1. Introduction

Jets in cross-flow, which are also known as transverse jets, are common in engineering applications, and the environment. Examples include: gas turbine film-cooling, dilution jets in gas turbine combustors, ash plumes from volcanic eruptions, etc. A comprehensive review of jets in cross-flow can be found in Mahesh [

1]. Most of the previous studies focused on the parameters of the jets and cross-flow that affect the flow field. The generation of complex coherent vortical structures was studied in [

2,

3,

4]. However, there is no general consensus about the genesis and evolution of these motions and their effects on passive scalars. The configuration of these vortical motions changes with the characteristic flow parameters like the blowing ratio (the ratio between the mass flow rates/velocities of the cross-flow and the jet) [

1].

Blowing and suction have been tested for controlling turbulence, as well. Park and Choi [

5] used direct numerical simulations (DNS) on a spatially-developing turbulent boundary layer to study the effect of small blowing and suction perturbations on wall skin friction. They imposed steady blowing and suction through a spanwise slot. Their results show that the skin friction coefficient significantly decreases near downstream and slightly increases far downstream of the slot. The number of coherent vortical structures is also increased downstream. Further, the increase of drag downstream of the slot was attributed to the stretching and tilting of vortices due to blowing. Kim and Sung [

6] applied periodic and steady blowing through a spanwise slot to study their effects on the spatially-developing boundary layer. Their results showed that local steady blowing increased the number of vortical structures downstream. Araya et al. [

7] studied the effects of steady and unsteady blowing on a turbulent channel flow. They found that forcing frequency,

(

, where

-kinematic viscosity and

-friction velocity), is responsible for the local increase in skin friction coefficient. Their findings also include the generation of more vortex structures downstream of blowing. The effects of localized steady blowing on the thermal transport were studied by using DNS in a turbulent channel flow by [

8,

9]. They imposed the blowing through a spanwise slot. The results of their numerical experiment demonstrate that the critical streamwise length of the blowing slot is 30 wall units. At the critical streamwise length of the slot, they detected a strong enhancement of heat flux. Although the previous studies have found interesting phenomena and mechanisms related to both velocity and thermal fields with blowing perturbations, most studies imposed blowing through spanwise slots. However, the blowing through spanwise slots is rarely encountered in practice. In studies pertaining to gas turbine film-cooling, blowing is imposed through round jets [

10]. However, those studies did not focus on local variations of velocity and temperature [

11]. Although it is known that jets in cross-flow generate coherent vortical structures and reduce the wall temperature downstream, the influence of vortices on heat fluxes and thereby on wall temperature has not been investigated.

Therefore, we seek to demonstrate the importance of coherent vortical structures in cooling or heating of the wall in a thermal turbulent channel flow. The study uses a turbulent channel flow with small steady blowing perturbations at the bottom wall. Both walls are kept at constant temperatures, and perturbations are set through five holes located at 25% of the channel length from the upstream end of the channel and distributed in the spanwise direction. The results show that the generation of coherent vortical structures increases the wall-normal heat flux compared to the streamwise heat flux. The article is organized as follows.

Section 2 describes the numerical procedure. The results are laid out in

Section 3, and the conclusions are given in

Section 4.

2. Numerical Procedure

In this section, a brief description of the numerical procedure of the current simulations is given. Continuity, momentum and passive scalar transport equations are shown in their non-dimensionalized form by Equations (

1)–(

3), respectively. The non-dimensional form of the equations was obtained by using velocity scale

and length sale

h, where

is the unitary mean laminar centerline velocity and

h is the channel half height. If the dimensional form of the variables is denoted by the superscript

,

,

,

, and

represent non-dimensional forms of instantaneous velocity, spatial coordinates, instantaneous pressure and the time coordinate. The non-dimensional temperature is given by

, where

is the constant temperature at the bottom wall and

is the temperature at the top wall. Here,

,

p and

represent the density of the fluid, instantaneous velocity components, instantaneous pressure and instantaneous temperature, respectively. In Equation (

2),

is the instantaneously-changing pressure gradient to maintain a constant flow rate in the channel. The governing equations were discretized in a staggered grid using a second order central differencing scheme. The Reynolds number of the flow is given by

, and

(=

) is the molecular Prandtl number of the fluid, where

and

stand for the thermal diffusivity and the kinematic viscosity of the fluid. The fractional step method was used in which viscous terms and advective terms are respectively treated implicitly and explicitly. An approximate factorization method was used to invert the large sparse matrix resulting from explicit treatment of viscous terms. Details of the numerical procedure can be found in [

12]. The equations are solved for the baseline case (unperturbed) and the perturbed case.

