Current Updates on Lactic Acid Production and Control during Baijiu Brewing

Abstract

1. Introduction

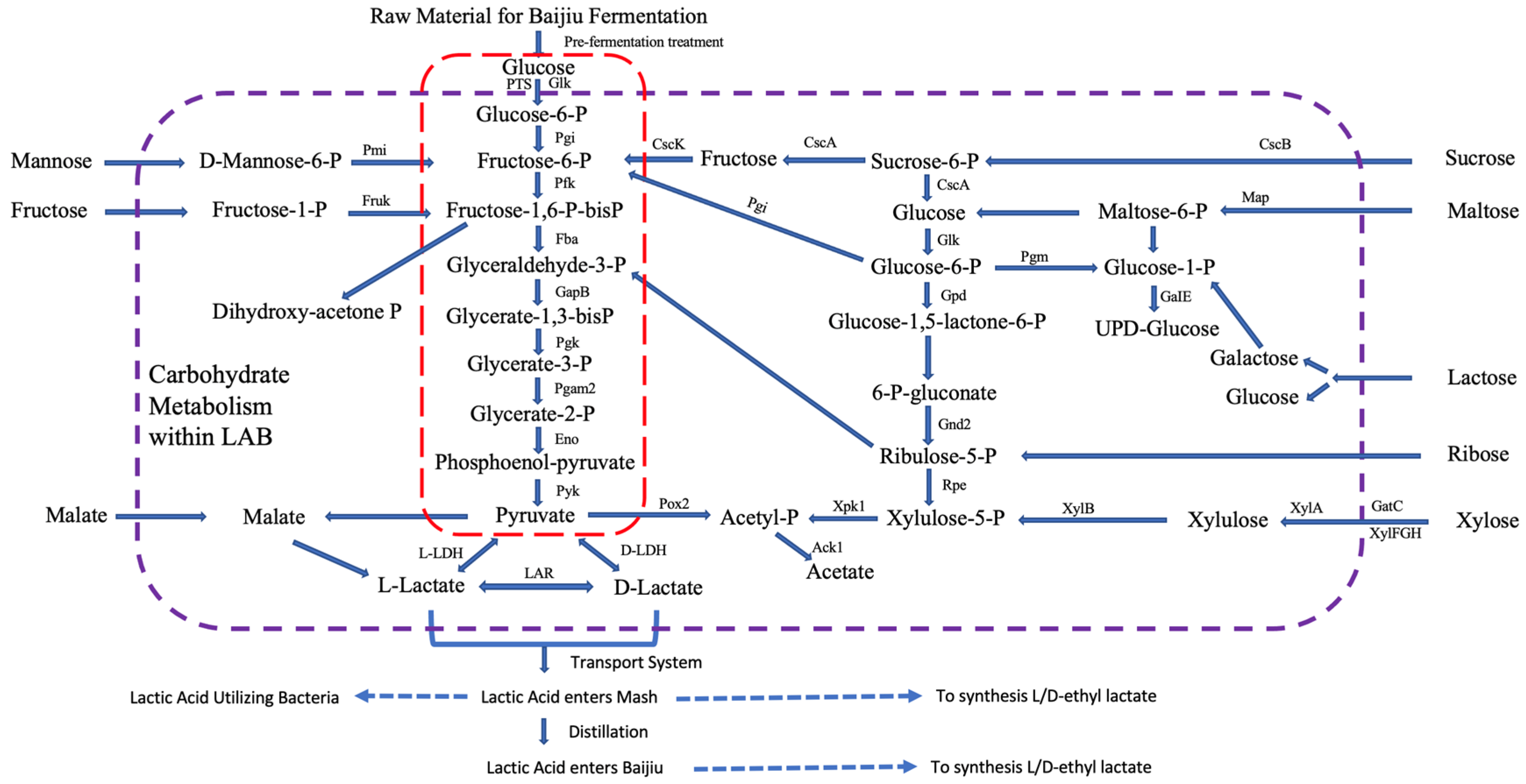

2. Fermentation Pathways of Lactic Acid Production in Baijiu

2.1. Homolactic Fermentation

2.2. Heterolactic Fermentation

2.3. Bifid Fermentation

3. Lactic Acid in Baijiu Brewing

3.1. The Role of Lactic Acid in Baijiu

3.2. The Causes of Abnormally High or Low Lactic Acid Levels during Baijiu Brewing

4. Lactic Acid Production Control in Baijiu Brewing

4.1. Impact of Brewing Ingredients on Lactic Acid in Baijiu

4.2. The Impact of Distiller’s Daqu on Lactic Acid in Baijiu

4.3. Control of Lactic Acid During Fermentation

4.3.1. Application of High-Yielding Lactic Acid Bacteria in Fermentation

4.3.2. Application of Lactic Acid-Degrading Bacteria in Fermentation

4.3.3. Impact of Fermentation Time on Lactic Acid

4.3.4. Using Microbial Interactions to Regulate Lactic Acid in Baijiu

4.4. Distillation Process Impact on Lactic Acid in Baijiu

4.5. Strictly Controlling Environmental Hygiene to Reduce Lactic Acid in Baijiu

4.6. Summary of Lactic Acid Production Control in Baijiu Brewing

- Early distillate collection: collecting distillate early in the distillation process when lactic acid concentration is lower can reduce its presence in the final product [68].

- Increasing lactic acid bacteria in the Daqu: enriching the distiller’s Daqu with lactic acid-producing bacteria can elevate lactic acid levels during fermentation [47].

- Microbial interactions: utilizing the synergistic effects of microorganisms can also increase lactic acid production [65].

- Late distillate collection: collecting distillate later in the process, when lactic acid concentrations are higher, can increase its presence in the final product [68].

