Abstract

Despite the current appreciation of pulque as a probiotic fermented beverage, pulque has been also regarded as a poor-quality product, particularly due to the lack of sanitary control during its elaboration. To address this problem, a semi-continuous fermentation system was established, emulating the artisanal production process. Microfiltration-sterilized aguamiel was employed as the substrate, whereas a good-quality pulque was used as the fermentation inoculum. During the fermentation, the physicochemical, microbiological (lactic acid and Leuconostoc-type bacteria and yeasts) and sensory characteristics of the must were monitored. The isolated microorganisms were identified by molecular biology and MALDI-MS techniques. The sterilization of aguamiel by microfiltration did not negatively affect its physicochemical attributes. After 6–8 days of operation of the semi-continuous bioreactor, the fermentation reached a quasi-stationary state considering most of the parameters monitored during the experiment. The final fermentation product presented similar physicochemical, microbial and sensory properties to those of the pulque inoculum. The genera identified were Leuconostoc, Lentilactobacillus, Lactobacillus, Liquorilactobacillus, Fructilactobacillus and Saccharomyces. The strains Lentilactobacillus diolivorans and Liquorilactobacillus capillatus and uvarum have not been previously isolated from pulque. In conclusion, the fermentation system developed in this work was effective to standardize the quality of pulque while preserving the positive attributes of the artisanal process, thus harnessing the probiotic properties of pulque.

1. Introduction

Pulque is a traditional Mexican fermented alcoholic beverage, not distilled, viscous in appearance, white in color and slightly acidic (pH~4.5), obtained by the fermentation of aguamiel, the sap extracted from maguey’s pines (agave). Pulque production in Mexico has gone through several critical stages, up to the point of almost disappearing. The first crisis occurred before the War of Independence, during which time its consumption and production were prohibited due to sanitary concerns. The second major collapse occurred during the Mexican Revolution, when the Law of Taxes on Aguamiel and Fermentation Products was decreed, which resulted in the positioning of beer as the most popular beverage in Mexico. After this stage, and until the 20th century, the decline in the production and consumption of pulque continued; it was only found in rural areas and in pulquerias located in the large Mexican cities frequented mainly by low-income consumers [1].

Nevertheless, in the last two decades, several studies have highlighted the benefits of pulque and concluded that this fermented product can be considered a healthy beverage, as it is a good source of essential amino acids, vitamins and energy [1]. In addition to the different nutritional benefits that have been associated with the consumption of aguamiel and pulque, recent reports have documented that pulque consumption can prevent or control several human diseases, particularly those related to gastrointestinal disorders, thus its use in traditional Mexican medicine. Currently, with the recent increase in studies on functional foods, these beneficial effects have been attributed to the probiotic and prebiotic activities of the components of this beverage [1,2].

Despite the resurgence of the scientific and commercial interest for pulque, one factor that has greatly reduced both the demand and the production of this product is the negative perception of some consumers towards pulquerias and, in some cases, regarding pulque itself [3,4]. One of the main reasons for this is that pulque has been perceived as a poor-quality product principally due to concerns about its sanitary safety. The quality of pulque is related to its physicochemical, sensory, microbiological and sanitary attributes. In this regard, the fermentation practices used for pulque production are very critical in terms of the quality of the final product. However, since pulque is produced almost invariably in an artisanal manner, there is a lack of control of most of the parameters of the fermentation process, which makes the standardization of the quality of pulque a very difficult task [5]. Accordingly, the production of pulque with poor quality, especially regarding its sanitary safety, hampers its commercial development and the exploitation of the beneficial properties of the beverage, such as its prebiotic and probiotic attributes.

The traditional process for pulque production begins with the extraction of aguamiel, which is harvested from mature agaves (between 7 and 10 years old) that are about to blossom and produce a flowering tree called quiote. The capping of the plant is usually done before the sprouting of the stem of the maguey (quiote) [1]. To produce the inoculum or seed for pulque fermentation, a small amount of fresh aguamiel is allowed to ferment in a dedicated vat. Subsequently, small amounts of fresh aguamiel are added to the must until the desired inoculum volume is obtained. After this, the inoculum is poured into the fermentation vat, and fresh aguamiel is added periodically (regularly at 12-h time intervals) in a fed-batch feeding regime until reaching a broth volume of approximately three-quarters of the fermentation vat [1]. Following this, it is a common practice among pulque producers to carry out 12-h fermentation cycles, in which a volume of pulque is harvested from the fermentation tank and the same volume of fresh aguamiel is added. These pulque–aguamiel volume exchanges, which can vary from one-third to one-fourth of the total fermentation volume or less, depending on the pulque producer, are synchronized with the times of aguamiel collection and agave scraping of the plant in the early morning (e.g., 5 or 6 a.m.) and afternoon (e.g., 5 or 6 p.m.) [5].

The artisanal production of pulque using the procedure described above can be regarded in the optics of fermentation engineering as a semi-continuous process. The fermentation process can continue for up to 6 months or even for many years, unless there is a contamination problem that produces flavors and odors that are not typical of pulque. Currently, there are no reports in the literature of a systematic study using a semi-continuous reactor for the production of pulque, and in general, very few reports about the use of semi-continuous processes applied to the production of fermented foods have been reported. Semi-continuous fermentation processes are characterized by starting in a dynamic state with regards to the composition of the fermentation medium, in which eventually the most important parameters of the process become constant, considering the different sequential batch cycles. A pseudo-steady-state process is achieved through the regular volume exchanges of fermentation broth and aguamiel substrate that are performed for every sequential batch [6,7,8]. In this regard, Lee et al. [6] reported the production of onion vinegar using a semi-continuous fermentation process with the strain Acetobacter orientalis, which consisted of three sequential batch cycles. The authors reported that, after 24 and 48 h of fermentation, concentrations of around 4.6% of acetic acid were reached, with a final fermentation efficiency of 76.7%. The authors concluded that this process significantly reduced the fermentation time in comparison with the submerged batch process that has been commonly used for onion fermentation.

On the other hand, to ensure the quality and innocuousness of the final fermentation products, these processes must be carried out under aseptic conditions using sterile substrates. The use of aseptic processes in bioprocesses prevents microorganisms other than the initial inoculum from entering the reactor. In this regard, thermal processes constitute the most widely used method for the sterilization of foods and beverages, in which the product to be sterilized is heated at a defined temperature for a certain period of time. However, the main disadvantage of using thermal processes lies in the loss of nutrients and the production of detrimental changes in the sensory characteristics of the fermentation products. In this regard, microfiltration allows the sterilization of food products while preserving their physicochemical and functional qualities, due to their high selectivity and low operating temperatures [9]. Currently, microfiltration is being used for a wide range of applications in the wine industry to obtain quality products by using aseptic fermentation processes [10]. Carneiro et al. [11] used crossflow microfiltration for the cold sterilization and clarification of pineapple juice. This process was carried out on a tubular polyethersulfone membrane with a nominal pore size of 0.3 µm. The authors reported that microbiological tests were carried out to the clarified juice at 7-day intervals, resulting in a good-quality pineapple juice that complied with local health standards for juices and beverages.

The main advantage of using microfiltration for the production of pulque is that the sterilization of aguamiel is achieved without causing changes to the sensory characteristics of the product, thus allowing the implementation of an aseptic fermentation process. Therefore, the main objective of this work was to improve and standardize the overall quality of pulque by evaluating the microbial, physicochemical and sensory dynamics of pulque produced using an aseptic semi-continuous process in a quasi-steady state with the use of microfiltration-sterilized aguamiel as the fermentation substrate.

