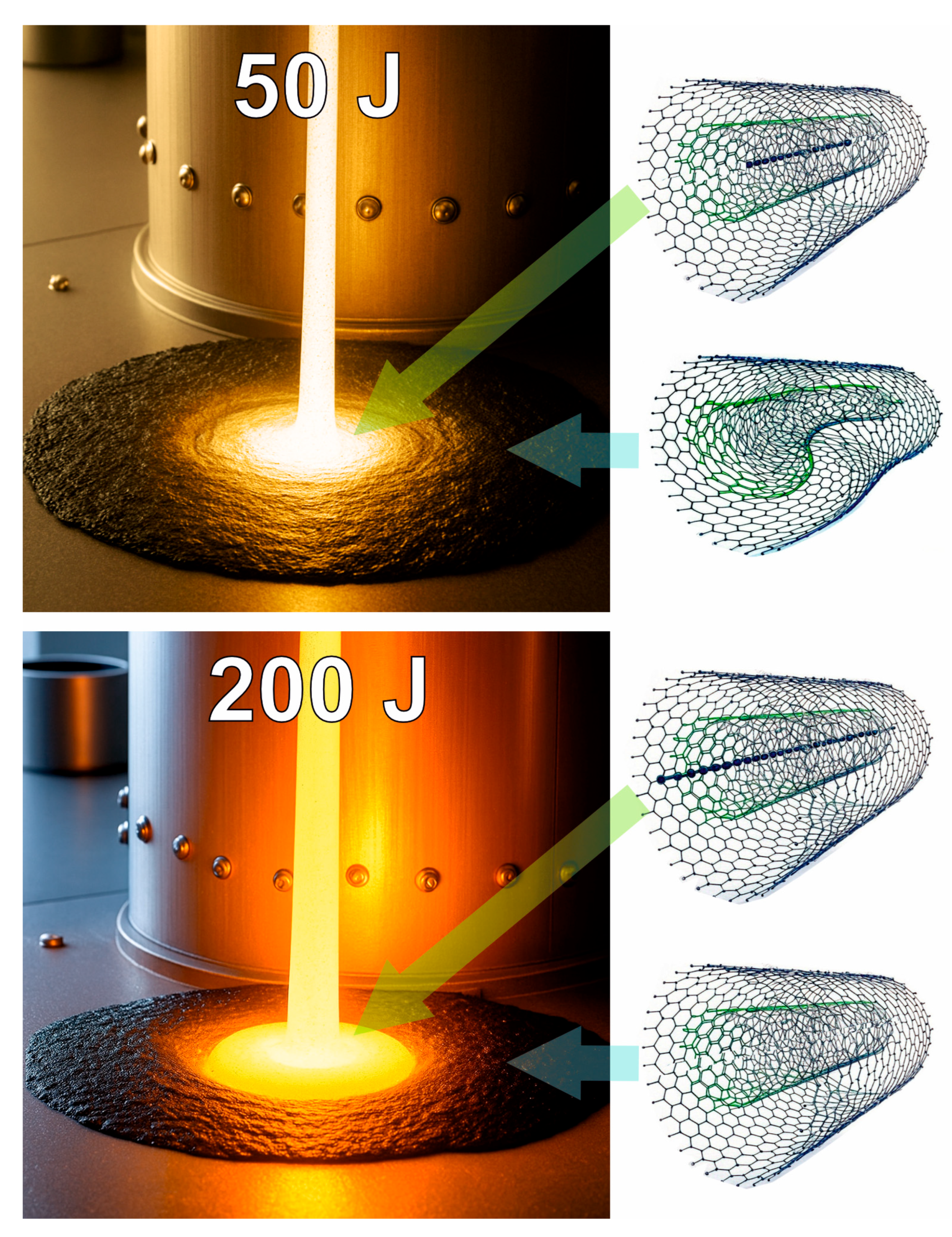

Spatially Controlled Plasma Jet Synthesis of Carbyne Encapsulated in Carbon Nanotubes

