Abstract

A common issue in water infrastructure is that it suffers from leakage. The hydroinformatics technique for recognizing the presence of leaks in the pipeline system by means of pressure transient analysis was briefly explored in this study. Various studies have been done of improvised leak detection methods, and Hilbert Huang Transform has the potential to overcome the concern. The HHT processing algorithm has been successfully proven through simulation and experimentally tested to evaluate the ability of pressure transient analysis to predict and locate the leakage in the pipeline system. However, HHT relies on the selection of the suitable IMF in the pre-processing phase which will determine the precision of the estimated leak location. This paper introduces a NIKAZ filter technique for automatic selector of Intrinsic Mode Function (IMF). A laboratory-scale experimental test platform was constructed with a 68-metre long Medium Polyethylene (MDPE) pipe with 63 mm in diameter used for this study and equipped with a circular orifice as an artificial leak in varying sizes with a system of 2 bar to 4 bar water pressure. The results showed that, although with a low ratio of signal-to-noise, the proposed method could be used as an automatic selector for Intrinsic Mode Function (IMF). Experimental tests showed the efficiency, and the work method was successful as an automatic selector of IMF. The proposed mathematical algorithm was then finally evaluated on field measurement tested on-site of a real pipeline system. The results recommended NIKAZ as an automatic selector of IMF to increase the degree of automation of HHT technique, subsequently enhancing the detection and identification of water pipeline leakage.

Keywords:

pressure transient; Hilbert Huang Transform; IKAZ; NIKAZ; EMD; leak prediction; leak location 1. Introduction

It is important to monitor water and ensure that every water drop is dispersed to the right spots. Water loss due to inadequate monitoring is classified as non-revenue water (NRW). Water shortage has become the number one global resource issue, recently reported by the World Economic Forum (WEF) Forum [1]. Lai [2] reported the first worldwide research study such that in the year 2016, NRW in most of the countries fell between 20–30%, with Malaysia at 39%. The water loss is a result of real losses, for example, damage to the pipeline distribution system, or apparent losses such as unauthorised connections, as well as metering inaccuracies [3]. The major contributor to NRW is water loss due to defects in the pipeline system. Leak, blockage, connection failure, and corrosion that happened either internally or externally are the typical defects of ageing pipeline systems installed several decades ago. The regular maintenance of pipeline distribution networks is needed to ensure there is a constant supply of water. Since water pipeline networks are often buried underground, there are major practical challenges for maintenance workers to monitor the pipeline health condition and provide early detection of defects [4].

The leak detection and pipe condition assessment techniques can be done externally or internally [5]. The external technique is a way to inspect the pipe conditions including visual inspection and this technique is limited, especially when the pipeline is buried underground. Internal methods involving inspection of the pipe conditions internally are the most attractive approach particularly when using the measured signal combined with mathematical computation and signal processing [6,7]. Pressure transient signal processing is amassing popularity amongst researchers because it can detect and locate disturbances (leakages) and blockages in the pipeline system at minimum costs [8]. Pressure transient evaluation is the internal technique of leak detection and its cost-effectiveness has attracted scholars [9]. Pressure transients are caused by sudden fluid propagating reforms often caused by rapid valve closure and opening. These pressure waves pass through the pipeline network at the speed of sound. The wave characteristics represent the information and conditions of the pipeline from different appearances, including pipe function, junction, and the existence of damage [10]. Signal analysis is a tool for determining the characteristics and identifying details on the pipeline distribution system for the pressure transient signal received. There is a variety of pressure transient analysis methods that have been applied by researchers to compile the details of pressure transient signal, for example, Cepstrum analysis [6], cross-correlation [11], Orthogonal wavelet transform (OWT) [6], instantaneous frequency analysis [12], and inverse transient analysis [13].

Time-frequency signal processing techniques such as HHT have allowed the study of the phenomenon both in the time and frequency domains. In many studies, the analysis of HHT was recommended for the detection of transient signatures in the non-stationary signal. The HHT approach was extensively used as a signal processing technique for time-frequency analysis [14,15] and was proposed as a reliable method for non-linear and non-stationary signal analysis [16]. The challenge of this method is the identification of the correct IMF for advanced post-processing data such as Hilbert Transform (HT). The Hilbert–Huang transform is a non-linear and non-stationary data processing approach that is empirically oriented. HHT decomposed a signal into numerous mono-components and symmetric components via the Empirical Mode Decomposition (EMD) by the shifting process. IMF is defined as the mono-component signal [17]. The main drawback of this approach is the knowledge of the original signals required by the frequencies [18]. In this case, the HHT is not entirely fully independent since the interaction of skilled users during the monitoring and diagnostic phase is needed to choose the IMF level that is suitable for HT. The simplified HHT method is convenient for online diagnoses with rapid response and not computationally extravagant by allowing the HHT to process the pressure transient signal independently from its ‘shapes’. Therefore, an automatic selection of the best IMF is necessary to fill the gap. Researchers have been using computational mathematical techniques and statistical value analyses to enhance the degree of automation that eliminates the user’s interaction to select the right IMF.

Few studies of statistical approaches are carried out to determine the effectiveness of automated selectors of the significant IMF. To comprehend the level of decomposition within the IMF, Maji et al. [19] proposed utilising standard deviation and variance as statistical significance. Electrocardiogram (ECG) signals were used to track rhythm and the natural rhythm of artificial fibrillation (AF). In Ricci et al.’s studies [18], the Merit Index (MI) is used as an indication for autonomous selector of IMF level. Their evaluation used rotating element (gear) signals to determine merit index effectiveness while choosing the appropriate and applicable IMF. The approach is driven by quantifying the absolute skewness and degree of the periodicity of each IMF level. Kedadouche et al. [20] introduced a method to compute the correlation coefficient value for every level of IMF as quantifiable quality to monitor the rotating machinery. The vibration signal was recorded from the rolling elements, and the signals are then extracted by the hybrid method of Minimum Entropy Deconvolution (MED), EMD, and Teager Energy Operator (TEO) methods. The IMF preferred is the IMF which demonstrates the highest value than the initial signal of the correlation coefficient. Dde Souza et al. [21] presented an energy proposition over Mutual Information (MI) coefficient as an approach of selecting significant IMF. Their investigation was done by applying a synthetic signal embedded in white noise and a real field measurement signal. The MI is also used to select significant IMF in biomedical signal processing [18]. The research from previous technique applies from researcher for selection suited of IMF have been carried out to studies the suitability to apply on the pressure transient signal. The studies simplify, the previous technique have some limitation if applies on pressure transient signal. Variance, standard deviation, Mutual Information and Power Distribution has low accuracy when the SNR is too lower and not advised when the signal is too noisy. The situation is also the same as Kurtosis since this statistical technique measured the value of peakness and spikiness, therefore not being advised for signals containing low SNR and being too noisy. The research proceeds to study the latest technique propose by Ricci et al. [18], that is, Merit Index. Since the merit index algorithm expresses the relationship between periodicity and degree of signal, therefore, for the case of the pressure transient signal, the algorithm cannot be computed due to the missing relationship expression.

In comparison to existing statistical assessments such as variances, standard deviation, and Kurtosis, both amplitude and frequency change can be indicated simultaneously with the IKAZ expressions, Zσ [22,23]. The detailed analysis was performed using IKAZ to classify the tool wear during turning processes on the vibrational signals from rotating sections of the unit (Bearing). Nuawi et al. (2014) [23] had compared IKAZ to variance and reported that the variance criterion is inadequate to identify both amplitude and frequency diverge in the non-stationary signal. They then concluded that IKAZ is more reliable, especially for monitoring purposes, whereby the examination on the amplitude and frequency changes in the non-stationary signal is crucial [22]. The study showed and simplified the method of IKAZ as successfully distinguishing the vibration signal towards developing tool wear machining monitoring [24]. The accomplishment of IKAZ was considered to deal with pressure transient signal since currently there is no substantiate against its effectiveness. The examination of IKAZ over pressure transient signal exhibits the method as extremely sensitive to the noise. Therefore, adjustment of IKAZ methods focused on filtering and normalising the noise are considered based on the statistical analysis approach.

In this paper, Normalised Integrated Kurtosis Algorithm for Z-notch filter (NIKAZ) is recommended for an automated selector of IMF. Since it is generally adaptive and can identify any adjustment or unpredictability in the signal measured, the NIKAZ method was chosen [22]. The focus of this paper is also the application of a Normalised IKAZ coefficient analysis for automated selector of right IMF by laboratory and field authentication. This method was examined through synthetic pressure transient signal simulation by using Transmission Line Modelling (TLM) software. The results from the simulation revealed that the IMF containing the highest NIKAZ coefficient is the best IMF for HT analysis [9]. The process for verification of NIKAZ as an automatic selector of right IMF proceeded for experimental analysis and field test authentication. The results are detailed in this paper.

2. Modification of Hilbert Huang Transform and Normalized Integrated Kurtosis Algorithm for Z-Notch Filter Technique as Analysis Technique

2.1. The Proposed Method

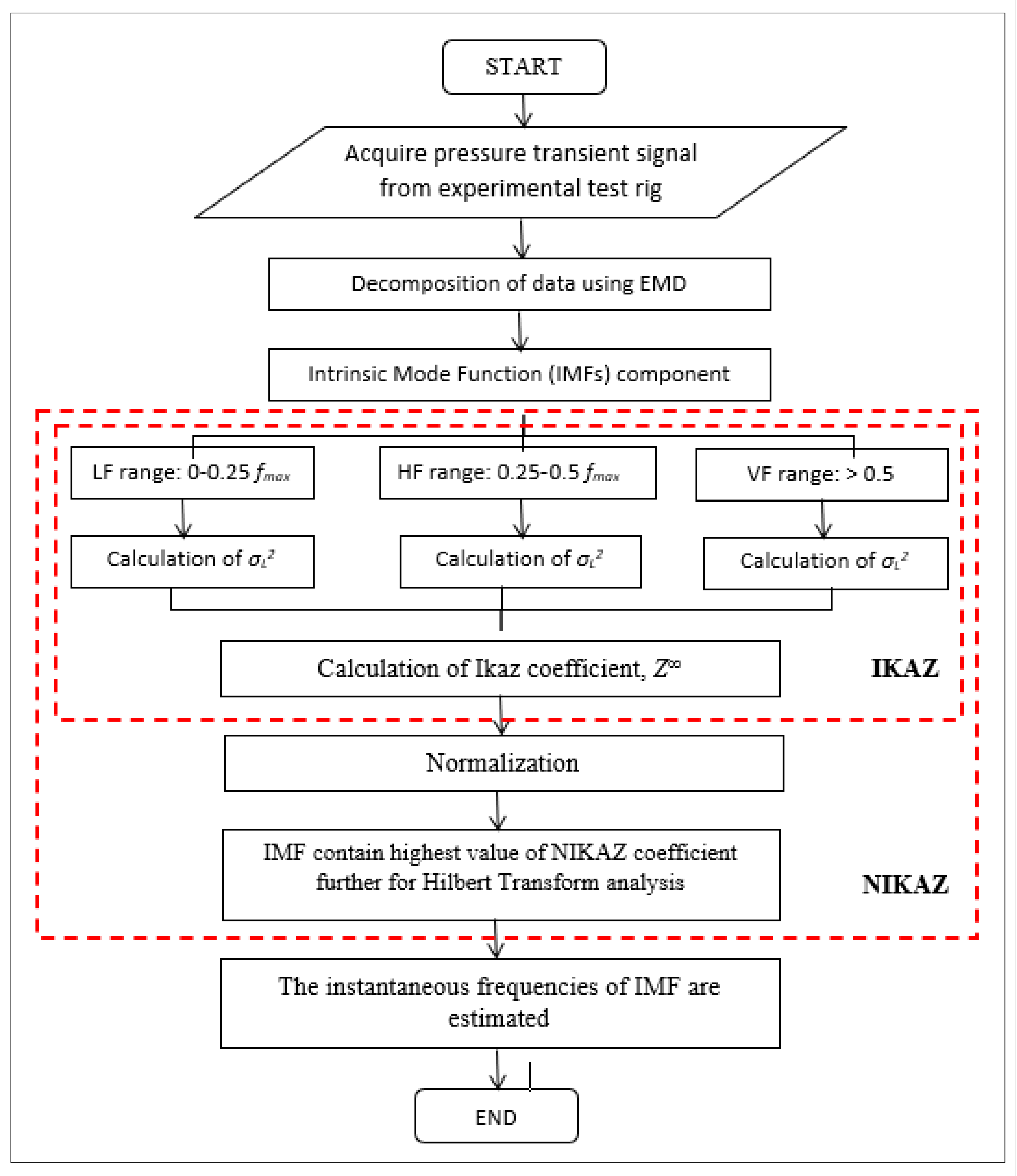

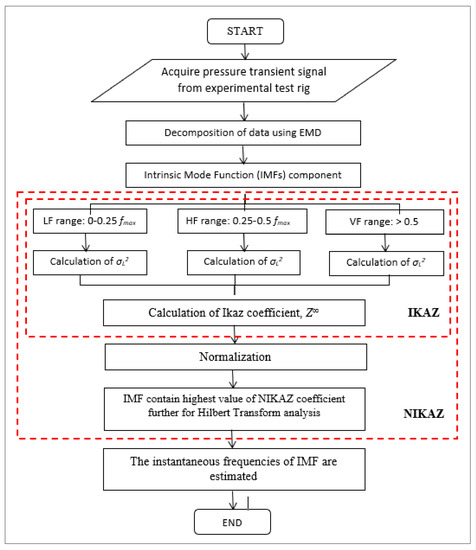

The process of faulty and feature extraction of the pressure transient signal begins with decomposing the signal into a series of Intrinsic Mode Functions (IMF) through Empirical Mode Decomposition (EMD) and computing the NIKAZ coefficient value of every series of IMF. The IMF containing the highest NIKAZ coefficient is then further used for the HT. The detailed process of the proposed method is shown in Figure 1.

Figure 1.

Flowchart of the proposed method.

2.2. Empirical Mode Decomposition

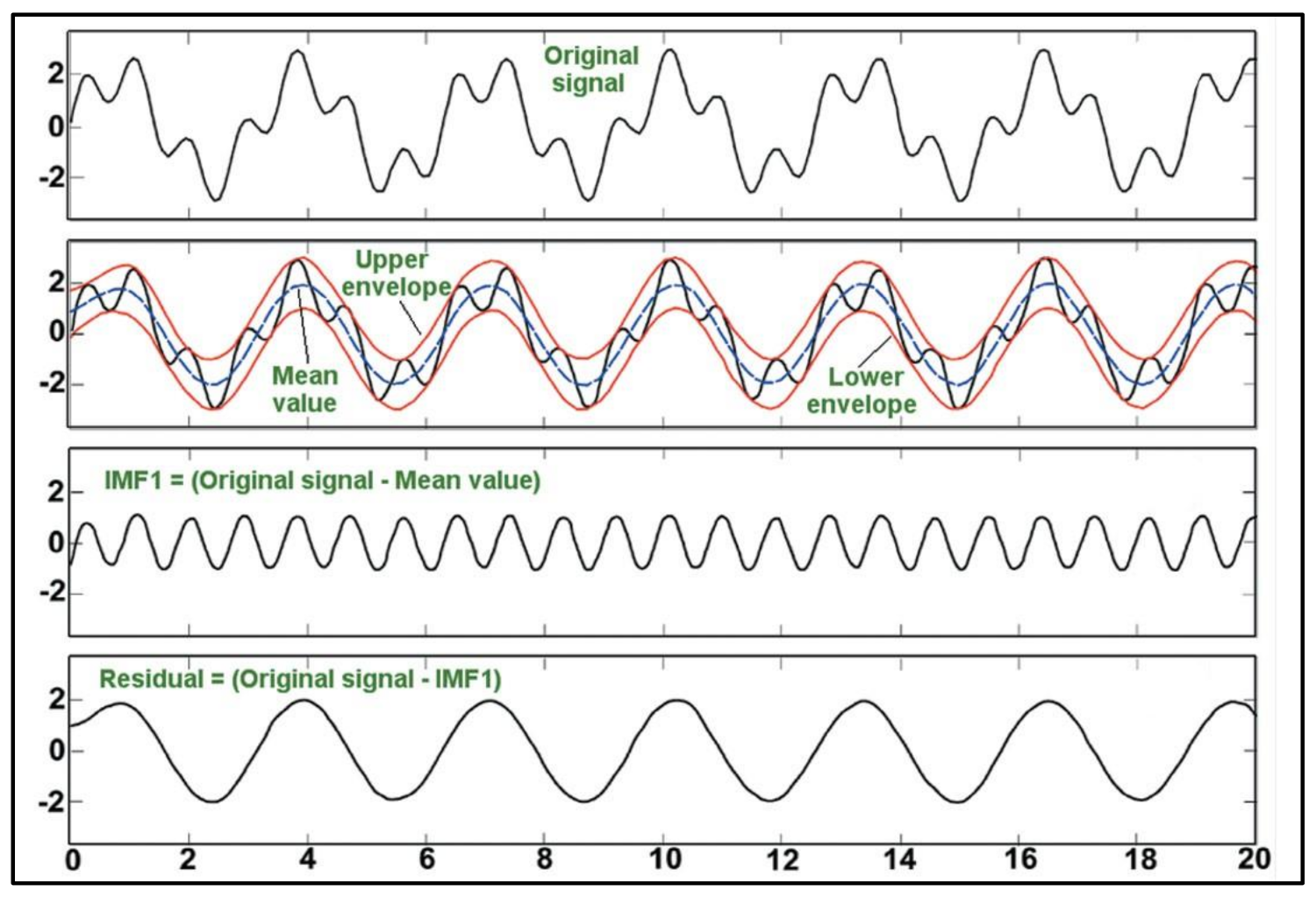

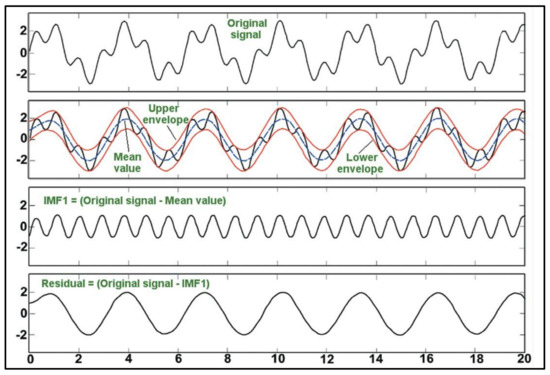

The decomposition by empirical modes (EMD) represents an extremely effective adaptive decomposition compared with other transformations [18]. This method was applicable for non-linear and non-stationary signal processing even though the method of decomposition is predicated on the data scale set for local characteristics [14]. As brevity and summary, only the basic steps of the procedure are presented. For details, more information is in the discussion [14]. EMD generates and decomposes the signal into a series of IMF. The data extraction and decomposition ways are predicated on direct extraction, which can be linear or non-linear as dictated by the data and are almost orthogonal [14]. The first step of the decomposition process is the research of the maxima and minima values along the signal x(t), and all the stationary points are stored.

Afterward, all maxima values are interpolated through a spline (smax(t)) and then the same process is done for minima (smin(t)) [18]. The boundaries of signal x(t), which includes all points of signal, are two segment lines, the regions between two curves. The interpretation of the interpolation of splines and the extraction of a mean function m(t) can be obtained from the initial signal x(t):

x1(t) = x(t) − m(t)

The signal issued, x1(t) was evaluated if the definition of IMF has been followed. The situation was satisfied by the two main conditions [14]:

- (a)

- The number of extrema and zero-crossing numbers shall be equal or only a difference of one may be permitted.

- (b)

- The means should at any point be equal to zero between the local total envelope and local minimum envelope.

- (c)

- This description is aimed at ensuring that each IMF has a significant instant frequency. With the definition, a signal x(t) EMD algorithm goes as follows [14]:

- (d)

- The x(t) from the given signal was defined for all local extremes, then bound to the top envelope by cubic splines. To find minima 1(b), the procedure has been repeatedly calculated.

- (e)

Figure 2. Data, upper and lower envelopes, and m1 mean value [26].

Figure 2. Data, upper and lower envelopes, and m1 mean value [26].- (f)

- Detailed information, d(t) as an IMF, d(t) = x(t) − m(t).

- (g)

- The iteration on residual m(t) until the residual data is too small, an interpretation that is residual becomes a monotonic function or a function with only one extremum from which no more IMF can be extracted. The remaining is the norm.

By the sifting process [14], the procedure described should be responsive. This phase is supposed to introduce the IMF definition [25]. With just the summing-up of all the IMF elements, the raw signal can be reconstructed. This paper prefers that all the IMF modes generated by this phase should be almost monochromatic and can be used to make an important determinant of the instantaneous frequency of the signal. Afterward, all maxima values are interpolated through a spline (smax(t)) and then the same process is done for minima (smin(t)) [18]. The boundaries of signal x(t), which includes all points of signal, are two segment lines, the regions between two curves. The interpretation of the interpolation of splines and the extraction of a mean function m(t) can be obtained from the initial signal x(t).