2. Materials and Methods

2.1. Raw Material

The pulque inoculum (a mature fermented pulque) and the substrate (aguamiel) were generously provided by Mr. Raymundo Ruiz, a pulque producer of Tinacal San Cristobal, located in the region of the Altiplanicie Pulquera, Municipality of Singuilucan, State of Hidalgo, Mexico (19°59′20″ N, 98°27′56″ W, altitude: 2588 m.a.s.l.). The collection of the pulque inoculum for the 2 fermentations performed in this work was carried out in the summer of 2021. The aguamiel employed in the first semi-continuous reactor (Batch 1) was collected on the same date, whereas the aguamiel for the second semi-continuous fermentation was obtained in the following winter (Batch 2). Samples were collected in previously sterilized jars and transported in a cooler. Immediately upon arrival to the laboratory, physicochemical analyses of the aguamiel and pulque inoculum were performed. Subsequently, the samples of aguamiel and pulque inoculum were subjected to freezing at −20 and −80 °C, respectively, for subsequent microbiological analyses and for the pulque fermentation process.

2.2. Aseptic Microfiltration of Aguamiel

The sterilization of aguamiel for its use as the fermentation substrate for pulque production was carried out in a Pellicon 2 Mini crossflow filtration module (Millipore, St. Louis, MO, USA) using a Pellicon 2 Mini microfiltration membrane cartridge, Biomax-10 (Millipore, USA) with a nominal pore size of 0.45 μm. During the process, the aguamiel fed was maintained at a temperature of 40 °C, and it was pumped in a recirculation mode at a constant flow rate of 400 mL/min.

The sterilization of the membrane equipment was performed by recirculating a sodium hypochlorite solution (200 ppm) for 15 min. To eliminate chlorine residues, sterile RO water was flushed through the membrane system for 10 min. The microfiltered aguamiel was collected in previously sterilized bottles. The sterile aguamiel was kept refrigerated until its further use. The sterility of the microfiltered aguamiel was verified using the spread plate culture method of an undiluted aguamiel sample using plate count agar in triplicate.

2.3. Semi-Continuous Process for Pulque Production

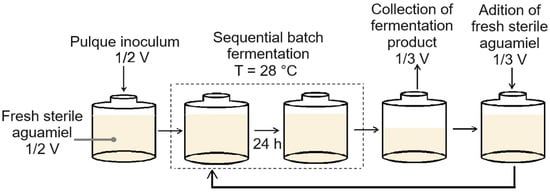

A bioreactor with a capacity of 500 mL was used. In accordance with the practices of artisanal producers, the fermentation process was carried out using 50% of ultra-frozen good-quality mature pulque, which was employed as the initial inoculum, and 50% of aguamiel previously sterilized by microfiltration as the fermentation substrate (1:1 ratio). A diagram of the semi-continuous process is depicted in Figure 1. The fermentation was carried out under aseptic conditions at a constant temperature of 28 °C without agitation. The semi-continuous reactor was performed by aseptically harvesting 1/3 of the volume of the fermented product and subsequently replacing it with the same volume of sterile fresh aguamiel. This pulque–aguamiel exchange was performed every 24 h, and the fermentation was continued until the main monitored parameters of the fermented product reached a quasi-steady state. Samples of the fermentation products were collected at every semi-continuous cycle (sequential batch) for physicochemical and microbiological analysis, as described in Section 2.4 and Section 2.7. Two independent experimental runs of the semi-continuous fermentation process for pulque production were carried out in this work.

Figure 1.

Diagram of the pulque production process using a semi-continuous reactor under aseptic conditions with microfiltration-sterilized aguamiel. V: broth reactor volume; T: fermentation temperature.

2.4. Physicochemical Characterization of Raw Materials and Products of the Pulque Fermentation Process

The following physicochemical tests were carried out on the aguamiel used as the fermentation substrate and on the pulque employed as the fermentation inoculum, as well as on the samples of the fermentation product harvested throughout the semi-continuous reactor process. Samples of aguamiel were collected before and after the fresh aguamiel was subjected to membrane microfiltration for cold sterilization. The semi-continuous reactor was monitored by collecting samples every 24 h. Color analysis of aguamiel, pulque and fermentation product samples were carried out using an UltraScan Vis spectrophotometric colorimeter (HunterLab, Reston, VA, USA) with illuminant D65, an area view of 9.525 mm and a standard observer of 8°, and the results were reported according to the CIE L*a*b* color space. In addition, the pH, total acidity, total soluble solids (°Brix) and total solids were determined by the standard methods. The tests for the total reducing sugars, fermentable sugars and ethanol content are described below. The analyses of the samples were performed in triplicate.

2.4.1. Total Reducing Sugars

The concentration of total sugars was determined using the Dubois method [12] with some modifications. For the determination, 150 μL of sample was mixed with 500 μL of 5% phenol. Subsequently, 2.5 mL of concentrated H2SO4 was added. The mixture was allowed to stand for 10 min at room temperature; after which, it was placed in a water bath at 25 °C for 20 min. Finally, the samples were analyzed in a Genesys 50 UV–Vis spectrophotometer (Thermo Scientific, Waltham, MA, USA) at a wavelength of 490 nm. For the calibration curve, glucose solutions with concentrations from 66 to 1000 ppm were prepared as calibration standards, using double-distilled water as the blank. The blank and the calibration standards were assayed using the same procedure described above for the samples.

2.4.2. Fermentable Reducing Sugars

The determination of fermentable reducing sugars was carried out using the Miller method [13], according to the methodology proposed by Gusakov et al. [14], using 3,5-dinitrosalicylic acid (DNS) as the reducing agent. For the calibration curve, glucose solutions were prepared in the range from 66 to 1000 ppm, and double-distilled water was used as the blank.

2.4.3. Ethanol Content

The determination of ethanol in pulque and in the final products of the semi-continuous fermentations was carried out by distilling a mixture of 20 mL of the sample with 10 mL of distilled water according to the Mexican norm NMX-V-013- NORMEX-2019 [15]. An ethanol refractometer was used to determine the alcoholic content of the distillates, thus allowing the quantification of the ethanol content in the fermented samples.

2.5. Sensory Analysis

A sensory analysis test was carried out with 6 trained panelists, where the following sensory attributes were assessed: acidity, astringency, bitterness, sweetness, effervescence, plant-like flavor and viscosity, as well as the characteristic aroma and flavor of pulque. For these tests, samples of both the pulque inoculum and the semi-continuous fermentation samples throughout the bioreactor runs were evaluated using a numerical scale from 1 to 10. In order to assess the sensory parameters of the fermented product throughout the semi-continuous process, a comparative descriptive analysis test was carried out, taking the pulque inoculum as the reference. These results were plotted in terms of the sequential batch to show the dynamics of the comparative sensory scores indicated by negative or positive values as related to the reference. In addition, a spider plot of the sensory profile of the pulque inoculum and the final fermentation products of the reactor runs was performed to make a comparison between the sample’s sensory attributes.

2.6. Quantification of Organic Acids, Sugars and Ethanol by HPLC

The concentrations of organic acids, sugars and ethanol in the pulque inoculum and in the different samples obtained during the semicontinuous fermentation were determined in a Waters HPLC system equipped with an Aminex HPX-87P (Bio-Rad, Hercules, CA, USA) column with an IR detector for the quantification of glucose, fructose, sucrose and glycerol and an Aminex HPX-87H (Bio-Rad, USA) column with a UV detector at 210 nm for the quantification of acetate, lactate, succinate and ethanol following the method reported by Astudillo et al. [16,17]. The HPLC analysis was performed on the following samples: raw aguamiel Batch 2, pulque inoculum and semi-continuous fermentation Run 2.