Abstract

1. Introduction

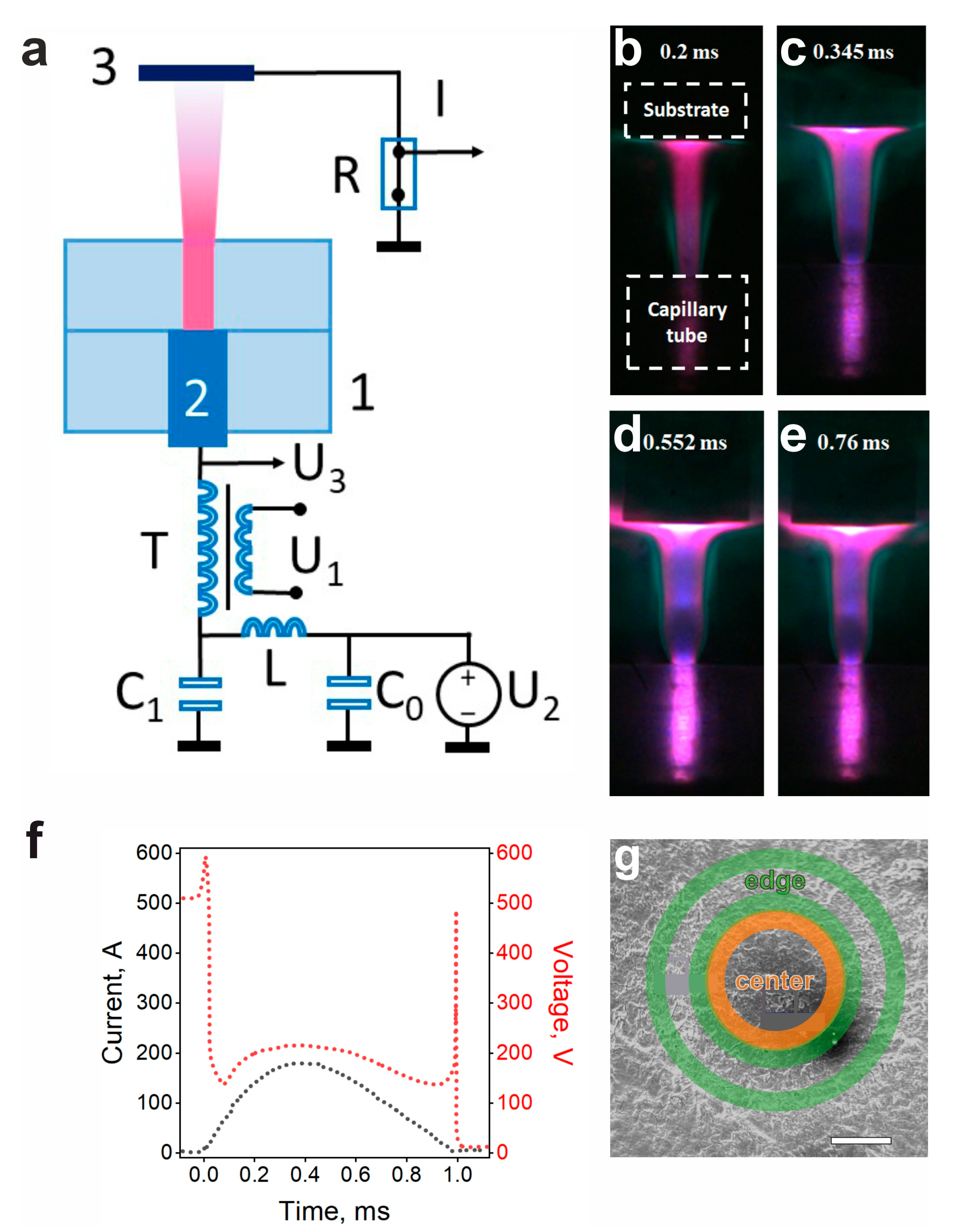

2. Materials and Methods

2.1. Samples Preparation

2.2. Sample Characterization

2.2.1. Scanning Electron Microscopy

2.2.2. Transmission Electron Microscopy

2.2.3. Raman Spectroscopy

3. Results

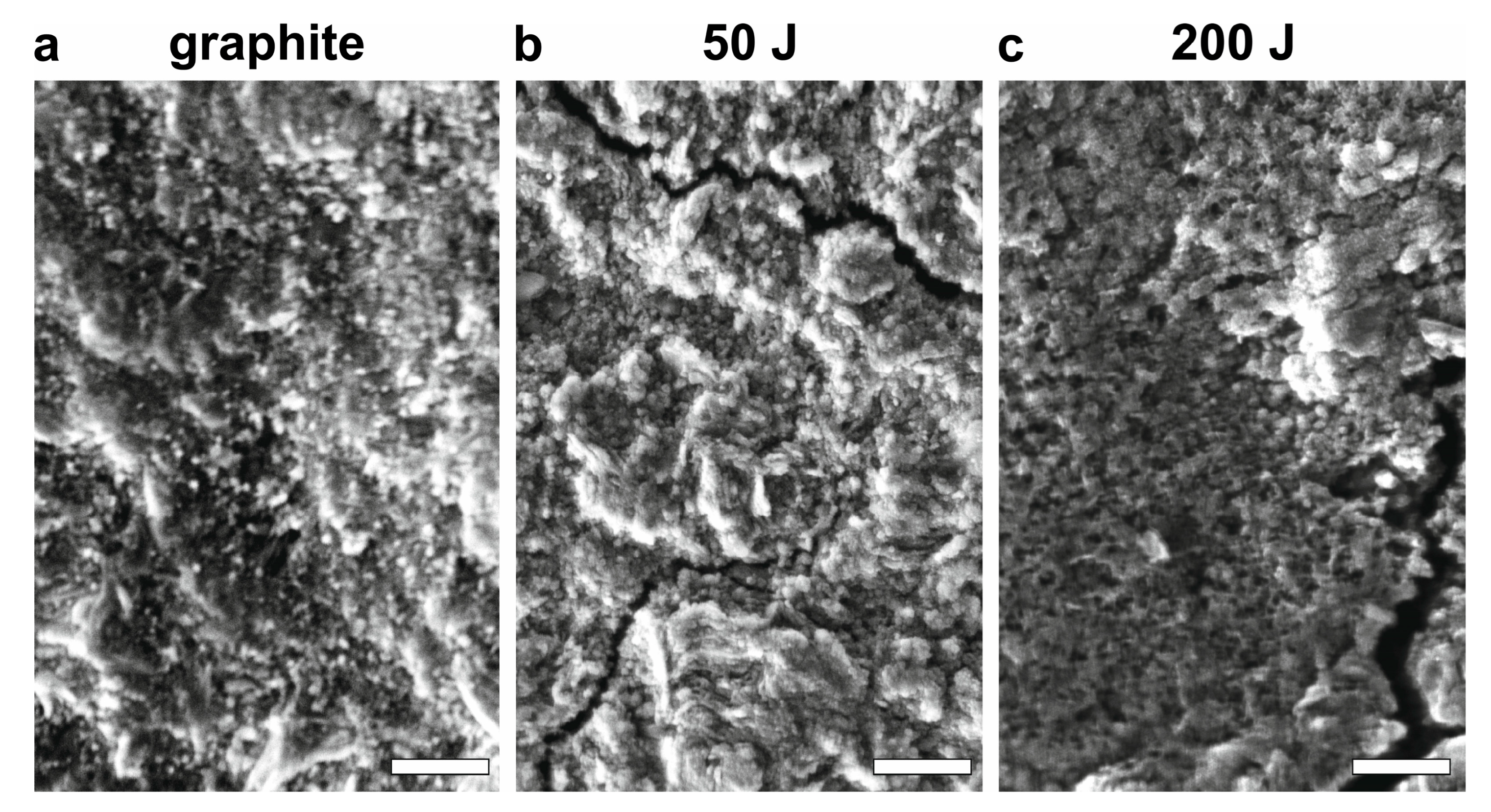

3.1. SEM