This research introduced a NIKAZ that had been improvised by a hybrid between two higher-order statistics methods, IKAZ and Kurtosis, respectively, as the technique to decide the relevant IMF for further consideration of HT analysis. The IKAZ has been selected as the method which has been flexible principally and firmly, identifying adjustment and uncertainties of the signal evaluated [22]. Contrasting to the established statistical approach such as variance, standard deviation, and Kurtosis, both amplitude and frequency variations would be demonstrated by the IKAZ process by simultaneously achieving the IKAZ representation and IKAZ coefficient, Zσ. In particular, for monitoring purposes, the IKAZ method was dependable when examining the changes in signal amplitude during pull-out, and the frequency generally required [22]. Rizal et al. (2014) [23] performed IKAZ as a method for identifying the tool wear on the base of cutting force signals. The IKAZ derivation was suitable for the analysis of force signals in the tool wear monitoring turning process. This presents a multi-resolution visualization that could be used for both coefficient values and graphical display data. It presents a multi-resolution analysis, which could be used in both coefficient values and graphical display illustration. The findings showed that wear changes based on the cutting force signals by means of IKAZ [24] are very significant in terms of the power feed strength. From the details reviewed on IKAZ, this method is chosen to be carried out as an automatic selection of IMF based on pressure transient signals due to its ability to trigger the transient trend in the non-stationary signal. The working principle, numerical simulations, and algorithms of NIKAZ are discussed in this subsection.

IKAZ is an approach formulated based on its centroid data dispersion layout. About the Nyquist number [22], the sampling frequency of the crude signal was set at 2.56. Most experts are satisfied with the number of signal analyses and processing. The maximum frequency spectrum is equating to Equation (2) to prevent the aliasing influence.

IKAZ decomposed the time domain signal into three scales of the frequency range: the x-axis describing the low frequency (LF) signal with a scale of 0–0.25 fmax, preceded by the y-axis reflecting the high frequency (HF) signal with a scale of 0.25–0.5 fmax. The decomposition ends with the signal of the very high frequency (VF) laid on the z-axis in the range 0.5 of fmax. In the signal decomposition process, 0.25 fmax and 0.5 fmax have indeed been identified as low and high-frequency scale limits, respectively, with reference to the 2nd order of the Daubechies principles [27]. The IKAZ method gives a three-dimensional graphical representation of the signal frequency distribution measured about kurtosis. The variation, σ2 and σV2 of each frequency range is a very high-frequency band, measured as in Equations (3)–(5) for determining the distribution dispersion of data.

The IKAZ approach, relying on the data dispersion definition, can be defined as Equation (6) as the IKAZ Coefficient, Z∞.

In cases where the value Xi, Yi, Zi is a discrete value in low frequency (LF), high frequency (HF), and very high frequency (VF), respectively, at the i-sample of time, the mean for each frequency band is μL, μH, and μV, and N is the number of data. In terms of variance, the IKAZ coefficient, Zσ could be generalised as well as Equation (7).

The 4th phase can then be determined from Equation (7) on the definition of the Kurtosis, K, and standard deviation, s such as Equation (8).

where M4 is the 4th order of sequence, K is the Kurtosis, the standard deviation is S, and the number of data is n. In the 4th order moment, M4 as shown in Equation (9), the IKAZ coefficient can be derived.

The 4th order moment of signals in the LF, HF, and VF ranges is the n number of data, , , and , respectively. By referring to Equations (7) and (8), the terms of Kurtosis, K, and standard deviation, s as in Equation (10) can be written in terms of IKAZ coefficient.

The standard deviations of signals in LF, HF, and VF sets, where n is the number of data for KL, KH, KV that are kurtosis signals to LF, HF, and VF are SL, SH, and SV. As stated in [22], the IKAZ algorithm has been summarised in detail as in Equation (12).

The summarised IKAZ algorithm (Equation (10)), is normalised by dividing Equation (10) with Kurtosis. Normalisation is the organising and managing process of the relation between signals, in an effort to minimise redundancy within the related database and eliminate abnormalities such as insertion, modification, and deletion from the signal. This helps to split huge relational signals into different components and establish a connection. The redundant signal can be deleted, and signal elements can be introduced, manipulated, or eliminated. A normalisation establishes the relation database guidelines as to whether the normal form is complied with. A normal form is a procedure in which each relationship is measured against established criteria, and which removes from a relationship the multivariable, functional and trivial dependence. If any information is updated, removed, or introduced, the signal database has no problem in assisting to enhance the integrity and efficiency of the relational signal [28,29]. This research intends to find out the redundancy and coincidence trends between Kurtosis and IKAZ. The coincidence trends are presented and explained in Section 5. Therefore, normalisation between Kurtosis and IKAZ would introduce a new signal element. This part of the analysis will eliminate and minimise redundancy series of IMF that contains the rich noise signal. This was discussed in the formulation of a standardised NIKAZ (Equation (12)), an alternative research technique. The NIKAZ approach is generally adaptive and senses very well any signal transitions. The NIKAZ model was able to express both amplitude and frequency differences through obtaining simultaneously the NIKAZ representation and the NIKAZ coefficient, Z∞, contrary to the established statistical analysis, standard deviation, variance, and Kurtosis.

2.3. Hilbert Transform

Commonly, the signal was defined by its frequency content. The frequency change for the non-stationary and non-linear signal is a valuable feature that extracts the characteristics of the signal in terms of instantaneous frequency analysis. The term instantaneous frequency is the frequency that fits in the signal. To get a well defined instantaneous frequency, the signal must be going through the analytic and must be within a narrow band by means of the Hilbert Transform (HT) [5].

The Hilbert Transform y(t) of the signal x(t) is defined as [14]:

The PV denotes the Cauchy principal value of the integral. The convolution of x(t) with 1/πt is represented by y(t). A coupling of y(t) and x(t) resulted in a complex conjugate pair, giving the analytic complex signal z(t) of x(t) as

By considering the last expression of the analytical signal Equation (3), A is an envelope of the signal, and (t) is a phase angle. ω(t) represents the instantaneous frequency of the analytical signal simply as:

Detailed explanations are presented by [30] on the HT producing a very physically meaningful result for the mono-component or nearly mono-component such as narrowband function. Consequently, the efficiency of the decomposition of EMD is particularly suitable for determining instantaneous frequency using the subsequent HT.

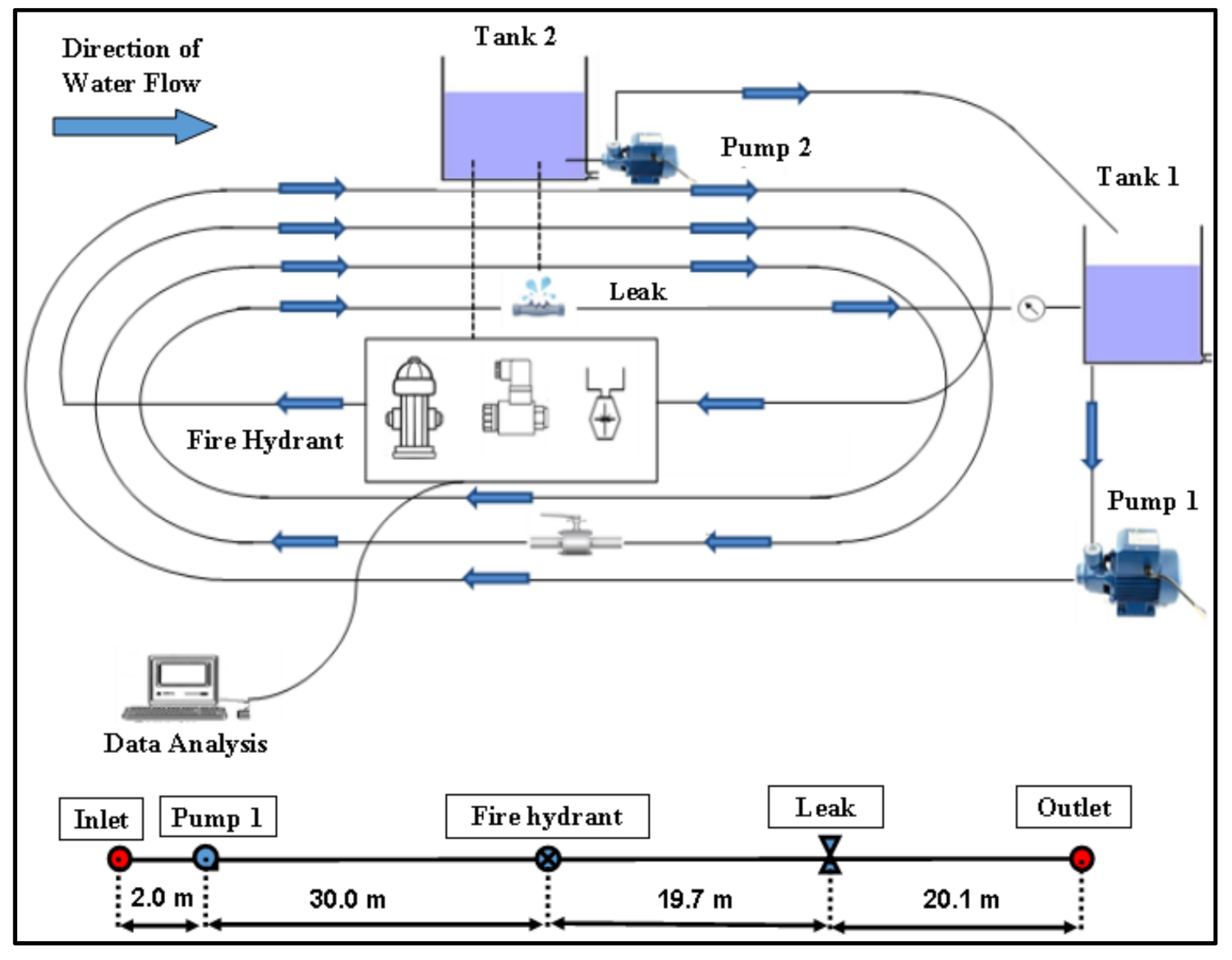

3. Laboratory Authentication Set Up

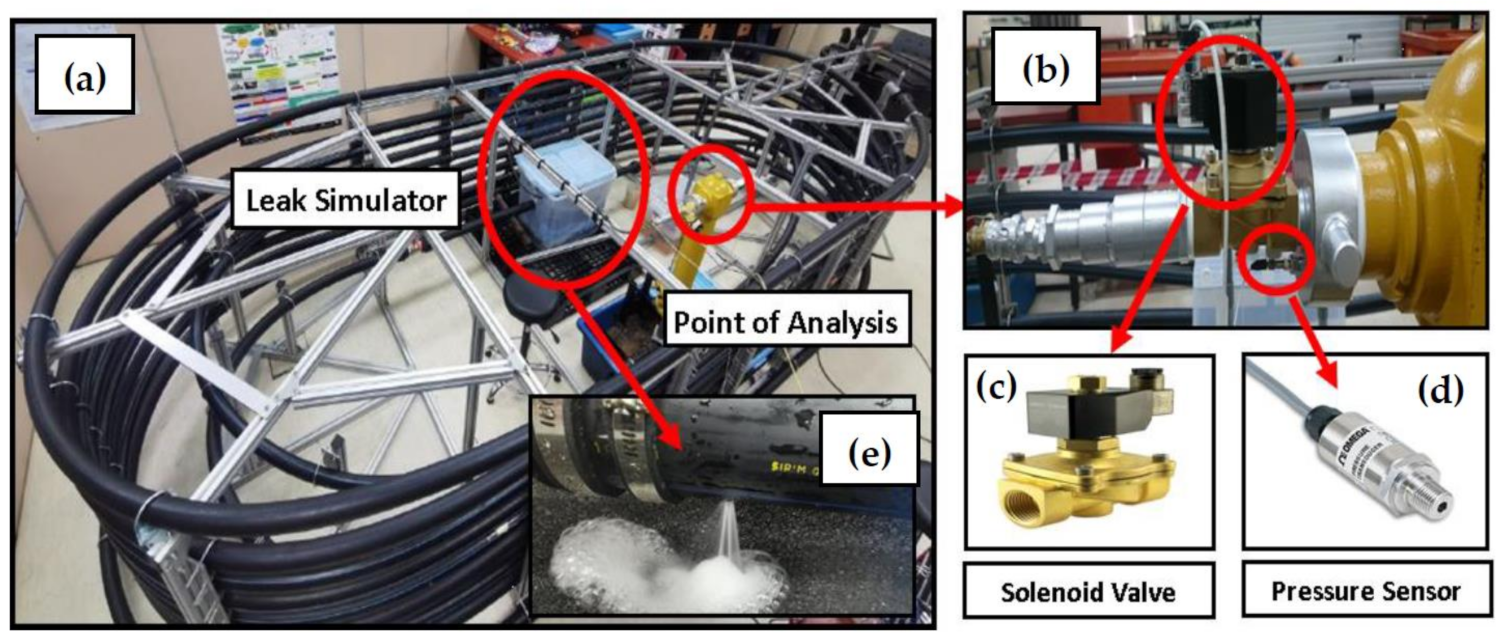

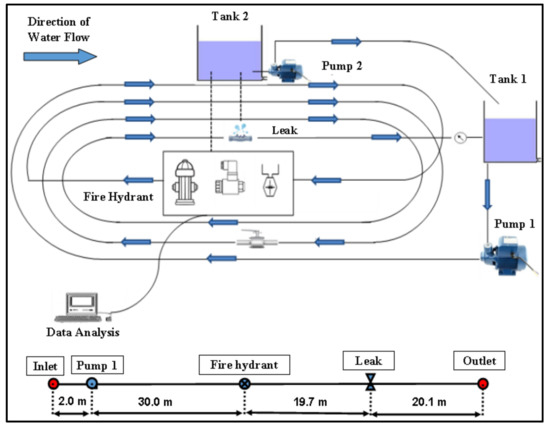

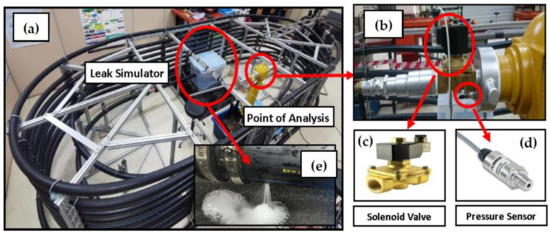

Acquiring real pressure transient signal was performed by a laboratory verification to validate the proposed technique. The test platform was installed throughout a 67.9 m long circular pipeline network. This can be seen in Figure 3 (Schematic diagram) and Figure 4 (laboratory test rig). The pipe is made up of medium-density polyethylene pipes (MDPE) of 60 mm of external diameter and 55 mm of internal diameter with a mean thickness of 2.6 mm. The leak is induced at the pipe at a distance of 19.7 m from the experimental point in the pipeline network using three variations of the sizes of the orifice (1 mm, 3 mm, 5 mm) and two types of pipe damage (crack and circular hole). This is shown in Figure 4e. The tube outlet remains linked to a free discharged water tank, in which the liquid is released in a free burst from the end of the pipe. This prevents sudden expansion due to the pressure waves and reduces the negative pressure wave because it influences the sensor details. Ref. [31] gives a detailed explanation of the transition in the dynamic wave pressure.

Figure 3.

Test rig schematic diagram.

Figure 4.

The laboratory experimental set-up: (a) Pipe loop; (b) Modified fire hydrant cap; (c) Solenoid valve; (d) Pressure transducer; (e) Circular hole (leak induced).

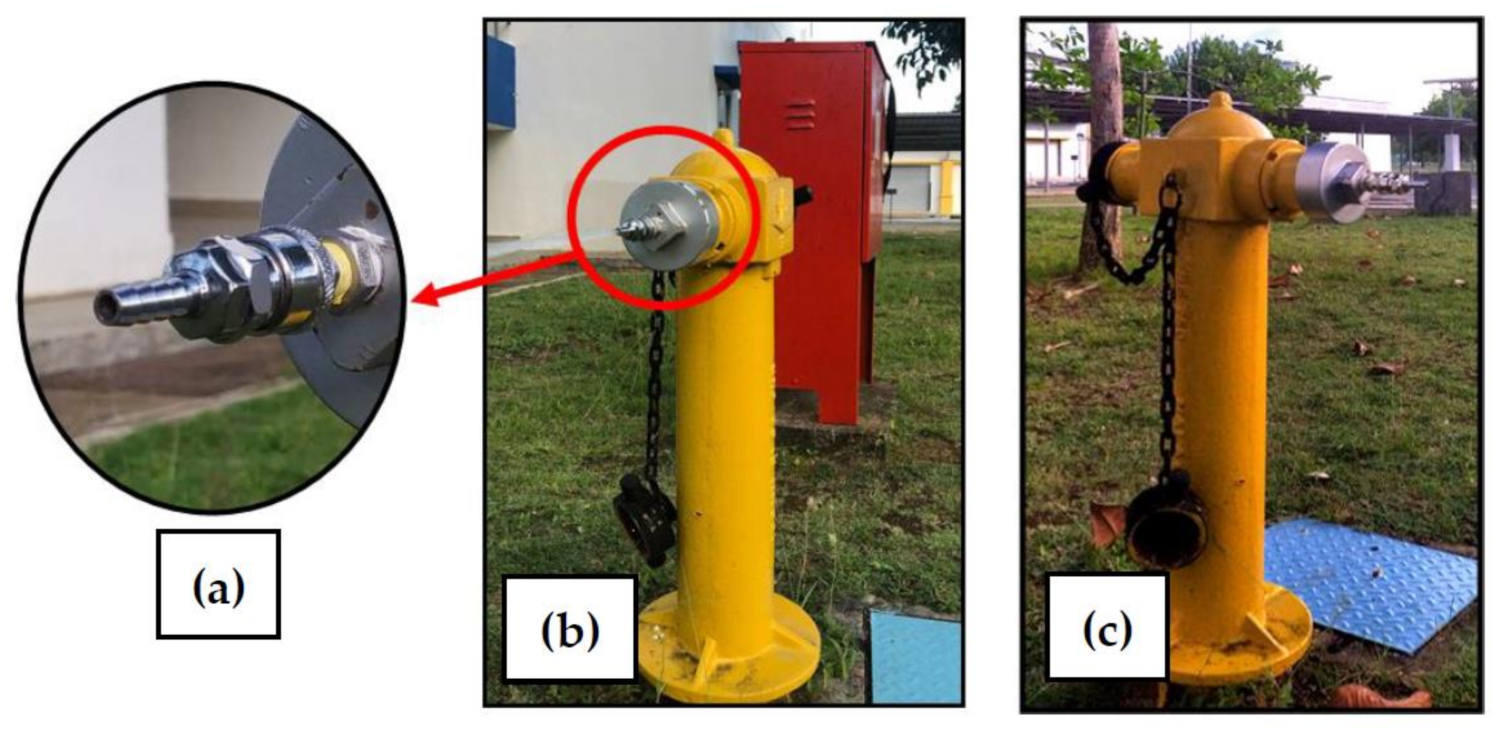

The pipe was mounted on the T-slot aluminium profile using U-clamp to reduce the vibrations and preventing any movements during the pipe pressurisation. A variable velocity centrifugal pump was installed at the entry of the pipe to generate the flow and pressure in the system. In the real water pipeline system, there are diverse entry points already fitted in the form of hydrants, and in order to make the rig similar to the real pipeline networking system, a fire hydrant (see Figure 4a) was installed on the rig acting as the point to get direct access to water in the pipeline system. A customised Malaysian standard fire hydrant cap mounted with a pressure transducer and solenoid valve (see Figure 4b) was connected to the pipe. The solenoid valve was used in order to generate the phenomenon of the hammer and piezoelectric pressure sensor (Figure 4d) for the acquisition of the reflective signal play, an essential role in both components. The detailed specification of the sensor and solenoid valve was presented in Table 1. The movements of two solenoids controlling the valve’s opening and closing generate the water hammer [32].

Table 1.

Device and Hardware Specification.

The laboratory validation was regulated at a steady-state system with normal running pressure from 2–4 bar with the system flow rates 1.4 L/s [33]. The signal response was acquired with sampling rates and block size of 10,000 samples per second, respectively. The primary advantage of this device is that both created water hammers and a signal response can be provided from only one default entry point (fire hydrant). To identify and accurately locate the pipe feature (leaks, piping fitting, blockage), the wave speed calibration for the pipeline system is necessary. By calculating the time required for propagation of the transition wave from the measurement point to the pipeline boundary and returning to the measuring point, the wave speed of the system pipeline is optimised. For this laboratory verification, the measured sound speed is 524.30 m/s [33].

