Biorefinery-Based Energy Recovery from Algae: Comparative Evaluation of Liquid and Gaseous Biofuels

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Analytical and Statistical Methods

2.3. Experimental Methods

2.3.1. Alcoholic Fermentation

2.3.2. Biomethane Potential (BMP) Assay

3. Results and Discussion

3.1. Composition

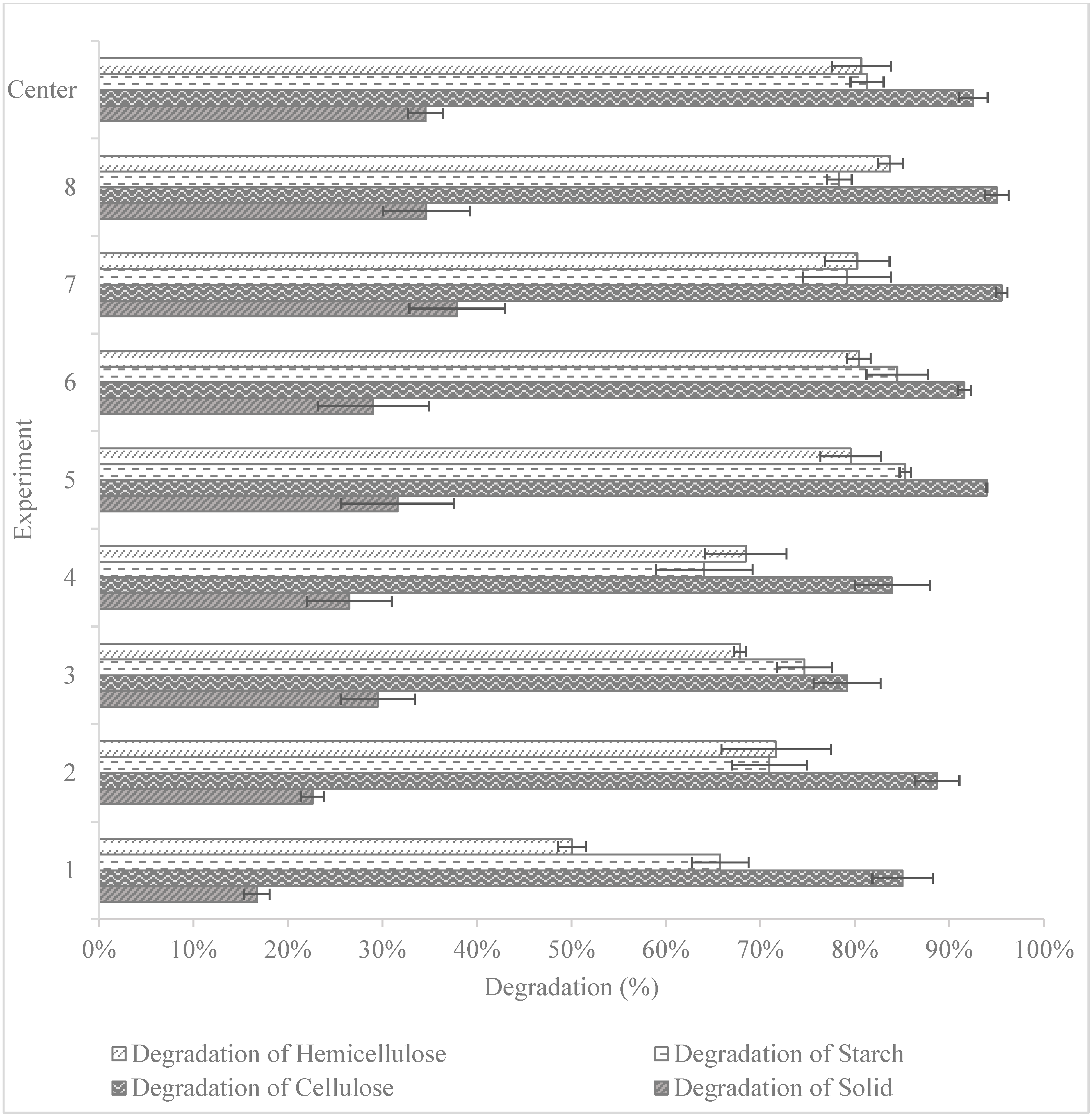

3.2. Factorial Design for Bioethanol Production