3.2. Elemental Composition

3.3. TEM and Electron Diffraction Studies

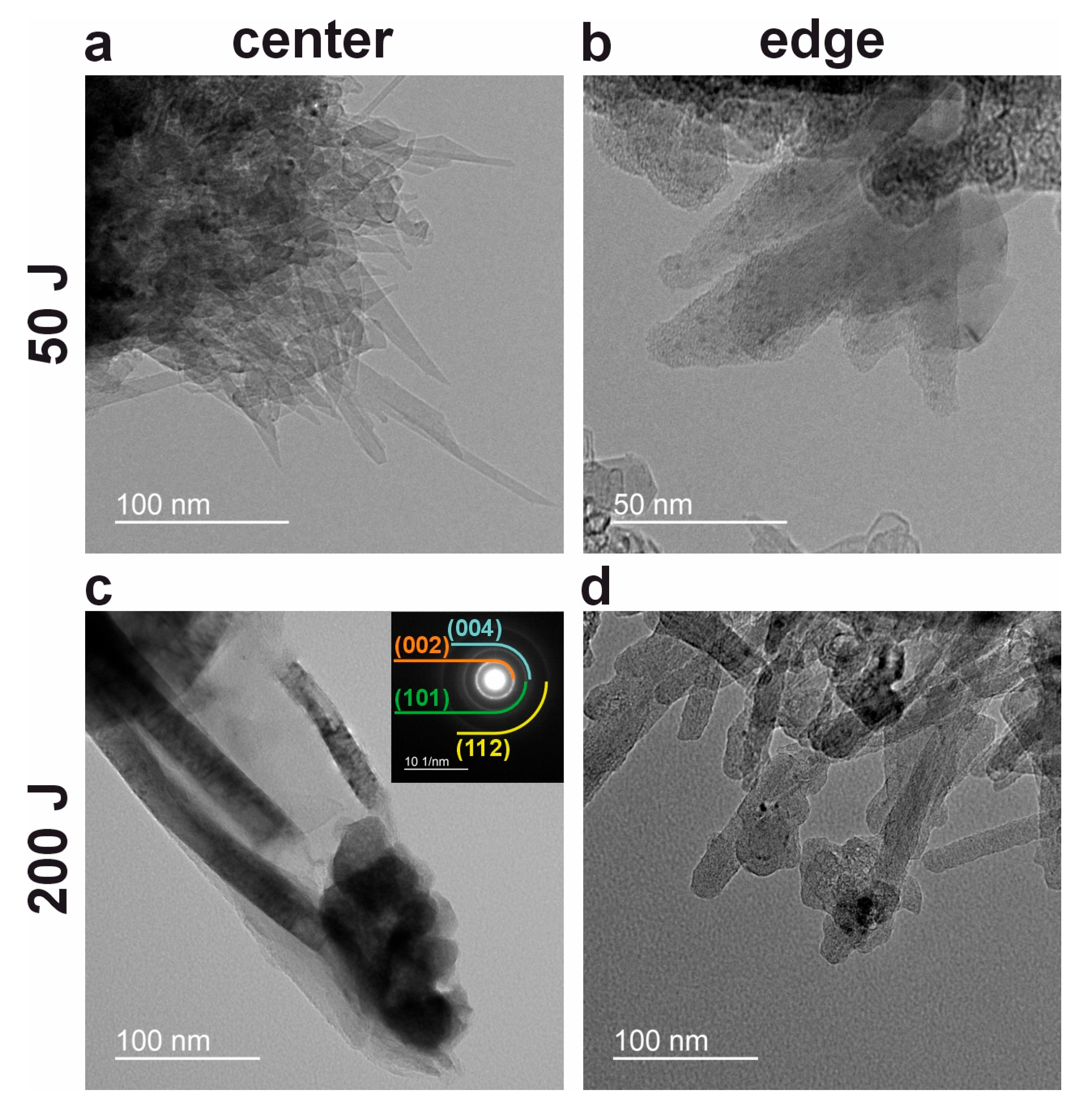

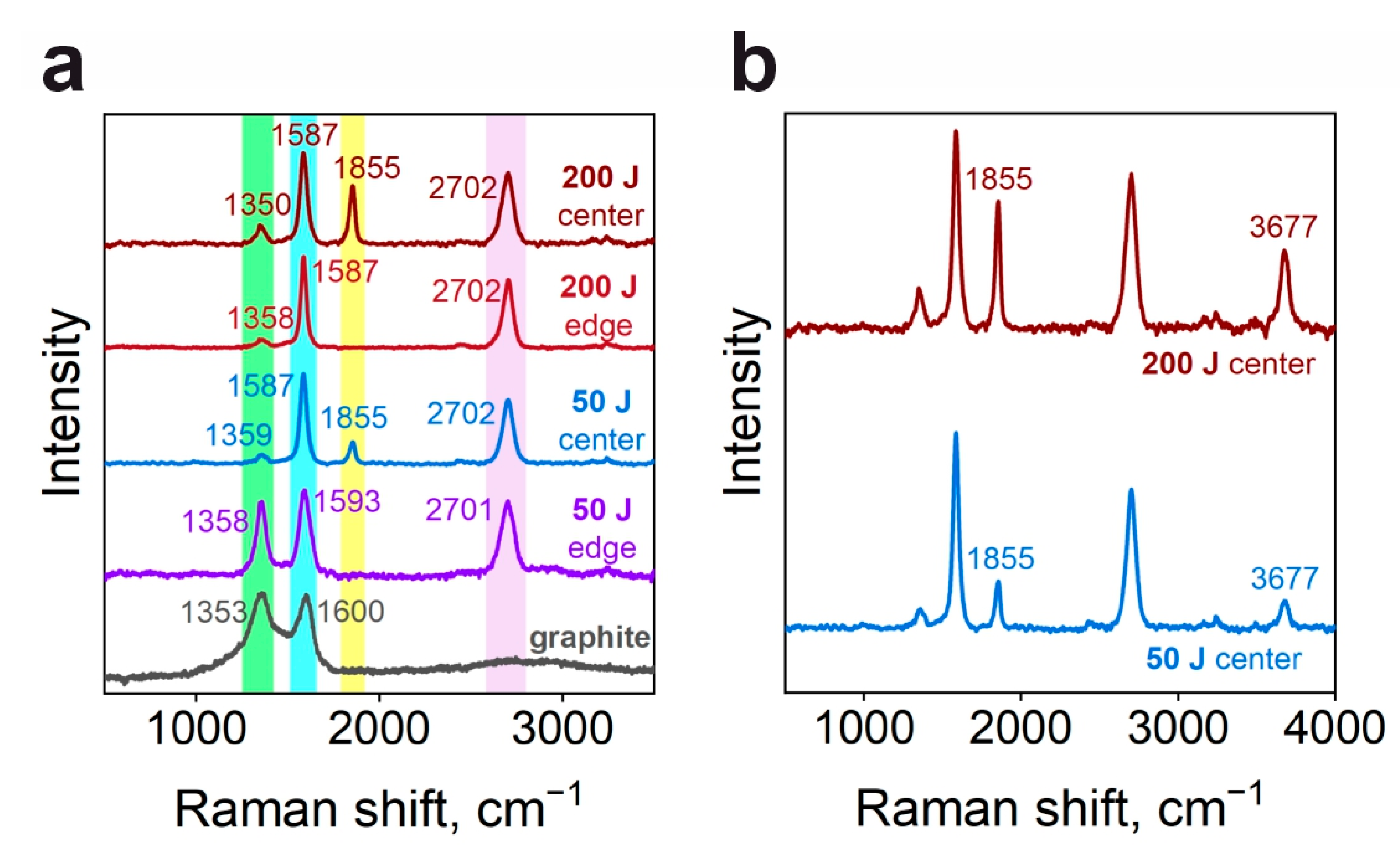

3.4. Vibrational Spectroscopy

4. Discussion

4.1. Heat-Mediated Self-Assembly of Carbyne Chains Encapsulated in MWCNT

4.2. Implications and Perspectives

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ali, Z.; Yaqoob, S.; Yu, J.; D’Amore, A. Critical Review on the Characterization, Preparation, and Enhanced Mechanical, Thermal, and Electrical Properties of Carbon Nanotubes and Their Hybrid Filler Polymer Composites for Various Applications. Compos. Part C Open Access 2024, 13, 100434. [Google Scholar] [CrossRef]

