Cavitation–Velocity Correlation in Cavitating Flows Around a Clark-Y Hydrofoil Using a Data-Driven U-Net

Abstract

1. Introduction

2. Numerical Methodology

2.1. Problem Description

2.2. Numerical Model

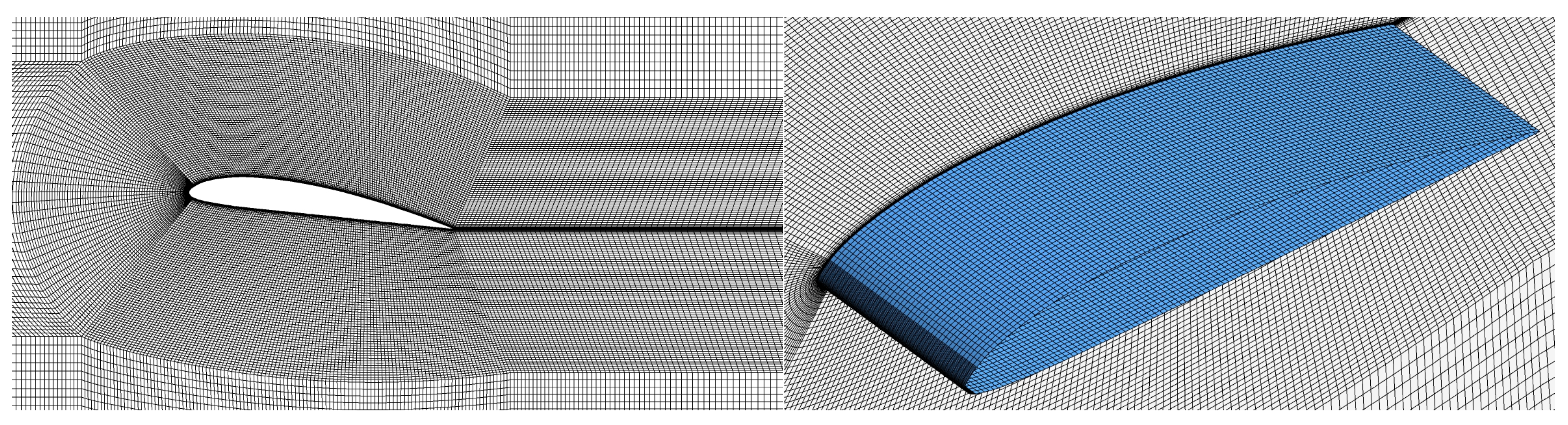

