2. Equations of the Present Model with Particle Migration

With the present model, hydrodynamics of an incompressible Newtonian fluid with distributed solid spherical particles of radius

rS is governed by the modified form of Navier-Stokes equations:

where

x and

t are spatial coordinates and time,

p(

x,

t) is the pressure field of the particle-fluid suspension,

v(

x,

t) is the velocity field of the suspension (defined as the velocity field of the geometrical center of the representative unit cell of suspension),

vm(

x,

t) is the velocity field of the mass center of the representative unit cell (defined by (A3) in

Appendix A), d/dt denotes the material derivative of the associated velocity field along its own streamlines, the effective density

ρ(

x,

t) (per unit volume) of the suspension is given by (A2) in

Appendix A,

ρS and

ρf are the densities of the particles and the carrier fluid, respectively,

δ(

x,

t) is the volume fraction of particles,

μ is the effective viscosity of the suspension which can be estimated by Einstein’s formula

, based on the viscosity μ

f of the carrier fluid and the volume fraction of particles, and

and

are the gradient and Laplacian operators, respectively. In general, if the particle volume fraction

δ(

x,

t) changes with spatial position and time due to particle migration, the mass density

ρ(

x,

t) and the effective viscosity

μ (then the coefficients

a and

b defined below in (5)) can depend on spatial position and time.

An additional relationship between

vm(

x, t) and

v(

x, t) is given as:

Here, d/dt denotes the material derivative of the associated velocity field along its own streamlines, the coefficients

a and

b are derived by considering the Stokes drag and the forces acting on dispersed particles due to added mass and fluid acceleration [

26,

27], which are expected to be dominant over other forces (such as the lift forces) for non-neutrally buoyant particles in the dilute limit, see

Appendix A for a derivation of Equations (1)–(5).

It is stated that the second terms inside the brackets in the expressions of

a and

b in (5) will be absent (then

) if only the Stokes drag is considered, and

a =

b and

vm(

x, t) =

v(

x, t) when either

δ = 0 or

ρS =

ρf (“neutrally buoyant particles”) and then the present model for

v(

x, t) reduces to single-phase models [

28,

29] (see Equation (A1) in

Appendix A). Here, it should be stated that the migration of neutrally buoyant particles (

) requests a more complete description of various lift forces acting on dispersed particles [

30,

31,

32,

33] which requests non-trivial numerical computation and have not been considered by the present model, and therefore the present model and derived formulas are not intended to be applied for the migration of neutrally buoyant particles.