- Zhang, C.; Ling, Y.; Zhang, X.; Liang, M.; Zou, H. Ultra-Thin Carbon Fiber Reinforced Carbon Nanotubes Modified Epoxy Composites with Superior Mechanical and Electrical Properties for the Aerospace Field. Compos. Part. A Appl. Sci. Manuf. 2022, 163, 107197. [Google Scholar] [CrossRef]

- Xing, G.; Xu, Y.; Huang, J.; Lu, Y.; Miao, P.; Chindasiriphan, P.; Jongvivatsakul, P.; Ma, K. Research on the Mechanical Properties of Steel Fibers Reinforced Carbon Nanotubes Concrete. Constr. Build. Mater. 2023, 392, 131880. [Google Scholar] [CrossRef]

- Hamouda, H.I.; Abdel-Ghafar, H.M.; Mahmoud, M.H.H. Multi-Walled Carbon Nanotubes Decorated with Silver Nanoparticles for Antimicrobial Applications. J. Environ. Chem. Eng. 2021, 9, 105034. [Google Scholar] [CrossRef]

- Kumar, S.; Sidhu, H.K.; Paul, A.K.; Bhardwaj, N.; Thakur, N.S.; Deep, A. Bioengineered Multi-Walled Carbon Nanotube (MWCNT) Based Biosensors and Applications Thereof. Sens. Diagn. 2023, 2, 1390–1413. [Google Scholar] [CrossRef]

- Nag, A.; Alahi, M.E.E.; Mukhopadhyay, S.C.; Liu, Z. Multi-Walled Carbon Nanotubes-Based Sensors for Strain Sensing Applications. Sensors 2021, 21, 1261. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhao, J.; Cao, J.; Zhao, Y.; Huang, J.; Zheng, Z.; Li, W.; Jiang, S.; Qiao, J.; Xing, B.; et al. Opportunities for Graphene, Single-Walled and Multi-Walled Carbon Nanotube Applications in Agriculture: A Review. Crop Des. 2022, 1, 100006. [Google Scholar] [CrossRef]

- Ramachandran, K.; Boopalan, V.; Bear, J.C.; Subramani, R. Multi-Walled Carbon Nanotubes (MWCNTs)-Reinforced Ceramic Nanocomposites for Aerospace Applications: A Review. J. Mater. Sci. 2022, 57, 3923–3953. [Google Scholar] [CrossRef]

- Zhao, Y.; Luo, Q.; Wu, J.; Sui, C.; Tong, L.; He, X.; Wang, C. Mechanical Properties of Helically Twisted Carbyne Fibers. Int. J. Mech. Sci. 2020, 186, 105823. [Google Scholar] [CrossRef]

- Cui, W.; Shi, L. Synthesis and Properties of Confined Carbyne and Beyond. Adv. Colloid. Interface Sci. 2025, 342, 103519. [Google Scholar] [CrossRef]

- Berdiyorov, G.R.; Khalilov, U.; Hamoudi, H.; Neyts, E.C. Effect of Chemical Modification on Electronic Transport Properties of Carbyne. J. Comput. Electron. 2021, 20, 848–854. [Google Scholar] [CrossRef]

- Karthik, H.J.; Sarga, P.K.; Bhattacharyya, S. Electronic Phase Transition, Vibrational Properties and Structural Stability of Single and Two Polyyne Chains under External Electric Field. Carbon Trends 2024, 14, 100319. [Google Scholar] [CrossRef]

- Shi, L.; Rohringer, P.; Suenaga, K.; Niimi, Y.; Kotakoski, J.; Meyer, J.C.; Peterlik, H.; Wanko, M.; Cahangirov, S.; Rubio, A.; et al. Confined Linear Carbon Chains as a Route to Bulk Carbyne. Nat. Mater. 2016, 15, 634–639. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhao, J.; Fang, Y.; Liu, Y.; Zhao, X. Preparation of Long Linear Carbon Chain inside Multi-Walled Carbon Nanotubes by Cooling Enhanced Hydrogen Arc Discharge Method. Nanoscale 2018, 10, 17824–17833. [Google Scholar] [CrossRef]

- Song, I.; Park, C.; Hong, M.; Baik, J.; Shin, H.; Choi, H.C. Patternable Large-Scale Molybdenium Disulfide Atomic Layers Grown by Gold-Assisted Chemical Vapor Deposition. Angew. Chem. Int. Ed. 2014, 53, 1266–1269. [Google Scholar] [CrossRef]

- Gwo, S.; Chen, H.-Y.; Lin, M.-H.; Sun, L.; Li, X. Nanomanipulation and Controlled Self-Assembly of Metal Nanoparticles and Nanocrystals for Plasmonics. Chem. Soc. Rev. 2016, 45, 5672–5716. [Google Scholar] [CrossRef]