2.3. Numerical Setup

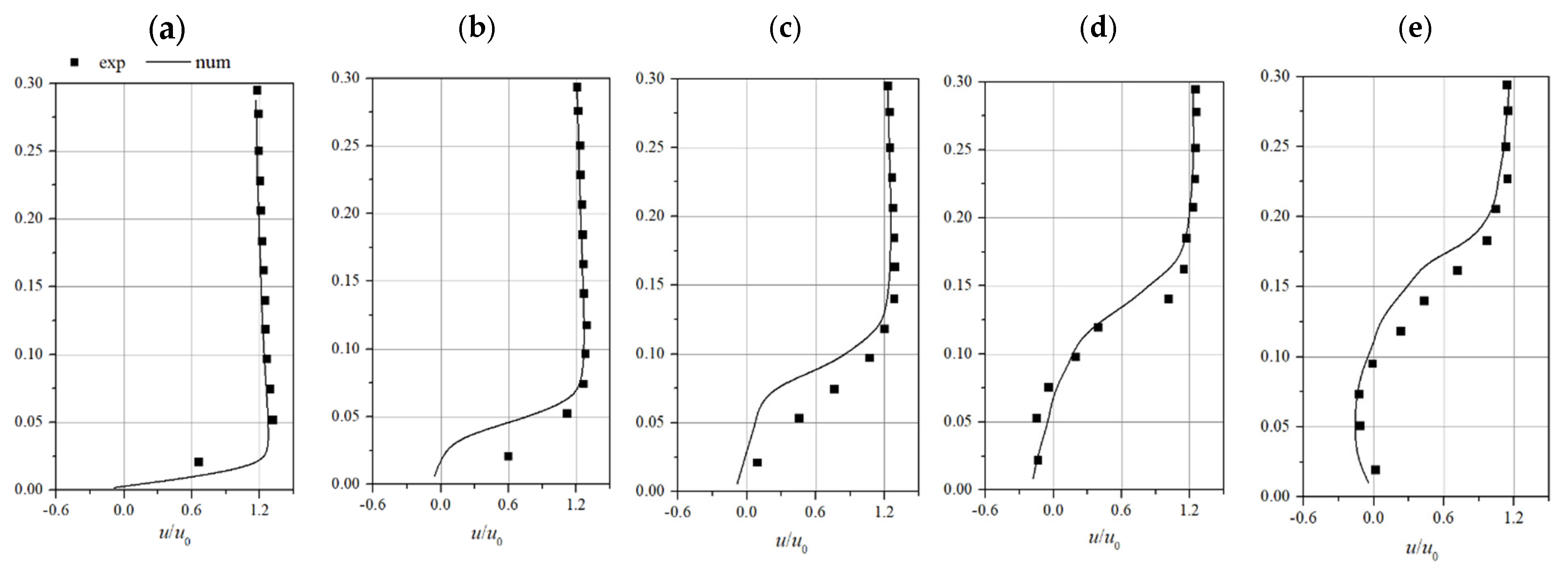

2.4. Validation of Simulation

3. U-Net Neural Network

3.1. Dataset Preparation

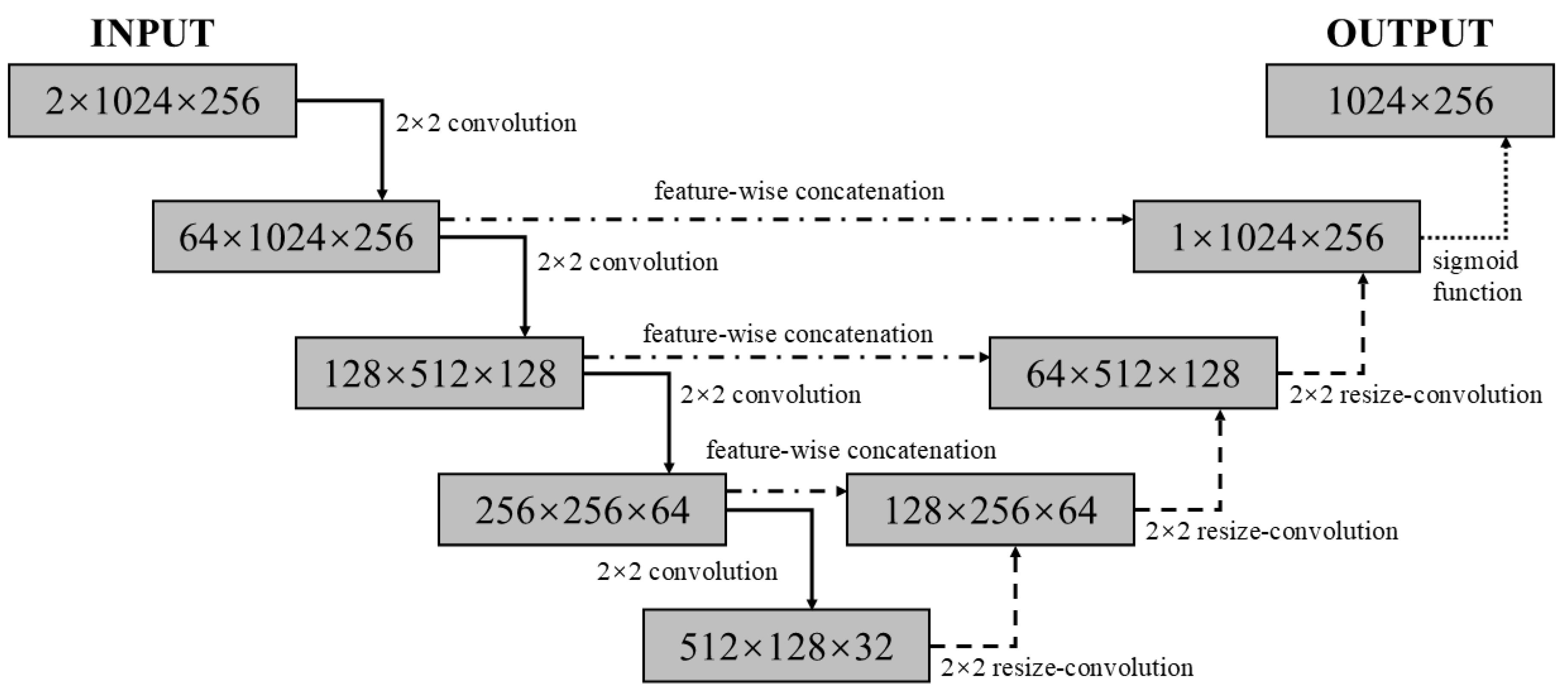

3.2. Neural Network Architecture

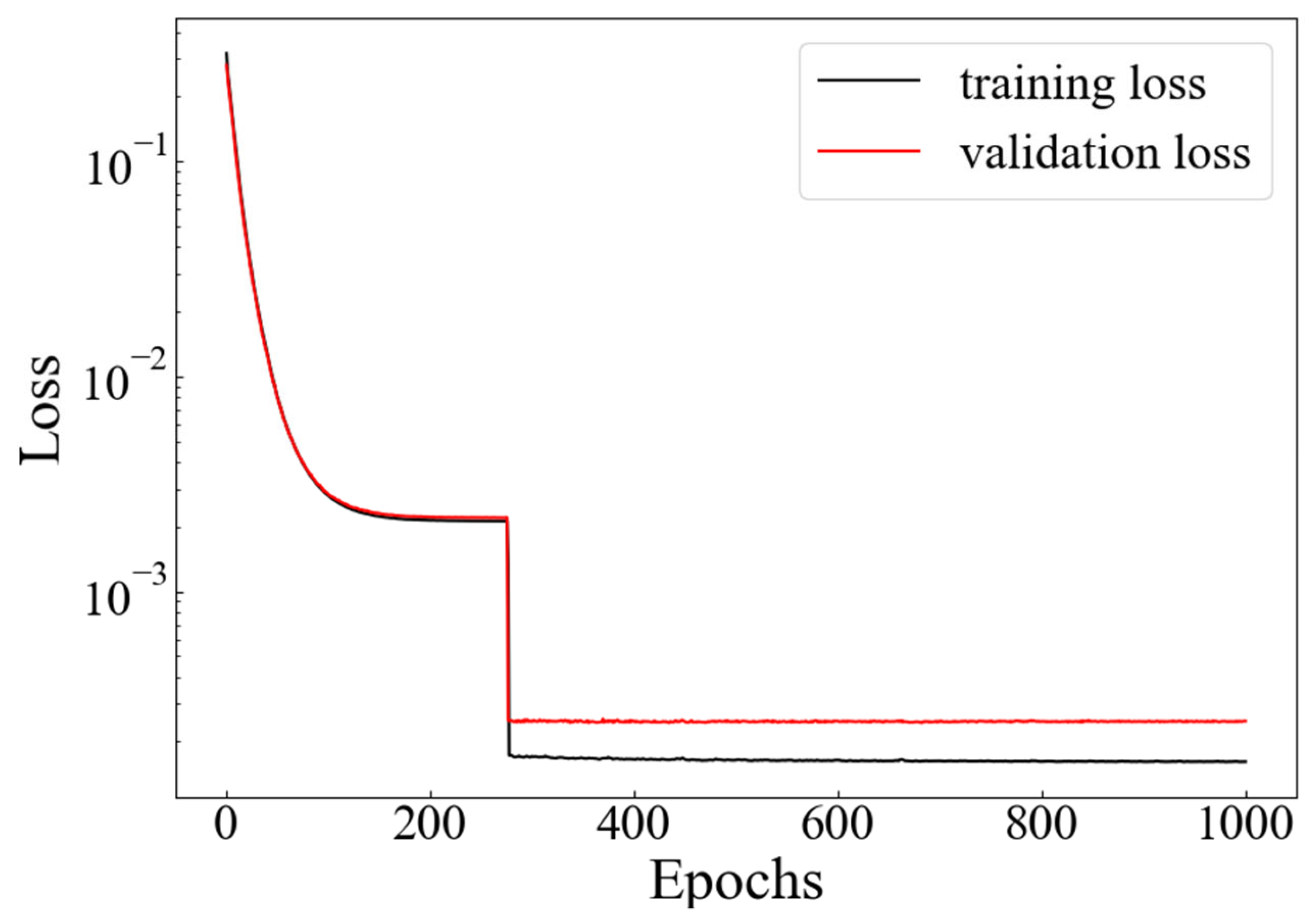