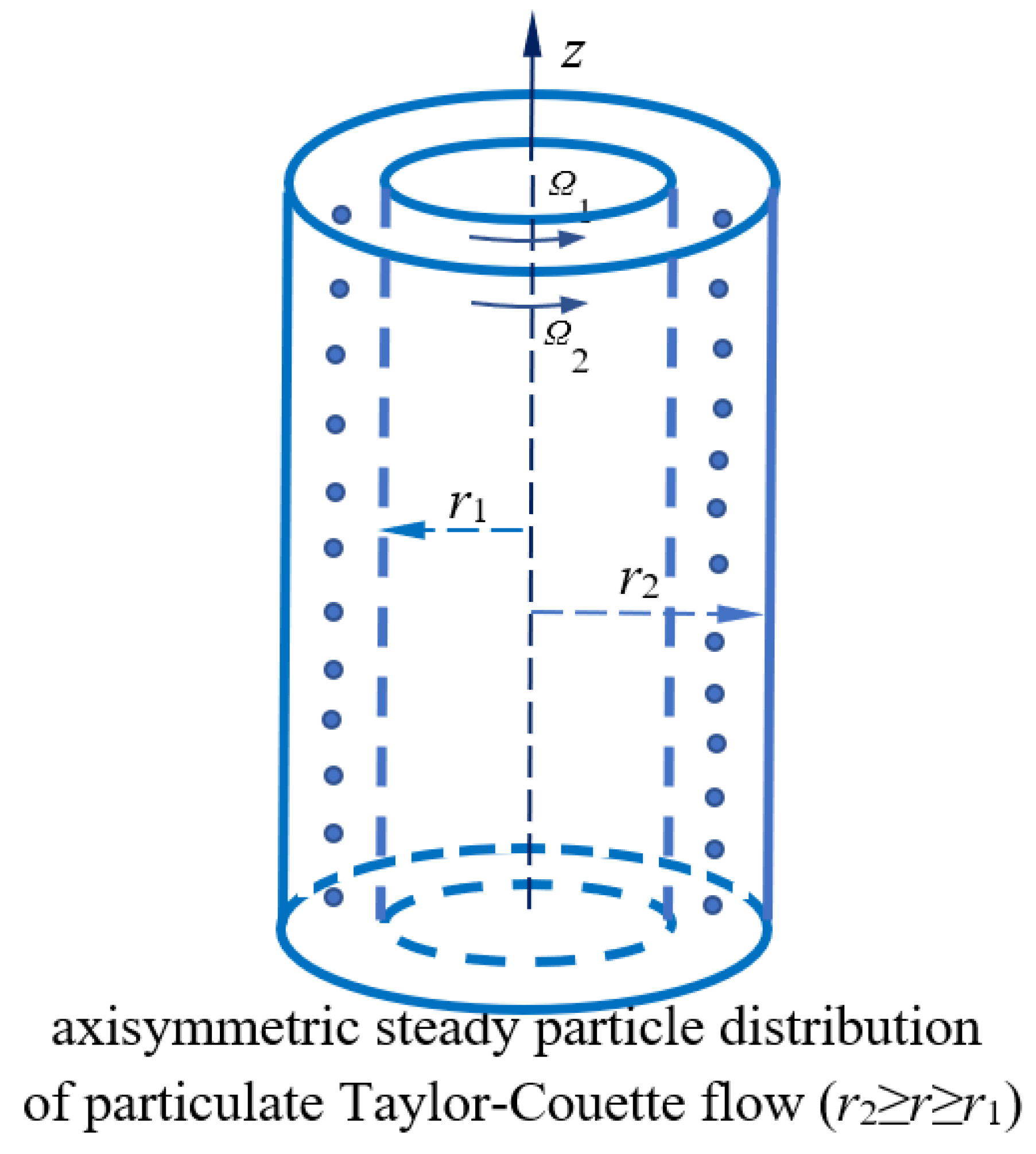

3. Steady Particulate Taylor-Couette Flow with Non-Neutrally Buoyant Particles

Let us consider the steady axisymmetric flow of an incompressible viscous fluid with axisymmetrically distributed particles between two infinitely long coaxial rotating cylinders, as shown in

Figure 1. With the cylindrical coordinates (

r,

θ,

z), the particle-fluid suspension occupies the space (

r1 ≤

r ≤

r2, -∞ ≤

z ≤ +∞), and the inner and outer cylinders, of radii

r1 and

r2, rotate at two counter-clockwise angular velocities

Ω1 and

Ω2, respectively.

For the axisymmetric steady TC flow between two infinitely long cylinders in the cylindrical coordinates (

r,

θ,

z), the flow is independent on (

θ,

z,

t) and we seek for the solution with (

u =

w = 0,

wm = 0) and

where

p(

r) is the pressure field, (

u,

v,

w) are the (

r,

θ,

z) components of the velocity filed

v of the suspension, while (

um,

vm,

wm) are the (

r,

θ,

z) components of the velocity field

vm of the mass center of representative unit cell,

δ(

r) is the particle volume fraction to be determined, and therefore the effective viscosity and mass density

μ(

r) and

ρ(

r) of the suspension which depend on

δ(

r) vary with the radial coordinate

r. In particular, the volume-averaged radial velocity of the suspension

implies that the radial flux

of the particles is equal but opposite to the radial flux

of the fluid and therefore the amplitude of radial velocity

uf of the fluid is vanishingly small as compared to the radial velocity

uS of the particles in the dilute limit (as δ is vanishingly small).

It is verified that three of the eight Equations (1)–(4) are met identically by (6) and the other five give the following 5 nonlinear equations for (

v,

um,

vm,

p,

δ) as the functions of the variable

r.Kinematic boundary conditions on the normal velocity (based on the volume conservation of the particle-fluid suspension) and no-slip boundary conditions on two tangential velocities imposed on the velocity field

v(

x,

t) of the suspension on the two rotating cylinders are met by (6) with

As shown below, all flow fields can be determined uniquely by Equations (1)–(4) with the above boundary conditions imposed on the velocity field v(x, t) of the suspension without additional boundary conditions on other velocity fields.