3.3. Biomethane Potential

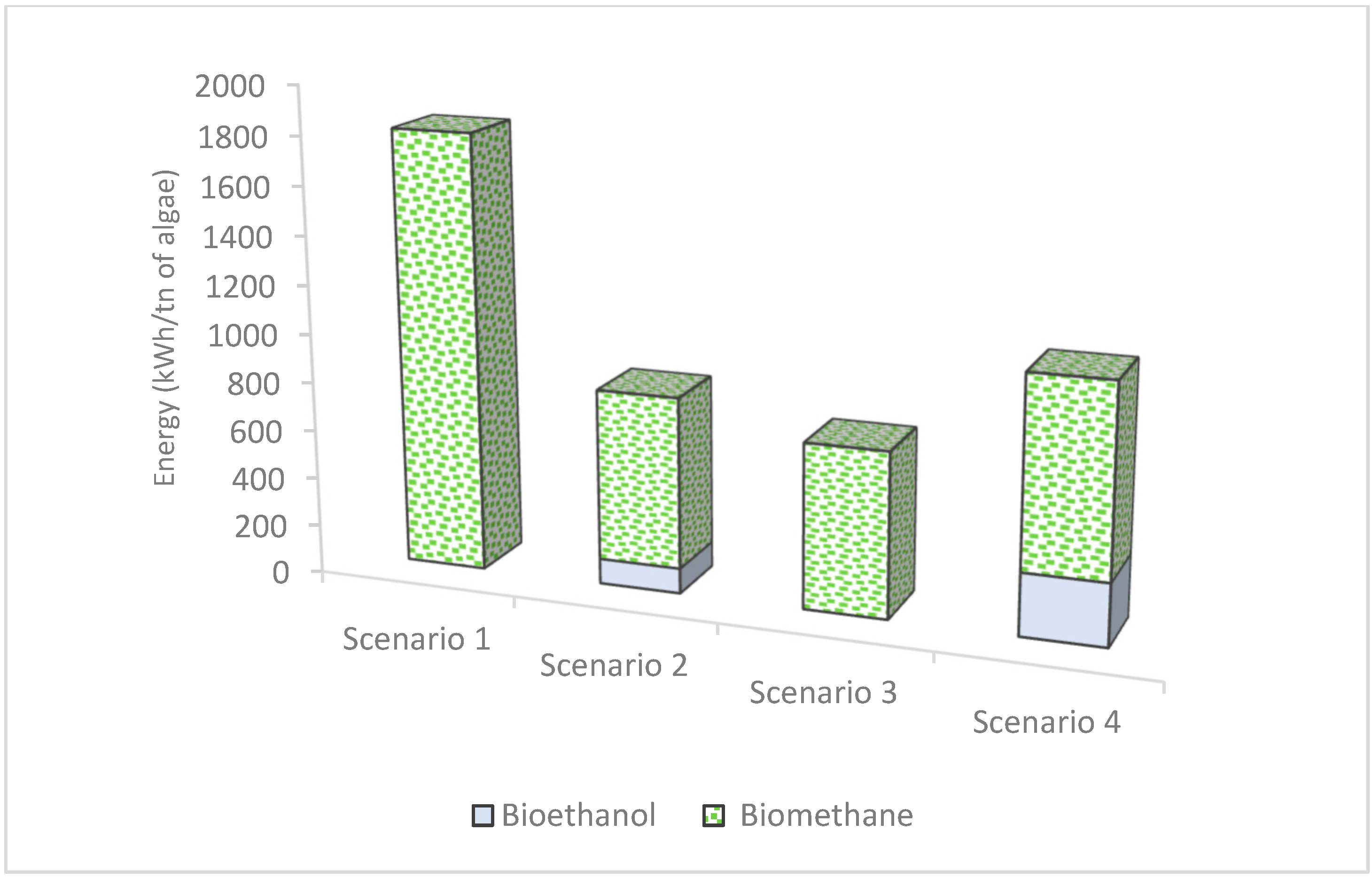

3.4. Energy Production Routes

| Study | Feedstock | Bioethanol Yield (g/L or % Theo.) | Methane Potential (mL CH4/g VS) | Total Energy Recovery (kWh/t algae) | Notes |

|---|---|---|---|---|---|

| This study | Fresh Scenedesmus-dominated microalgae | 2.75 g/L (45.13%) | 198.50 | 809.58 | Enzymatic hydrolysis + AD of stillage |

