Biohydrogen Production from Buckwheat Residue Using Anaerobic Mixed Bacteria

Abstract

:1. Introduction

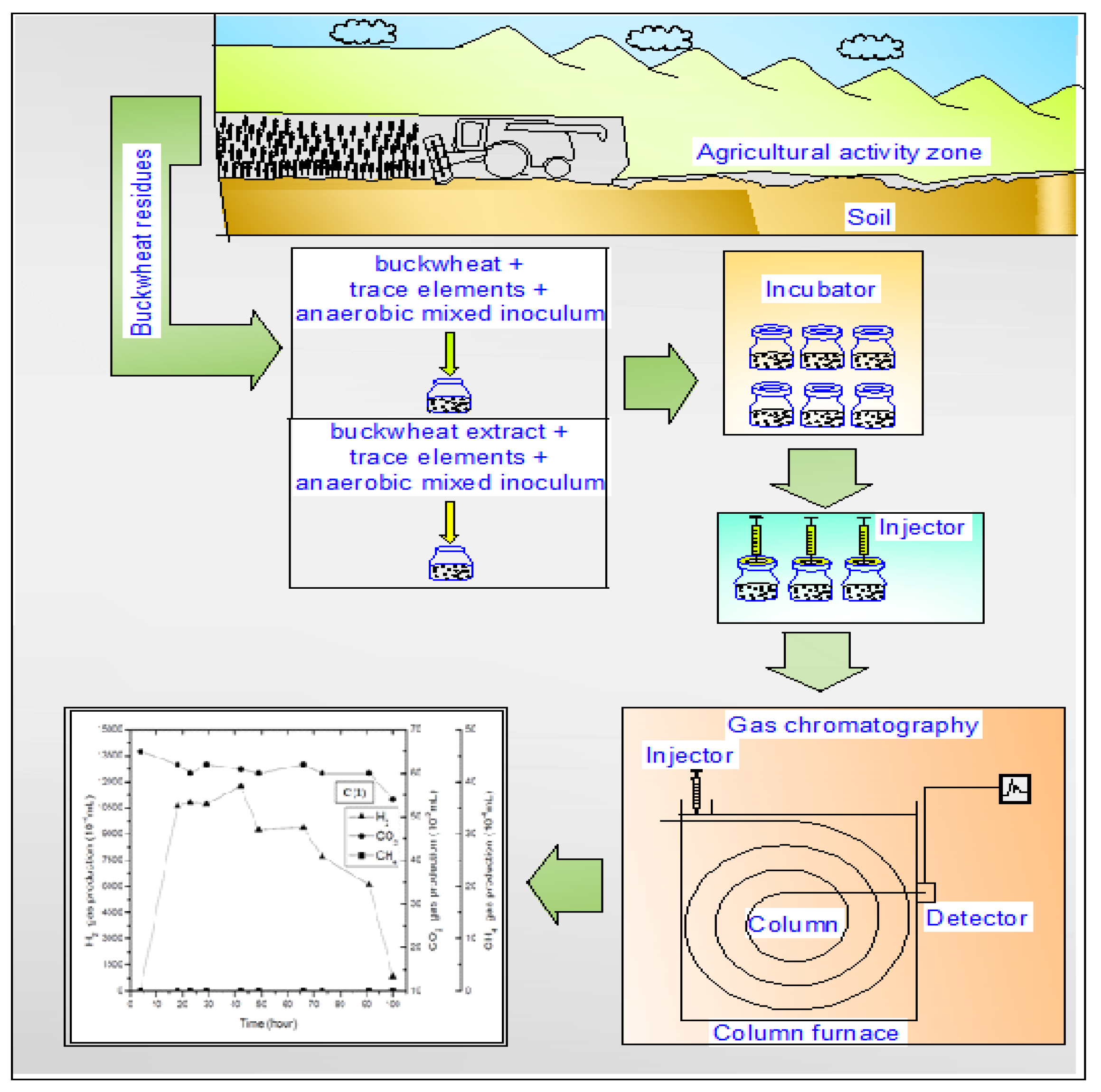

2. Materials and Methods

2.1. Nutritional Composition and Inoculum

2.2. Installation and Operation of Bioreactors

2.3. Analytical Methods

2.4. Microbial Community Analysis

3. Results and Discussion

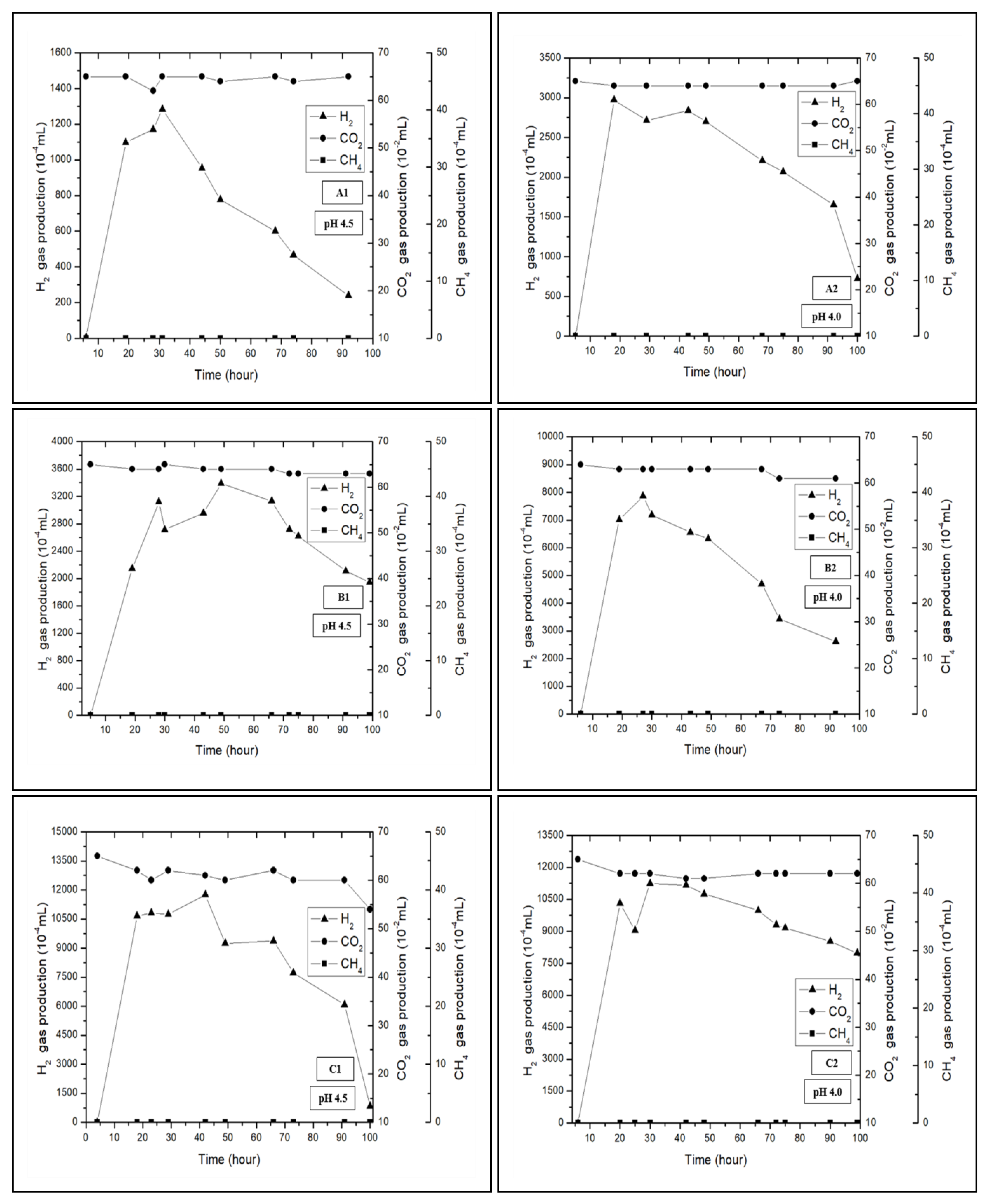

3.1. The Effect of Direct Use of Biomass on Biohydrogen Production

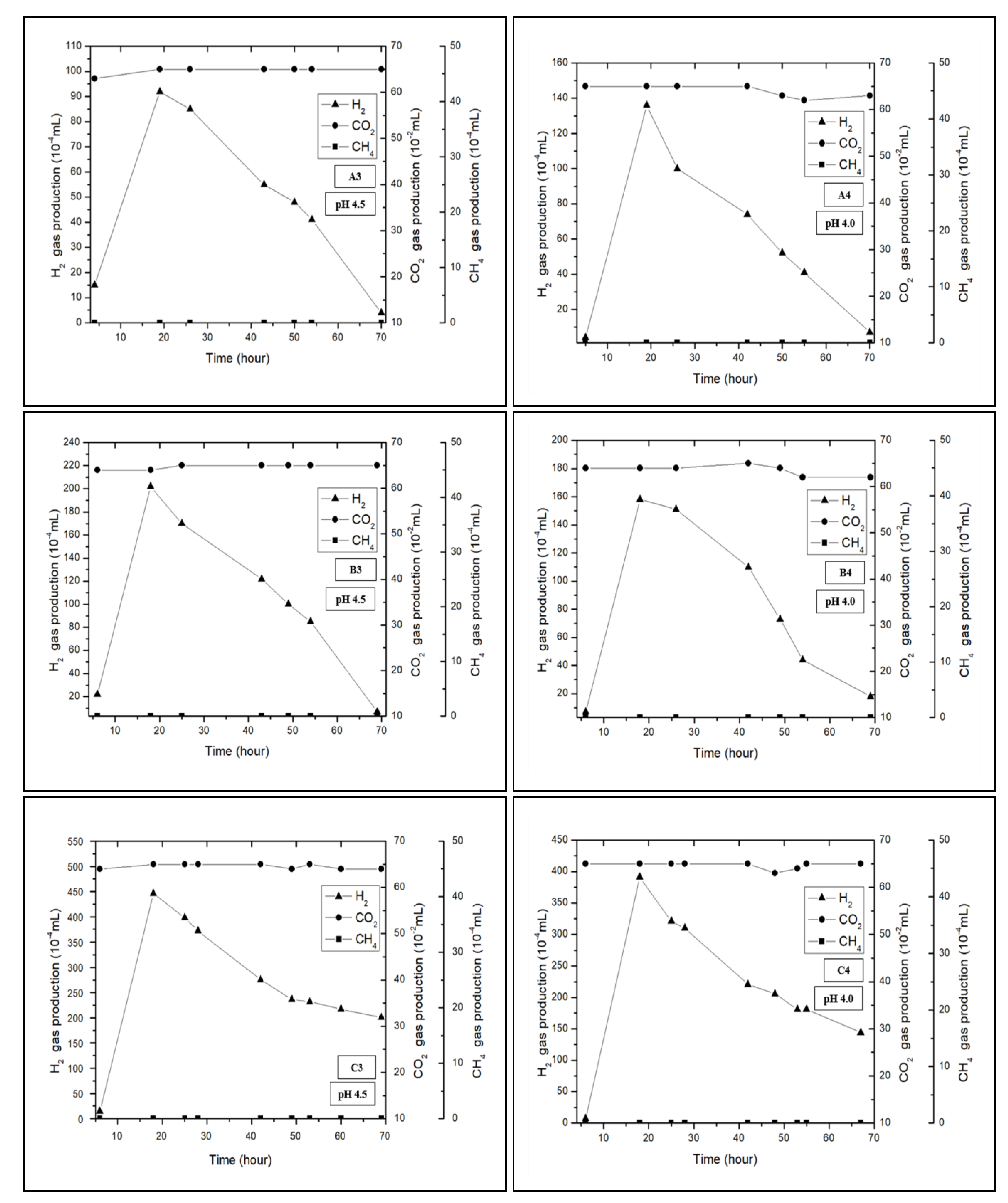

3.2. The Effect of the Use of Biomass Extract Fluid after Pretreatment on Biological Hydrogen Production

3.3. Microbial Community Content

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rusman, N.A.A.; Dahari, M. A review on the current progress of metal hydrides material for solid-state hydrogen storage applications. Int. J. Hydrogen Energy 2016, 41, 12108–12126. [Google Scholar] [CrossRef]

- Tryhuba, A.; Hutsol, T.; Glowacki, S.; Tryhuba, I.; Tabor, S.; Kwasniewski, D.; Sorokin, D.; Yermakov, S. Forecasting quantitative risk indicators of investors in projects of biohydrogen production from agricultural raw materials. Processes 2021, 9, 258. [Google Scholar] [CrossRef]

- Olabi, A.G.; Bahri, A.S.; Abdelghafar, A.A.; Baroutaji, A.; Sayed, E.T.; Alami, A.H.; Rezk, H.; Abdelkareem, M.A. Large-vscale hydrogen production and storage technologies: Current status and future directions. Int. J. Hydrogen Energy 2021, 46, 23498–23528. [Google Scholar] [CrossRef]