- Zhao, X.; Ando, Y.; Liu, Y.; Jinno, M.; Suzuki, T. Carbon Nanowire Made of a Long Linear Carbon Chain Inserted Inside a Multiwalled Carbon Nanotube. Phys. Rev. Lett. 2003, 90, 187401. [Google Scholar] [CrossRef]

- Chang, W.; Liu, F.; Liu, Y.; Zhu, T.; Fang, L.; Li, Q.; Liu, Y.; Zhao, X. Smallest Carbon Nanowires Made Easy: Long Linear Carbon Chains Confined inside Single-Walled Carbon Nanotubes. Carbon 2021, 183, 571–577. [Google Scholar] [CrossRef]

- Zhao, C.; Kitaura, R.; Hara, H.; Irle, S.; Shinohara, H. Growth of Linear Carbon Chains inside Thin Double-Wall Carbon Nanotubes. J. Phys. Chem. C 2011, 115, 13166–13170. [Google Scholar] [CrossRef]

- Asaka, K.; Toma, S.; Saito, Y. Raman Spectroscopy and Transmission Electron Microscopy of Long Linear Atomic Carbon Chains Generated by Field Electron Emission Accompanied with Electrical Discharge of Carbon Nanotube Films. SN Appl. Sci. 2019, 1, 493. [Google Scholar] [CrossRef]

- Shi, L.; Senga, R.; Suenaga, K.; Chimborazo, J.; Ayala, P.; Pichler, T. Photothermal Synthesis of Confined Carbyne. Carbon 2021, 182, 348–353. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, K.; Zhang, W.; Cao, H.; Zhang, H.; Feng, Y.; Cui, W.; Hu, Y.; Shi, L.; Yang, G. A Universal Method to Transform Aromatic Hydrocarbon Molecules into Confined Carbyne inside Single-Walled Carbon Nanotubes. ACS Nano 2025, 19, 12146–12154. [Google Scholar] [CrossRef]

- Baidak, V.A.; Zavidovskiy, I.A.; Tatarintsev, A.A.; Bychkov, V.L.; Streletskiy, O.A. Energy-Effective Synthesis of Multiwalled Carbon Nanotubes via Ambient-Air Atmospheric-Pressure Plasma Jet Treatment of Graphite. Surfaces 2025, 8, 16. [Google Scholar] [CrossRef]

- Pashchina, A.S.; Efimov, A.V.; Chinnov, V.F. Optical Investigations of the Multicomponent Plasma of the Capillary Discharge: Subsonic Outflow Regime. High Temp. 2016, 54, 488–502. [Google Scholar] [CrossRef]

- Pashchina, A.S.; Efimov, A.V.; Chinnov, V.F. Optical Investigations of Multicomponent Plasma of Capillary Discharge. Supersonic Outflow Regime. High Temp. 2017, 55, 650–664. [Google Scholar] [CrossRef]

- Evseev, A.P.; Vorobyeva, E.A.; Balakshin, Y.V.; Kushkina, K.D.; Stepanov, A.V.; Chernysh, V.S.; Chechenin, N.G.; Shemukhin, A.A. MWCNT-Based Surfaces with Tunable Wettability Obtained by He+ Ion Irradiation. Surf. Interfaces 2021, 23, 100955. [Google Scholar] [CrossRef]

- Streletskiy, O.A.; Zavidovskiy, I.A.; Nuriahmetov, I.F.; Nishchak, O.Y.; Pavlikov, A.V.; Savchenko, N.F. Resistive Gas Sensors Based on Porous Sp-Containing Films Obtained by Dehydrohalogenation of PVDC and PVDC-PVC Copolymer. C 2023, 9, 82. [Google Scholar] [CrossRef]

- Zavidovskiy, I.A.; Streletskiy, O.A.; Nuriahmetov, I.F.; Nishchak, O.Y.; Savchenko, N.F.; Tatarintsev, A.A.; Pavlikov, A.V. Highly Selective Polyene-Polyyne Resistive Gas Sensors: Response Tuning by Low-Energy Ion Irradiation. J. Compos. Sci. 2023, 7, 156. [Google Scholar] [CrossRef]

- Sidorov, N.V.; Palatnikov, M.N.; Gorelik, V.S.; Sverbil, P.P. Second-Order Raman Spectra of a LiNbO3:Tb Crystal. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 266, 120445. [Google Scholar] [CrossRef]

- Huso, J.; Morrison, J.L.; Bergman, L.; McCluskey, M.D. Anharmonic Resonant Raman Modes in Mg0.2Zn0.8O. Phys. Rev. B 2013, 87, 125205. [Google Scholar] [CrossRef]

- Parth, E.; Corradini, A.; Cui, W.; Romanin, D.; Schuster, C.; Freytag, C.; Shi, L.; Yanagi, K.; Calandra, M.; Pichler, T. Anharmonic Effects Control Interaction of Carbyne Confined in Carbon Nanotubes Shaping Their Vibrational Properties. Nat. Commun. 2025, 16, 4797. [Google Scholar] [CrossRef]

