Abstract

Dough retardation is commonly used to extend dough shelf-life, but it poses a challenge for flatbreads due to their large surface. This study explored the sourdough fermentation of oats and barley, addressing challenges in the retardation of dough for flatbread. Sourdough, using flour only or flour blended with bran (3:1), was fermented with a LIVENDO LV1 starter at 30 °C for 24 h. The pH value, microbial viable cell count, total titratable acidity and organic acids concentration of the sourdough were measured. The properties of dough and flatbread, depending on the retardation time (24 h and 48 h), sourdough type (oat or barley) and sourdough level (30% or 50% dough weight), were investigated. Oat flour’s limited acidification improved with the inclusion of bran, resulting in a desirable pH, TTA, and lactic to acetic acid ratio after 15 h of fermentation, which were comparable to results achieved with barley sourdough. The sourdough addition slowed down the enzymatic browning of dough during retardation. Dough retardation at 24 h reduced the phytates content (32–38%) and crumb hardness (9–16%), depending on the sourdough type and level. In dough retardation, β-glucans were degraded by up to 9% in the case of oats and by up to 28% in the samples with barley. Overall, adding oat or barley sourdough at a 30% dough weight can be recommended to enhance flatbread’s nutritional value and prolong its shelf life.

1. Introduction

Bread is the most consumed food in the world and is therefore an important product for nutritional improvement [1]. The oldest bread in the world is flatbread, a traditional staple food from the Mediterranean region [2]. The production of flatbread, having its roots in traditional methods, has now moved to mechanical industrial processes. Flatbreads are categorized as a single- and double-layered, whereby single-layered flatbreads can be leavened or unleavened [3]. In the Mediterranean region, the most common are single-layered flatbreads (77%) made of refined wheat flour leavened with baker’s yeast [2] that can be additionally garnished. Flatbread production includes steps such as kneading, optional dough proofing, shaping, and baking [4]. Flatbread products are characterized by a low dietary fiber (DF) content, due to the fact that refined wheat flour is the main ingredient [5]. Oat, barley, millet, rye, sorghum, or legume flour have been used as enriching ingredients to increase the protein, mineral, and DF content of wheat-based flatbreads [6,7,8,9,10,11]. By using different enriching ingredients and breadmaking processes, flatbreads with increased nutritional value and tailored to specific diets can be produced, while preserving their overall quality [6].

Alternative cereals, such as oats and barley, possess several valuable properties that meet the requirements for functional diet components. Oat and barley flour, but also bran as a by-product of flour milling, are a good source of DF, especially soluble ones such as mixed-linkage (1 → 3), (1 → 4)-β-D-glucans. The consumption of β-glucans has been associated with a reduction in diabetes symptoms, the ability to lower plasma cholesterol, the improvement of lipid metabolism and a reduction in colon cancer risk [12,13]. Although barley flour was traditionally used in breadmaking, its usage declined over time. Several studies addressed the challenge of using barley or oat flour in making flatbread. Wheat flour was supplemented with barley flour at levels of 15, 30, 45 and 60% (flour weight) in the development of Balzama flatbreads with a high β-glucan content and a relatively low glycemic index [14]. The replacement of 50% wheat flour with barley flour also significantly lowered the glycemic index of roti flatbread [15]. To improve the quality and nutritional value of barbari bread, barley flour was used together with wholewheat flour in a 1:1 ratio [16]. The use of oat flour at 25 and 50% to wheat flour was tested in chapatti flatbread, which increased the content of bioactive compounds [17]. The use of bran, as a by-product of the milling industry, could additionally play an important role in the environmental sustainability of flatbread production.

The fermentation process used influences the overall quality of the bread. In the modern bakery industry, sourdough is used not only as an alternative to baker’s yeast, but also to reduce the need for additives, improve sensory properties, nutritional value, and prolong the shelf-life of bread [18,19]. Sourdough can be spontaneously fermented by naturally present microorganisms (type I) or with added lactic acid bacteria (LAB) and yeast (type II sourdough) [20]. The interaction between flour and inoculated LAB has the greatest influence on achieving the desired nutritional and technological properties of bread [21]. The sourdough fermentation of wholegrain flour or bran under suitable hydration conditions successfully increases the bioavailability of minerals, protein digestibility [18], and the solubilization of DF [22]. Wholegrain and bran contain a high amount of phytic acid (PA), an antinutrient which impairs mineral bioavailability by forming insoluble complexes with iron, magnesium, zinc, and calcium cations [18]. Prolonged fermentation enables the degradation of most of the PA, which is due to the microbial phytase activity, but also due to the endogenous cereal enzyme activated at lower pH values [16,23]. Pejcz et al. [13] fermented wholegrain barley flour with LV1 starter (0.5%), dough yield (DY) 200, at 30 °C for 18 h, aiming to enrich wheat bread with dietary fiber, mainly β-glucans. With the same aim, Rieder et al. [22] used sourdough obtained from barley flour and oat bran fermented with L. plantarum at 30 °C for 18 h. Whereas the acidification of barley flour was found to be mostly successful, it was inadequately characterized in the case of oat flour or bran. To our knowledge, the influence of bran addition on the acidification kinetics of oat and barley flour has not been investigated. Hence, this paper presents a comparative study of the sourdough fermentation of the two most important β-glucan sources among cereals, oats and barley.

A retarded dough method is generally used to improve the flavor of sourdough bread [24]. Retarded dough stored between 0 and 10 °C for up to 14–24 h results in better-tasting products with a pleasant, slightly sour flavor, a light chewy crumb, and a thick, brown crust [24]. Further on, the retardation method was introduced to extend the shelf-life of the dough and perform the baking on demand [7]. However, due to a large surface area, retarded flat doughs are more prone to enzymatic browning, which eventually affects the consumer’s acceptance of the final product [25]. This browning is caused by the action of polyphenol oxidase (PPO) and peroxidase enzymes that are mainly concentrated in the bran fractions and catalyze the oxidation of free and reduced phenolic compounds to quinones, which interact and form brown pigments. Therefore, bran-containing dough is more susceptible to enzymatic browning [26].

Additives, such as ascorbic and citric acid, L-cysteine, and 4-hexylresorcinol, which is a competitive enzyme inhibitor, were tested as anti-browning agents, as well as heat and microwave treatment [25,27]. Discoloration of barley-based dough can be controlled by heat treatment, with oxygen exclusion, by lowering the phenolics content or PPO activity, and by using enzyme inhibitors [25,27]. A combination of chemicals and microwaves can slow down changes in the lightness of barley dough during 96 h of retardation for multigrain Indian flatbread [25,27]. However, on the market, there is a strong trend of breads enriched with bioactive compounds and clean label breads without additives. The use of sourdough as a natural improver in a retarded dough and its potential to inhibit enzymatic browning in the making of healthier flatbreads has not yet been well addressed.

Thus, the aim of this study was to investigate the acidification kinetics of the sourdough fermentation of oat and barley flour with or without adding bran using a commercial starter. We hypothesized that the addition of bran will improve the acidification kinetics of oat and barley sourdough and that the addition of sourdough will slow down the browning of the dough during retardation and additionally reduce the phytates content. Hence, the influence of sourdough type II on the nutritive value and quality of single-layered flatbread made using the no-time method, and retarded dough method (24 and 48 h) was investigated at two addition levels (30 and 50% dough weight).

