3.1. One 3D Bubble and Several Drops

We start by examining the motion of one relatively large bubble and several randomly placed smaller drops in a cubical computational domain with side lengths equal to 1, resolved by a

grid. The bubbles have a diameter

, and the droplets have diameters

. The density and viscosity of the continuous fluid are

and

, respectively; for the bubble, we have

and

, and for the drops

and

. Surface tension is

for the drop–liquid interface, but the surface tension for the bubble–liquid interface is varied, resulting in different Morton and Eötvös numbers, as shown in

Table 1. While the grid resolution is relatively low, grid refinement studies have confirmed that the results are reasonably accurate and correctly describe the dynamics of the system. Similarly, we have taken the density of the bubbles to be only 1/20 of the liquid, since we generally find that taking it smaller has only a minor influence on the dynamics, and systems with small density differences are easier to simulate. The number of drops is varied; we show results for

. The simulations were run up to time 200, at which time the bubble had passed about 40 times through the computational domain.

Figure 1 shows the bubble and the 12 drops at time 0 and time 100 for

and

. For the lower Eötvös number, the bubble deforms only slightly as it rises, but for the higher ones, more deformation is seen. The drops remain essentially spherical. The results for

are similar to the

case, and the

results fall in-between the

and the

case. In addition to the bubble and the drops, the enstrophy (

) is plotted in a plane cutting through the middle of the domain to gain insight into where vorticity is generated and where it ends up. The highest values are ahead and behind the bubble, spanning the region between the bubble in one period and the next, suggesting it is the bubble that produces most of the vorticity and that it remains in its wake.

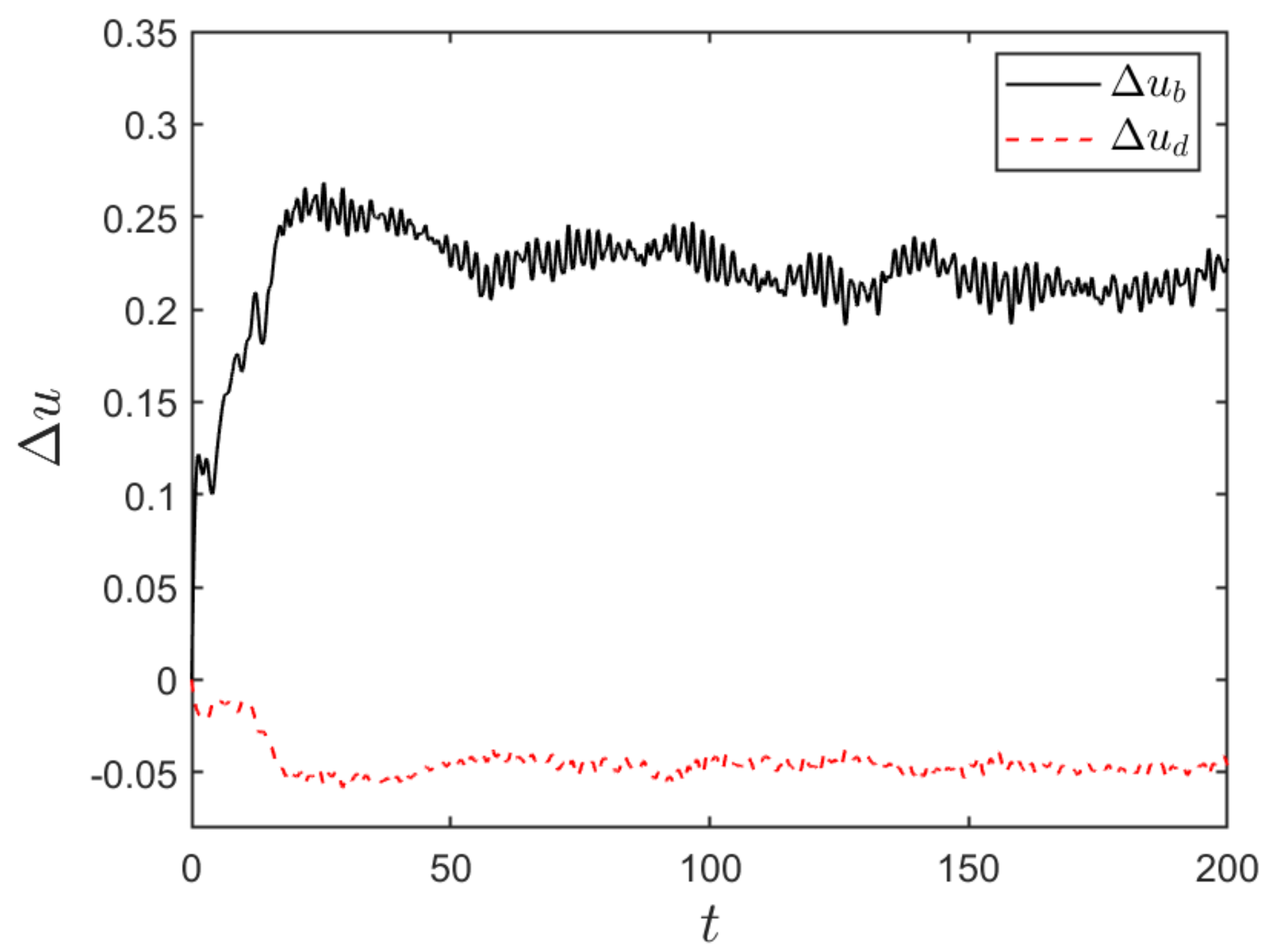

The slip velocities of the bubble and the drops are plotted versus time for

and

in

Figure 2. The bubble wobbles slightly as it rises, as is seen in the nearly periodic oscillations in the slip velocity. For the drops, we plot the average slip velocity, which is negative and relatively steady. After the initial transient, the system reaches an approximately stationary state where the average motion does not change. When we compute average steady-state quantities for the system (shown below), we start at time