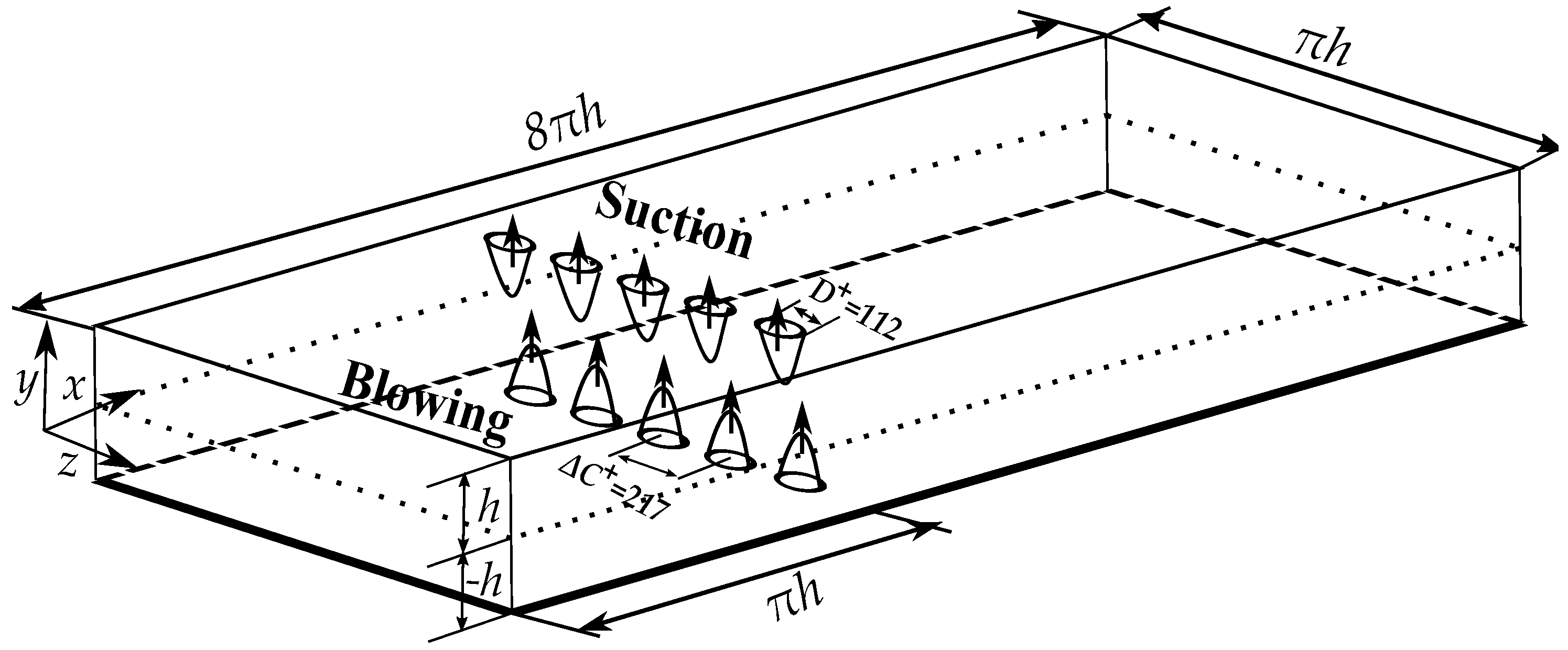

Figure 1 shows the physical domain of the flow, together with the profiles of perturbation velocity. The dimensions of the computational box are:

=

,

=

and

=

. A grid-independence test was performed as detailed in [

7]. The number of grid points in the streamwise, spanwise and wall-normal directions is 1153, 193, and 193 respectively. The mesh resolution in the unperturbed case is:

,

,

and

. Note that we use the friction velocity

of the unperturbed case in the scaling of the velocity field and both thermal and velocity fields were normalized using wall variables. The validation of the first and second order statistics for the unperturbed case is shown in Araya et al. [

7] and Dharmarathne et al. [

13].

Periodic conditions are prescribed along the streamwise and spanwise directions. The no-slip boundary condition is imposed at both walls, except at locations where the jets are placed. The temperature boundary condition at the bottom wall is 1, and that at the top wall is . The fluid that comes through jets at the bottom wall has a non-dimensional temperature of , and at the top wall, the jet temperature is . The Courant–Friedrichs–Lewy (CFL) parameter remains constant during simulations and the time step – for all cases.

A mean parabolic velocity profile with random fluctuations was used as an initial condition in the entire domain. The molecular Prandtl number,

, is

, and the friction Reynolds number (

=

, where

is the friction velocity of the unperturbed channel) is 394. Here,

is the shear stress at the wall. The local forcing,

, which creates the vertical perturbation, is modeled as follows:

where

R is the radius of a blowing/suction jet and

is the center of a perturbing jet. Therefore, the range of jets is within

,

. The circular jets are approximated to the Cartesian grid with a percentage error ≈

. The parameter

A represents the ratio of the jet centerline velocity to channel centerline velocity (blowing ratio), and

in this study. This value of

A complies with the widely-used blowing ratios in gas turbine film cooling [

14]. Five equally-spaced jets were imposed at both walls in the spanwise direction; they are located at

downstream from

as shown in

Figure 1. The spanwise separation between the centers of two adjacent jets,

, is approximately 217 in wall units, which accommodates the average separation of near-wall streaks in terms of spanwise wavelength,

[

15], in between two adjacent jets. The diameter of the jets in wall units,

, is 112. The value of

is approximately equal to the thickness of near-wall high and low speed streaks. In order to ensure the conservation of the mass flow rate inside the computational box, spatially-sinusoidal blowing at the bottom wall was synchronized with sinusoidal suction at the top wall, as shown in

Figure 1.

3. Results

First, the effect of blowing on the mean velocity and temperature fields will be demonstrated. The next subsection describes the changes of the velocity and temperature fluctuations due to blowing perturbations. Then, we show the existence of hot and cold spots in the near-wall region by using two-dimensional contours on the plane. We then direct our focus to the heat fluxes, and , in the following section. Subsequently, we show the generation of coherent vortical structures downstream of the jets.