- Roy, S.; Dikshit, P.K.; Sherpa, K.C.; Singh, A.; Jacob, S.; Rajak, R.C. Recent nanobiotechnological advancements in lignocellulosic biomass valorization: A review. J. Environ. Manag. 2021, 297, 113422. [Google Scholar] [CrossRef] [PubMed]

- Ren, N.; Wang, A.; Cao, G.; Xu, J.; Gao, L. Bioconversion of lignocellulosic biomass to hydrogen: Potential and challenges. Biotechnol. Adv. 2009, 27, 1051–1060. [Google Scholar] [CrossRef] [PubMed]

- Chatalova, L.; Balmann, A. The hidden costs of renewables promotion: The case of crop-based biogas. J. Clean. Prod. 2017, 168, 893–903. [Google Scholar] [CrossRef]

- FAO (Food and Agriculture Organization of the United Nations). The State of Food and Agriculture 2019: Moving Forward on Food Loss and Waste Reduction; FAO: Rome, Italy, 2019; ISBN 978-92-5-131789-1. [Google Scholar]

- Kothari, R.; Singh, D.P.; Tyagi, V.V.; Tyagi, S.K. Fermentative hydrogen production-An alternative clean energy source. Renew. Sust. Energy Rev. 2012, 16, 2337–2346. [Google Scholar] [CrossRef]

- Khanna, N.; Das, D. Biohydrogen production by dark fermentation. WIREs Energy Environ. 2013, 2, 401–421. [Google Scholar] [CrossRef]

- Azwar, M.Y.; Hussain, M.A.; Abdul-Wahab, A.K. Development of biohydrogen production by photobiological, fermentation and electrochemical processes: A review. Renew. Sust. Energy Rev. 2014, 31, 158–173. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Yang, G.; Sun, Z. Optimization of biohydrogen production using acid pretreated corn stover hydrolysate followed by nickel nanoparticle addition. Int. J. Energy Res. 2020, 44, 1843–1857. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, X.; Li, Y.; Jin, P.; Jiao, Y.; Ai, F.; Zhang, H.; Zhang, Q. Photo-fermentative biohydrogen production from corncob treated by microwave irradiation. Bioresour. Technol. 2021, 340, 125460. [Google Scholar] [CrossRef] [PubMed]

- Mishra, P.; ab Wahid, Z.; Singh, L.; Zaid, R.M.; Tabassum, S.; Sakinah, M.; Jiang, X. Synergistic effect of ultrasonic and microwave pretreatment on improved biohydrogen generation from palm oil mill effluent. Biomass Convers. Biorefinery 2022, 12, 3655–3662. [Google Scholar] [CrossRef]

- Bundhoo, Z.M.A. Effects of microwave and ultrasound irradiations on dark fermentative bio-hydrogen production from food and yard wastes. Int. J. Energy Res. 2017, 42, 4040–4050. [Google Scholar] [CrossRef]

- do Carmo Lamaison, F.; de Andrade, P.A.M.; Bigaton, A.D.; Andreote, F.D.; Antônio, R.V. Long-term effect of acid and heat pretreatment of sludge from a sugarcane vinasse treatment plant on the microbial community and on thermophilic biohydrogen production. Int. J. Hydrogen Energy 2015, 40, 14124–14133. [Google Scholar] [CrossRef]

- Chong, P.S.; Jahim, J.M.; Harun, S.; Lim, S.S.; Mutalib, S.A.; Hassan, O.; Nor, M.T.M. Enhancement of batch biohydrogen production from prehydrolysate of acid treated oil palm empty fruit bunch. Int. J. Hydrogen Energy 2013, 38, 9592–9599. [Google Scholar] [CrossRef]

- Valdez-Vazquez, I.; Ponce-Noyola, M.T.; Poggi-Varaldo, H.M. Nutrients related to spore germination improve H2 production from heat-shock-treated consortia. Int. J. Hydrogen Energy 2009, 34, 4291–4295. [Google Scholar] [CrossRef]

- Yang, G.; Hu, Y.; Wang, J. Biohydrogen production from co-fermentation of fallen leaves and sewage sludge. Bioresour. Technol. 2019, 285, 121342. [Google Scholar] [CrossRef]

- Bansal, S.K.; Sreekrishnan, T.R.; Singh, R. Effect of heat pretreated consortia on fermentative biohydrogen production from vegetable waste. Natl. Acad. Sci. Lett. 2013, 36, 125–131. [Google Scholar] [CrossRef]

- Bala-Amutha, K.; Murugesan, A.G. Biohydrogen production using corn stalk employing Bacillus licheniformis MSU AGM 2 strain. Renew. Energy 2013, 50, 621–627. [Google Scholar] [CrossRef]