3.3. Training Process

4. Results and Discussions

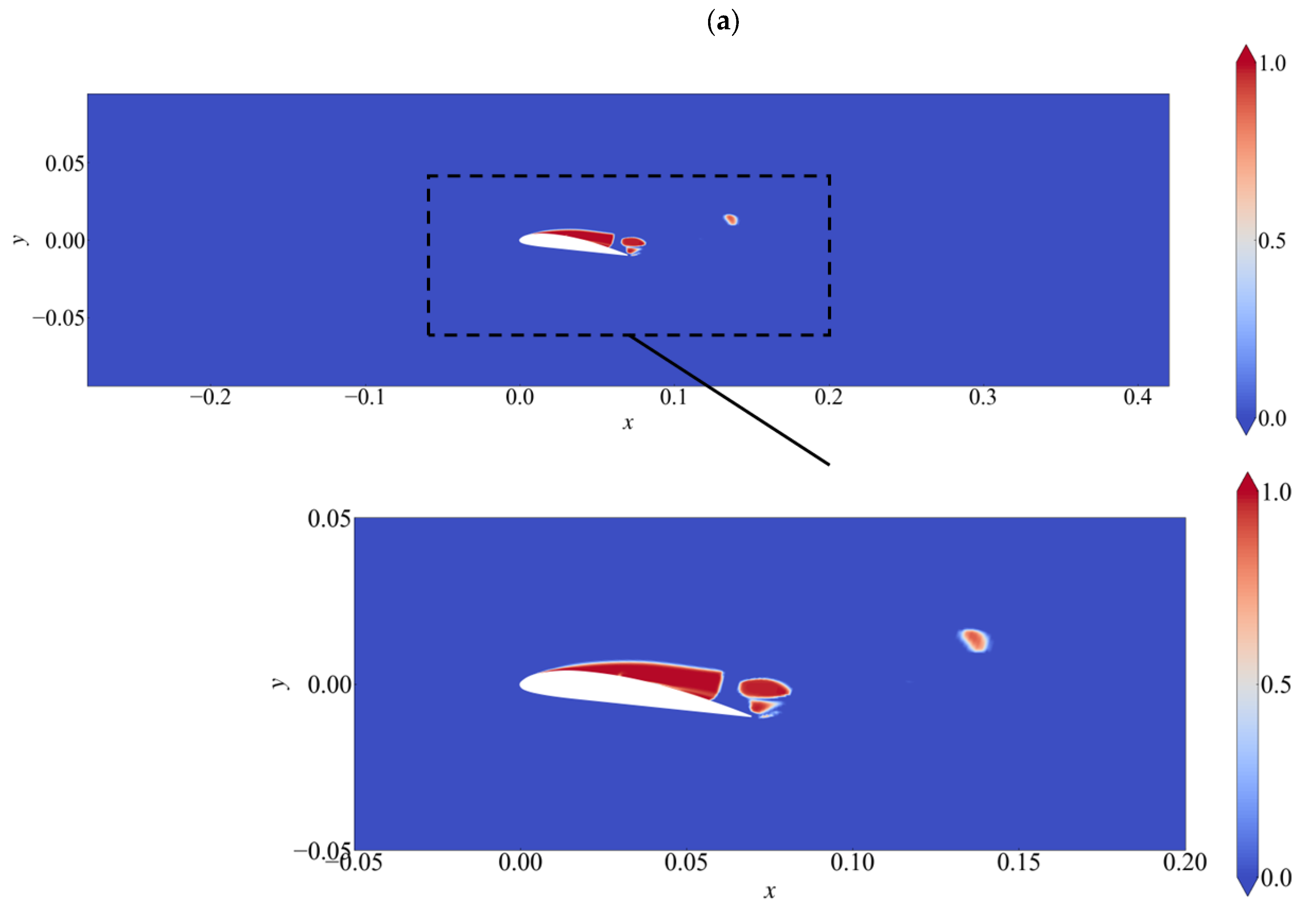

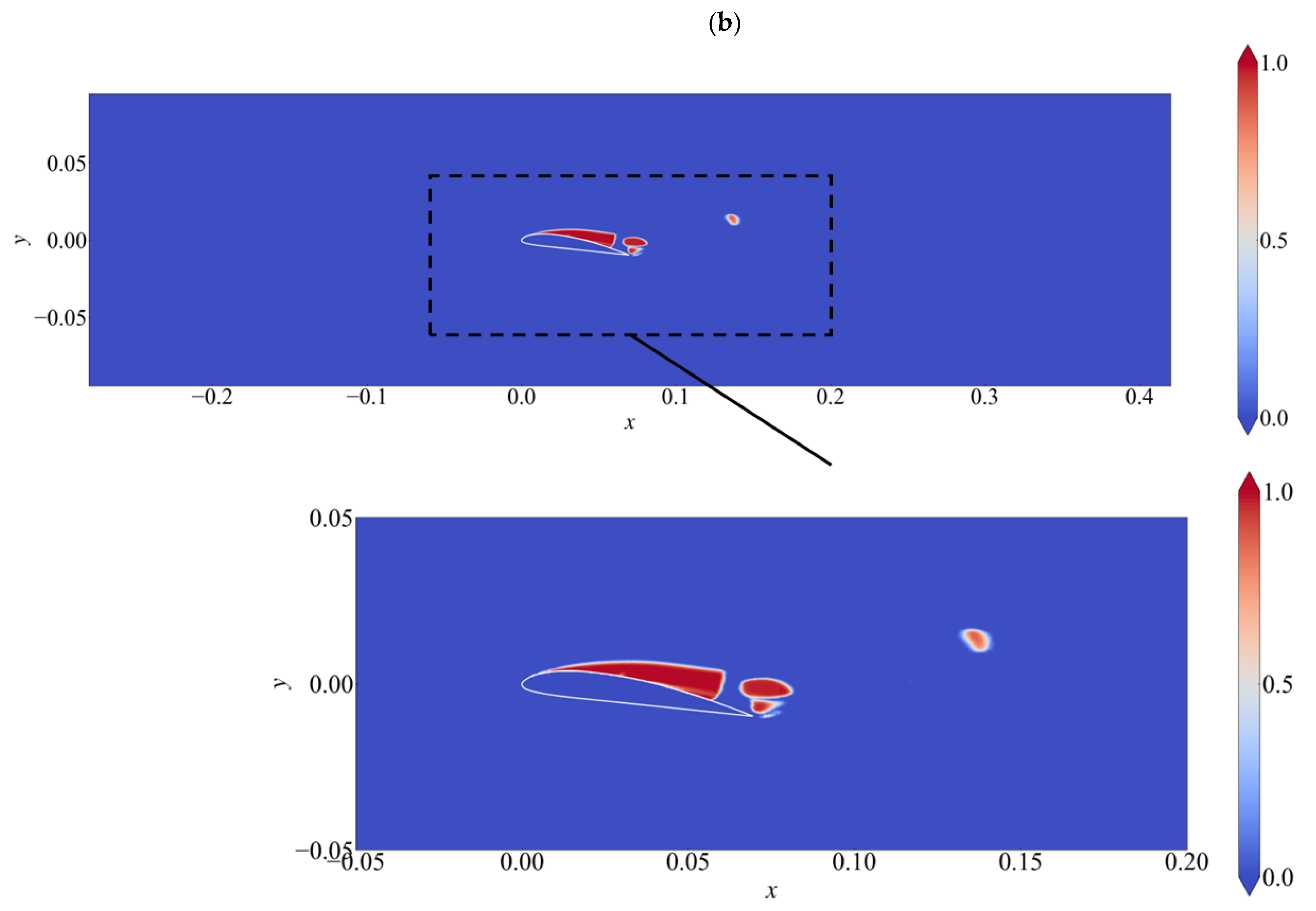

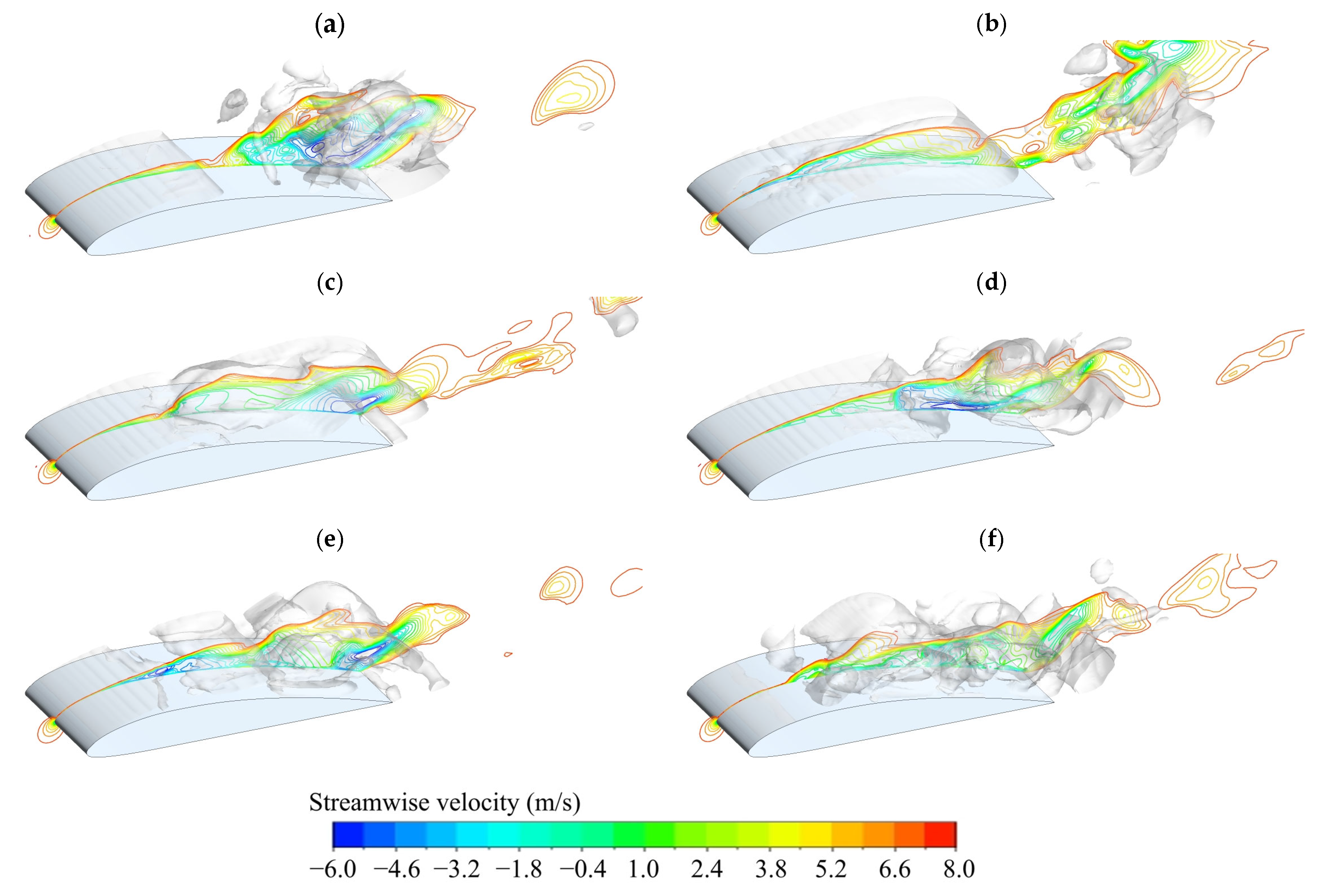

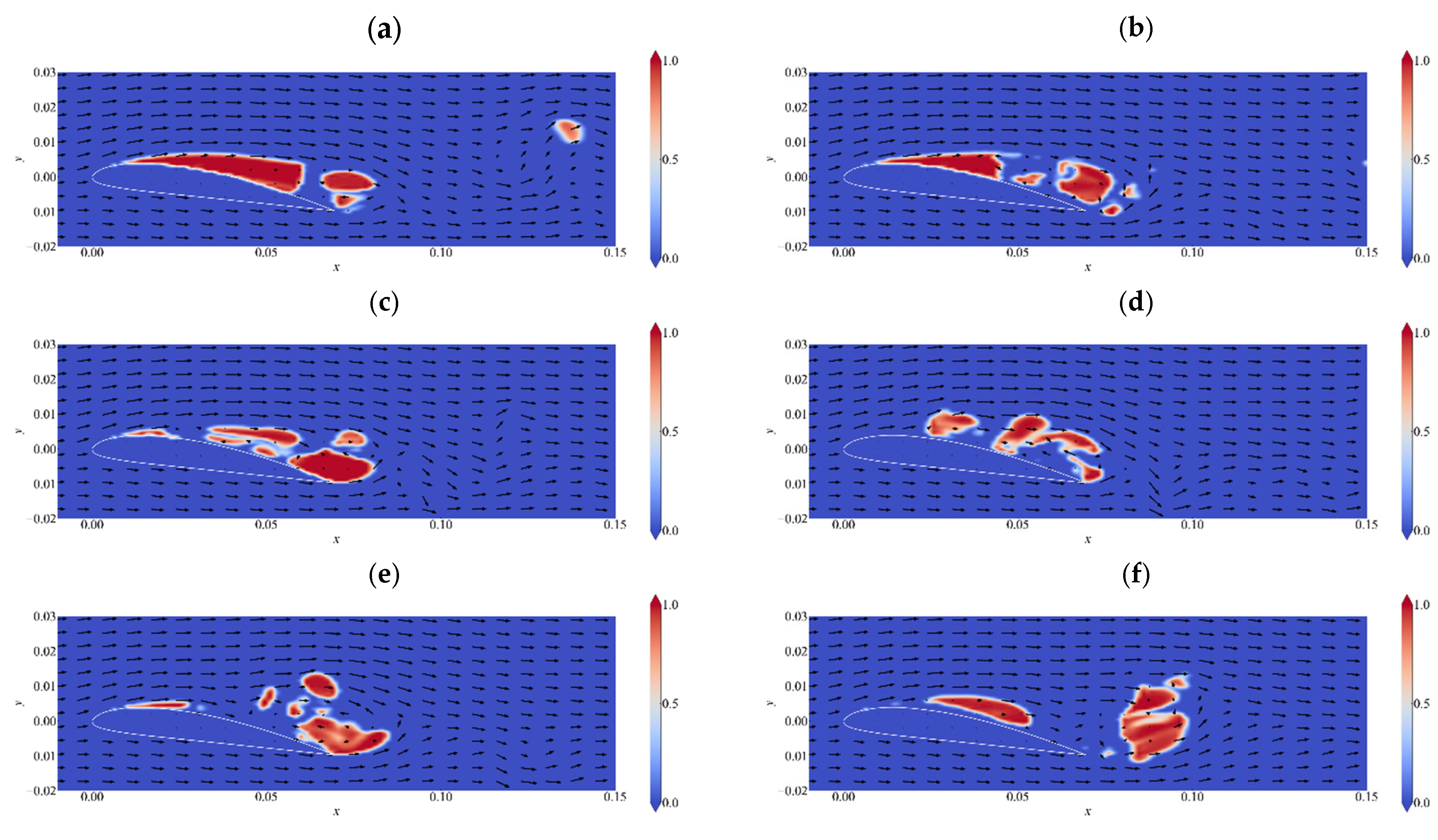

4.1. Evolution of Cavitating Flow