3.1. Mean Velocity and Temperature Field

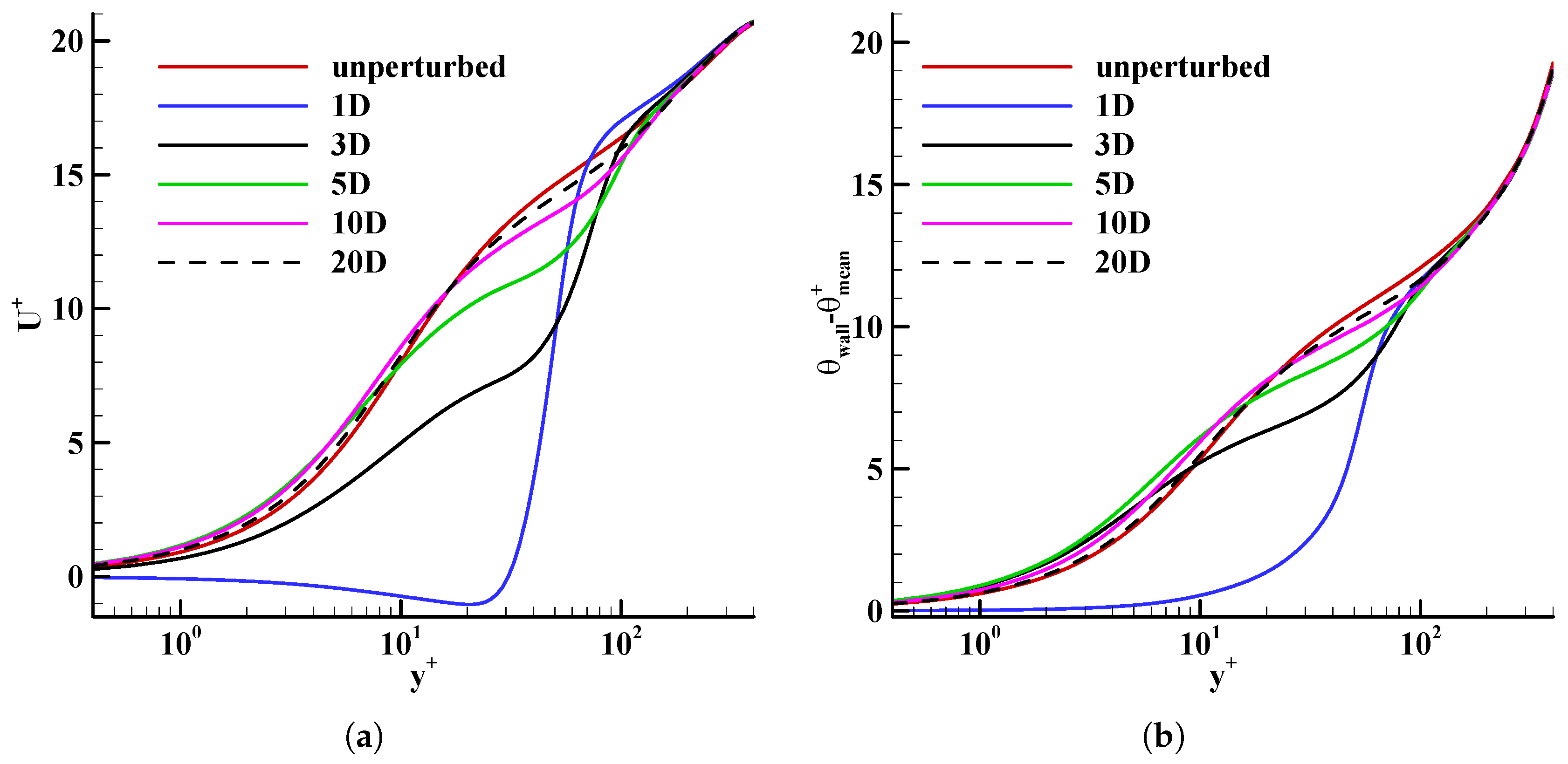

Figure 2 shows the variation of mean streamwise velocity (

Figure 2a) and mean temperature (

Figure 2b) along the centerline of the blowing jets (behind the jets, hereafter) at different downstream locations. The mean streamwise velocity at

downstream of blowing becomes negative in the near-wall region, as seen in

Figure 2a. The negative streamwise mean velocity implies a reversed flow region just behind the blowing jets. The presence of jets obstructs the incoming boundary layer, which in turn creates a reversed flow region behind the jets. This region may significantly change the exchange processes between the wall and the boundary layer. The reversed flow region exists until

. The velocity quickly recovers from

to

. This sudden change of velocity causes steep gradients of velocity. Steep velocity gradients generate more turbulence and increase turbulent momentum and heat transport in that region. The influence of blowing in the near-wall region is considerable even at

downstream of the jets. Although the deceleration of the flow in the near-wall region at

downstream is not as notable as at

downstream, it is noticeable at the outer-layer even at

downstream. Interestingly, we can observe a slight flow acceleration in the near-wall region at

and

downstream. This can be ascribed to the entrainment of accelerated flow in between two jets. The acceleration is a clear manifestation of the three-dimensionality of the perturbations, which may not be seen in slot blowing cases studied previously. The velocity deficit created by the presence of blowing jets gradually moves to the outer-layer of the channel, as suggested by the outward movement of the mean velocity deficit.