| Harun et al. [34] | C. infusionum (alkali-treated) | ~4.0 g/L | Not reported | Not reported | High ethanol via alkaline pretreatment |

| Passos et al. [26] | Mixed microalgae | Not applicable | 220–280 | ~1000 | Anaerobic digestion only |

| Liu et al. [20] | Dried Chlorella biomass | ~3.2 g/L | ~210 | ~700 | Dry biomass, two-step valorization |

| Chatzimaliakas et al. [27] | Dried Scenedesmus | 3.1 g/L (41%) | 180–220 | 640–790 | Integrated biorefinery, dried algae |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic Digestion |

| BMP | Biomethane Potential |

| d.w. | Dry Weight |

| LHV | Lower Heating Value |

| RED | Renewable Energy Directive |

| SSF | Simultaneous Saccharification and Fermentation |

References

- CO2 and Greenhouse Gas Emissions Data Explorer—Our World in Data. Available online: https://ourworldindata.org/explorers/co2?time=2003..latest&country=CHN~USA~OWID_EU27~RUS&Gas+or+Warming=CO%E2%82%82&Accounting=Territorial&Fuel+or+Land+Use+Change=All+fossil+emissions&Count=Per+country&Relative+to+world+total=false (accessed on 5 April 2025).

- Global Energy Sector CO2 Emissions and COP28 Pathway, 2030—Charts—Data & Statistics—IEA. Available online: https://www.iea.org/data-and-statistics/charts/global-energy-sector-co2-emissions-and-cop28-pathway-2030 (accessed on 5 April 2025).

- Bao, J.; Lu, W.H.; Zhao, J.; Bi, X.T. Greenhouses for CO2 Sequestration from Atmosphere. Carbon Resour. Convers. 2018, 1, 183–190. [Google Scholar] [CrossRef]

- Flach, B.; Phillips, S.; Lieberz, S.; Lappin, J.; Bolla, S. EU Biofuels Annual USDA Foreign Agricultural Service; United States Department of Agriculture: Washington, DC, USA, 2018.

- European Commission. Renewable Energy—Recast to 2030 (RED II)—European Commission. Available online: https://joint-research-centre.ec.europa.eu/welcome-jec-website/reference-regulatory-framework/renewable-energy-recast-2030-red-ii_en (accessed on 27 February 2024).

- Abdulla, G.A.; Alismaeel, Z.T. The Potential of Algal Oil for Biodiesel Production: A Systematic Review. IOP Conf. Ser. Earth Environ. Sci. 2025, 1507, 012046. [Google Scholar] [CrossRef]

- Adetunji, A.I.; Gumbi, S.T.; Erasmus, M. Harnessing the Potential of Microalgae in Sequestration of CO2 Emissions: Removal Mechanisms, Optimization Strategies, and Bioenergy Production. J. Hazard. Mater. Adv. 2025, 18, 100722. [Google Scholar] [CrossRef]

- Hartulistiyoso, E.; Farobie, O.; Anis, L.A.; Syaftika, N.; Bayu, A.; Amrullah, A.; Moheimani, N.R.; Karnjanakom, S.; Matsumura, Y. Co-Production of Hydrochar and Bioactive Compounds from Ulva Lactuca via a Hydrothermal Process. Carbon Resour. Convers. 2024, 7, 100183. [Google Scholar] [CrossRef]

- Banerjee, S.; Ray, A.; Das, D. Optimization of Chlamydomonas Reinhardtii Cultivation with Simultaneous CO2 Sequestration and Biofuels Production in a Biorefinery Framework. Sci. Total Environ. 2021, 762, 143080. [Google Scholar] [CrossRef]

- Pascon, G.; Messina, M.; Petit, L.; Maria, L.; Valente, P.; Oliveira, B.; Przybyla, C.; Dutto, G.; Tulli, F. Potential Application and Beneficial Effects of a Marine Microalgal Biomass Produced in a High-Rate Algal Pond (HRAP) in Diets of European Sea Bass, Dicentrarchus Labrax. Environ. Sci. Pollut. Res. 2021, 28, 62185–62199. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Xia, C.; Alqahtani, A.; Sharma, A.; Pugazhendhi, A. A Review on Optimistic Biorefinery Products: Biofuel and Bioproducts from Algae Biomass. Fuel 2023, 338, 127378. [Google Scholar] [CrossRef]