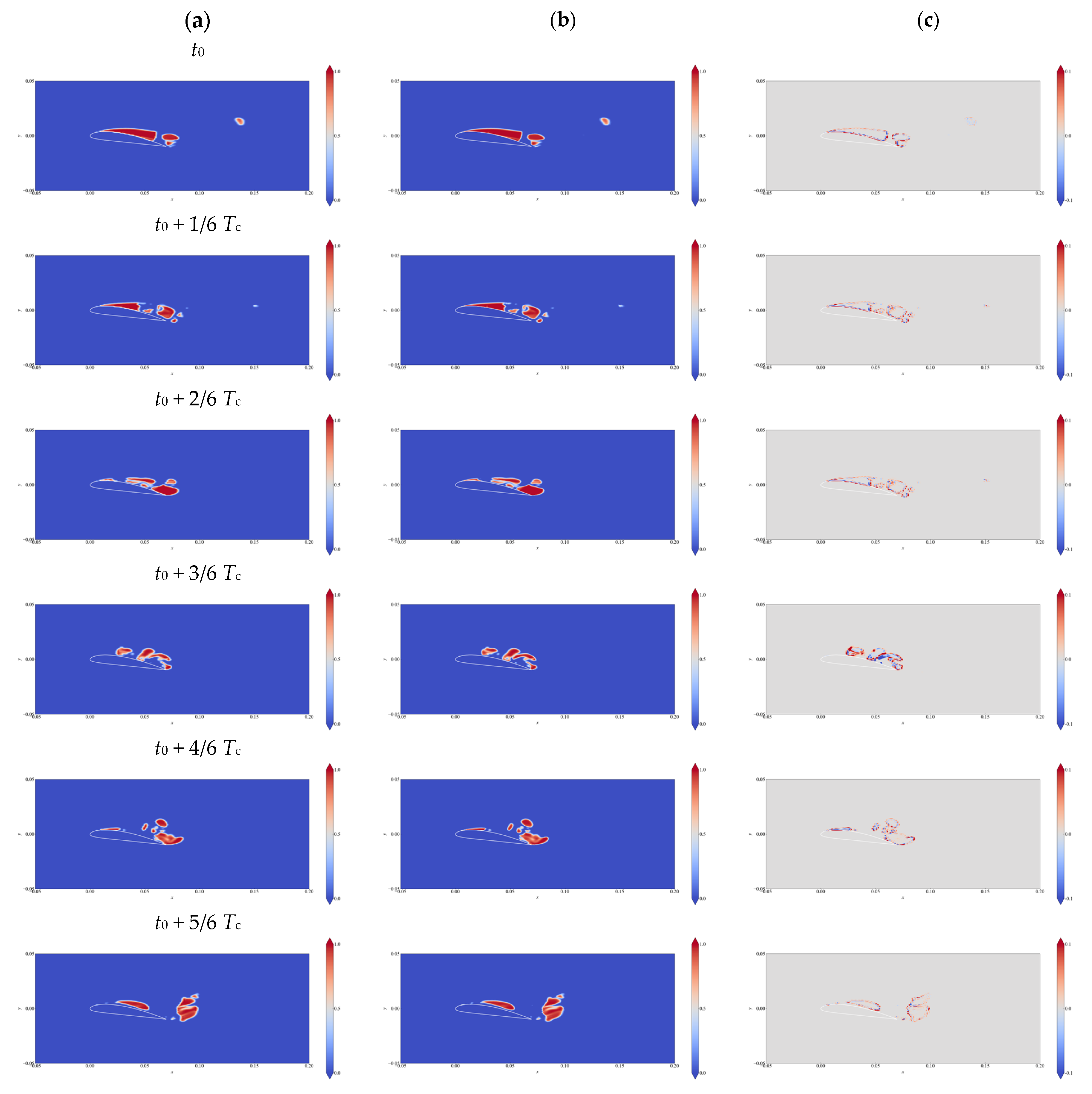

4.2. Prediction of Cavitation by U-Net

4.3. Cavitation–Velocity Correlation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, Y.P.; Tan, L.; Han, Y.D.; Liu, M. Cavitation-vibration correlation of a mixed flow pump under steady state and fast start-up conditions by experiment. Ocean Eng. 2022, 251, 11158. [Google Scholar] [CrossRef]

- Sun, W.H.; Tan, L. Cavitation-Vortex-Pressure Fluctuation Interaction in a Centrifugal Pump Using Bubble Rotation Modified Cavitation Model Under Partial Load. ASME J. Fluids Eng. 2020, 142, 051206. [Google Scholar] [CrossRef]

- Luo, X.W.; Ji, B.; Tsujimoto, Y. A review of cavitation in hydraulic machinery. J. Hydrodyn. 2016, 28, 335–358. [Google Scholar] [CrossRef]