We can observe simultaneous changes of the mean temperature profiles as

Figure 2b shows. Due to the reversed flow region in the near-wall region at

downstream of blowing, velocity fluctuations might have been reduced. The reduction of velocity fluctuations reduces turbulent heat transport in the near-wall region; therefore, the temperature of the flow close to the wall is nearly similar to that of the wall. At the end of the recirculation region (around

), the mean temperature starts rising rapidly, creating steep temperature gradients. Steep temperature gradients generate temperature fluctuations.

It is peculiar to see that the temperature in the near-wall region at downstream is lower than that of unperturbed flow. Because the mean velocity at downstream is lower than that of the unperturbed flow, one would expect the temperature to be higher than the unperturbed flow. This inconsistency in the near-wall region at downstream becomes more striking since the temperature profile becomes consistent with the velocity profile above the buffer region. Further, the mean temperature profiles at and downstream of the jets are also in compliance with the velocity profiles. The unpredictable behavior of the mean temperature profile (extra cooling effect) at downstream may be attributed to the fluctuations of velocity and temperature fields.

3.2. Fluctuations of Velocity and Temperature

In this section, we discuss the variations of velocity and temperature fluctuations.

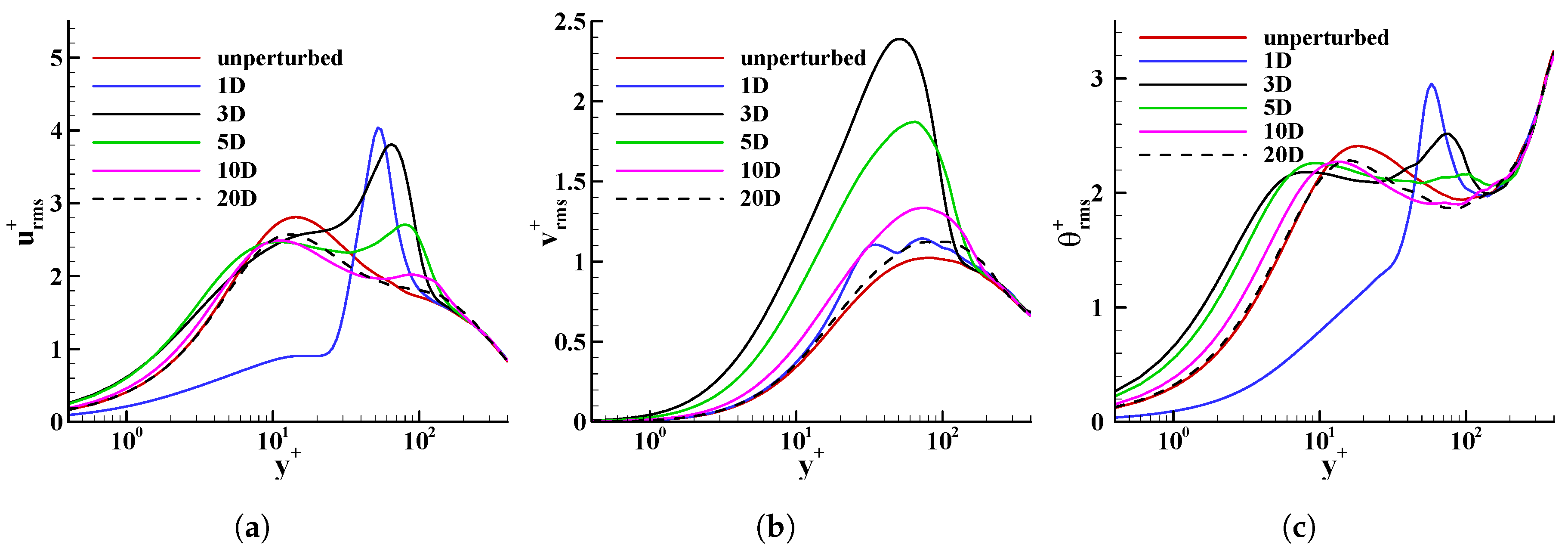

Figure 3a depicts the root mean square (RMS) value of streamwise velocity fluctuations,

, in wall coordinates. At the near-wall region (below

), the profiles of

at all downstream locations, except

downstream, are not significantly different from the unperturbed flow. At

downstream of blowing, streamwise velocity fluctuations are small compared to the unperturbed case. The obstruction of the cross-flow in the presence of blowing jet sets a wake at the immediate downstream of the jets. Since the wake is filled in with slowly-moving fluid, the recirculation region near the downstream of blowing jets attenuates turbulence. Above the reversed flow region (

), fluctuations increase rapidly due to the turbulence production caused by steep velocity gradients, and the maximum

occurs around

. Furthermore, for

,

and

downstream locations, peak values of

are in the log-layer. The movement of the peak values of

towards the outer-layer could be attributed to the high

v fluctuations due to blowing.

RMS values of wall-normal velocity fluctuations at different downstream locations are shown in

Figure 3b. It is interesting to see that

at

downstream is similar to that of the unperturbed flow particularly in the near-wall region. This indicates that the mechanism that creates wall-normal velocity fluctuations does not change due to the flow reversal just downstream of jets. However, wall-normal velocity fluctuations have considerably increased at

downstream. In fact, this location shows the highest increase in

from its unperturbed case out of all the observed locations. We speculate that wall-normal velocity fluctuations intensify due to the generation of more coherent vortical structures in the same region. The high fluctuations of wall-normal velocity move warm near-wall fluid upwards. Therefore, the amplification of wall-normal velocity fluctuations at the downstream of blowing may closely correspond to the low wall temperatures observed at

downstream. The increase of fluctuations is also significant at

and

downstream. However, the magnitude of fluctuations gradually reduces as the location moves away from the blowing jet.

