Exploring the Functionality of Microbes in Fermented Foods: Technological Advancements and Future Directions

Abstract

1. Introduction

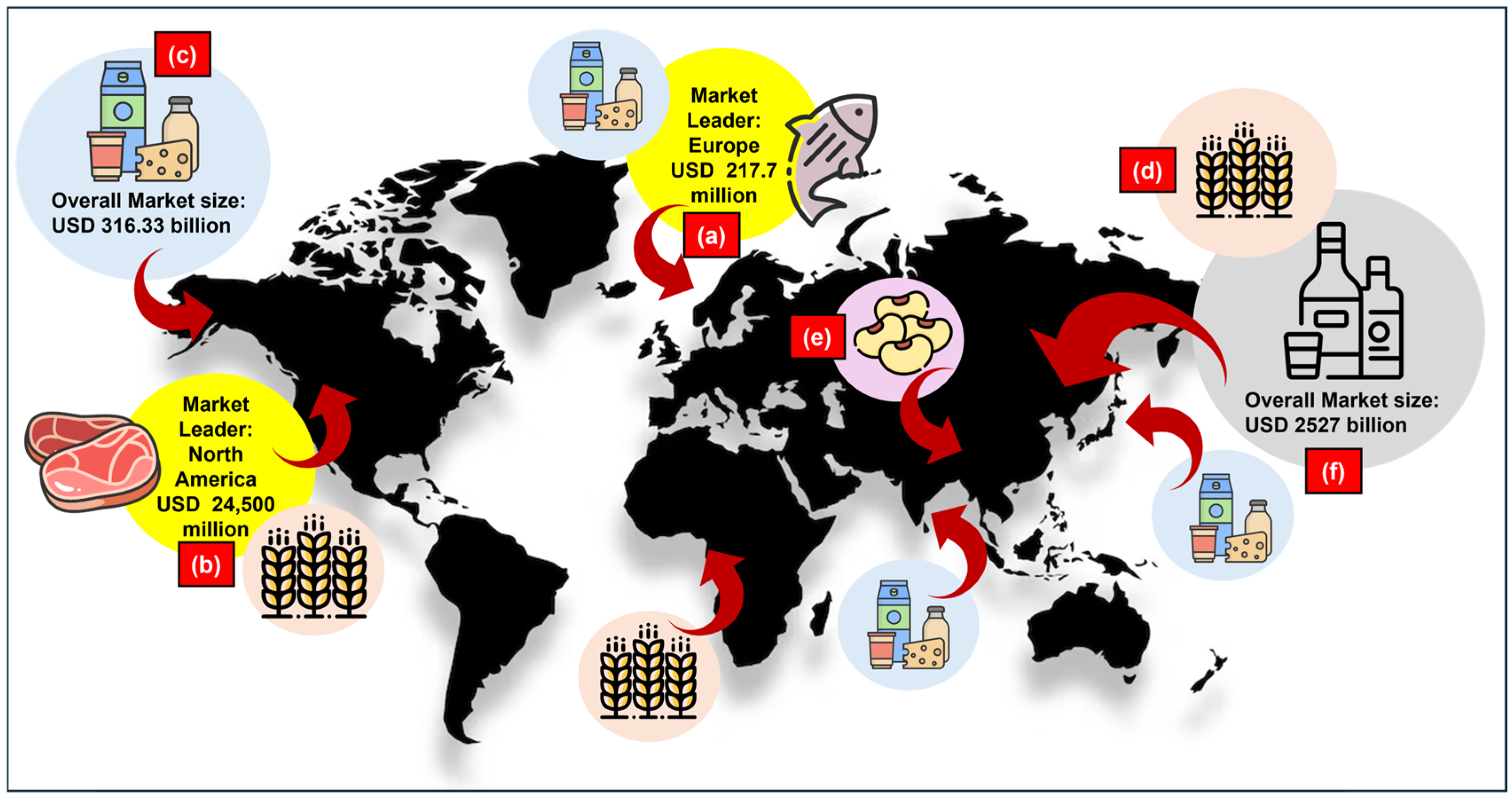

2. Functional Role of Microorganisms in Fermented Foods, Their Diversity Across Regions of the World, and Market Insights

2.1. Fermented Fish Products

2.2. Fermented Meat Products

2.3. Fermented Dairy Products

2.4. Fermented Cereal Products

2.5. Fermented Fruit, Vegetable, and Soy Products

2.6. Fermented Alcoholic Beverages

3. Omics Approach for Functional Food Development and Deciphering the Microbial Role in Fermentation

3.1. Types of Omics Utilized in Fermented Food

3.2. Real-World Applications of Omics in Fermented Food

3.3. Single-Omics or Multi-Omics: Which One Is More Effective?

4. Advancing the Role of Precision Fermentation in Food Fermentation and Microbial Functionality

4.1. Applications of Precision Fermentation in the Food Industry

4.2. Impact of Precision Fermentation on Various Aspects of the Food Industry

5. Role of Artificial Intelligence and Machine Learning in Food Fermentation

6. Current Challenges Faced by the Fermented Food Industry

7. Mitigation Strategies and Future Prospects

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CAGR | Compound annual growth rate |

| FAAs | Free amino acids |

| AI | Artificial intelligence |

| ML | Machine learning |

| IoT | Internet of Things |

| SCFAs | Short-chain fatty acids |

| LAB | Lactic acid bacteria |

| LDL | Low-density lipid |

| ODFM | Omics Database of Fermentative Microbes |

| EPSs | Exopolysaccharides |

| GRAS | Generally recognized as safe |

| FAO | Food and Agriculture Organization |

| GMO | Genetically Modified Organism |

| TRY | Titer, rate, yield |

| LCR | Leading Capacitance and Resistance |

| PCA | Principal component analysis |

| HCA | Hierarchical clustering analysis |

| SVMs | Support vector machines |

| RFs | Random forests |

| MF | Multilayer perceptron |

| PLSs | Partial least squares |

| RPD | Performance to deviation |

| RMSEP | Root mean square error of prediction |

| GA | Genetic algorithms |

| DT | Digital twin |

| GSCMMs | Genome-scale community metabolic models |

| HACCPs | Hazard Analysis and Critical Control Points |

References

- Rizo, J.; Guillén, D.; Farrés, A.; Díaz-Ruiz, G.; Sánchez, S.; Wacher, C.; Rodríguez-Sanoja, R. Omics in traditional vegetable fermented foods and beverages. Crit. Rev. Food Sci. Nutr. 2020, 60, 791–809. [Google Scholar] [CrossRef] [PubMed]

