The Effect of Varying the Air Flow in a Solar Collector on the Quality of Arabica Coffee Beans

Abstract

1. Introduction

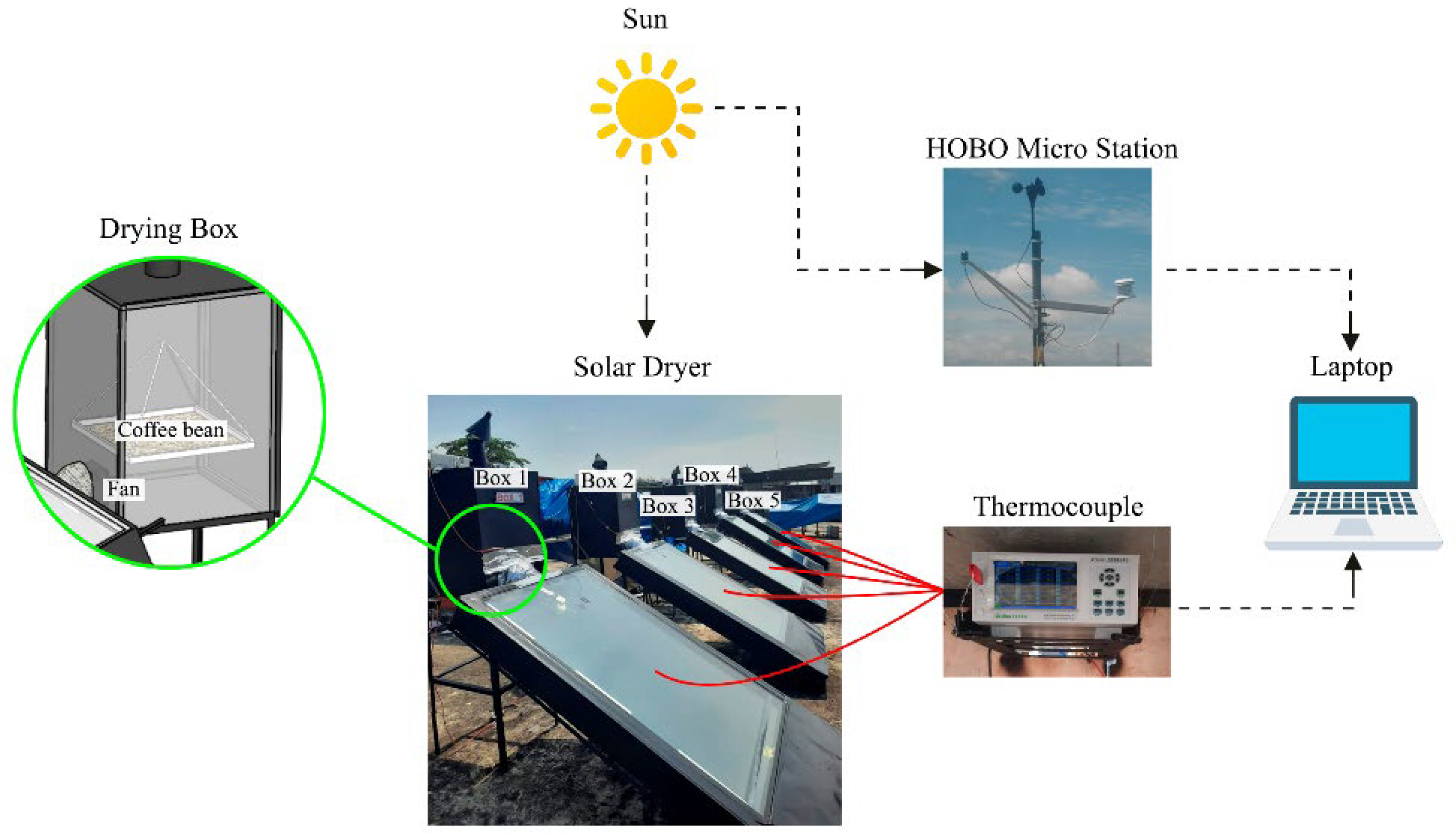