It should be stated that, instead of the above boundary conditions adopted by the present model, a different version of boundary conditions has been adopted in some two-fluid models of particle-laden fluids in Eulerian description. Specifically, the Saffman model [

34] and its extended versions [

35,

36,

37,

38,

39] have adopted the zero-velocity conditions (

vf = 0) of the velocity field

vf(

x,

t) of the carrier fluid (instead of the velocity field

v(

x,

t) of the suspension) on fixed solid boundary. The two versions of the boundary conditions do not impose the zero-normal flux condition on the dispersed particles, and therefore the particle accumulation (suction) or invasion (injection) (with

) on the solid boundary is allowed (see e.g., Michael and Norey [

35] for TC flow with the Saffman model, where it is assumed that the particles can be deposited on the solid wall and the particles deposited on the solid wall can move into the TC system between the two cylinders). Particle accumulation/sedimentation on the solid boundaries could be a realistic physical phenomenon [

5,

35,

40], although accurate description of particle accumulation on solid boundary requests extensive Lagrangian modeling of individual particles, which is beyond the scope of the two-fluid models in Eulerian description. On the other hand, if the zero-normal flux condition of particles is requested to be met on all sidewalls, the present model could be upgraded with a refined description of forces acting on dispersed particles (such as Faxen viscous force [

5,

22,

32,

41]), which adds higher-order terms to (A6), (A7), and (4) and makes it possible to impose additional zero-normal flux condition to the dispersed particles on solid boundary. It should be stated that this issue of the present model (

on the solid boundary, shared by the Saffman model and its many extended versions) does not appear in some important problems (such as stability of parallel plane or pipe flow, where the zero-normal velocity boundary condition of the carrier fluid or the suspension implies that the normal velocity of the particles vanishes on the solid boundary, see e.g., [

34,

39,

42,

43]), and particularly its influence on the flow field could be insignificant for a particle-laden fluid in the dilute limit.

Before our discussion on steady spatial distribution of particles, it is noted that exact solution of (9) gives

and it follows from

u = 0 and (A4) that

. Since the radial flux of the particles is equal but opposite to the radial flux of the fluid,

u = 0 and

um ≠ 0 can coexist for the non-neutrally buoyant particles

with the non-zero normal flux

of particles on the permeable solid walls [

3,

44,

45,

46,

47,

48,

49]. Therefore, if the solid walls are impermeable and the zero-normal flux boundary condition

of dispersed particles is imposed on the two cylinders, we shall have

um ≡ 0 identically between the two cylinders. It is easily verified from (11) and (12) that

um ≡ 0 implies that

v =

vm and

, and the non-trivial spatial distribution

of particles cannot exist. It concludes that the non-trivial steady distribution of particles can exist only if

is allowed on the cylinders which means that the solid walls are permeable [

3,

44,

45,

46,

47,

48,

49] and the particles and the fluid can be sucked or injected on the permeable cylinder walls with equal but opposite normal fluxes. The present paper is based on this assumption.

In what follows, we shall focus on Equations (9)–(12) for the three velocity fields and the particle distribution (

v,

um,

vm,

δ), and the pressure

p(

r) can be determined from (8) once (

um,

vm) are known. For a clear fluid (

δ = 0) without dispersed particles, we have [

1,

2]

Let us write the particle-disturbed flow fields as

It follows from the boundary conditions (13) that

Here, let us focus on the dilute limit of particle-laden fluids when the volume fraction of particles is vanishingly small. Therefore, it is assumed that the disturbed velocity fields (

v1,

u1m,

v1m) due to dispersed particles are small as compared to the original flow field of a clear fluid without particles and the volume fraction

δ(

r) is much smaller than unity. With the Einstein formula

, up to the first power of

δ(r), the

δ–dependent coefficients (

μ,

ρ,

a,

b) are expanded as:

Substituting (15) and (17) into (9)–(12) and ignoring all nonlinear terms of (

v1,

u1m,

v1m) and

δ(r), the linear equations for (

v1,

u1m,

v1m) and

give

And the pressure field p(r) can be determined from (8) once (um(r), vm(r), and δ(r)) are known.