- Elhalis, H.; Chin, X.H.; Chow, Y. Soybean fermentation: Microbial ecology and starter culture technology. Crit. Rev. Food Sci. Nutr. 2024, 64, 7648–7670. [Google Scholar] [CrossRef]

- Jang, H.J.; Lee, N.-K.; Paik, H.-D. Overview of Dairy-based Products with Probiotics: Fermented or Non-fermented Milk Drink. Korean J. Food Sci. Anim. Resour. 2024, 44, 255–268. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Mokoena, M.P.; Mutanda, T.; Olaniran, A.O. Perspectives on the probiotic potential of lactic acid bacteria from African traditional fermented foods and beverages. Food Nutr. Res. 2016, 60, 29630. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Deveci, G.; Çelik, E.; Ağagündüz, D.; Bartkiene, E.; Rocha, J.M.F.; Özogul, F. Certain Fermented Foods and Their Possible Health Effects with a Focus on Bioactive Compounds and Microorganisms. Fermentation 2023, 9, 923. [Google Scholar] [CrossRef]

- Ilango, S.; Antony, U. Probiotic microorganisms from non-dairy traditional fermented foods. Trends Food Sci. Technol. 2021, 118, 617–638. [Google Scholar] [CrossRef]

- Sharma, R.; Garg, P.; Kumar, P.; Bhatia, S.K.; Kulshrestha, S. Microbial Fermentation and Its Role in Quality Improvement of Fermented Foods. Fermentation 2020, 6, 106. [Google Scholar] [CrossRef]

- Tamang, J.P.; Shin, D.-H.; Jung, S.-J.; Chae, S.-W. Functional Properties of Microorganisms in Fermented Foods. Front. Microbiol. 2016, 7, 578. [Google Scholar] [CrossRef]

- Cao, Z.-H.; Green-Johnson, J.M.; Buckley, N.D.; Lin, Q.-Y. Bioactivity of soy-based fermented foods: A review. Biotechnol. Adv. 2019, 37, 223–238. [Google Scholar] [CrossRef]

- Ibrahim, S.A.; Yeboah, P.J.; Ayivi, R.D.; Eddin, A.S.; Wijemanna, N.D.; Paidari, S.; Bakhshayesh, R.V. A review and comparative perspective on health benefits of probiotic and fermented foods. Int. J. Food Sci. Technol. 2023, 58, 4948–4964. [Google Scholar] [CrossRef]

- Global Market Insights. Fermented Processed Food Market Size—By Product Type (Dairy Products, Bread and Bakery Products, Vegetables, Condiments, Beverages), Microorganism Type (Bacteria, Yeast, Mold), & Forecast, 2024–2032. July 2024. Available online: https://www.gminsights.com/industry-analysis/fermented-processed-food-market (accessed on 20 March 2025).

- Wei, L.; Chen, H.; Liu, R.; Wang, S.; Liu, T.; Hu, Z.; Lan, W.; Yu, Y.; She, Y.; Fu, H. Fluorescent sensor based on quantum dots and nano-porphyrin for highly sensitive and specific determination of ethyl carbamate in fermented food. J. Sci. Food Agric. 2021, 101, 6193–6201. [Google Scholar] [CrossRef] [PubMed]

- Ryu, J.-A.; Kim, E.; Yang, S.-M.; Lee, S.; Yoon, S.-R.; Jang, K.-S.; Kim, H.-Y. High-throughput sequencing of the microbial community associated with the physicochemical properties of meju (dried fermented soybean) and doenjang (traditional Korean fermented soybean paste). LWT 2021, 146, 111473. [Google Scholar] [CrossRef]

- Garofalo, C.; Norici, A.; Mollo, L.; Osimani, A.; Aquilanti, L. Fermentation of Microalgal Biomass for Innovative Food Production. Microorganisms 2022, 10, 2069. [Google Scholar] [CrossRef] [PubMed]

- Ferrocino, I.; Cocolin, L. Current perspectives in food-based studies exploiting multi-omics approaches. Curr. Opin. Food Sci. 2017, 13, 10–15. [Google Scholar] [CrossRef]

- Narzary, Y.; Das, S.; Goyal, A.K.; Lam, S.S.; Sarma, H.; Sharma, D. Fermented fish products in South and Southeast Asian cuisine: Indigenous technology processes, nutrient composition, and cultural significance. J. Ethn. Foods 2021, 8, 33. [Google Scholar] [CrossRef]

- Waché, Y.; Do, T.-L.; Do, T.-B.; Do, T.-Y.; Haure, M.; Ho, P.-H.; Anal, A.K.; Le, V.-V.; Li, W.-J.; Licandro, H.; et al. Prospects for Food Fermentation in South-East Asia, Topics From the Tropical Fermentation and Biotechnology Network at the End of the AsiFood Erasmus+Project. Front. Microbiol. 2018, 9, 2278. [Google Scholar] [CrossRef]

- LeGrand, K.; Borarin, B.; Young, G.M. Tradition and Fermentation Science of prohok, an ethnic fermented fish product of Cambodia. J. Ethn. Foods 2020, 7, 12. [Google Scholar] [CrossRef]

- Mao, J.; Wang, X.; Chen, H.; Zhao, Z.; Liu, D.; Zhang, Y.; Nie, X. The Contribution of Microorganisms to the Quality and Flavor Formation of Chinese Traditional Fermented Meat and Fish Products. Foods 2024, 13, 608. [Google Scholar] [CrossRef]

- Rawat, K.; Kumari, A.; Kumar, S.; Kumar, R.; Gehlot, R. Traditional Fermented Products of India. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 1873–1883. [Google Scholar] [CrossRef]

- Kwon, D.Y.; Nyakudya, E.; Jeong, Y.S. Fermentation: Food Products. In Encyclopedia of Agriculture and Food Systems; Elsevier Inc.: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Majumdar, R.K.; Roy, D.; Bejjanki, S.; Bhaskar, N. An overview of some ethnic fermented fish products of the Eastern Himalayan region of India. J. Ethn. Foods 2016, 3, 276–283. [Google Scholar] [CrossRef]

- Future Market Insights Inc. Fish Fermentation Market Outlook (2023 to 2033). pp. 1–14. Available online: https://www.futuremarketinsights.com/reports/fish-fermentation-market (accessed on 10 April 2025).