- Kan, K.; Binama, M.; Chen, H.X.; Zheng, Y.; Zhou, D.Q.; Su, W.T.; Muhirwa, A. Pump as turbine cavitation performance for both conventional and reverse operating modes: A review. Renew. Sustain. Energy Rev. 2022, 168, 112786. [Google Scholar] [CrossRef]

- Donmez, A.H.; Yumurtaci, Z.; Kavurmacioglu, L. The Effect of Inlet Blade Angle Variation on Cavitation Performance of a Centrifugal Pump: A Parametric Study. ASME J. Fluids Eng. 2019, 141, 021101. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, D.; Xu, B.; Shi, W.; van Esch, B.P.M. Experimental and numerical investigation on the effect of tip leakage vortex induced cavitating flow on pressure fluctuation in an axial flow pump. Renew. Energy 2021, 163, 1195–1209. [Google Scholar] [CrossRef]

- Han, Y.D.; Tan, L. Experimental investigation on spatial-temporal evolution of tip leakage cavitation in a mixed flow pump with tip clearance. Int. J. Multiph. Flow 2023, 164, 104445. [Google Scholar] [CrossRef]

- Han, Y.D.; Tan, L. Spatial-temporal evolution of tip leakage cavitation with double-hump in a mixed flow pump with tip clearance. Phys. Fluids 2023, 35, 045152. [Google Scholar]

- Wang, G.; Senocak, I.; Shyy, W.; Ikohagi, T.; Cao, S. Dynamics of attached turbulent cavitating flows. Prog. Aerosp. Sci. 2001, 37, 551–581. [Google Scholar] [CrossRef]

- Leroux, J.B.; Astolfi, J.A.; Billard, J.Y. An Experimental Study of Unsteady Partial Cavitation. ASME J. Fluids Eng. 2004, 126, 94–101. [Google Scholar] [CrossRef]

- Cervone, A.; Bramanti, C.; Rapposelli, E.; d’Agostino, L. Thermal Cavitation Experiments on a NACA 0015 Hydrofoil. ASME J. Fluids Eng. 2006, 128, 326–331. [Google Scholar] [CrossRef]

- Foeth, E.J.; van Doorne, C.W.H.; van Terwisga, T.; Wieneke, B. Time resolved PIV and flow visualization of 3D sheet cavitation. Exp. Fluids 2006, 40, 503–513. [Google Scholar] [CrossRef]

- Dular, M.; Bachert, R.; Stoffel, B.; Sirok, B. Experimental evaluation of numerical simulation of cavitating flow around hydrofoil. Eur. J. Mech. B/Fluids 2005, 24, 522–538. [Google Scholar] [CrossRef]

- Huang, B.; Young, Y.L.; Wang, G.; Shyy, W. Combined Experimental and Computational Investigation of Unsteady Structure of Sheet/Cloud Cavitation. ASME J. Fluids Eng. 2013, 135, 071301. [Google Scholar] [CrossRef]

- Coutier-Delgosha, O.; Fortes-Patella, R.; Rebound, J.L. Evaluation of the Turbulence Model Influence on the Numerical Simulations of Unsteady Cavitation. ASME J. Fluids Eng. 2003, 125, 38–45. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, Y.; Wang, G. Large Eddy Simulation of turbulent vortex-cavitation interactions in transient sheet/cloud cavitating flows. Comput. Fluids 2014, 92, 113–124. [Google Scholar] [CrossRef]

- Ji, B.; Luo, X.W.; Arndt, R.E.A.; Peng, X.; Wu, Y. Large Eddy Simulation and theoretical investigations of the transient cavitating vortical flow structure around a NACA66 hydrofoil. Int. J. Multiph. Flow 2015, 68, 121–134. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Liu, Y.B.; Xu, Y.; Cao, S.L. Large eddy simulation of cavitation vortex interaction and pressure fluctuation around hydrofoil ALE 15. Ocean. Eng. 2018, 163, 264–274. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Caso, S.L. Cavitation-Vortex-Turbulence Interaction and One-Dimensional Model Prediction of Pressure for Hydrofoil ALE15 by Large Eddy Simulation. ASME J. Fluids Eng. 2019, 141, 021103. [Google Scholar] [CrossRef]

- Lord Rayleigh, O.M.F.R.S. On the pressure developed in a liquid during the collapse of a spherical cavity. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1917, 34, 94–98. [Google Scholar] [CrossRef]

- Plesset, M.S. The dynamics of cavitation bubbles. ASME J. Appl. Mech. 1949, 16, 228–231. [Google Scholar] [CrossRef]

- Singhal, A.; Athavale, M.; Li, H.; Jiang, Y. Mathematical basis and validation of the full cavitation model. ASME J. Fluids Eng. 2002, 124, 617–624. [Google Scholar] [CrossRef]

- Zwart, P.; Gerber, A.; Belarmri, T. A two-phase flow model for predicting cavitation dynamics. In Proceedings of the 5th International Conference on Multiphase Flow, Yokohama, Japan, 30 May–3 June 2004. [Google Scholar]

- Sauer, J.; Schnerr, G. Unsteady cavitating flow-a new cavitation model based on a modified front capturing method and bubble dynamics. In Proceedings of the ASME Fluids Engineering Summer Conference, Boston, MA, USA, 11–15 June 2000. [Google Scholar]

- Schnerr, G.; Sauer, J. Physical and numerical modeling of unsteady cavitation dynamics. In Proceedings of the 4th International Conference on Multiphase Flow, New Orleans, LA, USA, 27 May–1 June 2001. [Google Scholar]

- Zhao, Y.; Wang, G.; Huang, B.; Wu, Q. Lagrangian investigations of vortex dynamics in time-dependent cloud cavitating flows. Int. J. Heat Mass Transf. 2016, 93, 167–174. [Google Scholar] [CrossRef]