2. Materials and Methods

3. Thermal Analysis

4. Results and Discussion

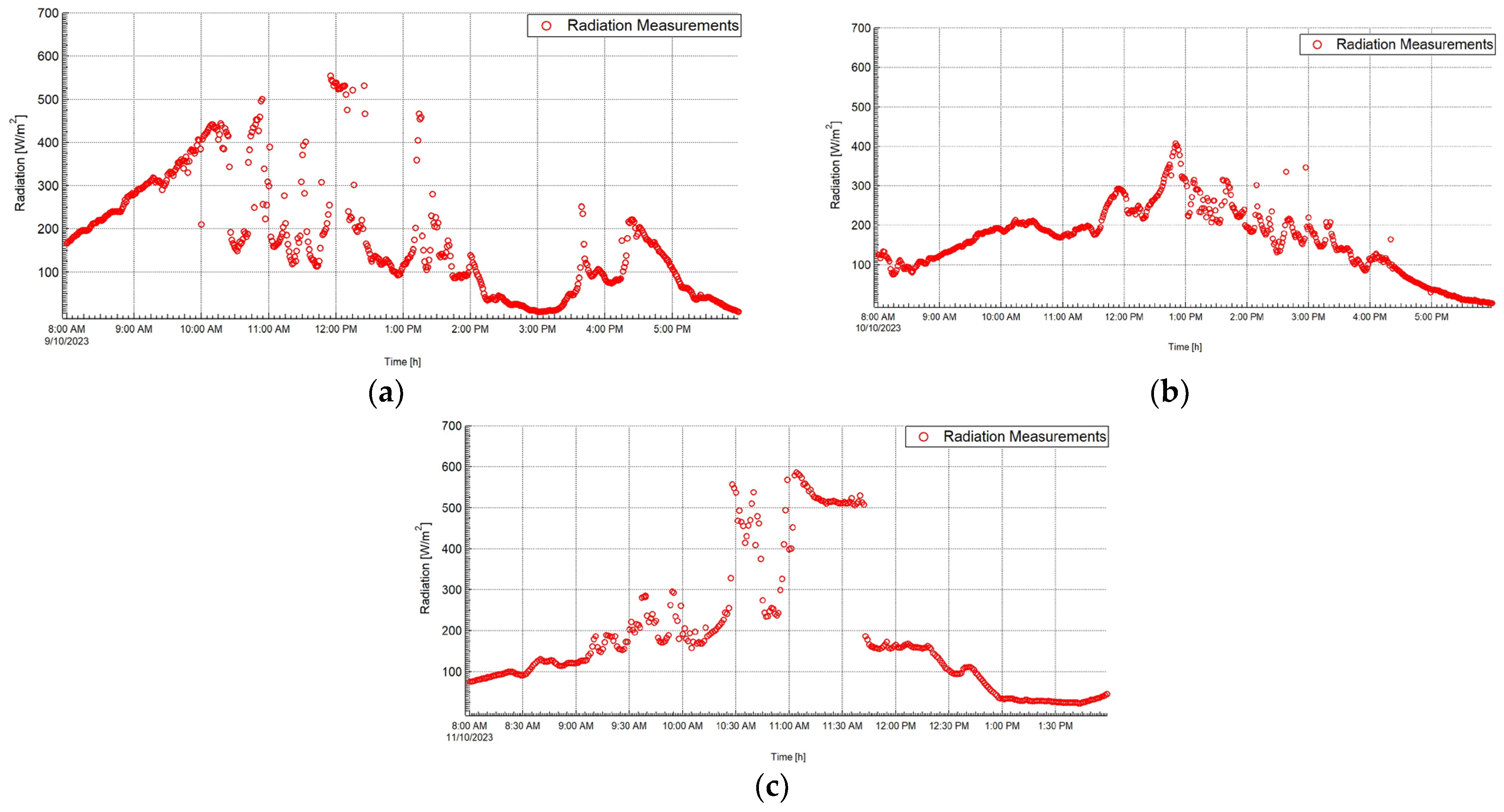