- Munekata, P.E.S.; Pateiro, M.; Tomasevic, I.; Domínguez, R.; da Silva Barretto, A.C.; Santos, E.M.; Lorenzo, J.M. Functional fermented meat products with probiotics—A review. J. Appl. Microbiol. 2022, 133, 91–103. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Hu, P.; Xie, Y.; Wang, X. Co-fermentation with Lactobacillus curvatus LAB26 and Pediococcus pentosaceus SWU73571 for improving quality and safety of sour meat. Meat Sci. 2020, 170, 108240. [Google Scholar] [CrossRef] [PubMed]

- Pedonese, F.; Torracca, B.; Mancini, S.; Pisano, S.; Turchi, B.; Cerri, D.; Nuvoloni, R. Effect of a Lactobacillus sakei and Staphylococcus xylosus protective culture on Listeria monocytogenes growth and quality traits of Italian fresh sausage (salsiccia) stored at abusive temperature. Ital. J. Anim. Sci. 2020, 19, 1363–1374. [Google Scholar] [CrossRef]

- Shehata, M.G.; El Sohaimy, S.A.; El-Sahn, M.A.; Youssef, M.M. Screening of isolated potential probiotic lactic acid bacteria for cholesterol lowering property and bile salt hydrolase activity. Ann. Agric. Sci. 2016, 61, 65–75. [Google Scholar] [CrossRef]

- Cuamatzin-García, L.; Rodríguez-Rugarcía, P.; El-Kassis, E.G.; Galicia, G.; Meza-Jiménez, M.d.L.; Baños-Lara, M.d.R.; Zaragoza-Maldonado, D.S.; Pérez-Armendáriz, B. Traditional Fermented Foods and Beverages from around the World and Their Health Benefits. Microorganisms 2022, 10, 1151. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Zong, X.; Wen, L.; Li, J.; Li, L. Influence of Plant Protein-Dietary Fiber Composite Gel and Lactiplantibacillus plantarum XC-3 on Quality Characteristics of Chinese Dry Fermented Sausage. J. Food Process. Preserv. 2022, 46, e17072. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, P.; Xie, Y.; Yang, P.; Zheng, S.; Tian, Y.; Li, J.; Feng, D. DNA damage protection and antioxidant activities of peptides isolated from sour meat co-fermented by P. pentosaceus SWU73571 and L. curvatus LAB26. CyTA—J. Food 2020, 18, 375–382. [Google Scholar] [CrossRef]

- Wise Guy Report. Global Fermenetd Meat Products Market Research Report (2023–2033). pp. 1–11. Available online: https://www.wiseguyreports.com/reports/fermented-meat-products-market (accessed on 11 April 2025).

- Precedence Research. Meat Products Market Report (2025–2034). Available online: https://www.precedenceresearch.com/meat-products-market (accessed on 12 April 2025).

- Shah, A.M.; Tarfeen, N.; Mohamed, H.; Song, Y. Fermented Foods: Their Health-Promoting Components and Potential Effects on Gut Microbiota. Fermentation 2023, 9, 118. [Google Scholar] [CrossRef]

- Leeuwendaal, N.K.; Stanton, C.; O’Toole, P.W.; Beresford, T.P. Fermented Foods, Health and the Gut Microbiome. Nutrients 2022, 14, 1527. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Hammam, A.R.A.; Ahmed, M.S.I. Technological aspects, health benefits, and sensory properties of probiotic cheese. SN Appl. Sci. 2019, 1, 1113. [Google Scholar] [CrossRef]

- Gomes da Cruz, A.G.; Alonso Buriti, F.C.; Batista de Souza, C.H.; Fonseca Faria, J.A.; Isay Saad, S.M. Probiotic cheese: Health benefits, technological and stability aspects. Trends Food Sci. Technol. 2009, 20, 344–354. [Google Scholar] [CrossRef]

- Rizzoli, R.; Biver, E. Role of fermented dairy products in the health benefits of a mediterranean diet. Aging Clin. Exp. Res. 2024, 36, 75. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Ye, X.; Shen, D.; Ma, C. Modulatory Effects of Gut Microbiota on Constipation: The Commercial Beverage Yakult Shapes Stool Consistency. J. Neurogastroenterol. Motil. 2019, 25, 475–477. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Yazdi, F.G.; Dalgaard, L.B.; Li, Q.; Ruscheweyh, H.-J.; Thøgersen, R.; Bertram, H.C.; Hansen, M.; Schwab, C. Long-term daily high-protein, drained yoghurt consumption alters abundance of selected functional groups of the human gut microbiota and fecal short-chain fatty acid profiles in a cohort of overweight and obese women. J. Funct. Foods 2022, 93, 105089. [Google Scholar] [CrossRef]

- Shabbir, I.; Al-Asmari, F.; Saima, H.; Nadeem, M.T.; Ambreen, S.; Kasankala, L.M.; Khalid, M.Z.; Rahim, M.A.; Özogul, F.; Bartkiene, E.; et al. The Biochemical, Microbiological, Antioxidant and Sensory Characterization of Fermented Skimmed Milk Drinks Supplemented with Probiotics Lacticaseibacillus casei and Lacticaseibacillus rhamnosus. Microorganisms 2023, 11, 2523. [Google Scholar] [CrossRef]

- García-Burgos, M.; Moreno-Fernández, J.; Alférez, M.J.; Díaz-Castro, J.; López-Aliaga, I. New perspectives in fermented dairy products and their health relevance. J. Funct. Foods 2020, 72, 104059. [Google Scholar] [CrossRef]

- GII Global Information. Fermented Dairy Products Market by Product Type (Butter, Cheese, Kefir), Distribution Channel (Convenience Stores, Online Retail, Specialty Stores), Source, End-User, Packaging—Global Forecast 2025–2030. Available online: https://www.giiresearch.com/report/ires1576550-fermented-dairy-products-market-by-product-type.html (accessed on 12 April 2025).

- Haard, N.F.; Odunfa, S.A.; Lee, C.-H.; Quintero-Ramírez, R.; Lorence-Quiñones, A.; Wacher-Radarte, C. FERMENTED CEREALS. A GLOBAL PERSPECTIVE. 1999. Available online: https://www.fao.org/4/x2184e/x2184e00.htm (accessed on 13 April 2025).

- Ye, G.; Guan, L.; Zhang, M. Research progress on processing and nutritional properties of fermented cereals. J. Food Sci. Technol. 2025, 62, 197–212. [Google Scholar] [CrossRef]

- Houngbédji, M.; Jespersen, J.S.; Padonou, S.W.; Jespersen, L. Cereal-based fermented foods as microbiota-directed products for improved child nutrition and health in sub-Saharan Africa. Crit. Rev. Food Sci. Nutr. 2024, 1–22. [Google Scholar] [CrossRef]

- Kitessa, D.A. Review on effect of fermentation on physicochemical properties, anti-nutritional factors and sensory properties of cereal-based fermented foods and beverages. Ann. Microbiol. 2024, 74, 32. [Google Scholar] [CrossRef]

- Wise Guy Reports. Global Non-Alcoholic Fermented Cereal Beverage Market Research Reports (2024–2032). Available online: https://www.wiseguyreports.com/reports/non-alcoholic-fermented-cereal-beverage-market (accessed on 15 April 2025).

