A Potential Field Description for Gravity-Driven Film Flow over Piece-Wise Planar Topography

Abstract

:1. Introduction

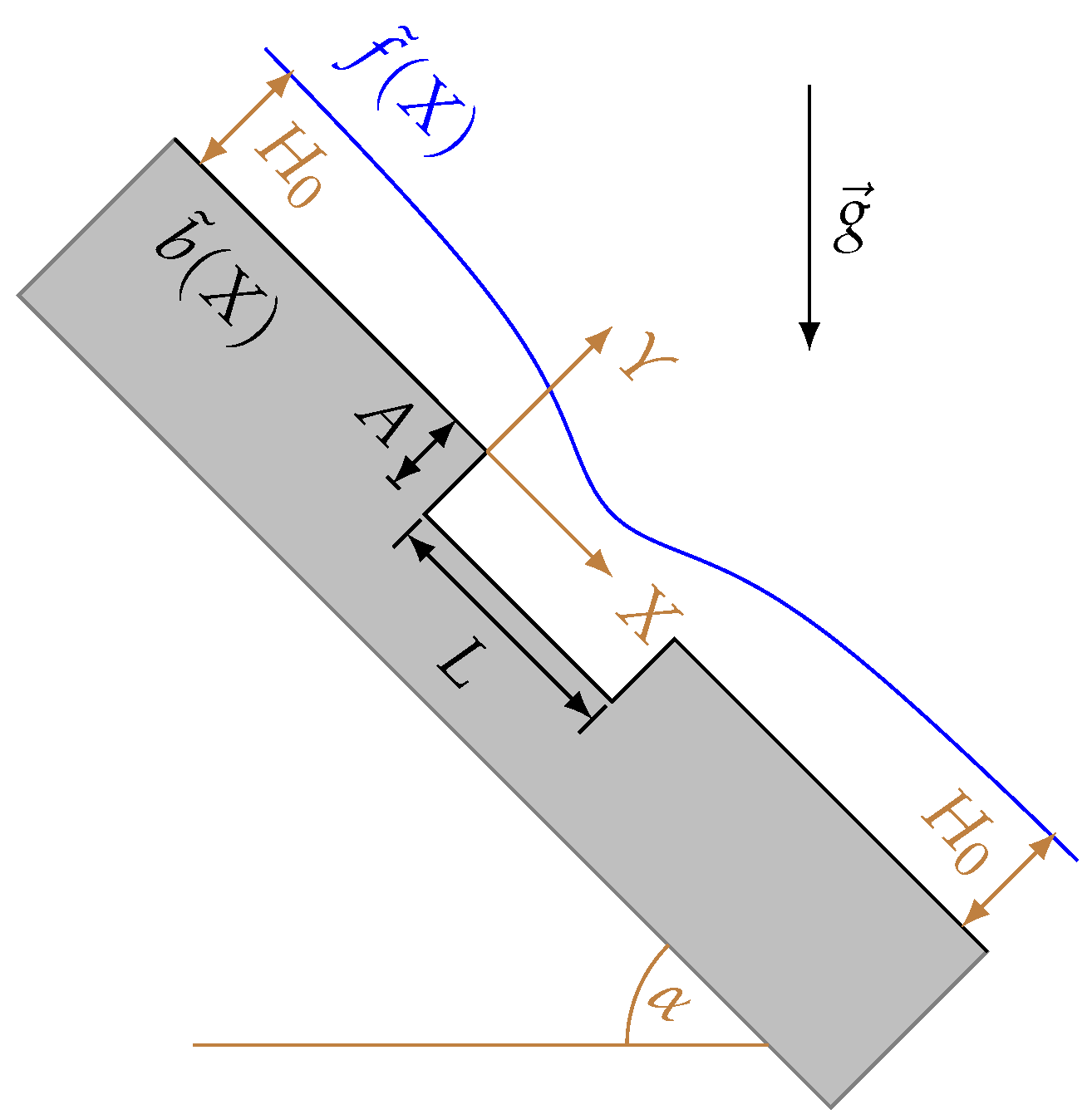

2. Problem Specification and Model Formulations

2.1. Standard Formulation

2.2. First Integral Formulation

2.2.1. Lubrication Model

3. Methods of Solution

3.1. FE Analysis

3.2. Linear Approximation

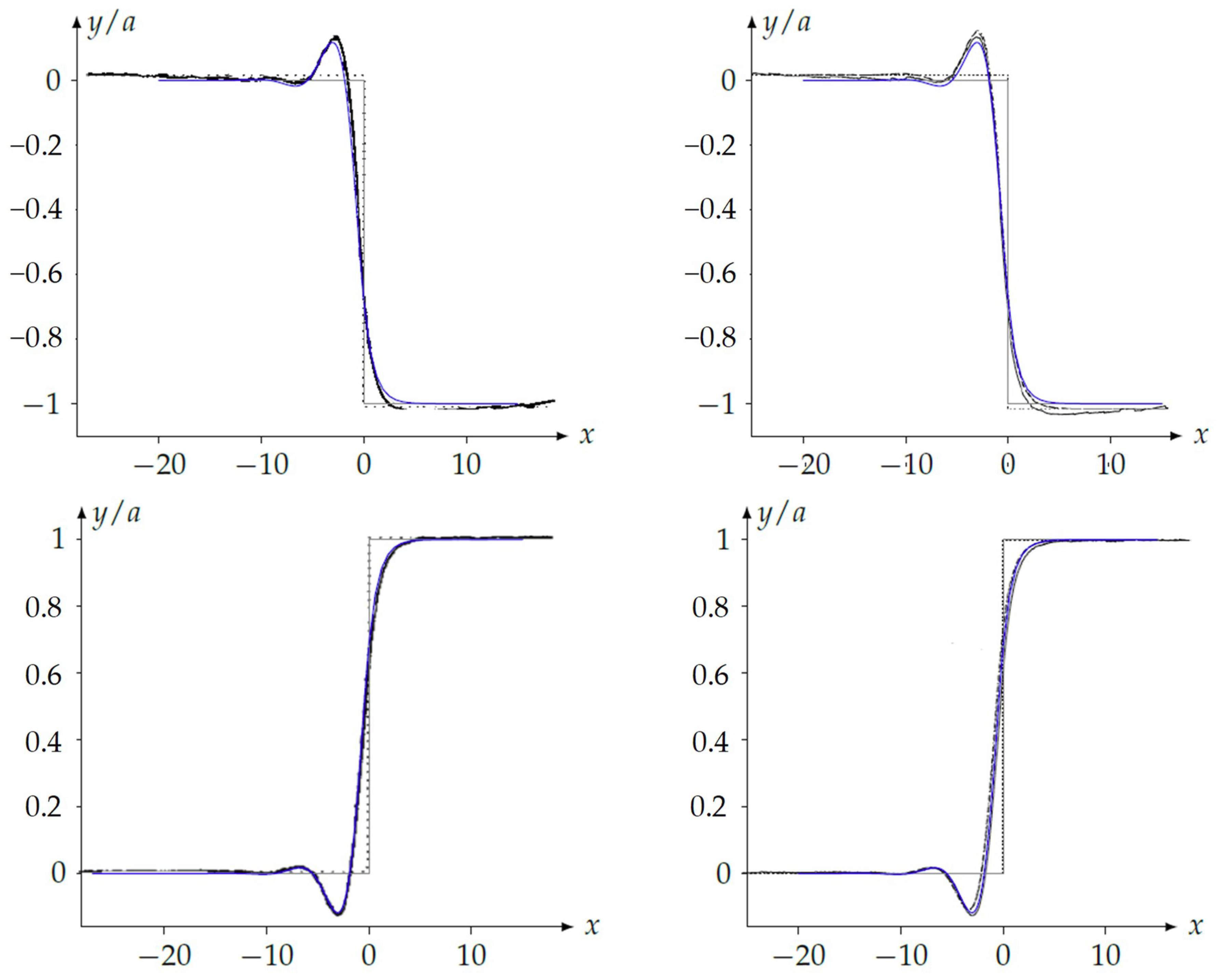

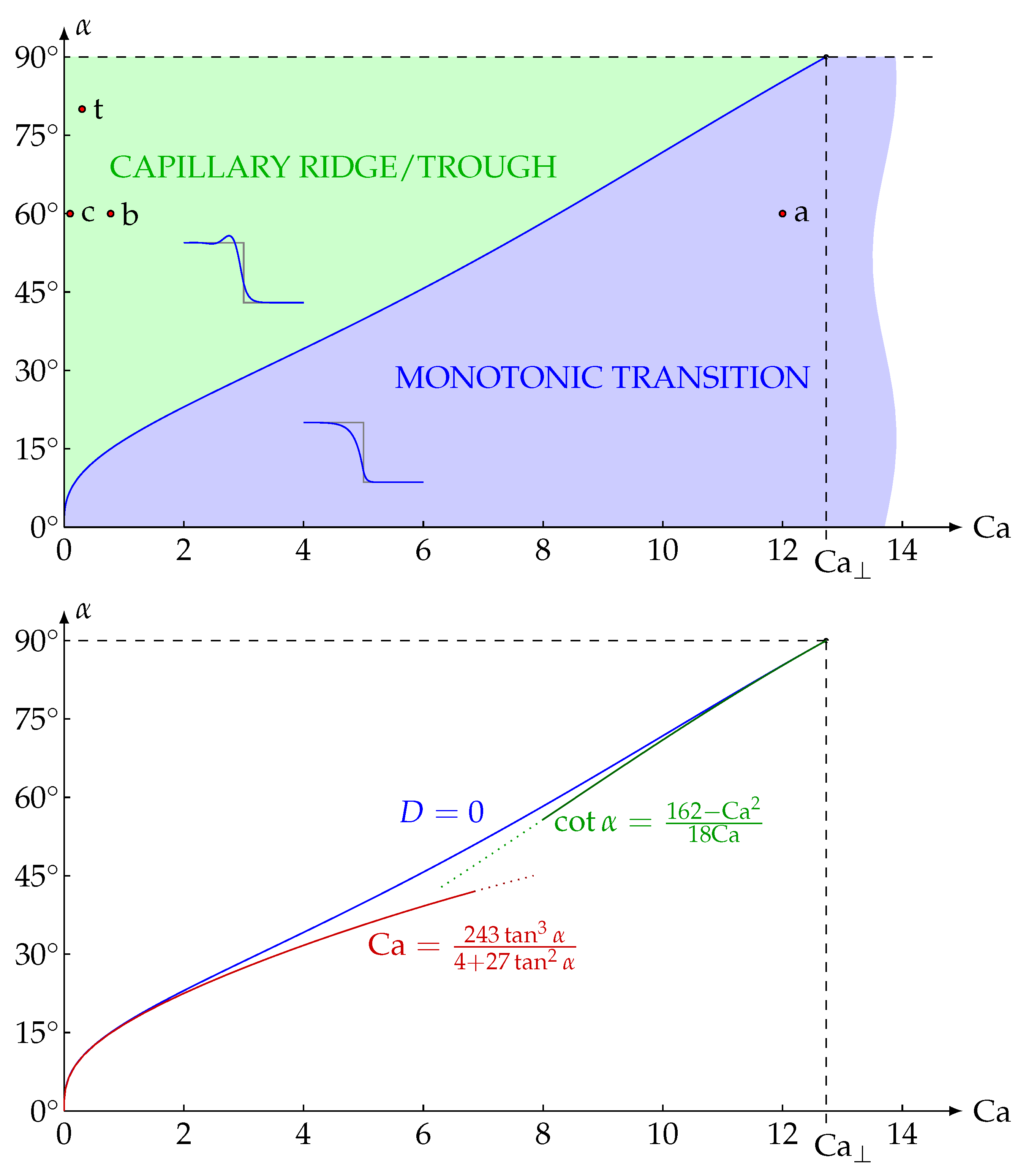

3.2.1. Free Surface Disturbance Types

- Monotonic transition If , three real-valued roots (A19–A21) result with and , giving rise to the general solution:as a superposition of pure exponential functions, indicating an exponential like spatial decay of the free surface disturbance, with decay length and downstream and upstream of the topography, respectively.

- Damped oscillations If , two of the roots, (A19, A20), are complex-valued with positive real part with one the complex conjugate of the other, i.e., with , while the third root, (A21), remains a negative real number, i.e., . Although by analytic continuation the general solution (40) is also valid in this case, it is useful to rearrange it using Euler’s formula , to give:where are given by:Unlike the previous mode, spatial oscillations occur upstream of the topography that are exponentially damped with decay length ; while a monotonic exponential transition downstream of the topography persists.

- Aperiodic limit The limit case indicated by a vanishing discriminant, , requires separate treatment, which is elegantly achieved by applying the limit to (41), giving:implying again a monotonic transition of the free surface disturbance spanning the upstream and downstream regions of the topography.

