Research on Internal Instability Characteristics of Centrifugal Impeller Based on Dynamic Mode Decomposition

Abstract

1. Introduction

2. Numerical Methodology

2.1. Computational Model

2.2. Modeling of Nitrogen as the Working Fluid

2.3. Simulation Methods

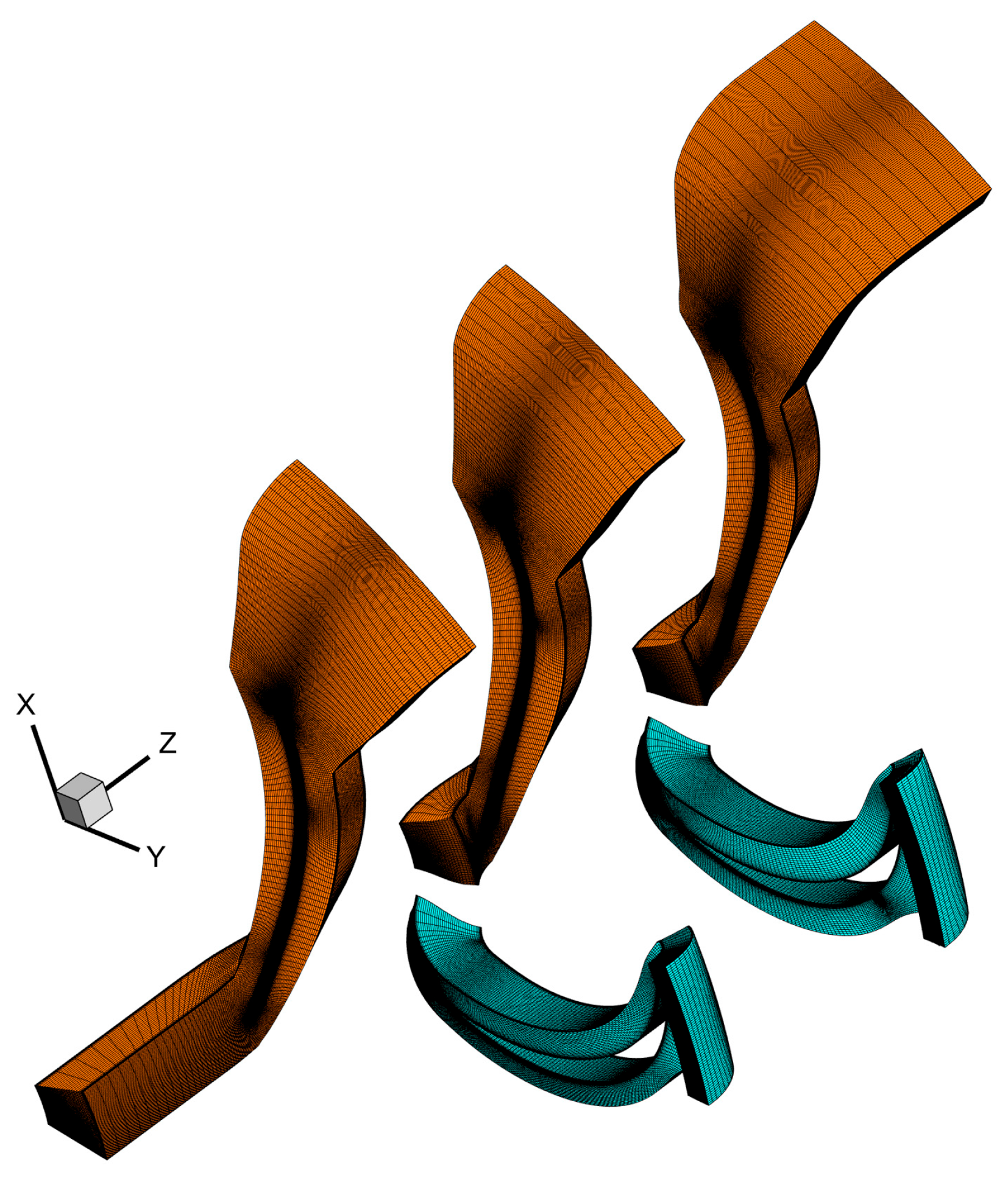