and average until the last time simulated (

). Results for other bubble Eötvös numbers and different numbers of drops are similar.

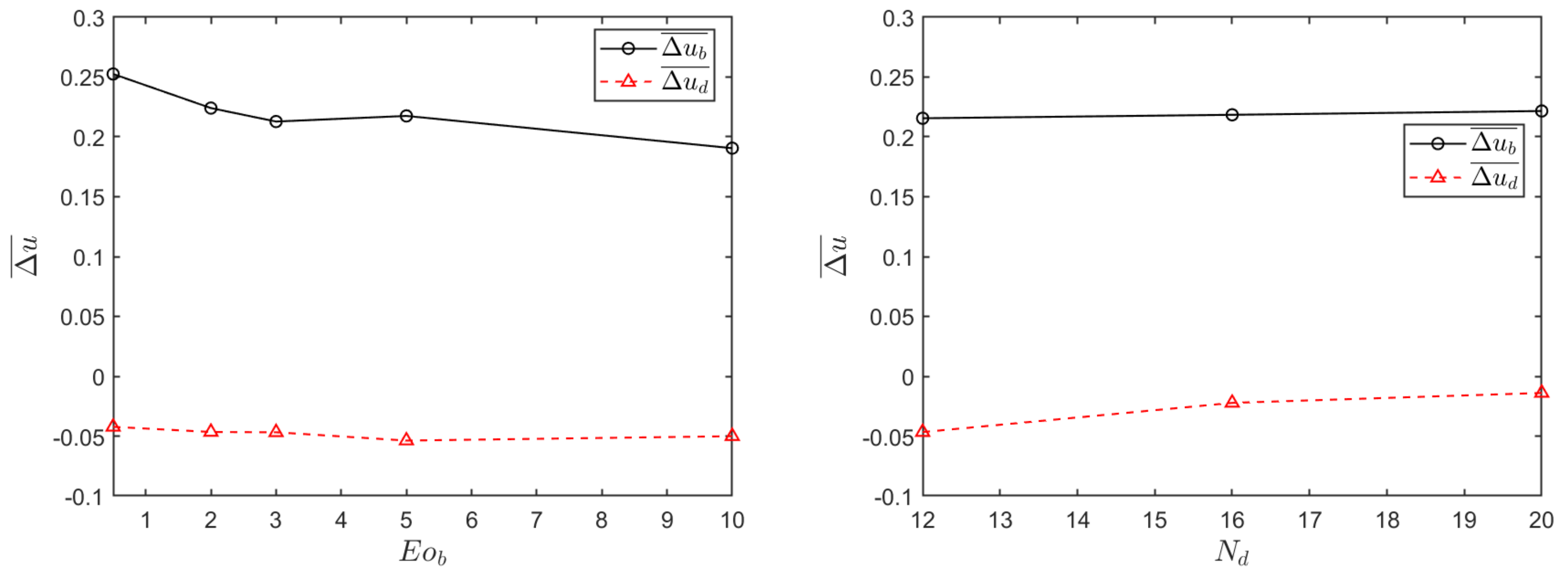

The slip velocity values between the bubble and the continuous liquid, as well as between the heavy drops and the continuous liquid averaged over time after the system reaches an approximate stationary state, are shown in the left frame of

Figure 3 versus Eötvös number of the bubble (

) and

. It is clear that while the droplet velocity remains nearly unchanged, the bubble slows down slightly as it becomes more deformable, although the decrease is relatively small and not completely monotonic. The right frame of

Figure 3 shows the averaged slip velocity for different numbers of drops for

, and while the bubble velocity is only minimally affected, the velocity of the drops decreases slightly as their number is increased.