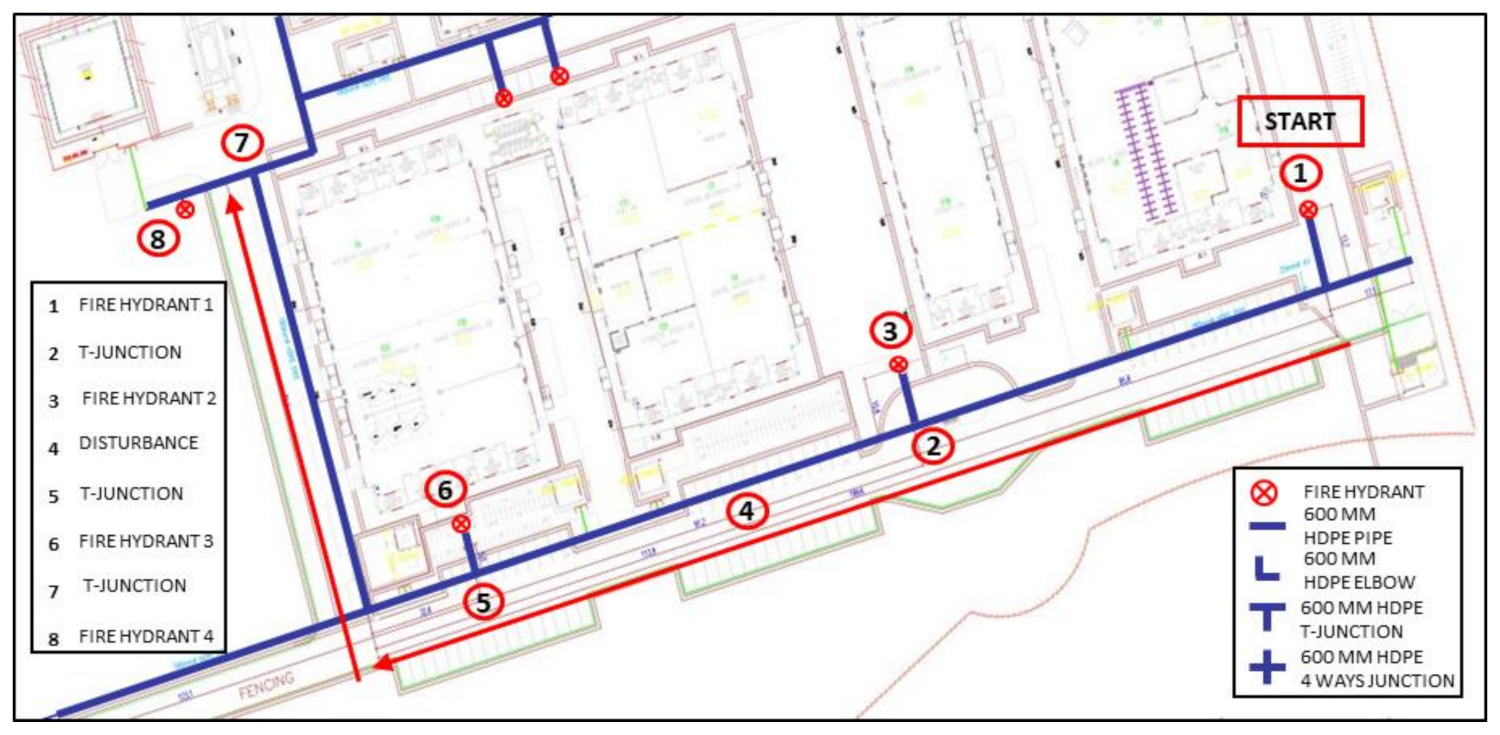

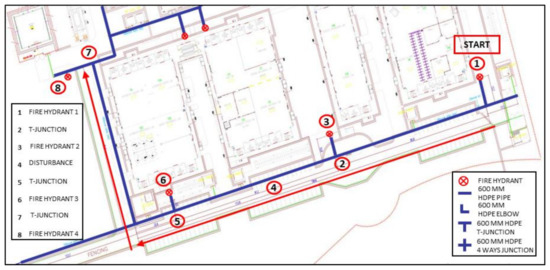

4. Field Authentication Set up

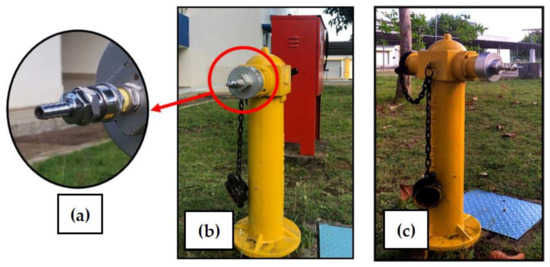

The field measurement experimental work with water pipeline system was 350 m in length from the point of analysis (Figure 5), 60 mm in external diameter, and the pipe materials are High-Density Polyethylene (HDPE). The measurement work on the service pipeline system network was conducted at the Faculty of Mechanical and Automotive Engineering Technology, Universiti Malaysia Pahang (Figure 6). The test was carried out on the maximum range achievable of the service pipeline system in the selected area. The length was nearly five times longer than the laboratory experimental test rig. Each pipe feature was identified and measured through a pipeline blueprint provided by the Department of Property Development and Management, Universiti Malaysia Pahang. The customised fire hydrant cap with a 5 mm diameter circular hole was used as induced damage to simulate the leak response at the two different fire hydrant points (Figure 7b,c) to study the trends of signal response between leaks and the distance from the point of analysis. In particular, the leak was induced through a 5 mm diameter gas connector fitted on a customised fire hydrant cap with working pressure of 3.75 bar and is measured to generate a leaking flow approximately up to 1.4 L/min [33]. In addition, for field authentication, the presence of pipe fittings (elbow, T-joint, valve, fire hydrant, and pipe socket) along the pipeline system were not preventing the detection of the leak but may alter the pressure transient response. This is because the reflection signal acquired during these processes may also be a response from pipe fitting. This condition was much contrasted with the laboratory verification since during signal acquisition, the reflection responses were just created from the leaks. The provided blueprint of the pipeline system is then utilised to identify the signal response acquired. Measurements were performed for both the non-leaking and the leaking circumstances to determine, respectively, the ambient noise and vibroacoustic phenomenon linked to active leaks.

Figure 5.

Fire Hydrant 1: Solenoid Valve and Pressure Sensor fitted at the point of analysis (Figure 6).

Figure 6.

Pipeline Network Blueprint at Faculty of Mechanical and Automotive Engineering Technology, Universiti Malaysia Pahang.

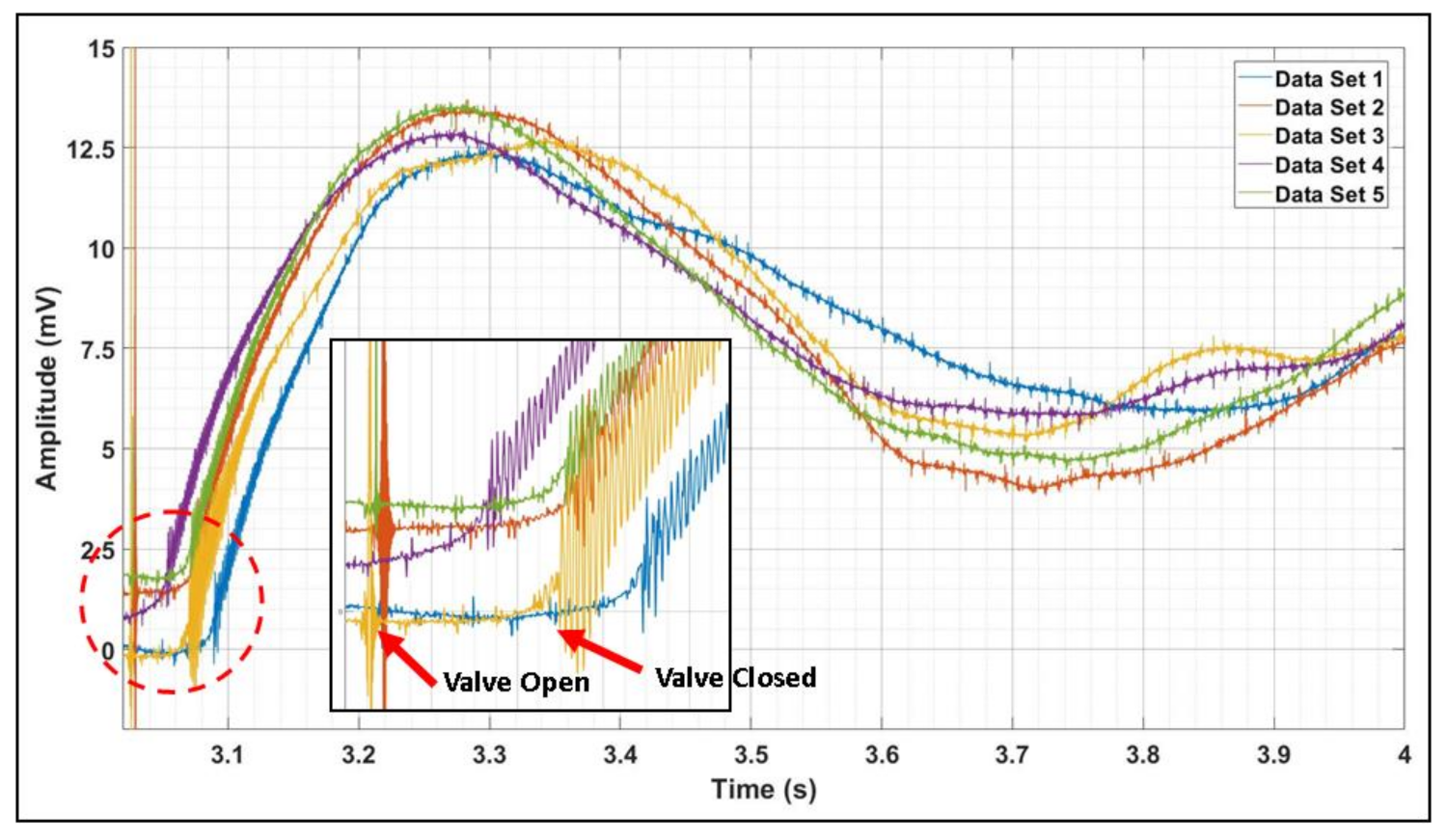

The wave speed of the device pipeline is optimised by determining the time taken for the transferred wave to propagate from the measurement point to the pipeline boundary and back to the measurement point. The estimated sound speed for this field measurement verification is 524.30 m/s [31]. The solenoid valve was located downstream from the leak point (Figure 5). The working pressure of the system is about 3.0–3.5 bar, which is a typical functioning condition of the network, the temperature was 25–27 degrees Celsius, duration was 5 s for each data set, and the sampling frequency was 10,000 Hz per sample. The acquired data were sampled using data acquisition hardware (Table 1). The experiments were repeated five times for every data set.

5. Results and Discussion

5.1. Laboratory Authentication Results and Discussion

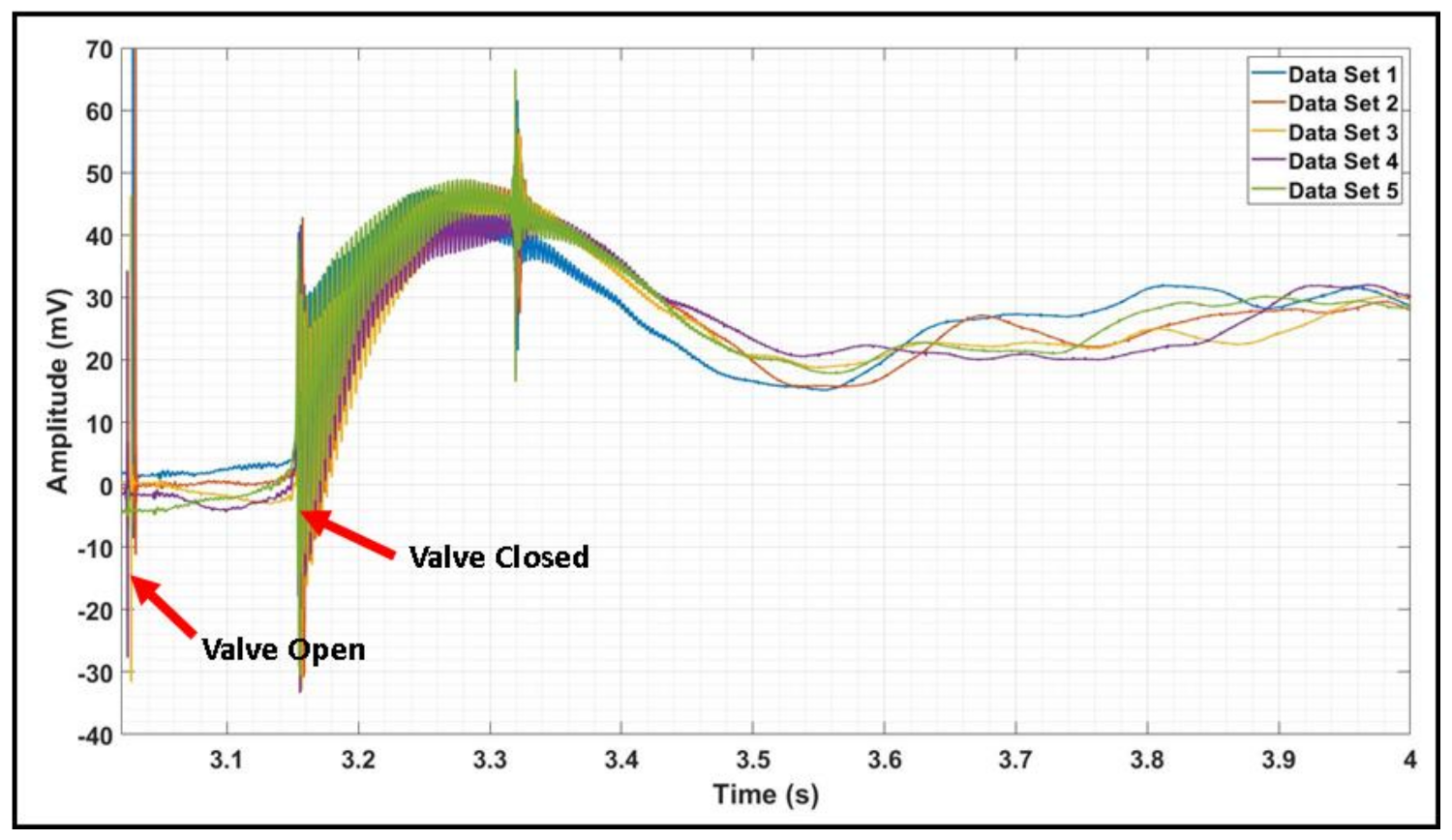

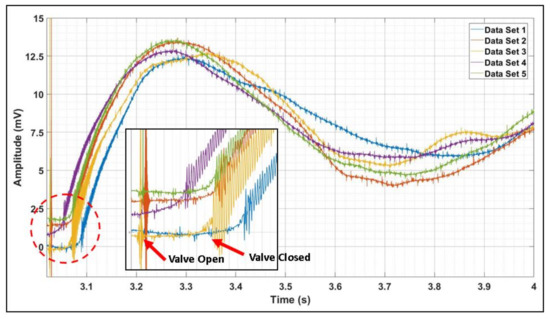

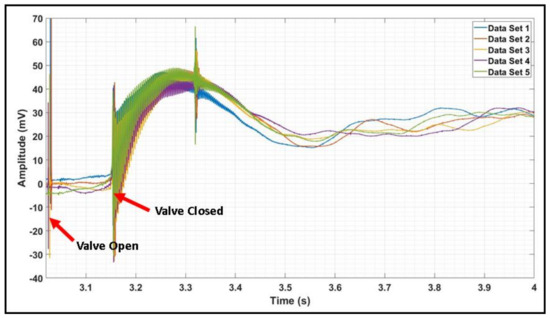

The ultimate focus of this laboratory experimental authentication was to evaluate the validity of using in-pipe measurements to detect pipe damage (leaks). Laboratory validation for the proposed method is tested on two pressure conditions of 2 bar and 4 bar. The only difference between them was the orifice (circular hole) size (1 mm, 3 mm, and 5 mm) for water discharging out of the system; acting as a leak and installed at fixed positions (see Figure 3 and Figure 4). Multiple tests on different days and room temperatures were also considered for the verification. Small water hammer effects were generated into the pipeline system by a 12 V solenoid valve, and the response signal occurred in the pipeline system was acquired by the pressure sensor. Both devices were mounted on customised fire hydrants (see Figure 4). The first example of signal response acquired by a pressure sensor for a 1 mm leak (damaged) pipeline system with the water pressure of 4 bar is illustrated in Figure 8. The signal acquired does retrieve the characteristics and pipe conditions of the whole pipeline system by itself. The pressurised transient waves transmitted through the speed of sound in the water pipeline network across the piping system in both directions away from the bursting point (fire hydrant). In this research, the HHT involved the EMD as the pre-processing technique, and the post-processing technique HT as a mechanism for the extraction of the transient signal. That maximum amplitude on the signal response illustrated in Figure 8 indicates that the solenoid valve, which generates a water hammer, is opened and closed rapidly across the pipe system. The initial response was measured at two different pressure rates: 2 bar and 4 bar. There have been different outcomes of the pulse detected using different pressure rates. The greater pressure induces a lower signal frequency, which triggers the greater signal amplitude [12].

Figure 8.

1 mm active leak, 4 bar water pressure, raw data from laboratory scale test rig.

The distance reflections in the pipe can be determined by multiplying the period of the pipeline system, which corresponds to the speeds of sound in the MDPE pipes (524.30 m/s), and by dividing that value by half to address for the return journey [33]. The reflection signal forming spikes or amplitudes of the leak should appear at time 0.075 s which is equal to 19.7 m, whereas 0.152 s is equal to 39.8 m for an outlet (see Figure 3). From the observation of Figure 8, there were no possible spikes or transients that represent the presence of leak and outlet due to the influence of low SNR and the reflection signal masking by environmental, electrical, and mechanical noise. The raw signal acquired from the test rig was disrupted through the various effects including noise generated from the electric pump, electrical appliances, surrounding and test rig frame vibrations. Due to this effect, the signal that contains pipeline information is masked inside the noise. Therefore, to extract the information of pipeline conditions from the raw signal (Figure 8), the signal analysis was implemented as a tool to reveal the presence of a leak at its location. This paper presents the implementation of the HHT to identify the present of leakage through the pressure transient signal. The NIKAZ technique is assigned as the automated selector for better and right IMF.