2.7. Enumeration of Selected Microbial Groups

Selective culture media were used to determine the cell concentration of the different microbial groups present both in the pulque inoculum and during the semi-continuous fermentation process. The media used for different microbial groups were the following: MRS agar (Man, Rogosa and Sharpe) for the isolation of lactic acid bacteria [5]; All Purpose Tween (APT) agar enriched with 20% sucrose for the cultivation of heterofermentative lactic acid bacteria of the genus Leuconostoc [18] (ATP-S) and potato dextrose agar (PDA) for yeast cultivations. The MRS media was added with 4 mg/L of cycloheximide (Sigma Aldrich, St. Louis, MO, USA) as a yeast inhibitor, while 25 mg/L of chloramphenicol (Sigma Aldrich, USA) was added to the PDA cultures as a bacteria inhibitor. For culturing the samples, a 1-mL aliquot was taken for analysis, and serial dilutions from 10−1 to 10−5 of the fermented samples were made in previously sterilized peptone water. Subsequently, the inoculation was carried out by spreading 0.1 mL of the inoculant at the appropriate dilution on plates containing the different selective media. The incubation of the sample aliquots in the different selective media was performed according to the following conditions: MRS, microaerophilic conditions at 37 °C for 24–72 h; ATP-S, 32 °C for 24–48 h [18,19,20]; and PDA, 28 °C for 24–72 h. After incubation, the cultured plates were enumerated using a standard countable range from 25 to 250. The enumeration test was carried out in duplicate for every dilution assayed.

2.8. Isolation and Identification of Microorganisms

The phenotypic classification of the microbial colonies was carried out according to the particular morphological characteristics of the different microbial groups considered in this work (Section 2.7), which included size, shape, border, transparency, brightness, color and elevation. Using these classification criteria, distinctive microbial colonies were selected for their further isolation and identification. This colony screening procedure was followed for cultures from both the pulque inoculum and the final fermented product of the reactor Run 2. The selected colonies were isolated by streaking techniques using the selective solid media mentioned in Section 2.7. After pure strains were obtained, catalase and Gram stain tests were performed on the microbial isolates, followed by microscopic characterization.

Microbial Genetic Identification

- Gene-sequencing genotyping

DNA extraction from the isolated bacterial colonies was performed using the Ultra Clean™ Microbial DNA isolation kit (MO BIO Laboratories Inc., Carlsbad, CA, USA). In addition, DNA extraction from the isolated yeast colonies was carried out employing the DNeasy Plant Mini Kit extraction kit (Qiagen, Germantown, MD, USA). The following genes were targeted for PCR amplification of the isolated strains using the recombinant Taq polymerase enzyme (Thermo Scientific, USA): the 16S rRNA gene for bacteria and the ITS region for yeasts. The universal primers 27F and 1492R were used for the amplification of the 16S rRNA gene. In the case of the ITS region, the universal primers ITS1 and ITS4 were used. The quality of the final amplification products was verified in a 1% agarose gel using a TBE electrophoresis buffer. Subsequently, the gel was visualized in the Molecular Imager Gel-DocTM XR+ System photodocumenter (Bio-Rad, USA) using Image Lab software v.5.0 (Bio-Rad, USA). Sequencing of the DNA amplicons of the isolated strains was performed by Macrogen Inc. Laboratories (Seoul, Republic of Korea). For each DNA sample, two sequences (forward and reverse) were obtained and aligned with the software Mega-X [21]. The resulting sequences were compared with the NCBI (National Center for Biotechnology Information) databases with the use of the online program Blast (refseq) https://www.ncbi.nlm.nih.gov/ (accessed on 27 March 2024) and the EzBioCloud repository, which is based on sequences of 16S rRNA genes of bacterial-type strains www.ezbiocloud.net (accessed on 30 March 2024).

- MALDI Biotyper® mass spectrometry

This technique was used to confirm the identification of the microbial isolates performed by PCR genotyping. The isolated strains were cultured for no more than 48 h; after which, a formic acid extraction was performed. The matrix was composed of alpha-Cyano acid-4-25 hydroxycinnamic dissolved in a saturated solution of acetonitrile and trifluoroacetic acid [2]. The MS spectra resulting from the analysis of the isolates were processed using the MALDI Biotyper® analyzer (Bruker Daltonik GmbH, Bremen, Germany), in which the spectra of the sample are compared with the equipment supplier´s databases for microbial identification.

2.9. Statistical Analysis

To analyze the results, a one-way ANOVA was carried out with a confidence level of 95% to identify if there were significant differences between the results obtained in the experimental treatments. Subsequently, multiple mean comparisons were performed using the Tukey’s honestly significant difference (HSD) test with a confidence level of 95% (p < 0.05). For mean comparisons of two samples, a Student’s t-test was used with the same level of significance.

3. Results and Discussion

3.1. Microfiltration of Aguamiel

The collected aguamiel was cold-sterilized by using a membrane microfiltration process in order to use it as a substrate in the semi-continuous fermentation for the aseptic production of pulque. At the end of the filtration, a volumetric concentration factor of 14.6 for the first batch and 26.0 for the second batch was obtained considering the retentate fractions. The sterility of the aguamiel passed through the microfiltration process was verified by the spread plate method. As a result of the analysis, the absence of microbial growth in the microfiltered aguamiel (<10 CFU/mL) was determined, thus concluding that the use of membrane microfiltration allowed the virtual sterilization of aguamiel.

The results obtained for the physicochemical parameters of the raw and microfiltered aguamiel samples are shown in Table 1. The physicochemical parameters of the raw aguamiel were in the ranges published in the literature (Table 1). In an aguamiel study, Enríquez-Salazar et al. [22] monitored the biochemical profile of aguamiel collected from two different species of agave during different seasons of the year, reporting that the collected aguamiel presented variations in pH from 4.5 to 7.0 and in °Brix from 7.3 to 13.8. Similarly, Rocha-Arriaga et al. [23] analyzed aguamiel and pulque samples collected from three different sites located in Hidalgo State, Mexico, reporting pH values for the aguamiel samples around 4.7. The pH values of the aguamiel employed in the present work were 5.3 and 6.6 for the collection Batches 1 and 2, respectively, which were within the pH range reported by Enríquez-Salazar et al. [22] and higher than the values reported by Rocha-Arriaga et al. [23].

Table 1.

Physicochemical characterization of the raw and microfiltration-sterilized aguamiel studied in the present work 1.

The concentrations of total sugars in the two aguamiel samples are in accordance with the values reported in the literature [22,23,24,25]. Additionally, these results can be compared to those reported by Valadez-Blanco et al. [5] in a study regarding the physicochemical and microbial characteristics of aguamiel in a single agave plant as a function of aguamiel collection from the time of the agave opening. The authors reported a drastic decrease in total soluble solids of aguamiel from 16 to 4 °Brix at collection times of 3 and 5 weeks, respectively, as well as a reduction in the total sugar contents from 66 g/L to 24 g/L for the same collection times. In contrast, an inverse behavior occurred in terms of the bacterial concentrations. The authors attributed this behavior to progressive aguamiel fermentation taking place within the plant cavity, called cajete. These findings explain the wide variability reported in the literature for both attributes of aguamiel, acidity and sugar content, considering that they are related to the progress of the fermentation of aguamiel within the cajete. Accordingly, it can be concluded that both batches of aguamiel used in this work are fresh and of good quality, since they do not present a high degree of fermentation, considering that their pH values are relatively high, particularly in the second batch, and their sugar contents are elevated in comparison to those reported in the literature.

