; Atasoy, A.F. Physico-chemical and sensorial properties of groundnut milk and it’s yoghurt. J. Food Meas. Charact. 2018, 12, 1997–2004. [Google Scholar] [CrossRef]

- Dinkçi, N.; Aktaş, M.; Akdeniz, V.; Sirbu, A. The Influence of Hazelnut Skin Addition on Quality Properties and Antioxidant Activity of Functional Yogurt. Foods 2021, 10, 2855. [Google Scholar] [CrossRef] [PubMed]

- Serafeimidou, A.; Zlatanos, S.; Laskaridis, K.; Sagredos, A. Chemical characteristics, fatty acid composition and conjugated linoleic acid (CLA) content of traditional Greek yogurts. Food Chem. 2012, 134, 1839–1846. [Google Scholar] [CrossRef] [PubMed]

- Mandalari, G.; Barreca, D.; Gervasi, T.; Roussell, M.A.; Klein, B.; Feeney, M.J.; Carughi, A. Pistachio Nuts (Pistacia vera L.): Production, Nutrients, Bioactives and Novel Health Effects. Plants 2021, 11, 18. [Google Scholar] [CrossRef]

- Clegg, M.E.; Tarrado Ribes, A.; Reynolds, R.; Kliem, K.; Stergiadis, S. A comparative assessment of the nutritional composition of dairy and plant-based dairy alternatives available for sale in the UK and the implications for consumers’ dietary intakes. Food Res. Int. 2021, 148, 110586. [Google Scholar] [CrossRef]

- Rebellato, A.P.; Fioravanti, M.I.A.; Milani, R.F.; Morgano, M.A. Composition and bioaccessibility of inorganic elements in plant-based yogurts. J. Food Compos. Anal. 2023, 123, 105639. [Google Scholar] [CrossRef]

- Yilmaz-Ersan, L.; Topcuoglu, E. Evaluation of instrumental and sensory measurements using multivariate analysis in probiotic yogurt enriched with almond milk. J. Food Sci. Technol. 2022, 59, 133–143. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wei, W.; Ma, W.; Yuan, A.; Ma, F.; Xue, Y.; Zhang, J. Effects of Dioscorea opposita mucilage addition on the physicochemical properties, texture, and stability of set-type yogurt. LWT 2024, 206, 116586. [Google Scholar] [CrossRef]

- Dhakal, R.; Bajpai, V.K.; Baek, K.H. Production of gaba (γ-Aminobutyric acid) by microorganisms: A review. Braz. J. Microbiol. 2012, 43, 1230–1241. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Miao, K.; Niyaphorn, S.; Qu, X. Production of Gamma-Aminobutyric Acid from Lactic Acid Bacteria: A Systematic Review. Int. J. Mol. Sci. 2020, 21, 995. [Google Scholar] [CrossRef] [PubMed]

- Akbarian, M.; Khani, A.; Eghbalpour, S.; Uversky, V.N. Bioactive Peptides: Synthesis, Sources, Applications, and Proposed Mechanisms of Action. Int. J. Mol. Sci. 2022, 23, 1445. [Google Scholar] [CrossRef]

- Borrego-Ruiz, A.; Gonzalez Domenech, C.M.; Borrego, J. The Role of Fermented Vegetables as a Sustainable and Health-Promoting Nutritional Resource. Appl. Sci. 2024, 14, 10853. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.; Hao, G.; Yu, H.; Tian, H.; Zhao, G. Role of lactic acid bacteria on the yogurt flavour: A review. Int. J. Food Prop. 2017, 20, S316–S330. [Google Scholar] [CrossRef]

| Parameters | |

|---|---|

| V max (m unit pH/min) | 6.4 |

| Tm (min) | 240 |

| Te (min) | 342 |

| Microbial Group | Period of Storage | |||

|---|---|---|---|---|

| 1 | 14 | 21 | p Value | |

| Streptococcus thermophilus (M-17) | 8.6 a ± 0.2 | 8.4 b ± 0.3 | 8.1 c ± 0.2 | 0.0007 |

| Lactobacillus bulgaricus (MRS) | 8.4 a ± 0.1 | 8.2 b ± 0.1 | 8.2 b ± 0.2 | 0.0085 |

| Total aerobic mesophilic bacteria (PCA) | 8.8 a ± 0.3 | 8.1 b ± 0.2 | 8.2 b ± 0.3 | 0.0041 |

| Time | pH | TA (%) | TS (%) | Fat (%) | Protein (%) | Calcium (mg/100 g) |

|---|---|---|---|---|---|---|

| 1 | 4.62 a ± 0.01 | 0.54 b ± 0.03 | 20.5 ± 0.1 | 5.8 b ± 0.3 | 5.6 ± 1.7 | 71.9 ± 3.2 |