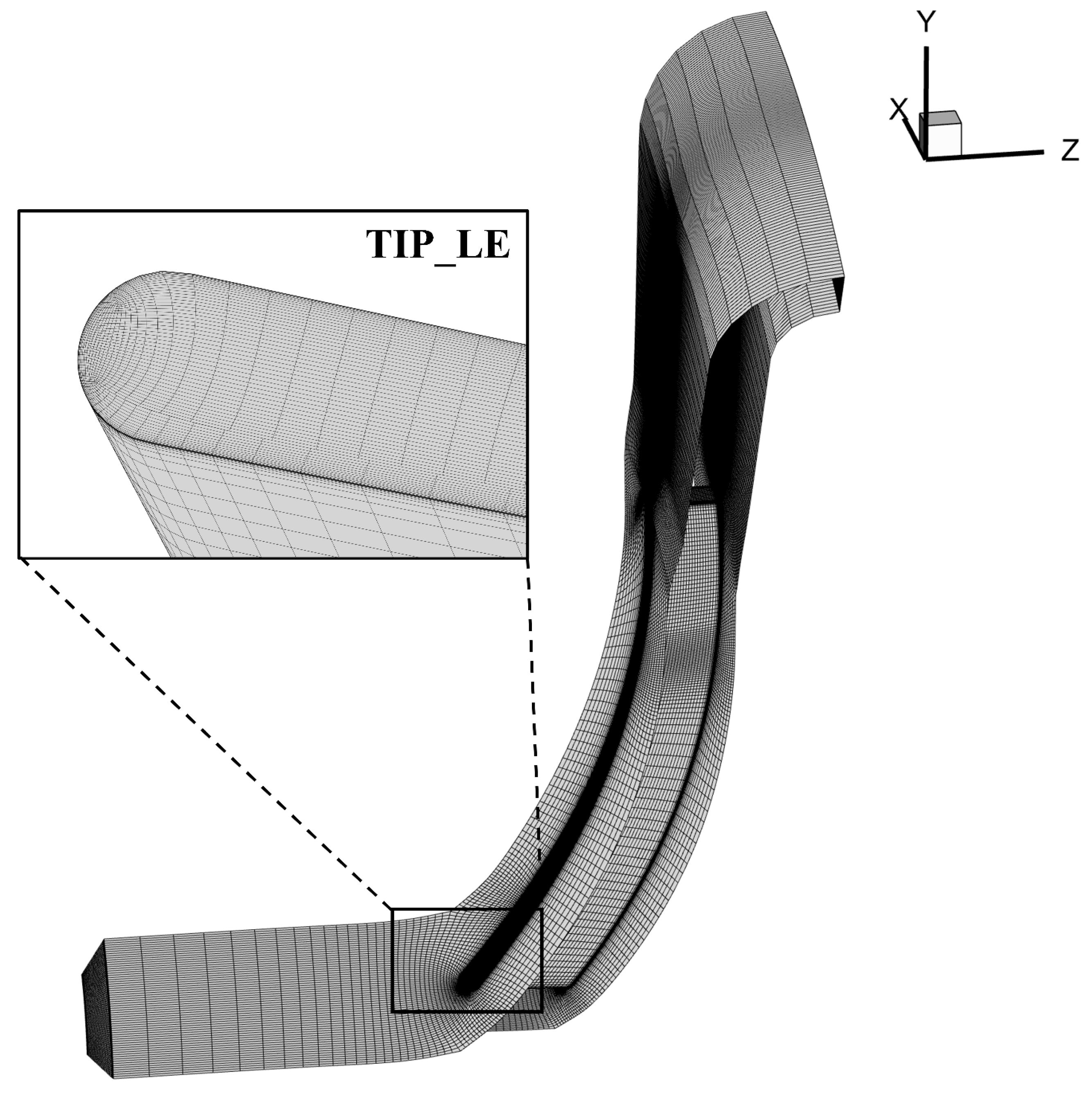

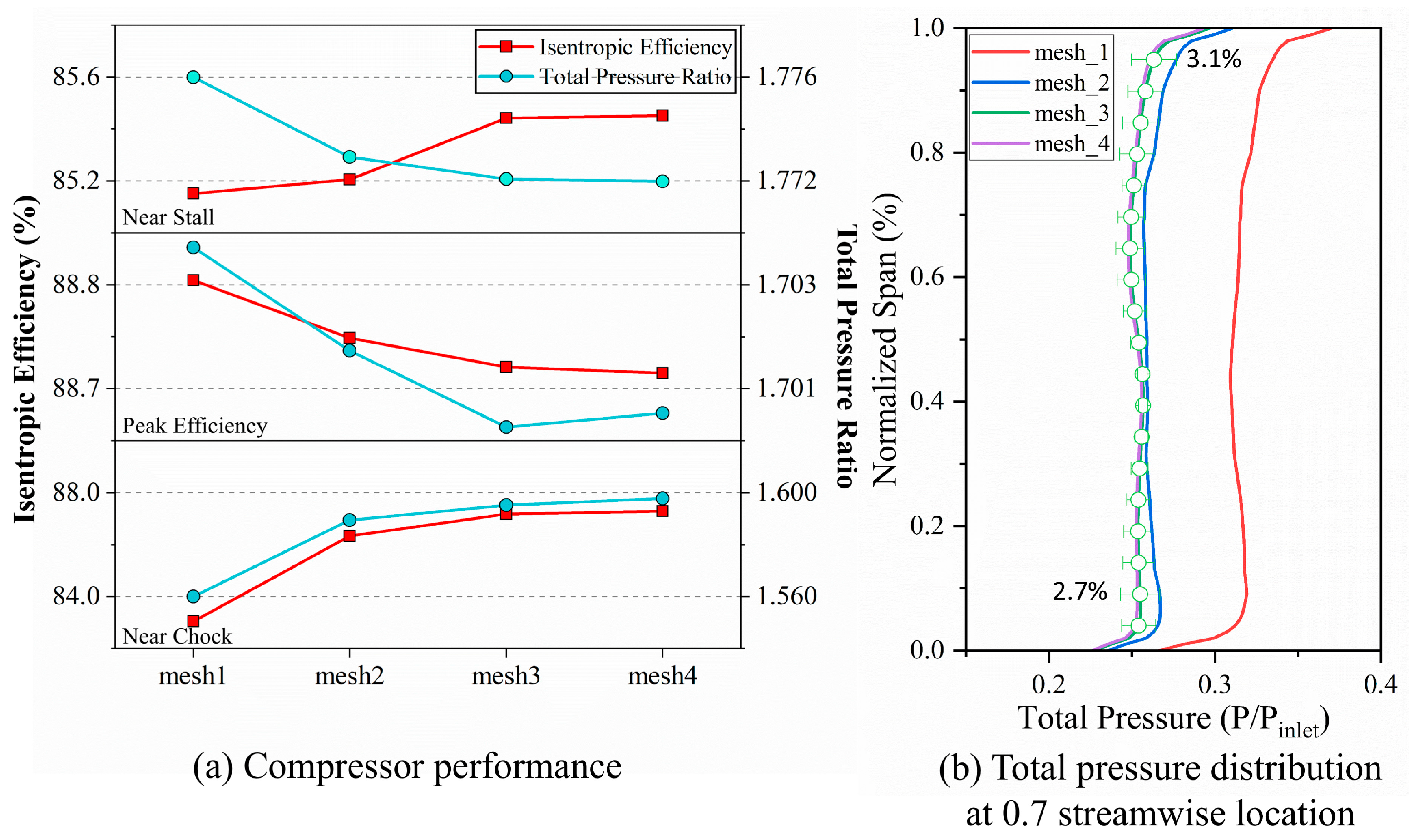

2.4. Mesh Generation

2.5. DMD Implementation

3. Experiment and Verification of Simulation

3.1. Experimental Instruments and Procedures

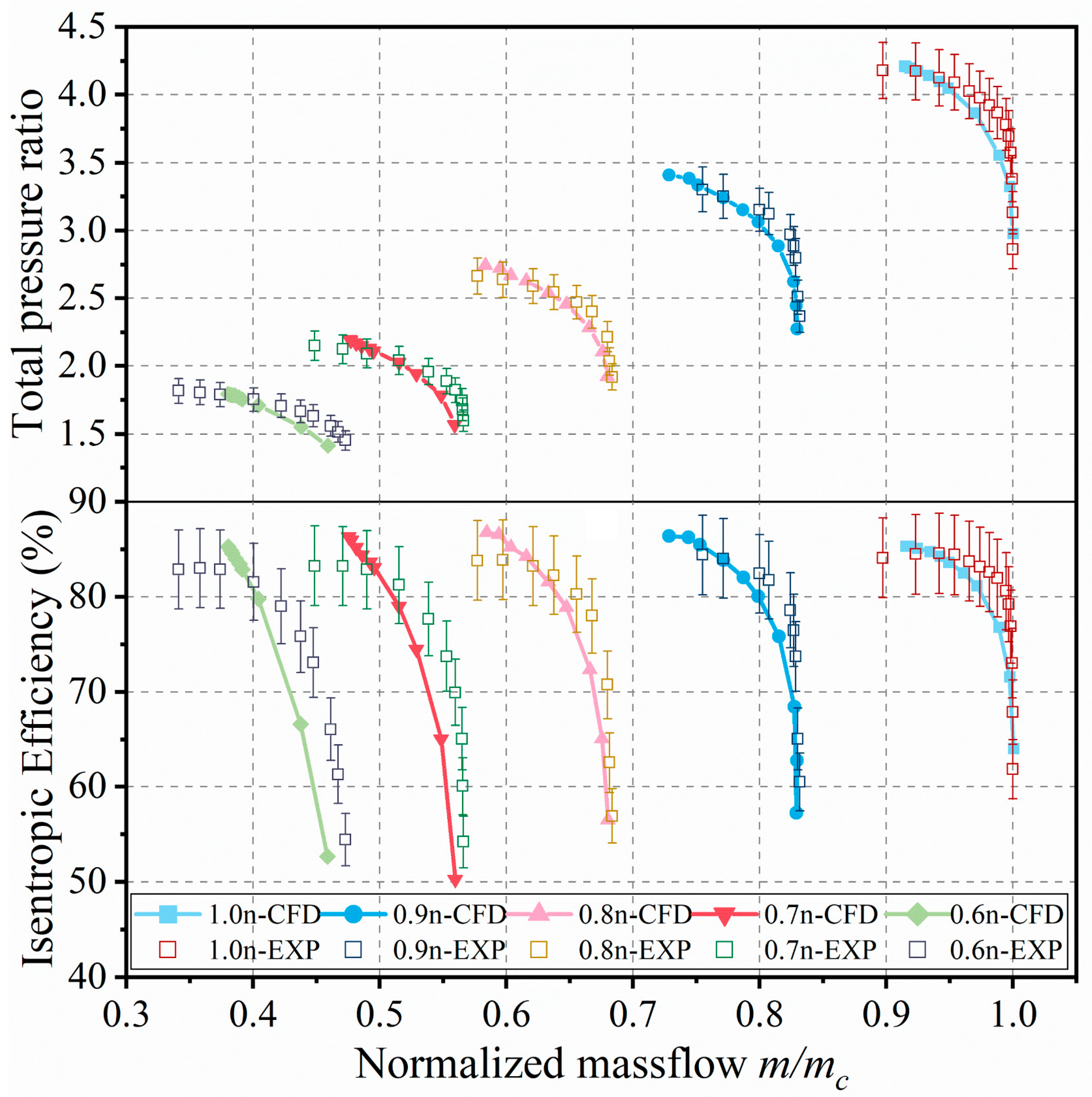

3.2. Validation of Numerical Simulation

4. Result and Discussion