5. Conclusions and Future Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Hua, J.; Zheng, Z.; Yang, R.; Huang, Z.; Zhou, Y. Investigation in Principleon Differential Impacts of Strong-Flavor Liquor and Pure Ethanol on Hepatic Lipid Level. J. Southwest China Norm. Univ. (Nat. Sci. Ed.) 2020, 47, 56–62. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Q.; Sun, B. Chinese Baijiu and Whisky: Research Reservoirs for Flavor and Functional Food. Foods 2023, 12, 2841. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Hua, J.; Huang, Z. Effects of beer, wine, and baijiu consumption on non-alcoholic fatty liver disease: Potential implications of the flavor compounds in the alcoholic beverages. Front. Nutr. 2022, 9, 1022977. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Hou, Y.; Chen, H.; Wang, J.; Zhang, C.; Zhao, Z.; Ao, R.; Huang, H.; Hong, J.; Zhao, D.; et al. “Key Factor” for Baijiu Quality: Research Progress on Acid Substances in Baijiu. Foods 2022, 11, 2959. [Google Scholar] [CrossRef]

- Yang, F.; Yang, Y.; Liu, Y.; Li, J.; Wang, L.; Chen, J. Identification of Key Environmental Factors of Lactic Acid Biosynthesis by Lactobacillus panis for Chinese Liquor Brewing. J. Food Sci. Biotechnol. 2021, 40, 36–42. [Google Scholar]

- Fan, J.; Chen, J.; Du, G.; Fang, F. Mechanism of Lactic Acid Synthesis during Strong-Flavor Baijiu Fermentation Revealed by Transcriptomic Analysis. Food Biosci. 2024, 58, 103780. [Google Scholar] [CrossRef]

- Zhao, X.; Li, J.; Du, G.; Chen, J.; Ren, T.; Wang, J.; Han, Y.; Zhen, P.; Zhao, X. The Influence of Seasons on the Composition of Microbial Communities and the Content of Lactic Acid during the Fermentation of Fen-Flavor Baijiu. Fermentation 2022, 8, 740. [Google Scholar] [CrossRef]