2. Materials and Methods

2.1. Ingredients

The semi-refined wheat flour (Čakovečki mlinovi Inc., Čakovec, Croatia) contained 11.0% protein, 11.9% moisture, and 2.3% fat. Its amylolytic activity was 1640 Brabender units (BU). The oat flour (Granolio Inc., Zagreb, Croatia) contained 12.4% protein, 11.5% moisture, and 7.9% fat. The barley flour (Ivan Varga family-run farm, Orehovica, Croatia) contained 11.2% protein, 12.4% moisture, and 1.8% fat. The oat bran (Eko-Jazo Ltd., Ivanovac, Croatia) and barley bran (Ivan Varga family-run farm, Orehovica, Croatia) contained 19.9 and 11.0% protein, 11.4 and 12.2% moisture, and 4.7 and 1.3% fat, respectively, as reported previously by Grgić et al. [28].

The particle geometric mean diameter was determined according to the ICC standard 207 by sieving at the mesh apertures of 670, 355, 282, 225, 180 and 125 µm [28], and was 231 µm for oat flour, 295 µm for barley flour, 531 µm for oat bran and 514 µm for barley bran.

A commercial freeze-dried starter LIVENDO LV1® (Lesaffre, France) was used to prepare the sourdough.

2.2. Chemical Analyses of Flour/Bran and Flatbread

The dry weight (d.w.) content of the flour and bran was determined in duplicate according to AOAC method 925.10 [29], whereas for the flatbread, AACC method 44-15.02 [30] was followed.

The total dietary fiber was determined in duplicate according to AOAC method 2011.25 using the Total Dietary Fibre Assay Kit (Megazyme, Bray, Ireland).

The concentrations of minerals in the oat, barley flour, and bran were determined using atomic absorption spectrometry (AAS). Ashing of a well-homogenized sample (5 g) was performed in a muffle furnace (KR-170, Heraeus, Hanau, Germany) at 550 °C according to AOAC method 923.03 [29]. After cooling to room temperature, the ash was weighed. Then, it was dissolved during heating with 5 mL of 5 M nitric acid, and quantitatively transferred to a 25 mL volumetric flask with deionized water. The sample solutions were further diluted to ensure that the concentration of each analyte was within the linear range of the method. Lanthanum (III)-chloride (1%, v/v) was added to the diluted solutions, standards, and to blank samples to avoid interference of the phosphates with magnesium. The atomic absorption spectrometer (Perkin Elmer 2380; Norwalk, CT, USA) was set to an acetylene flow of 2.2 L/min and an air flow of 14.5 L/min. The calibration curves were prepared for each analyte using standard solutions (Supelco, Darmstadt, Germany) at five concentration levels and the measurement was performed in at least five consecutive replicates at the following wavelengths: 324.7 nm for Cu, 248.3 nm for Fe, 213.9 nm for Zn, and 285.2 nm for Mg.

The activity of α-amylase was determined spectrophotometrically following the α-amylase SD method (K-AMYLSD 04/19, Megazyme, Bray, Ireland) and the manufacturer’s instructions.

Polyphenol oxidase (PPO) activity was assessed in accordance with the AACC 22-85.01 method [30] with a slight modification [31]. Sample (50 mg) was vortexed with a 10 mM solution of L-DOPA in a 50 mM MOPS buffer (1.5 mL) at 1.000 rpm for 15 min. After centrifugation at 14.800 rpm for 5 min, the resulting supernatant was used for spectrophotometric measurement at 475 nm. The PPO activity was calculated as the difference in the absorbance of sample and blank and expressed as Δ475/g sample.

The β-glucan content in flatbread was determined according to AOAC Method 995.16 and AACC Method 32-23 [30], using the Mixed-linkage β-glucan Assay Kit (Megazyme, Bray, Ireland). Phytic acid content was determined spectrophotometrically at 655 nm using the Phytic Acid Assay Kit (K-PHYT 05/19) following the manufacturer’s instructions (Megazyme, Bray, Ireland).

All spectrophotometric analyses were performed in duplicates using the spectrophotometer PerkinElmer Lambda 35 UV/Vis (Waltham, MA, USA).

2.3. Sourdough Fermentation and Characterization

Sourdough was prepared using flour only or a blend of flour and bran. The amount of the bran ratio added to flour for sourdough fermentation was determined in the preliminary experiment. In the bran-including fermentations, oat or barley flour was mixed with the bran in a ratio of 3:1. To obtain DY 300, 240 g of sterile tap water was added to 120 g of floury material. The starter LIVENDO LV1® was added at 0.5 g/100 g of the floury material, and the dough was mixed for 5 min. The sourdough was fermented in sealed jars in a thermostat (INB 500, Memmert, Schwabach, Germany) at 30 °C for 15–24 h.

Measurement of pH, Total Titratable Acidity and Viable Cell Counts in Sourdough

The pH value during sourdough fermentation was recorded every 5 min during 24 h of fermentation using a PH-230SD pH meter equipped with a data logger (Lutron Electronic Enterprise Co., Ltd., Taipei City, Taiwan).

The total titratable acidity (TTA) of the sourdough (10 g) was determined after suspending it in distilled water (90 mL) by titration with 0.1 M NaOH to a final pH of 8.5 [32]. The TTA is expressed as the average volume (mL) of NaOH consumed for two replicate titrations.

The organic acids were determined according to the method of Lefebvre et al. [33] with slight modifications. Ten grams of sourdough were suspended in distilled water on a magnetic stirrer for 30 min and diluted to 50 mL in a flask. After centrifugation (Rottina, Hettich, Kirchlengern, Germany) at 13.081 rpm for 5 min, the supernatant (5 mL) was transferred to a test tube. Carrez-I solution (1 mL) and Carrez-II solution (1 mL) were added, after which the sample was centrifuged at 4000 rpm for 5 min. A filtered supernatant was used for determination of the organic acids content in duplicate using the D-lactic acid and L-lactic acid Assay Kit (K-DLATE 08/18) and Acetic acid Assay Kit (K-ACETRM 04/20) (Megazyme, Bray, Ireland). A molar ratio between the lactic acid and acetic acid represents the fermentation quotient (FQ).

The number of viable cells in the sourdough at the end of fermentation was determined according to ISO 7954:2002 [34] for yeasts (Saccharomyces spp.) and ISO 15214:98 [35] for LAB (Lactobacillus spp.). Three decimal dilutions were analyzed in two replicates. The results are expressed as colony-forming units (CFU) per g of sourdough.

2.4. Modelling of Sourdough Fermentation Kinetics

Acidification data (difference in pH value) were modelled according to the Gompertz equation as modified by Zwietering et al. [36]:

where y is log (dpH dt−1, units of pH min−1); k is the initial level of the dependent variable; A (ΔpH) is the difference in pH (units) between the initial value and the value reached in the stationary phase of the sourdough fermentation; µmax is the maximum acidification rate, is the length of the latency phase expressed in minutes, and t is the time.

2.5. Experimental Design

After establishing the more desirable type of milling product (flour and bran) for sourdough fermentation, the application of sourdough in flatbread was investigated. Based on the results of selected properties of flatbreads, dough retardation lasting 24 h was further compared with a no-time process. A two-level full factorial design of the experiment involved three independent variables, i.e., substrate type, sourdough level, and retardation time (Table 1). The measured responses were specific volume, baking loss, spread ratio, crumb hardness, cohesiveness, resilience, crust and crumb color, PA, and β-glucans content.

Table 1.

Experimental plan and samples code used in the breadmaking.