- Vaidya, A.A.; Donaldson, L.A.; Newman, R.H.; Suckling, I.D.; Campion, S.H.; Lloyd, J.A.; Murton, K.D. Micromorphological changes and mechanism associated with wet ball milling of Pinus radiata substrate and consequences for saccharification at low enzyme loading. Bioresour. Technol. 2016, 214, 132–137. [Google Scholar] [CrossRef]

- Yu, H.; Xiao, W.; Han, L.; Huang, G. Characterization of mechanical pulverization/phosphoric acid pretreatment of corn stover for enzymatic hydrolysis. Bioresour. Technol. 2019, 282, 69–74. [Google Scholar] [CrossRef] [PubMed]

- Silva, G.G.D.; Couturier, M.; Berrin, J.-G.; Buléon, A.; Rouau, X. Effects of grinding processes on enzymatic degradation of wheat straw. Bioresour. Technol. 2012, 103, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Yi, W.; Nadeem, F.; Xu, G.; Zhang, Q.; Joshee, N.; Tahir, N. Modifying crystallinity, and thermo-optical characteristics of Paulownia biomass through ultrafine grinding and evaluation of biohydrogen production potential. J. Clean. Prod. 2020, 269, 122386. [Google Scholar] [CrossRef]

- Zhang, Z.; Tahir, N.; Li, Y.; Zhang, T.; Zhu, S.; Zhang, Q. Tailoring of structural and optical parameters of corncobs through ball milling pretreatment. Renew. Energy 2019, 141, 298–304. [Google Scholar] [CrossRef]

- Zhang, M.-L.; Fan, Y.-T.; Xing, Y.; Pan, C.-M.; Zhang, G.-S.; Lay, J.-J. Enhanced biohydrogen production from cornstalk wastes with acidification pretreatment by mixed anaerobic cultures. Biomass Bioenergy 2007, 31, 250–254. [Google Scholar] [CrossRef]

- Kumari, S.; Das, D. Improvement of biohydrogen production using acidogenic culture. Int. J. Hydrogen Energy 2017, 42, 4083–4094. [Google Scholar] [CrossRef]

- Fang, H.H.P.; Li, C.; Zhang, T. Acidophilic biohydrogen production from rice slurry. Int. J. Hydrogen Energy 2006, 31, 683–692. [Google Scholar] [CrossRef]

- Barakat, A.; Mayer-Laigle, C.; Solhy, A.; Arancon, R.A.D.; de Vriesa, H.; Luque, R. Mechanical pretreatments of lignocellulosic biomass: Towards facile and environmentally sound technologies for biofuels production. RSC Adv. 2014, 4, 48109–48127. [Google Scholar] [CrossRef]

- Özden, S.; Ertan, R.; Akı-Şener, E.; Yalçın, İ.; Nebioğlu, D.; Büyükbingöl, E.; Göker, H.; Yıldız, İ.; Altuntaş-Dinlenç, T.G.; Tunçbilek, M.; et al. Farmasötik Kimya Pratikleri 1-2; Ankara Üniversitesi Eczacılık Fakültesi: Ankara, Türkiye, 2004; pp. 21s–22s. [Google Scholar]

- APHA. Standard Methods for the Examination of Water and Wastewater; American Public Health Association/American Water Works Association/Water Environment Federation: Washington, DC, USA, 2005. [Google Scholar]

- Taffner, J.; Cernava, T.; Erlacher, A.; Berg, G. Novel insights into plant-associated archaea and their functioning in arugula (Eruca sativa Mill). J. Adv. Res. 2019, 19, 39–48. [Google Scholar] [CrossRef]

- Caporaso, J.G.; Kuczynski, J.; Stombaugh, J.; Bittinger, K.; Bushman, F.D.; Costello, E.K.; Fierer, N.; Peña, A.G.; Goodrich, J.K.; Gordon, J.I.; et al. QIIME allows analysis of high-throughput community sequencing data. Nat. Methods 2010, 7, 335–336. [Google Scholar] [CrossRef]

- Callahan, B.J.; McMurdie, P.J.; Rosen, M.J.; Han, A.W.; Johnson, A.J.A.; Holmes, S.P. DADA2: High-resolution sample inference from Illumina amplicon data. Nat. Methods 2016, 13, 581–583. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Béland, M. Evaluation of alternative methods of preparing hydrogen producing seeds from digested wastewater sludge. Int. J. Hydrogen Energy 2006, 31, 1980–1988. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, J.; Wu, X.; Miller, C.; Wang, L. The effect of pH on continuous biohydrogen production from swine wastewater supplemented with glucose. Appl. Biochem. Biotechnol. 2010, 162, 1286–1296. [Google Scholar] [CrossRef] [PubMed]