- Xu, H.; Qiu, S.; Dai, Y.; Wu, Y.; Zeng, X. Distribution and Quantification of Lactic Acid Enantiomers in Baijiu. Foods 2022, 11, 2607. [Google Scholar] [CrossRef]

- Pang, X.N.; Chen, C.; Huang, X.; Yan, Y.; Chen, J.; Han, B. Influence of indigenous lactic acid bacteria on the volatile flavor profile of light-flavor Baijiu. Food Sci. Technol. 2021, 147, 111540. [Google Scholar] [CrossRef]

- Wang, X.; Liu, F.; Zhang, Y.; Zhong, Y.; Mo, X.; Zhao, L. Research progress on lactic acid-degrading bacteria in Baijiu-making process. China Brew. 2021, 40, 7–10. [Google Scholar]

- Tu, W.; Cao, X.; Cheng, J.; Li, L.; Zhang, T.; Wu, Q.; Xiang, P.; Shen, C.; Li, Q. Chinese Baijiu: The Perfect Works of Microorganisms. Front. Microbiol. 2022, 13, 919044. [Google Scholar] [CrossRef]

- Yang, L.; Huang, D.; Li, Z. Study on the function and mechanism of lactic acid bacteria in the brewing process of Baijiu. Int. J. New Dev. Eng. Soc. 2023, 7, 51–59. [Google Scholar]

- Yang, F.; Chen, L.; Liu, Y.F.; Li, J.H.; Wang, L.; Chen, J. Identification of microorganisms producing lactic acid during solid-state fermentation of Maotai flavour liquor. J. Inst. Brew. 2019, 125, 171–177. [Google Scholar] [CrossRef]

- Endo, A.; Maeno, S.; Tanizawa, Y.; Kneifel, W.; Arita, M.; Dicks, L.; Salminen, S. Fructophilic Lactic Acid Bacteria, a Unique Group of Fructose-Fermenting Microbes. Appl. Environ. Microbiol. 2018, 84, e01290-18. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Han, X.; Zhang, L. Research advances of the osmotic stress-related compatible solutes of lactic acid bacteria and it’s transport mechanism. Microbiol. China 2013, 40, 2097–2016. [Google Scholar]

- Du, S.; Yao, L.; Zhong, B.; Qin, J.; He, S.; Liu, Y.; Wu, Z. Enhancing synthesis of ethyl lactate in rice baijiu fermentation by adding recovered granular cells. J. Biosci. Bioeng. 2024, 137, 388–395. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Chai, L.J.; Gao, T.; Pu, C.; Zhang, L.; Zhang, X.; Xu, Z. Seasonal Variation of Flavor Substances in Chinese Strong-Flavor Baijiu Base Liquor. Food Sci. 2023, 44, 164–171. [Google Scholar]

- Gänzle, M.G. Lactic metabolism revisited: Metabolism of lactic acid bacteria in food fermentations and food spoilage. Curr. Opin. Food Sci. 2015, 2, 106–117. [Google Scholar] [CrossRef]

- Fan, W.; Xue, Y. Liquor Flavor Chemistry, 2nd ed.; China Light Industry Press: Beijing, China, 2020. [Google Scholar]

- Nose, A.; Hojo, M. Hydrogen bonding of water-ethanol in alcoholic beverages. J. Biosci. Bioeng. 2006, 102, 269–280. [Google Scholar] [CrossRef]

- Qin, D.; Shen, Y.; Yang, S.; Zhang, G.; Wang, D.; Li, H.; Sun, J. Whether the Research on Ethanol-Water Microstructure in Traditional Baijiu Should Be Strengthened? Molecules 2022, 27, 8290. [Google Scholar] [CrossRef]

- Xiao, D. Baijiu Production, 3rd ed.; Chemical Industry Press: Beijing, China, 2023. [Google Scholar]