2.6. Breadmaking

A single-layered Croatian type of flatbread (‘Pogača’) was made using a no-time and retarded dough method. Four different types of control breads without sourdough and matching four types of breads with sourdough were prepared. Three pieces of each type of bread were baked either after a no-time (0 h) process or dough retardation (24 or 48 h) process. The sourdough, fermented for 15 h from a blend of oat or barley flour and bran, was used in the breadmaking within 1 h of storage in a refrigerator.

In the controls, 18 or 30% (w/w) of oat or barley flour/bran blend replaced wheat flour, while in the sourbreads, 30 or 50% of oat or barley sourdough was added at dough weight, respectively, which corresponded to the substituted flour weight in the controls. The other ingredients were semi-refined wheat flour (69.6 and 81.8%, respectively), water in an amount adjusted to 200 BU (82–88.5%, total flour), instant baker’s yeast (0.8%), oil (4%) and salt (2%). Water in the sourdough was taken into account so that the total amount of water in the controls and sourbreads was the same. The dough was mixed in a spiral mixer (Diosna SP12, Osnabrück, Germany). First flour was mixed with water for 2 min at 90 rpm, then yeast and salt were added, and fast mixing was continued for 5 min at 120 rpm. In the third minute, oil was added. After the bulk fermentation (28 °C, relative humidity 75%, 20 min), dough was divided into round balls (450 g) and placed in metal pans (20 cm diameter). Dough was subjected to retardation at a temperature 2 ± 2 °C, up to 48 h or to direct proofing at 28 °C, and relative humidity 75% for 1 h (Wiesheu, Affalterbach, Germany). Breads were baked in triplicates at 240 °C for 30 min with 0.21 mL cm−2 of steam in a deck oven (Wiesheu, Affalterbach, Germany). After cooling for 1.5 h at room temperature (20–22 °C) and 50–60% relative humidity, the breads were used for the subsequent measurements.

2.7. Evaluation of Dough and Bread Physical Properties

The pH of the bread dough was measured (in duplicates) at room temperature using the pH meter Testo 206 (Testo, Berlin, Germany).

Dough weight loss (in triplicates) was calculated by measuring the weight of the dough before and after retardation according to the Equation below (2):

where m1 is the weight of dough before retardation and m2 is the weight after retardation (tempered at room temperature).

The color of the dough during 0, 1, 2, 4, 6, 24 and 48 h of retardation was measured in triplicates, whereas the color of crumb and upper crust of bread baked after 0 and 24 h of retardation was measured at six points. All measurements were performed with a colorimeter (CM-700d, Konica Minolta, Osaka, Japan). In addition to the L* value, which expresses the brightness or whiteness of a sample with 0 as black and 100 as pure white, redness (a*) and yellowness (b*) were measured. The total color difference (TCD) before and after dough retardation was calculated using Equation (3):

Baking loss was calculated from the weight (in triplicates) of the dough before proofing and the bread after baking and 1 h of cooling at room temperature, according to Equation (4):

The volume of the bread was determined in triplicates according to AACC 10-05.01 method (AACC International, 2010) [30]. The specific volume was calculated as a ratio of volume to weight.

The width (at 2 points) and height (at 4 points) of the triplicate breads were measured with a caliper and the spread was calculated as their ratio.

The texture profile of the crumb was determined using a TA1 texture analyzer (Ametek Llyod Instruments Ltd., West Sussex, UK) with an aluminum probe of a diameter of 55 mm [37]. Immediately before the analysis, the crumb, with a thickness of 12.5 mm, was cut into 36 mm diameter pieces, and two pieces were stacked together. The double-compression test was performed in six replicates under the following conditions: probe speed before, during and after the test 2 mm/s, trigger force 5 N, strain 50%, and pause duration 30 s. The results processed using the program Nexygen PLUS 3 Software (Ametek Lloyd Instruments Ltd., West Sussex, UK) are expressed as hardness, cohesiveness, and the resilience of the crumb.

2.8. Statistical Analyses

To determine the influence of flour type, sourdough level, and retardation time on flatbread physical and nutritive properties, recorded data were subjected to factorial analysis of variance (ANOVA). The Tukey test for honest significant differences was used to assess differences between means. ANOVA, Tukey’s post hoc test, Pearson’s correlation test, and principal component analysis (PCA) were considered statistically significant when p < 0.05. Analyses were carried out with Statistica 14.1.0 (TIBCO Software Inc., Palo Alto, CA, USA).

3. Results and Discussion

3.1. Enzymatic Activity and Bioactive Components of Flour and Bran

Wholegrain cereals provide protein and energy, DF, minerals, vitamins, and antioxidants that are important for human health [38], but also possess a high enzymatic activity. Barley flour was richer in DF and minerals (magnesium in particular) compared to oat and wheat flour (Table 2). The DF content of oat bran was 121% higher than that in the oat flour, whereas it was 44% higher in barley bran compared to its flour. Unlike the barley samples, the mineral content (especially magnesium and iron) of oat bran was significantly higher than in oat flour. This suggested that bran samples were suitable for the enrichment of bread with DF and minerals.

Table 2.

Total dietary fiber, mineral content, TPC and enzymatic activity of oat and barley flour and bran compared with semi-refined wheat flour (mean ± standard deviation).

Among flours, semi-refined wheat flour showed the lowest concentration of phenolic compounds but also the lowest PPO activity (Table 2). The total phenolics of barley and oat flour were 66% or 200% lower than those previously reported for their bran, respectively, which was 0.84 mg FAE/g d.w. and 0.75 mg FAE/g d.w., respectively [28]. A similar difference (50% for barley and 150% for oat) between flour and bran was found in the PPO activity. Habuš et al. [26] obtained comparable results for the PPO activity of oat flour (2.17 Δ475/g), while the PPO activity of their barley flour was 2.5-fold lower (1.167 Δ475/g). Our results indicated a high risk of enzymatic browning of dough containing barley or oat flour, which was even higher when using bran.

3.2. Fermentation Kinetics of Oat and Barley Sourdough

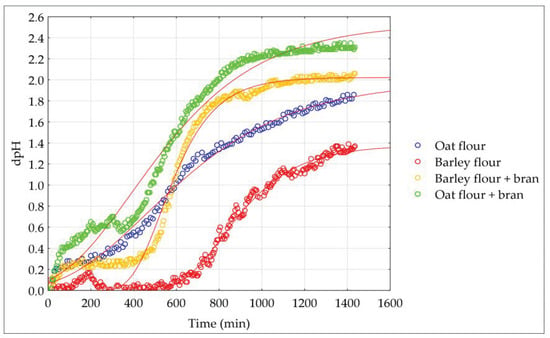

The pH changes during 24 h of sourdough fermentation were well fitted to the Gompertz model to show the difference in acidification kinetics of oat and barley flour depending on the bran addition (Figure 1, Table 3). Overall, barley flour had a higher acidification power than oat flour (Table 3). The addition of bran resulted in a 22–26% reduction in lag time and 13–14% reduction in the time required to reach the maximum acidification rate of barley and oat flour, respectively (Figure 1, Table 3). The bran addition positively affected an increase (46%) in the acidification rate of oats, while it remained unchanged for barley. Related, the addition of bran resulted in a 7% lower pH and 55% higher TTA in oats, while the pH and TTA of barley were only slightly changed with bran addition (5 or 10% respectively). This is probably because of the initially higher mineral content of barley flour [39]. Hence, the pH value and TTA at the end of 24 h fermentation were similar between the blend of oat flour and bran with barley sourdoughs. A similar pH value (3.81) but higher TTA (19.53 mL 0.1 M NaOH) at the end of 24 h fermentation of barley flour (DY = 148, 30 °C, multi-strain starter culture) was obtained by Mariotti et al. [39]. Huttner et al. [40] previously reported slightly higher pH (4.36–4.39) and TTA values (9.9–10.8 mL 0.1 M NaOH) after 24 h fermentation of wholegrain oat flour at 28 °C, depending on the starter cultures.