4.1. Solar Irradiation

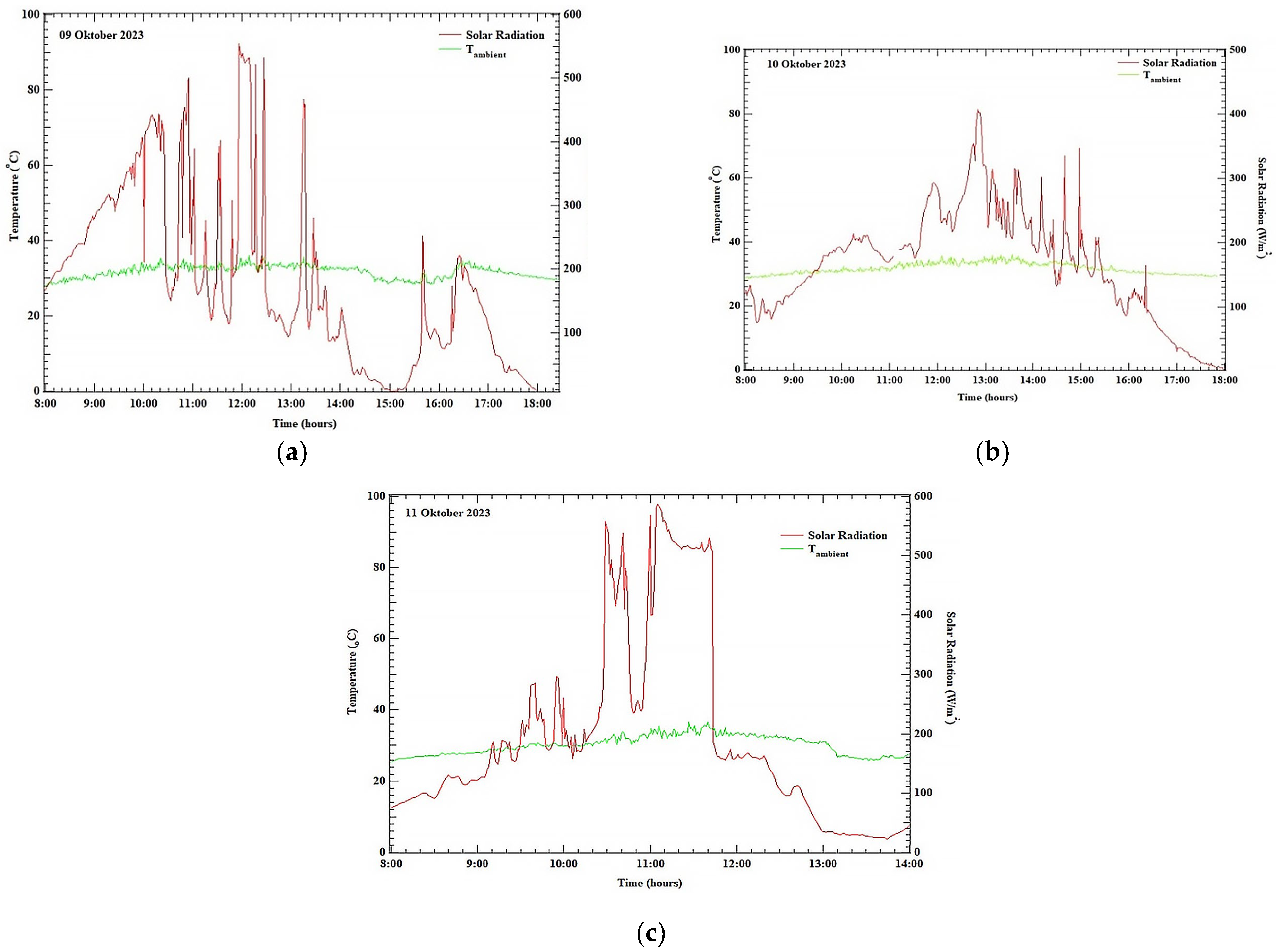

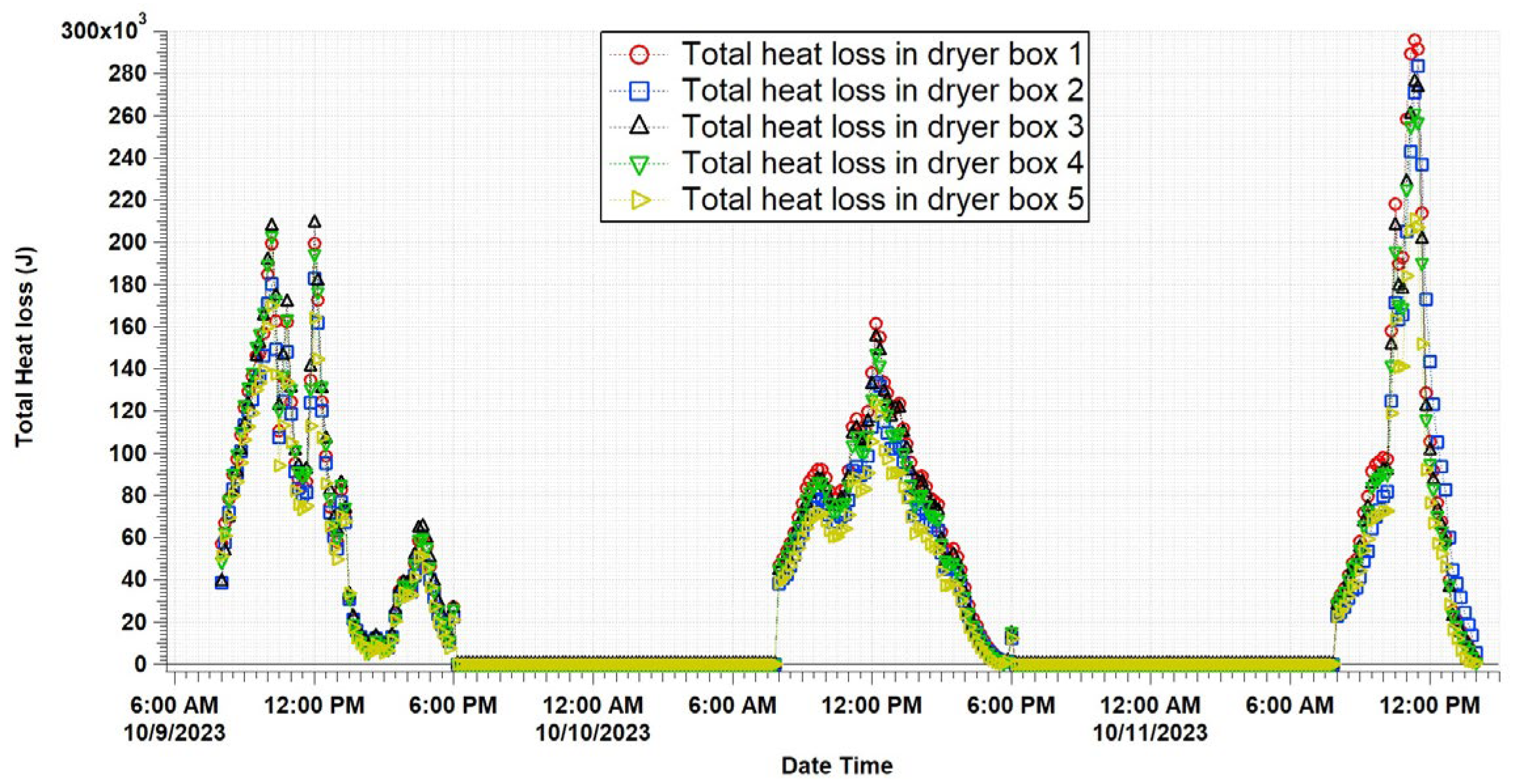

4.2. Solar Coffee Dryer Performance