A comparison of the chemical compositions of aguamiel between the raw and microfiltered samples was performed, and the results are presented in Table 1. The analysis of the acidity of both aguamiel samples, indicated by the parameters of pH and total acidity, suggested that both parameters were not significantly affected by microfiltration. However, it can be observed that there is a significant decrease in the concentration of sugars after microfiltration, which is probably due to the retention of these molecules by the membrane. On the other hand, from Table 1, it can be implied that there is no significant difference in the rest of the physicochemical parameters between the raw and microfiltered aguamiel, except for the parameters of color, total solids and total sugars. These results are in agreement with the separation mechanism of the microfiltration process, which is based on the retention of the solids present in the aqueous feed by size exclusion.

To analyze in greater detail the color difference between the raw and microfiltered aguamiel samples, the color change parameter, ΔE* value, was calculated, which is the total color difference for the sample as related to a standard, which considers the three parameters of the CIE color space L*a*b*. ΔE* values of 16.6 and 18.8 were obtained for the first and second aguamiel batches, respectively, with respect to the raw aguamiel. These results imply that the color of the microfiltered aguamiel is different than the raw aguamiel as theoretically perceived by the human eye. The observed change in color is due to the fact that, during the microfiltration process, solid removal occurred; therefore, the parameters a* and b* indicate a decrease in the chromatic values, while an increase in the parameter luminosity parameter, L*, indicates a clarification of the aguamiel due to the microfiltration process.

3.2. Physicochemical Characterization of the Pulque Inoculum

Table 2 shows the results of the physicochemical characteristics of the pulque inoculum. It can be observed that the pulque inoculum has a pH of close to 4 and an alcoholic content of 72.9 g/L, values that are in the range of those reported in the literature [1,5,16,26]. In addition, the total acidity of the pulque inoculum (0.7%) was within the interval reported by Valadez-Blanco et al. [5]. In terms of the content of the total soluble solids, the content measured in the pulque seed utilized in this work (3.7 °Brix) is in agreement with the range reported by Valadez-Blanco et al. [5] and quite below the value reported by Álvarez-Ríos et al. [26] for pulque samples (5.5 °Brix). Regarding the percentage of total solids, the value obtained in the inoculum (1.4%) is slightly below those reported by Rocha-Arriaga et al. [23], who studied pulque from three different locations of Hidalgo´s state (Table 2). In addition, the amount of total reducing sugars of the pulque inoculum (8.8 g/L) were within the range of the values reported by Rocha-Arriaga et al. [23] (Table 2). In the case of fermentable sugars, the values reported by those authors were below the content present in the pulque inoculum in this work (1.9 g/L).

Table 2.

Physicochemical characterization of the pulque inoculum utilized in the present work for the semi-continuous production of pulque 1.

In general, the physicochemical parameters of the pulque inoculum are within the range of the values reported in the literature. Considering the high ethanol and intermediate acid contents of the pulque inoculum, as well as its low content of total soluble solids, it can be implied that this product has a higher degree of fermentation than regular pulque products reported in the literature. In this regard, we can conclude that the pulque inoculum is a mature fermented product that is ideal to be used further as a seed in the semi-continuous fermentation for pulque production.

3.3. Production of Pulque in a Semi-Continuous Reactor

Physicochemical, microbiological and sensory analyses were carried out every 24-h sequential batch to evaluate the dynamics of the semi-continuous fermentation. From the overall data, it was determined that the reactor reached a quasi-steady state after 6 and 8 days for the fermentations Run 1 and 2, respectively. In this work, arrival to the quasi-steady state was considered when no significant fluctuations occurred in most of the physicochemical and sensory parameters of the fermentation product. In the following subsections, the analysis of the dynamics of the semi-continuous fermentation for the production of pulque is presented in terms of the physicochemical, microbial and sensory parameters.

3.3.1. Physicochemical Parameters

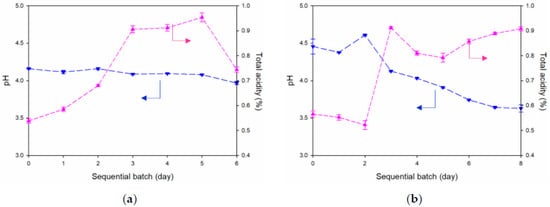

The results of the physicochemical analyses related to acidity of the fermentation broth throughout the fermentation are depicted for both independent runs in Figure 2. As it can be seen in the figure, the behavior of the two fermentation runs is similar. In general, it can be implied that the difference between the runs is due to the different characteristics of the two aguamiel batches, as discussed in Section 3.1. In terms of the acidity of the fermentation broth, the reactors presented their highest pH values on Day 3 for Run 1 and on Day 2 for Run 2; after which, there was a significant decline in this parameter in both experimental runs. Conversely, a reduction in the total acidity was observed at Day 2 for both fermentation runs, which was followed by a significant increase after the next sequential batch (Day 3). As expected, an inverse behavior was observed between the pH and the acidity of the fermentation samples. The increase in the acidity of the fermentation product as the reactor process took place was most likely due to the activation and optimal development of lactic acid bacteria in the broth, which occurred after the cells acclimatized to the culture conditions at 48 h of fermentation. In this regard, Escalante et al. [27] reported the dynamics of pulque fermentation in a batch reactor with a total duration of 6 h. The authors reported a pH of 4.5 at the beginning of the fermentation and 4.3 at the end, which was equivalent to a decrease of 0.2 pH units. In this work, a similar variation was observed in the semi-continuous reactor Run 2, with pH decreases of 0.1 to 0.2 pH units per day, with a global pH reduction from 4.5 to 3.6.

Figure 2.

Dynamics of the physicochemical parameters pH and total acidity in the semi-continuous fermentation for pulque production performed in this work: (a) Run 1; (b) Run 2. The mean ± standard deviation (error bars) are presented (n = 3).

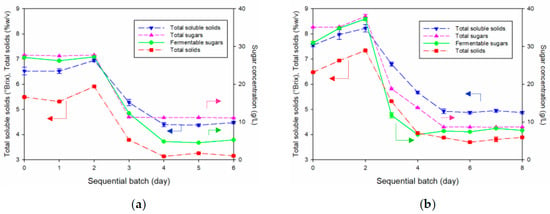

In the present work, the maximum concentrations of fermentable sugars for both fermentations were obtained on Day 2: 27.5 g/L and 37.5 for Runs 1 and 2, respectively (Figure 3); after which, the sugar concentrations decreased to values below 8 g/L at the end of the runs (Table 3) due to sugar consumption by the microorganisms present in the fermentation broth. In this regard, Chacón-Vargas et al. [29] monitored the fermentation for pulque production in a 12-h batch reactor, reporting that the content of fermentable sugars was around 15 g glucose eq./L. In addition, the authors reported that the reactor presented its maximum fermentable sugar concentration at 3 h into the fermentation process.

Figure 3.

Dynamics of the physicochemical parameters total soluble solids, total sugars, fermentable sugars and total solids during the semi-continuous fermentation for pulque production performed in this work: (a) Run 1; (b) Run 2. The mean ± standard deviation (error bars) are presented (n = 3).

Table 3.

Comparison of the physicochemical parameters of the pulque inoculum and the final products of the semi-continuous fermentation runs 1.