- Liu, L.; Li, G.; Cui, L.; Cai, R.; Yuan, Y.; Gao, Z.; Yue, T.; Wang, Z. The health benefits of fermented fruits and vegetables and their underlying mechanisms. Compr. Rev. Food Sci. Food Saf. 2024, 23, e70072. [Google Scholar] [CrossRef]

- Xu, J.; Peng, S.; Xiong, Y.; Zheng, Z.; Liu, M.; Xu, J.; Chen, W.; Liu, M.; Kong, J.; Wang, C.; et al. A review on fermented vegetables: Microbial community and potential upgrading strategy via inoculated fermentation. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13362. [Google Scholar] [CrossRef] [PubMed]

- Borrego-Ruiz, A.; González-Domenech, C.M.; Borrego, J.J. The Role of Fermented Vegetables as a Sustainable and Health-Promoting Nutritional Resource. Appl. Sci. 2024, 14, 10853. [Google Scholar] [CrossRef]

- Data Intelo. Fermented Soya Beans Market Report. 2025. Available online: https://dataintelo.com/report/global-fermented-soya-beans-market (accessed on 15 April 2025).

- Maicas, S. Advances in Wine Fermentation. Fermentation 2021, 7, 187. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, H.; Shuang, Q.; Xia, Y. Novel insights into flavor formation in whey fermented wine: A study of microbial metabolic networks. LWT 2024, 197, 115911. [Google Scholar] [CrossRef]

- World Population Review. Wine Producing Countries 2025. Available online: https://worldpopulationreview.com/country-rankings/wine-producing-countries (accessed on 16 April 2025).

- Loying, R.; Kalita, J.; Manna, P. Rice-Based Alcoholic Fermented Beverages of North-East India: Insight into Ethnic Preparation, Microbial Intervention, Ethnobotany, and Health Benefits. J. Food Biochem. 2024, 2024, 7769743. [Google Scholar] [CrossRef]

- Hans, S.; Zabetakis, I.; Lordan, R. The potential cardioprotective bioactive compounds in fermented alcoholic beverages: Mechanisms, challenges, and opportunities in beer and wine. Nutr. Res. 2024, 133, 108–126. [Google Scholar] [CrossRef]

- Şanlier, N.; Gökcen, B.B.; Sezgin, A.C. Health benefits of fermented foods. Crit. Rev. Food Sci. Nutr. 2019, 59, 506–527. [Google Scholar] [CrossRef] [PubMed]

- Read, J. Living Fermented Foods and Drinks. Oxford Research Encyclopedia of Food Studies. 17 April 2024. Available online: https://oxfordre.com/foodstudies/view/10.1093/acrefore/9780197762530.001.0001/acrefore-9780197762530-e-15 (accessed on 23 April 2025).

- Bhat, S.V.; Akhtar, R.; Amin, T. An Overview on the Biological Production of Vinegar. Int. J. Fermented Foods 2014, 3, 139–155. [Google Scholar] [CrossRef]

- Tamang, J.P.; Cotter, P.D.; Endo, A.; Han, N.S.; Kort, R.; Liu, S.Q.; Mayo, B.; Westerik, N.; Hutkins, R. Fermented foods in a global age: East meets West. Compr. Rev. Food Sci. Food Saf. 2020, 19, 184–217. [Google Scholar] [CrossRef]

- Coton, M.; Pawtowski, A.; Taminiau, B.; Burgaud, G.; Deniel, F.; Coulloumme-Labarthe, L.; Fall, A.; Daube, G.; Coton, E. Unraveling microbial ecology of industrial-scale Kombucha fermentations by metabarcoding and culture-based methods. FEMS Microbiol. Ecol. 2017, 93, fix048. [Google Scholar] [CrossRef]

- Tamang, J.P.; Watanabe, K.; Holzapfel, W.H. Review: Diversity of Microorganisms in Global Fermented Foods and Beverages. Front. Microbiol. 2016, 7, 377. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, P.; Dh, L.K.; Dhumal, C.; Panigrahi, S.S.; Choudhary, R. Traditional and ayurvedic foods of Indian origin. J. Ethn. Foods 2015, 2, 97–109. [Google Scholar] [CrossRef]

- Dong, L.; Li, Y. P09-010-24 Effects of Fresh and Fermented Poi, a Traditional Hawaiian Food, on Infection, Inflammation, and Lipid Metabolism in Caco-2 Cells. Curr. Dev. Nutr. 2024, 8, 102867. [Google Scholar] [CrossRef]

- Fabricio, M.F.; Schmidt, L.; Rother, P.D.H.; Augusti, P.R.; Candido, F.; Wagner, R.; Anzanello, M.J.; Rodrigues, E.; Ayub, M.A.Z. Targeted metabolomics of phenolic and volatile compounds during the fermentation of a potential probiotic tofu whey beverage. Food Chem. 2025, 478, 143689. [Google Scholar] [CrossRef]

- Oladipo, A.A.; Olatidoye, O.P.; Dickson, D.O. Development of Cassava Frying Machine for Local Garri Processors. IPS J. Nutr. Food Sci. 2025, 4, 352–357. [Google Scholar] [CrossRef]

- Ozdemir, S.; Gocmen, D.; Kumral, A.Y. A Traditional Turkish Fermented Cereal Food: Tarhana. Food Rev. Int. 2007, 23, 107–121. [Google Scholar] [CrossRef]

- Ozturkoglu-Budak, S.; Akal, H.C.; Türkmen, N. Use of kefir and buttermilk to produce an innovative quark cheese. J. Food Sci. Technol. 2021, 58, 74–84. [Google Scholar] [CrossRef] [PubMed]

- De Villa, B.D.M.; Domingo, T.M.M.; Ramirez, R.J.C.; Mercado, J.M.T. Explicating the culinary heritage significance of Filipino kakanin using bibliometrics (1934–2018). Int. J. Gastron. Food Sci. 2022, 28, 100522. [Google Scholar] [CrossRef]

- Yusuf, A.; Putra, T. Fermentation of Tapai and Alcohol Content Released From Tapai. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1053, 012050. [Google Scholar] [CrossRef]

- Alkaya, B.; Haytac, C.; Uçak, O.; Gökhan, H. Daily Probiotic Ayran Intake Reduces Gingival Inflammation: An Experimental Gingivitis Study. Oral Health Prev. Dent. 2024, 22, 511–518. [Google Scholar] [CrossRef]