Figure 3c depicts the variation of RMS values of temperature fluctuations,

. At

downstream, temperature fluctuations in the near-wall region are mitigated due to the reversed flow. It seems that temperature fluctuations correspond to streamwise velocity fluctuations at

downstream. As the location moves downstream,

behaves similar to

. Temperature fluctuations in the near-wall region are amplified at the

,

and

downstream locations. The observations of the temperature fluctuations suggest that turbulent mixing is intensified in the near-wall region after

downstream. The amplified wall-normal velocity fluctuations and temperature fluctuations relate to the abrupt change in mean temperature at

downstream. Moreover, we can predict significant differences between turbulent heat fluxes in the streamwise direction,

, and that of the wall-normal direction,

.

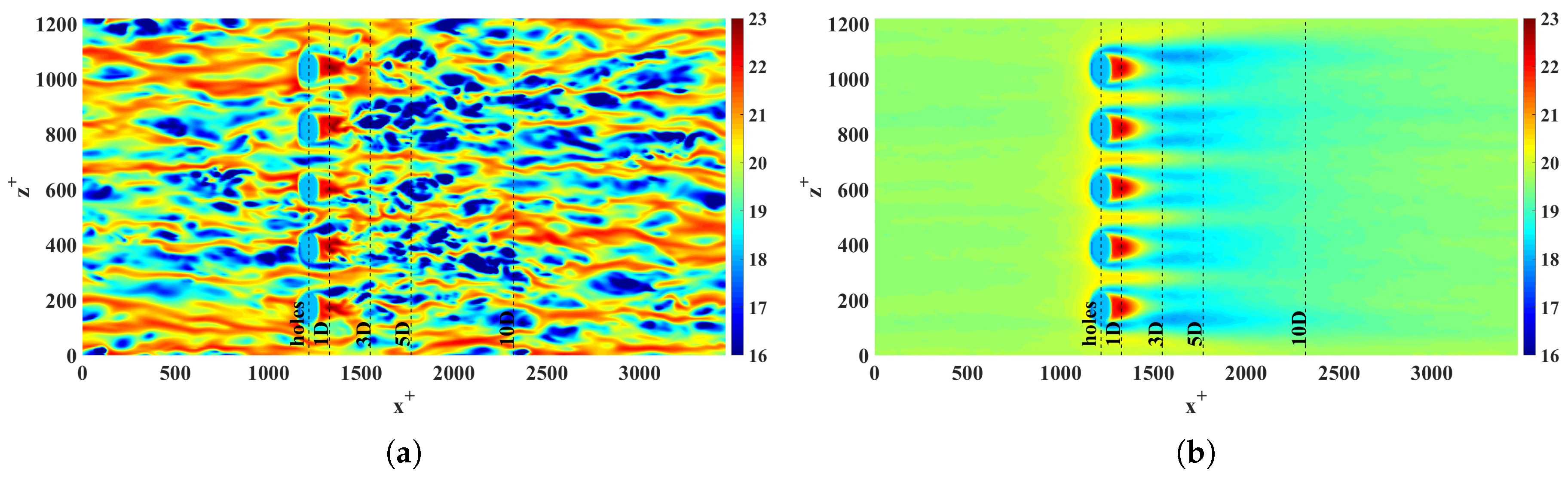

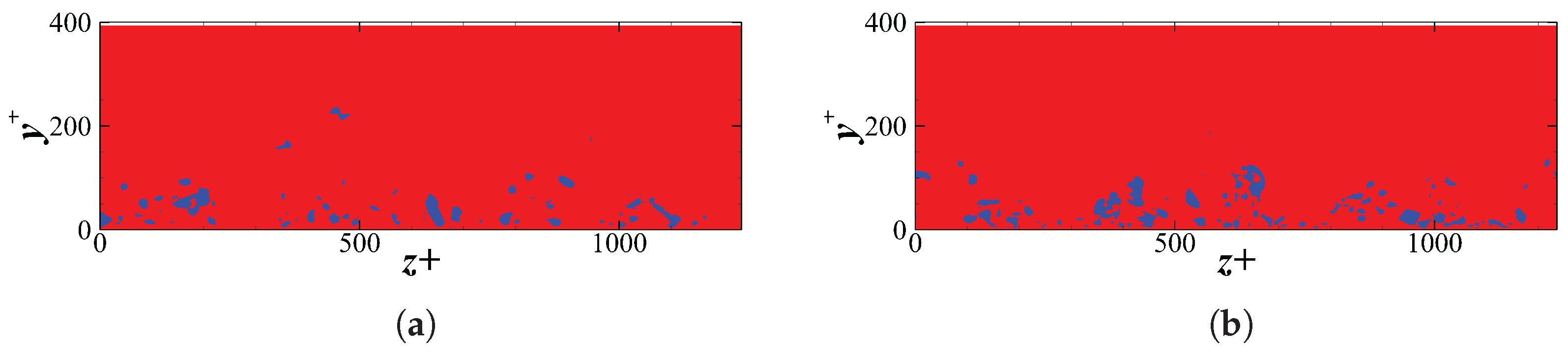

3.3. Hot Spots Near the Wall

To elucidate the changes of instantaneous and mean temperature in the near-wall region, we observe the temperature field around

.