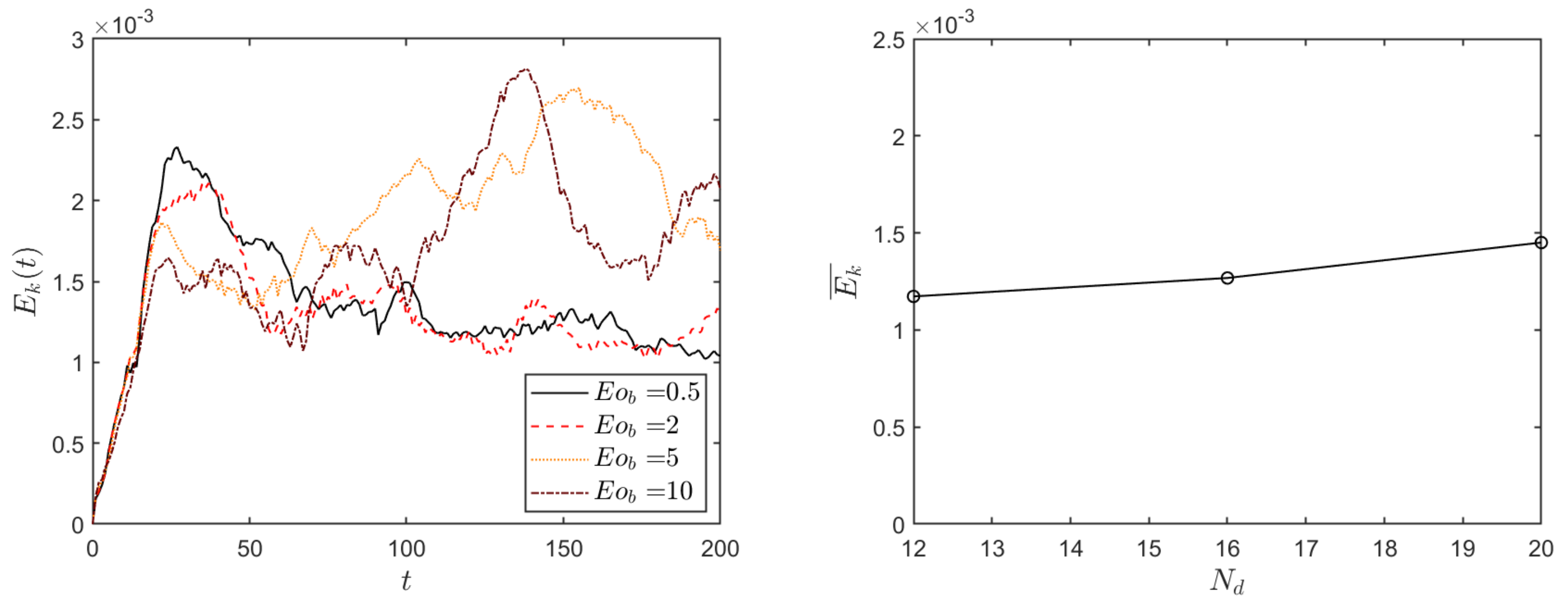

In

Figure 4, we examine the velocity fluctuations in the liquid by plotting the kinetic energy of the liquid versus time for four Eötvös numbers on the left and the average kinetic energy versus the number of drops for

on the right. For the less deformable bubbles the kinetic energy is relatively constant after an initial sharp rise, but for the more deformable bubbles, we see large fluctuations at later times. The dependency of the average kinetic energy in the liquid on the number of drops rises slightly with the number of drops, but the dependency is weak. Similar results are seen for other Eötvös numbers.