| 14 | 4.40 b ± 0.01 | 0.64 a ± 0.01 | 21.4 ± 0.8 | 5.4 b ± 0.6 | nd | nd |

| 21 | 4.34 c ± 0.01 | 0.64 a ± 0.02 | 20.6 ± 0.0 | 6.8 a ± 0.3 | nd | nd |

| p value | <0.0001 | 0.0021 | 0.080 | 0.0067 | - | - |

| Sample | L* | a* | b* |

|---|---|---|---|

| PBYA 1 d | 83.1 b ± 0.1 | −4.5 ± 0.6 | 36.9 a ± 3.4 |

| PBYA 14 d | 83.7 a ± 0.1 | −4.1 ± 0.1 | 33.6 b ± 0.2 |

| PBYA 21 d | 82.1 c ± 0.1 | −4.3 ± 0.1 | 33.5 b ± 0.1 |

| p value | 0.002 | 0.18 | 0.0005 |

| Free Amino Acid | PBYA | Commercial Soy Yogurt | Commercial Cow Yogurt | p Value |

|---|---|---|---|---|

| Essential amino acids | ||||

| Histidine | 11.2 a ± 1.6 | 12.2 a ± 4.8 | 4.15 b ± 0.81 | 0.017 |

| Isoleucine | 9.15 c ± 0.98 | 21.6 a ± 0.8 | 15.3 b ± 0.5 | <0.001 |

| Leucine | 13.0 b ± 0.4 | 20.3 a ± 0.5 | 9.35 c ± 0.38 | <0.001 |

| Lysine | 67.8 a ± 2.3 | 28.7 b ± 1.4 | 4.03 c ± 0.07 | <0.0001 |

| Methionine | 25.7 a ± 1.5 | 6.73 b ± 0.58 | 4.11 c ± 0.21 | <0.0001 |

| Phenylalanine | 9.91 b ± 0.15 | 11.7 a ± 0.2 | 5.12 c ± 0.97 | <0.001 |

| Threonine | 67.5 a ± 1.4 | 18.9 b ± 1.2 | 18.0 b ± 1.2 | <0.0001 |

| Tryptophan | 54.9 a ± 2.6 | 16.8 c ± 1.9 | 20.3 b ± 1.1 | <0.0001 |

| Valine | 46.7 a ± 3.9 | 23.7 b ± 2.5 | 28.9 b ± 1.0 | <0.001 |

| Nonessential amino acids | ||||

| Alanine | 47.8 b ± 3.0 | 51.9 a ± 1.9 | 17.3 c ± 0.8 | <0.001 |

| Arginine | 25.2 b ± 0.4 | 32.0 a ± 0.2 | 1.57 c ± 0.01 | <0.0001 |

| Aspartic acid + Serine | 51.5 a ± 1.3 | 38.1 b ± 0.7 | 25.6 c ± 0.11 | <0.0001 |

| Cystine | 27.9 a ± 1.6 | 17.2 b ± 0.9 | 26.4 a ± 0.23 | 0.002 |

| GABA | 112 a ± 1 | 71.4 c ± 1.1 | 83.6 b ± 1.3 | <0.0001 |

| Glutamate | 129 b ± 2 | 134 a ± 1 | 91.3 c ± 1.7 | <0.0001 |

| Glycine | 8.34 a ± 1.3 | 5.18 b ± 0.69 | 3.17 c ± 0.08 | 0.001 |

| Proline | 31.7 b ± 0.2 | 37.2 a ± 0.6 | 28.8 c ± 0.9 | <0.001 |

| Tyrosine | 15.6 a ± 0.8 | 9.87 b ± 0.47 | 3.55 c ± 0.14 | <0.0001 |

| Total | 754 a ± 8 | 557 b ± 5 | 390 c ± 2 | <0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos, I.M.; Rodríguez García, S.; Poveda, J.M. Development and Characterization of Pistachio Yogurt Analog: A Healthy, Sustainable, and Innovative Plant-Based Alternative. Fermentation 2025, 11, 467. https://doi.org/10.3390/fermentation11080467

Ramos IM, Rodríguez García S, Poveda JM. Development and Characterization of Pistachio Yogurt Analog: A Healthy, Sustainable, and Innovative Plant-Based Alternative. Fermentation. 2025; 11(8):467. https://doi.org/10.3390/fermentation11080467

Chicago/Turabian StyleRamos, Inés M., Samuel Rodríguez García, and Justa M. Poveda. 2025. "Development and Characterization of Pistachio Yogurt Analog: A Healthy, Sustainable, and Innovative Plant-Based Alternative" Fermentation 11, no. 8: 467. https://doi.org/10.3390/fermentation11080467

APA StyleRamos, I. M., Rodríguez García, S., & Poveda, J. M. (2025). Development and Characterization of Pistachio Yogurt Analog: A Healthy, Sustainable, and Innovative Plant-Based Alternative. Fermentation, 11(8), 467. https://doi.org/10.3390/fermentation11080467