Figure 1.

Acidification kinetics fitted to the Gompertz model for oat and barley flour and flour-bran blend. Fermented with starter LV1 at 30 °C for 24 h and DY = 300.

Table 3.

Total acidity (TTA, mL 0.1 M NaOH), pH value at the end of the 24 h fermentation, and the acidification kinetics according to the Gompertz model.

The optimum pH value of sourdough for breadmaking should be approx. 4, which requires a fermentation period of 6 to 24 h, depending on the temperature (25–35 °C) [41]. In our samples, after 15 h (900 min) of fermentation, a pH value in the range of 3.69 and 3.95 was reached (Figure 1, Table 3). This corresponded to a pH value of 1.43 and 1.53 for oat and barley flour, respectively, whereas the greater drop in pH (1.87 of oats and 2.17 in barley sample) was measured after adding bran (Figure 1).

The number of viable cells at the end of the 15 h fermentation was typical for the mature sourdough and similar between samples (Table 4). Huttner et al. [40] found a comparable LAB CFU after 24 h fermentation of wholegrain oat flour (7.7–8.9 × 108), while a small difference could be attributed to different amount of inoculum. In our study, the pH was lower and the TTA was higher for both oat and barley sourdough after adding bran (Table 4), regardless of the similar CFU.

Table 4.

Colony-forming units (CFU), total acidity (TTA), pH value, organic acids content and fermentation quotient (FQ) after 15 h of sourdough fermentation of oat or barley flour with or without added bran.

Both oat sourdough samples (flour only and flour and bran blend) had a 93–107% higher acetic acid concentration than barley sourdoughs (Table 4). On the other hand, sourdough from barley flour had the highest lactic acid concentration. The addition of bran reduced the amount of lactic acid in barley sourdough and the fermentation quotient of both types of sourdough. Therefore, the fermentation quotient of barley sourdough was 107–138% (2-fold) higher than that of oat sourdough. According to Arora et al. [18], the recommended fermentation quotient is below 5.0, but with large variations from 0.25 to 20.

Since the flour and bran blend had a higher acidification rate, a higher TTA and a lower pH value, it was selected for the breadmaking phase.

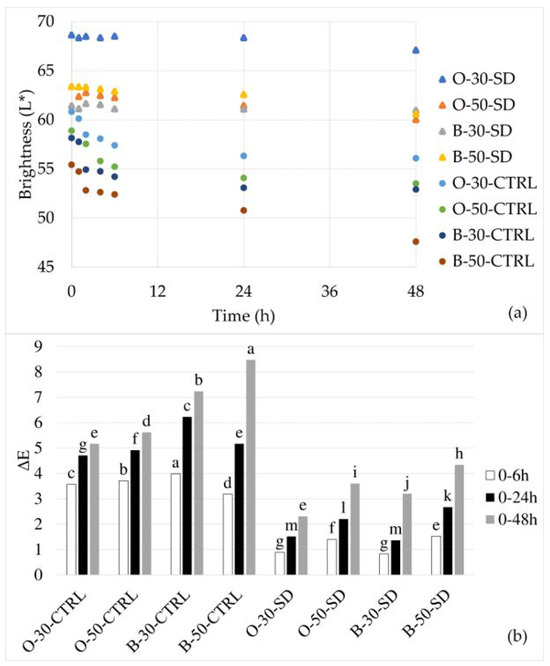

3.3. Changes in Color, pH, and Weight of the Dough during the Retardation Process

The color change of dough might affect the acceptability of the final baked product. The TCD can be classified as very distinct (TCD > 3), distinct (1.5 < TCD < 3) and as a small difference (TCD < 1.5) [42]. Figure 2a,b shows the lightness (L*) parameter and TCD of the dough during retardation. As expected, doughs with a higher amount of barley or oat were darker. Moreover, barley doughs were darker than oat doughs which can be related to higher content of phenolics and higher PPO activity in barley flour than in oat flour. Compared to the control without sourdough, the L* values of doughs with sourdough were higher during the whole time of retardation. After 24 and 48 h, the L* value was 17–21% and 15–23% higher in oat samples, while it was 11–20% and 15–27% higher in barley samples depending on the sourdough amount compared to the control dough (Figure 2a). All control doughs showed a very distinct (TCD > 3) color change already after 6 h of retardation (Figure 2b). In contrast, the TCD of samples with sourdough after 6 h was small (≤1.5). Only after 24 h of retardation, the TCD of sourdough-containing doughs was distinct (between 1.5 and 3), while after 48 h it was very distinct, except for O-30-SD dough. Hence, during retardation for 24 or 48 h, TCD was reduced by 36 or 75%, respectively, in oat dough, and even more by 48 or 79%, respectively, in barley dough, with the use of sourdough. Similar dough-darkening was previously reported for multigrain Indian flatbread (chapatti) and barley-based dough due to the activity of PPO [25,27]. In the presence of oxygen, and phenolic substrates, PPO catalyzes melanin formation. PPO is a type of copper-containing protein that hydroxylates p-hydroxy monophenol to o-dihydroxy phenol (EC 1.14.18.1), and then dehydrogenates o-dihydroxy phenol to o-quinone (EC 1.10.3.1) [43]. The quinone products of PPO react with various components, such as amines, thiols, and phenols, and forms melanin, a colored metabolic end-product [44]. In general, the optimum pH of PPO ranges between 4 and 8, while wheat PPO has two pH optimums, 5.3 and 6.9 [45]. The addition of sourdough lowered the pH of the dough (Table 5) which may have slowed down the activity of PPO and dough-darkening. Banerji et al. [25] found that the most effective approach to prevent dough browning is a synergistic effect of chemical and microwave treatment, while the L* values of the doughs with treated flours were stable and 16.5% higher after storage at 4 °C for 96 h [25]. Sourdough can therefore be used as a natural means of slowing down the darkening of the dough during short-term retardation to a comparable extent, as the chemical inhibitors were combined with the microwave treatment.

Figure 2.

Color changes of dough with sourdough compared to the control without sourdough during 48 h of retardation: (a) brightness (L*) of dough; and (b) total color difference (ΔE). CTRL—control sample without sourdough; SD—sample with sourdough. a–m Values marked with different letters differ significantly according to Tukey’s test (p < 0.05).

Table 5.

No-time (0 h) and retarded (24 h) dough properties depending on the oat (O) and barley (B) sourdough level (30 or 50% dough weight).

The pH of the control bread dough without sourdough was between 5.80 and 5.95, while it was 16–26% lower after adding sourdough (Table 5). When wheat, barley or wheat-barley sourdough was added at a concentration of 25 g/100 g, dough pH values of 4.23 to 4.63 were reported [39]. The slightly higher pH value of the bread dough found in this study, despite the higher sourdough content, could be due to the slightly higher pH value of the sourdough in this study than in the study by Mariotti et al. [30], which was in the range of 3.63–3.81. In our study, the pH value of the retarded oat dough was 5–7% lower than that of the no-time processed (non retarded) sample, while the difference in the barley dough was minimal, i.e., amounting to 1–2% (Table 5).

The dough weight loss during the retardation was lower than 1% (Table 5). In the first stages of retardation, the dough loses moisture from its surface as it tries to establish an equilibrium with the surrounding air [46]. It can be assumed that the elevated fiber content of our dough helped to maintain moisture and weight stability during refrigerated storage.