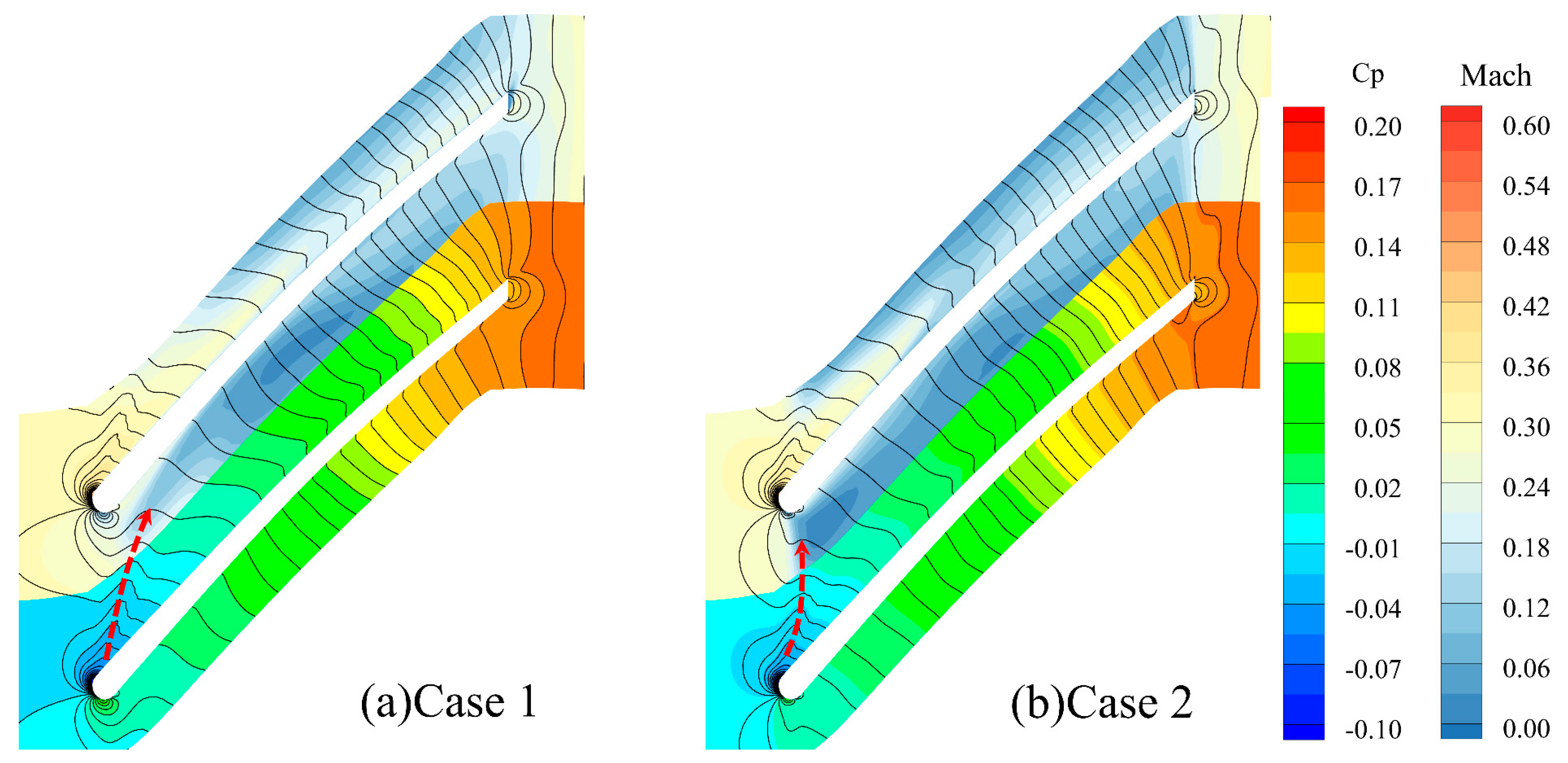

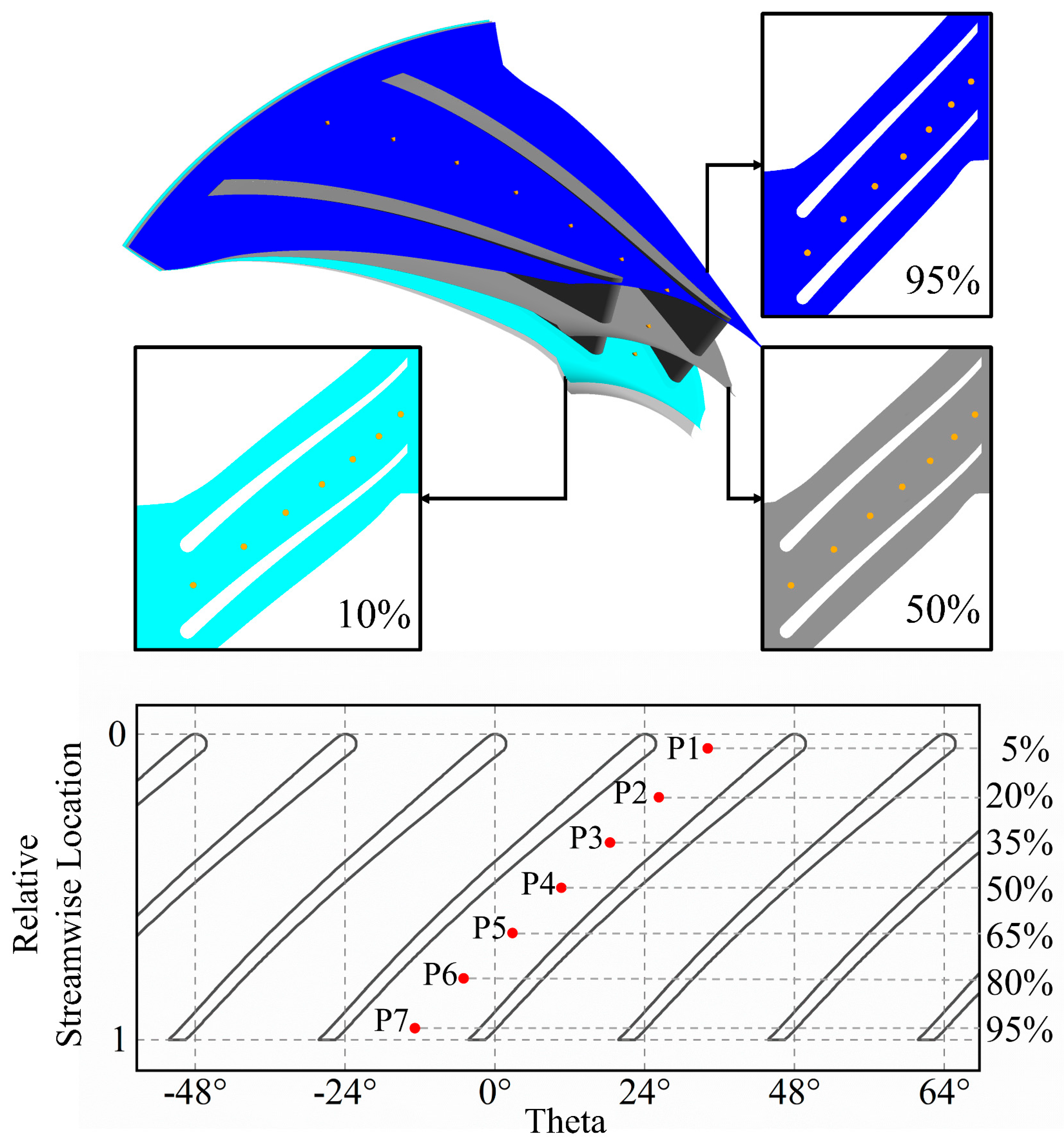

4.1. Time-Averaged Flow Analysis in Passage

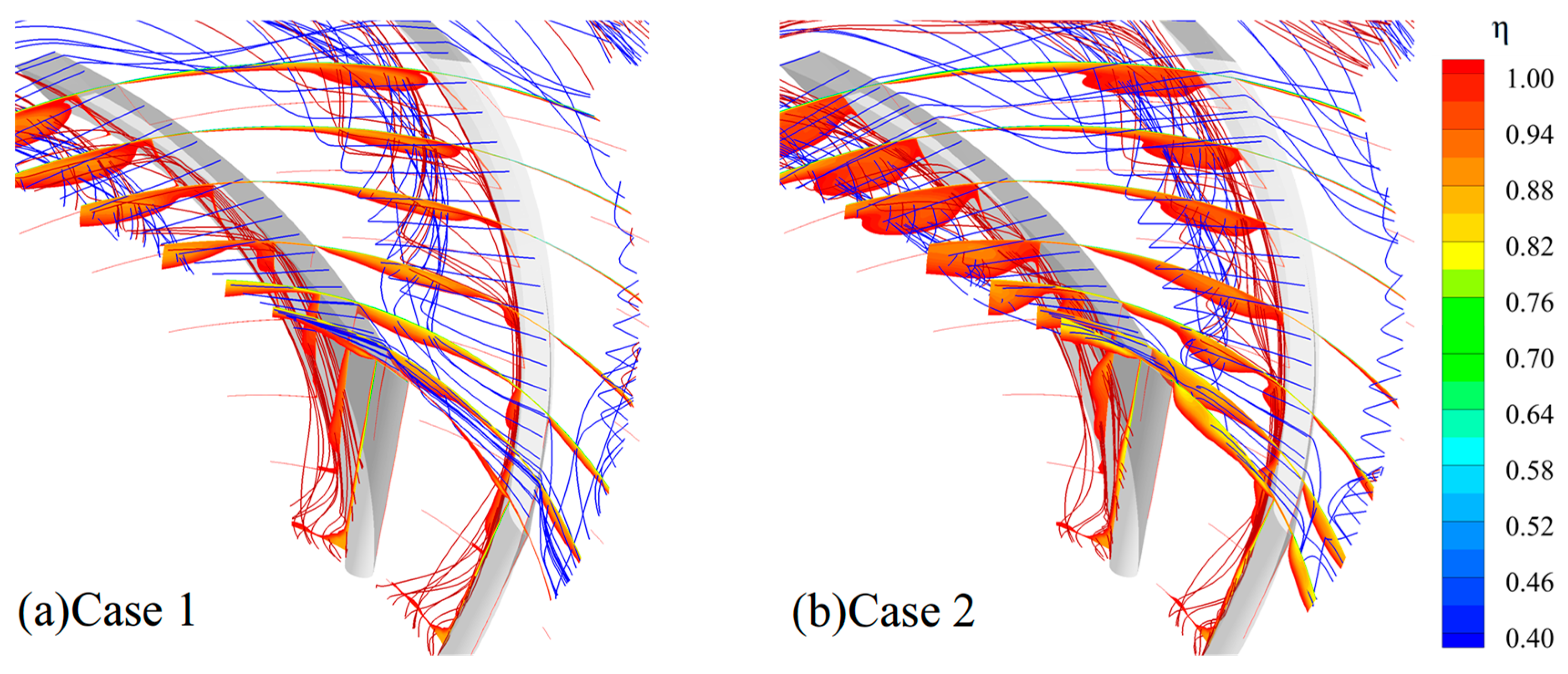

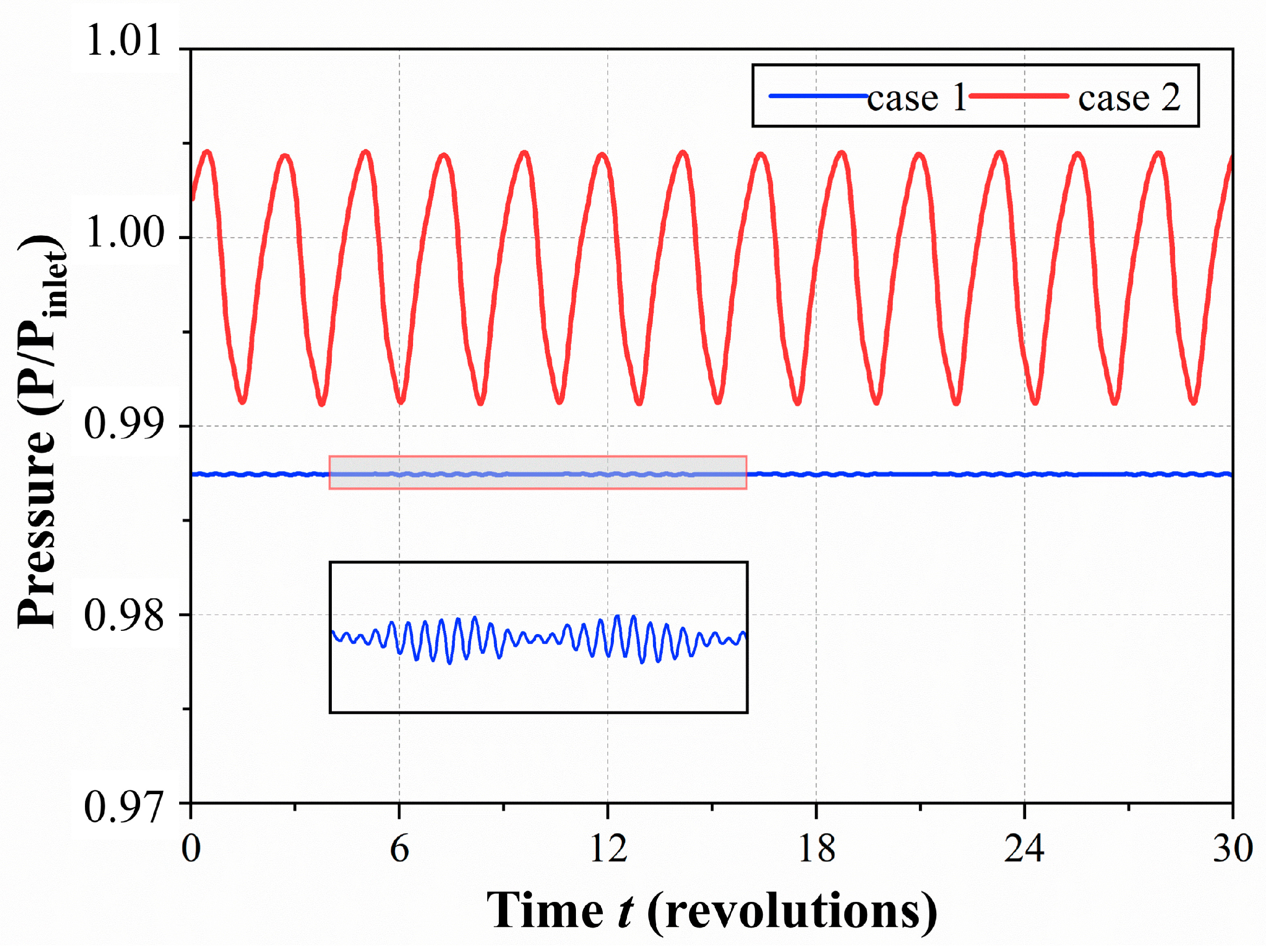

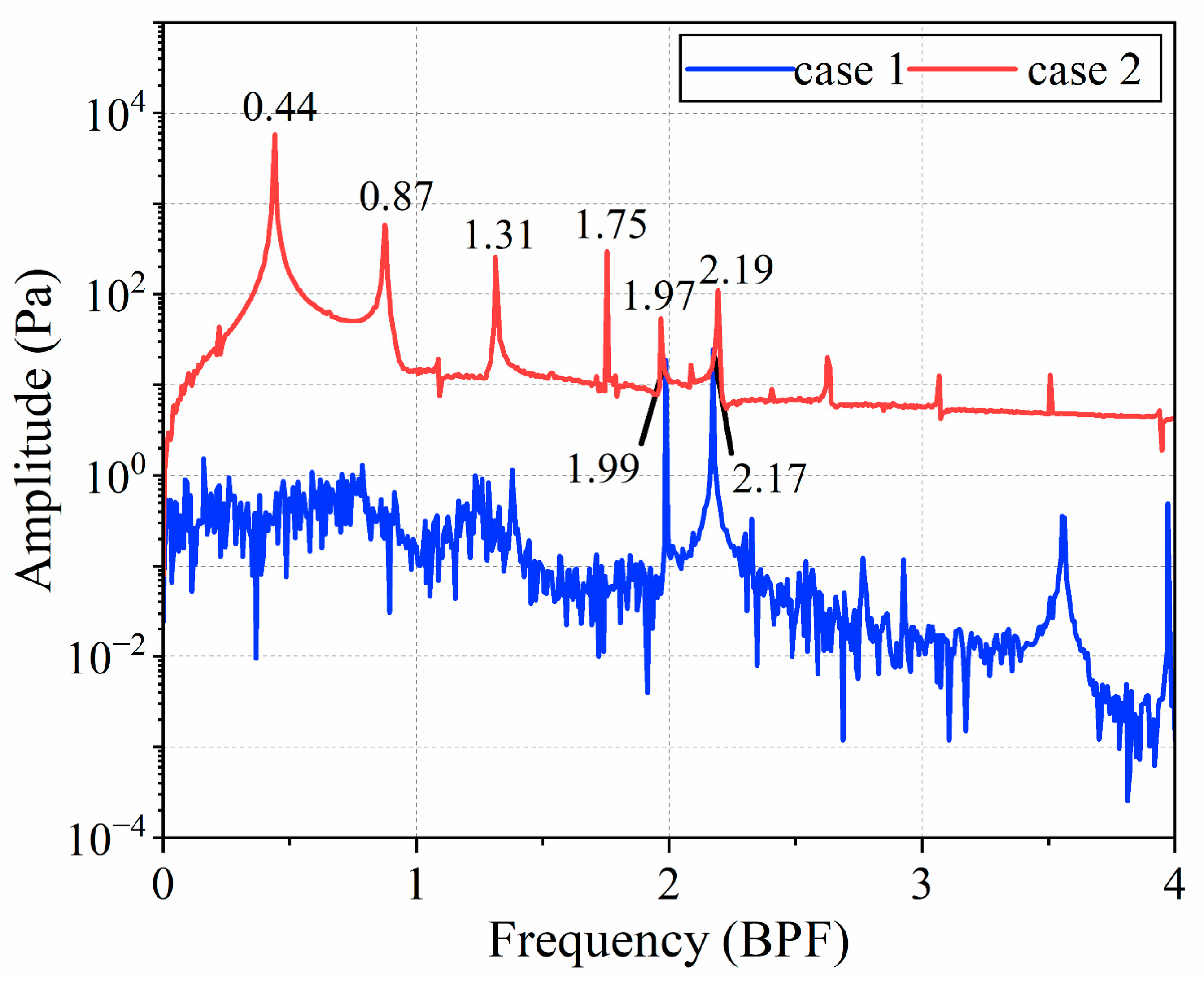

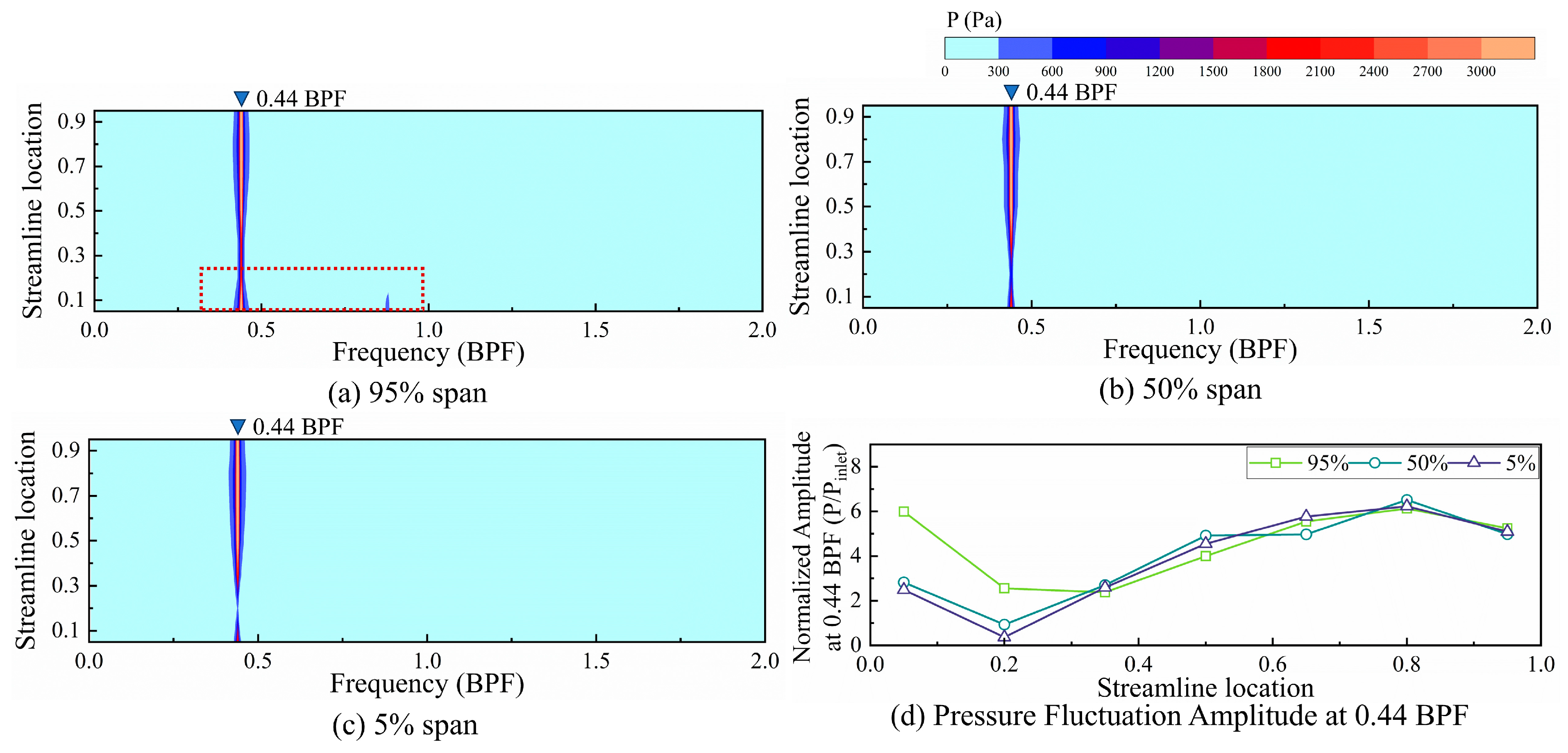

4.2. Transient Characteristics in the Passage

