Efficient Simulations of Propagating Flames and Fire Suppression Optimization Using Adaptive Mesh Refinement

Abstract

1. Introduction

2. Computational Framework: fireDyMFoam

2.1. Physical Treatment of the Gas Phase

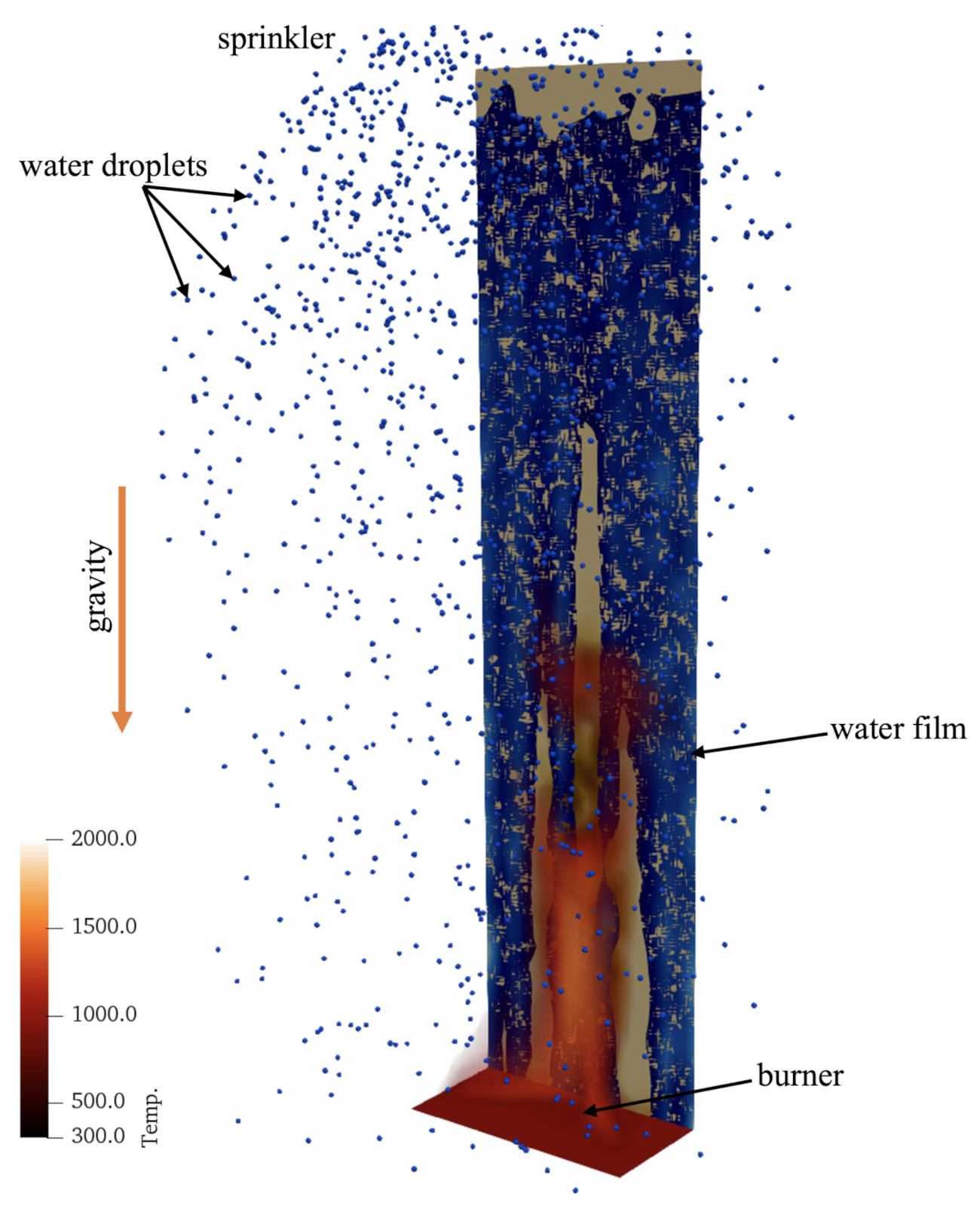

2.2. Physical Treatment of the Solid Phase

2.3. Physical Treatment of Liquid Films and Lagrangian Particles

2.4. Phase Coupling

2.5. Adaptive Mesh Refinement (AMR)

- If the simulation timestep index is a multiple of a user-specified refinement interval, trigger the mesh update.

- Scan the user-defined refinement field for cells eligible for refinement. Eligible cells are determined by comparing values of the field to lower and upper refinement bounds. If the cell value lies within the refinement bounds, it is marked as a candidate for refinement. Candidates are then scanned and checked for “refineability”, namely, candidates are considered refinable if they are below the max refinement level and if they are hexagonal cells.

- Refine the selected cells and protect “buffer” cells around the newly refined cells from un-refinement. Map the solution to the new mesh.

- Scan points in the mesh for un-refinement, comparing point values to an un-refine level; values lower than this level are tagged for recombination. Cells are then recombined and the solution is mapped once more.