3.2.2. Film Flow over Isolated Step-Like Topographical Features

3.2.3. Green’s Function and Linear Solution for Arbitrary Topography

4. Results: General Analysis and the Effect of Piece-Wise Planar Topography

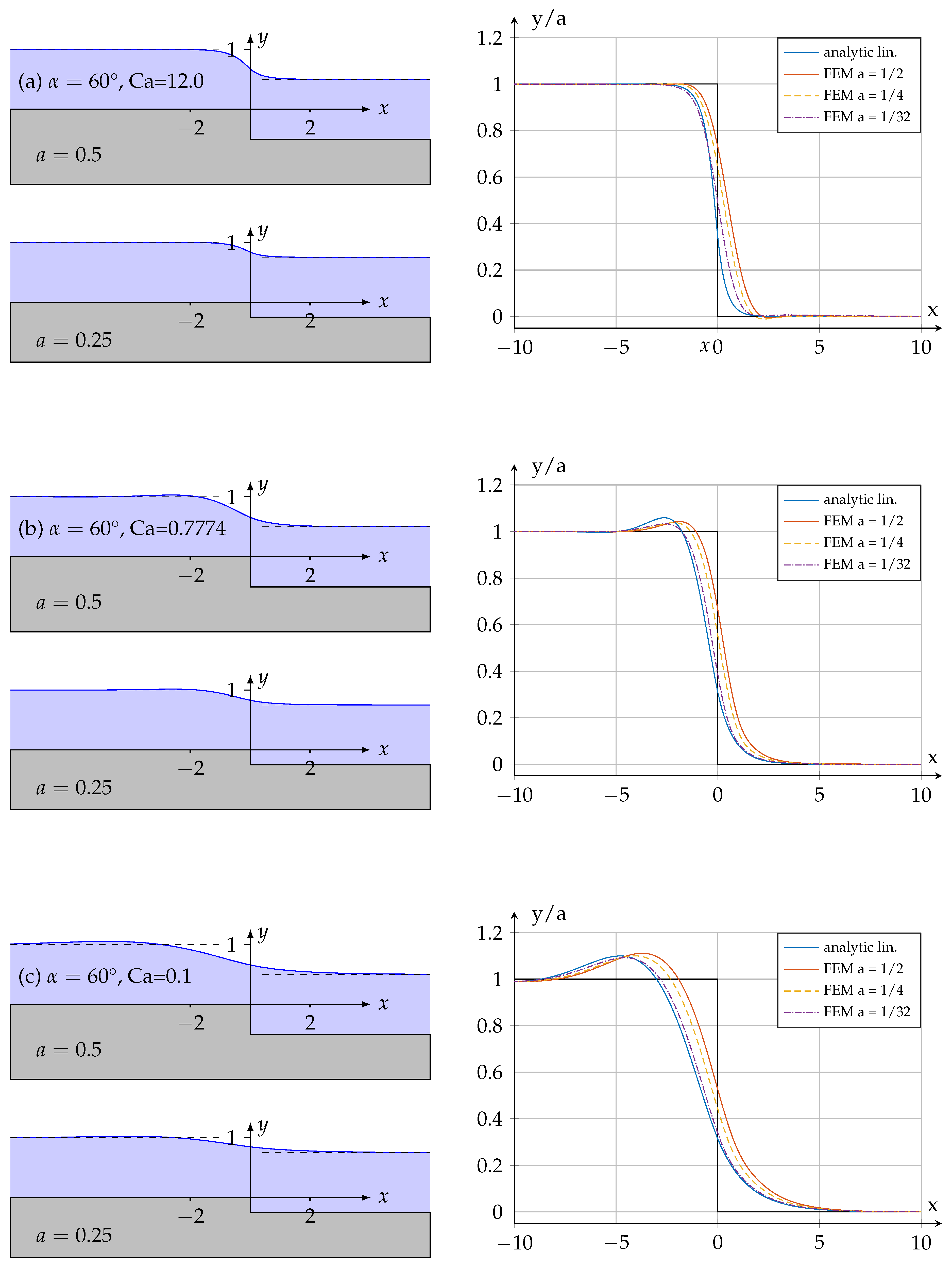

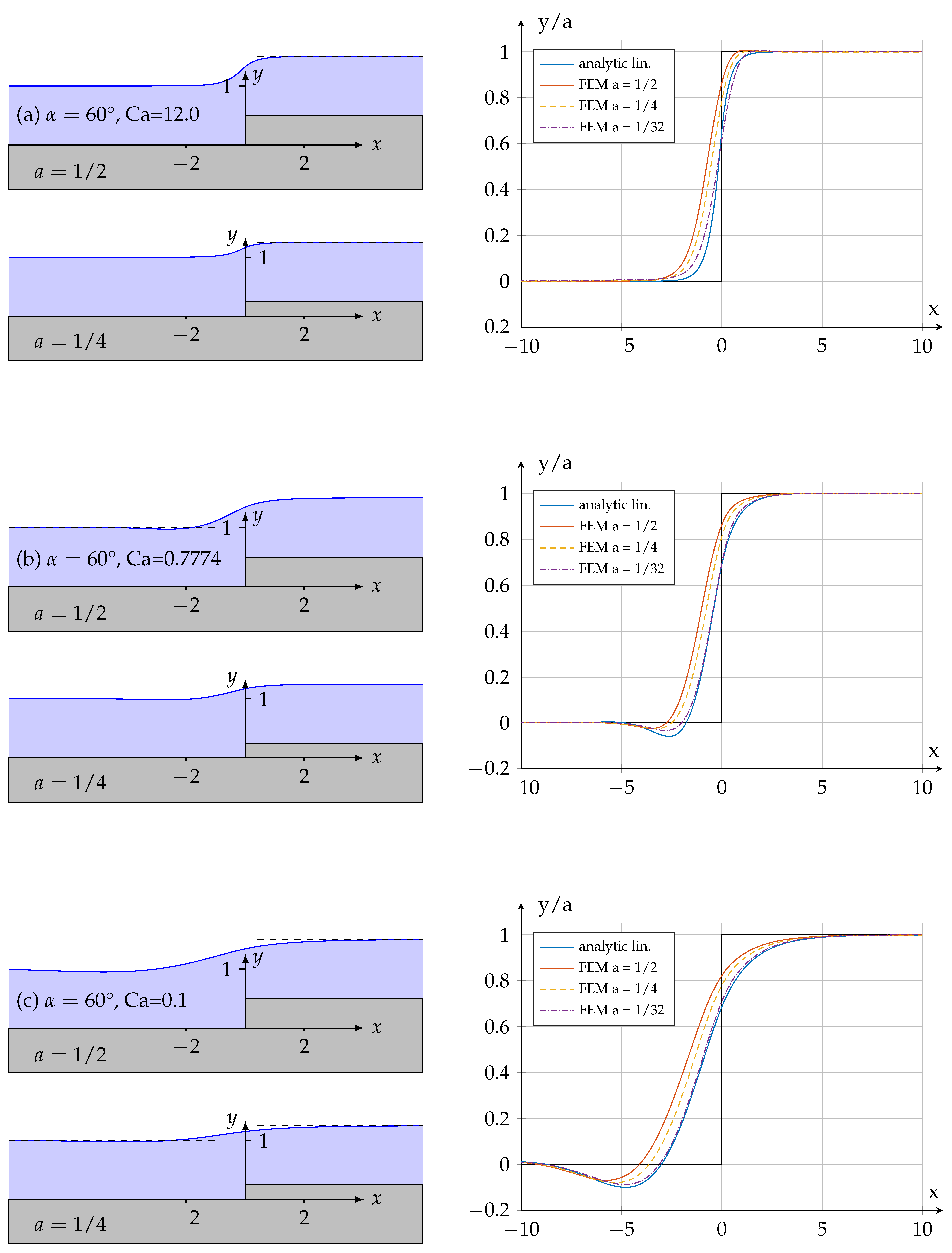

4.1. Step-Up and Step-Down Topography

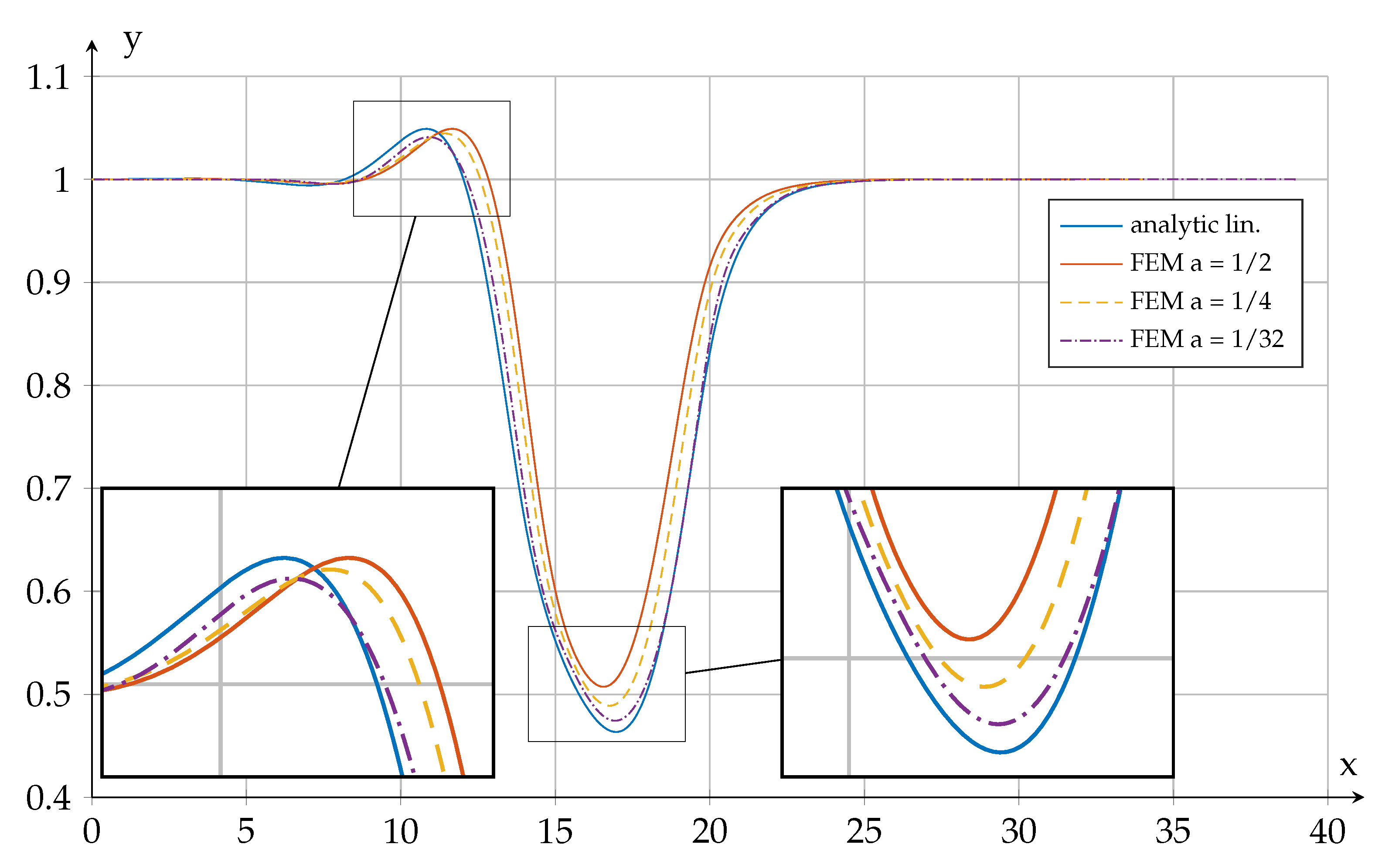

4.2. Trench Topography

4.3. Capillary Criterion and Characteristic Free Surface Parameter Map

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| FE / FEM | finite element / finite element method |

| NS | Navier-Stokes (equation) |

| OLED | organic light emitting diode |

| ODE | ordinary differential equation |

| 2D / 3D | two-dimensional / three-dimensional |

Appendix A Mathematical Derivations

Appendix A.1. Implementation of the Boundary Conditions for the Lubrication Solution (16, 17, 18)

Appendix A.2. Reduction of the Equation Set

Appendix A.3. Benchmark Solution for Film Flow down Planar Substrate

Appendix A.4. Roots of the Characteristic Polynomial (39)

Appendix A.5. Approximation Formulae for the Neutral Curve D = 0