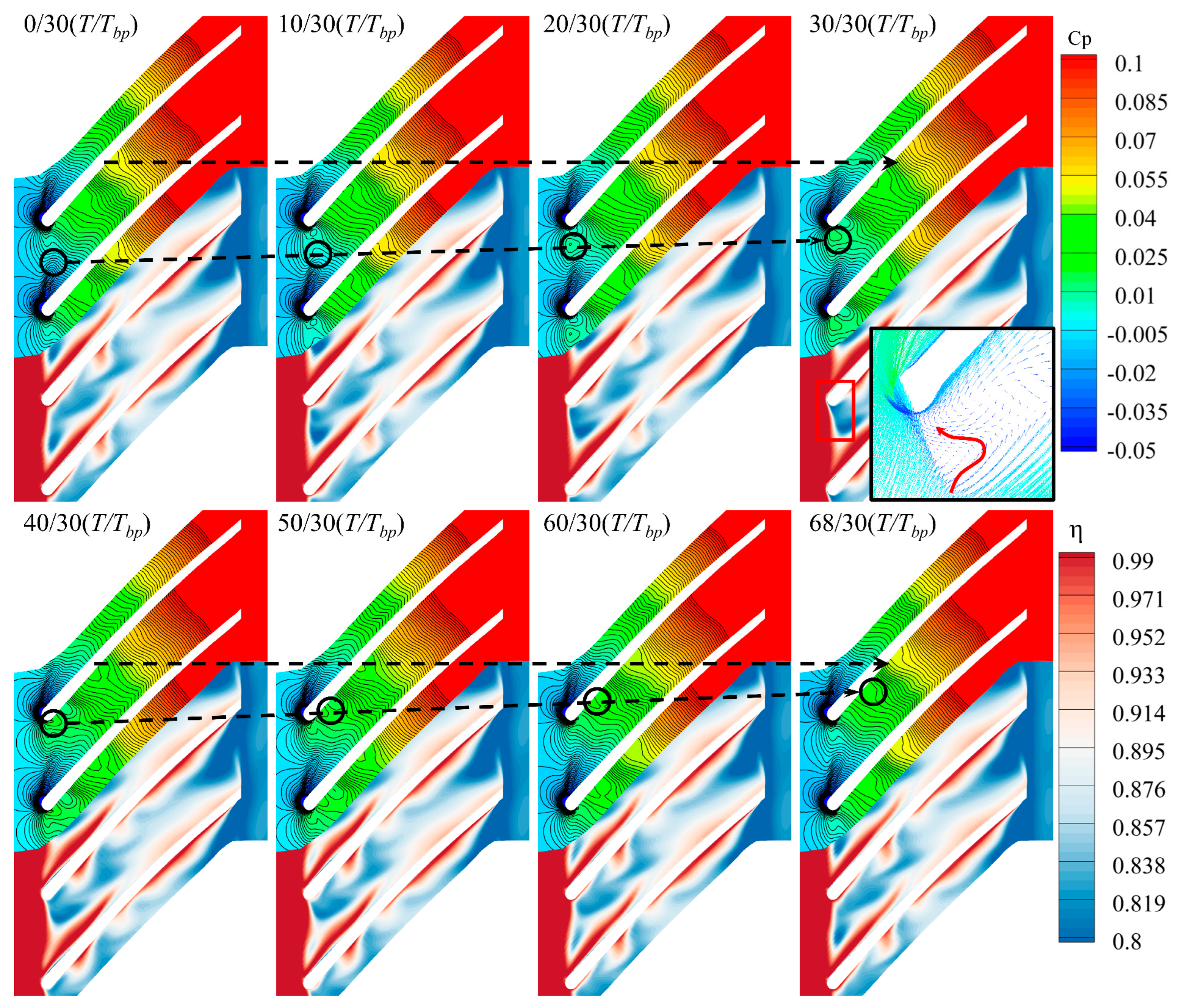

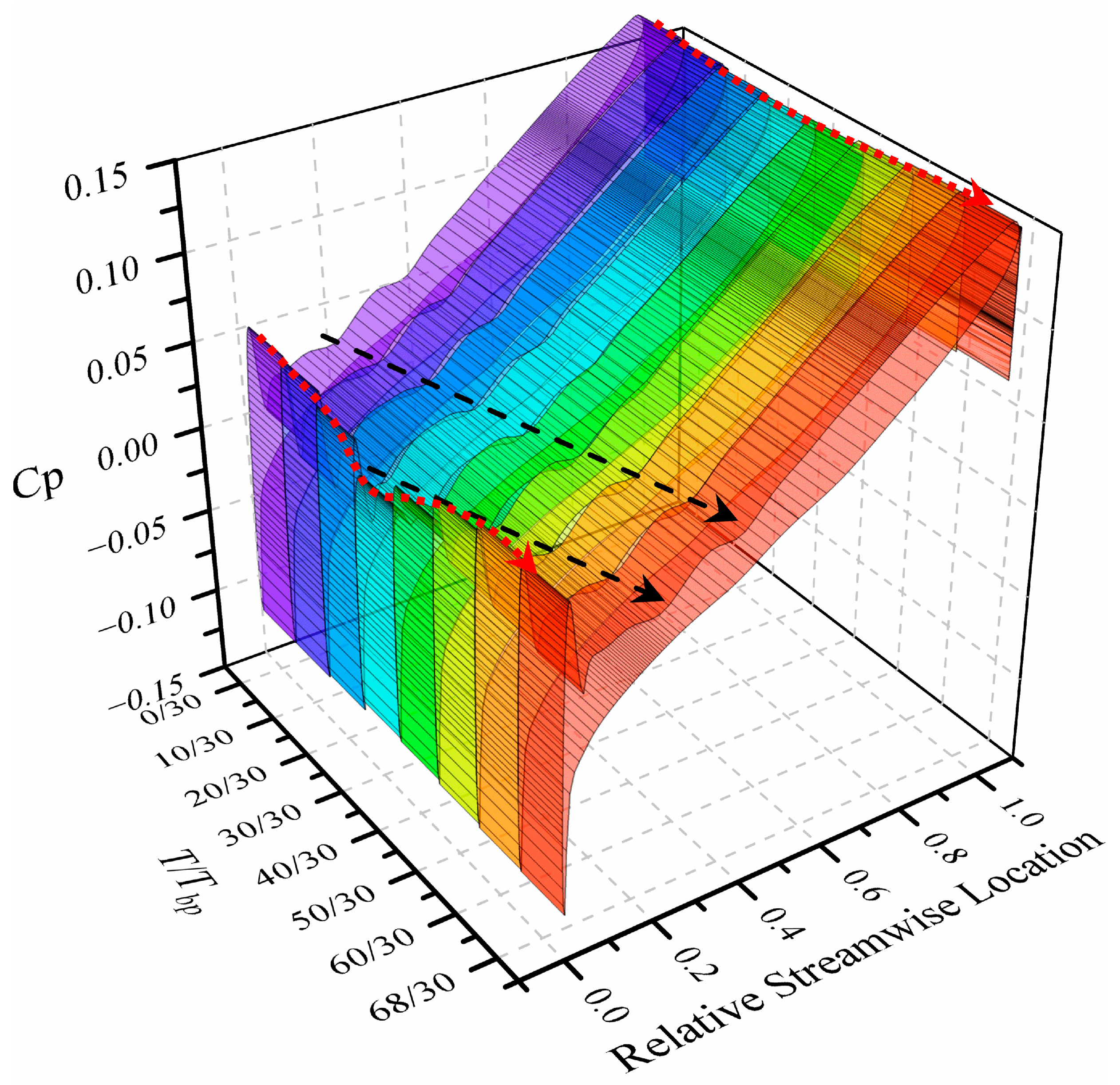

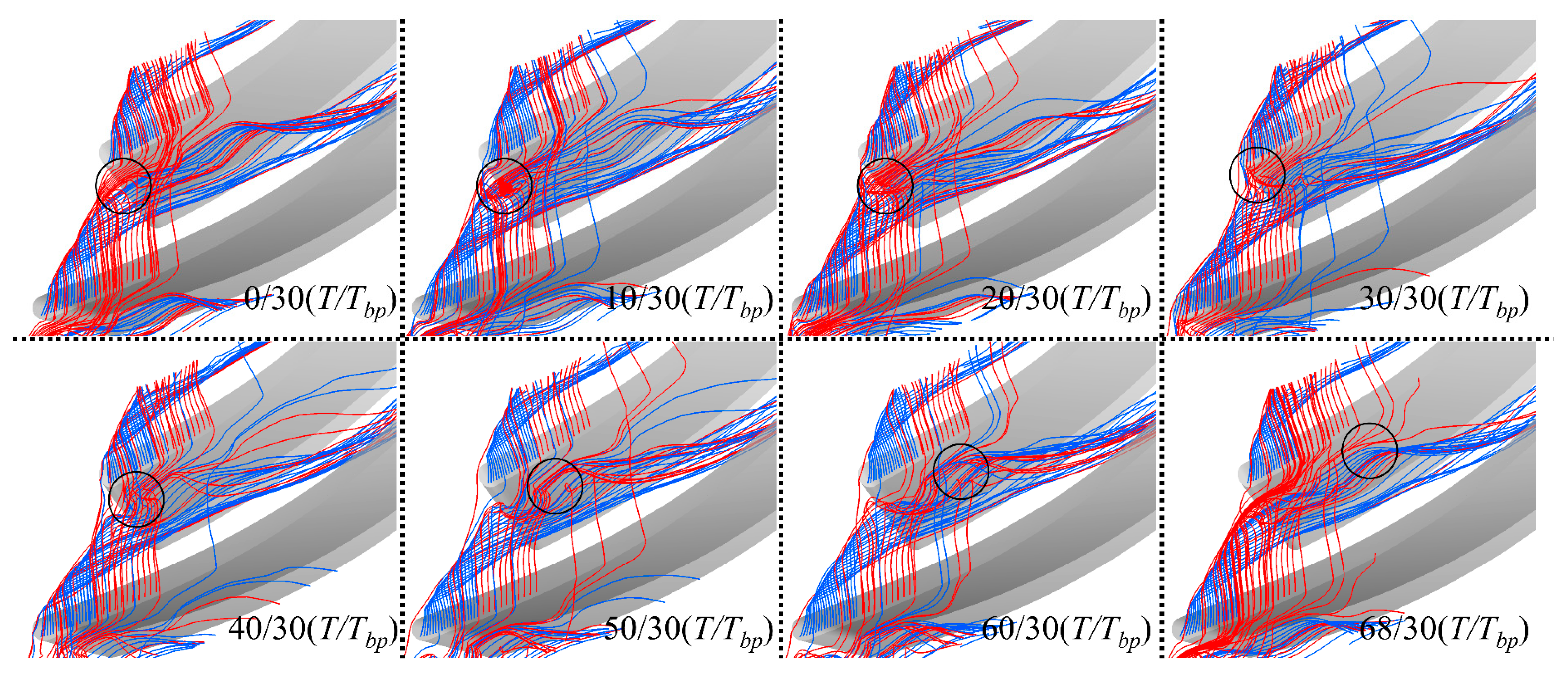

4.3. Unstable Flow Structure in Passage

4.4. DMD Analysis of Unstable Flow in the Passage

5. Conclusions

- 1

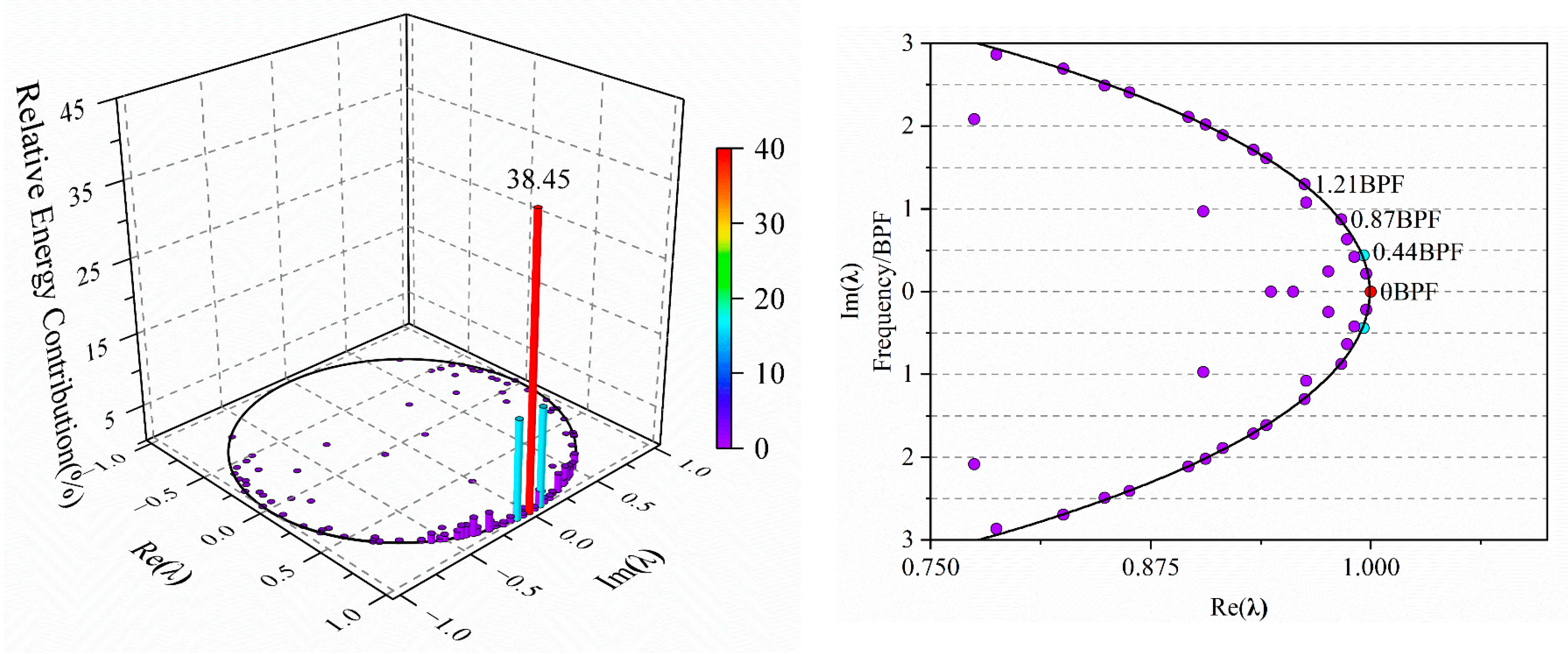

- Under stable conditions, high-frequency oscillations exceeding the blade passing frequency (1.983 BPF and 2.17 BPF) predominate within the impeller. The peak amplitudes are concentrated around twice the blade passing frequency. The former originates from tip leakage vortex shedding, while the latter arises from trailing-edge vortex shedding.