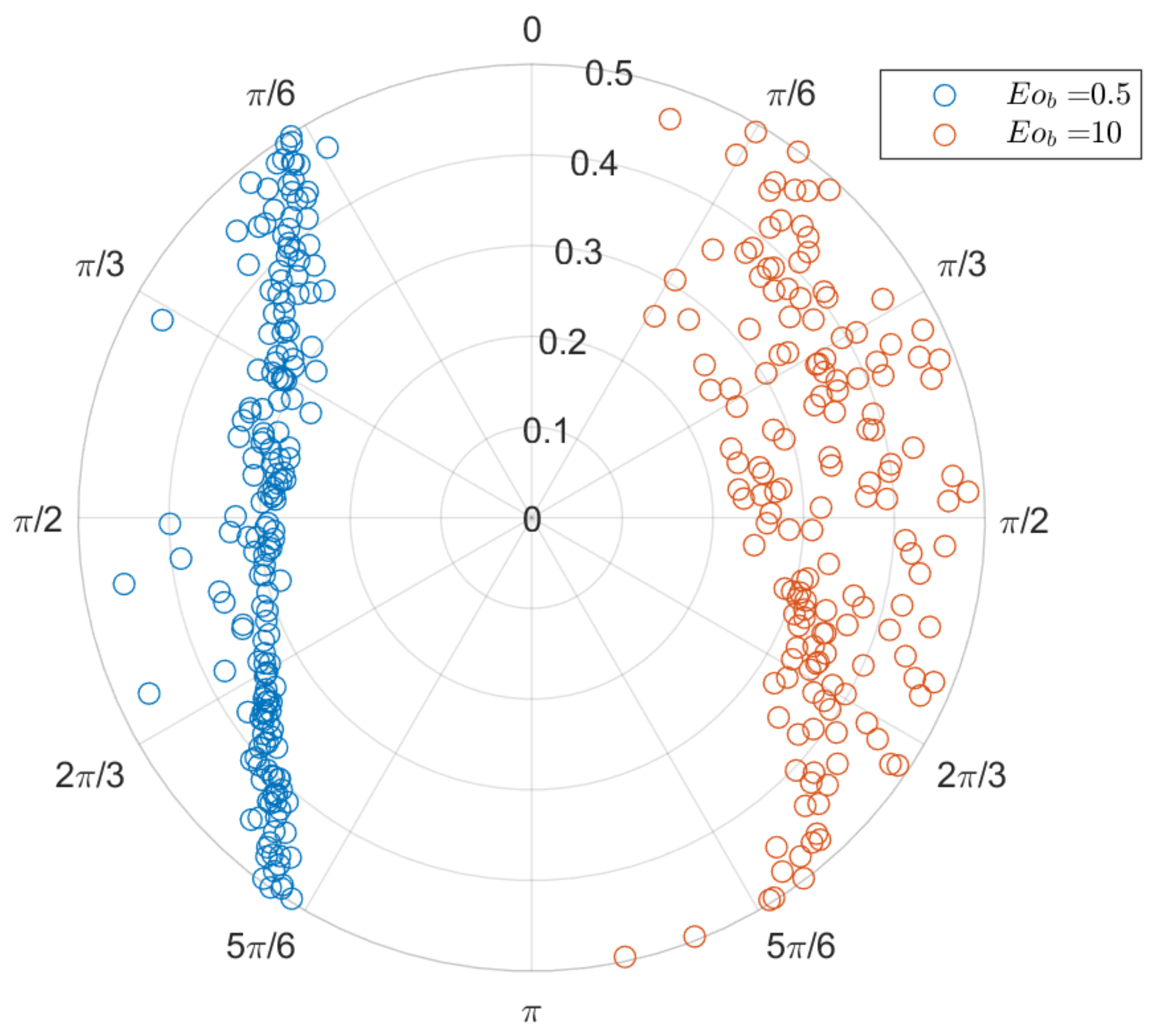

One of the main questions in many applications of dispersed three-phase flows is how the drops (or solids) and the bubbles interact. In wastewater remediation, the efficiency of the process depends critically on the bubbles colliding with and capturing droplets, and the same is true for flotation in mineral processing, where the drops are replaced by solid particles. To examine how the droplets are distributed around the bubble, we show the angular and radial location of droplets with respect to the bubble in

Figure 5 at 21 equispaced times, for 12 drops (

). Data for

are shown on the left and for

on the right. In both cases, the drops move past the bubble, with essentially no drops directly ahead or behind the bubble. For the nearly spherical bubble, the drops are clustered in a relatively narrow column that almost touches the bubble since the sum of the bubble and drop radii is

, but for the more deformable bubble, the droplets are more spread out, and we see more drops closer to the centerline in front of the bubble. Since the high

bubble becomes relatively “flat” as it rises and can change its orientation, a few drops are found closer to the center than for the nearly spherical bubbles.

To examine the droplet distribution in more detail, we define a distribution function by

where

is the location of the bubble center,

is where the center of drop

i is,

r is the distance of the drop center from the bubble center, and

and

are the azimuthal and polar angles, respectively.

K is a smoothing kernel to produce a continuous curve, where the width of the kernel is selected by trial and error. When averaging over the azimuthal angle, we divide by