- Tseng, C.C.; Liu, P.B. Dynamic behaviors of the turbulent cavitating flows based on the Eulerian and Lagrangian viewpoints. Int. J. Heat Mass Transf. 2016, 102, 479–500. [Google Scholar] [CrossRef]

- Long, X.; Cheng, H.; Ji, B.; Arndt, R.E.A.; Peng, X. Large eddy simulation and Euler–Lagrangian coupling investigation of the transient cavitating turbulent flow around a twisted hydrofoil. Int. J. Multiph. Flow 2018, 100, 41–56. [Google Scholar] [CrossRef]

- Berkooz, G.; Holmes, P.; Lumley, J.L. The proper orthogonal decomposition in the analysis of turbulent flows. Annu. Rev. Fluid Mech. 1993, 25, 539–575. [Google Scholar] [CrossRef]

- Meyer, K.E.; Pedersen, J.M.; Ozcan, O. A turbulent jet in cross flow analysed with proper orthogonal decomposition. J. Fluid Mech. 2007, 583, 199–227. [Google Scholar] [CrossRef]

- Schmid, P.J. Dynamic mode decomposition of numerical and experimental data. J. Fluid Mech. 2010, 656, 5–28. [Google Scholar] [CrossRef]

- Schmid, P.J. Application of the dynamic mode decomposition to experimental data. Exp. Fluids 2011, 50, 1123–1130. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Dynamic mode decomposition of cavitating flow around ALE 15 hydrofoil. Renew. Energy 2019, 139, 214–227. [Google Scholar] [CrossRef]

- Yin, T.; Pavesi, G.; Yuan, S. Numerical investigation of unsteady cavitation around a twisted hydrofoil. Int. J. Multiph. Flow 2021, 135, 103506. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Fontanarosa, D.; Ficarella, A. Characterization of unsteady cavitating flow regimes around a hydrofoil, based on an extended Schnerr–Sauer model coupled with a nucleation model. Int. J. Multiph. Flow 2015, 115, 158–180. [Google Scholar] [CrossRef]

- Brunton, S.L.; Noack, B.R.; Koumoutsakos, P. Machine Learning for Fluid Mechanics. Annu. Rev. Fluid Mechanics 2020, 52, 477–508. [Google Scholar] [CrossRef]

- Kim, H.; Kim, J.; Won, S.; Lee, C. Unsupervised deep learning for super-resolution reconstruction of turbulence. J. Fluid Mech. 2021, 910, A29. [Google Scholar] [CrossRef]

- List, B.; Chen, L.W.; Thuerey, N. Learned turbulence modelling with differentiable fluid solvers: Physics-based loss functions and optimisation horizons. J. Fluid Mech. 2022, 949, A25. [Google Scholar] [CrossRef]

- Nicoud, F.; Ducros, F. Subgrid-scale stress modelling based on the square of the velocity gradient tensor. Flow Turbul. Combust. 1999, 62, 183–200. [Google Scholar] [CrossRef]

- Long, X.P.; Cheng, H.Y.; Ji, B.; Arndt, R.E. Numerical investigation of attached cavitation shedding dynamics around the Clark-Y hydrofoil with the FBDCM and an integral method. Ocean Eng. 2017, 137, 247–261. [Google Scholar] [CrossRef]

- Long, Y.; Long, X.P.; Ji, B.; Xing, T. Verification and validation of Large Eddy Simulation of attached cavitating flow around a Clark-Y hydrofoil. Int. J. Multiph. Flow 2019, 115, 93–107. [Google Scholar] [CrossRef]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. Int. Conf. Med. Image Comput. Comput.-Assist. Interv. 2015, 9351, 234–241. [Google Scholar]

- Thuerey, N.; Weibenow, K.; Prandtl, L.; Hu, X. Deep Learning Methods for Reynolds-Averaged Navier–Stokes Simulations of Airfoil Flows. AIAA J. 2020, 58, 25–36. [Google Scholar] [CrossRef]

- Paszke, A.; Gross, S.; Massa, F.; Lerer, A.; Bradbury, J.; Chanan, G.; Killeen, T.; Gimelshein, N.; Antiga, L.; Desmaison, A.; et al. PyTorch: An imperative style, high-performance deep learning library. In Proceedings of the 33rd International Conference on Neural Information Processing Systems, Red Hook, NY, USA, 8 December 2019; Volume 721, pp. 8026–8037. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Han, B.; Liu, M.; Tan, L. Cavitation–Velocity Correlation in Cavitating Flows Around a Clark-Y Hydrofoil Using a Data-Driven U-Net. Fluids 2025, 10, 213. https://doi.org/10.3390/fluids10080213

Han Y, Han B, Liu M, Tan L. Cavitation–Velocity Correlation in Cavitating Flows Around a Clark-Y Hydrofoil Using a Data-Driven U-Net. Fluids. 2025; 10(8):213. https://doi.org/10.3390/fluids10080213

Chicago/Turabian StyleHan, Yadong, Bingfu Han, Ming Liu, and Lei Tan. 2025. "Cavitation–Velocity Correlation in Cavitating Flows Around a Clark-Y Hydrofoil Using a Data-Driven U-Net" Fluids 10, no. 8: 213. https://doi.org/10.3390/fluids10080213

APA StyleHan, Y., Han, B., Liu, M., & Tan, L. (2025). Cavitation–Velocity Correlation in Cavitating Flows Around a Clark-Y Hydrofoil Using a Data-Driven U-Net. Fluids, 10(8), 213. https://doi.org/10.3390/fluids10080213