- Roychowdhury, S.; Cox, D.; Levandowsky, M. Production of hydrogen by microbial fermentation. Int. J. Hydrogen Energy 1988, 13, 407–410. [Google Scholar] [CrossRef]

- Sivagurunathan, P.; Kumar, G.; Bakonyi, P.; Kim, S.-H.; Kobayashi, T.; Xu, K.Q.; Lakner, G.; Tóth, G.; Nemestóthy, N.; Bélafi-Bakó, K. A critical review on issues and overcoming strategies for the enhancement of dark fermentative hydrogen production in continuous systems. Int. J. Hydrogen Energy 2016, 41, 3820–3836. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y.; Zhao, S.; Wang, D.; Zheng, X.; Luo, J. Lactic acid accumulation from sludge and food waste to improve the yield of propionic acid-enriched VFA. Biochem. Eng. J. 2014, 84, 28–35. [Google Scholar] [CrossRef]

- Kim, D.-H.; Kim, S.-H.; Jung, K.-W.; Kim, M.-S.; Shin, H.-S. Effect of initial pH independent of operational pH on hydrogen fermentation of food waste. Bioresour. Technol. 2011, 102, 8646–8652. [Google Scholar] [CrossRef]

- Wang, K.; Yin, J.; Shen, D.; Li, N. Anaerobic digestion of food waste for volatile fatty acids (VFAs) production with different types of inoculum: Effect of pH. Bioresour. Technol. 2014, 161, 395–401. [Google Scholar] [CrossRef]

- Ghimire, A.; Sposito, F.; Frunzo, L.; Trably, E.; Escudié, R.; Pirozzi, F.; Lens, P.N.L.; Esposito, G. Effects of operational parameters on dark fermentative hydrogen production from biodegradable complex waste biomass. Waste Manag. 2016, 50, 55–64. [Google Scholar] [CrossRef]

- Cai, M.; Liu, J.; Wei, Y. Enhanced biohydrogen production from sewage sludge with alkaline pretreatment. Environ. Sci. Technol. 2004, 38, 3195–3202. [Google Scholar] [CrossRef]

- Rasi, S.; Vainio, M.; Blasco, L.; Kahala, M.; Leskinen, H.; Tampio, E. Changes in volatile fatty acid production and microbiome during fermentation of food waste from hospitality sector. J. Environ. Manag. 2022, 308, 114640. [Google Scholar] [CrossRef] [PubMed]

- Si, B.; Liu, Z.; Zhang, Y.; Li, J.; Xing, X.-H.; Li, B.; Duan, N.; Lu, H. Effect of reaction mode on biohydrogen production and its microbial diversity. Int. J. Hydrogen Energy 2015, 40, 3191–3200. [Google Scholar] [CrossRef]

- Chen, Y.; Yin, Y.; Wang, J. Recent advance in inhibition of dark fermentative hydrogen production. Int. J. Hydrogen Energy 2021, 46, 5053–5073. [Google Scholar] [CrossRef]

- Bundhoo, M.A.Z.; Mohee, R. Inhibition of dark fermentative bio-hydrogen production: A review. Int. J. Hydrogen Energy 2016, 41, 6713–6733. [Google Scholar] [CrossRef]

- Moreno-Andrade, I.; Buitrón, G. Evaluation of particle size and initial concentration of total solids on biohydrogen production from food waste. Fresen Environ. Bull. 2015, 24, 2289–2295. [Google Scholar]

- Mahmoodi-Eshkaftaki, M.; Mockaitis, G.; Rafiee, M.R. Dynamic optimization of volatile fatty acids to enrich biohydrogen production using a deep learning neural network. Biomass Convers. Biorefinery 2022, 1–12. [Google Scholar] [CrossRef]

- Mañunga, T.; Barrios-Pérez, J.D.; Zaiat, M.; Rodríguez-Victoria, J.A. Evaluation of pretreatment methods and initial pH on mixed inoculum for fermentative hydrogen production from cassava wastewater. Biofuels 2022, 13, 301–308. [Google Scholar] [CrossRef]