- Sialve, B.; Bernet, N.; Bernard, O. Anaerobic Digestion of Microalgae as a Necessary Step to Make Microalgal Biodiesel Sustainable. Biotechnol. Adv. 2009, 27, 409–416. [Google Scholar] [CrossRef]

- Silva, T.A.; de Araujo, M.N.; de Rezende, E.G.F.; Saia, F.T.; Magalhães, I.B.; de Paula Pereira, A.S.A.; Ferreira, J.; Gregoracci, G.B.; Tallarico Adorno, M.Â.; Fuess, L.T.; et al. Biohydrogen Production from Wastewater-Grown Microalgae-Bacteria Consortia: Optimizing Inoculum Selection for Enhanced Yield. Renew. Energy 2025, 247, 123079. [Google Scholar] [CrossRef]

- Biswal, T.; Shadangi, K.P.; Sarangi, P.K. Algae Biofuel Production Techniques: Recent Advancements. In Biorefineries: Production of Fuels and Platform Chemicals; Wiley Blackwell: Hoboken, NY, USA, 2024; pp. 131–146. [Google Scholar] [CrossRef]

- Santurbano, V.; Marangon, B.; Castro, J.; Calijuri, M.L.; Leme, M.; Assemany, P. Enhancing Environmental Performance in Biogas Production from Wastewater-Grown Microalgae: A Life Cycle Assessment Perspective. J. Environ. Manag. 2024, 362, 121251. [Google Scholar] [CrossRef]

- Chandrasekhar, T.; Reddy, P.C.O.; Swapna, B.; Veeranjaneya Reddy, L.; Anuprasanna, V.; Dakshayani, L.; Ramachandra Reddy, P.; Reddy, M.C. Algae: The Game-Changers in Biohydrogen Sector. Crit. Rev. Biotechnol. 2025, 45, 509–529. [Google Scholar] [CrossRef]

- Faraloni, C.; Torzillo, G.; Balestra, F.; Moia, I.C.; Zampieri, R.M.; Jiménez-Conejo, N.; Touloupakis, E. Advances and Challenges in Biohydrogen Production by Photosynthetic Microorganisms. Energies 2025, 18, 2319. [Google Scholar] [CrossRef]

- Ballenghien, D.; Kempegowda, R.S.; Chen, W.H.; Tran, K.Q. Comparative Assessment of Hydrothermal Gasification and Anaerobic Digestion Using Aspen Plus and SuperPro. In E3S Web of Conferences; EDP Sciences: London, UK, 2024; Volume 514. [Google Scholar] [CrossRef]

- Kaur, M.; Peshwani, H.; Goel, M. High-Value Products from Microalgae—Unlocking the Potential for Large-Scale Commercialization. In Microalgal Biofuels: Sustainable Production, Conversion, and Life Cycle Assessment; Elsevier: Amsterdam, The Netherlands, 2025; pp. 257–276. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, Z.; Gong, G.; Wu, B.; Todhanakasem, T.; Li, J.; Zhuang, Y.; He, M. Economic Co-Production of Cellulosic Ethanol and Microalgal Biomass through Efficient Fixation of Fermentation Carbon Dioxide. Bioresour. Technol. 2024, 396, 130420. [Google Scholar] [CrossRef]

- Suhartini, S.; Pangestuti, M.B.; Elviliana; Rohma, N.A.; Junaidi, M.A.; Paul, R.; Nurika, I.; Rahmah, N.L.; Melville, L. Valorisation of Macroalgae for Biofuels in Indonesia: An Integrated Biorefinery Approach. Environ. Technol. Rev. 2024, 13, 269–304. [Google Scholar] [CrossRef]

- Slade, R.; Bauen, A. Micro-Algae Cultivation for Biofuels: Cost, Energy Balance, Environmental Impacts and Future Prospects. Biomass Bioenergy 2013, 53, 29–38. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Talluri, G.; Scarlat, N.; Prussi, M. The Challenge of Forecasting the Role of Biofuel in EU Transport Decarbonisation at 2050: A Meta-Analysis Review of Published Scenarios. Renew. Sustain. Energy Rev. 2021, 139, 110715. [Google Scholar] [CrossRef]

- Chew, K.W.; Yap, J.Y.; Show, P.L.; Suan, N.H.; Juan, J.C.; Ling, T.C.; Lee, D.J.; Chang, J.S. Microalgae Biorefinery: High Value Products Perspectives. Bioresour. Technol. 2017, 229, 53–62. [Google Scholar] [CrossRef]