- 2

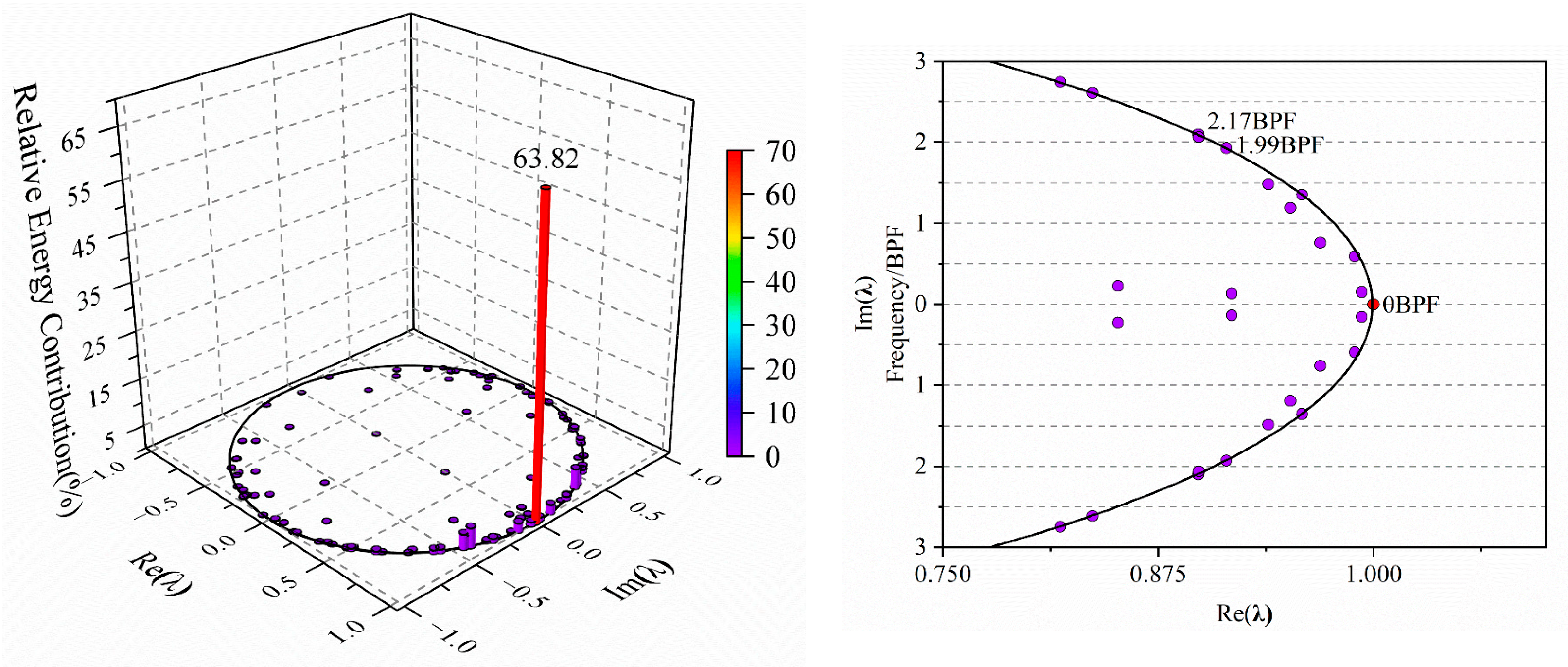

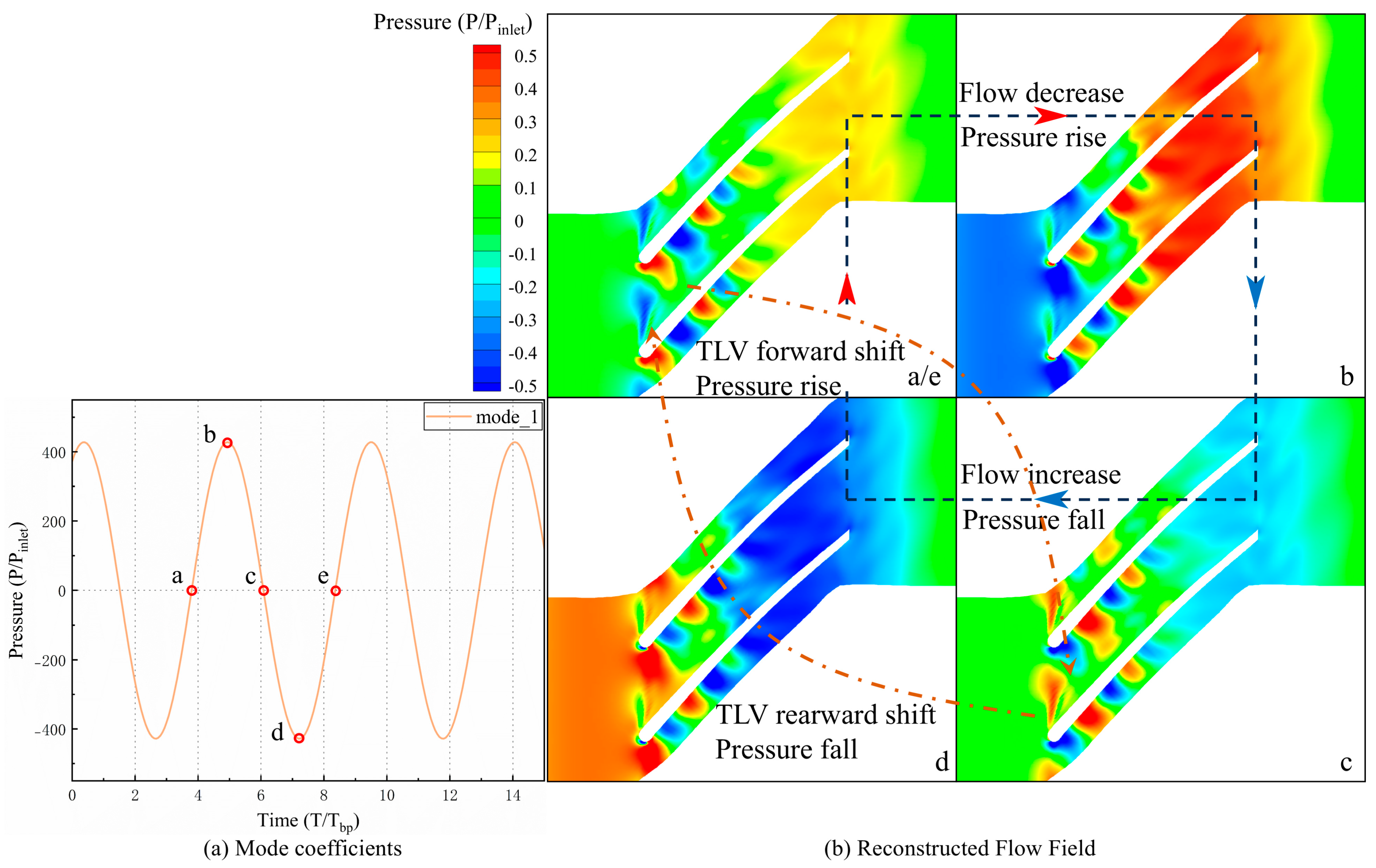

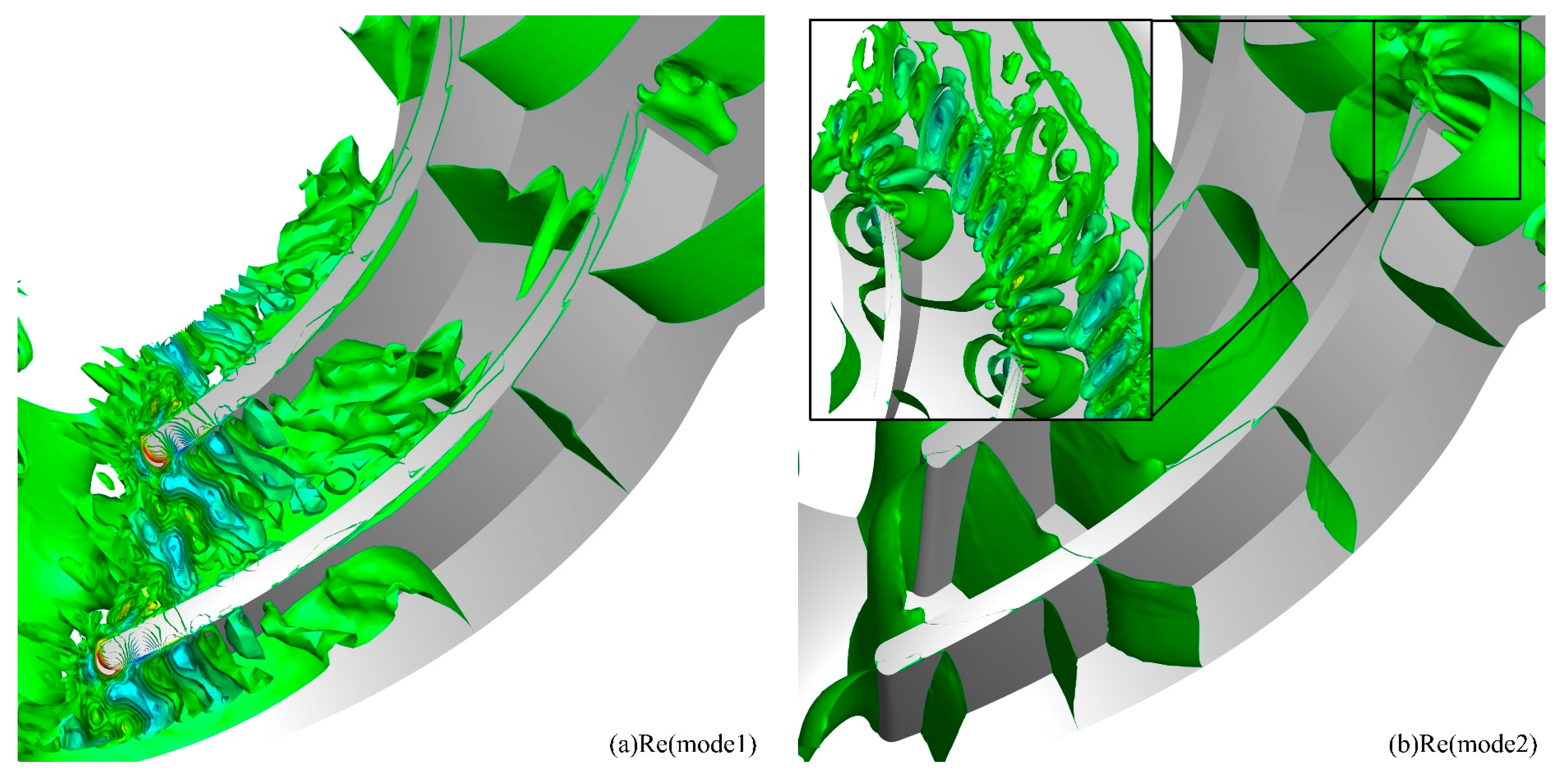

- Under near-stall conditions, unstable fluctuations are induced by the periodic passage blockage caused by the interaction of tip leakage flow and induced vortices entering the passage. These fluctuations correspond to the first-order DMD mode, manifesting as a dynamic cycle of high- and low-pressure fluctuations throughout the entire passage, with a frequency of 0.44 BPF. The tip leakage flow is identified as a triggering factor for the fluctuations but is not considered the primary source of the oscillations.