- Lee, Y.J.; Miyahara, T.; Noike, T. Effect of pH on microbial hydrogen fermentation. J. Chem. Technol. Biotechnol. 2002, 77, 694–698. [Google Scholar] [CrossRef]

- Li, Z.; Chen, Z.; Ye, H.; Wang, Y.; Luo, W.; Chang, J.-S.; Li, Q.; He, N. Anaerobic co-digestion of sewage sludge and food waste for hydrogen and VFA production with microbial community analysis. Waste Manag. 2018, 78, 789–799. [Google Scholar] [CrossRef]

- Mota, V.T.; Ferraz Júnior, A.D.N.; Trably, E.; Zaiat, M. Biohydrogen production at pH below 3.0: Is it possible? Water Res. 2018, 128, 350–361. [Google Scholar] [CrossRef]

- Cruz-López, A.; Cruz-Méndez, A.; Suárez-Vázquez, S.I.; Reyna-Gómez, L.M.; Pecina-Chacón, D.E.; León Gómez, H. Effect of hydraulic retention time on continuous biohydrogen production by the codigestion of brewery wastewater and cheese whey. BioEnergy Res. 2022, 1–12. [Google Scholar] [CrossRef]

- Alexandropoulou, M.; Antonopoulou, G.; Trably, E.; Carrere, H.; Lyberatos, G. Continuous biohydrogen production from a food industry waste: Influence of operational parameters and microbial community analysis. J. Clean. Prod. 2018, 174, 1054–1063. [Google Scholar] [CrossRef]

- Jankowska, E.; Chwiałkowska, J.; Stodolny, M.; Oleskowicz-Popiel, P. Effect of pH and retention time on volatile fatty acids production during mixed culture fermentation. Bioresour. Technol. 2015, 190, 274–280. [Google Scholar] [CrossRef] [PubMed]

- Rafrafi, Y.; Trably, E.; Hamelin, J.; Latrille, E.; Meynial-Salles, I.; Benomar, S.; Giudici-Orticoni, M.-T.; Steyer, J.-P. Sub-dominant bacteria as keystone species in microbial communities producing bio-hydrogen. Int. J. Hydrogen Energy 2013, 38, 4975–4985. [Google Scholar] [CrossRef]

- Sarkar, O.; Kumar, A.N.; Dahiya, S.; Krishna, K.V.; Yeruva, D.K.; Mohan, S.V. Regulation of acidogenic metabolism towards enhanced short chain fatty acid biosynthesis from waste: Metagenomic profiling. RSC Adv. 2016, 6, 18641. [Google Scholar] [CrossRef]

- Liu, N.; Jiang, J.; Yan, F.; Gao, Y.; Meng, Y.; Aihemaiti, A.; Ju, T. Enhancement of volatile fatty acid production and biogas yield from food waste following sonication pretreatment. J. Environ. Manag. 2018, 217, 797–804. [Google Scholar] [CrossRef]

- Jiang, D.; Fang, Z.; Chin, S.-X.; Tian, X.-F.; Su, T.-C. Biohydrogen production from hydrolysates of selected tropical biomass wastes with Clostridium butyricum. Sci. Rep. 2016, 6, 27205. [Google Scholar] [CrossRef]

- Pachapur, V.L.; Sarma, S.J.; Brar, S.K.; Bihan, Y.L.; Buelna, G.; Verma, M. Hydrogen production from biodiesel industry waste by using a co-culture of Enterobacter aerogenes and Clostridium butyricum. Biofuels 2017, 8, 651–662. [Google Scholar] [CrossRef]

- Moura, A.G.L.; Rabelo, C.A.B.S.; Okino, C.H.; Maintinguer, S.I.; Silva, E.L.; Varesche, M.B.A. Enhancement of Clostridium butyricum hydrogen production by iron and nickel nanoparticles: Effects on hydA expression. Int. J. Hydrogen Energy 2020, 45, 28447–28461. [Google Scholar] [CrossRef]

- Kenney, N.M.; Vanzant, E.S.; Harmon, D.L.; McLeod, K.R. Direct-fed microbials containing lactate-producing bacteria influence ruminal fermentation but not lactate utilization in steers fed a high-concentrate diet. J. Anim. Sci. 2015, 93, 2336–2348. [Google Scholar] [CrossRef]

- Hernández, J.; Benedito, J.L.; Abuelo, A.; Castillo, C. Ruminal acidosis in feedlot: From aetiology to prevention. Sci. World J. 2014, 702572. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-H.; Kim, S.-H.; Shin, H.-S. Hydrogen fermentation of food waste without inoculum addition. Enzym. Microb. Technol. 2009, 45, 181–187. [Google Scholar] [CrossRef]