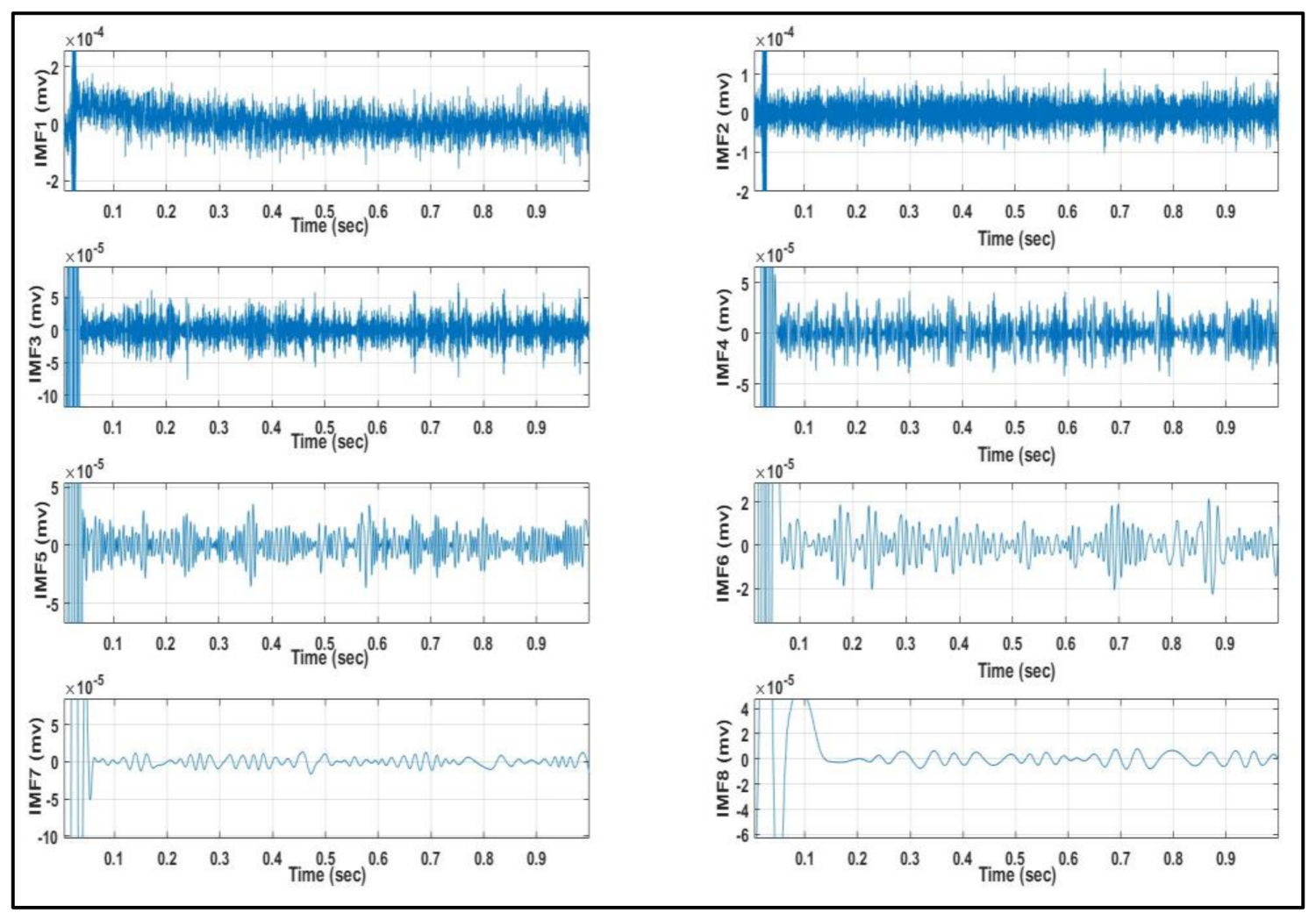

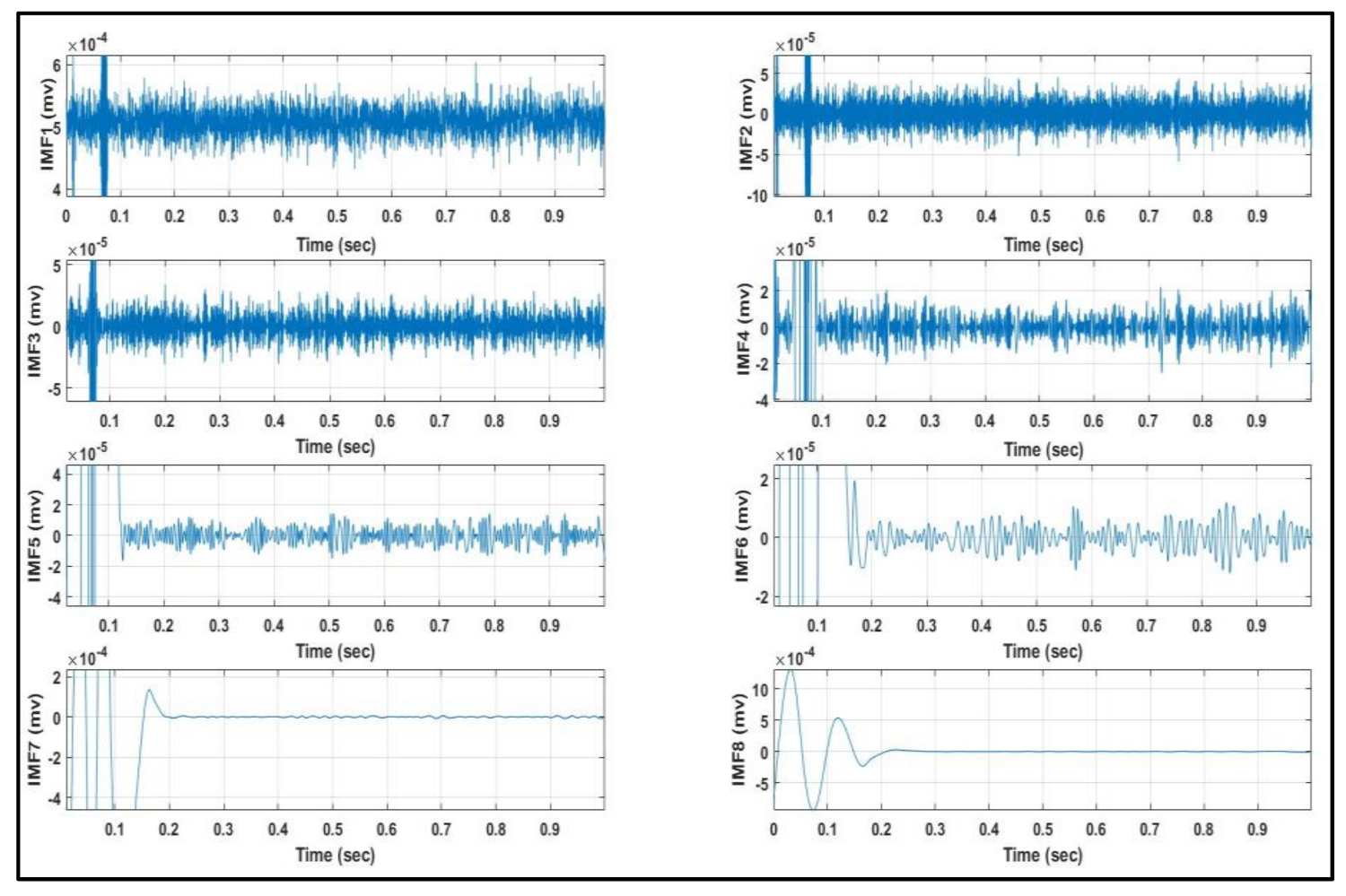

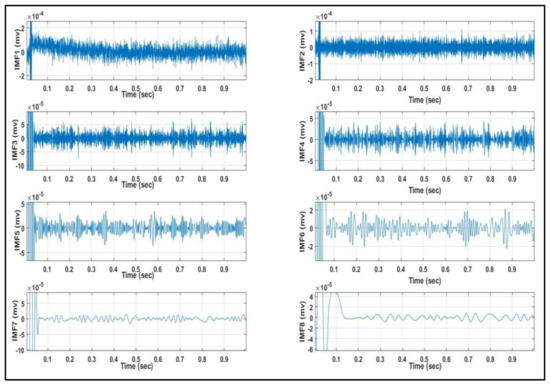

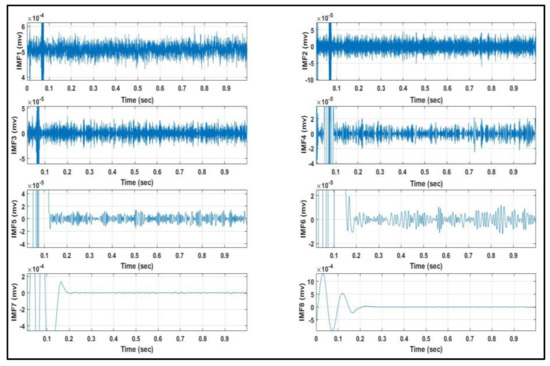

As presented in Figure 1, the first step of the signal analysis was done by performing EMD on a signal response from the pipeline. EMD is a way to decompose the signal into the series of IMF [20]. In this case, the EMD decomposed the signal into 13 series of IMF. The series of IMF was differentiated by higher frequency signals to lower frequency signals. From 13 series of IMF, series 1–3 contained the highest frequency, which essentially consisted of background noise. Meanwhile, series 7 and residue consisted of the elemental response of the system. All of these IMF series were discontinued for further observation because it may not be physically meaningful and could be due to the stop criteria set in the sifting process [18]. The rest of the IMF series was considered, which are series 4–6, which have been recombined to produce a signal without noise [5]. In consideration of the complexities of the system, identities are correlated with both the frequency of reflection and very low-frequency components should be of no concern. This theory was supported and proven by observing the first 8 series of IMFs decomposed from undamaged (no-leak induced) and damaged (leak induced) pipeline signal responses, which are illustrated in Figure 9 and Figure 10.

Figure 9.

IMFs for a no-leak signal response with water pressure condition of 2 bar.

Figure 10.

IMFs with leak signal response with pressure condition of 2 bar.

By observing Figure 9 and Figure 10, each series of IMF of the same order highlights alteration in both shape and amplitude depending on the pipeline condition. Nonetheless, the pipeline condition assessment is still quite difficult at this stage. This is because, from the observation, the healthy condition of the pipeline system still cannot be identified and assessed. Obviously, in accordance with the previous statement, not all IMF series were examined for the Hilbert Transform (HT).

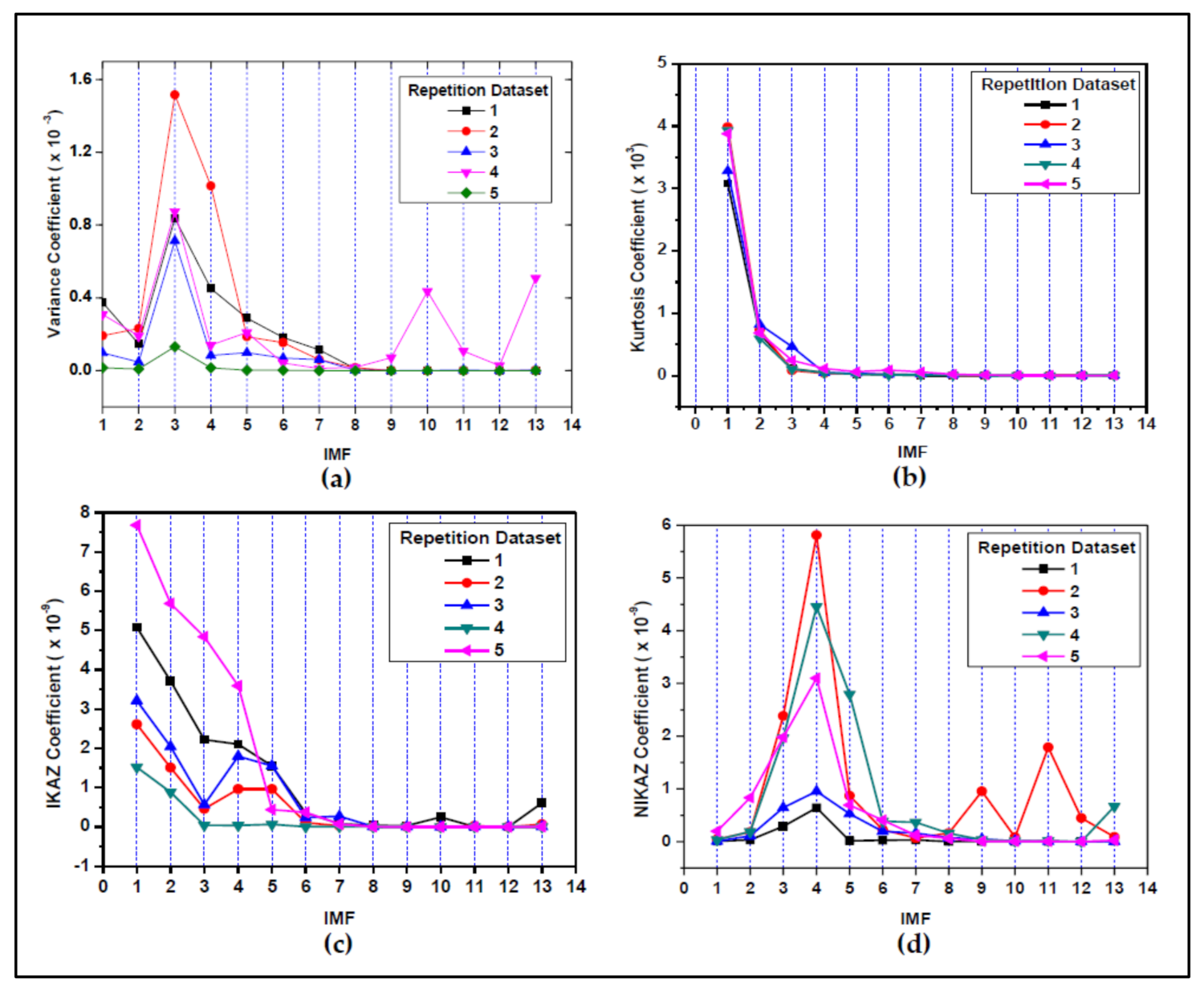

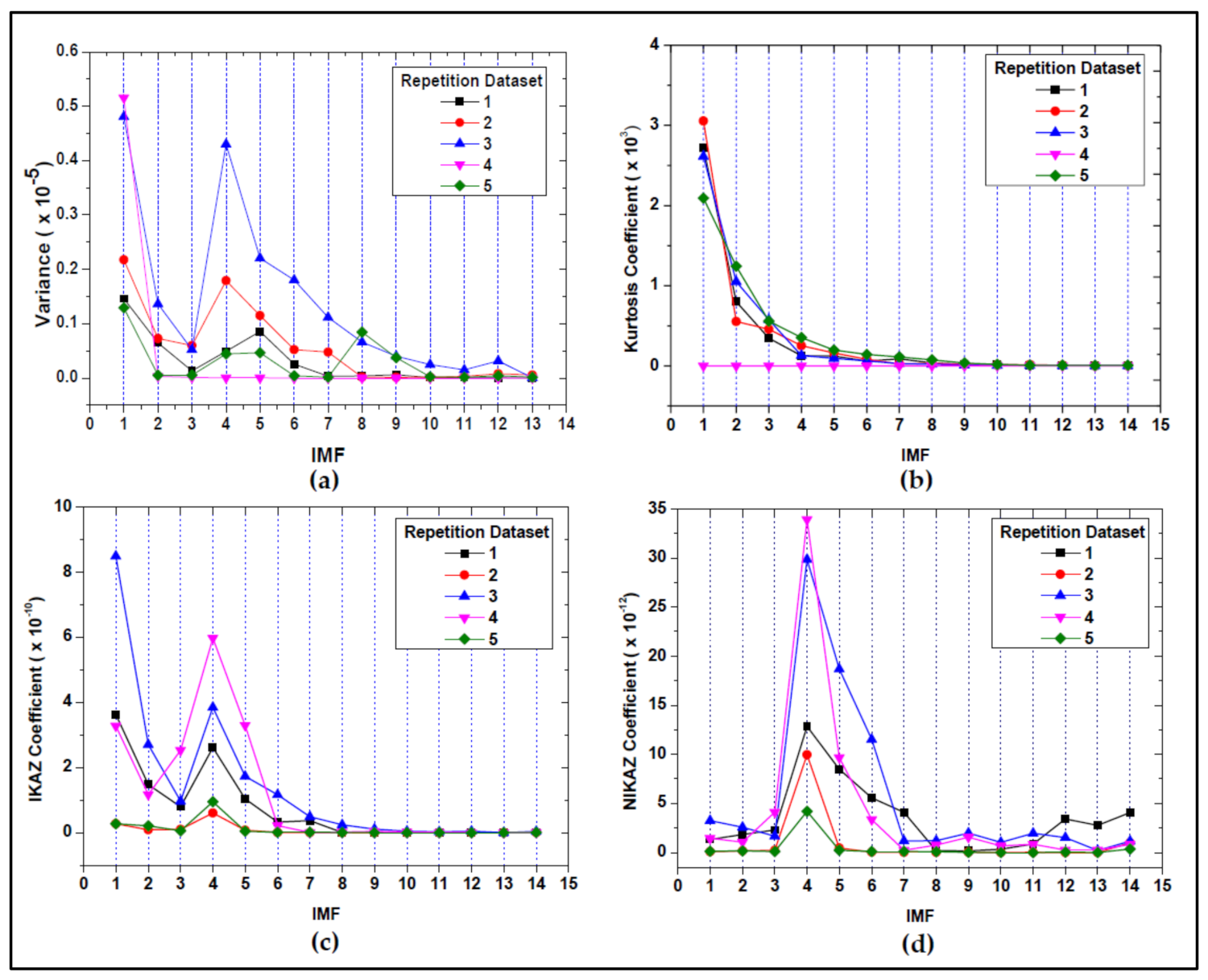

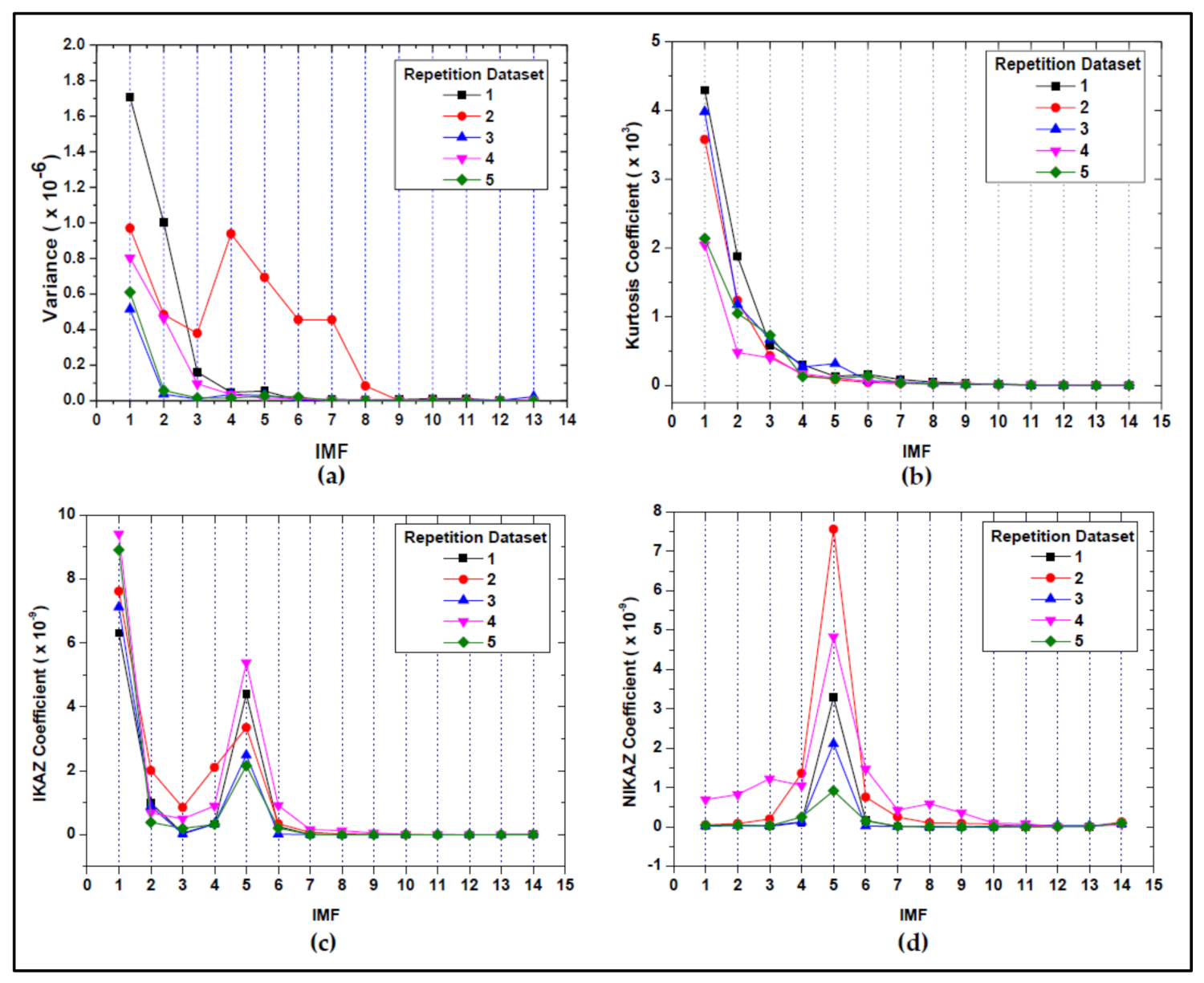

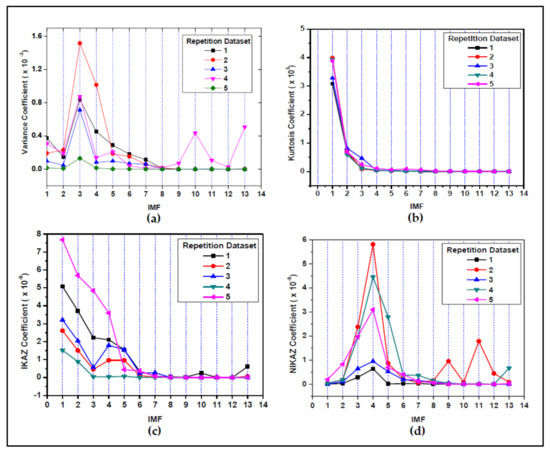

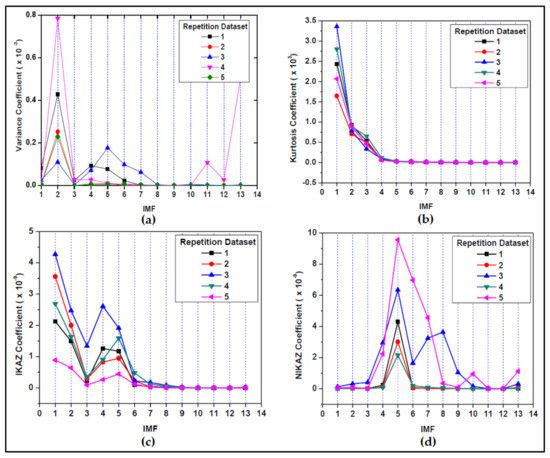

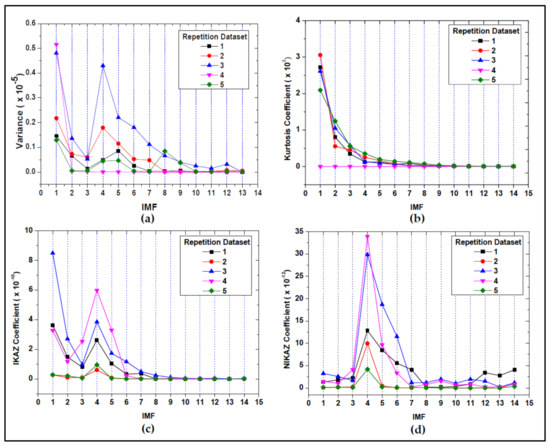

The NIKAZ coefficient for each series of IMFs was computed using Equation (12). To get a clear observation, the coefficient of NIKAZ was compared with primary order and another two higher-order statistical analysis methods: variance, Kurtosis, and IKAZ, respectively. All the coefficients were observed and assessed to get clear different coefficient values for each series of IMF to set the benchmarking in selecting the right IMF for HT analysis. The graphical trend expectations to the parameter of the pipeline condition assessment are reported, respectively, in Figure 11 and Figure 12.