- Hawaz, H.; Bottari, B.; Scazzina, F.; Carini, E. Eastern African traditional fermented foods and beverages: Advancements, challenges, and perspectives on food technology, nutrition, and safety. Compr. Rev. Food Sci. Food Saf. 2025, 24, e70137. [Google Scholar] [CrossRef] [PubMed]

- Santos, H.C.; Leonel, G.V.F.; da Silva Ramos, L.C.; Hudson, E.A.; Pinto, M.S.; de Paula Rezende, J.; Vidigal, M.C.T.R.; dos Santos Pires, A.C. Enhancing dairy sustainability: Rheological, sensory, and physical-chemical properties of low-fat fermented beverages incorporating buttermilk. J. Clean. Prod. 2024, 443, 141159. [Google Scholar] [CrossRef]

- Esepenok, K.; Zemtsova, L.; Gorbachova, M. Development of a recipe and technology for the production of sour cream with sea buckthorn juice added. AIP Conf. Proc. 2024, 3184, 020040. [Google Scholar] [CrossRef]

- Rolim, M.E.; Fortes, M.I.; Von Frankenberg, A.; Duarte, C.K. Consumption of sourdough bread and changes in the glycemic control and satiety: A systematic review. Crit. Rev. Food Sci. Nutr. 2024, 64, 801–816. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, Y.; Jay-Russell, M.; Lemay, D.G.; Mills, D.A. Reservoirs of antimicrobial resistance genes in retail raw milk. Microbiome 2020, 8, 99. [Google Scholar] [CrossRef]

- Pal, M. Shrikhand: A Delicious Fermented Dairy Product of India. Beverage Food World 2018, 45, 39–40. [Google Scholar]

- Chen, W. Demystification of fermented foods by omics technologies. Curr. Opin. Food Sci. 2022, 46, 100845. [Google Scholar] [CrossRef]

- Fu, J.; Chen, L.; Yang, S.; Li, Y.; Jin, L.; He, X.; He, L.; Ao, X.; Liu, S.; Liu, A.; et al. Metagenome and analysis of metabolic potential of the microbial community in pit mud used for Chinese strong-flavor liquor production. Food Res. Int. 2021, 143, 110294. [Google Scholar] [CrossRef]

- Coughlan, L.M.; Cotter, P.D.; Hill, C.; Alvarez-Ordóñez, A. Biotechnological applications of functional metagenomics in the food and pharmaceutical industries. Front. Microbiol. 2015, 6, 672. [Google Scholar] [CrossRef]

- Liu, X.-F.; Liu, C.-J.; Zeng, X.-Q.; Zhang, H.-Y.; Luo, Y.-Y.; Li, X.-R. Metagenomic and metatranscriptomic analysis of the microbial community structure and metabolic potential of fermented soybean in Yunnan Province. Food Sci. Technol. 2020, 40, 18–25. [Google Scholar] [CrossRef]

- Chen, Q.; Shi, J.; Mu, B.; Chen, Z.; Dai, W.; Lin, Z. Metabolomics combined with proteomics provides a novel interpretation of the changes in nonvolatile compounds during white tea processing. Food Chem. 2020, 332, 127412. [Google Scholar] [CrossRef] [PubMed]

- Alseekh, S.; Aharoni, A.; Brotman, Y.; Contrepois, K.; D’auria, J.; Ewald, J.; Ewald, J.C.; Fraser, P.D.; Giavalisco, P.; Hall, R.D.; et al. Mass spectrometry-based metabolomics: A guide for annotation, quantification and best reporting practices. Nat. Methods 2021, 18, 747–756. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Shi, H.; An, F.; Lin, H.; Li, M.; Wu, J.; Wu, R. Advances in fermented foods revealed by multi-omics: A new direction toward precisely clarifying the roles of microorganisms. Front. Microbiol. 2022, 13, 1044820. [Google Scholar] [CrossRef] [PubMed]

- Mannaa, M.; Han, G.; Seo, Y.-S.; Park, I. Evolution of Food Fermentation Processes and the Use of Multi-Omics in Deciphering the Roles of the Microbiota. Foods 2021, 10, 2861. [Google Scholar] [CrossRef]

- Chen, G.; Chen, C.; Lei, Z. Meta-omics insights in the microbial community profiling and functional characterization of fermented foods. Trends Food Sci. Technol. 2017, 65, 23–31. [Google Scholar] [CrossRef]

- An, F.; Li, M.; Zhao, Y.; Zhang, Y.; Mu, D.; Hu, X.; You, S.; Wu, J.; Wu, R. Metatranscriptome-based investigation of flavor-producing core microbiota in different fermentation stages of dajiang, a traditional fermented soybean paste of Northeast China. Food Chem. 2021, 343, 128509. [Google Scholar] [CrossRef]

- Ferrocino, I.; Rantsiou, K.; McClure, R.; Kostic, T.; de Souza, R.S.C.; Lange, L.; FitzGerald, J.; Kriaa, A.; Cotter, P.; Maguin, E.; et al. The need for an integrated multi-OMICs approach in microbiome science in the food system. Compr. Rev. Food Sci. Food Saf. 2023, 22, 1082–1103. [Google Scholar] [CrossRef]

- Lee, S.H.; Whon, T.W.; Roh, S.W.; Jeon, C.O. Unraveling microbial fermentation features in kimchi: From classical to meta-omics approaches. Appl. Microbiol. Biotechnol. 2020, 104, 7731–7744. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.-K.; Tang, Y.-M.; Guo, X.-J.; Zhao, K.; Penttinen, P.; Tian, X.-H.; Zhang, X.-Y.; Ren, D.-Q.; Zhang, X.-P. Structural and Functional Changes in Prokaryotic Communities in Artificial Pit Mud during Chinese Baijiu Production. mSystems 2020, 5, e00829-19. [Google Scholar] [CrossRef]

- Pan, M.; Barrangou, R. Combining omics technologies with CRISPR-based genome editing to study food microbes. Curr. Opin. Biotechnol. 2020, 61, 198–208. [Google Scholar] [CrossRef]

- Wu, Q.; Chu, H.; Padmanabhan, A.; Shah, N.P. Functional Genomic Analyses of Exopolysaccharide-Producing Streptococcus thermophilus ASCC 1275 in Response to Milk Fermentation Conditions. Front. Microbiol. 2019, 10, 1975. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Lin, F.; Ye, C.; Aihemaitijiang, S.; Halimulati, M.; Huang, X.; Jiang, Z.; Li, L.; Zhang, Z. Multi-omics analysis reveals therapeutic effects of Bacillus subtilis-fermented Astragalus membranaceus in hyperuricemia via modulation of gut microbiota. Food Chem. 2022, 399, 133993. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Tao, Y.; Jin, J.; Tong, S.; Li, S.; Zhang, L. Multi-omics analyses of the mechanism for the formation of soy sauce-like and soybean flavor in Bacillus subtilis BJ3-2. BMC Microbiol. 2022, 22, 142. [Google Scholar] [CrossRef]