4.2.1. Absorber Temperature

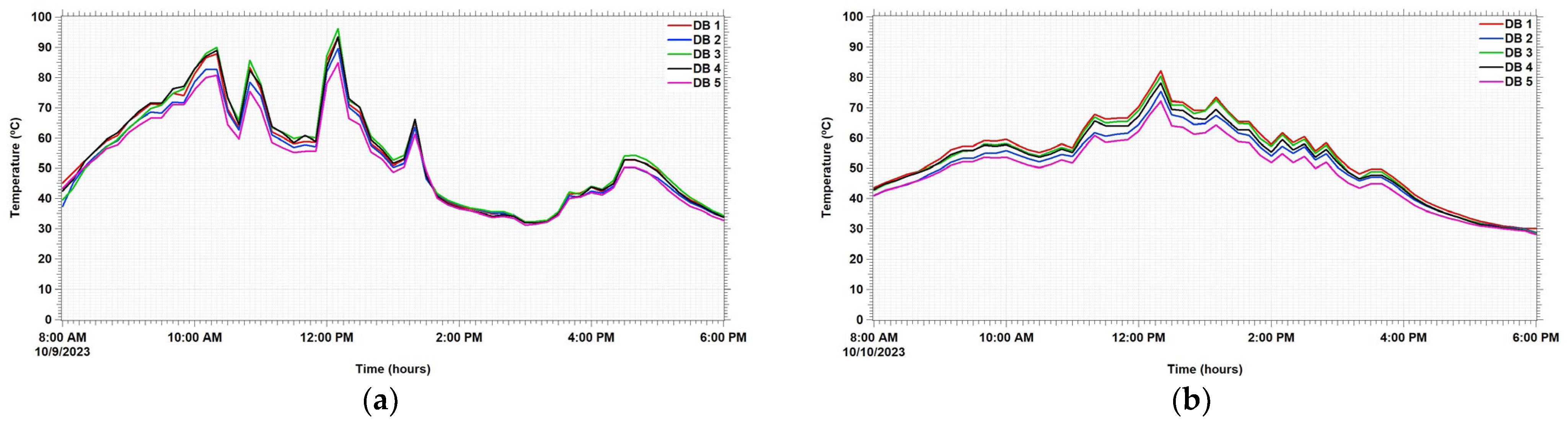

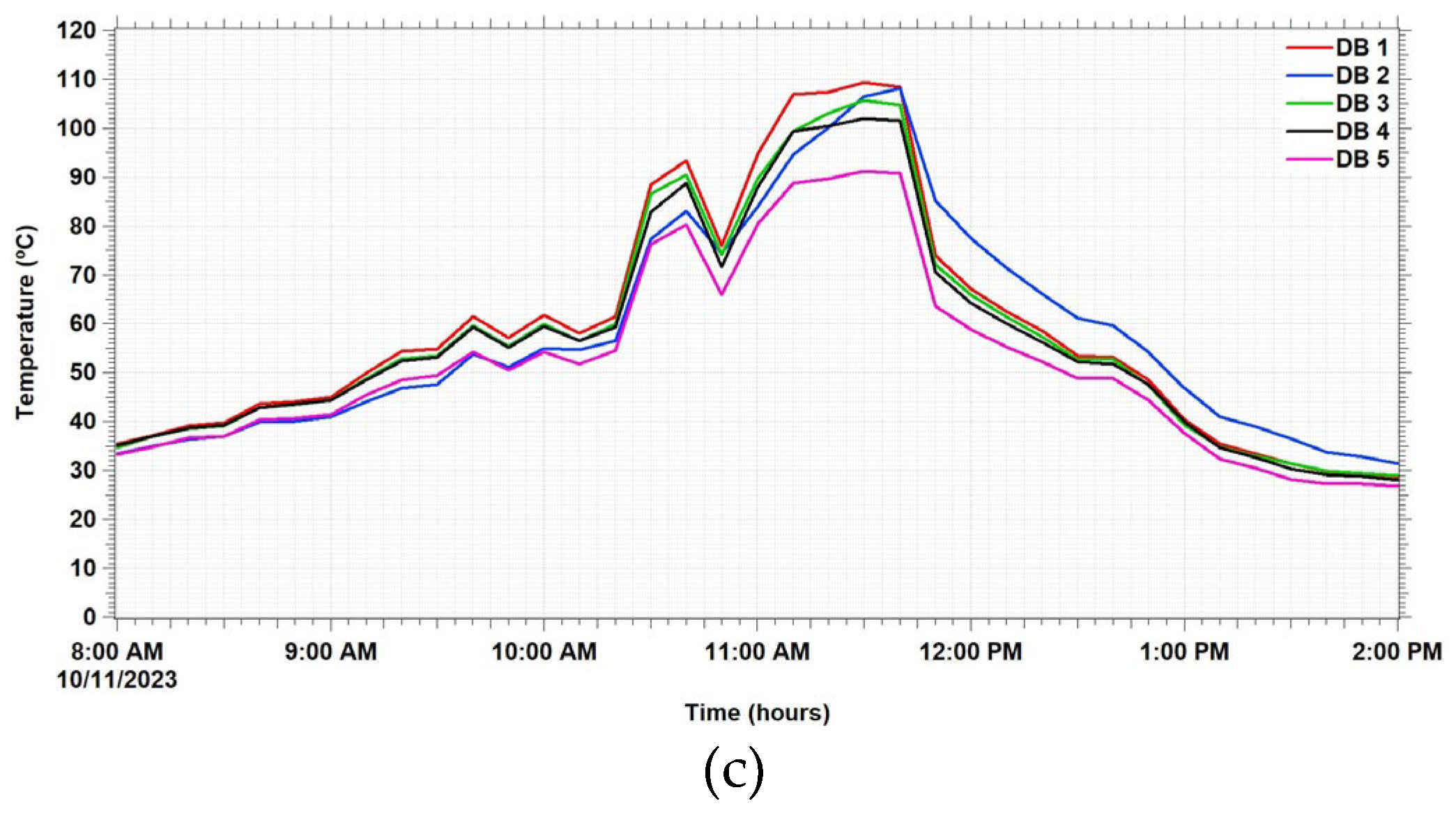

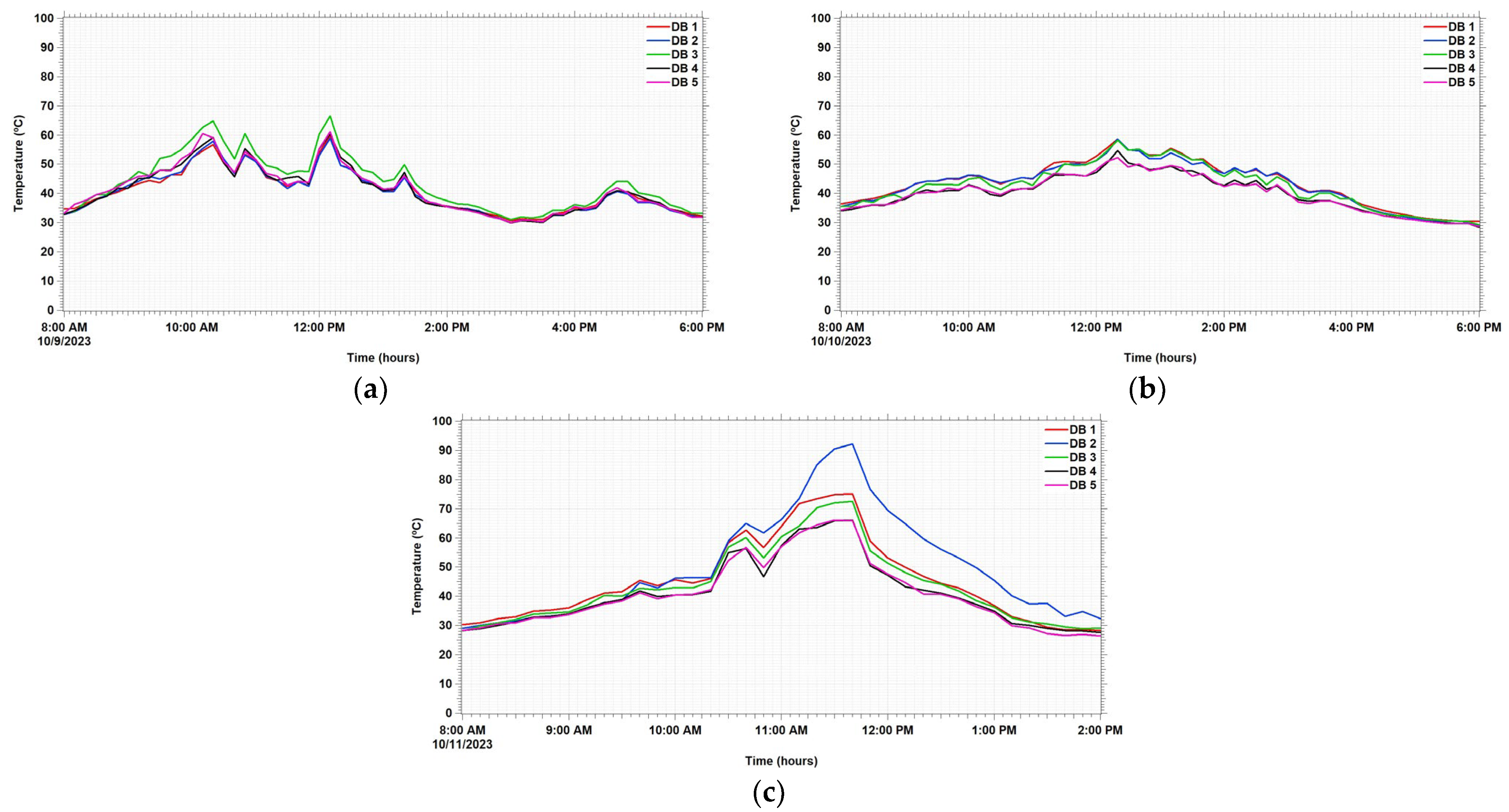

4.2.2. Drying Chamber Temperature

4.3. Coffee Drying Quality

4.3.1. Reduction in the Amount of Moisture

4.3.2. Quality of Coffee Content

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Coffee Organization (ICO). Available online: https://icocoffee.org/ (accessed on 2 October 2023).