- Wang, J.; Lu, C.; Xu, Q.; Li, Z.; Song, Y.; Zhou, S.; Zhang, T.; Luo, X. Bacterial Diversity and Lactic Acid Bacteria with High Alcohol Tolerance in the Fermented Grains of Soy Sauce Aroma Type Baijiu in North China. Foods 2022, 11, 1794. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Zhou, J.; He, G. Effect of microbial interaction on flavor quality in Chinese baijiu fermentation. Front. Nutr. 2022, 9, 960712. [Google Scholar] [CrossRef] [PubMed]

- Du, P.; Jiao, G.; Zhang, Z.; Wang, J.; Li, P.; Dong, J.; Wang, R. Relationship between Representative Trace Components and Health Functions of Chinese Baijiu: A Review. Fermentation 2023, 9, 658. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, S.; Su, Z.; Huang, T.; Ding, H.; Wang, C.; Li, D.; Yang, Y.; Luo, J. Research progress in the effects of organic acids on the quality of Nongxiang baijiu and its production process. Liquor-Mak. Sci. Technol. 2016, 1, 94–97+102. [Google Scholar]

- Zong, X.; Wen, L.; Mou, T.; Wang, Y.; Li, L. Effects of multiple cycles of sorghum starch gelatinization and fermentation on production of Chinese strong flavor Baijiu. J. Cereal Sci. 2022, 108, 103561. [Google Scholar] [CrossRef]

- Liu, H.; Sun, B. Effect of Fermentation Processing on the Flavor of Baijiu. J. Agric. Food Chem. 2018, 66, 5425–5432. [Google Scholar] [CrossRef]

- Xia, Z.; Wang, S.; Chen, Y.; Gou, M.; Sun, Z.; Wang, S.; Zhang, S.; Tang, Y. Comparison of the microbial communities in pits with different sealing methods for Chinese strong-flavor liquor production. Food Sci. Technol. 2023, 173, 114248. [Google Scholar] [CrossRef]

- Tang, J.; Liu, Y.; Lin, B.; Zhu, H.; Jiang, W.; Yang, Q.; Chen, S.A.-O. Effects of ultra-long fermentation time on the microbial community and flavor components of light-flavor Xiaoqu Baijiu based on fermentation tanks. World J. Microbiol. Biotechnol. 2022, 38, 3. [Google Scholar] [CrossRef]

- Liang, C.; Liu, L.-X.; Liu, J.; Aihaiti, A.; Tang, X.-J.; Liu, Y.-G. New Insights on Low-Temperature Fermentation for Food. Fermentation 2023, 9, 477. [Google Scholar] [CrossRef]

- Kang, J.; Zheng, X.; Yang, X.; Li, H.; Cheng, J.; Fan, L.; Zhao, H.; Xue, Y.; Ding, Z.; Han, B. Contrasting summer versus winter dynamic microbial communities and their environmental driving factors in the solid-state saccharification process of Fuyu-flavor Baijiu. Food Res. Int. 2022, 154, 111008. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, L.; Zhang, Z.; Yang, Q.; Chen, S.; Zhang, L.; Xia, X.; Tu, J.; Liang, Y.; Zhao, S. Microbial community changes during the mechanized production of light aroma Xiaoqu baijiu. Biotechnol. Biotechnol. Equip. 2021, 35, 487–495. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, H.; Sun, Y.; Huang, H.; Chen, Y.; Hong, J.; Liu, X.; Wei, H.; Tian, W.; Zhao, D.A.-O.; et al. Integration of Chemometrics and Sensory Metabolomics to Validate Quality Factors of Aged Baijiu (Nianfen Baijiu) with Emphasis on Long-Chain Fatty Acid Ethyl Esters. Foods 2023, 12, 3087. [Google Scholar] [CrossRef] [PubMed]