2.6. Numerical Treatment

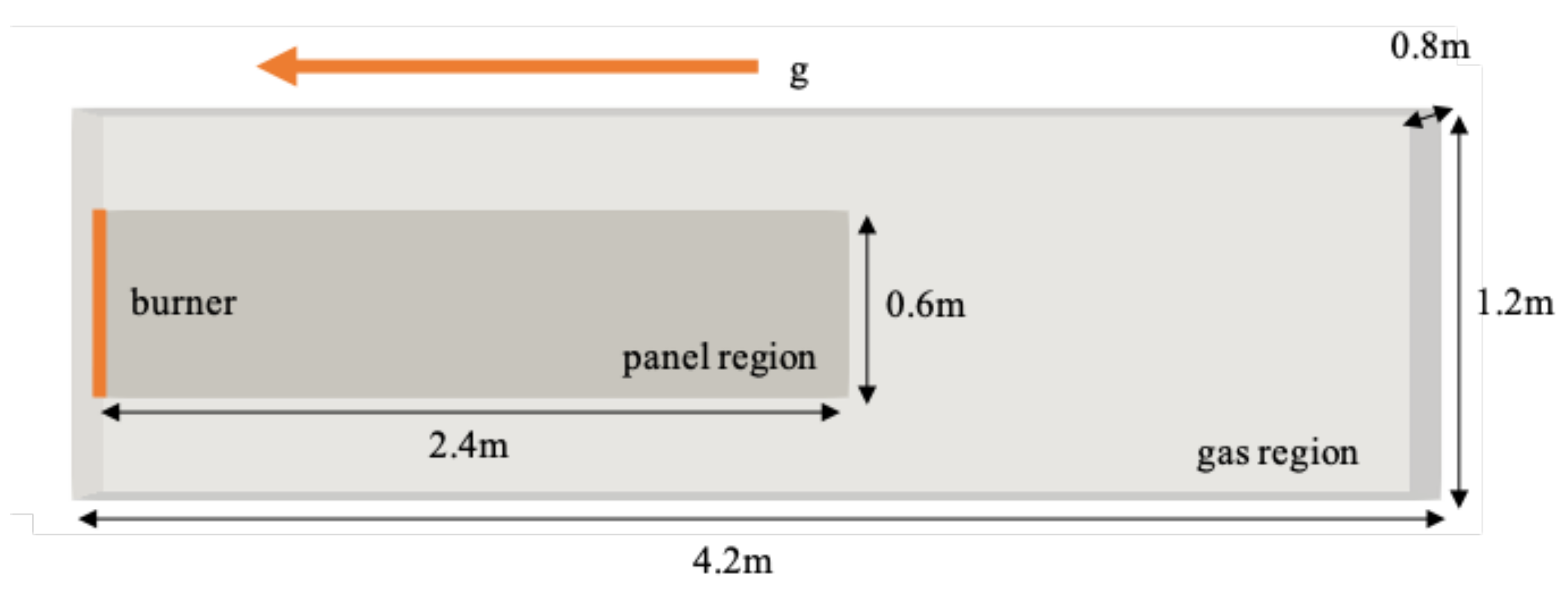

3. Verification: Single Panel Vertical Fire Spread

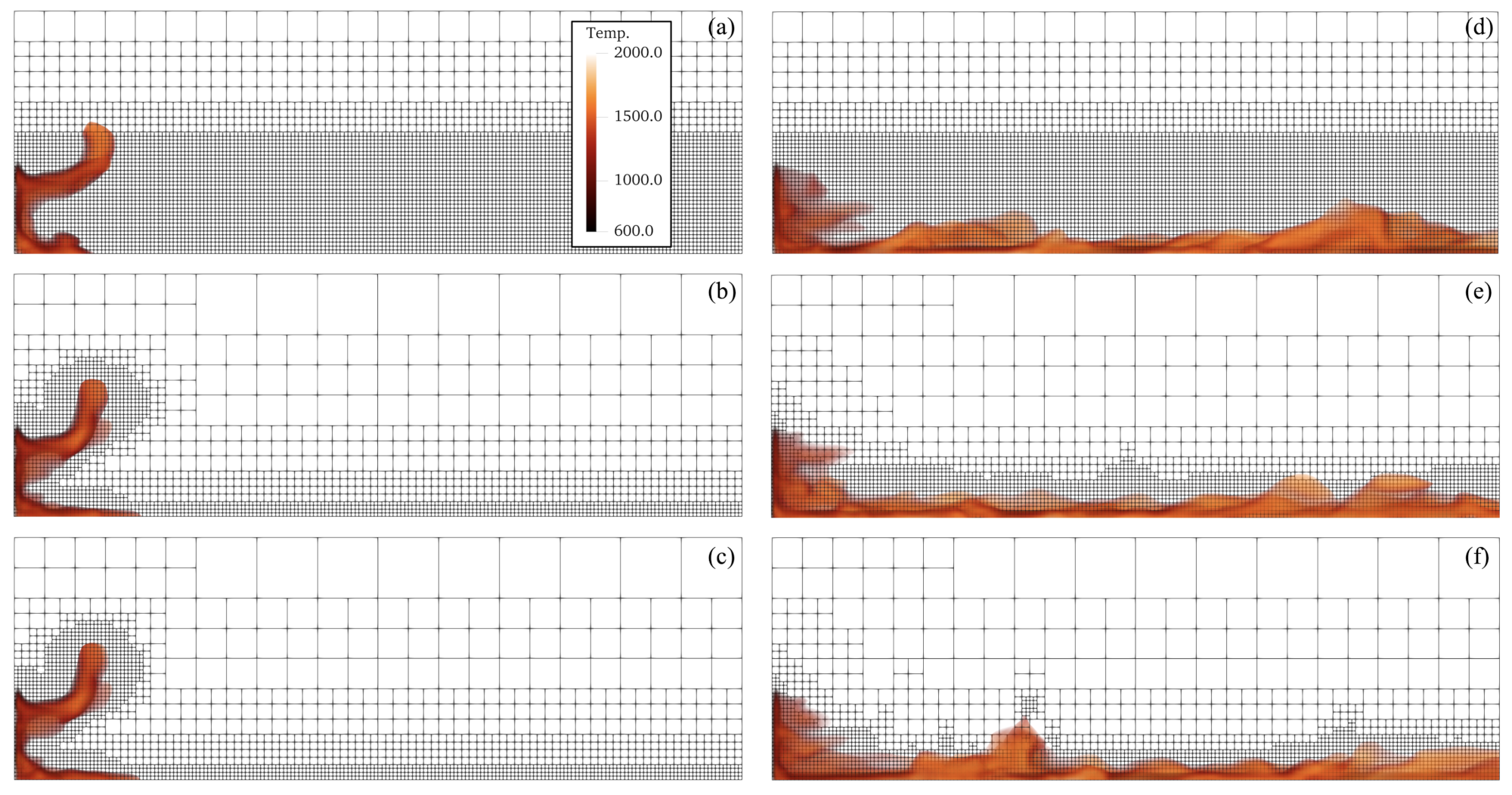

3.1. Statically Refined Simulation

3.2. AMR Simulation

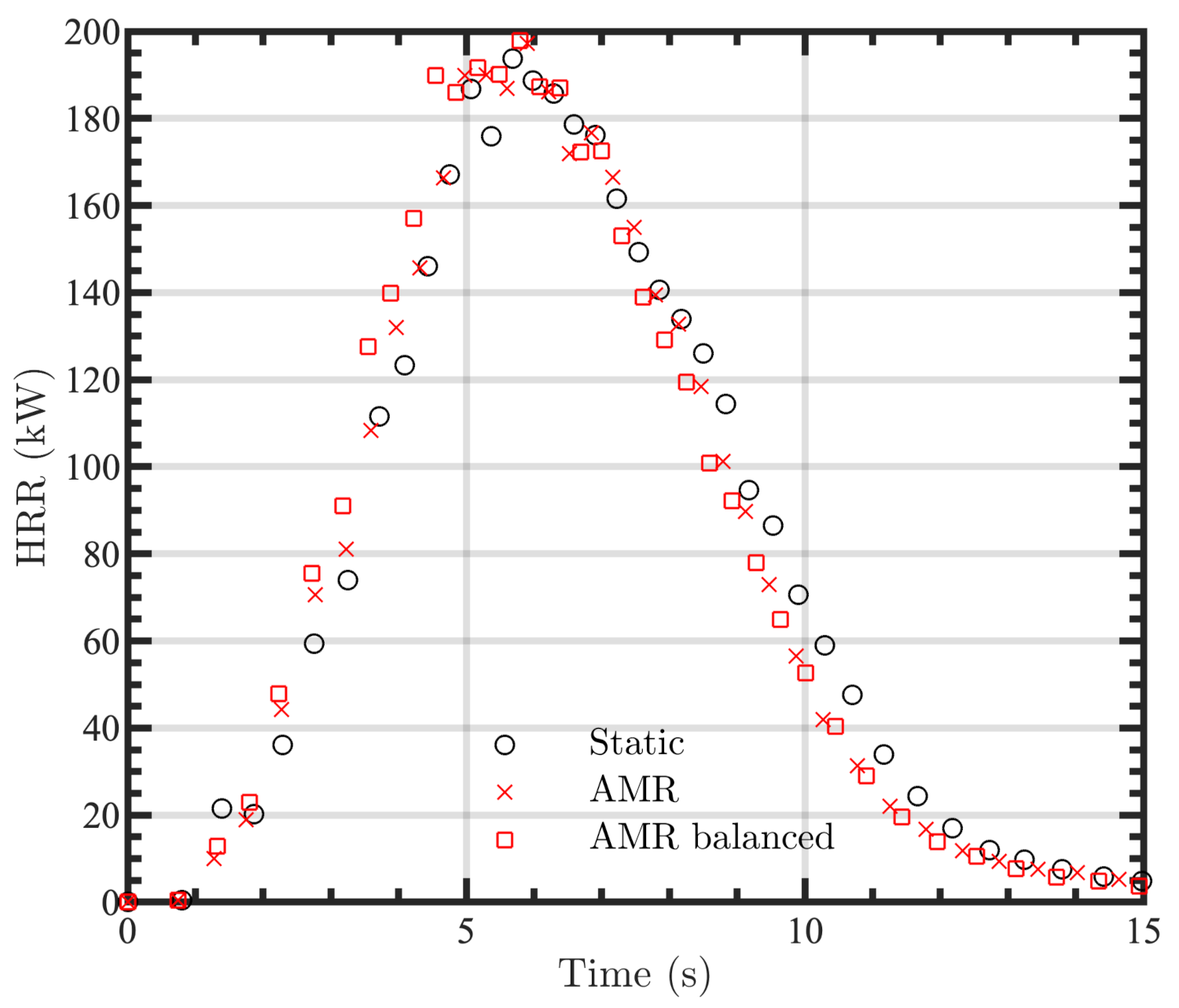

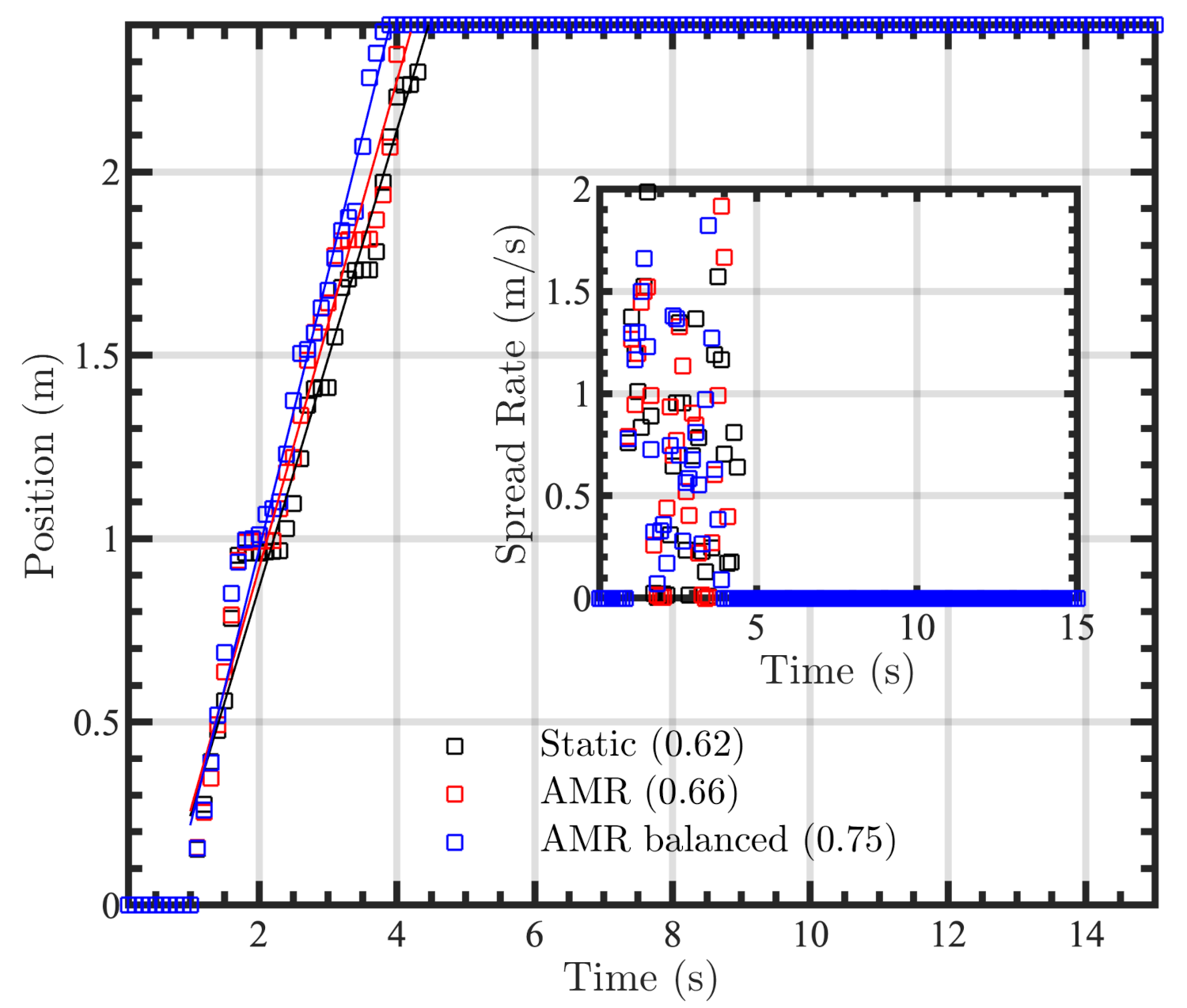

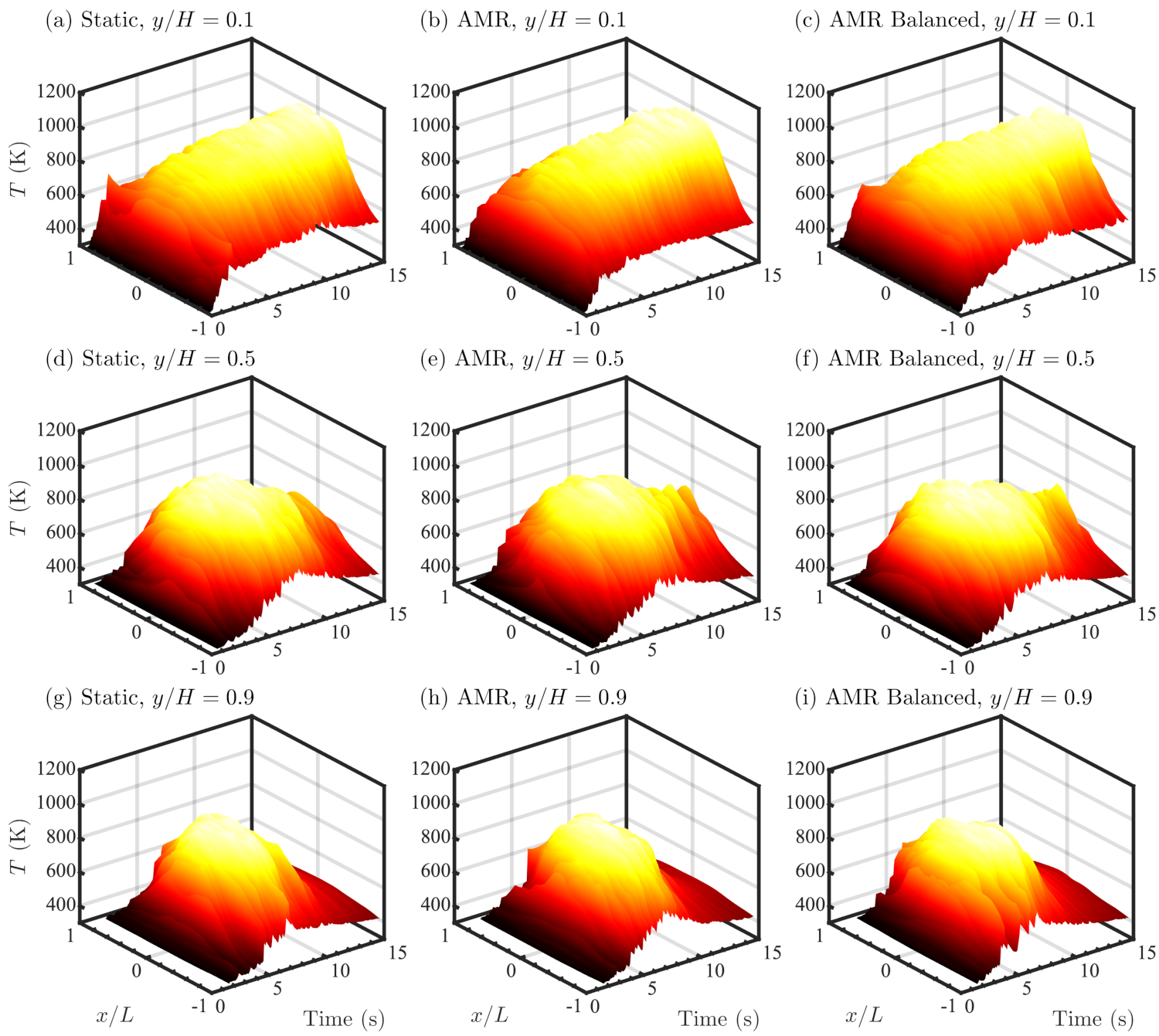

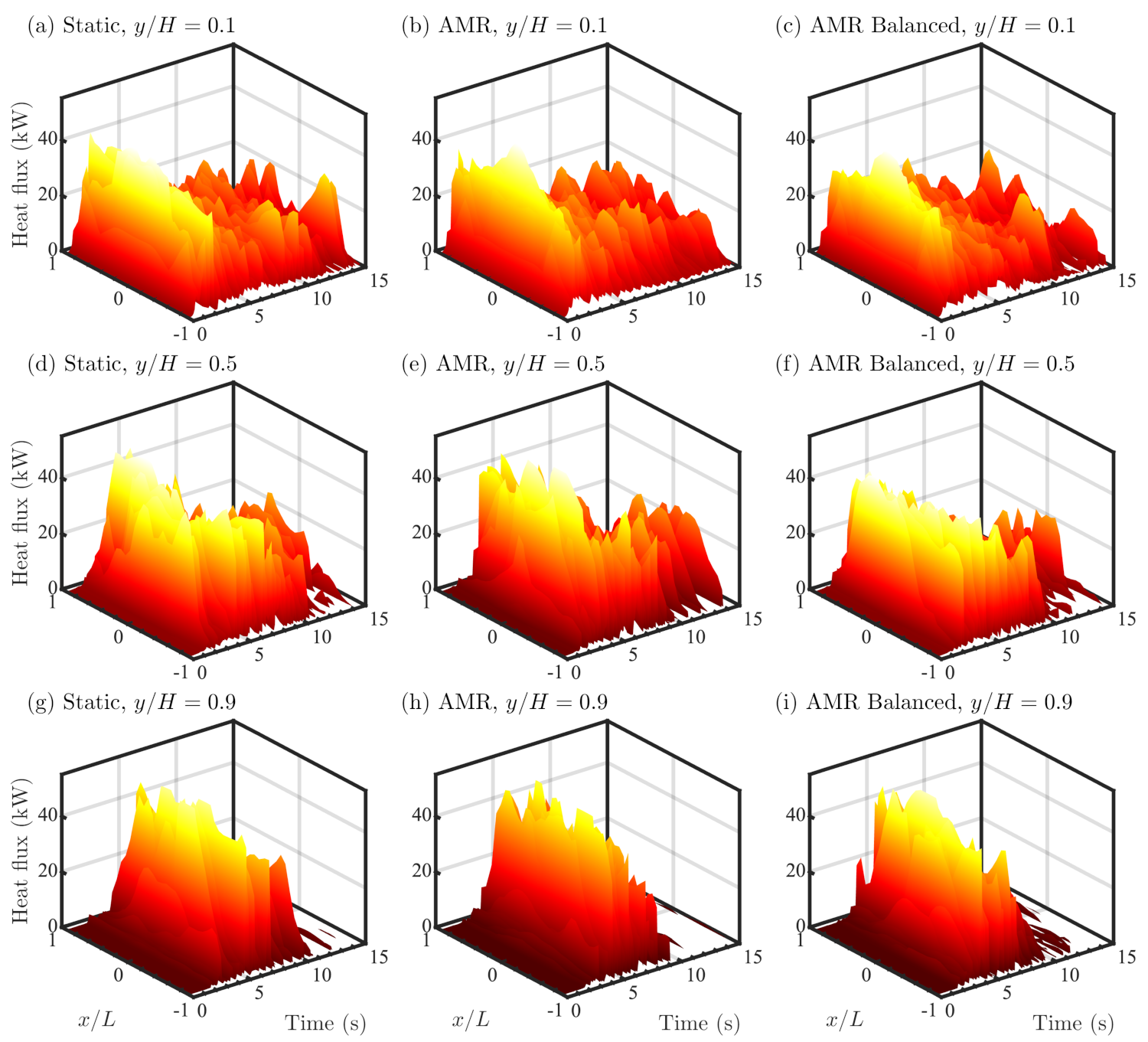

3.3. Results and Discussion

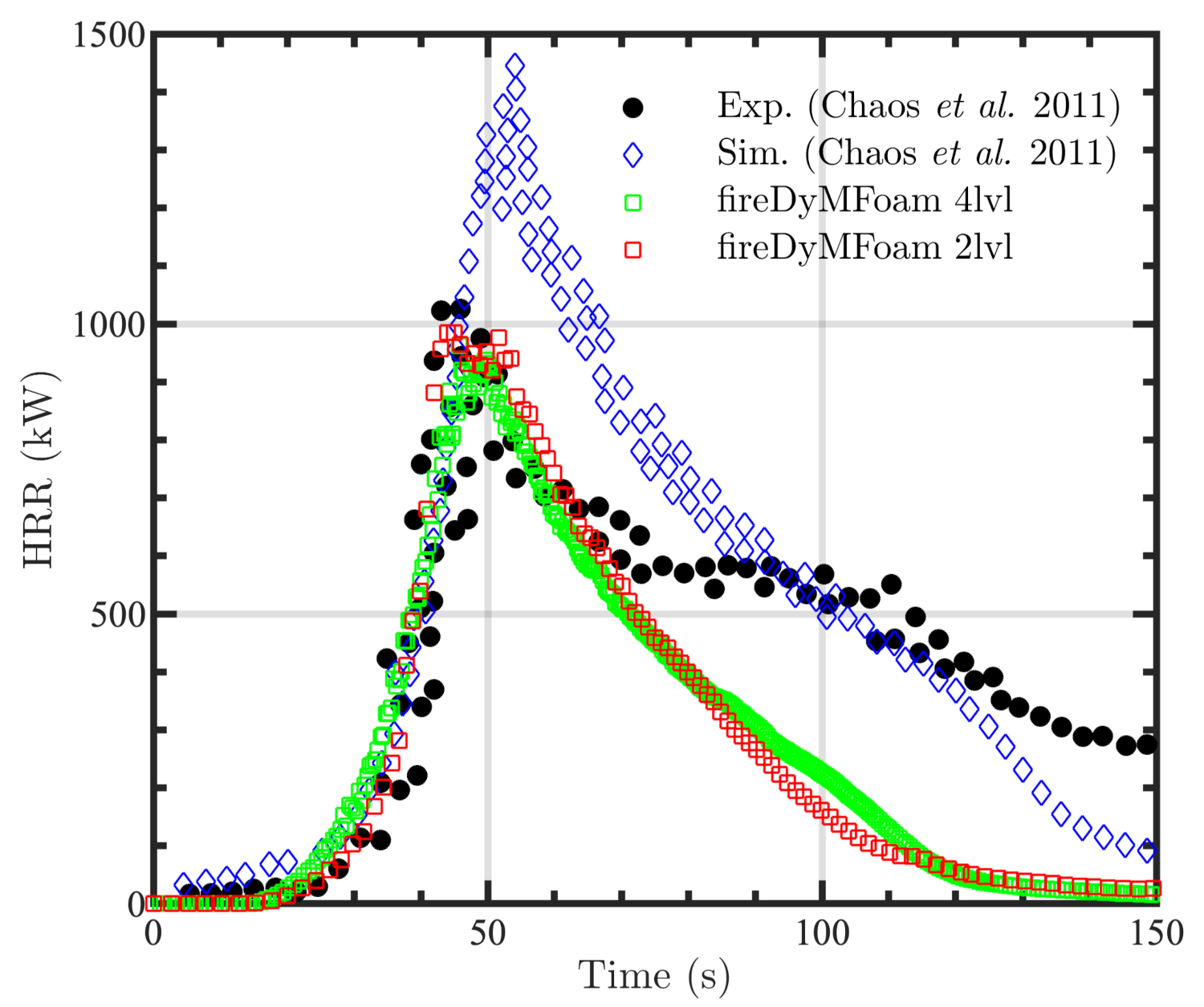

4. Validation: Two-Panel Vertical Fire Spread

4.1. AMR Simulation

4.2. Results and Discussion