- Unno, R.; Suzuki, T.; Matsutani, M.; Ishikawa, M. Evaluation of the Relationships Between Microbiota and Metabolites in Soft-Type Ripened Cheese Using an Integrated Omics Approach. Front. Microbiol. 2021, 12, 681185. [Google Scholar] [CrossRef]

- Hu, S.; He, C.; Li, Y.; Yu, Z.; Chen, Y.; Wang, Y.; Ni, D. Changes of fungal community and non-volatile metabolites during pile-fermentation of dark green tea. Food Res. Int. 2021, 147, 110472. [Google Scholar] [CrossRef]

- Song, H.S.; Whon, T.W.; Kim, J.; Lee, S.H.; Kim, J.Y.; Kim, Y.B.; Choi, H.-J.; Rhee, J.-K.; Roh, S.W. Microbial niches in raw ingredients determine microbial community assembly during kimchi fermentation. Food Chem. 2020, 318, 126481. [Google Scholar] [CrossRef] [PubMed]

- Medina, E.; Ruiz-Bellido, M.; Romero-Gil, V.; Rodríguez-Gómez, F.; Montes-Borrego, M.; Landa, B.; Arroyo-López, F. Assessment of the bacterial community in directly brined Aloreña de Málaga table olive fermentations by metagenetic analysis. Int. J. Food Microbiol. 2016, 236, 47–55. [Google Scholar] [CrossRef]

- Zhao, G.; Yao, Y.; Hao, G.; Fang, D.; Yin, B.; Cao, X.; Chen, W. Gene regulation in Aspergillus oryzae promotes hyphal growth and flavor formation in soy sauce koji. RSC Adv. 2015, 5, 24224–24230. [Google Scholar] [CrossRef]

- Zheng, Q.; Lin, B.; Wang, Y.; Zhang, Q.; He, X.; Yang, P.; Zhou, J.; Guan, X.; Huang, X. Proteomic and high-throughput analysis of protein expression and microbial diversity of microbes from 30- and 300-year pit muds of Chinese Luzhou-flavor liquor. Food Res. Int. 2015, 75, 305–314. [Google Scholar] [CrossRef]

- Chun, B.H.; Han, D.M.; Kim, K.H.; Jeong, S.E.; Park, D.; Jeon, C.O. Genomic and metabolic features of Tetragenococcus halophilus as revealed by pan-genome and transcriptome analyses. Food Microbiol. 2019, 83, 36–47. [Google Scholar] [CrossRef]

- Sirén, K.; Mak, S.S.T.; Fischer, U.; Hansen, L.H.; Gilbert, M.T.P. Multi-omics and potential applications in wine production. Curr. Opin. Biotechnol. 2019, 56, 172–178. [Google Scholar] [CrossRef] [PubMed]

- Wen, L.; Yang, L.; Chen, C.; Li, J.; Fu, J.; Liu, G.; Kan, Q.; Ho, C.-T.; Huang, Q.; Lan, Y.; et al. Applications of multi-omics techniques to unravel the fermentation process and the flavor formation mechanism in fermented foods. Crit. Rev. Food Sci. Nutr. 2024, 64, 8367–8383. [Google Scholar] [CrossRef] [PubMed]

- Eastham, J.L.; Leman, A.R. Precision fermentation for food proteins: Ingredient innovations, bioprocess considerations, and outlook—A mini-review. Curr. Opin. Food Sci. 2024, 58, 101194. [Google Scholar] [CrossRef]

- FAO. Cell-Based Food and Precision Fermentation Products, Safety and the Future Role. Stakeholder Roundtable Meeting Report, Shanghai, China, 6 November 2023; FAO: Rome, Italy, 2023; Available online: https://openknowledge.fao.org/handle/20.500.14283/cc7157en (accessed on 17 April 2025).

- Chai, K.F.; Ng, K.R.; Samarasiri, M.; Chen, W.N. Precision fermentation to advance fungal food fermentations. Curr. Opin. Food Sci. 2022, 47, 100881. [Google Scholar] [CrossRef]

- Knychala, M.M.; Boing, L.A.; Ienczak, J.L.; Trichez, D.; Stambuk, B.U. Precision Fermentation as an Alternative to Animal Protein, a Review. Fermentation 2024, 10, 315. [Google Scholar] [CrossRef]

- Augustin, M.A.; Hartley, C.J.; Maloney, G.; Tyndall, S. Innovation in precision fermentation for food ingredients. Crit. Rev. Food Sci. Nutr. 2024, 64, 6218–6238. [Google Scholar] [CrossRef]

- Lee, Y.-G.; Kim, B.-Y.; Bae, J.-M.; Wang, Y.; Jin, Y.-S. Genome-edited Saccharomyces cerevisiae strains for improving quality, safety, and flavor of fermented foods. Food Microbiol. 2022, 104, 103971. [Google Scholar] [CrossRef]

- Holt, S.; Cordente, A.G.; Williams, S.J.; Capone, D.L.; Jitjaroen, W.; Menz, I.R.; Curtin, C.; Anderson, P.A. Engineering Saccharomyces cerevisiae To Release 3-Mercaptohexan-1-ol during Fermentation through Overexpression of an S. cerevisiae Gene, STR3, for Improvement of Wine Aroma. Appl. Environ. Microbiol. 2011, 77, 3626–3632. [Google Scholar] [CrossRef]

- Denby, C.M.; Li, R.A.; Vu, V.T.; Costello, Z.; Lin, W.; Chan, L.J.G.; Williams, J.; Donaldson, B.; Bamforth, C.W.; Petzold, C.J.; et al. Industrial brewing yeast engineered for the production of primary flavor determinants in hopped beer. Nat. Commun. 2018, 9, 965. [Google Scholar] [CrossRef]

- Ibarra-Sánchez, L.A.; Van Tassell, M.L.; Miller, M.J. Antimicrobial behavior of phage endolysin PlyP100 and its synergy with nisin to control Listeria monocytogenes in Queso Fresco. Food Microbiol. 2018, 72, 128–134. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, Y.; Li, L.; Jiang, X.; Chen, Z.; Zhao, F.; Yi, Y. Biosynthesis and Production of Class II Bacteriocins of Food-Associated Lactic Acid Bacteria. Fermentation 2022, 8, 217. [Google Scholar] [CrossRef]