Figure 11.

The curve for no-leak IMFs with 4 bar pressurised pipe: (a) Variance, (b) Kurtosis, (c) IKAZ, (d) NIKAZ.

Figure 12.

The curve for 1 mm leak IMFs with 4 bar pressurised pipe: (a) Variance, (b) Kurtosis, (c) IKAZ, (d) NIKAZ.

From the observations of Figure 11 and Figure 12, the clear differences between these statistical coefficient analyses were the highest value from the 13 series of IMFs. By comparing the value of variance, Kurtosis, IKAZ, and NIKAZ, the highest value coefficient of Kurtosis and IKAZ was presented by IMF series 1, variance presented IMF 2 for no-leak condition and IMF 3 for leakage condition, while NIKAZ coefficient presents the highest value on the range of IMF series 4–6 for all conditions of the pipeline. By referring to [5,18], IMFs series 1–3 were described as high-frequency phenomena, which contain rich noise. These IMF series were discarded because they are not physically meaningful and should not be of interest [18]. Besides that, IMFs 4–6 consist of the highest NIKAZ coefficient and by referring to [5], this level in the range of IMF 4–6 should consist of the signal without noise. To assure IMF 4–6 as the benchmark for examination and as the IMF of interest for HT, the IMF series containing the highest coefficient range for variance, Kurtosis, IKAZ, and NIKAZ were subjected to further analyses using HT. The detailed results of HT are presented in Figure 13 and Figure 14.

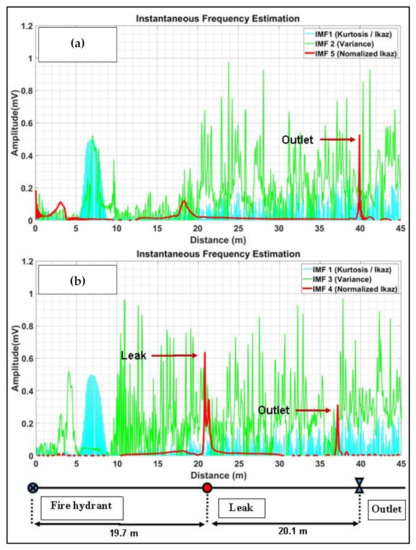

Figure 13.

Hilbert Transform (HT) analysis with 2 bar for pipeline system pressure: (a) IMF series 5 (no-leak) (b) IMF series 5 (1 mm circular hole).

Figure 14.

Hilbert Transform (HT) analysis with 4 bar for pipeline system pressure: (a) IMF series 5 (no-leak) (b) IMF series 5 (1 mm circular hole).

The graph presented in Figure 13a,b and Figure 14a,b is the instantaneous frequency estimation for the pipeline without leak (Figure 13a and Figure 14a) and pipeline with leak induced (Figure 13b and Figure 14b), respectively. During this phase, the non-stationary signal in terms of instantaneous frequency of the signal is more beneficial in characterising the frequency change at any time. Instantaneous frequency is the frequency that aligns the signal locally [12]. As the pipe system used the circular pipe (Figure 4a) without fixing any pipe fitting, therefore, by referring to the schematic diagram in Figure 3, there are two main features in the pipeline network that produce the reflection waves, being the outlet and control valves. The control valve was installed at the end (near an outlet) of the pipeline system due to control and stabilised the variation of pressure in the pipeline system. All amplitudes and spikes presence as seen in the analysed results corresponded to the time that the wave took to travel along with the pipeline system from the reflection points (pipe feature/leak) and return to the point of analysis (pressure transducer).

The distance of the reflection from the point of analysis (pressure sensor) is acquired by essentially multiplying the time delay data corresponding to each of the peaks by the speed of sound in the pipeline system (c = 524.30 m/s), and divided by two, that accounts as the return journey [6]. From the observation, it can be seen that there were peaks up to about 0.03 s or 7 m. These can be ignored as they were a part of the analysis process (these can be set to zero using the liftering process) [6]. Referring to Figure 13a and Figure 14a, the peaks appeared on the red line, which represents the HT analysis of IMF 5, and can be described as the pipeline condition, where the peak/spikes appeared at 38.34 m (Figure 13b) and 41.08 m (Figure 14b). Remarking on Figure 13 and Figure 14, the blue and green lines represent the HT analysis of IMF 1 and 2 (Figure 13) and IMF 1 and 3 (Figure 14), respectively. The IMF 1 (blue line) (Figure 13 and Figure 14) was chosen to remark the highest Kurtosis and IKAZ coefficient value; meanwhile, IMF 2 (green line) (Figure 13a and Figure 14a) and IMF 3 (green line) (Figure 13b and b) remark the highest variance coefficient. From the observation on the blue and green lines (Figure 13 and Figure 14), it is hard to conclude and find the possible spikes that represent the leak and pipe outlet since too many spikes appeared on the graph. Referring to [5,18], IMFs series 1–3 were described as high-frequency phenomena which contain rich noise. These IMF series were discarded because they are not physically meaningful and should not be of interest [18]. Therefore, the widespread spikes shown on the blue and green line are commonly spikes representing the noise from the signal; meanwhile, the red line clearly showed the spikes that are representing the reflection of the leak and pipe outlet because, quoting [5], this IMF level is in the range of IMF 4–6 that should consist of the signal without noise. By comparing the results with the measured distance, the presence of peaks on the time and distance represented the reflection signal from the pipe outlet or control valve. Because the pipe outlet and control valve were too close to each other, therefore, the reflection of both features is concluded as overlapping each other.

Referring to Figure 13b and Figure 14b (red line) which present the HT analysis for leak signal, starting at 0.03 s or 7 m away, peaks can also be seen such as described the pipeline characteristics [6]. However, there is the presence of peaks/spikes appearing at 21.18 m in Figure 13b subjected to the response of the reflection signal from the leak, while the peaks/spikes appearing at 39.23 m (Figure 13b) are subjected to the response of the reflection signal from the pipe outlet. The same phenomena can also be seen in Figure 14b, whereby a couple of spikes present at the distance of 18.5 m and 39.23 m are present in the reflection signal from the leak and outlet, respectively. By comparing the results of the IMF presented before, the obvious spikes and peaks are more clearly seen after subjection to the HT in this phase. The laboratory verification was repeated for various sizes of leaks and horizontal cracks that act as leaks with the water pressure of 2 bar and 4 bar. The results and error analysis are presented in Table 2 and Table 3.

Table 2.

NIKAZ evaluation for 2 bar pressurised pipe.

Table 3.

NIKAZ evaluation for 4 bar pressurised pipe.

Table 2 and Table 3 illustrates the comparison of measured position and analysed the position for leak and outlet based on the IMF that contains the highest coefficient value of NIKAZ with the water pressure at 2 bar and 4 bar, respectively. Error analysis for both conditions of 2 bar and 4 bar showed a mean error of 3.02% and 3.66%, respectively. Both experimental conditions confirm that the series of IMF subjected to the highest NIKAZ coefficient provided simple and clear results, which indicate that the HT analysis technique is able to identify the pipeline condition assessment in simple pipe systems. Meanwhile, from the examination, the IMF containing the highest value of the NIKAZ coefficient could be set as the benchmark for the self-decision method to select the right and relevant IMF for subjection to Hilbert Transform (HT).

5.2. Field Authentication Results and Discussion Discussion

The efficiency and stability of proposed signal processing (NIKAZ) were then examined on real field authentication in order to determine the best and short way of finding the pipeline leakage internally. The methodology on how the signal was acquired and the signal processing of laboratory work were repeated for this field measurement. The real field signal on the buried pipeline system was used in this work with service pressure measured as 3.75 bar equivalent to 375 kPa and 54.38 psi. The leakage in the pipeline system was induced using a 5 mm diameter gas connector that is fixed on a modified fire hydrant cap as shown in Figure 7a. The leakage was induced on fire hydrant 2 (Figure 7b) and fire hydrant 3 (Figure 7c); meanwhile, the point of analysis where the modified fire hydrant is fitted with the pressure sensor and solenoid valve is located at fire hydrant 1 (Figure 5). This field authentication was split into four conditions of measurement: 1: No-leak, 2: Leak induced on fire hydrant 2; 3: Leak induced on fire hydrant 3; 4: Leak induced on fire hydrant 2 and 3. The signal illustrated in Figure 15 was measured from point of analysis (fire hydrants 1; Figure 5) when leaking was induced on fire hydrant 2 (Figure 7b). Similarly, as with the raw signal on the laboratory measurement, the real raw signal acquired in-field measurement still does not retrieve the condition of the pipeline system. Due to the effect of low SNR and reflection signal masked by environmental noise, there were no potential spikes or transients that represented the presence of a leak or pipe fitting (elbow, valve, T-joint, valve), as observed in the blueprint presented in Figure 6. The sudden spikes on the signal response in Figure 15 showed that the 12 V solenoid valve, which causes a water hammer, is quickly opened and closed through the pipe structure. In this study, the HHT, which includes the EMD as a pre-processing technique and the HT as a post-processing technique, is used to reveal the pipeline condition. The methodology of the signal processing technique in this work is as presented in Figure 1.

Figure 15.

5 mm active on Fire Hydrant 1 leak, 3.5 bar water pressure, raw data from field signal.

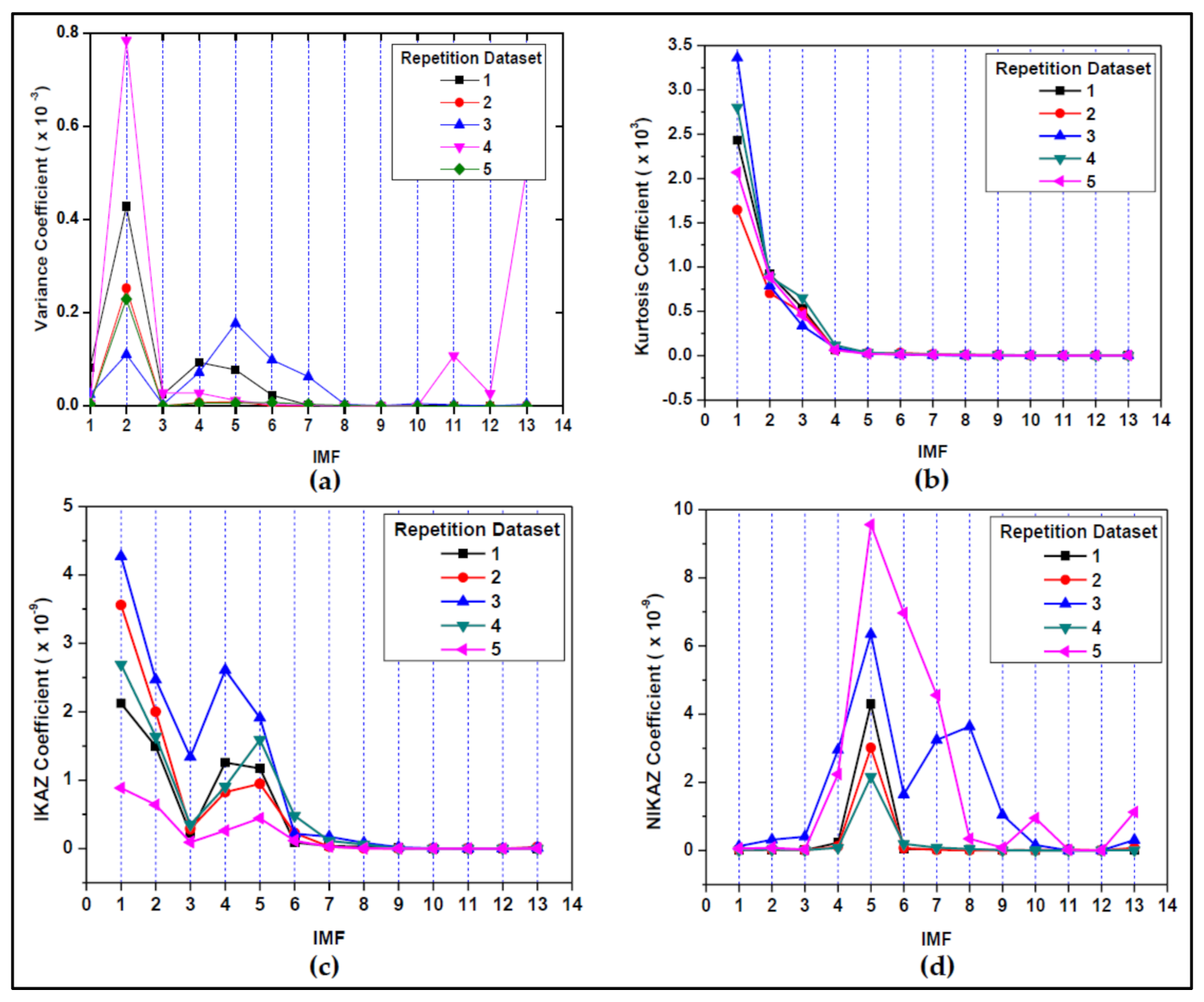

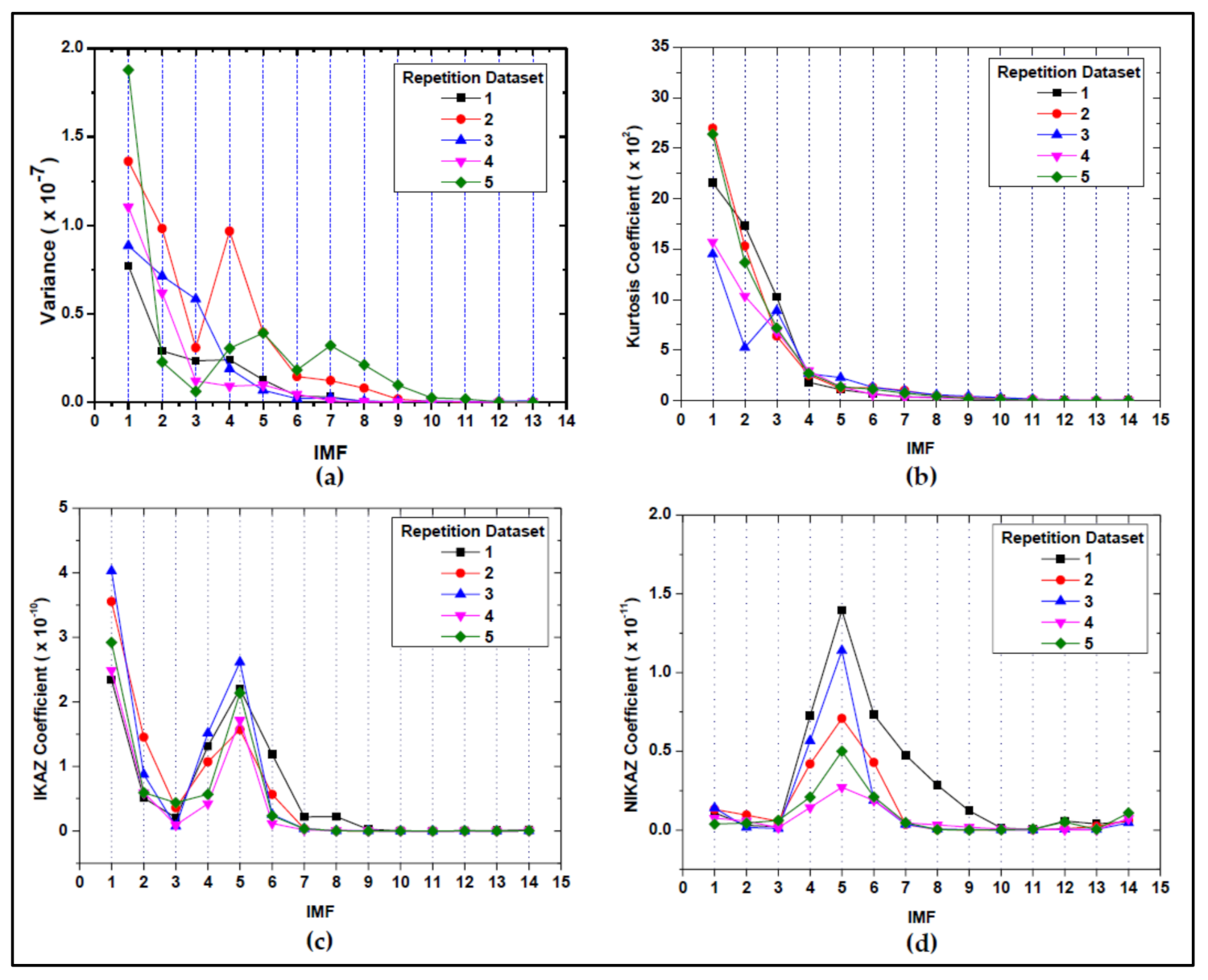

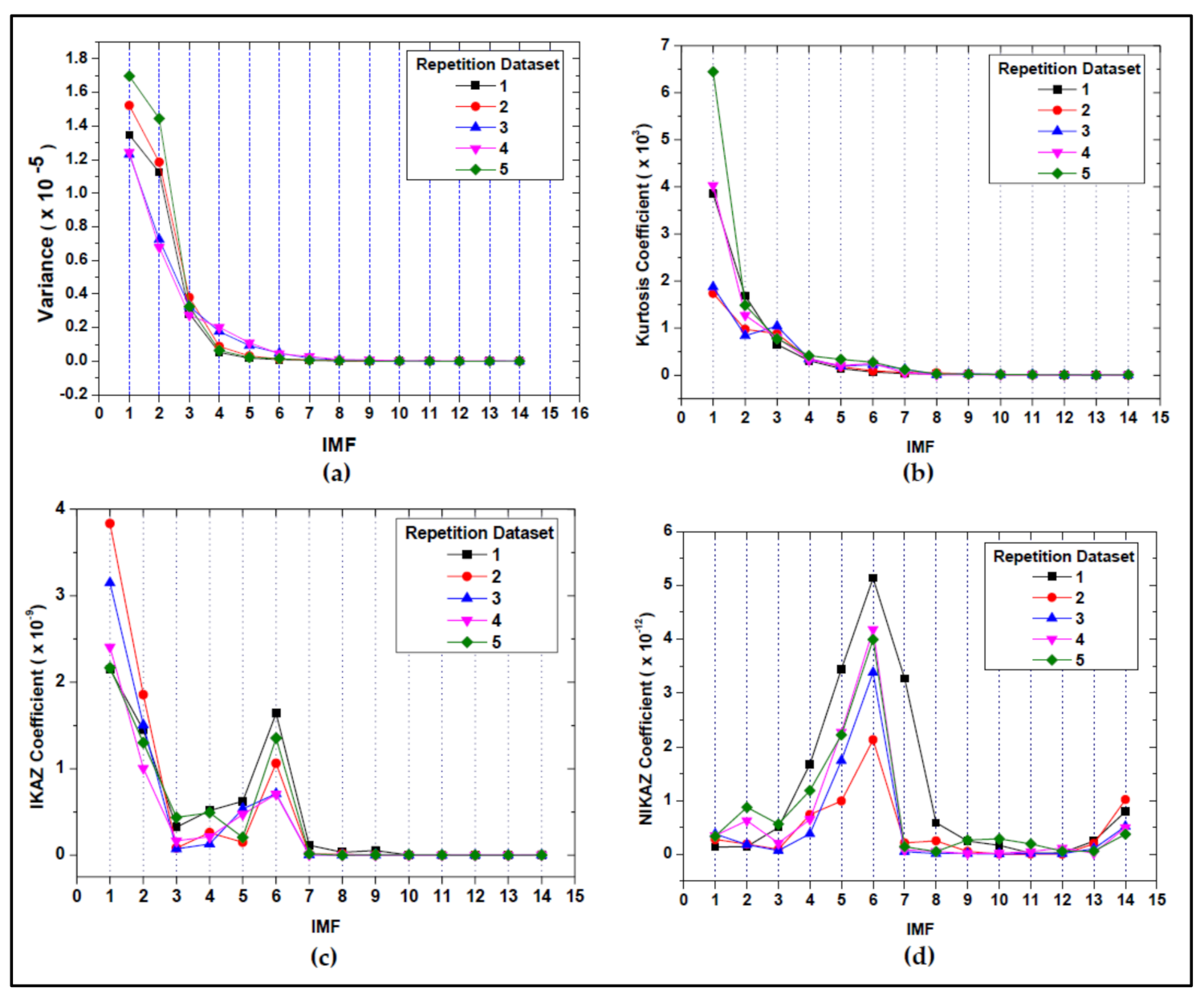

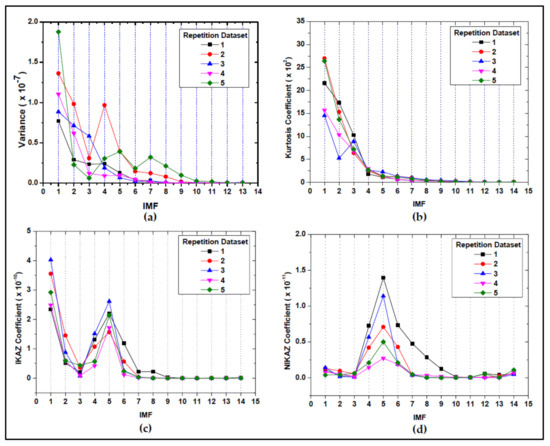

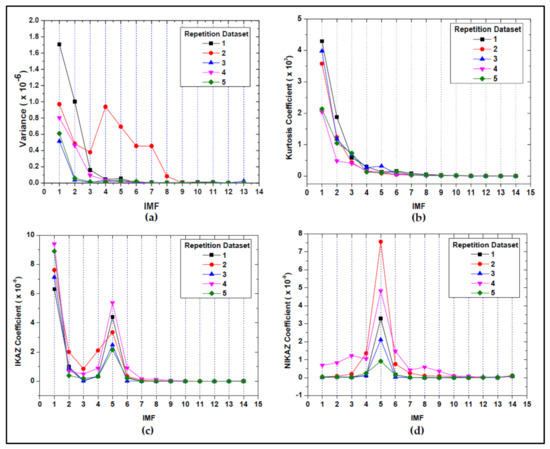

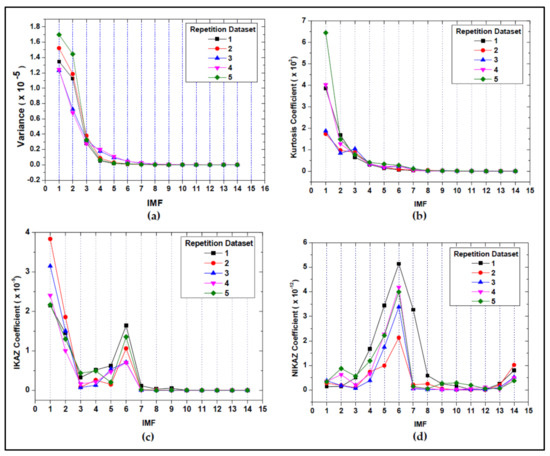

Equation (12) is being used to determine the NIKAZ factor for each sequence of IMFs. In order to acquire a straightforward finding, similar to be laboratory work presentation, the NIKAZ coefficient was compared to primary order statistical analysis: variance, and two other higher-order statistical analysis methods; Kurtosis, as well as IKAZ. All of the coefficients were observed and evaluated to acquire distinct coefficient values for each sequence of IMF in an attempt to provide a baseline for choosing the suitable IMF for HT analysis. The graphical trend predicts the parameter. Figure 16, Figure 17, Figure 18 and Figure 19 present the results of the pipeline state evaluation in four states of pipeline condition.