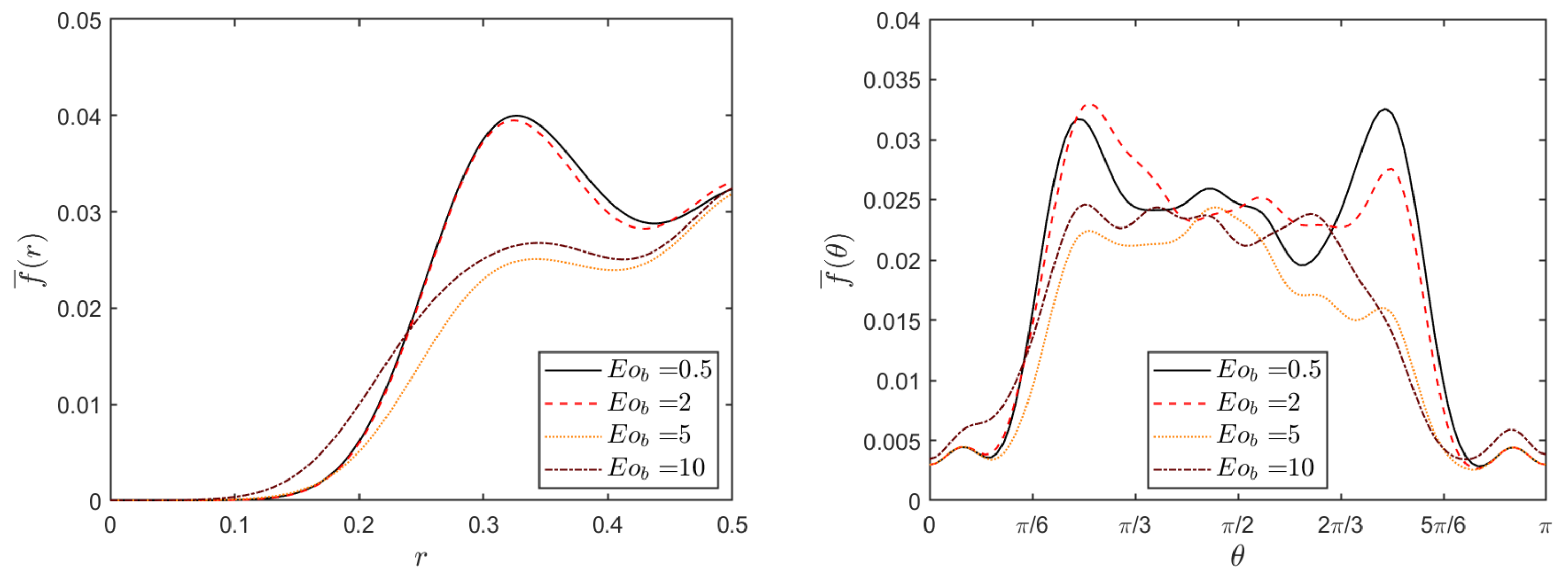

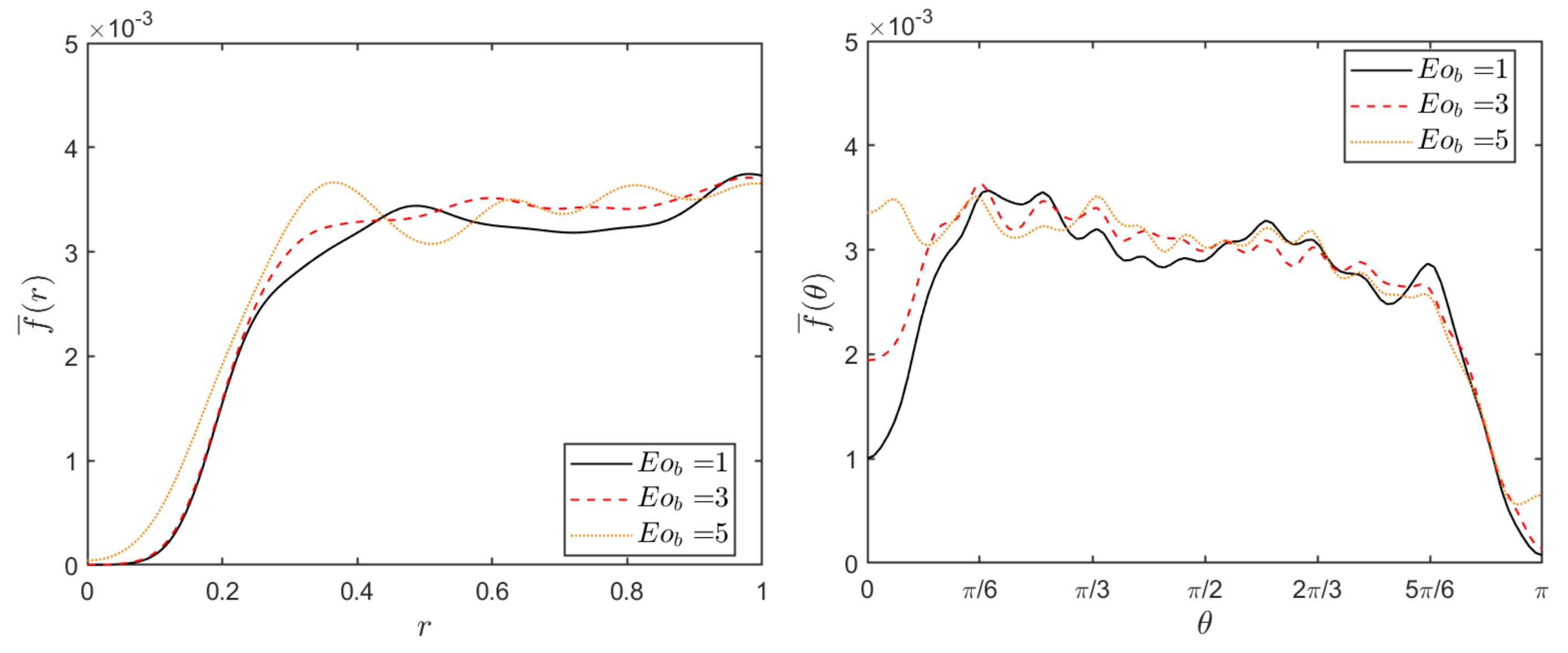

to account for the dependency of the volume on the polar angle. The weighted average radial and angular distributions are shown in

Figure 6. The left frame shows the radial distribution, averaged over the polar direction. The curves for the two lower

are similar, and the curves for the two higher

are similar. For the nearly spherical bubbles (lower

), there is a distinct maximum at

, as also seen in

Figure 5, but for the two higher

, the distribution is more uniform, and there are fewer drops close to the bubble. The angular distribution, averaged for

, is shown in the right frame, and it is clear that for the lower Eötvös numbers, the distribution is highest at around

, then relatively uniform but with another peak at around

. At the poles, we see very low values, consistent with the left-hand side of

Figure 5, which shows no drops there. For the higher

, the distribution is more uniform but tapers slightly off at the back.

In

Figure 7, we examine the effect of the number of drops on the relative velocity between the bubble and the drops by plotting the probability that the relative tangential velocity (left frame) and the relative radial velocity (right frame) are positive, following [

6]. The tangential velocity is taken to be positive if the drop is moving toward the back of the bubble, and the radial velocity is positive if the drops move away from the bubble. In all cases, the plot on the left shows that the drops slide along the bubble surface from the front to the back, as expected, with the highest probability at around

. Similarly, the plot on the right shows that the drops are likely to be moving away from the bubble near its back but not the front, as expected. Overall the results show relatively weak dependency on the number of drops.