- Niu, J.; Yang, S.; Shen, Y.; Cheng, W.; Li, H.; Sun, J.; Huang, M.; Sun, B. What Are the Main Factors That Affect the Flavor of Sauce-Aroma Baijiu. Foods 2022, 11, 3534. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Ma, Z.; Xi, Y.; Chen, Y.; Zhang, X.; Yang, E.; Wang, Z. Influence of Different Sorghum Varieties on the Production of Jiangxiang Baijiu. Liquor-Mak. Sci. Technol. 2023, 9, 93–96. [Google Scholar]

- Wang, G.; Zhao, Z.; Pu, W.; Chen, J. Comparison between Sichuan Red Sorghum and Japonica Sorghum as Raw Materials in Jiangxiang Baijiu Production. Liquor-Mak. Sci. Technol. 2017, 9, 61–64. [Google Scholar]

- Li, K.; Xiong, Q.; Fu, Y.; Hu, X.; Peng, S.; Xie, X. Effects of Premium Rice/Regular Rice on the Quality and the Yield of Texiang Baijiu. Liquor-Mak. Sci. Technol. 2016, 6, 84–87. [Google Scholar]

- Han, J.; Xiao, D. L-lactic acid fermentation process for Baijiu production. Food Ferment. Ind. 2019, 45, 134–139. [Google Scholar]

- Tang, P.; Shan, Q.; Wang, L.; Wang, F.; Li, C.; Lu, J. A Review of Research Methods in Baijiu Flavor Chemistry and Recent Progress in the Flavor Chemistry of Maotai-Flavored Baijiu. Food Sci. 2020, 41, 315–324. [Google Scholar]

- Niu, J.; Shen, Y.; Zhang, G.; Cheng, W.; Li, H.; Zheng, F.; Sun, B. Research progress on the relationship between raw materials and Baijiu quality. Food Ferment. Ind. 2022, 49, 322–324. [Google Scholar]

- Ren, J.; Chen, J.; Li, Z.; Jia, W.; Yan, Z. Research overview of twelve flavor types Baijiu. China Brew. 2022, 41, 13–19. [Google Scholar]

- Chang, Q.; Wu, Z.; Sun, W.; Cui, L.; Han, X.; Hu, J.; Jiang, C.; Dong, S. Application of Tannin of Different Content in the Production of Nongxiang Baijiu. Liquor-Mak. Sci. Technol. 2022, 5, 47–51, 55. [Google Scholar]

- Li, L. Diversity and Metabolic Characteristics of Lactic Acid Bacteria and Lactate-Degrading Bacteria in Fermented Grains of Luzhou-Flavor Liquor. Master’s Thesis, Jiang Nan University, Wuxi, China, 2016. [Google Scholar]

- Zhang, J.; Cheng, W.; Peng, B.; Xie, G.; Wang, X.; Wu, L. Research on Brewing Techniques About a Kinds of Multi-grain Composite Flavor Liquors. Liquor Mak. 2020, 47, 39–43. [Google Scholar]

- Li, L.; Xiao, C.; Lu, Z.; Zhang, X.; Wang, S.; Shen, C.; Shi, J.; Xu, Z. Origin, Succession and Potential Function of Lactic Acid Bacteria in Fermented Grains of Luzhou-Flavor Liquor. J. Food Sci. Biotechnol. 2018, 37, 1242–1247. [Google Scholar]

- Yang, F.; Qin, Y. Impact and mechanism of Eurotium critatum on the saccharification ability of Jiuqu. Food Ferment. Ind. 2023, 49, 81–87. [Google Scholar]

- Wu, Z.; Miao, L.; Zhang, M.; Zhou, F. Diversity and tolerance of lactic acid bacteria in high temperature Daqu at different storage periods. China Brew. 2018, 37, 61–67. [Google Scholar]

- Ding, H. Application of Lactobacillus Casei in Laobaigan Flavor Liquor. Master’s Thesis, Tianjin University of Science and Technology, Tianjin, China, 2013. [Google Scholar]