On the other hand, regarding the alcohol content, the pulque inoculum presented 72.9 g/L, while the fermentation products obtained at the end of the semi-continuous fermentations presented alcoholic contents of 38.5 ± 0.2 and 45.8 ± 0.1 g/L in Runs 1 and 2, respectively. Despite the fact that the physicochemical characteristics of the final fermentation products were significantly different than those of the pulque inoculum (Table 3), a quasi-steady state was reached for most of the physicochemical parameters during the semi-continuous fermentation runs (Figure 2 and Figure 3).

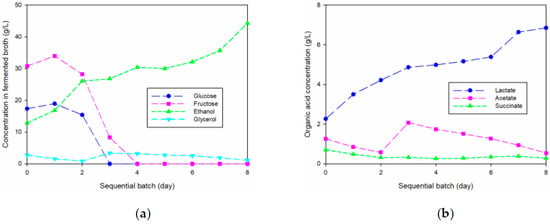

3.3.2. Sugar, Ethanol and Organic Acids

The contents of the main fermentation products, ethanol; sugars and organic acids (lactic, acetic and succinic), were monitored every 24-h sequential batch during the semi-continuous fermentation. In this regard, HPLC analyses were performed on the samples of the semi-continuous fermentation Run 2 (Figure 4). According to the results, ethanol was the most abundant product during the fermentation. At the beginning of the run (Figure 4a), the concentration of ethanol was 12.9 g/L; after which, the ethanolic content increased until reaching a concentration of 44.3 g/L at the end of the semi-continuous fermentation (Table 4). This result is similar to that obtained in the fermentation product of the Run 2 (45.8 g/L) by the distillation method. A progressive increase of the alcoholic content over time was observed, which was mainly due to ethanolic fermentation carried out by microorganisms such as Sacharomyces spp. and Zymomonas spp. during the reactor run [16].

Figure 4.

Dynamics of the composition of the main metabolites during the semi-continuous fermentation for pulque production performed in this work: (a) ethanol and sugars; (b) organic acids.

Table 4.

Contents of ethanol, sugars and organic acids determined by HPLC analyses for aguamiel and pulque samples: (i) raw aguamiel, (ii) pulque inoculum and (iii) the product of the semi-continuous fermentation 1.

In addition, the concentration dynamics of sugars during the semi-continuous fermentation was studied in this work. At the beginning of the run, the content of fructose was the highest among the sugars analyzed, with a concentration of 30.8 g/L. As the semi-continuous fermentation progressed, the concentration of fructose drastically decreased in Days 2 and 3 until the sugar was undetectable after Day 4 and continued like that towards the end of the run. A very similar behavior was observed for glucose, which was detected in quantities of 17.4 g/L at the beginning of the fermentation and suffered a drastic decrease after Day 3 of the run. In addition, from the sugars analyzed in this work, sucrose was the third-most abundant component in aguamiel (8.7 g/L), but it was completely absent in the pulque inoculum, a result which is in agreement with that reported by Astudillo-Melgar et al. [16]. On the other hand, an increase in the glycerol content was observed at Day 3 of the fermentation, probably produced by yeast [16], from 2.7 g/L at the beginning of the fermentation to 3.37 g/L, a level that was maintained for a couple of days. After Day 6, a decrease in the presence of glycerol was observed until the end of the fermentation, with a final concentration of 1.1 g/L (Table 4).

The pulque seed used as the inoculum in this work presented undetectable concentrations of glucose and fructose, which might have been due to the fact that the fermented product was a mature pulque with a long period of fermentation (Section 3.3.1), which was also reflected in its high content of ethanol (72.9 g/L). However, at the beginning of the semi-continuous fermentation, high amounts of these sugars were detected. This can be explained by considering the addition of fresh aguamiel at the sequential batch fermentation exchange, which contained 19.6 g/L and 46.8 g/L of glucose and fructose, respectively (Table 4). During the semi-continuous fermentation process (Figure 4a), the concentration of ethanol increased while the concentrations of glucose and fructose decreased until the sugars were undetectable after 3 h of fermentation, which indicates that the semi-continuous reactor was operating under substrate limitations [30].

In this regard, the low levels of fructose and glucose from Day 4 appear to be due to the fact that they were being consumed by the microbiota present in the reactor, a behavior typical of continuous processes in which the maximum biomass production is achieved when the substrate concentration is close to zero [30]. In the traditional pulque production process, two sequential batches (pulque–aguamiel exchanges) are performed per day, every 12 h, in the early morning and in the afternoon [1]. Therefore, the productivity of the artisanal system performed as above is double that of the semi-continuous process studied in this work. Furthermore, this sequential batch regime also gives enough time to the plant to secrete aguamiel for the following semi-continuous cycle.

On the other hand, lactic acid was the second-most abundant fermentation product produced during the semi-continuous process, starting with a concentration of 2.3 g/L and ending with an average of 6.5 g/L (Figure 4b). In addition, the contents of succinic and acetic acids at the beginning of the fermentation were around 1 g/L and suffered a decrease in the final product to concentrations of 0.28 and 0.54 g/L, respectively (Table 4). The high production of lactic acid during the semi-continuous fermentation is mainly related to the presence of lactic acid bacteria (LAB) in the reactor broth that ferment carbohydrates and produce lactic acid as the main product of their metabolism [16]. The concentration of lactic acid in the fresh aguamiel was 1.5 g/L, and that of the pulque inoculum was 4.7 g/L. During the semi-continuous fermentation process, the concentration of lactic acid progressively increased (Figure 4), a behavior that has been previously reported for the production of pulque in a batch fermentation system [16]. In addition, the production of lactic acid during the fermentation causes changes in the pH and in the acidity of the fermentation broth, as previously discussed in this section.

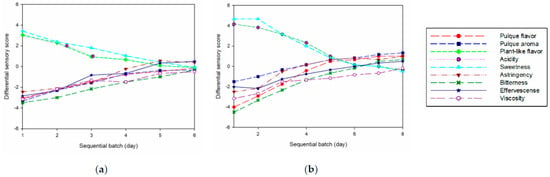

3.3.3. Sensory Attributes

A comparative sensory analysis was performed during the semi-continuous fermentations carried out in this work. Figure 5 shows the dynamics of the sensory attributes during the semi-continuous bioreactor runs in relation to the pulque inoculum. Drastic changes in the sensory characteristics of the sequential batch samples were observed during the semi-continuous fermentations. In general, the dynamic profiles of the sensory attributes of the fermentation product samples were similar for the two fermentation runs. A decrease in the intensities of the characteristic sensory attributes of aguamiel was observed as the fermentation progressed, such as its high sweetness and plant-like flavor. In contrast, the sensory attributes related to pulque, such as astringency, acidity and characteristic flavor and aroma of pulque, increased in intensity with the fermentation time. This result was expected, considering that the microbiota of pulque increased as the fermentation proceeded, as will be described in the following section, thus modifying the physicochemical and sensory characteristics of the fermentation product throughout the reaction runs.

Figure 5.

Dynamics of the sensory attributes of product fermentation samples during the semi-continuous processes for pulque production performed in this work: (a) Run 1; (b) Run 2.