3.2. Several Bubbles and Drops

While examination of the interaction of several drops with one bubble in a “unit cell” allows us to study some aspects of the system with relatively little effort, in real systems, we expect to have several bubbles and many drops. Here, we present a few results for 8 freely moving bubbles and 48, 96, and 192 drops in fully periodic domains. The parameters are the same as in the previous section, and the bubble surface tension is varied to give different Eötvös and Morton numbers. Initially, the bubbles and the drops are located randomly in the domain. The simulations are run on

grids, up to time

at which time the bubbles have moved 10 times through the domain, on average.

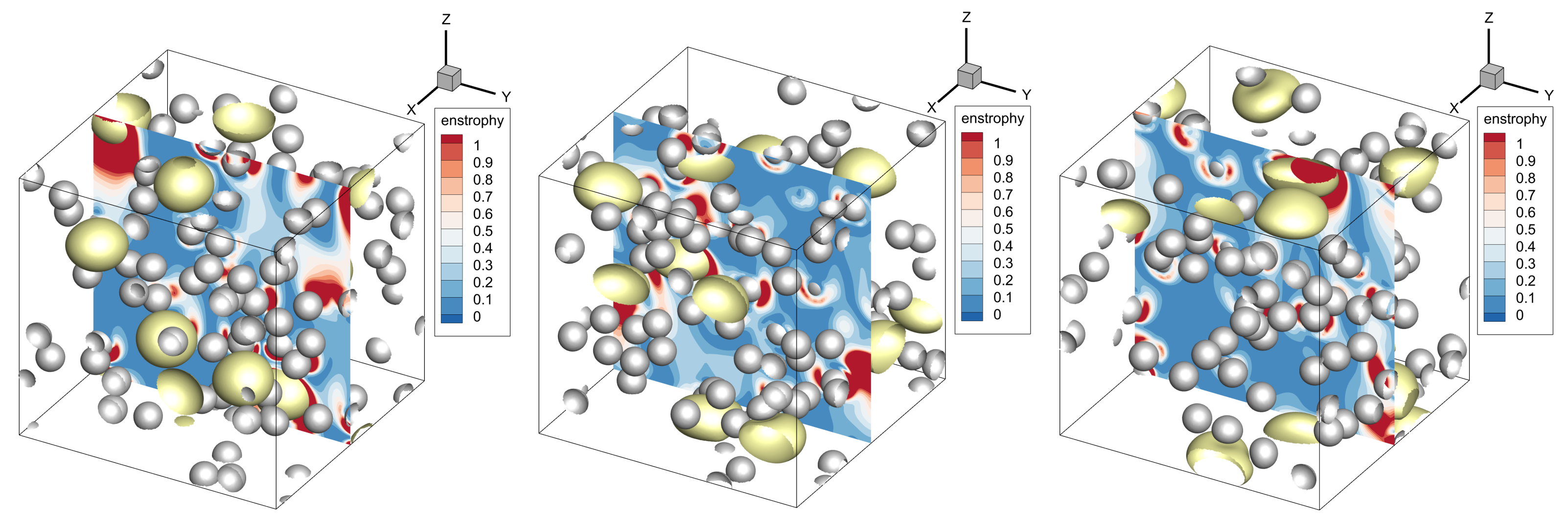

Figure 8 shows the solution at the last time simulated for

(left frame),

(middle frame), and

(right frame). In addition to showing the bubbles and the drops, we also show the enstrophy in a plane cutting through the middle of the domain. An examination of those plots, as well as others at different times, shows that overall, the flows are relatively similar. Both the bubbles and the drops are distributed throughout the domain, although small clusters of drops are often seen, such as here. Similarly, although sometimes the bubbles collide with each other, persistent clusters or “streams”, as sometimes found for deformable bubbles in fully three-dimensional flows, due to the differences in lift on spherical and deformable bubbles [

30,

31], are not seen. Although we do see regions of high vorticity, it is clear that it is not only concentrated in the wake of the bubbles, as we saw for the single bubble in a unit cell. We note that for the freely moving and interacting bubbles, we have not included results for

since the bubbles sometimes break, as they interact when the surface tension is low. While we believe that the breakup is physical, we have not implemented a topology change algorithm for the front in the current version of the code, since we do not want the number of bubbles and their sizes to change during each simulation.