References

- Tabeling, P.; Chen, S. Introduction to Microfluidics; OUP Oxford: Oxford, UK, 2005. [Google Scholar]

- Kang, B.; Lee, W.H.; Cho, K. Recent Advances in Organic Transistor Printing Processes. ACS Appl. Mater. Interfaces 2013, 5, 2302–2315. [Google Scholar] [CrossRef] [PubMed]

- Müller, C.D.; Falcou, A.; Reckefuss, N.; Rojahn, M.; Wiederhirn, V.; Rudati, P.; Frohne, H.; Nuyken, O.; Becker, H.; Meerholz, K. Multi-colour organic light-emitting displays by solution processing. Nature 2003, 421, 829–833. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.; Dell’Erba, G.; Luzio, A.; Bucella, S.G.; Perinot, A.; Calloni, A.; Berti, G.; Bussetti, G.; Duò, L.; Facchetti, A.; et al. Fully-printed, all-polymer, bendable and highly transparent complementary logic circuits. Org. Electron. 2015, 20, 132–141. [Google Scholar] [CrossRef]

- Kistler, S.F.; Schweizer, P.M. Liquid Film Coating; Monographs and Studies in Mathematics; Chapman and Hall: New York, NY, USA, 1997. [Google Scholar]

- Gaskell, P.H.; Jimack, P.K.; Sellier, M.; Thompson, H.M. Flow of evaporating, gravity-driven thin liquid films over topography. Phys. Fluids 2006, 18, 013601. [Google Scholar] [CrossRef]

- Stillwagon, L.E.; Larson, R.G. Fundamentals of topographic substrate leveling. J. Appl. Phys. 1988, 63, 5251–5258. [Google Scholar] [CrossRef]

- Stillwagon, L.E.; Larson, R.G. Leveling of thin films over uneven substrates during spin coating. Phys. Fluids A Fluid Dyn. 1990, 2, 1937–1944. [Google Scholar] [CrossRef]

- Peurrung, L.M.; Graves, D.B. Spin coating over topography. IEEE Trans. Semicond. Manuf. 1993, 6, 72–76. [Google Scholar] [CrossRef]

- Decré, M.M.; Baret, J.C. Gravity-driven flows of viscous liquids over two-dimensional topographies. J. Fluid Mech. 2003, 487, 147–166. [Google Scholar] [CrossRef]

- Wierschem, A.; Pollak, T.; Heining, C.; Aksel, N. Suppression of eddies in films over topography. Phys. Fluids 2010, 22, 113603. [Google Scholar] [CrossRef]

- Schörner, M.; Reck, D.; Aksel, N. Does the topography’s specific shape matter in general for the stability of film flows? Phys. Fluids 2015, 27, 042103. [Google Scholar] [CrossRef]