Figure 4a illustrates instantaneous high temperature spots (red color) in between jets where the flow is susceptible to acceleration. Right behind the jets where a reverse flow region is observed, high wall temperatures can also be detected. These instantaneous hot spots in between and right behind the jets contribute to the regions of high mean temperature in those regions, as we see in

Figure 4b. According to

Figure 4a, at

behind the jets, the high temperature spots exist. They are also observed on the mean temperature contours. When we move slightly downstream, around

, we can see that cold (blue) spots are emerging right behind the jets. These sporadic events are directly coupled with sudden changes of flow phenomena like coherent vortical structure proliferation. The difference of instantaneous temperature between the hot and cold spots around

downstream is clearly noticeable. However, the changes that we see in mean temperature contours at the same region is not very distinguishable. Therefore, these instantaneous changes of thermal field are absolutely necessary in the design process. This highlights the importance of understanding the underlying flow physics of the changes in the instantaneous temperature field.

Comparing the thermal field behind the jets with the unperturbed incoming flow, one can notice a significant reduction of hot spots behind the jets, i.e.,

–2400. This further confirms the importance of blowing jets in the proliferation of coherent vortical structures, which in turn, promotes the cooling of the wall, particularly beyond

. These observations are clearly noticed in both the instantaneous and mean temperature contours, which extend far downstream in the channel, as shown in

Figure 4.

3.4. Turbulent Heat Fluxes

This section discusses the changes of turbulent heat fluxes (streamwise heat flux, , and wall-normal heat flux, ) due to blowing. Here, we are particularly interested in heat fluxes in the near-wall region to see which one of and influences temperature more.

In

Figure 5, we observe that both

and

are negligibly small in the near-wall region at

downstream. The flow reversal just downstream of blowing jets diminishes the fluctuations of streamwise velocity and temperature. The reduction of fluctuations decreases turbulent transport near the downstream of the blowing jets. This observation complies with the high mean temperature at that location. A clear distinction between

and

can be seen at the

,

and

downstream locations particularly in the near-wall region. At the

,

and

locations, both

and

are higher than the respective values of the unperturbed case in the near-wall region until

. In between

and

, one can clearly see that

downstream of the perturbations is lower than that of the unperturbed flow.

at downstream locations surpasses unperturbed conditions beyond . On the other hand, is higher than its unperturbed counterpart for most of the boundary layer at all downstream locations, except at downstream. The intensification of at downstream locations suggests a change in the mechanism that generates turbulent heat fluxes. We examine the changes of vortex structures downstream of blowing to see whether the vortex structure generation influences turbulent heat fluxes.

3.5. Generation of Vortex Structures

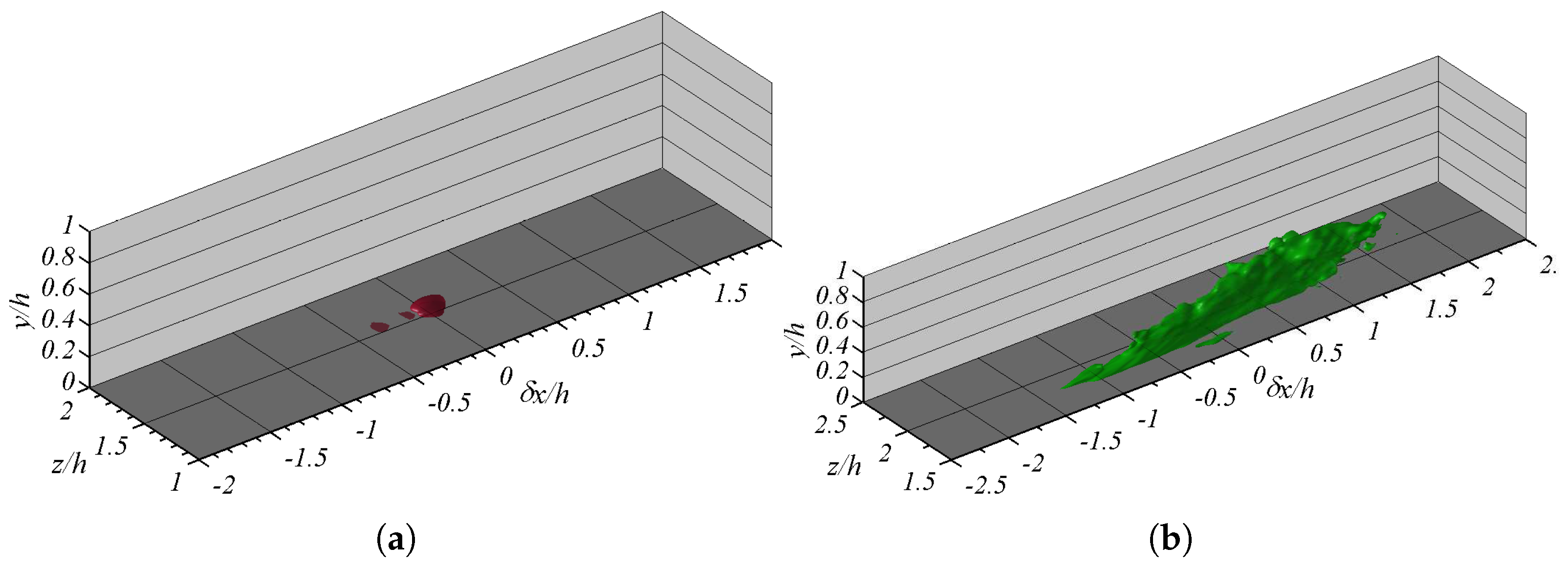

Figure 6a,b illustrates two-point correlations of streamwise velocity fluctuations,