It is easily verified from (20) and (21) that if

u1m = 0, we have

v1 =

v1m and

It is the case when

r1 = 0 (then (18) gives

u1m = 0). In what follows, let us consider TC flow with two cylinders

r1 > 0. Thus, (18) gives

u1m =

X/

r with a constant

X (which represents the magnitude of the steady particle distribution, as shown below), and

v1(

r) can be determined by two no-slip boundary conditions (16) and

Explicit expression for

δ(

r) ≥ 0 in the dilute limit is determined from (20) and (21) by

Evidently, v1m(r) can be determined from (21) once v1(r) is determined. In particular, the expression for steady particle distribution given by (22) and (23) remains unchanged if the no-slip boundary conditions for the two tangential velocity components are imposed on the velocity field vf of the carrier fluid (adopted by Saffman model and its extended versions) instead of the velocity field v of the suspension (assumed by the present model).

It is seen from (A4), (A8), and (22) that, up to the lowest-order approximation, the condition (∂δ/∂t = 0) for steady particle distribution is met by

u1m =

X/

r. Specifically, Equation (9) or its linearized version (18) ensures that, up to the lowest-order approximation, the volume fraction of particles at any location will not change with time, although the particle migration is not ceased due to the radial velocity field

of dispersed particles. This explains why the coefficient

X represents the magnitude of the steady particle distribution, and why such non-trivial steady spatial distribution does not exist when the inner cylinder is absent (

X = 0). As stated previously, particle accumulation on solid boundary could be a realistic physical phenomenon [

5,

35,

40], although a more accurate description requests numerical modeling in Lagrangian description of individual particles and usually beyond the scope of the two-fluid models in Eulerian description.

Clearly, the homogeneous Equation (22) has two independent solutions (

r, 1/

r), and an explicit particular solution of (22) can be obtained using the method of variation of parameters, as explained in [

50]. For instance, for two co-rotating cylinders with

Ω1 =

Ω2 and

B = 0, (22) has a particular solution

, and we have

4. Discussions

TC flow causes particle migration and could possibly lead to a non-trivial steady axisymmetric spatial distribution of particles. Here, our interest focuses on the steady radial distribution

δ(r) of particles determined by (23). In a recent study on TC flow with uniform distribution of particles without particle migration [

50], it is shown that, up to the first-order solutions, the radial velocity

uS(r) of dispersed particles is determined by (with

a0 and

v0(r) defined in (14) and (17))

Thus, the speed of uS(r) is roughly dominated by the square of the mean azimuthal speed v0(r) and its direction is determined by the signs of and . Although Formula (25) is derived based on the assumption that particle migration is ignored and the volume fraction of particles is uniform, as seen below, it helps understand the final steady distribution of particles under the present assumption of dilute particulate flow.

It is noticed that, depending on the values of (

r1,

r2) and (

Ω1,

Ω2),

on left-hand side of (23) can change its sign (for instance, it is the case for examples 3 and 4 discussed below), and consequently

u1m(

r) given by (22) has a discontinuity at the location determined by the root of

at which

u1m(

r) changes its sign. Since steady spatial distribution of particles is determined by particle migration, and the latter is inactive when the particle Stokes number

St (defined by the ratio of the Stokes relaxation time

to the characteristic time of the flow, as shown in (29)) is much small or large than unity [

50]. Therefore, we are particularly interested in the cases of Stokes number of the order of unity. As shown by (14), (17), and (29),

Aa0 scales with the Stokes number

St of particles. Let us discuss the following four different cases of TC flow for the values of

Aa0 of the order of unity. It is seen from the definition that the size of particles determines the Stokes number which plays a key role in particulate flow.