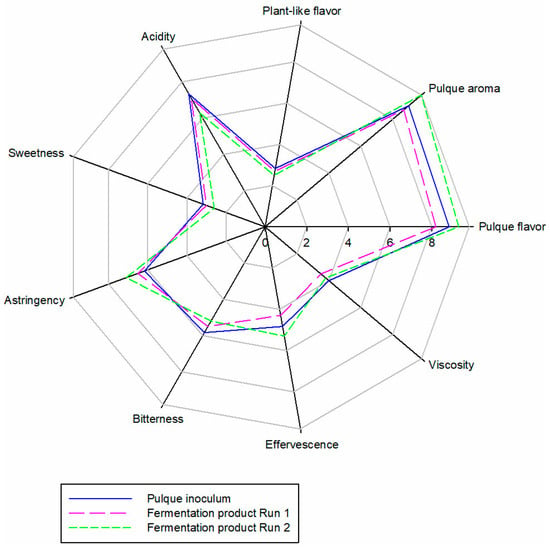

It could be observed that, at the end of the semi-continuous fermentation runs, the sensory profiles of the fermentation products were very similar to that of the pulque inoculum, as shown in Figure 6. In the case of the reactor Run 1, the sensory characteristics were similar to those of the pulque seed, except for the characteristic flavor and aroma attributes, which were slightly below those of the inoculum. On the other hand, the pulque produced in the reactor Run 2, which was fermented for two additional days in comparison to Run 1, presented a greater intensity in the sensory parameters related to pulque, resulting in a product that was sensorially similar to the pulque inoculum. In conclusion, the sensory evaluation of the samples of the pulque products obtained through semi-continuous fermentation for the production of pulque resulted in minimal sensory differences with respect to the pulque seed, whereas a slight reduction in the bitterness attribute was observed.

Figure 6.

Spider plot showing the sensory profiles of the pulque inoculum and the final products of the semi-continuous fermentation runs for pulque production performed in this work.

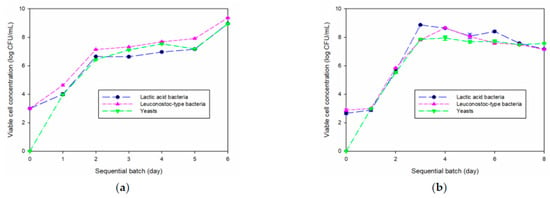

3.3.4. Microbial Populations

A study of the population dynamics of the selected microbial groups was performed during the semi-continuous fermentations for pulque production developed in this work. The microbial groups monitored during the reactor runs were the following: yeasts, lactic acid bacteria (LAB) and Leuconostoc-type bacteria, considering that these microbial groups are responsible for the alcoholic, lactic and viscous fermentations during pulque production, respectively [1]. The kinetic profiles of the different microbial populations followed a similar trend (Figure 7), in which all the groups of microorganisms presented a 5 log increase with respect to the initial fermentation broths. In this regard, Escalante et al. [27] reported the kinetics of LAB and yeast cell growths during a 6-h batch fermentation process for pulque production. The authors reported LAB cell concentrations of 1.2 × 107 and 1.5 × 108 CFU/mL at the beginning and at the end of the fermentation, respectively. In addition, the yeast concentration in the fermentation broth increased from 8.8 × 106 CFU/mL at the beginning of the fermentation to 1.4 × 107 CFU/mL in the final product. In both cases, increases in the microbial population accounted for just a 1 log increment during the 6-h fermentation batch. It should be noted that, to date, no study has been reported in the scientific literature on the microbial dynamics related to pulque processing using a semi-continuous reactor. In the following lines, we describe the dynamics of the microbial groups tested in this study during the semi-continuous fermentation for the production of pulque.

Figure 7.

Dynamics of the microbial populations during the semi-continuous fermentation for pulque production performed in this work: (a) Run 1; (b) Run 2. The mean ± standard deviation (error bars) are presented (n = 3).

With regards to the growth kinetics of LAB populations (Figure 7), it could be observed that the initial bacterial concentrations were similar in both reactors; however, bacterial growth in the reactor Run 1 started from the fermentation Day 1, reaching a high concentration at Day 2 (6.7 log CFU/mL). Meanwhile, in Run 2, a lag phase seemed to have occurred, since the exponential growth started after 48 h; after which, a LAB maximum concentration (8.9 log CFU/mL) was achieved at Day 3 of the run. At the end of the fermentations (Table 5), the amounts of LAB cells were around 9 and 7 log CFU/mL for Runs 1 and 2, respectively, with both cell concentrations being higher than that of the pulque inoculum. It is well documented in the literature that LAB strains such as those belonging to the Lactobacillaceae family and to the Leuconostoc genus are the main bacteria responsible for lactic acid fermentation during the production of pulque, a process in which these bacteria catabolize the sugars present in the must and produce lactic acid as the main fermentation product, thus giving pulque its characteristic acidity and flavor [20,27].

Table 5.

Concentrations of viable cells of the microbial groups targeted in the present work (lactic acid bacteria, Leuconostoc-type bacteria and yeasts) in the pulque inoculum and in the final fermentation products of the semi-continuous pulque fermentations 1.

A study of the yeast growth in both reactors runs was also performed. Yeasts were not countable on the first day of fermentation (<10 CFU/mL) in both reactor runs. However, an exponential growth was observed in the first 2 days of fermentation of the reactor Run 1. In this experiment, a second growth stage was observed at Day 6 of the fermentation, reaching 9 log CFU/mL at the end of the run, a concentration that was higher than that of the pulque inoculum (Table 5). Similarly, in Run 2, a steady yeast growth was observed during the first 3 days; after which, the yeast concentration remained almost constant for the rest of the run, with a final cell concentration of 7.6 log CFU/mL, which was lower than that present in the pulque seed (Table 5). Yeasts are the main microorganisms that carry out alcoholic fermentation in pulque, a process in which sugars are converted into ethanol and carbon dioxide, giving pulque its characteristic alcoholic content and related aroma, as well as a certain degree of effervescence [1,31].

The growth kinetics of Leuconostoc-type bacteria were also studied during the semi-continuous fermentation runs (Figure 7). In the case of the reactor Run 1, the growth of Leuconostoc-type bacteria began at the start of the fermentation, while, in the Run 2, a 24-h lag phase was observed. Similarly to the kinetic behavior of the other microbial groups, in Run 2 a quasi-stationary phase was reached in terms of the Leuconostoc bacterial loads, with a cell concentration of 107 CFU/mL at the end of the bioreactor run. On the other hand, in the case of Run 1, a second growth stage was observed on Day 6 at the end of the fermentation, reaching a final cell concentration close to 109 CFU/mL. The microorganisms of the genus Leuconostoc are responsible for the production of exopolysaccharides using sucrose as the principal substrate, a process called viscous fermentation, which gives pulque its characteristic viscosity [1,19,32].

3.4. Genotyping Characterization of Strains Isolated from Pulque Samples

The genetic identification of the isolates of the pulque samples (inoculum and the final product of the fermentation Run 2) was performed by sequencing the 16S rRNA gene of the isolated strains (Table 6). The identification analyses resulted in similarity scores greater than 95%, which indicated that a reliable identification was achieved at the genus and species level. The genotyping characterization of the isolates was confirmed by MALDI-MS for some of the microbial species identified by 16S gene sequencing: Leuconostoc mesenteroides, Lentilactobacillus diolivorans, Lactobacillus uvarum, Liquorilactobacillus capillatus, Fructilactobacillus sanfranciscensis and Saccharomyces cerevisiae (Table 6). The lack of accurate identification of the isolates by MALDI-MS is relatively normal, considering that the MALDI Biotyper® database is mostly comprised of microorganisms from the clinical area but not of those related to foodstuffs.

Table 6.

Results of the microbial identification by MALDI Biotyper® and sequencing of the 16S rRNA gene (bacteria) and ITS region (yeast) of the isolates obtained from the pulque inoculum and from the product of the semi-continuous fermentation.