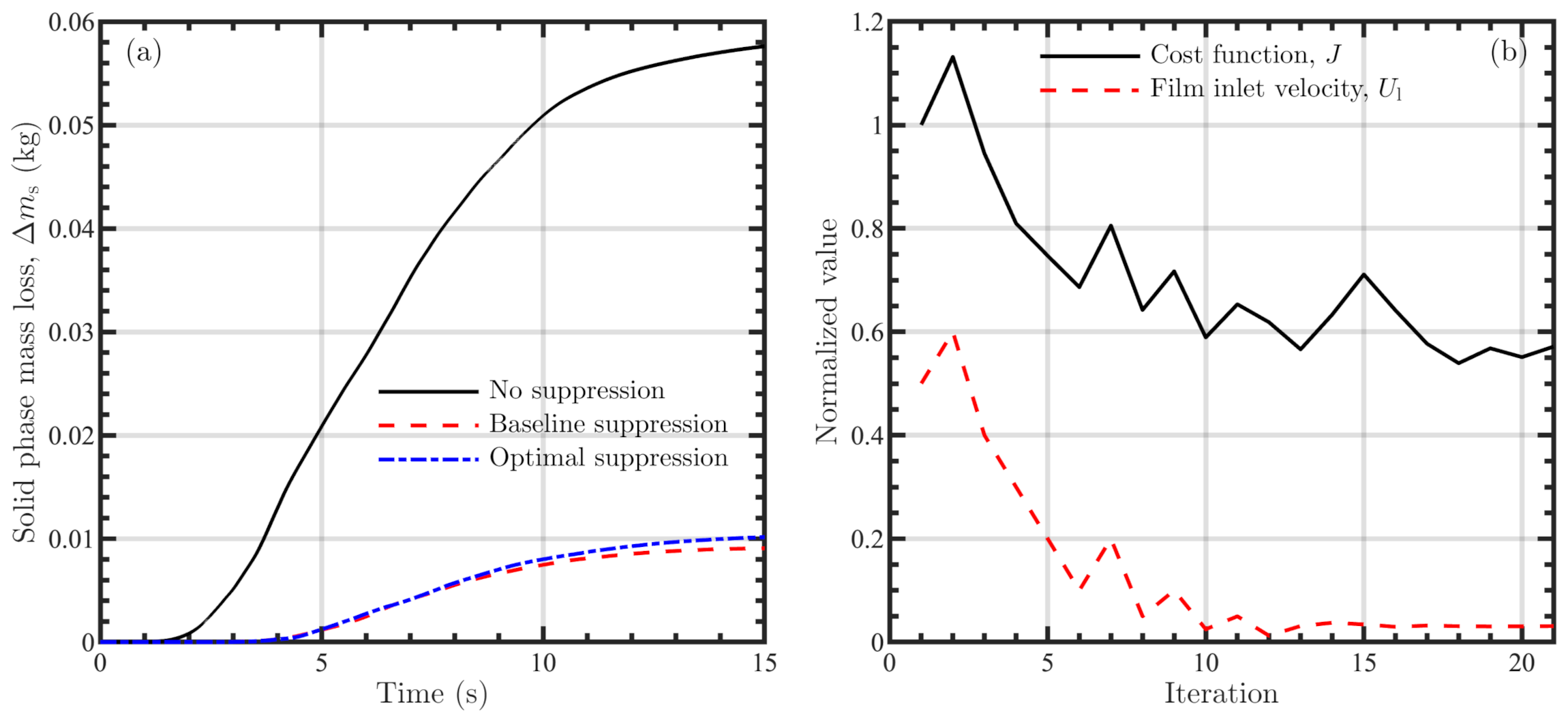

5. Optimization: Fire Suppression Using Liquid Films and Lagrangian Particles

- Retrieve values (e.g., model parameters and boundary coefficients; initial or updated) from Dakota and convert to a format readable by OpenFOAM;

- Edit OpenFOAM files with values from Dakota;

- Run OpenFOAM case and post-process as necessary;

- Compute cost function and pass to Dakota for updated parameter evaluation.

5.1. Water Film Suppression

5.2. Sprinkler Suppression

6. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hanson, H.; Bradley, M.; Bossert, J.; Linn, R.; Younker, L. The potential and promise of physics-based wildfire simulation. Environ. Sci. Policy 2000, 3, 161–172. [Google Scholar] [CrossRef]

- Chen, Z.; Wen, J.; Xu, B.; Dembele, S. Extension of the eddy dissipation concept and smoke point soot model to the LES frame for fire simulations. Fire Saf. J. 2014, 64, 12–26. [Google Scholar] [CrossRef]

- Chen, Z.; Wen, J.; Xu, B.; Dembele, S. Large eddy simulation of a medium-scale methanol pool fire using the extended eddy dissipation concept. Int. J. Heat Mass Transf. 2014, 70, 389–408. [Google Scholar] [CrossRef]

- Pope, S. Computationally efficient implementation of combustion chemistry using in situ adaptive tabulation. Combust. Theory Model. 1997, 1, 41–63. [Google Scholar] [CrossRef]

- Singer, M.; Pope, S.; Najm, H. Operator-splitting with ISAT to model reacting flow with detailed chemistry. Combust. Theory Model. 2006, 10, 199–217. [Google Scholar] [CrossRef]

- Singer, M.; Pope, S. Exploiting ISAT to solve the reaction-diffusion equation. Combust. Theory Model. 2004, 8, 361–383. [Google Scholar] [CrossRef][Green Version]

- Niemeyer, K.; Sung, C.; Raju, M. Skeletal mechanism generation for surrogate fuels using directed relation graph with error propagation and sensitivity analysis. Combust. Flame 2010, 157, 1760–1770. [Google Scholar] [CrossRef]

- Glusman, J.; Niemeyer, K.; Makowiecki, A.; Wimer, N.; Lapointe, C.; Rieker, G.; Hamlington, P.; Daily, J. Reduced Gas-Phase Kinetic Models for Burning of Douglas Fir. Front. Mech. Eng. 2019, 5, 40. [Google Scholar] [CrossRef]