- 3

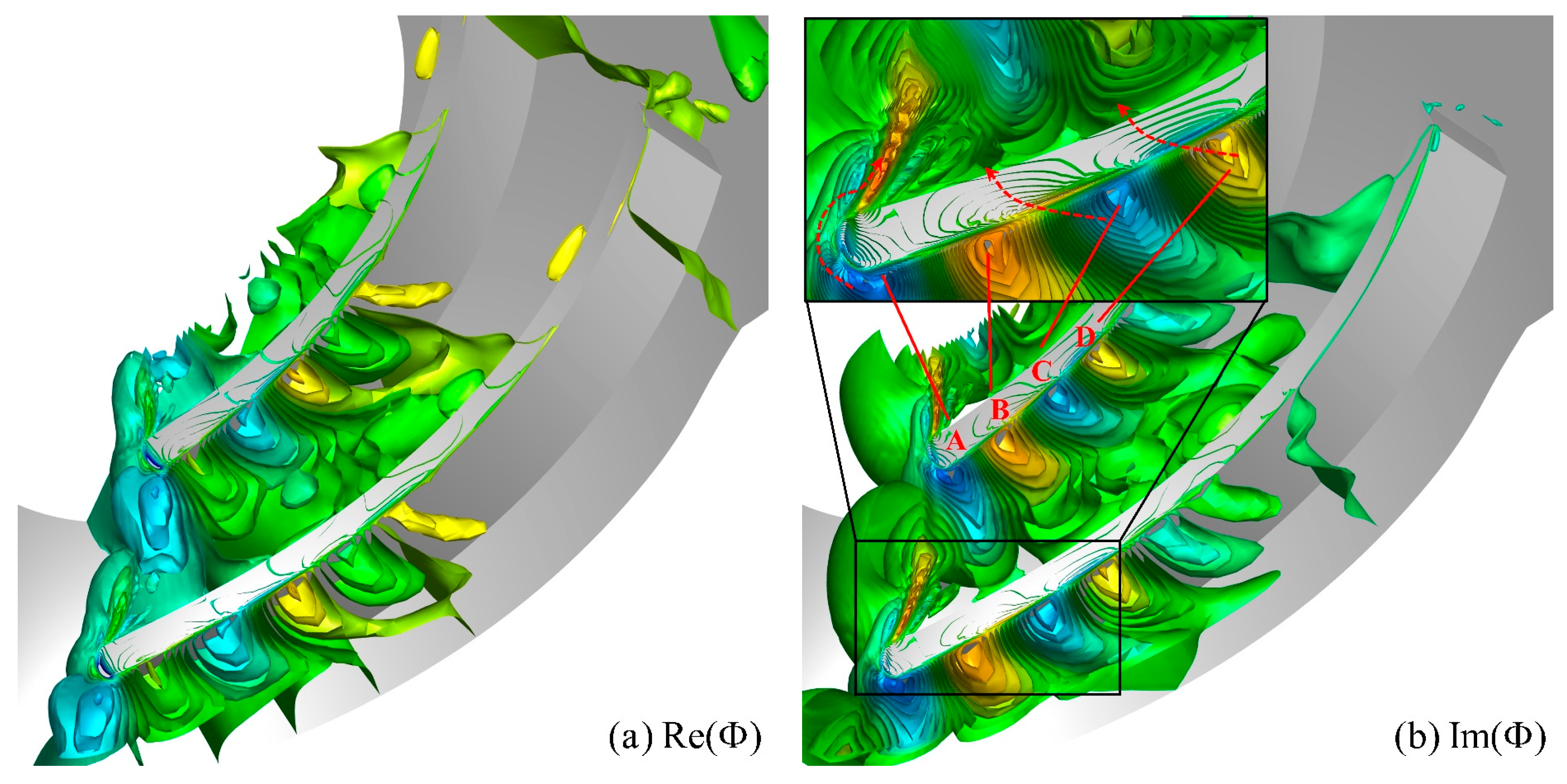

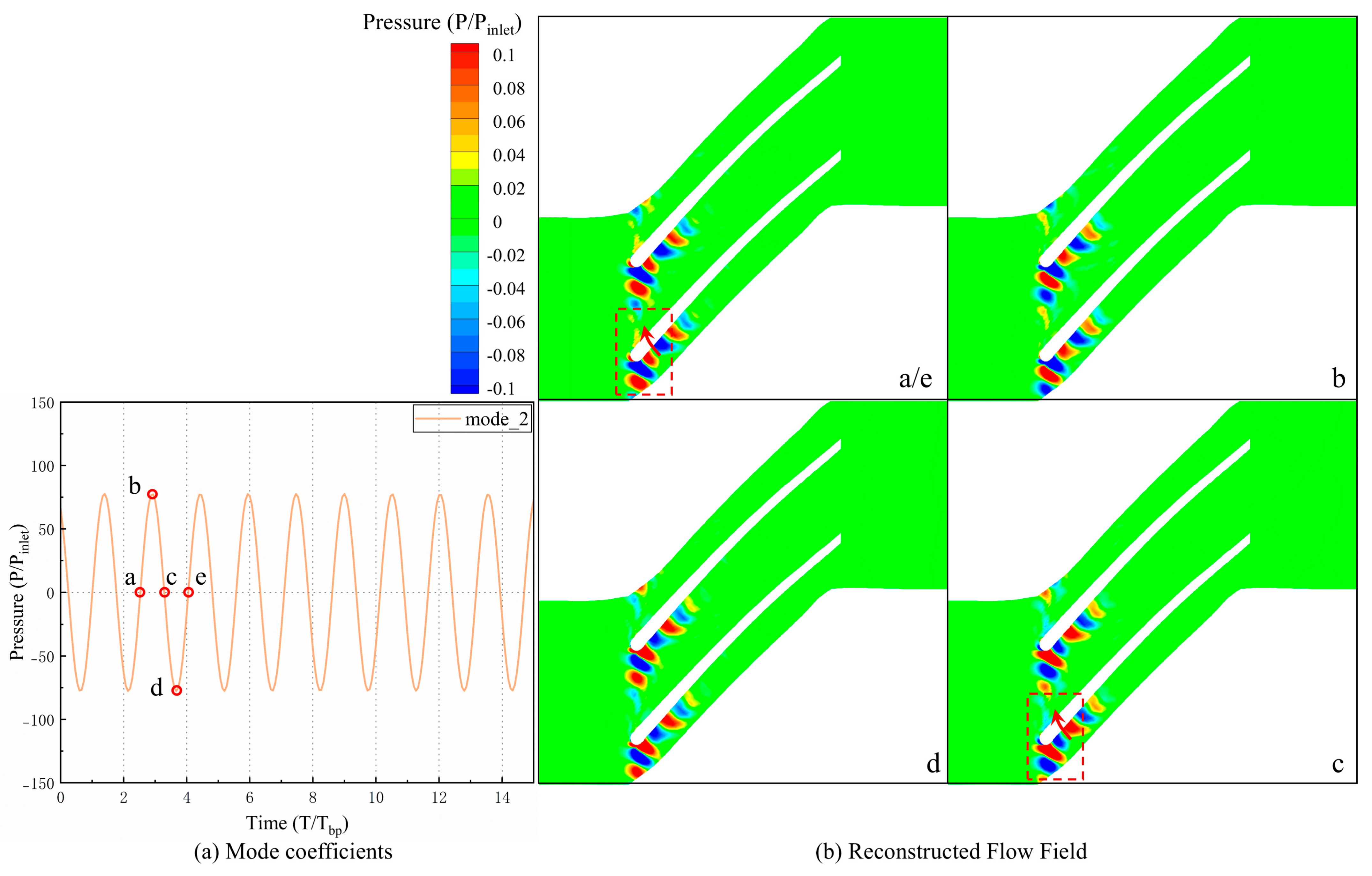

- Under near-stall conditions, the periodic dynamic cycle formed by the interaction between the tip leakage flow and the pressure surface of the adjacent blade is associated with the second-order DMD mode. After the tip leakage flow is discharged, it is observed to interact with the mainstream flow and is directed rearward along the pressure surface of the adjacent blade. The low-energy fluid at the 10% chord length position on the pressure surface is found to significantly influence the tip leakage flow.

- 4

- The DMD method effectively captures the unsteady flow structures within the impeller passage. The spatial distribution of the modal real part directly reflects regions of high-amplitude fluctuations, while the imaginary part elucidates the wave propagation process. Under stable conditions, high-frequency oscillations are primarily induced by tip leakage vortex shedding and trailing-edge vortex shedding. Upon throttling to near-stall conditions, the low-frequency modal energy increases substantially, with the dominant frequency centering on half the blade passing frequency and its harmonics; consequently, the high-frequency, small-amplitude oscillations induced by vortex shedding become masked.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DMD | Dynamic Mode Decomposition |

References

- Day, I.J. Stall, Surge, and 75 Years of Research. J. Turbomach. 2016, 138, 011001. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, C.; Wang, W.; Yang, C.; Li, Y. Experimental Investigation of the Pre-Stall and Stall Evolution in a Centrifugal Compressor With a Volute. J. Turbomach. 2022, 144, 081012. [Google Scholar] [CrossRef]

- Yamada, K.; Furukawa, M.; Fukushima, H.; Ibaraki, S.; Tomita, I. The Role of Tip Leakage Vortex Breakdown in Flow Fields and Aerodynamic Characteristics of Transonic Centrifugal Compressor Impellers. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Volume 7: Turbomachinery, Parts A, B, and C. Vancouver, BC, Canada, 6–10 June 2011; pp. 2111–2123. [Google Scholar] [CrossRef]

- Marconcini, M.; Bianchini, A.; Checcucci, M.; Ferrara, G.; Arnone, A.; Ferrari, L.; Biliotti, D.; Rubino, D.T. A 3D Time-Accurate CFD Simulation of the Flow Field Inside a Vaneless Diffuser During Rotating Stall Conditions. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Volume 2D: Turbomachinery. Seoul, Republic of Korea, 13–17 June 2016; p. V02DT42A029. [Google Scholar] [CrossRef]

- Dehner, R.; Selamet, A. Three-Dimensional Computational Fluid Dynamics Prediction of Turbocharger Centrifugal Compression System Instabilities. J. Turbomach. 2019, 141, 081004. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, X.; Yang, F.; Spence, S. Review of unsteady aerodynamic problems and control strategies for the blade tip flow of axial compressors. Prog. Aerosp. Sci. 2025, 152, 101063. [Google Scholar] [CrossRef]

- Yamada, K.; Kikuta, H.; Furukawa, M.; Gunjishima, S.; Hara, Y. Effects of Tip Clearance on the Stall Inception Process in an Axial Compressor Rotor. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, Volume 6C: Turbomachinery. San Antonio, TX, USA, 3–7 June 2013; p. V06CT42A035. [Google Scholar] [CrossRef]

- Mailach, R.; Lehmann, I.; Vogeler, K. Rotating Instabilities in an Axial Compressor Originating From the Fluctuating Blade Tip Vortex. J. Turbomach. 2001, 123, 453–460. [Google Scholar] [CrossRef]

- Benjamin, P.; Ulf, T.; Lars, E. Time-resolved Rotating Instability Waves in an annular Cascade. In Proceedings of the 18th AIAA/CEAS Aeroacoustics Conference (33rd AIAA Aeroacoustics Conference), Colorado Springs, CO, USA, 4–6 June 2012. [Google Scholar] [CrossRef]

- Everitt, J.N.; Spakovszky, Z.S. An Investigation of Stall Inception in Centrifugal Compressor Vaned Diffuser. J. Turbomach. 2013, 135, 011025. [Google Scholar] [CrossRef]