- Tang, T.; Chen, Y.; Liu, M.; Du, Y.; Tan, Y. Effect of pH on the performance of hydrogen production by dark fermentation coupled denitrification. Environ. Res. 2022, 208, 112663. [Google Scholar] [CrossRef] [PubMed]

- Balakrishnan, D.; Manmai, N.; Ponnambalam, S.; Unpaprom, Y.; Chaichompoo, C.; Ramaraj, R. Optimized model of fermentable sugar production from Napier grass for biohydrogen generation via dark fermentation. Int. J. Hydrogen Energy 2023, 48, 21152–21160. [Google Scholar] [CrossRef]

| Nutritional Composition | Unit (mg/L) |

|---|---|

| KH2PO4 | 250 |

| NH4Cl | 2500 |

| CaCl2 · 2H2O | 500 |

| MgSO4 · 7H2O | 320 |

| MnCl2 · 4H2O | 30 |

| NiSO4 | 32 |

| ZnCl2 | 23 |

| CoCl2 · 6H2O | 21 |

| FeCl3 · 6H2O | 20 |

| CuCl2 · H2O | 10 |

| Na2MoO4 · 2H2O | 14.4 |

| pH–Hour | Acetic Acid (mg/mL) | Butyric Acid (mg/mL) | Propionic Acid (mg/mL) |

|---|---|---|---|

| 4.5–18 | 1.647 ± 0.001 | 0.836 ± 0.001 | 0.022 ± 0.003 |

| 4.5–23 | 1.722 ± 0.004 | 0.838 ± 0.000 | 0.034 ± 0.000 |

| 4.5–42 | 1.775 ± 0.002 | 0.844 ± 0.001 | 0.041 ± 0.001 |

| 4.5–66 | 1.535 ± 0.016 | 0.814 ± 0.004 | 0.018 ± 0.004 |

| 4.5–73 | 1.338 ± 0.000 | 0.747 ± 0.000 | 0.006 ± 0.000 |

| 4.0–20 | 1.560 ± 0.004 | 0.990 ± 0.001 | 0.036 ± 0.000 |

| 4.0–25 | 1.302 ± 0.001 | 0.894 ± 0.003 | 0.017 ± 0.001 |

| 4.0–30 | 1.790 ± 0.002 | 1.015 ± 0.001 | 0.052 ± 0.001 |

| 4.0–42 | 1.788 ± 0.001 | 1.022 ± 0.002 | 0.053 ± 0.001 |

| 4.0–48 | 1.693 ± 0.009 | 1.004 ± 0.001 | 0.046 ± 0.004 |

| pH–Hour | Acetic Acid (mg/mL) | Butyric Acid (mg/mL) | Propionic Acid (mg/mL) |

|---|---|---|---|

| 4.5–18 | 1.114 ± 0.009 | 0.244 ± 0.001 | 0.038 ± 0.001 |

| 4.5–25 | 0.980 ± 0.001 | 0.255 ± 0.004 | 0.020 ± 0.001 |

| 4.5–28 | 0.835 ± 0.001 | 0.236 ± 0.001 | 0.008 ± 0.000 |

| 4.0–18 | 0.935 ± 0.001 | 0.237 ± 0.001 | 0.020 ± 0.001 |

| 4.0–25 | 0.790 ± 0.001 | 0.221 ± 0.000 | 0.013 ± 0.000 |

| 4.0–28 | 0.732 ± 0.003 | 0.237 ± 0.001 | 0.005 ± 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dursun, N. Biohydrogen Production from Buckwheat Residue Using Anaerobic Mixed Bacteria. Fermentation 2024, 10, 15. https://doi.org/10.3390/fermentation10010015

Dursun N. Biohydrogen Production from Buckwheat Residue Using Anaerobic Mixed Bacteria. Fermentation. 2024; 10(1):15. https://doi.org/10.3390/fermentation10010015

Chicago/Turabian StyleDursun, Nesrin. 2024. "Biohydrogen Production from Buckwheat Residue Using Anaerobic Mixed Bacteria" Fermentation 10, no. 1: 15. https://doi.org/10.3390/fermentation10010015

APA StyleDursun, N. (2024). Biohydrogen Production from Buckwheat Residue Using Anaerobic Mixed Bacteria. Fermentation, 10(1), 15. https://doi.org/10.3390/fermentation10010015