The slip velocity between the bubbles and the continuous liquid, averaged over the eight bubbles, and the slip velocity between the drops and the continuous liquid, averaged over all the drops, are shown in the left frame of

Figure 9 versus time for all 3 Eötvös numbers and 96 drops. In the right frame, the time average of the slip velocities is shown for

, versus the number of drops

. The bubbles rise due to buoyancy, so their slip velocity is positive, while the drops are denser than the continuous liquid and fall down with a negative slip velocity. The left frame shows that the flow reaches a statistically stationary state very quickly, although the average bubble slip velocity fluctuates slightly. This is presumably due to the relatively small size of the system, both in terms of the number of bubbles and domain size. However, even in a larger system where the average over all the bubbles might be better converged, we still expect individual bubbles to move very unsteadily. The slip velocity of the drops fluctuates much less, in part because there are more of them, so the average is better converged. As the number of drops increases, the density of the liquid mixture (continuous liquid and drops) increases, but the resistance (or effective viscosity) of the droplet/continuous liquid mixture also increases, overcoming the increase in buoyancy and leading to a slight decrease of the average bubble slip velocity. Similarly, we see a very slight decrease in the average drop slip velocity. Plots of the average slip velocity versus

for a fixed

(not included) show essentially no dependency on

. Although the flow reaches a stationary state quickly, the time average in the right frame has been computed between time

and

, using a time increment of

, except for the

case, which was only run up to time

. The averages discussed below have all been computed in the same way.

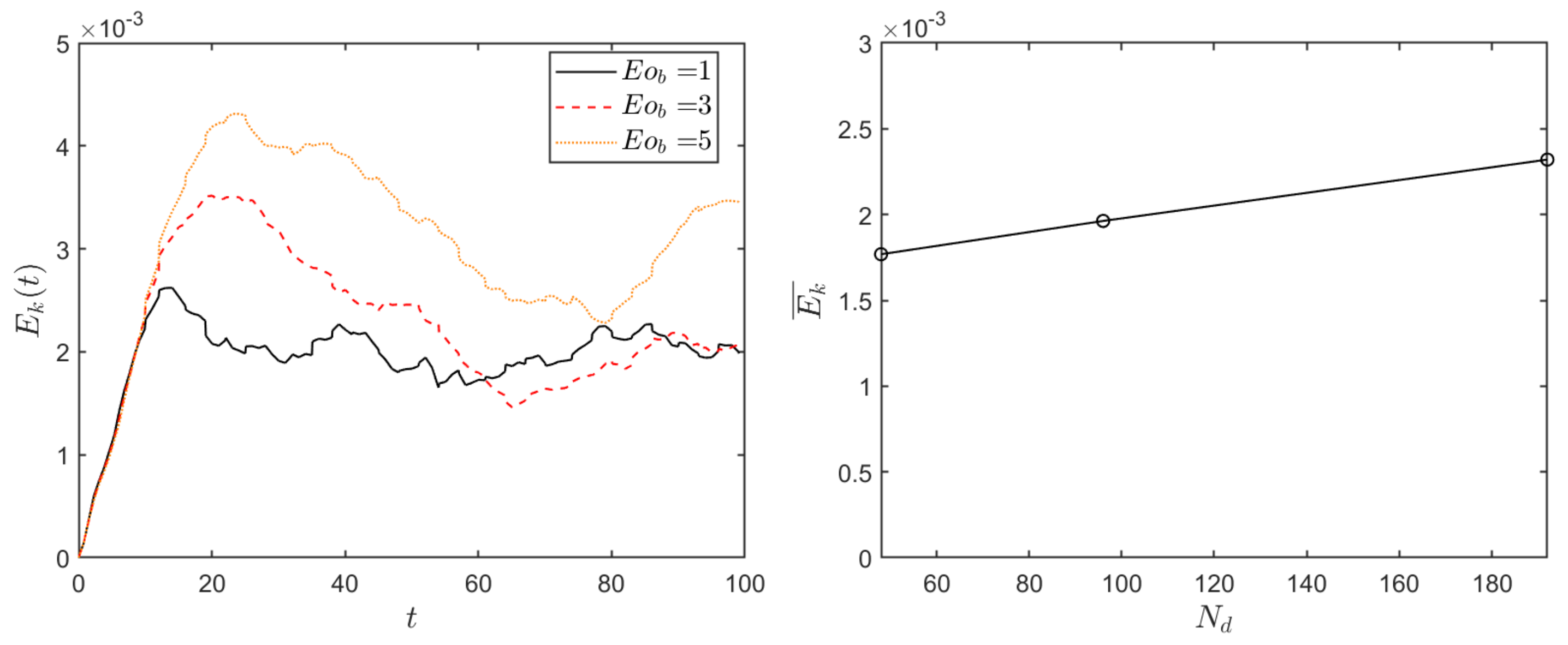

The kinetic energy of the continuous liquid is plotted versus time in the left frame of

Figure 10 for 96 drops and

,

, and

. For the nearly spherical bubbles (

), the fluctuations quickly reach a relatively constant level, but as the deformability of the bubbles increases, the kinetic energy initially becomes much larger, although for

, it then settles down to a similar value, as seen for the

case. For

, large-scale fluctuations seem to continue. We note that [

30] found that the velocity fluctuations were much larger for deformable bubbles, as compared to nearly spherical ones, even when their rise velocity was similar and the deformable bubbles were distributed relatively uniformly in the computational domain (not in a “streaming” state).

Figure 4 for a single bubble also shows similar differences in the average kinetic energy between nearly spherical bubbles (low

) and more deformable ones (high

). The time average of the kinetic energy of the continuous liquid is plotted in the right frame of

Figure 10 versus

for

. The dependency on the number of drops is relatively weak, although it increases slightly with

. We note that the relatively large fluctuations and the short time over which the averaging is performed suggest a large uncertainty. Reducing the uncertainty would require a longer averaging time and/or a larger system, but we believe that the trend is correctly captured.