Figure 16.

The curve for no-leak IMFs: (a) Variance, (b) Kurtosis, (c) IKAZ, (d) NIKAZ.

Figure 17.

The curve for 5 mm leak IMFs induced on fire hydrant 2: (a) Variance, (b) Kurtosis, (c) IKAZ, (d) NIKAZ.

Figure 18.

The curve for 5 mm leak IMFs induced on fire hydrant 3: (a) Variance, (b) Kurtosis, (c) IKAZ, (d) NIKAZ.

Figure 19.

The curve for 5 mm leak IMFs induced on fire hydrant 2 and 3: (a) Variance, (b) Kurtosis, (c) IKAZ, (d) NIKAZ.

From the illustration presented in Figure 16, Figure 17, Figure 18 and Figure 19, similar as the experimental evaluation factor, the most significant coefficient values of the 13 IMFs series were the substantial variations between them. In this kind of condition (field authentication), the presented coefficient of variance showed obvious changes in curve trend when the maximum value of variance shifted to IMF 1 for all kinds of measurement conditions; meanwhile, the curve trend of Kurtosis, IKAZ, and NIKAZ were interpreted as no big changes as compared to the results shown in laboratory measurement. In examining the computed coefficient values of Variance, Kurtosis, IKAZ, and NIKAZ, apparently the highest value coefficient value of Variance, Kurtosis, and IKAZ was represented by IMF series 1, while the NIKAZ coefficient contained the highest value on the range of IMF series 4–6 for all kinds of measurement conditions. By means of reference [5,18], IMFs series 1–3 were described as high-frequency phenomena which contain rich noise. These IMF series were discarded because they are not physically meaningful and should not be of interest [18]. Besides that, IMF 4–6 consists of the highest NIKAZ coefficient and by referring to [5], this level is in the range of IMF 4–6, which should consist of the signal without noise. To assure the proposed method of automatic selection IMFs (NIKAZ) to be a success in field condition, and to prove the robustness of this method, the IMF that contains the highest NIKAZ value is set as the benchmark for examination where these IMFs of interest were subjected to further analysis using the HT. The detailed results for the four conditions of measurement of HT are presented in Figure 20, Figure 21, Figure 22 and Figure 23.

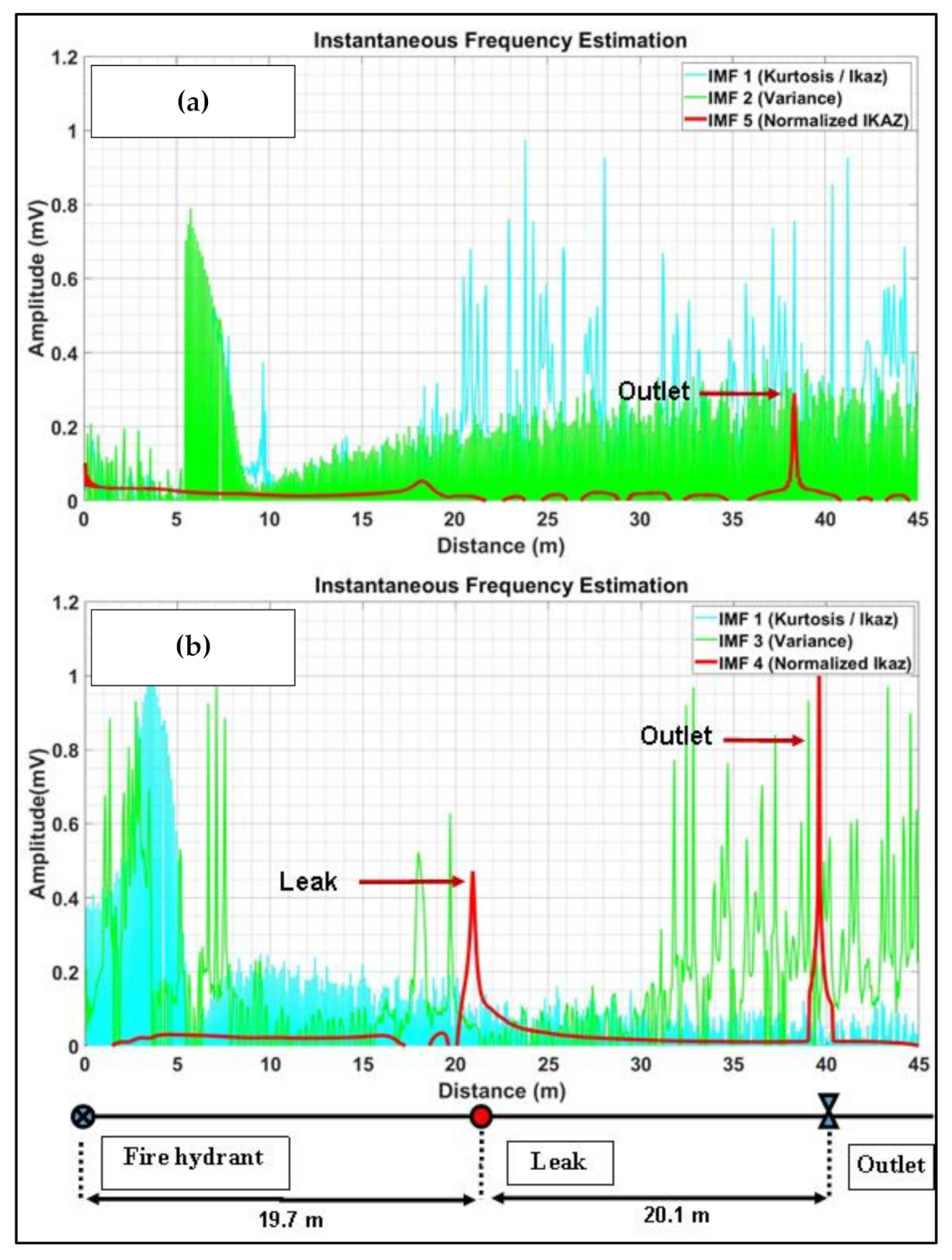

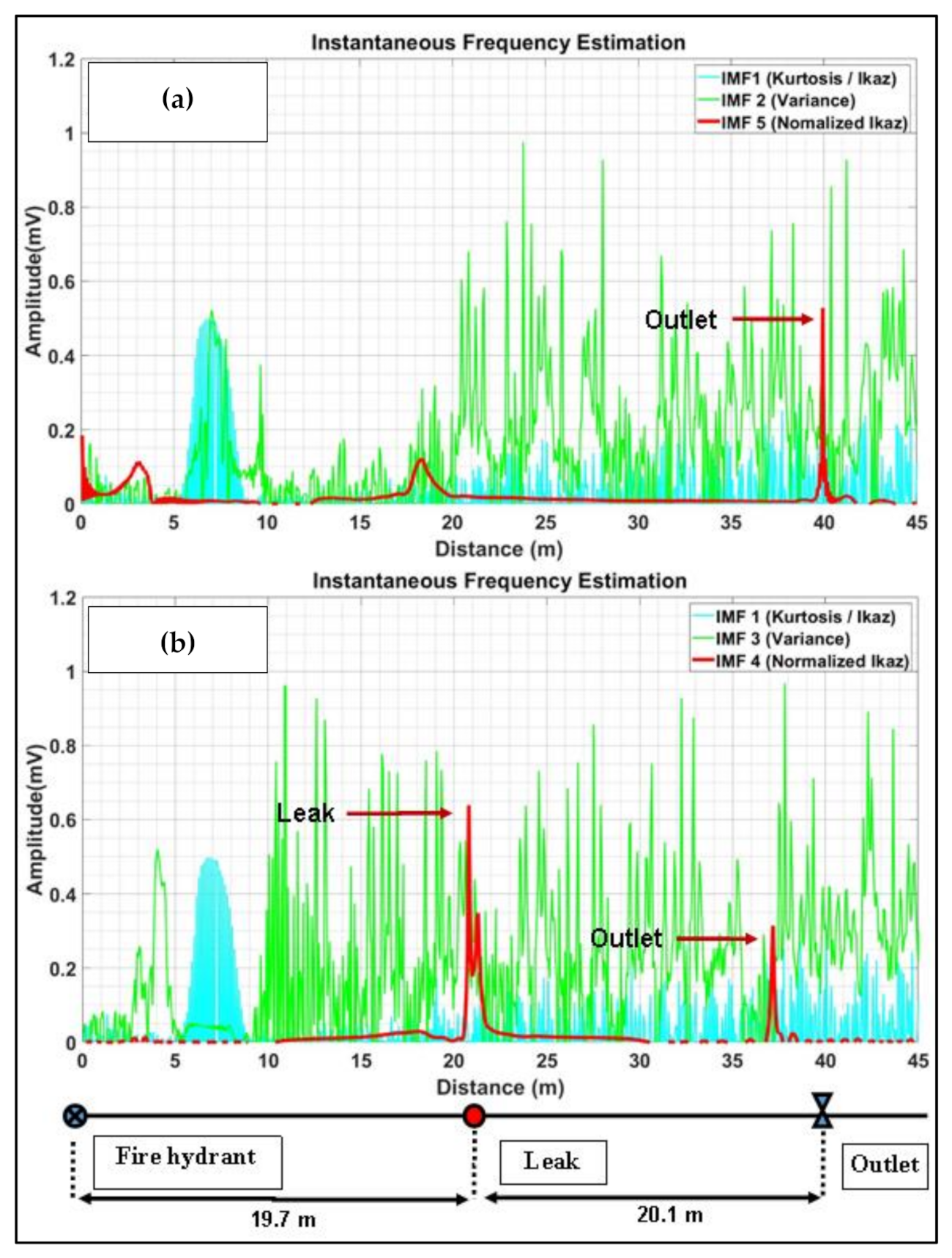

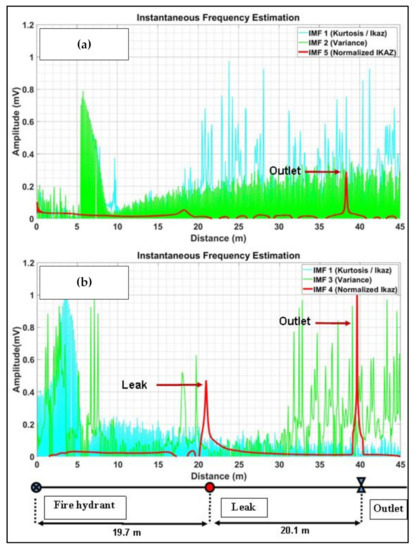

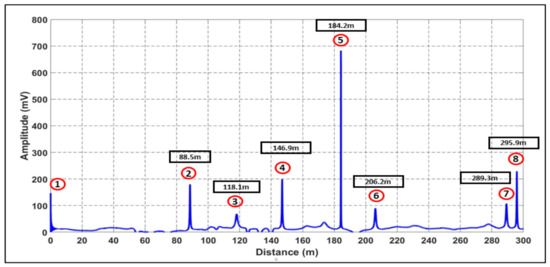

Figure 20.

Hilbert Transform (HT) analysis IMF series 4 for no-leak induced.

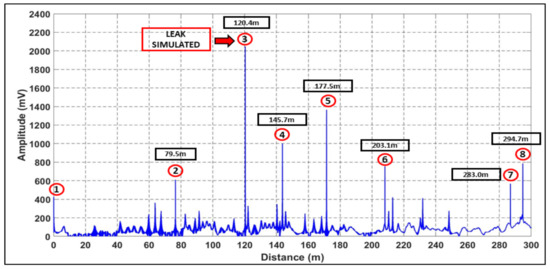

Figure 21.

Hilbert Transform (HT) analysis IMF series 6 for 5 mm leak induced on fire hydrant 2.

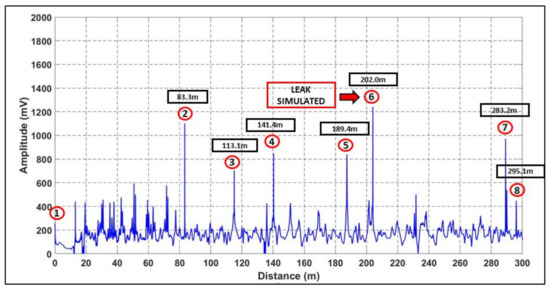

Figure 22.

Hilbert Transform (HT) analysis IMF series 6 for 5 mm leak induced on fire hydrant 3.

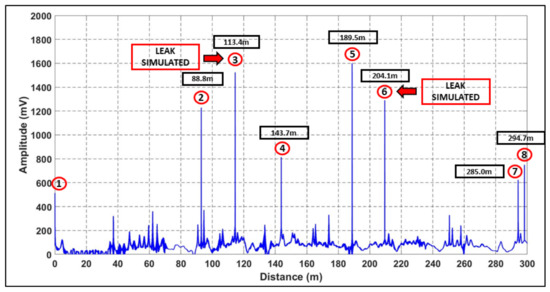

Figure 23.

Hilbert Transform (HT) analysis IMF series 6 for 5 mm leak induced on fire hydrant 2 and 3.