- Nyazika, T.; Jimenez, M.; Samyn, F.; Bourbigot, S. Pyrolysis modeling, sensitivity analysis, and optimization techniques for combustible materials: A review. J. Fire Sci. 2019, 37, 377–433. [Google Scholar] [CrossRef]

- Lapointe, C.; Wimer, N.; Glusman, J.; Makowiecki, A.; Daily, J.; Rieker, G.; Hamlington, P. Efficient simulation of turbulent diffusion flames in OpenFOAM using adaptive mesh refinement. Fire Saf. J. 2020, 111, 102934. [Google Scholar] [CrossRef]

- Wang, Y.; Chatterjee, P.; de Ris, J. Large eddy simulation of fire plumes. Proc. Combust. Inst. 2011, 33, 2473–2480. [Google Scholar] [CrossRef]

- Adams, B.; Bohnhoff, W.; Dalbey, K.; Eddy, J.; Eldred, M.; Gay, D.; Haskell, K.; Hough, P.; Swiler, L. DAKOTA, a multilevel parallel object-oriented framework for design optimization, parameter estimation, uncertainty quantification, and sensitivity analysis: Version 5.0 user’s manual. In Sandia National Laboratories, Tech. Rep. SAND2010-2183; Sandia National Laboratories: Livermore, CA, USA, 2009. [Google Scholar]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; Weinschenk, C.; Overholt, K. Fire dynamics simulator user’s guide. NIST spe Fire Dynamics Simulator User’s Guide. NIST Spec. Publ. 2013, 1019, 1–339. [Google Scholar]

- Lee, J. Numerical analysis on the rapid fire suppression using a water mist nozzle in a fire compartment with a door opening. Nucl. Eng. Technol. 2019, 51, 410–423. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, W.; Wang, Q. Optimization of water mist droplet size by using CFD modeling for fire suppressions. J. Loss Prev. Process Ind. 2016, 44, 626–632. [Google Scholar] [CrossRef]

- The OpenFOAM Foundation. OpenFOAM Development Repository; Github: San Francisco, CA, USA, 2021. [Google Scholar]

- FM Global. FireFOAM Development Repository; Github: San Francisco, CA, USA, 2020. [Google Scholar]

- Maragkos, G.; Rauwoens, P.; Merci, B. Application of FDS and FireFOAM in Large Eddy Simulations of a Turbulent Buoyant Helium Plume. Combust. Sci. Technol. 2012, 184, 1108–1120. [Google Scholar] [CrossRef]

- Maragkos, G.; Rauwoens, P.; Wang, Y.; Merci, B. Large eddy simulations of the flow in the near-field region of a turbulent buoyant helium plume. Flow, Turbul. Combust. 2013, 90, 511–543. [Google Scholar] [CrossRef]

- Maragkos, G.; Merci, B. Large Eddy simulations of CH4 fire plumes. Flow, Turbul. Combust. 2017, 99, 239–278. [Google Scholar] [CrossRef]

- Maragkos, G.; Beji, T.; Merci, B. Implementation and Evaluation of the Dynamic Smagorinsky Model and an Eddy Dissipation Model with Multiple Reaction Time Scales in FireFOAM. In Proceedings of the 10th Mediterranean Combustion Symposium, Naples, Italy, 17–21 September 2017. [Google Scholar]

- Vilfayeau, S.; Ren, N.; Wang, Y.; Trouvé, A. Numerical simulation of under-ventilated liquid-fueled compartment fires with flame extinction and thermally-driven fuel evaporation. Proc. Combust. Inst. 2015, 35, 2563–2571. [Google Scholar] [CrossRef]

- Salmon, F.; Lacanette, D.; Mindeguia, J.; Sirieix, C.; Ferrier, C.; Leblanc, J. FireFOAM simulation of a localised fire in a gallery. J. Phys. Conf. Ser. 2018, 1107, 042017. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, C.; Lu, S. Modeling the pyrolysis of wet wood using FireFOAM. Energy Convers. Manag. 2015, 98, 500–506. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, C.; Lu, S. Large Eddy Simulation of Fire Spread. Procedia Eng. 2014, 71, 537–543. [Google Scholar] [CrossRef][Green Version]

- Meredith, K.; de Vries, J.; Wang, Y.; Xin, Y. A comprehensive model for simulating the interaction of water with solid surfaces in fire suppression environments. Proc. Combust. Inst. 2013, 34, 2719–2726. [Google Scholar] [CrossRef]

- Fukumoto, K.; Wang, C.; Wen, J. Large eddy simulation of upward flame spread on PMMA walls with a fully coupled fluid-solid approach. Combust. Flame 2018, 190, 365–387. [Google Scholar] [CrossRef]

- Trouvé, A.; Wang, Y. Large eddy simulation of compartment fires. Int. J. Comput. Fluid Dyn. 2010, 24, 449–466. [Google Scholar] [CrossRef]

- Ren, N.; de Vries, J.; Zhou, X.; Chaos, M.; Meredith, K.; Wang, Y. Large-scale fire suppression modeling of corrugated cardboard boxes on wood pallets in rack-storage configurations. Fire Saf. J. 2017, 91, 695–704. [Google Scholar] [CrossRef]

- Meredith, K.; Xin, Y.; de Vries, J. A numerical model for simulation of thin-film water transport over solid fuel surfaces. Fire Saf. Sci. 2011, 10, 415–428. [Google Scholar] [CrossRef]

- Meredith, K.; Heather, A.; De Vries, J.; Xin, Y. A numerical model for partially-wetted flow of thin liquid films. Comput. Methods Multiph. Flow VI 2011, 70, 239. [Google Scholar]

- Chaos, M.; Khan, M.; Krishnamoorthy, N.; de Ris, J.; Dorofeev, S. Evaluation of optimization schemes and determination of solid fuel properties for CFD fire models using bench-scale pyrolysis tests. Proc. Combust. Inst. 2011, 33, 2599–2606. [Google Scholar] [CrossRef]

- Vinayak, A. Mathematical Modeling & Simulation of Pyrolysis & Flame Spread in OpenFOAM. Master’s Thesis, Bergische Universität Wuppertal, Wuppertal, Germany, October 2017. [Google Scholar]

- Jasak, H.; Gosman, A.D. Automatic Resolution Control for the Finite-Volume Method, Part 2: Adaptive Mesh Refinement and Coarsening. Numer. Heat Transf. Part B Fundam. 2000, 38, 257–271. [Google Scholar]