- Rawat, I.; Ranjith Kumar, R.; Mutanda, T.; Bux, F. Dual Role of Microalgae: Phycoremediation of Domestic Wastewater and Biomass Production for Sustainable Biofuels Production. Appl. Energy 2011, 88, 3411–3424. [Google Scholar] [CrossRef]

- Passos, F.; Carretero, J.; Ferrer, I. Comparing Pretreatment Methods for Improving Microalgae Anaerobic Digestion: Thermal, Hydrothermal, Microwave and Ultrasound. Chem. Eng. J. 2015, 279, 667–672. [Google Scholar] [CrossRef]

- Chatzimaliakas, P.F.; Koutsaftis-Fragkos, E.; Mai, S.; Malamis, D.; Barampouti, E.M. From Microalgae to Biofuels: Investigating Valorization Pathways Towards Biorefinery Integration. Processes 2024, 12, 2936. [Google Scholar] [CrossRef]

- Angelidaki, I.; Alves, M.; Bolzonella, D.; Borzacconi, L.; Campos, J.L.; Guwy, A.J.; Kalyuzhnyi, S.; Jenicek, P.; Van Lier, J.B. Defining the Biomethane Potential (BMP) of Solid Organic Wastes and Energy Crops: A Proposed Protocol for Batch Assays. Water Sci. Technol. 2009, 59, 927–934. [Google Scholar] [CrossRef]

- Jabłońska-Trypuć, A.; Wołejko, E.; Ernazarovna, M.D.; Głowacka, A.; Sokołowska, G.; Wydro, U. Using Algae for Biofuel Production: A Review. Energies 2023, 16, 1758. [Google Scholar] [CrossRef]

- Kusmiyati, K.; Hadiyanto, H.; Fudholi, A. Treatment Updates of Microalgae Biomass for Bioethanol Production: A Comparative Study. J. Clean. Prod. 2022, 383, 135236. [Google Scholar] [CrossRef]

- de Carvalho Silvello, M.A.; Severo Gonçalves, I.; Patrícia Held Azambuja, S.; Silva Costa, S.; Garcia Pereira Silva, P.; Oliveira Santos, L.; Goldbeck, R. Microalgae-Based Carbohydrates: A Green Innovative Source of Bioenergy. Bioresour. Technol. 2022, 344, 126304. [Google Scholar] [CrossRef]

- Felekis, V.; Stavraki, C.; Malamis, D.; Mai, S.; Barampouti, E.M. Optimisation of Bioethanol Production in a Potato Processing Industry. Fermentation 2023, 9, 103. [Google Scholar] [CrossRef]

- Nikolaou, M.; Stavraki, C.; Bousoulas, I.; Malamis, D.; Loizidou, M.; Mai, S.; Barampouti, E.M. Valorisation of Bakery Waste via the Bioethanol Pathway. Energy 2023, 280, 128185. [Google Scholar] [CrossRef]

- Harun, R.; Jason, W.S.Y.; Cherrington, T.; Danquah, M.K. Exploring Alkaline Pre-Treatment of Microalgal Biomass for Bioethanol Production. Appl. Energy 2011, 88, 3464–3467. [Google Scholar] [CrossRef]

- Huang, M.; Jin, Z.; Ni, H.; Zhang, P.; Li, H.; Liu, J.; Weng, C.; Jiang, Z. Engineering the Xylose Metabolism of Saccharomyces Cerevisiae for Ethanol and Single Cell Protein Bioconversion. Biomass Bioenergy 2024, 190, 107372. [Google Scholar] [CrossRef]

- An Introduction to Biogas and Biomethane—Outlook for Biogas and Biomethane: Prospects for Organic Growth—Analysis—IEA. Available online: https://www.iea.org/reports/outlook-for-biogas-and-biomethane-prospects-for-organic-growth/an-introduction-to-biogas-and-biomethane (accessed on 9 April 2025).