- Oron, A.; Davis, S.H.; Bankoff, S.G. Long-scale evolution of thin liquid films. Rev. Mod. Phys. 1997, 69, 931–980. [Google Scholar] [CrossRef]

- Gaskell, P.H.; Lee, Y.C.; Thompson, H.M. Thin film flow over and around surface topography: A general solver for the long-wave approximation and related equations. Comput. Model. Eng. Sci. 2010, 62, 77–112. [Google Scholar] [CrossRef]

- Kalliadasis, S.; Bielarz, C.; Homsy, G.M. Steady free-surface thin film flows over topography. Phys. Fluids 2000, 12, 1889–1898. [Google Scholar] [CrossRef]

- Mazouchi, A.; Homsy, G.M. Free surface Stokes flow over topography. Phys. Fluids 2001, 13, 2751–2761. [Google Scholar] [CrossRef]

- Gaskell, P.H.; Jimack, P.K.; Sellier, M.; Thompson, H.M.; Wilson, M.C.T. Gravity-driven flow of continuous thin liquid films on non-porous substrates with topography. J. Fluid Mech. 2004, 509, 253–280. [Google Scholar] [CrossRef]

- Veremieiev, S.; Thompson, H.M.; Lee, Y.C.; Gaskell, P.H. Inertial thin film flow on planar surfaces featuring topography. Comput. Fluids 2010, 39, 431–450. [Google Scholar] [CrossRef]

- Hayes, M.; O’Brien, S.B.G.; Lammers, J.H. Green’s function for steady flow over a small two-dimensional topography. Phys. Fluids 2000, 12, 2845–2858. [Google Scholar] [CrossRef]

- Scholle, M.; Haas, A.; Aksel, N.; Wilson, M.C.T.; Thompson, H.M.; Gaskell, P.H. Competing geometric and inertial effects on local flow structure in thick gravity-driven fluid films. Phys. Fluids 2008, 20, 123101. [Google Scholar] [CrossRef]

- Blyth, M.G.; Pozrikidis, C. Film flow down an inclined plane over a three-dimensional obstacle. Phys. Fluids 2006, 18, 052104. [Google Scholar] [CrossRef]

- Baxter, S.J.; Power, H.; Cliffe, K.A.; Hibberd, S. Three-dimensional thin film flow over and around an obstacle on an inclined plane. Phys. Fluids 2009, 21, 032102. [Google Scholar] [CrossRef]

- Veremieiev, S.; Thompson, H.M.; Gaskell, P.H. Free-surface film flow over topography: Full three-dimensional finite element solutions. Comput. Fluids 2015, 122, 66–82. [Google Scholar] [CrossRef]

- Heining, C.; Pollak, T.; Aksel, N. Pattern formation and mixing in three-dimensional film flow. Phys. Fluids 2012, 24, 042102. [Google Scholar] [CrossRef]

- Ataki, A.; Bart, H.J. The Use of the VOF-Model to Study the Wetting of Solid Surfaces. Chem. Eng. Technol. 2004, 27, 1109–1114. [Google Scholar] [CrossRef]

- Singh, R.K.; Galvin, J.E.; Sun, X. Three-dimensional simulation of rivulet and film flows over an inclined plate: Effects of solvent properties and contact angle. Chem. Eng. Sci. 2016, 142, 244–257. [Google Scholar] [CrossRef]

- Singh, R.K.; Galvin, J.E.; Whyatt, G.A.; Sun, X. Breakup of a liquid rivulet falling over an inclined plate: Identification of a critical Weber number. Phys. Fluids 2017, 29, 052101. [Google Scholar] [CrossRef]

- Trifonov, Y.Y. Stability of a viscous liquid film flowing down a periodic surface. Int. J. Multiph. Flow 2007, 33, 1186–1204. [Google Scholar] [CrossRef]

- Pollak, T.; Aksel, N. Crucial flow stabilization and multiple instability branches of gravity-driven films over topography. Phys. Fluids 2013, 25, 024103. [Google Scholar] [CrossRef]

- D’Alessio, S.J.D.; Pascal, J.P.; Jasmine, H.A. Instability in gravity-driven flow over uneven surfaces. Phys. Fluids 2009, 21, 062105. [Google Scholar] [CrossRef]

- Argyriadi, K.; Vlachogiannis, M.; Bontozoglou, V. Experimental study of inclined film flow along periodic corrugations: The effect of wall steepness. Phys. Fluids 2006, 18, 012102. [Google Scholar] [CrossRef]

- Nguyen, P.K.; Bontozoglou, V. Steady solutions of inertial film flow along strongly undulated substrates. Phys. Fluids 2011, 23, 052103. [Google Scholar] [CrossRef]