- Zhang, W.; Almgren, A.; Beckner, V.; Bell, J.; Blaschke, J.; Chan, C.; Day, M.; Friesen, B.; Gott, K.; Graves, D.; et al. AMReX: A framework for block-structured adaptive mesh refinement. J. Open Source Softw. 2019, 4, 1370. [Google Scholar] [CrossRef]

- Rettenmaier, D.; Deising, D.; Ouedraogo, Y.; Gjonaj, E.; De Gersem, H.; Bothe, D.; Tropea, C.; Marschall, H. Load balanced 2D and 3D adaptive mesh refinement in OpenFOAM. SoftwareX 2019, 10, 100317. [Google Scholar] [CrossRef]

- Github. hyStrath Repository; Github: San Francisco, CA, USA, 2021. [Google Scholar]

- The National Renewable Energy Lab. Simulator for Wind Farm Applications (SOWFA) Repository; Github: San Francisco, CA, USA, 2021. [Google Scholar]

- UniCFD Web-Laboratory. Hybrid Central Solvers Repository; Github: San Francisco, CA, USA, 2021. [Google Scholar]

- Chaos, M.; Khan, M.; Krishnamoorthy, N.; Chatterjee, P.; Wang, Y.; Dorofeev, S. Experiments and modeling of single-and triple-wall corrugated cardboard: Effective material properties and fire behavior. In Proceedings of the Fire and Materials 2011, 12th International Conference and Exhibition, San Francisco, CA, USA, 31 January–2 February 2011; pp. 625–636. [Google Scholar]

- Yoshizawa, A. Statistical theory for compressible turbulent shear flows, with the application to subgrid modeling. Phys. Fluids 1986, 29, 2152–2164. [Google Scholar] [CrossRef]

- Vilfayeau, S. Large Eddy Simulation of Fire Extinction Phenomena. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2015. [Google Scholar]

- Ren, N.; Wang, Y.; Vilfayeau, S.; Trouvé, A. Large eddy simulation of turbulent vertical wall fires supplied with gaseous fuel through porous burners. Combust. Flame 2016, 169, 194–208. [Google Scholar] [CrossRef]

- Ren, N.; Wang, Y. A convective heat transfer model for LES fire modeling. Proc. Combust. Inst. 2020, 38, 4535–4542. [Google Scholar] [CrossRef]

- Wang, Y.; Meredith, K.; Zhou, X.; Chatterjee, P.; Xin, Y.; Chaos, M.; Ren, N.; Dorofeev, S. Numerical simulation of sprinkler suppression of rack storage fires. Fire Saf. Sci. 2014, 11, 1170–1183. [Google Scholar] [CrossRef]

- Jareteg, A. Coupling of Dakota and OpenFOAM for automatic parameterized optimization. In Proceedings of CFD with OpenSource Software 2013; Nilsson, H., Ed.; Gothenburg, Sweden, September 2013; Available online: http://www.tfd.chalmers.se/~hani/kurser/OS_CFD_2013/AdamJareteg/report_opensource_AJ.pdf (accessed on 24 June 2021).

- Holzmann, T. DAKOTA—OpenFOAM Coupling Training Cases: Geometric Variation. Available online: https://holzmann-cfd.com/community/training-cases/geometric-variation (accessed on 24 June 2021).

- Gurreroo, J. Design of experiments, space exploration, and numerical optimization using Dakota and OpenFOAM. In Proceedings of the 11th OpenFOAM Workshop, Vila Flor, Portugal, 26–30 June 2016. [Google Scholar]

- Nigam, S. Large Eddy Simulations of Industrial Burners. Master’s Thesis, University of Colorado, Boulder, CO, USA, 2018. [Google Scholar]

- Isaacs, S.; Lapointe, C.; Hamlington, P. Development and Application of a Thin Flat Heat Pipe Design Optimization Tool for Small Satellite Systems. J. Electron. Packag. 2020, 143, 011010. [Google Scholar] [CrossRef]

- Fletcher, R.; Reeves, C.M. Function minimization by conjugate gradients. Comput. J. 1964, 7, 149–154. [Google Scholar] [CrossRef]

- Fletcher, R. A new approach to variable metric algorithms. Comput. J. 1970, 13, 317–322. [Google Scholar] [CrossRef]

- Powell, M. A direct search optimization method that models the objective and constraint functions by linear interpolation. In Advances in Optimization and Numerical Analysis; Springer: Berlin/Heidelberg, Germany, 1994; pp. 51–67. [Google Scholar]

- Grant, G.; Brenton, J.; Drysdale, D. Fire suppression by water sprays. Prog. Energy Combust. Sci. 2000, 26, 79–130. [Google Scholar] [CrossRef]

- Lachaud, J.; Scoggins, J.; Magin, T.; Meyer, M.; Mansour, N. A generic local thermal equilibrium model for porous reactive materials submitted to high temperatures. Int. J. Heat Mass Transf. 2017, 108, 1406–1417. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lapointe, C.; Wimer, N.T.; Simons-Wellin, S.; Glusman, J.F.; Rieker, G.B.; Hamlington, P.E. Efficient Simulations of Propagating Flames and Fire Suppression Optimization Using Adaptive Mesh Refinement. Fluids 2021, 6, 323. https://doi.org/10.3390/fluids6090323

Lapointe C, Wimer NT, Simons-Wellin S, Glusman JF, Rieker GB, Hamlington PE. Efficient Simulations of Propagating Flames and Fire Suppression Optimization Using Adaptive Mesh Refinement. Fluids. 2021; 6(9):323. https://doi.org/10.3390/fluids6090323

Chicago/Turabian StyleLapointe, Caelan, Nicholas T. Wimer, Sam Simons-Wellin, Jeffrey F. Glusman, Gregory B. Rieker, and Peter E. Hamlington. 2021. "Efficient Simulations of Propagating Flames and Fire Suppression Optimization Using Adaptive Mesh Refinement" Fluids 6, no. 9: 323. https://doi.org/10.3390/fluids6090323

APA StyleLapointe, C., Wimer, N. T., Simons-Wellin, S., Glusman, J. F., Rieker, G. B., & Hamlington, P. E. (2021). Efficient Simulations of Propagating Flames and Fire Suppression Optimization Using Adaptive Mesh Refinement. Fluids, 6(9), 323. https://doi.org/10.3390/fluids6090323