3.4. The Physical Properties of Flatbread

The properties of flatbreads made with the addition of sourdough fermented from oat/barley flour-bran blend using the no-time or retarded dough processes are shown in Table 6 and Figure 3. The physical properties of flatbreads were affected by the flour type, sourdough level, retardation time or their interactions (Table 7).

Table 6.

Baking loss, physical and nutritive properties of flatbread from the no-time (0 h) and retarded dough (24 h) processes, depending on the oat (O) and barley (B) sourdough level (30 or 50% dough weight).

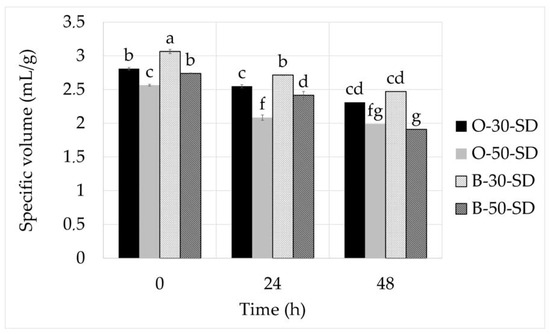

Figure 3.

Specific volume of flatbreads from the no-time method and after 24 or 48 h of dough retardation, depending on the flour type and sourdough level. a–d, f, g Values marked with different letters differ significantly according to Tukey’s test (p < 0.05).

Table 7.

ANOVA p-values for the influence of flour type, sourdough level and retardation time on flatbread physical and nutritive properties.

The increasing level of oat or barley blends in flatbreads resulted in a lower specific volume (Figure 3). An increasing amount of fiber, including β-glucans, which have a high-water binding capacity, limit the water for the formation of the gluten network and negatively affects bread volume [47]. In addition, the use of sourdough at the higher level reduced the bread volume, due to the acidic weakening of gluten [16]. Moreover, flatbreads made after dough retardation had a significantly lower specific volume with a bigger spread ratio than those from the no-time process (Figure 3, Table 6). After 24 h of dough retardation, the specific volume decreased by 9–12% with the 30% sourdough addition and by 12–18% with the 50% sourdough addition. After 48 h of dough retardation, the specific volume of the flatbread with 30% of sourdough was 18–20% lower, while it decreased by 20–30% when using 50% sourdough. With a prolonged retardation time, although the volume of the dough piece increases, there is usually a progressive loss in the volume of the baked product [46]. As the gas fraction increases during fermentation, the thickness of the gluten–starch matrix surrounding the gas cells decreases, i.e., the gluten network becomes weaker to trap the CO2, which leads to a significant decrease in the bread volume [48,49]. Wang et al. [24] reported the highest specific volume of sourdough steamed bread after 24 h of retardation compared to 15, 18, 21, 27 and 30 h. In their study, the type of sourdough as well as the type of bread was different. Although a high volume is not a prerequisite for high-quality flatbread, and the shape can be flattened due to the volume and color degradation, we found the dough shelf-life of 48 h in retardation unacceptable. Since the dough browning and volume reduction after the 24 h retardation was still acceptable for some samples, it was selected for further analyses.

The crumb of the flatbread with 30 or 50% oat sourdough was harder (12–16%) compared to its barley counterpart. Compared to both flatbread types with 30% sourdough, the crumb was harder with the addition of 50% sourdough (4% in barley and 10% in oat bread). In addition, the crumb of flatbreads with 50% oat or barley sourdough was slightly less cohesive (4–11%), and resilient (5–18%) than in breads with 30% sourdough. This is in agreement with Flander et al. [50], who found that increasing the level of wheat sourdough increased the hardness and reduced the resilience of the mixed oat–wheat bread. Although sourdough is known for improving crumb texture, here, with the increasing sourdough levels, the amount of barley flour/bran was also increased, whereas the proportion of wheat flour decreased, which negatively affected the crumb texture. As the bran concentration increases, the hardness of the sourdough bread increases, since it is influenced by the ingredients added to the dough [51]. Our oat and barley flour, and particularly the bran, was high in DF (Table 2). The high fiber content, especially the high-molecular-weight β-glucan in oat bran and the high arabinoxylan content in barley bran, can interfere with the formation of the reaction between starch and protein in wheat flour, resulting in a harder crumb [52].

The crumb texture of the flatbreads made from the retarded dough was less hard (9–16%), less cohesive (6–10%), and less resilient (6–14%) compared to breads made from the no-time process, which agrees with Wang et al. [24]. One possible explanation is that the lower pH value of the dough (Table 5) and the retardation reduced the strength of the wheat gluten. The acidification caused by the growth of LAB changes the gluten network. At a pH of around 4.0, the solubility of the proteins is increased, and the formation of new bonds is prevented, i.e., the reduction of inter- and intramolecular disulfide bonds solubilizes the gluten proteins, resulting in gluten weakness [53]. In addition, an acidic pH (4.1–5.0) during dough retardation is favorable for proteolytic enzymes, which allows for greater proteolysis of the gluten [53]. On the other hand, the solubility and swelling properties of dietary fiber (mainly β-glucans, arabinoxylans) increases at the low pH value characteristic of the sourdough and retardation process, which also aids in crumb softening [53].

After the dough retardation, color differences in the crust and crumb of the flatbreads were observed (Table 6). The TCD of the crumb was very distinct, with values ≥ 3 for all flatbreads. Only parameter a* of the dough was positively correlated with the a* of the crumb (r = 0.871, p = 0.005). This means that the TCD of bread could not be attributed only to a higher phenolic content and higher PPO activity, but also to other enzymes of cereal and microbial origin (such as amylases, proteases, and peptidases) as well as to non-enzymatic browning (e.g., Maillard reactions, dextrinization, and caramelization).

The phenomenon of darkening was even more pronounced in the crust than in the crumb, as shown by the TCD values (Table 6). The intensification of the crust color was more pronounced in oat bread than in barley bread which could be attributed to a three-fold higher activity of α-amylase in oat (322 U/kg d.w.) than in barley (101.6 U/kg d.w.) flour. The α-amylase activity during fermentation and baking (high temperatures and low moisture conditions) is responsible for enhancing Maillard reactions, as the resulting reducing sugars react with amino acids (proteins), which leads to a darkening of the bread surface during baking [54]. The darkening of the breadcrust is not only attributed to α-amylase activity but can also be caused by other enzymes activated in the dough retardation process. Glycoside hydrolases, in general, and proteases, increase the content of reducing sugars or free amino groups, i.e., precursors for Maillard reactions [55]. In addition, Olaerts et al. [56] found that the endoxylanase activity of flour has a significant correlation with breadcrust color. The amount of the Maillard reaction precursors that are initially present in the flour or added in the form of sugar, and enzyme activities, determine the intensity of the color change of the breadcrust the most. As with the crumb color, the exposure to high temperatures leads to the breakdown of starch and the formation of brown dextrins, which are responsible for the dark color of the breadcrust, but also for the caramelization of sugar and the formation of the brown color.

3.5. Nutritive Value of Bread

The type of flour, the sourdough addition level, the retardation time, or their combination had a significant influence on the PA and β-glucans content of the flatbreads (Table 6). The content of PA and β-glucans was higher with higher amounts of oat or barley.