- Coffee Review. Available online: https://www.coffeereview.com/ (accessed on 2 October 2023).

- Badan Pusat Statistic Indonesia (BPS). Available online: https://www.bps.go.id/ (accessed on 3 October 2023).

- Menya, E.; Komakec, A.J. Investigating the effect of different loading densities on selected properties of dried coffee using a GHE dryer. Agric. Eng. Int. CIGR J. 2013, 15, 231–237. [Google Scholar]

- Essalhi, H.; Tadili, R.; Bargach, M.N. Conception of a Solar Air Collection for an Indirect Solar Dryer. Pear Dry. Test 2017, 141, 29–33. [Google Scholar]

- Ortiz-Rodríguez, N.; García-Valladares, O.; Pilatowsky-Figueroa, I.; Menchaca-Valdez, A. Solar-LP Gas Hybrid Plant for Dehydration of Food. Appl. Therm. Eng. 2020, 177, 115496. [Google Scholar] [CrossRef]

- Atalay, H. Assesment of energy and cost analysis of packed bed and phase change material thermal Energy storage system for the solar energy-sissted drying process. Sol. Energy 2020, 198, 124–138. [Google Scholar] [CrossRef]

- Ghaffari, A. Solar dryer performance simulation: Experimental and numerical study. J. Food Process Eng. 2021, 44, e13875. [Google Scholar]

- Siagian, P.; Setyawan, E.Y.; Gultom, T.; Napitupulu, F.H.; Ambarita, H. A field survey on coffee beans drying methods of Indonesian small holder farmers. In 1st Nommensen International Conference on Technology and Engineering IOP Publishing IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 237, p. 012037. [Google Scholar] [CrossRef]

- Nukulwar, M.R.; Tungikar, V.B. Design and Development of Steam-Based Solar Dryer for Agricultural Products. Smart Innov. Syst. Technol. 2020, 174, 365–375. [Google Scholar]

- Cormio, C.; Dicorato, M.; Minoia, A.; Trovato, M. A regional energy planning methodology including renewable energy sources and environmental constraints. Renew. Sustain. Energy Rev. 2003, 7, 99–130. [Google Scholar] [CrossRef]

- Singh, P.; Pandey, B.K.; Gaur, M.K. Performance evaluation of evacuated solar collector assisted hybrid greenhouse solar dryer under active and passive mode. Mater. Today Proc. 2022, 57, 2002–2008. [Google Scholar] [CrossRef]

- Singh, S.; Gill, R.; Hans, V.; Mittal, T. Experimental performance and economic viability of evacuated tube solar collector assisted greenhouse dryer for sustainable development. Energy 2022, 241, 122794. [Google Scholar] [CrossRef]

- Lingayat, A.; Chandramohan, V.P. Numerical investigation on solar air collector and its practical application in the indirect solar dryer for banana chips drying with energy and exergy analysis. Therm. Sci. Eng. Prog. 2021, 26, 101077. [Google Scholar] [CrossRef]

- Gupta, A.; Biswas, A.; Das, B.; Reddy, B.V. Development and testing of novel photovoltaic-thermal collector-based solar dryer for green tea drying application. Sol. Energy 2022, 231, 1072–1091. [Google Scholar] [CrossRef]

- Pruengam, P.; Pathaveerat, S.; Pukdeewong, P. Fabrication and testing of double-sided solar collector dryer for drying banana. Case Stud. Therm. Eng. 2021, 27, 101335. [Google Scholar] [CrossRef]

- Murali, S.; Delfiya, D.S.A.; Alfiya, P.V.; Samuel, M.P.; Ninan, G. Development of sensible heat storage based solar hybrid dryer with evacuated tube collector and biomass gasifier for shrimp drying. Sol. Energy 2023, 262, 111836. [Google Scholar] [CrossRef]

- Salhi, M.; Chaatouf, D.; Raillani, B.; Bria, A.; Amraqui, S.; Mezrhab, A. Numerical investigation of an indirect solar dryer equipped with two solar air collectors using computational fluid dynamics. J. Stored Prod. Res. 2023, 104, 102189. [Google Scholar] [CrossRef]