- Aro, N.; Ercili-Cura, D.; Andberg, M.; Silventoinen, P.; Lille, M.; Hosia, W.; Nordlund, E.; Landowski, C.P. Production of bovine beta-lactoglobulin and hen egg ovalbumin by Trichoderma reesei using precision fermentation technology and testing of their techno-functional properties. Food Res. Int. 2023, 163, 112131. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.I.; Li, Y.; Pan, J.; Liu, F.; Dai, H.; Fu, Y.; Huang, T.; Farooq, S.; Zhang, H. Collagen and gelatin: Structure, properties, and applications in food industry. Int. J. Biol. Macromol. 2024, 254, 128037. [Google Scholar] [CrossRef]

- Xue, J.; Zhou, J.; Li, J.; Du, G.; Chen, J.; Wang, M.; Zhao, X. Systematic engineering of Saccharomyces cerevisiae for efficient synthesis of hemoglobins and myoglobins. Bioresour. Technol. 2023, 370, 128556. [Google Scholar] [CrossRef]

- Devaere, J.; De Winne, A.; Dewulf, L.; Fraeye, I.; Šoljić, I.; Lauwers, E.; de Jong, A.; Sanctorum, H. Improving the Aromatic Profile of Plant-Based Meat Alternatives: Effect of Myoglobin Addition on Volatiles. Foods 2022, 11, 1985. [Google Scholar] [CrossRef]

- Cho, S.; Jung, S.Y.; Eun, H.; Lee, S.Y. Precision fermentation for producing food ingredients. Curr. Opin. Food Sci. 2025, 61, 101242. [Google Scholar] [CrossRef]

- Ajayeoba, T.A.; Ijabadeniyi, O.A. Transforming Food for the Future: Precision Fermentation as a Key to Sustainability, Nutrition, and Health. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5119686 (accessed on 19 March 2025). [CrossRef]

- Japanese Brewery Tries AI-Assisted Sake Making. Kyodo News. 2 June 2018. Available online: https://english.kyodonews.net/news/2018/06/a770f2fc94a6-feature-japanese-brewery-tries-ai-assisted-sake-making.html (accessed on 20 March 2025).

- Zhu, H.; Liu, F.; Ye, Y.; Chen, L.; Liu, J.; Gui, A.; Zhang, J.; Dong, C. Application of machine learning algorithms in quality assurance of fermentation process of black tea—Based on electrical properties. J. Food Eng. 2019, 263, 165–172. [Google Scholar] [CrossRef]

- Dongre, S.M.; Patel, A.M. Sustainable Food Systems: The Role of AI and Microorganisms in Korean Fermented Foods. Int. J. Sci. Eng. Res. 2025, 13, 17–23. [Google Scholar]

- Zhao, S.; Jiao, T.; Adade, S.Y.-S.S.; Wang, Z.; Ouyang, Q.; Chen, Q. Digital twin for predicting and controlling food fermentation: A case study of kombucha fermentation. J. Food Eng. 2025, 393, 112467. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Sadler, N.C.; Egbert, R.G.; Anderton, C.R.; Hofmockel, K.S.; Jansson, J.K.; Song, H.-S. Deep learning predicts microbial interactions from self-organized spatiotemporal patterns. Comput. Struct. Biotechnol. J. 2020, 18, 1259–1269. [Google Scholar] [CrossRef]

- Sudarsini, B.; Venkateswarulu, T.C.; Krupanidhi, S.; Sumalatha, B.; Indira, M. Advancing Fermented Food Products: Exploring Bioprocess Technologies and Overcoming Challenges. Food Bioprocess Technol. 2024, 17, 3461–3482. [Google Scholar] [CrossRef]

- EL Sheikha, A.F. Why Fermented Foods are the Promising Food Trends in the Future? Curr. Res. Nutr. Food Sci. J. 2022, 10, 827–829. [Google Scholar] [CrossRef]

- Capozzi, V.; Fragasso, M.; Bimbo, F. Microbial Resources, Fermentation and Reduction of Negative Externalities in Food Systems: Patterns toward Sustainability and Resilience. Fermentation 2021, 7, 54. [Google Scholar] [CrossRef]

- Rastogi, Y.R.; Thakur, R.; Thakur, P.; Mittal, A.; Chakrabarti, S.; Siwal, S.S.; Thakur, V.K.; Saini, R.V.; Saini, A.K. Food fermentation—Significance to public health and sustainability challenges of modern diet and food systems. Int. J. Food Microbiol. 2022, 371, 109666. [Google Scholar] [CrossRef] [PubMed]

- Skowron, K.; Budzyńska, A.; Grudlewska-Buda, K.; Wiktorczyk-Kapischke, N.; Andrzejewska, M.; Wałecka-Zacharska, E.; Gospodarek-Komkowska, E. Two Faces of Fermented Foods—The Benefits and Threats of Its Consumption. Front. Microbiol. 2022, 13, 845166. [Google Scholar] [CrossRef]

| Fermented Food | Substrate for Fermentation | Region | Microorganisms Used | Functional Components | Health Benefits | References |

|---|---|---|---|---|---|---|

| Vinegar | Alcoholic fermentation of fruit juice/grain mash followed by acetic acid fermentation | World-wide | Saccharomyces cerevisiae, Acetobacter aceti, Gluconobacter, and Komagataeibacter | Acetic acid, polyphenols, organic acids, amino acids, enzymes, minerals, and probiotics | Blood sugar regulation, antioxidant activity, digestion support, and antimicrobial effects | [59] |

| Dosa | Rice and black gram | India | Lactobacillus fermentum and Saccharomyces cerevisiae | Probiotic bacteria and organic acids | Supports digestion and improves nutrient absorption | [20] |

| Dawadawa | Locust beans | West Africa | Bacillus subtilis and Bacillus licheniformis | Peptides and antioxidants | Enhances protein digestibility and antimicrobial effects | [60] |

| Kinema | Soybeans | Nepal | Bacillus subtilis | Polyglutamic acid and isoflavones | Rich in bioactive peptides and supports digestion | [60] |

| Cheonggukjang | Soybeans | Korea | Bacillus subtilis | Polyglutamic acid and isoflavones | Anti-inflammatory and gut microbiota modulation | [60] |

| Kombucha | Sweetened tea | China and world-wide | Saccharomyces cerevisiae and Gluconacetobacter xylinus | Organic acids, polyphenols, and probiotic bacteria | Detoxification, gut health, and antioxidant | [61] |