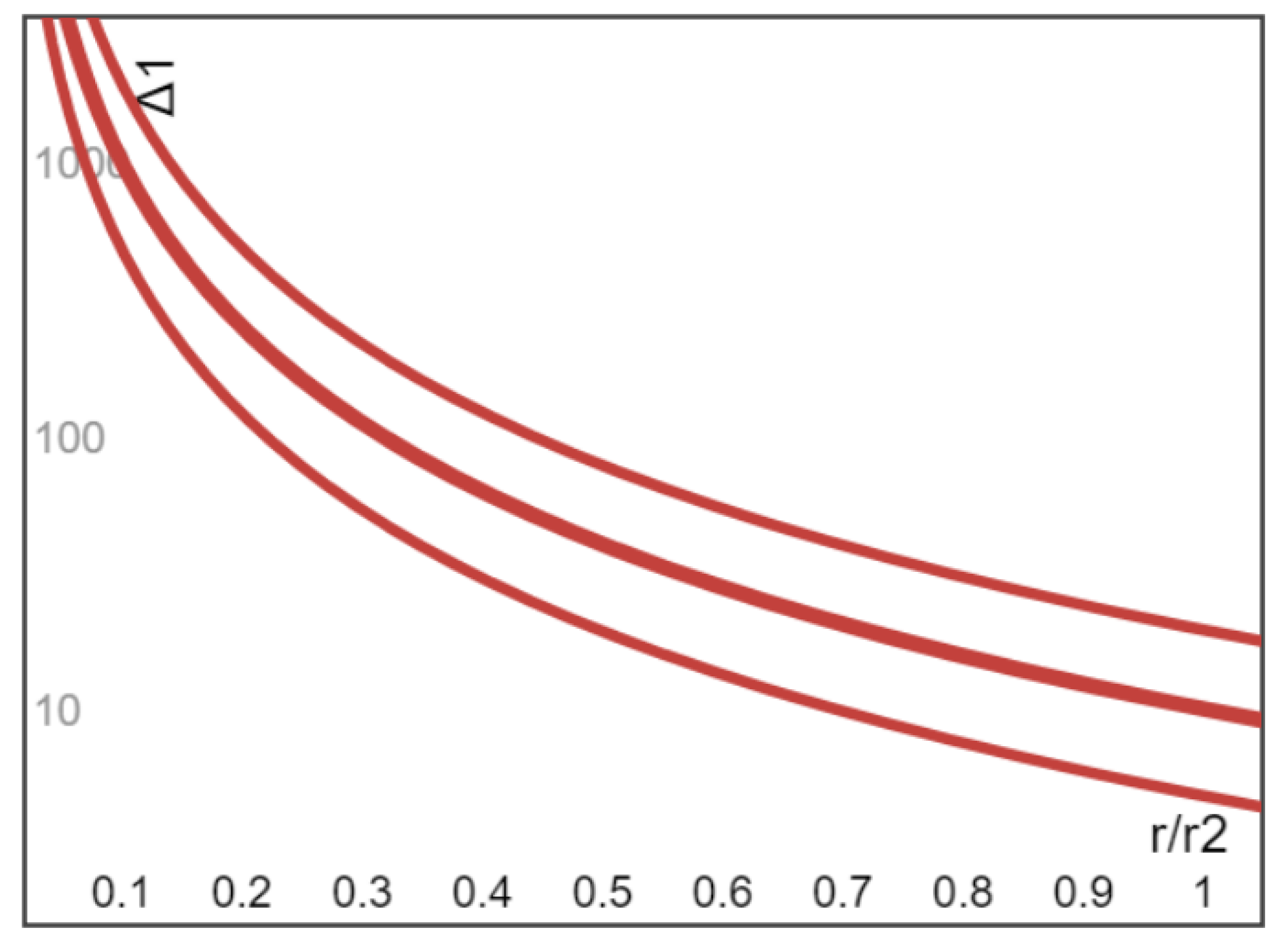

Example 1 (Ω2 = Ω1 > 0). Let us begin with the case of co-rotating cylinders (Ω2 = Ω1), thus it follows from (23) that the dimensionless particle distribution Δ1(r) defined below with δ(r) ≥ 0 is given by

The radial variation of Δ

1(r) vs (r/r

2) is plotted in

Figure 2 for three values of

Aa0 = 0.1 (middle bold curve), 1.0 (lowest curve), and 5.0 (highest curve). Unlike a uniform distribution of particles [

50], the non-uniformity of

δ(r) has an effect on the rate of particle migration and leads to a non-uniform loss rate of the particles. As a result, the magnitude of the loss rate of particles for the co-rotating TC flow (

Ω2 =

Ω1) increases with azimuthal speed for increasing

r, all particles moving to the outer cylinder are eventually deposited at

r =

r2 and no longer remain inside the suspension, therefore final steady distribution

δ(r) inside the suspension is a decreasing function of

r. For example, it is seen from

Figure 2 that when

r1 = 0.5

r2 with

Aa0 = 1, the particle volume fraction near the inner cylinder is a few times higher than the particle volume fraction near the outer cylinder.