The results of the genotypic characterization of the isolates studied in this work are in agreement with the reports in the literature of pulque [1,16,20,23,26,27,28,29]. Chacón-Vargas et al. [29], using NGS methods, reported the following microbial genera as the most abundant in pulque samples obtained from a 6-h fermentation process: Leuconostoc (14.3%), Saccharomyces (13.5%), Lactococcus (13.0%) and Lactobacillus (7.5%), in which the following species were present in higher amounts: Lactococcus plantarum (8.1%), Fructilactobacillus sanfranciscensis (3.7%), S. cerevisiae (2.9%), Lacc. piscium (1.6%), Ln. gelidum (1.5%) and Ln. citreum (1.0%).

From the analysis of the inoculum and fermented product, it was observed that most of the identified strains were present in both fermented samples (Table 6), except for the strain Llb. diolivorans PP548090, which was found only in the pulque inoculum, and for the bacteria Lqb. capillatus PP548075 and Lqb. uvarum PP548077, which were isolated solely from the product of the semi-continuous fermentation. The reason for this could be two-fold: (i) The strain Llb. diolivorans was lost or significantly reduced during the semi-continuous fermentation process due to microbial competence or lack of adaptation, and (ii) the lack of isolation of the strain in the final fermented product was due to the poor efficiency of the microbial detection method, which is inherent in the traditional microbial techniques employed for isolation and identification in this work. The latter argument seems to adequately explain the case of the bacterial strains that were detected in the fermentation product only, which can also be coupled to the low abundance of these bacteria in the pulque inoculum. To have a greater understanding about the microbial dynamics at the genus or species level, nonculturable methods, such as NGS, could be effectively employed in future studies. In addition, it is worth mentioning that the microbial strains Lentilactobacillus diolivorans, Liquorilactobacillus capillatus and Liquorilactobacillus uvarum have not been reported in the studies carried out on pulque based on culturable methods.

4. Conclusions

In this work, it was reported for the first time in the literature the successful production of pulque under standardized conditions by using microfiltration-sterilized aguamiel and a semi-continuous reactor process, thus emulating the traditional artisanal processes for pulque production. Particularly, the cold sterilization of raw aguamiel by membrane microfiltration made it possible to obtain a sterile substrate with physicochemical characteristics similar to the original aguamiel for the aseptic production of pulque. The semi-continuous process resulted in fermentation products with physicochemical, microbiological and sensory characteristics similar to the pulque inoculum, thus fulfilling the main objective of this work, which was to standardize the overall quality of aseptically produced pulque while preserving the richness of pulque´s original microbiota. Additionally, the aseptic production of pulque was successfully carried out in a semi-continuous reactor, resulting in the physicochemical, microbial and sensory parameters reaching a quasi-steady state at Days 6 and 8 for the different reactor runs carried out in this work. In addition, with regards to the microbial dynamics, the final fermentation products reached concentrations of the groups of microorganisms studied (lactic acid bacteria, Leuconostoc-type bacteria and yeasts) greater or similar to those of the pulque inoculum in the order of 7 to 9 log CFU/mL. In terms of the sensory attributes of the pulque produced with the semi-continuous process developed in this work, they were similar to those of the pulque inoculum.

On the other hand, the isolation and identification of the main culturable microorganisms present in the pulque inoculum and in the fermentation product of the semi-continuous reactor were successfully achieved through the use of molecular biology techniques, some of which were confirmed through the use of a MALDI-MS genotyping technique. It should be noted that the strains Lactobacillus diolivorans, Liquorilactobacillus capillatus and Lactobacillus uvarum have not been reported in pulque in the current literature. From the results obtained in this work, it can be concluded that the fermentation system developed in this work can be implemented at the semi-industrial level to produce high-quality pulque in a standardized manner that preserves the beneficial characteristics of the artisanal processes, such as the physicochemical quality of fresh aguamiel and the indigenous microbiota of the pulque seed.

Author Contributions

Conceptualization, C.C.-G., P.C.G.-M. and R.V.-B.; Methodology, C.C.-G., P.C.G.-M., A.E. and R.V.-B.; Investigation, C.C.-G., A.E., E.P.-A., P.C.G.-M. and R.V.-B.; Data curation and Formal analysis, C.C.-G., Y.R.-R., E.P.-A. and R.V.-B.; Supervision, P.C.G.-M., E.P.-A. and R.V.-B.; Project administration, P.C.G.-M. and R.V.-B.; Funding acquisition, E.P.-A. and R.V.-B.; Writing—original draft, C.C.-G., P.C.G.-M. and R.V.-B.; Writing—reviewing and editing, C.C.-G., Y.R.-R., E.P.-A. and R.V.-B. All authors have read and agreed to the published version of the manuscript.

Funding

C.C.G. thanks the Consejo Nacional de Humanidades, Ciencia y Tecnología (CONAHCyT), Mexico, for the support of her M.Sc. studies through scholarship no. 1080629. The authors also wish to thank the financial support from CONAHCyT, Mexico, grant Ciencia-Básica no. 239567.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the data generated or analyzed during this study are included in the published article. The 16S rDNA sequences reported in the present work are available in the NCBI GenBank nucleotide repository with the corresponding accession numbers https://www.ncbi.nlm.nih.gov/genbank/ (accessed on 27 March 2024).

Acknowledgments

We thank Mónica Rincón for the identification of the strains by mass spectrometry at the Laboratorio Divisional de Espectrometría de Masas, Universidad Autónoma Metropolitana, Campus Iztapalapa. In addition, we want to thank Raymundo Cruz from Tinacal San Cristobal for providing the aguamiel and pulque used in the present study.

Conflicts of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Escalante, A.; Soto, D.R.L.; Gutiérrez, J.E.V.; Giles-Gómez, M.; Bolívar, F.; López-Munguía, A. Pulque, a Traditional Mexican Alcoholic Fermented Beverage: Historical, Microbiological, and Technical Aspects. Front. Microbiol. 2016, 7, 1026. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Ramírez, Y.; Valadez-Blanco, R.; Calderón-García, C.; Chikindas, M.L.; Ponce-Alquicira, E. Probiotic and functional potential of lactic acid bacteria isolated from pulque and evaluation of their safety for food applications. Front. Microbiol. 2023, 14, 1241581. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Rivas, E.; Viesca-González, F.C.; Favila-Cisneros, H.J.; Cuffia, F. Consumers’ perception of a traditional fermented beverage in Central Mexico. Br. Food J. 2019, 122, 708–721. [Google Scholar] [CrossRef]

- Rojas-Rivas, E.; Cuffia, F. Identifying consumers’ profile and factors associated with the valorization of pulque: A traditional fermented beverage in Central Mexico. Food Sci. Technol. Int. 2020, 26, 593–602. [Google Scholar] [CrossRef] [PubMed]

- Valadez-Blanco, R.; Bravo-Villa, G.; Santos-Sánchez, N.F.; Velasco-Almendarez, S.I.; Montville, T.J. The Artisanal Production of Pulque, a Traditional Beverage of the Mexican Highlands. Probiotics Antimicrob. Proteins 2012, 4, 140–144. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Lee, J.-A.; Park, G.-G.; Jang, J.-K.; Park, Y.-S. Semi-Continuous Fermentation of Onion Vinegar and Its Functional Properties. Molecules 2017, 22, 1313. [Google Scholar] [CrossRef] [PubMed]

- de Ory, I.; Romero, L.E.; Cantero, D. Operation in semi-continuous with a closed pilot plant scale acetifier for vinegar production. J. Food Eng. 2004, 63, 39–45. [Google Scholar] [CrossRef]