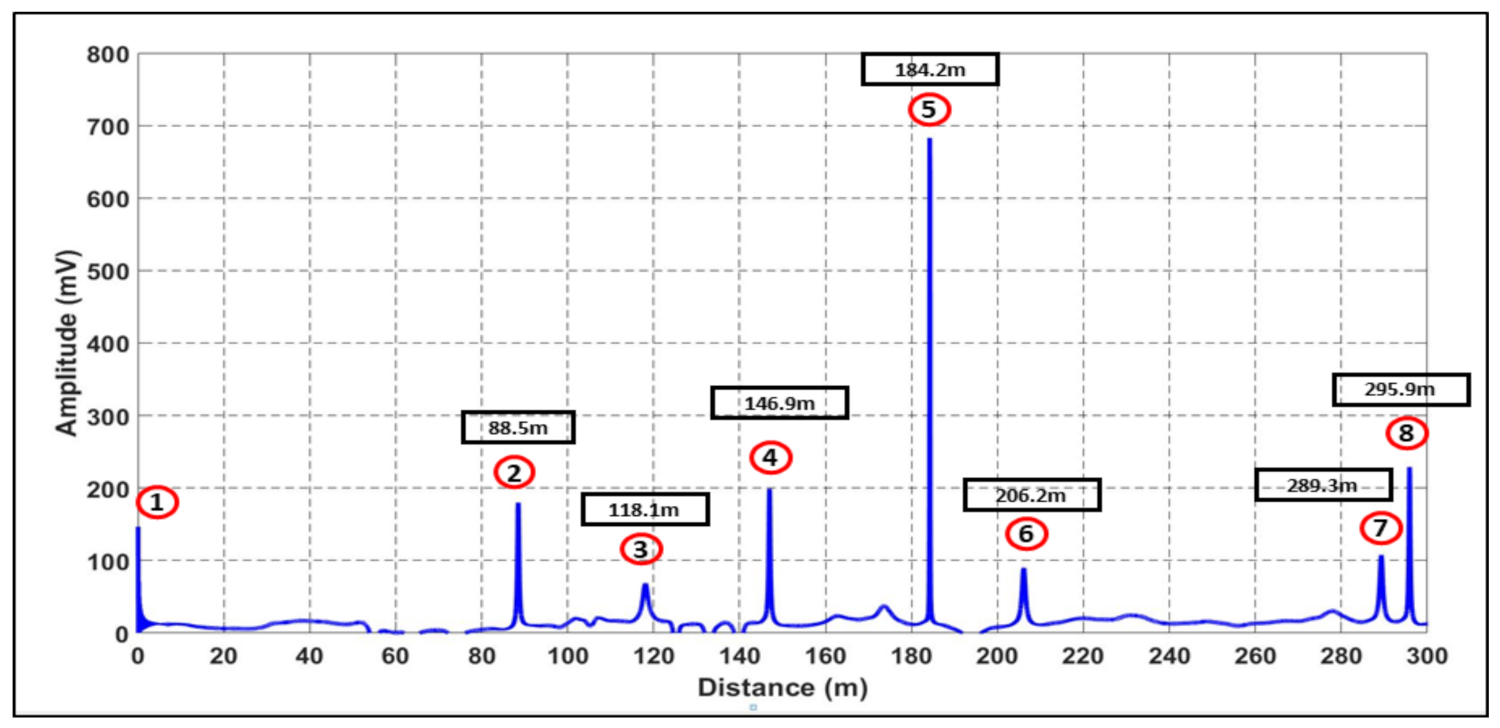

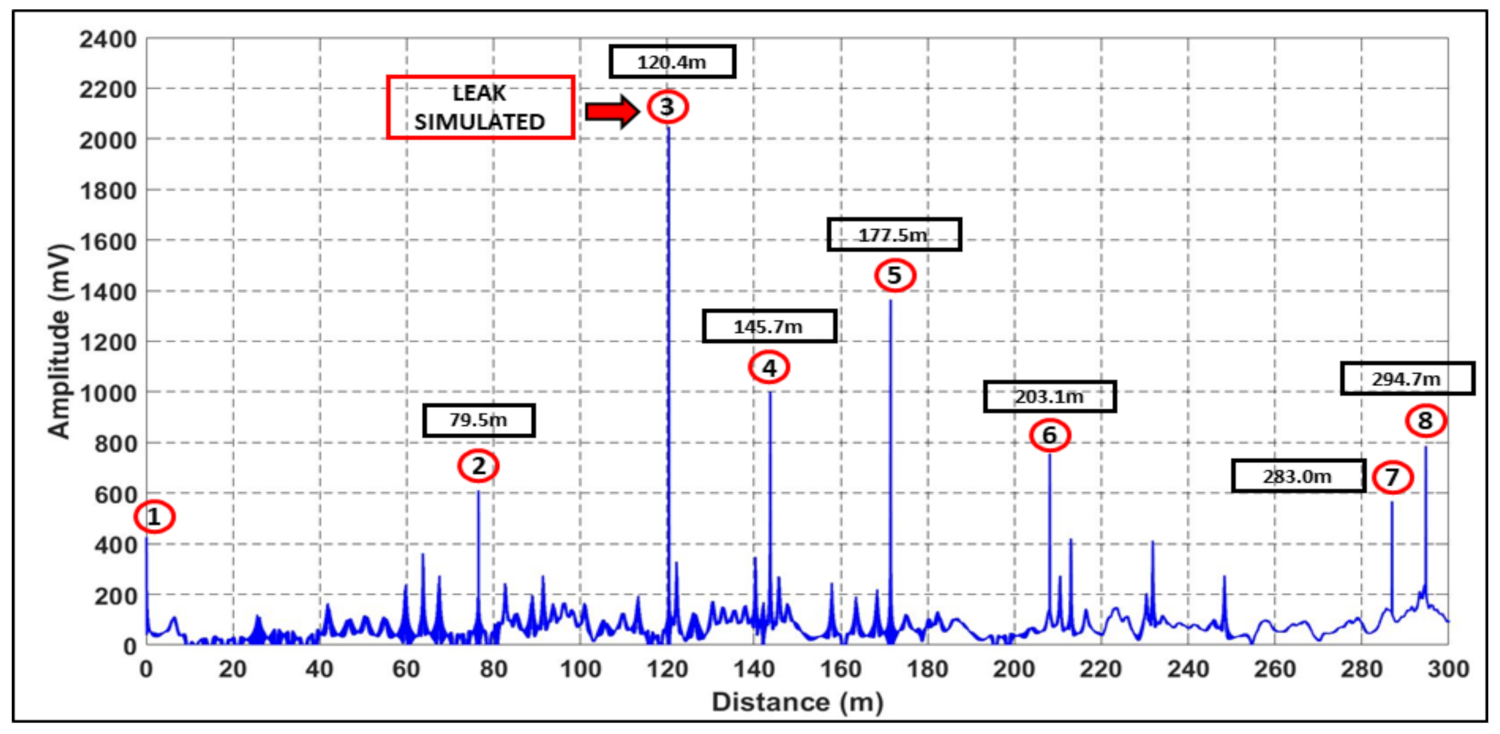

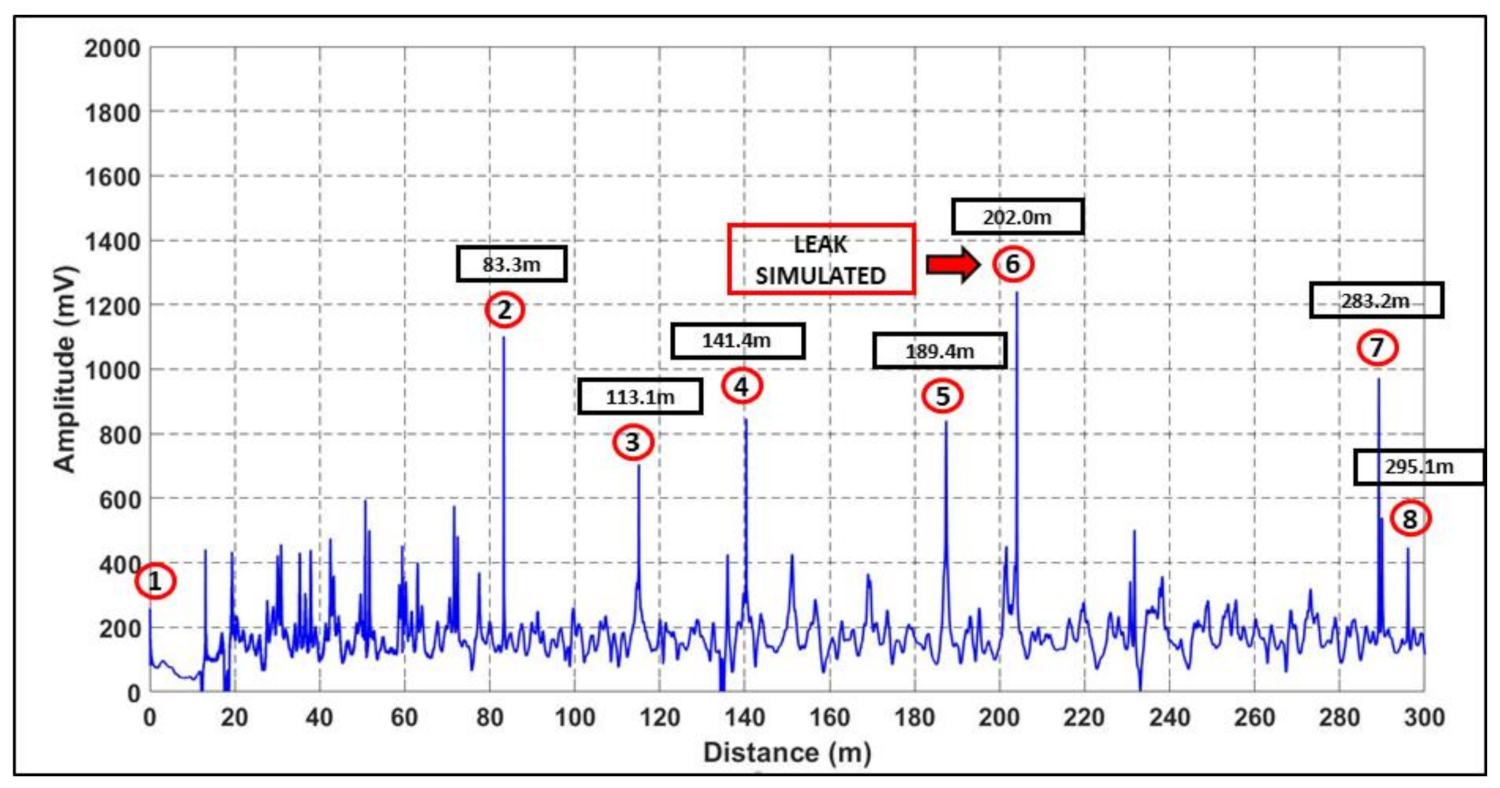

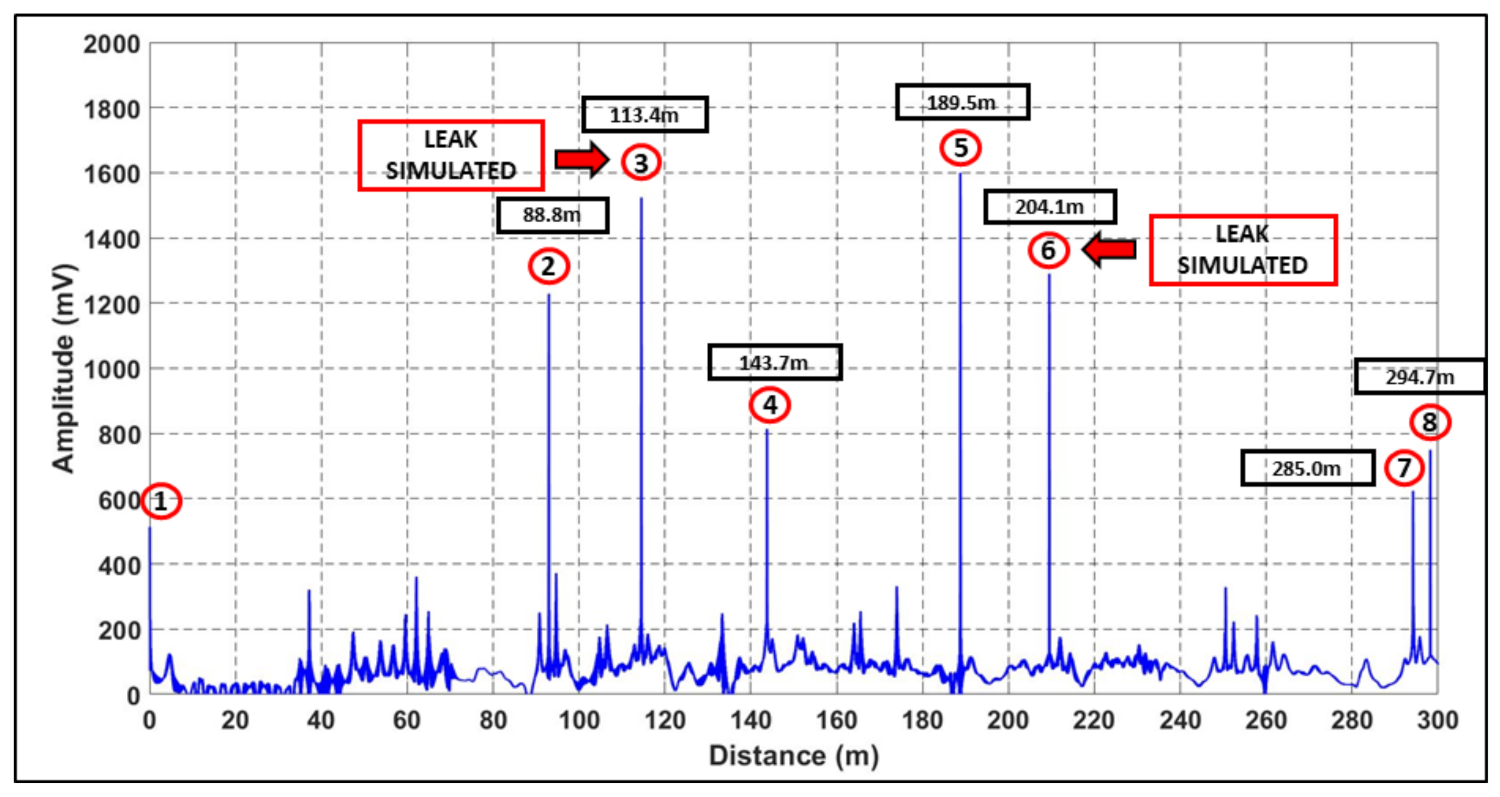

The graph (amplitude (mV) vs. distance (m)) illustrated in Figure 20, Figure 21, Figure 22 and Figure 23 is the instantaneous frequency estimation (from HT analysis) for the pipeline with no-leak condition (Figure 20), 5 mm leak induced on fire hydrant 2 (Figure 21), 5 mm leak induced on fire hydrant 3 (Figure 22), and 5 mm leak induced on fire hydrant 2–3 (Figure 23), respectively. The non-stationary signal is the most beneficial for characterising frequency change at any time during this period with regards to the instantaneous frequency of the signal. Instant frequency is the frequency that locally aligns the signal [12]. The field pipeline system used in the Faculty of Mechanical and Automotive Engineering Technology is a service pipe fixed with various types of pipe fittings such as valve, fire hydrant, junction, and socket, referring to the blueprint provided in Figure 7. For the first 300-metre distance (from fire hydrant 1) analysis, there are seven main features in the pipeline network that produce the reflection waves. The analysed results are based on the time the wave took to move along the pipe network from the reflection points (pipe feature/leak) back to the analysing point (pressure transducer). Each of the reflection spikes’ amplitude presented in Figure 20, Figure 21, Figure 22 and Figure 23 represents the reflection point induced by the leak (Fire hydrant 2 and 3) and pipe feature (junction, valve) fixed along the first 300 m from the analysis point (fire hydrant 1). The distance analysis of reflection amplitude (Figure 20, Figure 21, Figure 22 and Figure 23) was then compared to measured distance from the blueprint of service pipeline system as provided (Figure 6).

This technique is to identify the source of each reflection spikes presented in Figure 20, Figure 21, Figure 22 and Figure 23. As illustrated in the results (Figure 20, Figure 21, Figure 22 and Figure 23), the reflection spikes consistently formed for all pipeline features either on no-leak and leak conditions. The obvious adjustment of no-leak and leak condition induced on fire hydrants 2 and 3 is the amplitude elevation. For no-leak condition, the elevation of reflection spikes formed lower than the condition when the 5 mm leak was induced at that same point. This happens when in no-leak condition, the reflection spikes are formed by a fire hydrant, and for leak conditions, the spikes were formed by the two sources, the fire hydrant and the leak, respectively. Deriving from the results (Figure 20, Figure 21, Figure 22 and Figure 23), there were also seemingly strange spikes formed consistently at the distance ranging from 142.4–146.9 m away from the analysis point (fire hydrant 1); meanwhile, when verified with the blueprint provided (Figure 7), there should be no pipe feature that can form these reflection spikes. Therefore, it was assumed that the spikes formed from the disturbance in the pipeline system are either from the blockage or leak. With the information obtained from distance analysis, the sources that formed strange spikes and peaks were then identified. The speculation of the strange spikes were then resolved when the brass faucet for gardening purpose was identified as directly tapped on the service pipeline system (Figure 24). The obvious spikes and peaks are more clearly seen after the IMF that contains the highest NIKAZ value subjection to the HT in this phase. The field authentication was repeated five times for each condition to measure the stability of the proposed technique and to compute the means error. The results and error analysis are presented in Table 4, Table 5, Table 6 and Table 7.

Figure 24.

Brass faucet tapping directly to the service pipe.

Table 4.

NIKAZ evaluation for no-leak condition pipeline system.

Table 5.

NIKAZ evaluation for the system with 5 mm leak induced on fire hydrant 2.

Table 6.

NIKAZ evaluation for the system with 5 mm leak induced on fire hydrant 2.

Table 7.

NIKAZ evaluation for a system with 5 mm leak induced on fire hydrants 1 and 2.

Table 4, Table 5, Table 6 and Table 7 illustrated the comparison of measured position and analysed the position for four conditions of the pipeline system based on the IMF that contains the highest coefficient value of NIKAZ. An error analysis showed a mean error of less than 5% in all conditions of the pipeline system, respectively. All field authentication conditions confirmed and proved that the IMF series provided the highest NIKAZ coefficient as present simple and clear results, indicating that the pipeline condition assessment in simple pipeline systems can be identified with the HT-analysis technique. During the review, the IMF with the highest NIKAZ coefficient value could be defined as a benchmark for the method of self-decision in order to select the right IMF for Hilbert Transform (HT).