| Amasi | Cow milk | Southern Africa | Lactococcus lactis and Leuconostoc mesenteroides | Organic acids and probiotic bacteria | Gut microbiota enhancement and immune support | [62] |

| Lassi | Fermented cow/buffalo milk | India | Lactobacillus spp. | Probiotic bacteria and organic acids | Enhances gut flora and cooling effect | [63] |

| Chhaang | Barley, millet, or rice | Nepal and Tibet | Wickerhamomyces anomalus | Polyphenols and organic acids | Antioxidant and supports gut microbiota | [55] |

| Poi | Corm of taro plant | Hawaii | Lactobacillus spp. and Geotrichum spp. | Organic acids and probiotic bacteria | Improves gut health and prebiotic properties | [64] |

| Sufu | Soybean curd | China and Taiwan | Actinomucor elegans and Rhizopus spp. | Isoflavones and peptides | Cardioprotective and antioxidant | [60] |

| Idli | Rice and black gram | India | Lactobacillus fermentum and Leuconostoc spp. | Probiotic bacteria and organic acids | Enhances digestibility and nutrient bioavailability | [20] |

| Puto | Rice flour | Philippines | Saccharomyces cerevisiae and Lactic acid bacteria | Probiotic bacteria and organic acids | Supports digestion and enhances nutrient uptake | [60] |

| Tofu | Dried soybeans | China and Japan | Lactobacillus spp. and Aspergillus spp. | Isoflavones and peptides | Cardioprotective and gut microbiota modulation | [65] |

| Garri | Cassava tubers | Nigeria | Lactobacillus plantarum and Saccharomyces spp. | Cyanide-reducing enzymes and organic acids | Detoxification and gut health | [66] |

| Tarhana | Yoghurt, flour, and vegetables | Turkey | Lactobacillus delbrueckii and Saccharomyces cerevisiae | Organic acids and probiotic bacteria | Enhances gut health and immune boosting | [67] |

| Kvarg (Quark) | Milk | Sweden | Lactococcus lactis and Streptococcus thermophilus | Probiotic bacteria and organic acids | Gut microbiota enhancement | [68] |

| Puto Bumbong | Glutinous rice, Pirurutong | Philippines | Saccharomyces cerevisiae | Probiotic bacteria and organic acids | Improves digestion and antioxidant | [69] |

| Tapai | Cassava or rice | Southeast Asia | Saccharomyces cerevisiae and Rhizopus spp. | Organic acids and probiotic bacteria | Enhances digestion and prebiotic benefits | [70] |

| Ayran | Yoghurt | Turkey | Lactobacillus bulgaricus and Streptococcus thermophilus | Probiotic bacteria and organic acids | Gut microbiota support and cooling effect | [71] |

| Togwa | Maize flour and finger millet | Tanzania | Lactobacillus plantarum and Saccharomyces cerevisiae | Organic acids and probiotic bacteria | Digestive support and immune enhancement | [72] |

| Buttermilk | Fermented milk | USA, Europe, and India | Lactococcus lactis and Leuconostoc spp. | Probiotic bacteria and lactic acid | Supports gut health and reduces cholesterol | [73] |

| Sour Cream | Fermented regular cream | USA and Europe | Lactococcus lactis and Streptococcus thermophilus | Probiotic bacteria and organic acids | Enhances digestion and gut microbiome support | [74] |

| Sourdough | Flour | Europe and USA | Lactobacillus sanfranciscensis and Saccharomyces cerevisiae | Organic acids and exopolysaccharides | Improves digestibility and supports gut microbiota | [75] |

| Clabber | Milk | Southern USA | Lactobacillus spp. and Streptococcus spp. | Probiotic bacteria and lactic acid | Enhances gut health and rich in probiotics | [76] |

| Shrikhand | Yoghurt | India | Lactobacillus spp. | Probiotic bacteria and lactic acid | Enhances digestion and rich in probiotics | [77] |

| Omics Technique | Microorganism Used | Applications in Food Fermentation Industry | References |

|---|---|---|---|

| Metagenomics and metatranscriptomics | Providencia stuartii | To understand the metabolic potential and microbial community structure of fermented soybeans | [81] |

| Transcriptomics | Aspergillus oryzae | To analyze the gene expression related to enzyme production in Koji (Soy Sauce) fermentation | [99] |

| Multi-omics | Bacillus subtilis BJ3-2 | To investigate the fermentative strains to gain a better understanding of soybean flavour compounds and Soy Sauce-like flavor formation | [94] |

| Metatranscriptomics | Lactobacillus Tetragenococcus | To investigate the role of microorganisms in the flavour development of Dajiang during fermentation | [87] |

| Metagenomics and metabolomics | Moulds and bacteria | To confirm the microbes impacted by the variations in ripening techniques and to elucidate the relationship between the metabolites and microbiota of cheese ripened by surface mould and cheese ripened by bacterial smear | [95] |

| Proteomics | Methanobacterium spp. and Clostridium spp. | To compare the levels of protein expression in the 30- and 300-year pit muds of Luzhou flavour liquor | [100] |

| Metabolomics | Lactobacillus plantarum | To monitor the citric acid quantity in batch fermentation for production of Kimchi | [86] |

| Metabolomics and proteomics | Mixed fungi and Aspergillus spp. | To assess the change in mechanisms of non-volatile compounds during the white tea (Camellia sinensis) fermentation process | [82] |

| Transcriptomics | Chromohalobacter, Halomonas, Marinobacter, Debaryomyces, and Wickerhamomyces | To explore role of microorganisms in the development of the flavour and taste of fermented gajang (Soy Sauce) | [101] |

| Genomics, proteomics, and metabolomics | Saccharomyces cerevisiae and Oenococcus oeni. | To investigate the relationships between microbial communities and the factory environment during wine fermentation | [102] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, A.; Kumar, S. Exploring the Functionality of Microbes in Fermented Foods: Technological Advancements and Future Directions. Fermentation 2025, 11, 300. https://doi.org/10.3390/fermentation11060300

Singh A, Kumar S. Exploring the Functionality of Microbes in Fermented Foods: Technological Advancements and Future Directions. Fermentation. 2025; 11(6):300. https://doi.org/10.3390/fermentation11060300

Chicago/Turabian StyleSingh, Akanksha, and Sanjay Kumar. 2025. "Exploring the Functionality of Microbes in Fermented Foods: Technological Advancements and Future Directions" Fermentation 11, no. 6: 300. https://doi.org/10.3390/fermentation11060300

APA StyleSingh, A., & Kumar, S. (2025). Exploring the Functionality of Microbes in Fermented Foods: Technological Advancements and Future Directions. Fermentation, 11(6), 300. https://doi.org/10.3390/fermentation11060300