, in the near-wall region at

downstream of blowing behind the jets and in between jets, respectively. The streamwise length of

demonstrates the flow acceleration in between jets (

Figure 6b) in comparison to the deceleration of the flow behind the jets (

Figure 6a). It is clear that the streamwise length scale of

in between jets is much larger than

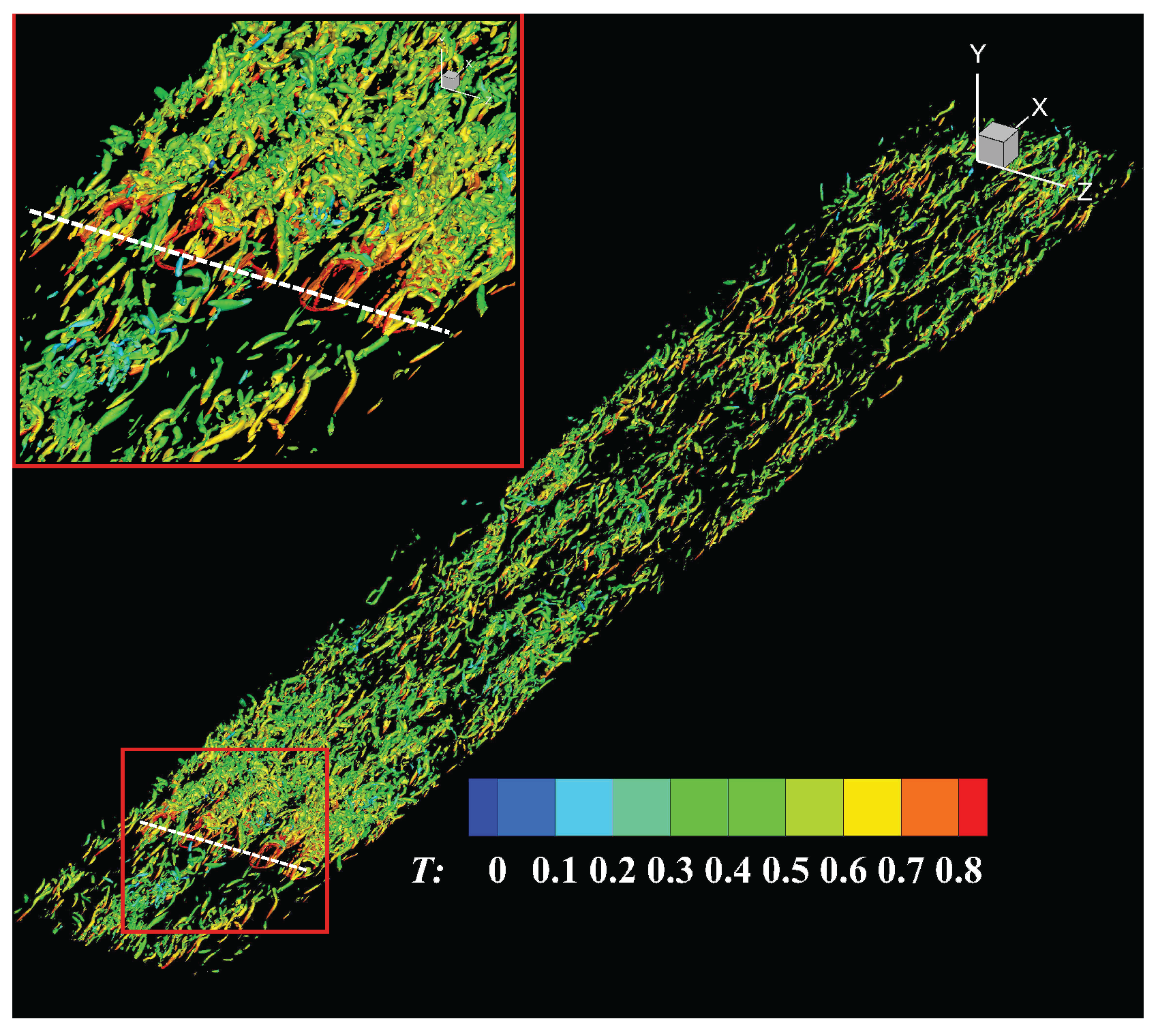

behind the jets. This suggests that streaks in the near-wall region are stabilized in between jets, while they are destabilized behind the jets. In other words, the flow acceleration in between jets stabilizes low and high speed streaks. The flow acceleration is a result of the favorable pressure gradient that occurs between the jets. Conversely, there exists an adverse pressure gradient behind the jets. This spanwise pressure heterogeneity leads to a difference in coherent vortical structures’ generation in between and behind the jets.

Figure 7 shows coherent vortical structures identified by

[

16] iso-contours. The color spectrum of the contours depicts instantaneous temperature on the surfaces of the vortices. The number of coherent vortical structures downstream is higher right behind the blowing jets than that in between blowing jets because of the adverse pressure gradient. The rapid generation of coherent vortical structures has recently also been observed in reverse flow regions, even in high Reynolds number adverse pressure gradient flows, by Vinuesa et al. [

17]. In fact, between the jets, the flow is accelerated (this is evident from the streamwise length of

shown in

Figure 6b), and this shows the evidence of less coherent vortical structures than behind the jets.