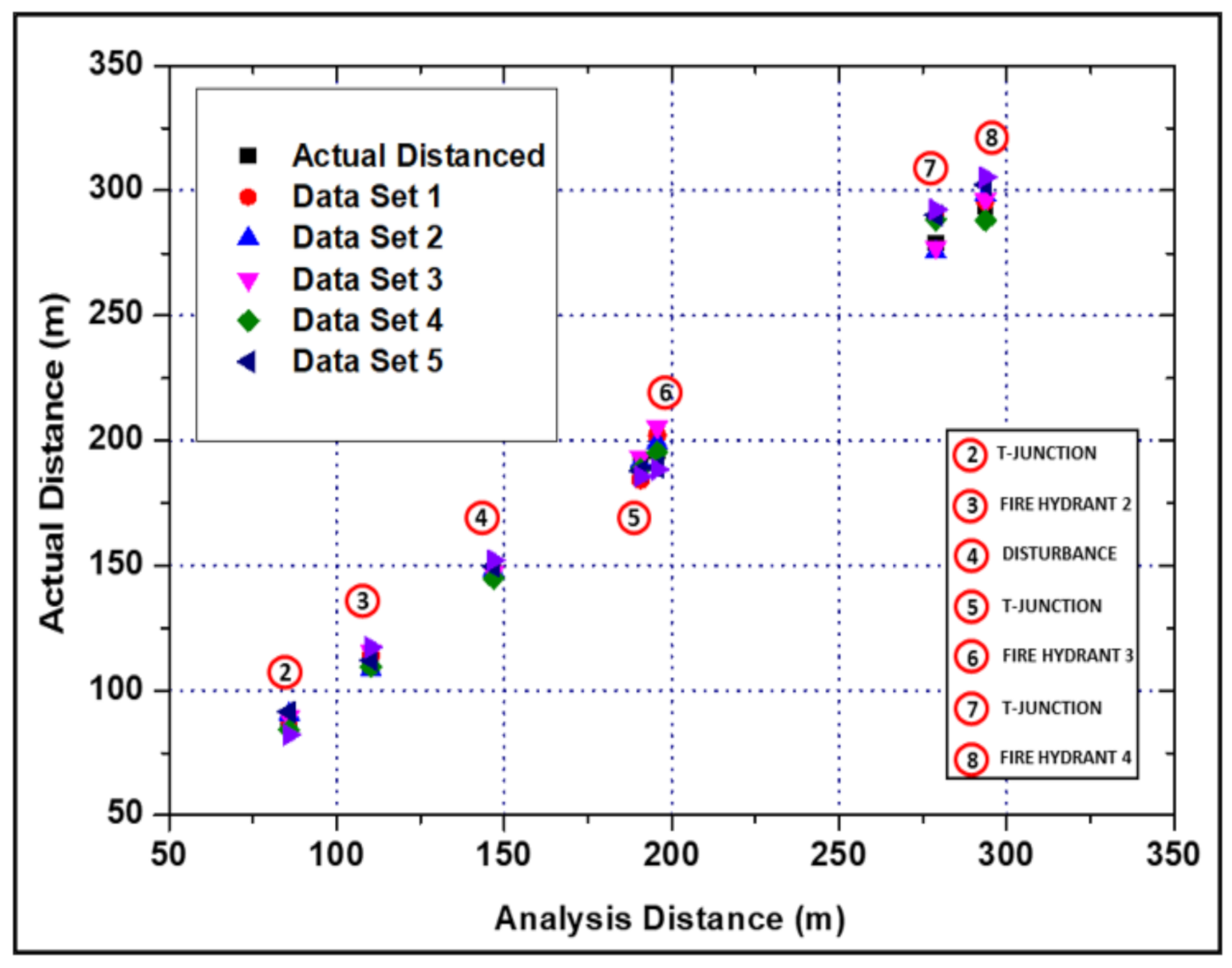

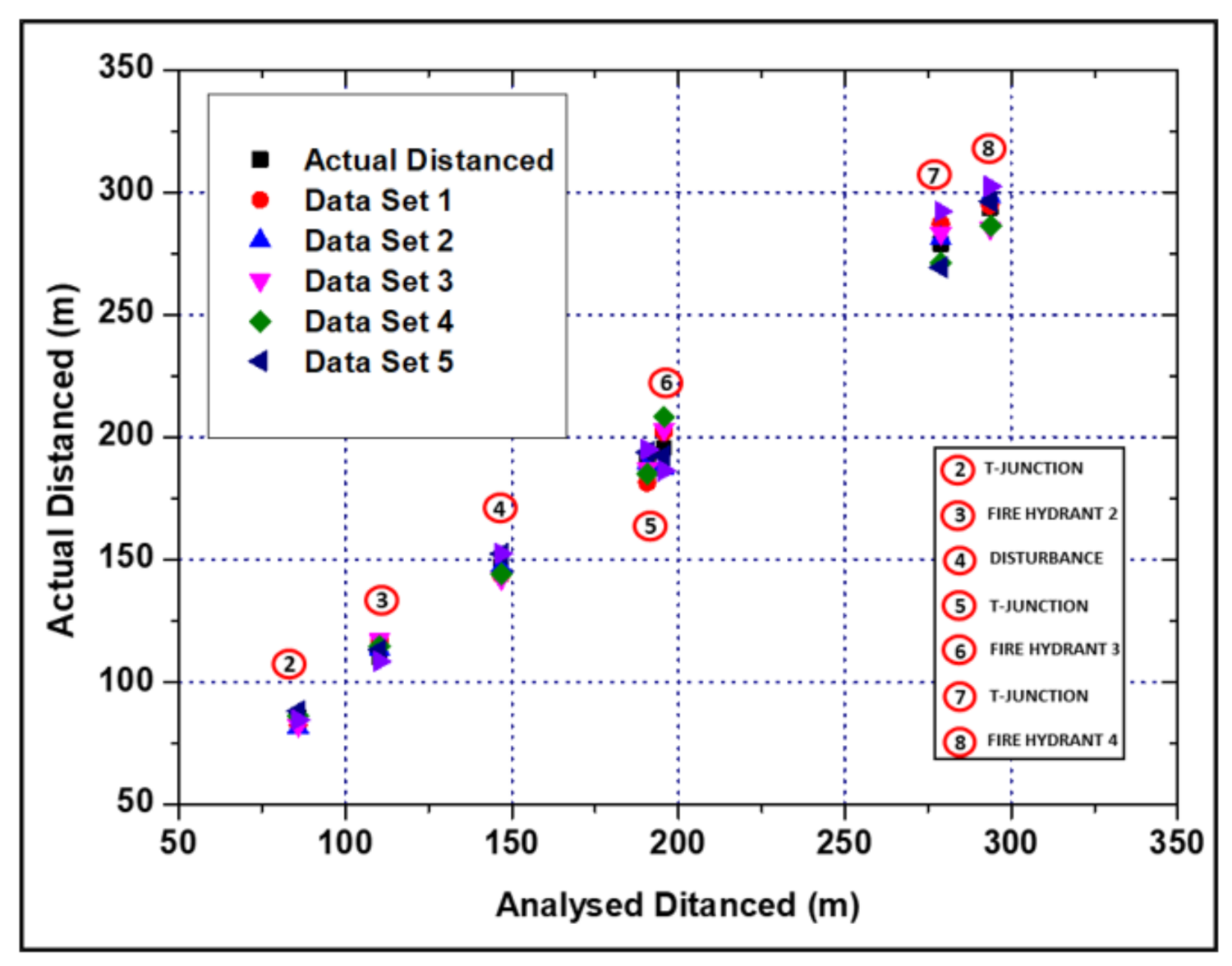

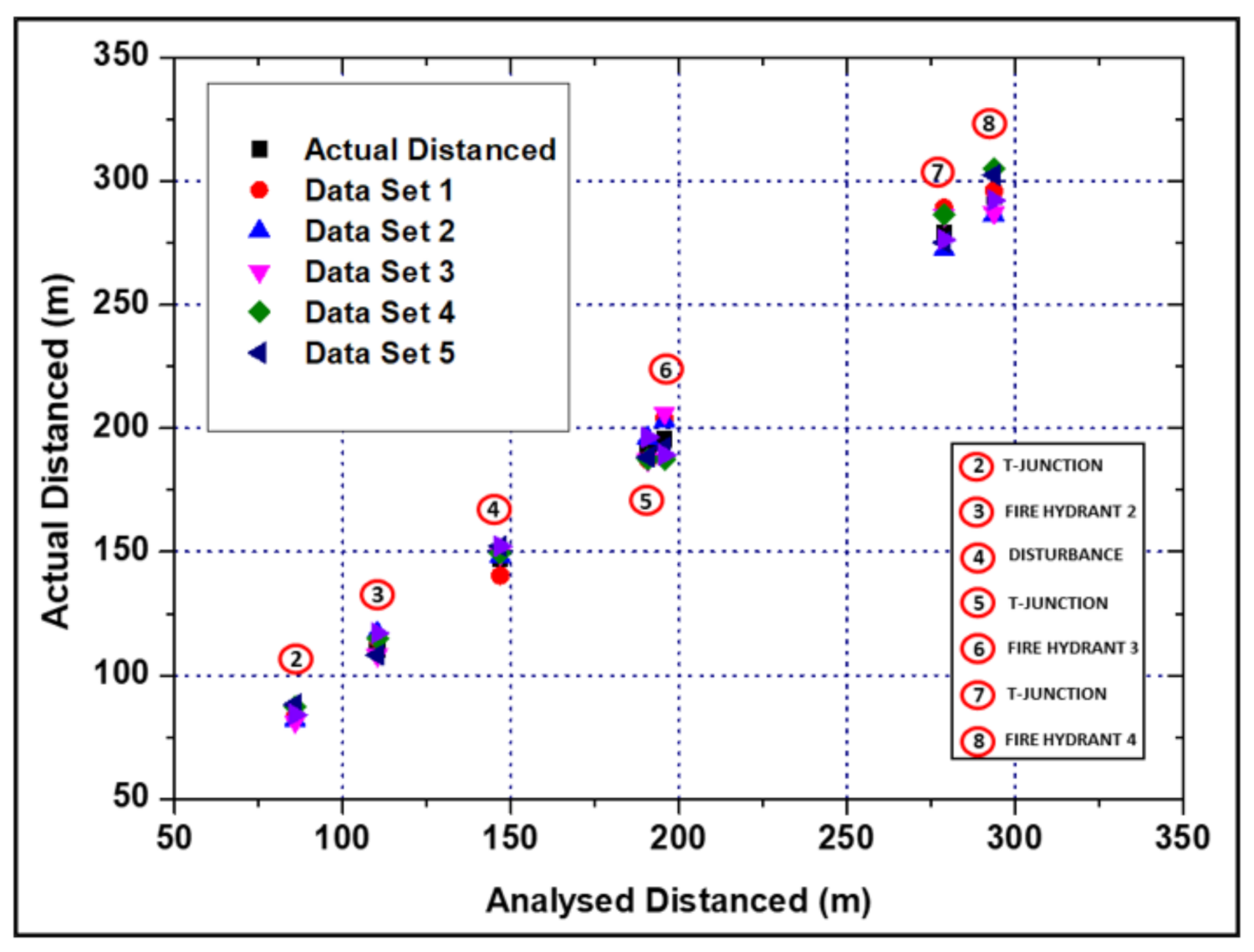

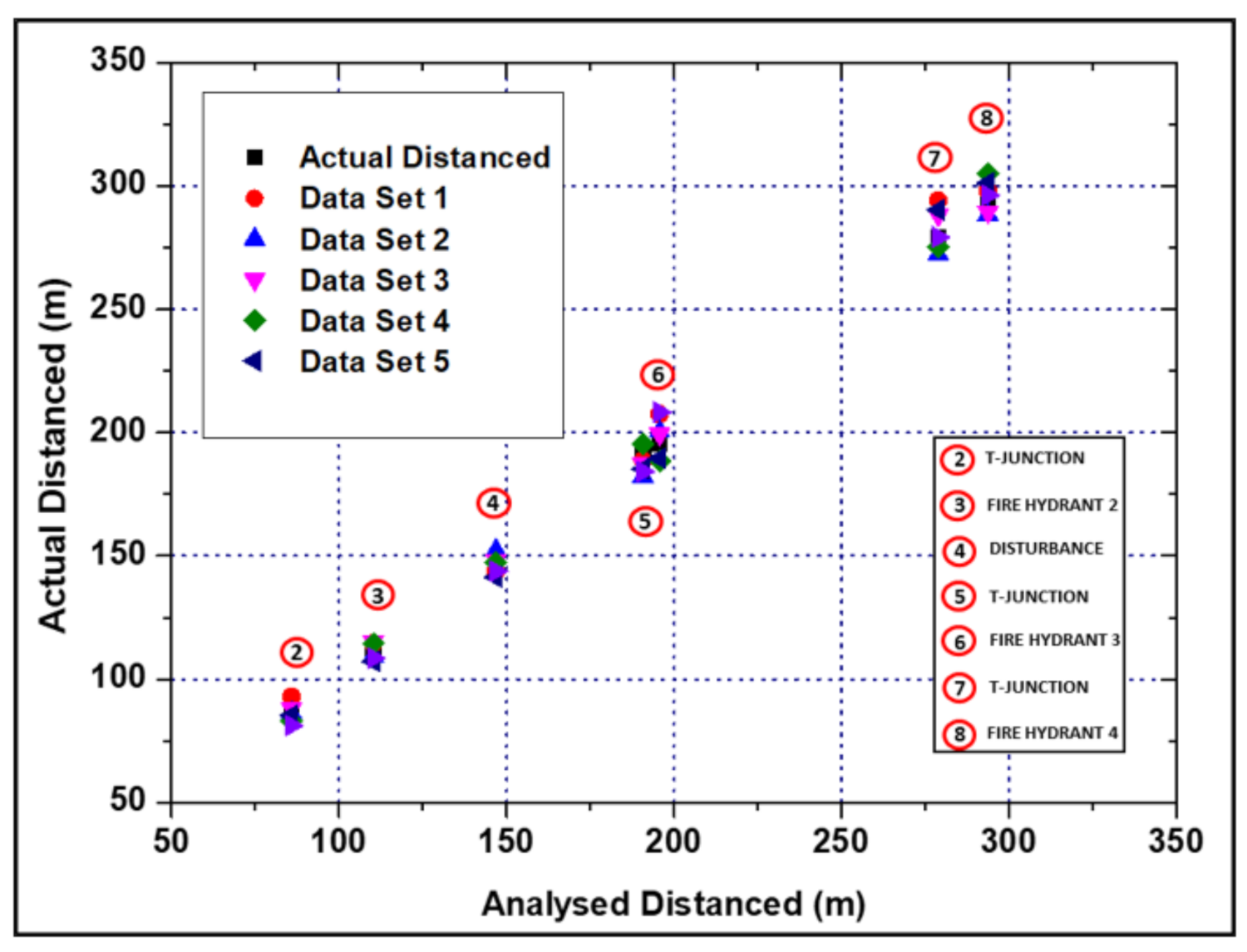

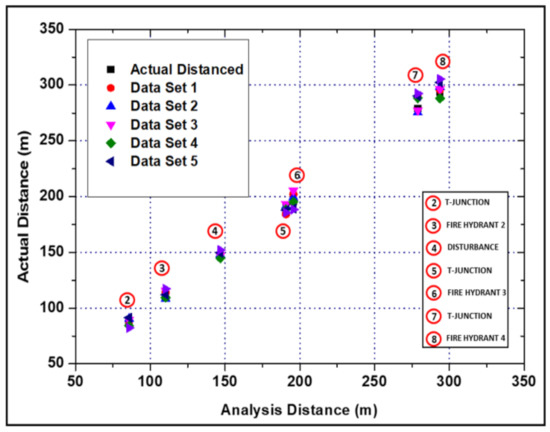

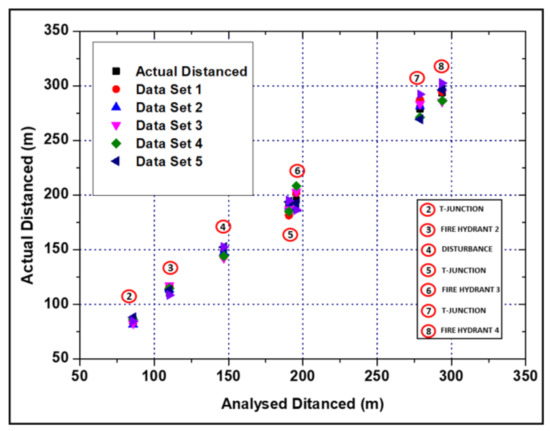

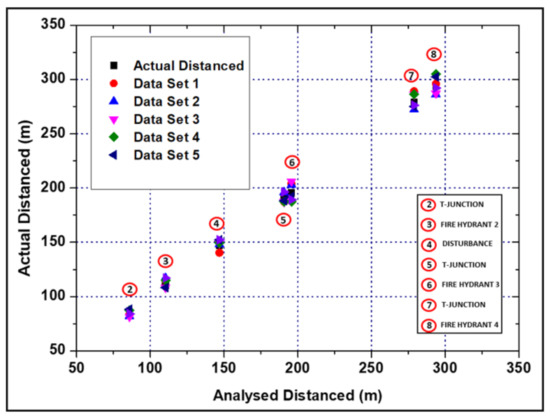

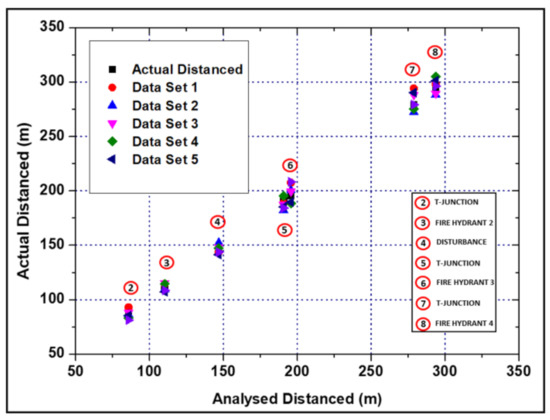

Figure 25, Figure 26, Figure 27 and Figure 28 display the consistency of the scatter plots that represent the precision and accuracy of the prediction between measured and analysed distance. The data were repeated five times and were clustered into seven groups. From the results, it was observed that the data points were tightly and consistently clustered together. All the values and data analysed using scatter plot (Figure 25, Figure 26, Figure 27 and Figure 28) presented the degree of closeness to the correct value (accuracy) and the degree of closeness value on the same quantity (precision) is scattered on the group they belong to. Straightforwardly, the cluster were easily distinguished.

Figure 25.

Scatter plot on repetition for no-leak pipeline system analysis.

Figure 26.

Scatter plot on repetition for 5 mm leak induced on fire hydrant 1 pipeline system analysis.

Figure 27.

Scatter plot on repetition for 5 mm leak induced on fire hydrant 2 pipeline system analysis.

Figure 28.

Scatter plot on repetition for 5 mm leak induced on fire hydrant 1 and 2 pipeline system analysis.

6. Conclusions

This paper explains the automatic selector methods for IMF selection through HHT by analysis of pressure transient signals. The proposed technique was examined through laboratory and field authentication. This method overcame the constrain of the old HHT technique whereas the phase of IMF selection was fully automatised. Therefore, no human interactions were involved for this phase. The results of the analysis for variation of pipeline conditions demonstrate that NIKAZ is proven as possible technique of self-deciding method for IMF selection and could be implemented in the HHT analysis with acceptable precision errors between 2.2–7.5%. NIKAZ has built up and statistically evaluated the development of automated IMF decision making through HHT. This approach is therefore suggested and approved. NIKAZ can be used effectively to develop a live or real-time water supply monitoring system and can be used to handle the IMF selection issue. An effective online leak identification and assessment monitoring system could then be established. The tests also assess the ability of the piezoelectric pressure sensor to sense a rapid change in the pipeline system’s success rate. This paper shows that the performance of NIKAZ for laboratory-scale validation and field measurement (commercial pipeline system) is successfully verified and validated.

Author Contributions

Conceptualization, M.H.Y., M.F.G. and M.F.M.Y.; methodology, M.H.Y., M.F.G. and M.F.M.Y.; software, M.H.Y. and M.F.M.Y.; validation, M.F.G. and M.F.M.Y.; formal analysis, M.H.Y.; investigation, M.H.Y. and M.A.P.R.; resources, M.H.Y. and M.A.P.R.; data curation M.H.Y.; writing—original draft preparation, M.H.Y.; writing—review and editing, M.H.Y.; visualization, M.H.Y. and M.F.M.Y.; supervision, M.F.G. and M.F.M.Y.; project administration, M.F.G. and M.F.M.Y.; funding acquisition, M.F.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Higher Education (MOHE), Malaysia grant FRGS/1/2017/TK03/UMP/02/1(RDU170121), University Malaysia Pahang, internal grant RDU190346 and Postgraduates Grant Research Scheme (PGRS 1903174).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors would like to thank the University Malaysia Pahang for the support, facilities, and sources for this research. Deepest gratitude to the Department of Property Development and Management (JPPH), University Malaysia Pahang and Pahang Water Management (Pengurusan Air Pahang (PAIP)) for the support on completion of field measurement. Acknowledgment is also made to the Ministry of Higher Education (MOHE), Malaysia grant FRGS/1/2017/TK03/UMP/02/1(RDU170121), University Malaysia Pahang for providing internal grant RDU190346 and Postgraduates Grant Research Scheme (PGRS 1903174).

Conflicts of Interest

The authors declare no conflict of interest.

References

- World Economic Forum. Water Crises Are a Top Global Risk; Circle of Blue: Traverse City, MI, USA, 2015. [Google Scholar]

- Lai, C. Unaccounted for water and the economics of leak detection. Water Supply 1991, 9, 4. [Google Scholar]

- Yusop, H.M.; Ghazali, M.; Azmi, W.; Yusof, M.; PiRemli, M.; Rahim, M. A Study of Ikaz and Normalized Hilbert transform for solving faulty in pipeline distribution system using transmission line modelling. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Yusop, H.M.; Ghazali, M.; Yusof, M.; Hamat, W. Improvement of Cepstrum Analysis for the Purpose to Detect Leak, Feature and Its Location in Water Distribution System based on Pressure Transient Analysis. J. Mech. Eng. 2017, 4, 103–122. [Google Scholar]

- Ghazali, M.; Beck, S.; Shucksmith, J.; Boxall, J.; Staszewski, W. Comparative study of instantaneous frequency based methods for leak detection in pipeline networks. Mech. Syst. Signal Process. 2012, 29, 187–200. [Google Scholar] [CrossRef]

- Taghvaei, M.; Beck, S.; Staszewski, W. Leak detection in pipelines using cepstrum analysis. Meas. Sci. Technol. 2006, 17, 367. [Google Scholar] [CrossRef]

- Lee, P.J.; Lambert, M.F.; Simpson, A.R.; Vítkovský, J.P.; Liggett, J. Experimental verification of the frequency response method for pipeline leak detection. J. Hydraul. Res. 2006, 44, 693–707. [Google Scholar] [CrossRef]

- Lee, P.J.; Duan, H.-F.; Ghidaoui, M.; Karney, B. Frequency domain analysis of pipe fluid transient behaviour. J. Hydraul. Res. 2013, 51, 609–622. [Google Scholar] [CrossRef]

- Yusop, H.M.; Ghazali, M.; Azmi, W.; Yusof, M.; Remli, M.P.; Noordin, M. Application of Ikaz and direct quadrature for solving leakage in pipeline distribution by using transmission line modelling. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Yusop, H.M.; Ghazali, M.; Yusof, M.; Remli, M.P.; Kamarulzaman, M. Pipe leak diagnostic using high frequency piezoelectric pressure sensor and automatic selection of intrinsic mode function. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Liou, C.P. Pipeline leak detection by impulse response extraction. J. Fluids Eng. 1998, 120, 833–838. [Google Scholar] [CrossRef]

- Ghazali, M.F. Leak Detection Using Instantaneous Frequency Analysis; University of Sheffield: Sheffield, UK, 2012. [Google Scholar]

- Stephens, M.L.; Simpson, A.R.; Lambert, M.F.; Vítkovský, J.; Nixon, J. The detection of pipeline blockages using transients in the field. In Proceedings of the South Australian Regional Confence, Perth, WA, Australia, 15–16 July 2002. [Google Scholar]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. In Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences; The Royal Society: London, UK, 1998. [Google Scholar]

- Shi, C.-X.; Luo, Q.-F. Hilbert-Huang transform and wavelet analysis of time history signal. Acta Seismol. Sin. 2003, 16, 422–429. [Google Scholar] [CrossRef]

- Bin, G.; Gao, J.; Li, X.; Dhillon, B. Early fault diagnosis of rotating machinery based on wavelet packets—Empirical mode decomposition feature extraction and neural network. Mech. Syst. Signal Process. 2012, 27, 696–711. [Google Scholar] [CrossRef]

- Manjula, M.; Sarma, A. Comparison of empirical mode decomposition and wavelet based classification of power quality events. Energy Procedia 2012, 14, 1156–1162. [Google Scholar] [CrossRef][Green Version]

- Ricci, R.; Pennacchi, P. Diagnostics of gear faults based on EMD and automatic selection of intrinsic mode functions. Mech. Syst. Signal Process. 2011, 25, 821–838. [Google Scholar] [CrossRef]

- Maji, U.; Mitra, M.; Pal, S. Automatic Detection of Atrial Fibrillation Using Empirical Mode Decomposition and Statistical Approach. Procedia Technol. 2013, 10, 45–52. [Google Scholar] [CrossRef]

- Kedadouche, M.; Thomas, M.; Tahan, A. Monitoring machines by using a hybrid method combining MED, EMD, and TKEO. Adv. Acoust. Vib. 2014, 2014, 592080. [Google Scholar] [CrossRef]

- De Souza, D.B.; Chanussot, J.; Favre, A.-C. On selecting relevant intrinsic mode functions in empirical mode decomposition: An energy-based approach. In Proceedings of the 2014 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Florence, Italy, 4–9 May 2014. [Google Scholar]

- Nuawi, M.Z.; Nor, M.J.M.; Jamaludin, N.; Abdullah, S.; Lamin, F.; Nizwan, C. Development of integrated kurtosis-based algorithm for z-filter technique. J. Appl. Sci. 2008, 8, 1541–1547. [Google Scholar] [CrossRef][Green Version]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Haron, C.H.C. A Comparative Study of I-kaz Based Signal Analysis Techniques: Application to Detect Tool Wear during Turning Process. J. Teknol. 2013, 66. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Haron, C.H.C. The application of I-kazTM-based method for tool wear monitoring using cutting force signal. Procedia Eng. 2013, 68, 461–468. [Google Scholar] [CrossRef]

- Rilling, G.; Flandrin, P.; Goncalves, P. On empirical mode decomposition and its algorithms. In Proceedings of the IEEE-EURASIP Workshop on Nonlinear Signal and Image Processing NSIP-03, Grado, Italy, 8–11 June 2003. [Google Scholar]

- Hassan, H.H. Empirical mode decomposition (EMD) of potential field data: Airborne gravity data as an example. In SEG Technical Program Expanded Abstracts 2005; Society of Exploration Geophysicists: Tulsa, OK, USA, 2005; pp. 704–706. [Google Scholar]

- Daubechies, I. Ten Lectures on Wavelets; SIAM: Philadelphia, PA, USA, 1992; Volume 61. [Google Scholar]

- DiScala, M.; Abadi, D.J. Automatic generation of normalized relational schemas from nested key-value data. In Proceedings of the 2016 International Conference on Management of Data, San Francisco, CA, USA, 26 June–1 July 2016. [Google Scholar]

- Craig, A.; Cloarec, O.; Holmes, E.; Nicholson, J.K.; Lindon, J.C. Scaling and normalization effects in NMR spectroscopic metabonomic data sets. Anal. Chem. 2006, 78, 2262–2267. [Google Scholar] [CrossRef] [PubMed]

- Boashash, B. Estimating and interpreting the instantaneous frequency of a signal. I. Fundamentals. Proc. IEEE 1992, 80, 520–538. [Google Scholar]

- Isenmann, G.; Bellahcen, S.; Vazquez, J.; Dufresne, M.; Joannis, C.; Mose, R. Stage—Discharge relationship for a pipe overflow structure in both free and submerged flow. Eng. Appl. Comput. Fluid Mech. 2016, 10, 283–295. [Google Scholar] [CrossRef]

- Nguyen, S.T.N.; Gong, J.; Lambert, M.F.; Zecchin, A.C.; Simpson, A.R. Least squares deconvolution for leak detection with a pseudo random binary sequence excitation. Mech. Syst. Signal Process. 2018, 99, 846–858. [Google Scholar] [CrossRef]

- Ghazali, M.; Staszewski, W.; Shucksmith, J.; Boxall, J.; Beck, S. Instantaneous phase and frequency for the detection of leaks and features in a pipeline system. Struct. Health Monit. 2011, 10, 351–360. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).