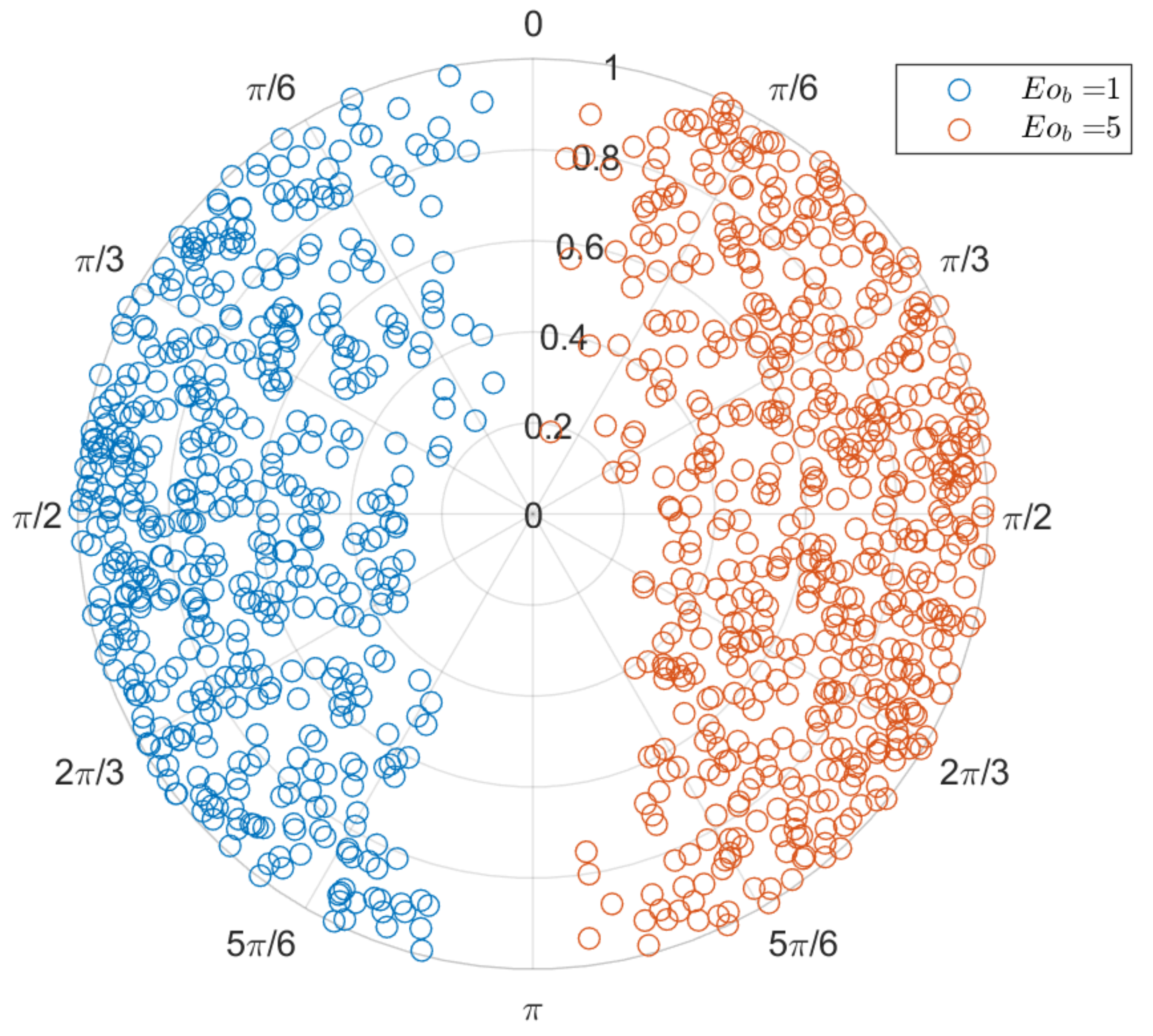

We also examined the distribution of drops around the bubbles.

Figure 11 shows the locations of drops with respect to the center of a single bubble, at 11 evenly spaced times between

and

, for

on the left of the symmetry axis, and for

on the right. It is clear that the droplets are distributed relatively uniformly around the bubbles. There are drop-free regions in front and behind the bubbles, with the behind region slightly larger than the one in front, and a few more drops closer to the centerline for the more deformable bubbles. Thus, unlike for the single three-dimensional bubble in a “unit cell,” there is little dependency on the Eötvös number. This is shown by a more detailed analysis, such as by examining the average radial and polar distributions of the drops,

and

averaged over the eight bubbles, shown in

Figure 12 for different

and 96 drops. The radial distribution is shown in the frame on the left and the polar direction in the right frame, both found in the same way as in

Figure 6 and smoothed in the same way using a kernel function. The radial distribution is nearly uniform and very similar for all three Eötvös numbers, but although the polar distribution is mostly similar, the probability of finding drops ahead of the bubble increases with its deformability (

).