- Li, X. Isolation and Metabolic Characteristics of Lactic Acid Bacteria from Maotai-Flavor Liquor. Master’s Thesis, Tianjin University of Science and Technology, Tianjing, China, 2021. [Google Scholar]

- Zhang, L.; Liang, Z.; Hao, J.; Li, G.; Ye, J.; Wan, R.; Wu, J.; Zhou, B.; Luo, D. Effect of Lactic Acid Bacteria on the Production of Lactic Acid and Ethyl Lactate during the Fermentation of Mixiang Baijiu. Liquor-Mak. Sci. Technol. 2022, 11, 29–35. [Google Scholar]

- Zhao, X.; Zhen, P.; Zhao, X.; Han, Y.; Li, J.; Wang, J.; Du, G.; Chen, J. Dynamic analysis of main acids and bacterial flora structure in the Fen-flavor fermented grains during LiPeiQi. Food Ferment. Ind. 2022, 48, 26–33. [Google Scholar]

- Zhang, Y.; Du, H.; Wu, Q.; Xu, Y. Impacts of two main lactic acid bacteria on microbial communities during Chinese Maotai-flavor liquor fermentation. Microbiol. China 2015, 42, 2087–2097. [Google Scholar]

- Zhao, W.; Zhao, X.; Cui, M.; Zhang, X. Screening of high-yield lactic acid strains from fermented grains of light-flavor Baijiu and isolation and purification of lactic acid. China Brew. 2022, 41, 63–68. [Google Scholar]

- Yang, W.; Cao, J.; Wang, D.; Han, X.; Wang, X. Isolation, application and identification of the lactate-utilizing bacteria. China Brew. 2012, 31, 120–123. [Google Scholar]

- Wu, S.; Xin, X.; Deng, D.; Xiong, Q. Isolation and identification of propionibacterium in pit mud and how it to affect style and flavor of Te-type liquor. China Food Addit. 2011, 4, 130–134+199. [Google Scholar]

- Xin, X.; Wu, S.; Deng, D.; Chen, F. Investigation on the influence of propionibacterium on the style and flavor substances of Te-type liquor. Sci. Technol. Food Ind. 2012, 33, 240–243. [Google Scholar]

- Liao, C. Investigation on the Key Factors of Imcreasing Propionibacterium in Te-Type Liquor; Saint Liquor Co., Ltd.: Zhangshu, China, 2013. [Google Scholar]

- Li, W.; Li, J.; Wang, Y.; Yang, F.; Zhao, H. Screening and identification of lactic acid-utilizing bacteria from Fen-flavor Baijiu. China Brew. 2017, 36, 87–91. [Google Scholar]

- Song, K.; Zhou, S.; Wei, J.; Wang, Y.; Zhang, R.; Hu, J.; Hu, J.; Zhao, W. Screening and Application of a Bacterial Strain for the Degradation of Lactic Acid. Liquor-Mak. Sci. Technol. 2015, 3, 74–76. [Google Scholar]

- Zhen, D.; Guo, Y.; Chen, M. Separation & Identification of Lactic Acid-utilizing Bacteria in Luzhou-flavor Liquor Production and Study of Its Properties. Liquor-Mak. Sci. Technol. 2009, 8, 52–54. [Google Scholar]

- Zhang, B.; Li, L.; Wu, H.; Liu, S.; Tian, P.; Zhang, C.; Dong, X. Determination of Lactic Acid Content in Fermented Grains by HPLC. Liquor-Mak. Sci. Technol. 2019, 2, 109–112. [Google Scholar]

- Yang, F. Lactic Acid Metabolic Mechanism Investigation and Control Strategy Development during Chinese Jiang-Flavor Liquor Making. Ph.D. Thesis, Jiang Nan Univeristy, Wuxi, China, 2020. [Google Scholar]