Barley-containing flatbreads had a 13–31% lower PA content than oat flatbreads, probably because barley bran had a 33.6% lower PA content than oat bran [28]. The 24 h dough retardation significantly reduced the PA content by 38% in oat breads and by 27–32% in barley breads compared to the no-time process (Table 6). Fermentation is the crucial step in degrading PA in bread and can reduce its content by 31 to 85% [16]. Previous studies showed that sourdough fermentation successfully reduces the PA content of bread. It was demonstrated that the application of 30% Lactobacillus brevis and Lactobacillus plantarum sourdough (dough weight) resulted in PA degradation in the range of 31% to 67% for the whole-wheat bread [56,57], and that Lactobacillus plantarum sourdough with DY 300 and a 30% addition resulted in a 45% reduction in PA content of Iranian sangak flatbread [56,57]. Our study shows that the retardation of dough that contains sourdough further contributes to the degradation of PA. The retardation process resulted in a decrease in dough pH of 1.05 to 1.39 units (Table 6), which may correspond to the optimum pH (4.5–5.0) of cereal phytase [57]. The reduction in PA content in flatbreads from the retarded process could contribute to improving the bioavailability of minerals in flatbreads.

The β-glucan content was higher in oat than in barley flatbreads, since the oat flour–bran blend had a 21% higher β-glucan content compared to the barley flour–bran blend (4.35 vs. 3.60 g/100 g d.w.). Following this, an increasing trend was observed when increasing amounts of oat or barley sourdough were incorporated in the flatbread. Nevertheless, after dough retardation, the β-glucan content decreased by 4–9% in oat-containing flatbreads and even more, by 8–28%, in the barley flatbreads (Table 6). This was only partly caused by the activity of endogenous β-glucanase, whose activity in our semi-refined wheat flour was 1.68 U/MBG4 kg d.w. This is in agreement with a previous finding showing that wheat flour has low β-glucanase activity [58]. In our case, β-glucans were mostly degraded due to the activity of oat or barley β-glucanase, which was especially high in bran (13.3 and 9.1 MBG4 U/kg d.w., respectively), as reported by Grgić et al. [28]. β-glucans preservation was more successful with the higher (50%) addition of sourdough, most likely due to the lower pH of the dough, which may have slowed down the activity of β-glucanase. Flander et al. [50] found 12% less β-glucans in wheat–oat mixed bread containing wheat sourdough compared to straight dough bread. They concluded that the degradation of β-glucans occurred during the fermentation, which was not influenced by variations in the acidity of the breads between pH 4.9 and 5.8, but by endogenous β-glucanase activity and the fermentation time. Gamel et al. [59] also demonstrated a reduction (18–23%) in β-glucan content in whole-wheat/oat bread containing sourdough in different proportions (40, 60 and 80%, dough weight). In our study, the activity of β-glucanase, whose optimum is at 30 °C (approximate dough-proofing temperature), was reduced at the low retardation temperature (0–4 °C), which explains the small changes in the glucan concentrations of the retarded flatbread.

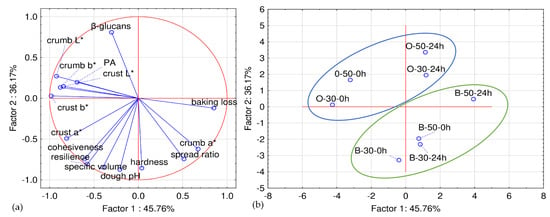

3.6. Principal Component Analysis

The PCA extracted 15 factors, and the first two components with eigenvalues of 6.864 and 5.425, accounting for 82% of the total variance, were considered (Figure 4). The first component contrasts variables crumb a* and baking loss with crumb L* and b* crust color parameters (Figure 4a). The second component contrasts the β-glucans with specific volume, dough pH, hardness, cohesiveness, and resilience. The first component separates samples from the no-time-processed and from the retarded-dough flatbread, although the B-50-0h flatbread was confused with the retarded samples (Figure 4b). Overall, oat flatbreads were better differentiated along the process than barley flatbreads. Flatbreads from the no-time process were contrasted to the retarded samples due to a darker crust and crumb color. Also, the separation of oats from barley flatbreads was evident. Oat flatbreads were characterized by higher β-glucans content whereas higher crumb hardness, spread ratio, and crumb redness were attributed to barley flatbreads.

Figure 4.

(a) the projection of responses on the factor plane according to principal component analysis; and (b) the projection of samples.

4. Conclusions

In this study, the sourdough fermentation of oat and barley flour with bran and commercially available starter cultures was comparatively investigated, and the quality of a mixed flatbread was examined as a function of the sourdough level and the dough retardation time. Oat flour showed a low acidification capacity when fermented with the commercially available starter. The partial replacement of flour with bran for sourdough fermentation proved to be advantageous due to its higher dietary fiber and minerals content, which enabled the desired pH value, total acidity, and lactic acid/acetic acid ratio to be achieved in a shorter timeframe. While the addition of oat or barley sourdough at the higher level (50% of dough weight) contributed to the higher β-glucan content of the mixed bread, sourdough addition at a lower level (30% of dough weight) resulted in a more desirable bread volume, crumb texture and a lower amount of phytic acid. Dough retardation in breadmaking was also shown to improve texture and reduce phytic acid content. Enzymatic browning of the dough during retardation, which is primarily caused by polyphenol oxidase activity in the bran, can be effectively delayed by adding sourdough, providing a natural approach to breadmaking. Future research should investigate the use of non-thermally treated cereal ingredients to reduce glucans and volume degradation, and to maximize the nutritional value of the bread.

Author Contributions

Conceptualization, T.G. and D.N.; methodology, S.D., B.V. and N.Č.M.; validation, D.N. and N.Č.M.; formal analysis, T.G. and S.D.; investigation, T.G. and S.D.; resources, D.N.; writing—original draft preparation, T.G.; writing—review and editing, D.N., B.V. and N.Č.M.; supervision and funding acquisition, D.N. All authors have read and agreed to the published version of the manuscript.

Funding

This paper is supported by the PRIMA programme under grant agreement No 2031 project “FLAT BREAD MINE.” This project is part of the PRIMA programme, which is an Art.185 initiative supported and funded under Horizon 2020, the European Union’s Framework Programme for Research and Innovation. Disclaimer: The results and content found in this Paper/Report reflect only the authors’ views. The PRIMA Foundation is not responsible for any use that may be made of the information it contains.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors wish to thank Lidija Drobac of the Laboratory for Cereal Chemistry and Technology, Faculty of Food Technology and Biotechnology, University of Zagreb, for her precious technical support. We thank Lesaffre Adriatic Inc. for donating LivendoTM LV1 starter.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dymchenko, A.; Geršl, M.; Gregor, T. Trends in bread waste utilisation. Trends Food Sci. Technol. 2023, 132, 93–102. [Google Scholar] [CrossRef]

- Pasqualone, A.; Vurro, F.; Summo, C.; Abd-El-Khalek, M.H.; Al-Dmoor, H.H.; Grgić, T.; Ruiz, M.; Magro, C.; Deligeorgakis, C.; Helou, C.; et al. The Large and Diverse Family of Mediterranean Flat Breads: A Database. Foods 2022, 11, 2326. [Google Scholar] [CrossRef]

- Kumar, A. Chapatis and related products. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 724–734. [Google Scholar] [CrossRef]

- Pasqualone, A. Traditional flat breads spread from the Fertile Crescent: Production process and history of baking systems. J. Ethn. Foods 2018, 5, 10–19. [Google Scholar] [CrossRef]

- Garzon, R.; Gasparre, N.; Pasqualone, A.; Papageorgiou, M.; Grgic, T.; Le-Bail, P.; Mínguez Pablos, I.; El Tomb, C.; Magro, C.; Rosell, C.M. Flatbreads on the rise, what about their nutritional quality? The current state of the Mediterranean market. Med. Res. Arch. 2022, 10, 1–16. [Google Scholar] [CrossRef]