- Rani, P.; Tripathy, P.P. CFD coupled heat and mass transfer simulation of pineapple drying process using mixed-mode solar dryers integrated with flat plate and finned collector. Renew. Energy 2023, 217, 119210. [Google Scholar] [CrossRef]

- Ekka, J.P.; Muthukumar, P.; Bala, K.; Kanaujiya, D.K.; Pakshirajan, K. Performance studies on mixed-mode forced convection solar cabinet dryer under different air mass flow rates for drying of cluster fig. Sol. Energy 2021, 229, 39–51. [Google Scholar] [CrossRef]

- Tagnamas, Z.; Lamsyehe, H.; Moussaoui, H.; Bahammou, Y.; Kouhila, M.; Idlimam, A.; Lamharrar, A. Energy and exergy analyses of carob pulp drying system based on a solar collector. Renew. Energy 2021, 163, 495–503. [Google Scholar] [CrossRef]

- Rani, P.; Tripathy, P.P. Drying characteristics, energetic and exergetic investigation during mixed-mode solar drying of pineapple slices at varied air mass flow rates. Renew. Energy 2021, 167, 508–519. [Google Scholar] [CrossRef]

- Hassan, A.; Nikbahkt, A.M.; Welsh, Z.; Yarlagadda, P.; Fawzia, S.; Karim, A. Experimental and thermodynamic analysis of solar air dryer equipped with V-groove double pass collector: Techno-economic and exergetic measures. Energy Convers. Manag. X 2022, 16, 100296. [Google Scholar] [CrossRef]

- César, L.V.; Lilia, C.M.; Octavio, G.V.; Isaac, P.F.; Rogelio, B.O. Thermal performance of a passive, mixed-type solar dryer for tomato slices (Solanum lycopersicum). Renew. Energy 2019, 147, 845–855. [Google Scholar] [CrossRef]

| No. | Time | Total Solar Irradiation (MJ/m2) |

|---|---|---|

| 1 | Day 1 | 6.5 |

| 2 | Day 2 | 5.9 |

| 3 | Day 3 | 4.2 |

| No | Dryer | Collector Efficiency |

|---|---|---|

| 1 | Dryer box 1 | 32.3% |

| 2 | Dryer box 2 | 38.1% |

| 3 | Dryer box 3 | 33.7% |

| 4 | Dryer box 4 | 35.5% |

| 5 | Dryer box 5 | 44.8% |

| Composition | Sample and Proximate Test | ||||

|---|---|---|---|---|---|

| DB1 | DB2 | DB3 | DB4 | DB5 | |

| Water (%) | 12.0 | 13.6 | 18.5 | 12.9 | 15.2 |

| Protein (%) | 11.7 | 12.2 | 11.5 | 11.6 | 11.3 |

| Carbohydrate (%) | 21.7 | 22.8 | 19.9 | 18.1 | 20.4 |

| Free fatty acid (%) | 0.05 | 0.05 | 0.09 | 0.09 | 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siagian, P.; Napitupulu, F.H.; Ambarita, H.; Sihombing, H.V.; Sibagariang, Y.P.; Siagian, H.S. The Effect of Varying the Air Flow in a Solar Collector on the Quality of Arabica Coffee Beans. Fluids 2024, 9, 75. https://doi.org/10.3390/fluids9030075

Siagian P, Napitupulu FH, Ambarita H, Sihombing HV, Sibagariang YP, Siagian HS. The Effect of Varying the Air Flow in a Solar Collector on the Quality of Arabica Coffee Beans. Fluids. 2024; 9(3):75. https://doi.org/10.3390/fluids9030075

Chicago/Turabian StyleSiagian, Parulian, Farel Hasiholan Napitupulu, Himsar Ambarita, Hendrik Voice Sihombing, Yogie Probo Sibagariang, and Horas Sotardodo Siagian. 2024. "The Effect of Varying the Air Flow in a Solar Collector on the Quality of Arabica Coffee Beans" Fluids 9, no. 3: 75. https://doi.org/10.3390/fluids9030075

APA StyleSiagian, P., Napitupulu, F. H., Ambarita, H., Sihombing, H. V., Sibagariang, Y. P., & Siagian, H. S. (2024). The Effect of Varying the Air Flow in a Solar Collector on the Quality of Arabica Coffee Beans. Fluids, 9(3), 75. https://doi.org/10.3390/fluids9030075