- Chen, J.-Z.; Wang, C.; Hsu, C.-C.; Cheng, I.-C. Ultrafast Synthesis of Carbon-Nanotube Counter Electrodes for Dye-Sensitized Solar Cells Using an Atmospheric-Pressure Plasma Jet. Carbon 2016, 98, 34–40. [Google Scholar] [CrossRef]

- Deng, Y.; Cranford, S.W. Mapping Temperature and Confinement Dependence of Carbyne Formation within Carbon Nanotubes. Carbon 2019, 141, 209–217. [Google Scholar] [CrossRef]

- Netcheva, S.; Bertrand, P. Surface Topography Development of Thin Polystyrene Films under Low Energy Ion Irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1999, 151, 129–134. [Google Scholar] [CrossRef]

- Tschannen, C.D.; Frimmer, M.; Gordeev, G.; Vasconcelos, T.L.; Shi, L.; Pichler, T.; Reich, S.; Heeg, S.; Novotny, L. Anti-Stokes Raman Scattering of Single Carbyne Chains. ACS Nano 2021, 15, 12249–12255. [Google Scholar] [CrossRef] [PubMed]

- Tschannen, C.D.; Gordeev, G.; Reich, S.; Shi, L.; Pichler, T.; Frimmer, M.; Novotny, L.; Heeg, S. Raman Scattering Cross Section of Confined Carbyne. Nano Lett. 2020, 20, 6750–6755. [Google Scholar] [CrossRef]

- Lahiri, B.B.; Bagavathiappan, S.; Jayakumar, T.; Philip, J. Medical Applications of Infrared Thermography: A Review. Infrared Phys. Technol. 2012, 55, 221–235. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Lamichhane, N.; Kim, C.; Shrestha, R. Innovations in Building Diagnostics and Condition Monitoring: A Comprehensive Review of Infrared Thermography Applications. Buildings 2023, 13, 2829. [Google Scholar] [CrossRef]

- Barnett, P.D.; Angel, S.M. Miniature Spatial Heterodyne Raman Spectrometer with a Cell Phone Camera Detector. Appl. Spectrosc. 2017, 71, 988–995. [Google Scholar] [CrossRef]

- Crocombe, R.A.; Kammrath, B.W.; Leary, P.E. Portable Raman Spectrometers: How Small Can They Get? Spectroscopy 2023, 38, 32–40. [Google Scholar] [CrossRef]

- Yang, W.; Knorr, F.; Latka, I.; Vogt, M.; Hofmann, G.O.; Popp, J.; Schie, I.W. Real-Time Molecular Imaging of near-Surface Tissue Using Raman Spectroscopy. Light Sci. Appl. 2022, 11, 90. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, G.; Li, Y. Thermal Cracking and Friction Performance of Two Kinds of Compacted Graphite Iron Brake Discs under Intensive Braking Conditions. Metals 2024, 14, 332. [Google Scholar] [CrossRef]

- Wang, G.; Xu, Z.; Liu, Z.; Chen, X.; Li, Y. Thermal Fatigue and Wear of Compacted Graphite Iron Brake Discs with Various Thermomechanical Properties. China Foundry 2024, 21, 248–256. [Google Scholar] [CrossRef]

- Zhu, T.; Li, Y.; Sang, S. Heightening Mechanical Properties and Thermal Shock Resistance of Low–Carbon Magnesia–Graphite Refractories through the Catalytic Formation of Nanocarbons and Ceramic Bonding Phases. J. Alloys Compd. 2019, 783, 990–1000. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Dana, K.; Moitra, S.; BasuMallick, S.; Mukhopadhyay, T.K. Thermal and Thermomechanical Characteristics of Monolithic Refractory Composite Matrix Containing Surface-Modified Graphite. Ceram. Int. 2016, 42, 6015–6024. [Google Scholar] [CrossRef]

- Parvej; Sharma, A.K. On Heating Characteristics and Mass Depletion of Structurally Different SiC and Graphite Susceptors under Microwave Irradiation. Mater. Chem. Phys. 2025, 341, 130928. [Google Scholar] [CrossRef]

- Suriapparao, D.V.; Nagababu, G.; Yerrayya, A.; Sridevi, V. Optimization of Microwave Power and Graphite Susceptor Quantity for Waste Polypropylene Microwave Pyrolysis. Process Saf. Environ. Prot. 2021, 149, 234–243. [Google Scholar] [CrossRef]

- Alhusseny, A.; Al-Aabidy, Q.; Al-Zurfi, N.; Nasser, A.; Aljanabi, M. Cooling of High-Performance Electronic Equipment Using Graphite Foam Heat Sinks. Appl. Therm. Eng. 2021, 191, 116844. [Google Scholar] [CrossRef]

- Zhao, Y.; Xue, K.; Tan, T.; Yu, D.Y.W. Thermal Stability of Graphite Electrode as Cathode for Dual-Ion Batteries. ChemSusChem 2023, 16, e202201221. [Google Scholar] [CrossRef]

- Tuersun, Y.; Luo, P.; Chen, Y.; Huang, X.; Huang, M.; Chu, S. Preparation and Surface Modification of Vertically Structured Indium/Graphite Elastomer Thermal Pad for Effective Heat Dissipation. Compos. Commun. 2025, 58, 102518. [Google Scholar] [CrossRef]