- Bousquet, Y.; Binder, N.; Dufour, G.; Carbonneau, X.; Roumeas, M.; Trebinjac, I. Numerical Simulation of Stall Inception Mechanisms in a Centrifugal Compressor With Vaned Diffuser. J. Turbomach. 2016, 138, 121005. [Google Scholar] [CrossRef]

- Toyama, K.; Runstadler, P.W.; Dean, R.C. An Experimental Study of Surge in Centrifugal Compressors. J. Fluids Eng. 1997, 99, 115–131. [Google Scholar] [CrossRef]

- Hong, S.; Chi, J.; Xiang, X.; Lu, W. Theoretical Model and Numerical Analysis of the Tip Leakage Vortex Variations of a Centrifugal Compressor. Aerospace 2022, 9, 830. [Google Scholar] [CrossRef]

- Xiang, X.; Tong, W.; Bo, Y. Mechanism of stall and surge in a centrifugal compressor with a variable vaned diffuser. Chin. J. Aeronaut. 2018, 31, 1222–1231. [Google Scholar] [CrossRef]

- Iwakiri, K.; Furukawa, M.; Ibaraki, S.; Tomita, I. Unsteady and Three-Dimensional Flow Phenomena in a Transonic Centrifugal Compressor Impeller at Rotating Stall. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Volume 7: Turbomachinery, Parts A and B. Orlando, FL, USA, 8–12 June 2009; pp. 1611–1622. [Google Scholar] [CrossRef]

- Li, Z.L.; Cheng, H.Z.; Wu, Y.F.; Lu, X.G.; Han, G. Numerical investigation of the self-induced unsteadiness phenomenon in the impeller of a high-loading centrifugal compressor. Phys. Fluids 2023, 35, 106119. [Google Scholar] [CrossRef]

- Wang, W.L.; Yang, C.; Hu, C.X.; Zhang, H. Investigation of tip leakage flow unsteadiness and rotating instability in a centrifugal compressor impeller. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 236, 621–638. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Z.; Xi, G. Unsteady flow structures in the tip region for a centrifugal compressor impeller before rotating stall. Sci. China Technol. Sci. 2017, 60, 924–934. [Google Scholar] [CrossRef]

- Kowshik, C.K.P.; Tsugita, D.; Takeyama, Y.; Ohta, Y. Rotating Instability in a Centrifugal Blower With Shrouded Impeller. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Volume 3: Cycle Innovations; Education; Electric Power; Fans and Blowers; Industrial and Cogeneration. Copenhagen, Denmark, 11–15 June 2012; pp. 685–694. [Google Scholar] [CrossRef]

- Jyothishkumar, V.; Mihaescu, M.; Senmlitsch, B.; Fuchs, L. Numerical flow analysis in centrifugal compressor near surge condition. In Proceedings of the 43rd Fluid Dynamics Conference, San Diego, CA, USA, 24–27 June 2013. [Google Scholar] [CrossRef]

- Grondin, J.; Trébinjac, I.; Rochuon, N. Rotating Instabilities Versus Rotating Stall in a High-Speed Centrifugal Compressor. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Volume 2B: Turbomachinery. Oslo, Norway, 11–15 June 2018; p. V02BT44A025. [Google Scholar] [CrossRef]

- Tomita, I.; Ibaraki, S.; Furukawa, M.; Yamada, K. The Effect of Tip Leakage Vortex for Operating Range Enhancement of Centrifugal Compressor. J. Turbomach. 2013, 135, 051020. [Google Scholar] [CrossRef]

- Inoue, M.; Kuroumaru, M.; Tanino, T.; Yoshida, S.; Furukawa, M. Comparative Studies on Short and Long Length-Scale Stall Cell Propagating in an Axial Compressor Rotor. J. Turbomach. 2001, 123, 24–30. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, W. Role of the Inducer in Flow Instability of a High-Speed Centrifugal Compressor Impeller. In Proceedings of the ASME Turbo Expo 2023: Turbomachinery Technical Conference and Exposition, Volume 13D: Turbomachinery—Multidisciplinary Design Approaches, Optimization, and Uncertainty Quantification; Radial Turbomachinery Aerodynamics; Unsteady Flows in Turbomachinery. Boston, MA, USA, 26–30 June 2023; p. V13DT35A016. [Google Scholar] [CrossRef]

- Yang, B.; Cao, T.; Hayashi, Y.; Kanzaka, T.; Tomita, I. Effects of the Blade Tip Loading Distribution on Transonic Centrifugal Impeller Stability. In Proceedings of the ASME Turbo Expo 2024: Turbomachinery Technical Conference and Exposition, Volume 12D: Turbomachinery—Multidisciplinary Design Approaches, Optimization, and Uncertainty Quantification; Radial Turbomachinery Aerodynamics; Unsteady Flows in Turbomachinery. London, UK, 24–28 June 2024; p. V12DT35A017. [Google Scholar] [CrossRef]

- Baltadjiev, N.D.; Lettieri, C.; Spakovszky, Z.S. An Investigation of Real Gas Effects in Supercritical CO2 Centrifugal Compressors. J. Turbomach. 2015, 137, 091003. [Google Scholar] [CrossRef]

- Wang, Y.; Song, M.; Xin, J.; Yang, B. Analysis of the Flow Field at the Tip of an Axial Flow Compressor during Rotating Stall Process Based on the POD Method. Processes 2023, 11, 69. [Google Scholar] [CrossRef]

- Schmid, P. Dynamic mode decomposition of numerical and experimental data. J. Fluid Mech. 2010, 656, 5–28. [Google Scholar] [CrossRef]

- He, X.; Fang, Z.; Rigas, G.; Vahdati, M. Spectral proper orthogonal decomposition of compressor tip leakage flow. Phys. Fluids 2021, 33, 105105. [Google Scholar] [CrossRef]

- Yang, Z.R.; Liu, Y.M.; Sun, S.J.; Wang, J.H. Investigation of modal evolution and flow instability characteristics during radial diffuser stall in high-load centrifugal compressor with a throttle model. Phys. Fluids 2025, 37, 075221. [Google Scholar] [CrossRef]

- Xu, L.C.; Liu, Z.X.; Li, X.J.; Zhao, M.; Zhao, Y.J.; Zhou, T. Dynamic mode characteristics of flow instabilities in a centrifugal compressor impeller. Aerosp. Sci. Technol. 2023, 142, 108707. [Google Scholar] [CrossRef]

- Broatch, A.; García-Tíscar, J.; Roig, F.; Sharma, S. Dynamic mode decomposition of the acoustic field in radial compressors. Aerosp. Sci. Technol. 2019, 90, 388–400. [Google Scholar] [CrossRef]

- Sun, L.H.; Yang, J.; Liu, X.H.; Sun, D.K.; Dong, X. Diagnosis of unsteady disturbance characteristics induced by the tip leakage vortex in a compressor based on data-driven modal decomposition methods. Phys. Fluids 2024, 36, 055151. [Google Scholar] [CrossRef]

- Kou, J.Q.; Zhang, W.W. An improved criterion to select dominant modes from dynamic mode decomposition. Eur. J. Mech. B/Fluids 2017, 62, 109–129. [Google Scholar] [CrossRef]

- Brokopp, R.; Gronski, R. Small engine components test facility compressor testing cell at NASA Lewis Research Center. In Proceedings of the 17th Aerospace Ground Testing Conference, Nashville, TN, USA, 6–8 July 1992; p. 3980. [Google Scholar] [CrossRef]

- Denton, J.D. Loss Mechanisms in Turbomachines. In Proceedings of the ASME 1993 International Gas Turbine and Aeroengine Congress and Exposition, Volume 2: Combustion and Fuels; Oil and Gas Applications; Cycle Innovations; Heat Transfer; Electric Power; Industrial and Cogeneration; Ceramics; Structures and Dynamics; Controls, Diagnostics and Instrumentation; IGTI Scholar Award. Cincinnati, OH, USA, 24–27 May 1993; p. V002T14A001. [Google Scholar] [CrossRef]

- Hah, C.; Bergner, J.; Schiffer, H. Tip Clearance Vortex Oscillation, Vortex Shedding and Rotating Instabilities in an Axial Transonic Compressor Rotor. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Volume 6: Turbomachinery, Parts A, B, and C. Berlin, Germany, 9–13 June 2008; pp. 57–65. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Number of impeller blades | Stage1 (15), Stage2 (15), Stage3 (15) |

| Tip gap height | 0.8mm |

| Impeller inlet diameter | 36.8mm |

| Impeller outlet diameter | 66.0mm |

| Number of diffuser blades | Stage1 (23), Stage2 (19) |

| Diffusers inlet diameter | 51.0mm |

| Diffusers outlet diameter | 22.0mm |

| Design parameters | |

| Mass flow rate | 55.55 kg/s |

| Rotating speed | 5225 r/min |

| Property | Nitrogen |

|---|---|

| Inlet Total Pressure (kPa) | 1511 |

| Inlet Total Temperature (K) | 303.25 |

| Inlet Density(kg·m−3) | 17 |

| Specific Heat at Constant Pressure Cp (J·kg−1·K−1) | 104 |

| Dynamic viscosity (kg·m−1·s−1) | 1.77 × 10−5 |

| Critical Pressure (kPa) | 2.59 × 10−2 |

| Critical Temperature (K) | 126.2 |

| Compressibility factor | 0.995 |

| Inlet Reynolds Number | 5.31 × 106 |

| Mass Flow (kg/s) | Total Pressure Ratio | Isentropic Efficiency (%) | |

|---|---|---|---|

| Exp | 55.55 | 1.604 | 86.12 |

| Sim | 55.55 | 1.716 | 89.88 |

| relative error (%) | 6.98 | 4.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, X.; Zhong, Z.; Chen, H.; Chen, Y.; Wang, M.; Lu, X. Research on Internal Instability Characteristics of Centrifugal Impeller Based on Dynamic Mode Decomposition. Fluids 2025, 10, 246. https://doi.org/10.3390/fluids10090246

Fan X, Zhong Z, Chen H, Chen Y, Wang M, Lu X. Research on Internal Instability Characteristics of Centrifugal Impeller Based on Dynamic Mode Decomposition. Fluids. 2025; 10(9):246. https://doi.org/10.3390/fluids10090246

Chicago/Turabian StyleFan, Xiaoping, Zhuhai Zhong, Hongfen Chen, Yang Chen, Meng Wang, and Xiaodong Lu. 2025. "Research on Internal Instability Characteristics of Centrifugal Impeller Based on Dynamic Mode Decomposition" Fluids 10, no. 9: 246. https://doi.org/10.3390/fluids10090246

APA StyleFan, X., Zhong, Z., Chen, H., Chen, Y., Wang, M., & Lu, X. (2025). Research on Internal Instability Characteristics of Centrifugal Impeller Based on Dynamic Mode Decomposition. Fluids, 10(9), 246. https://doi.org/10.3390/fluids10090246