- Kahlon, T.S.; Avena-Bustillos, R.J.; Brichta, J.L.; Kahlon, A.K. High-protein nutritious flatbreads and an option for gluten-sensitive individuals. Foods 2019, 8, 591. [Google Scholar] [CrossRef]

- Boukid, F. Flatbread—A canvas for innovation: A review. Appl. Food Res. 2022, 2, 100071. [Google Scholar] [CrossRef]

- Boers, H.M.; MacAulay, K.; Murray, P.; Dobriyal, R.; Mela, D.J.; Spreeuwenberg, M.A.M. Efficacy of fibre additions to flatbread flour mixes for reducing post-meal glucose and insulin responses in healthy Indian subjects. Br. J. Nutr. 2017, 117, 386–394. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Kaur, C.; Jambh, H.K. Rheological, textural, and technological modifications in wheat unleavened flatbread substituted with extruded finger millet. J. Texture Stud. 2021, 52, 400–409. [Google Scholar] [CrossRef] [PubMed]

- Mehfooz, T.; Ali, T.M.; Arif, S.; Hasnain, A. Effect of barley husk addition on rheological, textural, thermal and sensory characteristics of traditional flat bread (chapatti). J. Cereal Sci. 2018, 79, 376–382. [Google Scholar] [CrossRef]

- Bhavya, S.N.; Prakash, J. Nutritional properties of iron fortified flatbreads enriched with greens and legumes. J. Food Process. Preserv. 2021, 45, e15495. [Google Scholar] [CrossRef]

- EFSA. EFSA Panel of dietetic products, nutrition and allergies (NDA). Scientific Opinion on the substantiation of health claims related to beta-glucans from oats and barley and maintenance of normal blood LDL-cholesterol concentrations (ID 1236, 1299), increase in satiety leading to a reduction in energy intake (ID 851, 852), reduction of post-prandial glycaemic responses (ID 821, 824), and “digestive function” (ID 850) pursuant to Article 13(1) of Regulation (EC) No 1924/2006. EFSA J. 2011, 9, 1–21. [Google Scholar] [CrossRef]

- Pejcz, E.; Czaja, A.; Wojciechowicz-Budzisz, A.; Gil, Z.; Spychaj, R. The potential of naked barley sourdough to improve the quality and dietary fibre content of barley enriched wheat bread. J. Cereal Sci. 2017, 77, 97–101. [Google Scholar] [CrossRef]

- Koksel, H.; Tekin-Cakmak, Z.H.; Oruc, S.; Kilic, G.; Ozkan, K.; Cetiner, B.; Sagdic, O.; Sestili, F.; Jilal, A. A New Functional Wheat Flour Flatbread (Bazlama) Enriched with High-β-Glucan Hull-Less Barley Flour. Foods 2024, 13, 236. [Google Scholar] [CrossRef]

- Mansoor, R.; Ali, T.M.; Arif, S.; Moin, A.; Hasnain, A. Effects of barley flour on dough rheology, texture, sensory and glycemic index of traditional unleavened flat bread (Roti). Cereal Chem. 2019, 96, 1170–1179. [Google Scholar] [CrossRef]

- Naji-Tabasi, S.; Shahidi-Noghabi, M.; Hosseininezhad, M. Improving the quality of traditional Iranian bread by using sourdough and optimizing the fermentation conditions. SN Appl. Sci. 2022, 4, 148. [Google Scholar] [CrossRef]

- Gujral, H.S.; Sharma, P.; Gill, B.S.; Kaur, S. Effect of incorporating hydrothermal, kilned and defatted oats on antioxidant and chapatti making properties of wheat flour. Food Chem. 2013, 138, 1400–1406. [Google Scholar] [CrossRef] [PubMed]

- Arora, K.; Ameur, H.; Polo, A.; Di Cagno, R.; Rizzello, C.G.; Gobbetti, M. Thirty years of knowledge on sourdough fermentation: A systematic review. Trends Food Sci. Technol. 2021, 108, 71–83. [Google Scholar] [CrossRef]

- Gänzle, M.; Ripari, V. Composition and function of sourdough microbiota: From ecological theory to bread quality. Int. J. Food Microbiol. 2016, 239, 19–25. [Google Scholar] [CrossRef] [PubMed]

- Weckx, S.; Van Kerrebroeck, S.; De Vuyst, L. Omics approaches to understand sourdough fermentation processes. Int. J. Food Microbiol. 2019, 302, 90–102. [Google Scholar] [CrossRef] [PubMed]

- Galli, V.; Venturi, M.; Guerrini, S.; Blandino, M.; Luti, S.; Pazzagli, L.; Granchi, L. Antioxidant properties of sourdoughs made with whole grain flours of hull-less barley or conventional and pigmented wheat and by selected lactobacilli strains. Foods 2020, 9, 640. [Google Scholar] [CrossRef] [PubMed]

- Rieder, A.; Holtekjølen, A.K.; Sahlstrøm, S.; Moldestad, A. Effect of barley and oat flour types and sourdoughs on dough rheology and bread quality of composite wheat bread. J. Cereal Sci. 2012, 55, 44–52. [Google Scholar] [CrossRef]

- Fang, L.; Wang, W.; Dou, Z.; Chen, J.; Meng, Y.; Cai, L.; Li, Y. Effects of mixed fermentation of different lactic acid bacteria and yeast on phytic acid degradation and flavor compounds in sourdough. LWT 2023, 174, 114438. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, R.; Yuan, W. Type I sourdough steamed bread made by retarded sponge-dough method. Food Chem. 2020, 311, 126029. [Google Scholar] [CrossRef] [PubMed]

- Banerji, A.; Ananthanarayan, L.; Lele, S.S. Dough browning inhibition of multigrain Indian flatbread (chapatti) using a combination of chemical and microwave treatment. J. Food Measur. Charact. 2019, 13, 807–820. [Google Scholar] [CrossRef]

- Habuš, M.; Golubić, P.; Vukušić Pavičić, T.; Čukelj Mustač, N.; Voučko, B.; Herceg, Z.; Ćurić, D.; Novotni, D. Influence of Flour Type, Dough Acidity, Printing Temperature and Bran Pre-processing on Browning and 3D Printing Performance of Snacks. Food Bioproc. Technol. 2021, 14, 2365–2379. [Google Scholar] [CrossRef]

- Quinde-Axtell, Z.; Powers, J.; Baik, B.K. Retardation of discoloration in barley flour gel and dough. Cereal Chem. 2006, 83, 385–390. [Google Scholar] [CrossRef]

- Grgić, T.; Pavišić, Z.; Maltar-Strmečki, N.; Voučko, B.; Čukelj Mustač, N.; Ćurić, D.; Le-Bail, A.; Novotni, D. Ultrasound-assisted Modification of Enzymatic and Antioxidant Activities, Functional and Rheological Properties of Oat and Barley Bran. Food Bioproc. Technol. 2023, 16, 2416–2429. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis: Association of Analytical Chemists, 19th ed.; AOAC: Washington, DC, USA, 2012. [Google Scholar]

- AACC. Official Methods of Analysis: Approved Methods of the American Association of Cereal Chemists International, 10th ed.; AACC: St. Paul, MN, USA, 2000. [Google Scholar]

- Habuš, M.; Novotni, D.; Gregov, M.; Štifter, S.; Čukelj Mustač, N.; Voučko, B.; Ćurić, D. Influence of particle size reduction and high-intensity ultrasound on polyphenol oxidase, phenolics, and technological properties of wheat bran. J. Food Process. Preserv. 2021, 45, e15204. [Google Scholar] [CrossRef]

- Katina, K.; Salmenkallio-Marttila, M.; Partanen, R.; Forssell, P.; Autio, K. Effects of sourdough and enzymes on staling of high-fibre wheat bread. LWT 2006, 39, 479–491. [Google Scholar] [CrossRef]

- Lefebvre, D.; Gabriel, V.; Vayssier, Y.; Fontagné-Faucher, C. Simultaneous HPLC determination of sugars, organic acids and ethanol in sourdough process. LWT 2002, 35, 407–414. [Google Scholar] [CrossRef]

- ISO 15214:1998; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Numeration of Mesophilic Lactic acid Bacteria—Colony-Count Technique at 30 Degrees C. International Organization for Standardization (ISO): Geneva, Switzerland, 1998.