- Fu, H.; Xiao, Y.; Li, P.; Qian, W.; Li, D.; Zhao, X.; He, D. Ultrasonic-Assisted Soldering for Graphite Films as Heat Sinks with Durably Superior Heat Dissipating Efficiency. Adv. Compos. Hybrid Mater. 2022, 5, 2154–2162. [Google Scholar] [CrossRef]

- Durif, O. Design of de Laval Nozzles for Gas-Phase Molecular Studies in Uniform Supersonic Flow. Phys. Fluids 2022, 34, 013605. [Google Scholar] [CrossRef]

- Lu, H.; Ma, Y.; Peng, B.; Xin, J.; Tian, Z.; Guo, S.; Li, D. Performance Differences and Design Method Improvement of Laval Nozzles under Superatmospheric and Subatmospheric Conditions. Phys. Fluids 2025, 37, 096117. [Google Scholar] [CrossRef]

- Zheng, G.; Jiang, J.; Wang, X.; Li, W.; Liu, J.; Fu, G.; Lin, L. Nanofiber Membranes by Multi-Jet Electrospinning Arranged as Arc-Array with Sheath Gas for Electrodialysis Applications. Mater. Des. 2020, 189, 108504. [Google Scholar] [CrossRef]

- Streletskiy, O.A.; Zavidovskiy, I.A.; Nischak, O.Y.; Pavlikov, A.V. Multiphonon Replicas in Raman Spectra and Conductivity Properties of Carbon Films with Different Concentrations of Sp1-Bonds. Thin Solid Film. 2019, 671, 31–35. [Google Scholar] [CrossRef]

| Capacitance, μF | 470 |

| Initial voltage, V | 500–800 |

| Energy stored in the capacitance, J | 50–200 |

| Capillary surface, mm2 | 0.8 |

| Voltage drop, V | 200–280 |

| Current, A | 180–320 |

| Discharge duration, ms | 1 |

| Line | kmax, cm−1 | HWHM, cm−1 | Irel, % | |

|---|---|---|---|---|

| 50 J edge | D-line | 1356 ± 1 | 29 ± 1 | 26 ± 1 |

| G-line | 1592 ± 1 | 31 ± 1 | 34 ± 1 | |

| 2D | 2699 ± 1 | 43 ± 1 | 40 ± 1 | |

| 50 J center | D-line | 1358 ± 1 | 23 ± 1 | 4 ± 1 |

| G-line | 1586 ± 1 | 19 ± 1 | 39 ± 1 | |

| LO | 1853 ± 1 | 14 ± 1 | 7 ± 1 | |

| 2D | 2701 ± 1 | 30 ± 1 | 42 ± 1 | |

| 2LO | 3677 ± 1 | 31 ± 1 | 9 ± 1 | |

| 200 J edge | D-line | 1359 ± 2 | 33 ± 1 | 6 ± 1 |

| G-line | 1586 ± 1 | 17 ± 1 | 42 ± 1 | |

| 2D | 2701 ± 1 | 28 ± 1 | 52 ± 1 | |

| 200 J center | D-line | 1353 ± 1 | 25 ± 1 | 6 ± 1 |

| G-line | 1586 ± 1 | 21 ± 1 | 29 ± 1 | |

| LO | 1852 ± 1 | 15 ± 1 | 13 ± 1 | |

| 2D | 2699 ± 1 | 33 ± 1 | 35 ± 1 | |

| 2LO | 3677 ± 1 | 32 ± 1 | 17 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Streletskiy, O.A.; Zavidovskiy, I.A.; Baidak, V.A.; Pashchina, A.S.; Khaidarov, A.A.; Bychkov, V.L. Spatially Controlled Plasma Jet Synthesis of Carbyne Encapsulated in Carbon Nanotubes. C 2025, 11, 74. https://doi.org/10.3390/c11040074

Streletskiy OA, Zavidovskiy IA, Baidak VA, Pashchina AS, Khaidarov AA, Bychkov VL. Spatially Controlled Plasma Jet Synthesis of Carbyne Encapsulated in Carbon Nanotubes. C. 2025; 11(4):74. https://doi.org/10.3390/c11040074

Chicago/Turabian StyleStreletskiy, Oleg A., Ilya A. Zavidovskiy, Vladimir A. Baidak, Anatoly S. Pashchina, Abdusame A. Khaidarov, and Vladimir L. Bychkov. 2025. "Spatially Controlled Plasma Jet Synthesis of Carbyne Encapsulated in Carbon Nanotubes" C 11, no. 4: 74. https://doi.org/10.3390/c11040074

APA StyleStreletskiy, O. A., Zavidovskiy, I. A., Baidak, V. A., Pashchina, A. S., Khaidarov, A. A., & Bychkov, V. L. (2025). Spatially Controlled Plasma Jet Synthesis of Carbyne Encapsulated in Carbon Nanotubes. C, 11(4), 74. https://doi.org/10.3390/c11040074