- Wang, J.; Chen, H.; Wu, Y.; Zhao, D. Uncover the flavor code of strong-aroma baijiu: Research progress on the revelation of aroma compounds in strong-aroma baijiu by means of modern separation technology and molecular sensory evaluation. J. Food Compos. Anal. 2022, 109, 104499. [Google Scholar] [CrossRef]

- Zhou, X.; Zhou, W.; Yang, G.; Zeng, Y. Study on the Effect of The Mircoorganism Derived From Pit Mud on the Formation of Luzhou-flavor Baijiu Flavors. Liquor Mak. 2022, 49, 29–33. [Google Scholar]

- Luo, H.; Zeng, X.; Chen, L.; Yan, F.; Du, H.; Huang, X. Microbial intervention to reduce lactic acid in Moutai-flavor liquor brewing. Food Ferment. Ind. 2023, 49, 63–68. [Google Scholar]

- Deng, N.; Du, H.; Xu, Y. Cooperative Response of Pichia kudriavzevii and Saccharomyces cerevisiae to Lactic Acid Stress in Baijiu Fermentation. J. Agric. Food Chem. 2020, 68, 4903–4911. [Google Scholar] [CrossRef]

- Huang, T.; Yang, Y.; Liu, M.; Huang, H.; Feng, F.; Wang, M.; Zhao, J. Discriminant Analysis of Luzhou-flavor Original Liquor from Different Producing Areas in Sichuan Based on Chemometrics Methods. Liquor. Mak. 2022, 49, 64–70. [Google Scholar]

- Wang, A. Research Progress in Reducing the Content of Ethyl Lactate in Nongxiang Baijiu. Liquor-Mak. Sci. Technol. 2017, 5, 93–98. [Google Scholar]

| Abnormally High/Low Lactic Acid Levels | The Causes | The Type of Baijiu | Reference |

|---|---|---|---|

| High | High starch content in raw materials, rapid temperature rise in the pit, high residual sugar, large proliferation of lactic acid bacteria | Strong aroma | [11,27] |

| Lactic acid bacteria introduced into the fermentation mash from starter culture and pit mud | Strong aroma | [28] | |

| Cracks in the pit mud after sealing the pit, allowing lactic acid bacteria to invade the fermentation mash | Strong aroma | [29] | |

| High ambient temperature during summer production, lactic acid bacteria resistant to high temperatures and widely distributed in the fermentation mash | Light aroma | [7,30] | |

| Use of high-temperature starter culture and heap fermentation, rapid temperature rise in the pit, large proliferation of lactic acid bacteria | Strong aroma | [7,30] | |

| Low | Container fermentation (lower temperature inside the container), because lactic acid bacteria prefer higher-temperature environments | Strong aroma | [31,32] |

| Lower ground and air temperatures during winter production, leading to lower lactic acid bacteria content in the fermentation mash | Strong aroma | [31,32] | |

| Application of mechanized and clean production processes, reducing the chance of lactic acid bacteria entering the fermentation mash from the environment | Light aroma | [33] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Hua, J. Current Updates on Lactic Acid Production and Control during Baijiu Brewing. Fermentation 2024, 10, 505. https://doi.org/10.3390/fermentation10100505

Zhou Y, Hua J. Current Updates on Lactic Acid Production and Control during Baijiu Brewing. Fermentation. 2024; 10(10):505. https://doi.org/10.3390/fermentation10100505

Chicago/Turabian StyleZhou, Yabin, and Jin Hua. 2024. "Current Updates on Lactic Acid Production and Control during Baijiu Brewing" Fermentation 10, no. 10: 505. https://doi.org/10.3390/fermentation10100505

APA StyleZhou, Y., & Hua, J. (2024). Current Updates on Lactic Acid Production and Control during Baijiu Brewing. Fermentation, 10(10), 505. https://doi.org/10.3390/fermentation10100505