- ISO 7954:2002; General Guidance for Enumeration of Yeasts and Moulds—Colony Count Technique at 25 degrees C. International Organization for Standardization (ISO): Geneva, Switzerland, 2002.

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; Van, K.; Riet, T. Modeling of the Bacterial Growth Curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [CrossRef]

- Aboshora, W.; Lianfu, Z.; Dahir, M.; Quingran, M.; Musa, A.; Gasmalla, M.A.A.; Omar, K.A. Influence of doum (Hyphaene thebaica L.) flour addition on dough mixing properties, bread quality and antioxidant potential. J. Food Sci. Technol. 2016, 53, 591–600. [Google Scholar] [CrossRef]

- Rawat, M.; Varshney, A.; Rai, M.; Chikara, A.; Pohty, A.L.; Joshi, A.; Binjola, A.; Singh, C.P.; Rawat, K.; Rather, M.A.; et al. A comprehensive review on nutraceutical potential of underutilized cereals and cereal-based products. J. Agric. Food Res. 2023, 12, 100619. [Google Scholar] [CrossRef]

- Mariotti, M.; Garofalo, C.; Aquilanti, L.; Osimani, A.; Fongaro, L.; Tavoletti, S.; Hager, A.S.; Clementi, F. Barley flour exploitation in sourdough bread-making: A technological, nutritional and sensory evaluation. LWT 2014, 59, 973–980. [Google Scholar] [CrossRef]

- Hüttner, E.K.; Dal Bello, F.; Arendt, E.K. Identification of lactic acid bacteria isolated from oat sourdoughs and investigation into their potential for the improvement of oat bread quality. Eur. Food Res. Technol. 2010, 230, 849–857. [Google Scholar] [CrossRef]

- De Vuyst, L.; Neysens, P. The sourdough microflora: Biodiversity and metabolic interactions. Trends Food Sci. Technol. 2005, 16, 43–56. [Google Scholar] [CrossRef]

- Adekunte, A.O.; Tiwari, B.K.; Cullen, P.J.; Scannell, A.G.M.; O’Donnell, C.P. Effect of sonication on colour, ascorbic acid and yeast inactivation in tomato juice. Food Chem. 2010, 122, 500–507. [Google Scholar] [CrossRef]

- Brütsch, L.; Rugiero, S.; Serrano, S.S.; Städeli, C.; Windhab, E.J.; Fischer, P.; Kuster, S. Targeted Inhibition of Enzymatic Browning in Wheat Pastry Dough. J. Agric. Food Chem. 2018, 66, 12353–12360. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, T.; Lu, Y.; Yang, Q.; Li, Y.; Deng, X.; Liu, Y.; Du, X.; Qiao, L.; Zheng, J. Effect of high oxygen pretreatment of whole tuber on anti-browning of fresh-cut potato slices during storage. Food Chem. 2019, 301, 125287. [Google Scholar] [CrossRef]

- Taranto, F.; Pasqualone, A.; Mangini, G.; Tripodi, P.; Miazzi, M.M.; Pavan, S.; Montemurro, C. Polyphenol oxidases in crops: Biochemical, physiological and genetic aspects. Int. J. Mol. Sci. 2017, 18, 377. [Google Scholar] [CrossRef]

- Cauvain, S.P. Dough retarding and freezing. In Technology of Breadmaking, 2nd ed.; Cauvain, S.P., Young, L.S., Eds.; Springer: New York, NY, USA, 2007; pp. 175–205. [Google Scholar]

- Gill, S.; Vasanthan, T.; Ooraikul, B.; Rossnagal, B. Wheat bread quality as influenced by the substitution of waxy and regular barley flours in their native and cooked forms. J. Cereal Sci. 2002, 36, 239–251. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Relationship of gliadin and glutenin proteins with dough rheology, flour pasting and bread making performance of wheat varieties. LWT 2013, 51, 211–217. [Google Scholar] [CrossRef]

- Grenier, D.; Rondeau-Mouro, C.; Dedey, K.B.; Morel, M.H.; Lucas, T. Gas cell opening in bread dough during baking. Trends Food Sci. Technol. 2021, 109, 482–498. [Google Scholar] [CrossRef]

- Flander, L.; Suortti, T.; Katina, K.; Poutanen, K. Effects of wheat sourdough process on the quality of mixed oat-wheat bread. LWT 2011, 44, 656–664. [Google Scholar] [CrossRef]

- Deasy, A.; Dewi, R.; Tjahjono, A.; Kalirungkut Surabaya, J. The Making of Rice Bran Flour-Based Sourdough Bread. JPA 2022, 10, 28–37. [Google Scholar]

- Liu, W.; Brennan, M.; Serventi, L.; Brennan, C. The Effect of Oat Bran on the Dough Rheology and Quality of Chinese Steamed Bread. GOST 2018, 1, 126–130. [Google Scholar] [CrossRef]

- Arendt, E.K.; Ryan, L.A.M.; Dal Bello, F. Impact of sourdough on the texture of bread. Food Microbiol. 2007, 24, 165–174. [Google Scholar] [CrossRef] [PubMed]

- Olaerts, H.; Vandekerckhove, L.; Courtin, C.M. A closer look at the bread making process and the quality of bread as a function of the degree of preharvest sprouting of wheat (Triticum aestivum). J. Cereal Sci. 2018, 80, 188–197. [Google Scholar] [CrossRef]

- Kulp, K. Enzymes as dough improvers. In Advances in Baking Technology; Camel, B.S., Stauffer, C.E., Eds.; Springer: New York, NY, USA, 1993; pp. 152–178. [Google Scholar]

- Yildirim, R.M.; Arici, M. Effect of the fermentation temperature on the degradation of phytic acid in whole-wheat sourdough bread. LWT 2019, 112, 108224. [Google Scholar] [CrossRef]

- Leenhardt, F.; Levrat-Verny, M.A.; Chanliaud, E.; Rémésy, C. Moderate decrease of pH by sourdough fermentation is sufficient to reduce phytate content of whole wheat flour through endogenous phytase activity. J. Agric. Food Chem. 2005, 53, 98–102. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Miller, R.A.; Hoseney, R.C. Effects of (1 → 3) (1 → 4)-β-D-Glucans of Wheat Flour on Breadmaking. Cereal Chem. 1998, 75, 629–633. [Google Scholar] [CrossRef]

- Gamel, T.H.; Abdel-Aal, E.S.M.; Tosh, S.M. Effect of yeast-fermented and sour-dough making processes on physicochemical characteristics of β-glucan in whole wheat/oat bread. LWT 2015, 60, 78–85. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).