- Qi, Z.; Yang, H.; Xia, X.; Xin, Y.; Zhang, L.; Wang, W.; Yu, X. A protocol for optimization vinegar fermentation according to the ratio of oxygen consumption versus acid yield. J. Food Eng. 2013, 116, 304–309. [Google Scholar] [CrossRef]

- Pabby, A.K.; Rizvi, S.S.H.; Requena, A.M.S. Handbook of Membrane Separations: Chemical, Pharmaceutical, Food, and Biotechnological Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

- Alehosseini, E.; Mohammadi, Z.; Jafari, S.M. Introduction to unit operations and process description in the food industry. In Engineering Principles of Unit Operations in Food Processing; Jafari, S.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Carneiro, L.; Sa, I.d.S.; Gomes, F.d.S.; Matta, V.M.; Cabral, L.M.C. Cold sterilization and clarification of pineapple juice by tangential microfiltration. Desalination 2002, 148, 93–98. [Google Scholar] [CrossRef]

- DuBois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric method for determination of sugars and related substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Gusakov, A.V.; Kondratyeva, E.G.; Sinitsyn, A.P. Comparison of Two Methods for Assaying Reducing Sugars in the Determination of Carbohydrase Activities. Int. J. Anal. Chem. 2011, 2011, 283658. [Google Scholar] [CrossRef]

- NMX-V-013-NORMEX-2019; Bebidas Alcohólicas Destiladas. Determinación del por Ciento de Alcohol en Volumen en la Escala Gay—Lussac a 288 K (15 °C). Diario Oficial de la Federación. Secretaria de Gobernación, Ciudad de México, México. Available online: https://dof.gob.mx/nota_detalle.php?codigo=5594809&fecha=11/06/2020#gsc.tab=0 (accessed on 23 June 2024).

- Astudillo-Melgar, F.; Hernández-Chávez, G.; Rodríguez-Alegría, M.E.; Bolívar, F.; Escalante, A. Analysis of the Microbial Diversity and Population Dynamics during the Pulque Fermentation Process. Fermentation 2023, 9, 342. [Google Scholar] [CrossRef]

- Astudillo-Melgar, F.; Ochoa-Leyva, A.; Utrilla, J.; Huerta-Beristain, G. Bacterial Diversity and Population Dynamics during the Fermentation of Palm Wine from Guerrero Mexico. Front. Microbiol. 2019, 10, 531. [Google Scholar] [CrossRef]

- Giles-Gómez, M.; Sandoval García, J.G.; Matus, V.; Campos Quintana, I.; Bolívar, F.; Escalante, A. In vitro and in vivo probiotic assessment of Leuconostoc mesenteroides P45 isolated from pulque, a Mexican traditional alcoholic beverage. SpringerPlus 2016, 5, 708. [Google Scholar] [CrossRef]

- Diana, C.-R.; Humberto, H.-S.; Jorge, Y.F. Probiotic Properties of Leuconostoc mesenteroides Isolated from Aguamiel of Agave salmiana. Probiotics Antimicrob. Proteins 2015, 7, 107–117. [Google Scholar] [CrossRef]

- Ruíz-Ramírez, Y.; Guadarrama-Mendoza, P.C.; Escalante, A.; Giles-Gómez, M.; Valadez-Blanco, R. Probiotic activity traits in vitro and production of antimicrobial peptides by Lactobacillaceae isolates from pulque using Lactobacillus acidophilus NCFM as control. Braz. J. Microbiol. 2022, 53, 921–933. [Google Scholar] [CrossRef]

- Kumar, S.; Stecher, G.; Li, M.; Knyaz, C.; Tamura, K. MEGA X: Molecular Evolutionary Genetics Analysis across Computing Platforms. Mol. Biol. Evol. 2018, 35, 1547–1549. [Google Scholar] [CrossRef]

- Enríquez-Salazar, M.I.; Veana, F.; Aguilar, C.N.; De la Garza-Rodríguez, I.M.; López, M.G.; Rutiaga-Quiñones, O.M.; Morlett-Chávez, J.A.; Rodríguez-Herrera, R. Microbial diversity and biochemical profile of aguamiel collected from Agave salmiana and A. atrovirens during different seasons of year. Food Sci. Biotechnol. 2017, 26, 1003–1011. [Google Scholar] [CrossRef]

- Rocha-Arriaga, C.; Espinal-Centeno, A.; Martinez-Sánchez, S.; Caballero-Pérez, J.; Alcaraz, L.D.; Cruz-Ramírez, A. Deep microbial community profiling along the fermentation process of pulque, a biocultural resource of Mexico. Microbiol. Res. 2020, 241, 126593. [Google Scholar] [CrossRef]

- NMX-V-022-1972; Aguamiel. Hydromel. Normas Mexicanas. Dirección General de Normas: Ciudad de México, México, 1978. Available online: https://gotomexico.today/media/doc/nmx-v-022-1972.pdf (accessed on 23 June 2024).

- Ortiz-Basurto, R.I.; Pourcelly, G.; Doco, T.; Williams, P.; Dornier, M.; Belleville, M.-P. Analysis of the Main Components of the Aguamiel Produced by the Maguey-Pulquero (Agave mapisaga) throughout the Harvest Period. J. Agric. Food Chem. 2008, 56, 3682–3687. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-Ríos, G.D.; Figueredo-Urbina, C.J.; Casas, A. Physical, Chemical, and Microbiological Characteristics of Pulque: Management of a Fermented Beverage in Michoacán, Mexico. Foods 2020, 9, 361. [Google Scholar] [CrossRef] [PubMed]

- Escalante, A.; Giles-Gómez, M.; Hernández, G.; Córdova-Aguilar, M.S.; López-Munguíia, A.; Gosset, G.; Bolívar, F. Analysis of bacterial community during the fermentation of pulque, a traditional Mexican alcoholic beverage, using a polyphasic approach. Int. J. Food Microbiol. 2008, 124, 126–134. [Google Scholar] [CrossRef] [PubMed]

- Escalante, A.; Rodrãguez, M.E.; Martãnez, A.; Lã³Pez-Munguãa, A.; Bolãvar, F.; Gosset, G.; López-Munguía, A. Characterization of bacterial diversity in Pulque, a traditional Mexican alcoholic fermented beverage, as determined by 16S rDNA analysis. FEMS Microbiol. Lett. 2004, 235, 273–279. [Google Scholar] [CrossRef] [PubMed]

- Chacón-Vargas, K.; Torres, J.; Giles-Gómez, M.; Escalante, A.; Gibbons, J.G. Genomic profiling of bacterial and fungal communities and their predictive functionality during pulque fermentation by whole-genome shotgun sequencing. Sci. Rep. 2020, 10, 15115. [Google Scholar] [CrossRef]

- Bailey, J.E.; Ollis, D.F. Biochemical Engineering Fundamentals; McGraw-Hill: New York, NY, USA, 2018. [Google Scholar]

- Lau, M.W.; Gunawan, C.; Balan, V.; E Dale, B. Comparing the fermentation performance of Escherichia coli KO11, Saccharomyces cerevisiae 424A(LNH-ST) and Zymomonas mobilis AX101 for cellulosic ethanol production. Biotechnol. Biofuels 2010, 3, 11. [Google Scholar] [CrossRef]

- Torres-Rodríguez, I.; Rodríguez-Alegría, M.E.; Miranda-Molina, A.; Giles-Gómez, M.; Morales, R.C.; López-Munguía, A.; Bolívar, F.; Escalante, A. Screening and characterization of extracellular polysaccharides produced by Leuconostoc kimchii isolated from traditional fermented pulque beverage. SpringerPlus 2014, 3, 583. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).