The interaction of the jet and the incoming flow sets Kelvin–Helmholtz instability at the interface of the jet and the cross-flow. The process creates strong spanwise vortices. These spanwise vortices connect with quasi-streamwise vortices that are generated by destabilized low-speed streaks [

18] behind the jet due to blowing perturbations. This leads to proliferation of hairpin vortices (as shown in

Figure 7) downstream of blowing perturbations. In between jets, flow accelerates due to wall pressure gradient effects induced by blowing perturbations. The accelerated flow stabilizes low-speed streaks and these stabilized streaks are less vulnerable to break up; therefore, suppressing the generation of streamwise vortices downstream. This leads to a significant reduction in the number of vortices between two jets (leading to hot spots). The quasi-heterogeneity of vortex structure generation in the spanwise direction of the flow creates spanwise heterogeneity of turbulent thermal transport, as well. The red color of the temperature contours of

Figure 7 directly downstream of blowing jets implies that vortical motions efficiently lift up hot fluid from the near-wall region to the outer region, thus promoting cooling. However, in between jets, heat fluxes are seen to be significantly lower than at

from the blowing jets; thus, they do not effectively remove hot fluid from the wall to the outer region. This is contrary to what we observed behind the jets in which high proliferation of coherent vortical structures led to effective cooling of the wall and, thus, generated extensive cold spot regions.

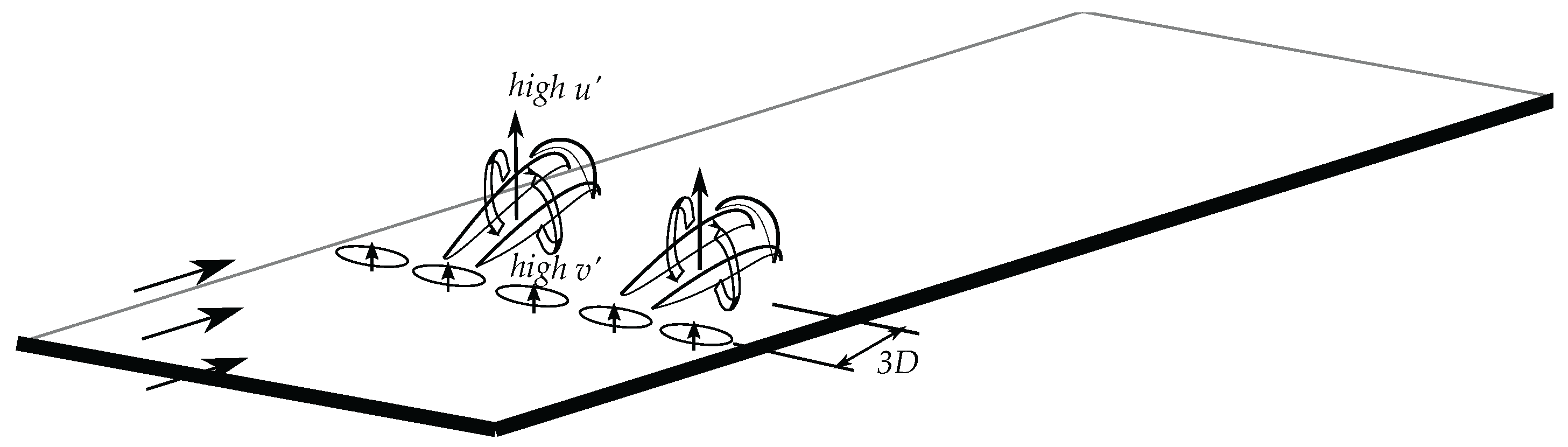

The previous section demonstrated that the wall-normal heat flux is highest around

downstream. To see whether this increase of turbulent heat transport has any relation to the generation of coherent vortical structures downstream of blowing,

structures are taken on two cross-sectional views at the

and

downstream locations, as shown in

Figure 8a,b, respectively. It can be seen that the number of coherent vortical structures is greater at

downstream of blowing jets than at

downstream. The generation of more coherent vortical structures amplifies wall-normal velocity fluctuations in the near-wall region.

The wall-normal fluctuations in the near-wall region move low-speed fluid away from the wall. This action increases streamwise velocity fluctuations further from the wall.

Figure 9 clearly shows the generation of wall-normal and streamwise velocity fluctuations with respect to the generation of vortex structures downstream of blowing. As the figure depicts, wall-normal velocity fluctuations increase at the near-wall region due to the proliferation of vortices. This is different than what we see in the unperturbed case in general, where wall-normal fluctuations are lower in the near-wall region due to boundary conditions. The increase of

in the near-wall region due to the proliferation of vortices moves the peak of

away from the wall. The steep mean velocity gradient in the streamwise direction is due to the wake recovery as observed previously in

Figure 2a. The velocity gradients in the streamwise direction stretch vortices, and vortex stretching strengthens them. Since vortex stretching and the generation of vortices intensify near

downstream, wall-normal turbulent heat fluxes also amplify at the same region. This phenomena transports more heat flux from the wall, which in turn, reduces the temperature at

downstream. Importantly, streamwise heat fluxes in the near-wall region do not amplify due to the generation of coherent vortical structures. This is why one could see reduced

at

,

and

downstream than that of unperturbed flow (see in

Figure 5a), particularly in the near-wall region. However,

Figure 5b clearly shows that the generation and stretching of vortices directly affect the wall-normal heat flux throughout the boundary layer.