- Schörner, M.; Reck, D.; Aksel, N.; Trifonov, Y. Switching between different types of stability isles in films over topographies. Acta Mech. 2018, 229, 423–436. [Google Scholar] [CrossRef]

- Dauth, M.; Aksel, N. Breaking of waves on thin films over topographies. Phys. Fluids 2018, 30, 082113. [Google Scholar] [CrossRef]

- Veremieiev, S.; Wacks, D.H. Modelling gravity-driven film flow on inclined corrugated substrate using a high fidelity weighted residual integral boundary-layer method. Phys. Fluids 2019, 31, 022101. [Google Scholar] [CrossRef]

- Sellier, M. Substrate design or reconstruction from free surface data for thin film flows. Phys. Fluids 2008, 20, 062106. [Google Scholar] [CrossRef]

- Heining, C.; Pollak, T.; Sellier, M. Flow domain identification from free surface velocity in thin inertial films. J. Fluid Mech. 2013, 720, 338–356. [Google Scholar] [CrossRef]

- Sellier, M. Inverse problems in free surface flows: A review. Acta Mech. 2016, 227, 913–935. [Google Scholar] [CrossRef]

- Saprykin, S.; Koopmans, R.J.; Kalliadasis, S. Free-surface thin-film flows over topography: Influence of inertia and viscoelasticity. J. Fluid Mech. 2007, 578, 271–293. [Google Scholar] [CrossRef]

- Veremieiev, S.; Thompson, H.M.; Scholle, M.; Lee, Y.C.; Gaskell, P.H. Electrified thin film flow at finite Reynolds number on planar substrates featuring topography. Int. J. Multiph. Flow 2012, 44, 48–69. [Google Scholar] [CrossRef]

- Papageorgiou, D.T. Film Flows in the Presence of Electric Fields. Ann. Rev. Fluid Mech. 2019, 51, 155–187. [Google Scholar] [CrossRef]

- Ranger, K.B. Parametrization of general solutions for the Navier-Stokes equations. Q. J. Appl. Math. 1994, 52, 335–341. [Google Scholar] [CrossRef]

- Coleman, C.J. On the use of complex variables in the analysis of flows of an elastic fluid. J. Non-Newtonian Fluid Mech. 1984, 15, 227–238. [Google Scholar] [CrossRef]

- Scholle, M.; Haas, A.; Gaskell, P.H. A first integral of Navier-Stokes equations and its applications. Proc. R. Soc. 2011, A467, 127–143. [Google Scholar] [CrossRef]

- Marner, F.; Gaskell, P.H.; Scholle, M. On a potential-velocity formulation of Navier-Stokes equations. Phys. Mesomech. 2014, 17, 341–348. [Google Scholar] [CrossRef]

- Marner, F. Potential-Based Formulations of the Navier-Stokes Equations and Their Application. Ph.D. Thesis, Durham University, Durham, UK, 2019. [Google Scholar]

- Bochev, P.B.; Gunzburger, M.D. Least-Squares Finite Element Methods; Applied Mathematical Sciences, Volume 166; Springer: New York, NY, USA, 2009. [Google Scholar]

- Veremieiev, S. Gravity-Driven Continuous Thin Film Flow over Topography. Ph.D. Thesis, University of Leeds, Leeds, UK, 2011. [Google Scholar]

- Scholle, M.; Gaskell, P.H.; Marner, F. Exact integration of the unsteady incompressible Navier-Stokes equations, gauge criteria, and applications. J. Math. Phys. 2018, 59, 043101. [Google Scholar] [CrossRef]

- Takagi, D.; Huppert, H.E. Flow and instability of thin films on a sphere. J. Fluid Mech. 2009, 647, 221–238. [Google Scholar] [CrossRef]

- Selby, S.M. CRC Standard Mathematical Tables, 23rd ed.; CRC Press: Boca Raton, FL, USA, 1975. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scholle, M.; Gaskell, P.H.; Marner, F. A Potential Field Description for Gravity-Driven Film Flow over Piece-Wise Planar Topography. Fluids 2019, 4, 82. https://doi.org/10.3390/fluids4020082

Scholle M, Gaskell PH, Marner F. A Potential Field Description for Gravity-Driven Film Flow over Piece-Wise Planar Topography. Fluids. 2019; 4(2):82. https://doi.org/10.3390/fluids4020082

Chicago/Turabian StyleScholle, Markus, Philip H. Gaskell, and Florian Marner. 2019. "A Potential Field Description for Gravity-Driven Film Flow over Piece-Wise Planar Topography" Fluids 4, no. 2: 82. https://doi.org/10.3390/fluids4020082

APA StyleScholle, M., Gaskell, P. H., & Marner, F. (2019). A Potential Field Description for Gravity-Driven Film Flow over Piece-Wise Planar Topography. Fluids, 4(2), 82. https://doi.org/10.3390/fluids4020082