| Category | Parameter | Value (% d.w.) |

|---|---|---|

| Moisture and Solids | Total Solids | 7.00 ± 0.52 |

| Moisture | 93.00 ± 0.52 | |

| Volatile Solids | 66.40 ± 0.25 | |

| Ash | 33.60 ± 0.25 | |

| Biochemical Components | Lipids and Photosynthetic Pigments | 7.31 ± 0.01 |

| Water Soluble Solids | 5.62 ± 0.11 | |

| Free Glucose | 0.05 ± 0.01 | |

| Hemicellulose | 12.53 ± 0.66 | |

| Cellulose | 14.42 ± 0.33 | |

| Starch | 0.87 ± 0.10 | |

| Acid-Insoluble Residue | 27.58 ± 0.74 | |

| Nitrogen Content | Total Nitrogen (Kjeldahl) | 3.95 ± 0.20 |

| Experiment No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Center of Factorial Design |

|---|---|---|---|---|---|---|---|---|---|

| NaOH (M) | 0.1 | 0.1 | 0.1 | 0.1 | 0.3 | 0.3 | 0.3 | 0.3 | 0.2 |

| CelicTec3 (μL/gcellulose) | 250 | 750 | 250 | 750 | 250 | 750 | 250 | 750 | 500 |

| Spirizyme (μL/gstarch) | 25 | 25 | 65 | 65 | 25 | 25 | 65 | 65 | 45 |

| Ethanol (g/L) | 1.06 ± 0.27 | 1.19 ± 0.09 | 0.58 ± 0.28 | 0.69 ± 0.09 | 2.75 ± 0.18 | 2.44 ± 0.09 | 1.81 ± 0.44 | 2.38 ± 0.02 | 2.48 ± 0.10 |

| Glucose (g/L) | 0.10 ± 0.01 | 0.09 ± 0.02 | 0.07 ± 0.01 | 0.06 ± 0.01 | 0.12 ± 0.03 | 0.14 ± 0.02 | 0.14 ± 0.04 | 0.09 ± 0.05 | 0.07 ± 0.01 |

| Ethanol Yield (%) | 17.43 ± 4.35 | 19.49 ± 1.45 | 9.44 ± 4.64 | 11.28 ± 1.45 | 45.13 ± 2.90 | 40.00 ± 1.45 | 29.74 ± 7.25 | 38.97 ± 1.95 | 40.61 ± 1.57 |

| BMP (mL CH4/g VS) | 171.67 ± 36.27 | 190.14 ± 42.83 | 198.50 ± 33.57 | 164.46 ± 36.18 | 102.36 ± 24.74 | 116.74 ± 11.46 | 153.39 ± 27.78 | 116.98 ± 31.43 | 80.31 ± 20.67 |

| Ethanol (kWh/t algae) | 286.14 | 304.60 | 280.70 | 323.22 | 258.39 | 359.98 | 341.47 | 406.13 | 290.94 |

| Methane (kWh/t algae) | 722.68 | 698.54 | 604.46 | 574.20 | 786.08 | 492.43 | 607.90 | 585.89 | 678.70 |

| Energy (kWh) | 1008.82 | 1003.14 | 885.16 | 897.42 | 1044.48 | 851.41 | 949.36 | 991.02 | 969.64 |

| Bioethanol (%) | 28.36 | 30.36 | 31.71 | 36.02 | 24.74 | 42.23 | 35.97 | 40.94 | 30.01 |

| Biomethane (%) | 71.64 | 69.64 | 68.29 | 63.98 | 75.26 | 57.77 | 64.03 | 59.06 | 69.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chatzimaliakas, P.F.; Malamis, D.; Mai, S.; Barampouti, E.M. Biorefinery-Based Energy Recovery from Algae: Comparative Evaluation of Liquid and Gaseous Biofuels. Fermentation 2025, 11, 448. https://doi.org/10.3390/fermentation11080448

Chatzimaliakas PF, Malamis D, Mai S, Barampouti EM. Biorefinery-Based Energy Recovery from Algae: Comparative Evaluation of Liquid and Gaseous Biofuels. Fermentation. 2025; 11(8):448. https://doi.org/10.3390/fermentation11080448

Chicago/Turabian StyleChatzimaliakas, Panagiotis Fotios, Dimitrios Malamis, Sofia Mai, and Elli Maria Barampouti. 2025. "Biorefinery-Based Energy Recovery from Algae: Comparative Evaluation of Liquid and Gaseous Biofuels" Fermentation 11, no. 8: 448. https://doi.org/10.3390/fermentation11080448

APA StyleChatzimaliakas, P. F., Malamis, D., Mai, S., & Barampouti, E. M. (2025). Biorefinery-Based Energy Recovery from Algae: Comparative Evaluation of Liquid and Gaseous Biofuels. Fermentation, 11(8), 448. https://doi.org/10.3390/fermentation11080448