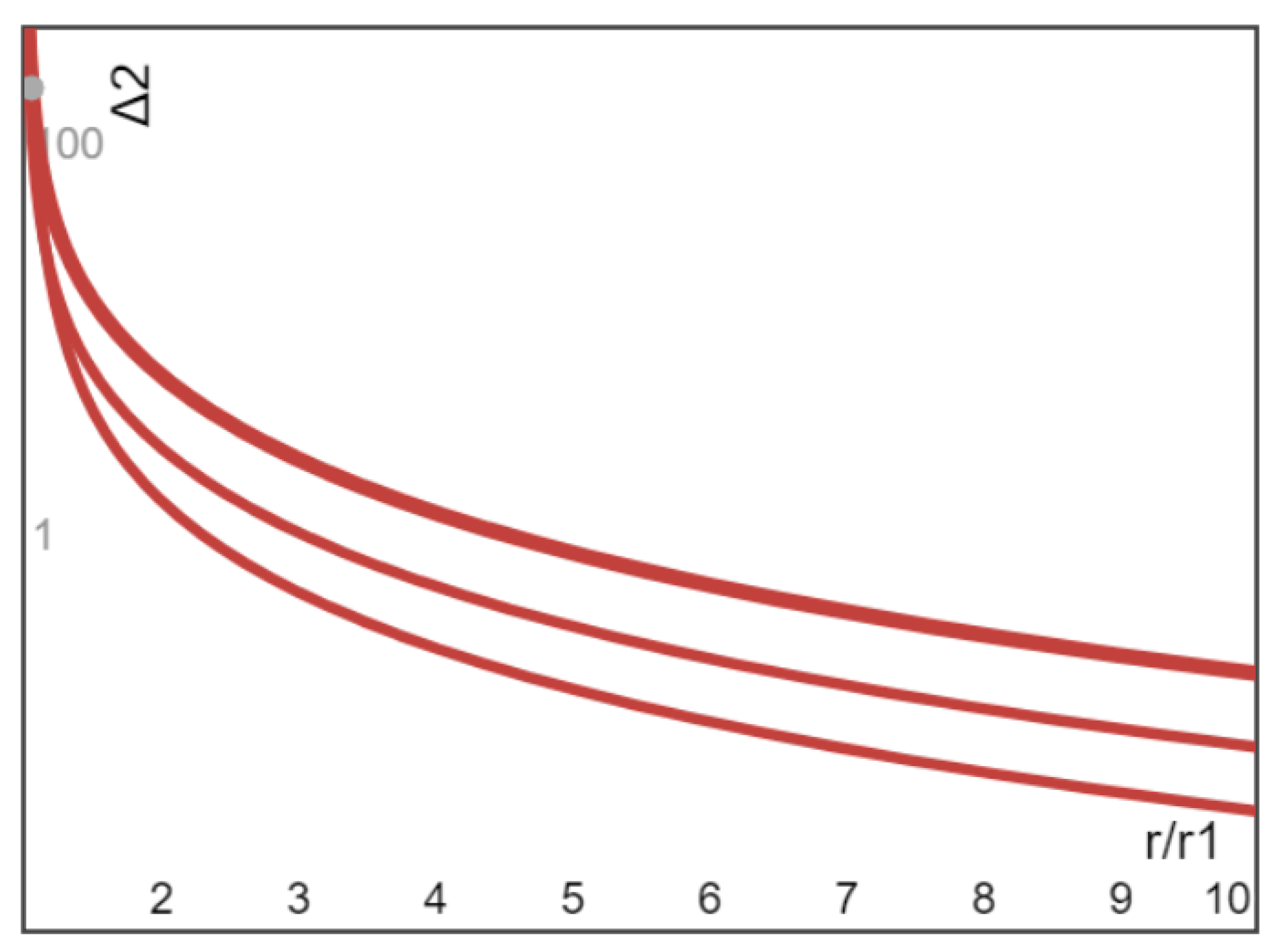

Example 2 (Ω1 = 0, Ω2 > 0). If the outer cylinder rotates with the inner cylinder fixed (Ω1 = 0), we have the dimensionless particle distribution Δ2(r) with δ(r) ≥ 0 given by

The radial variation of Δ

2(r) for Example 2 (

Ω1 = 0) vs. (

r/

r1) is plotted in

Figure 3 for three values of

Aa0 = 0.5 (lowest curve), 2.0 (middle curve), and 5.0 (highest bold curve). Similar to Example 1 shown in

Figure 2, because the loss rate of

δ(r) monotonically increases with azimuthal speed for increasing r, from the fixed inner cylinder to the rotating outer cylinder, final steady distribution of particles inside the suspension is a decreasing function of

r. For instance, it is seen from

Figure 3 that when

r2 = 2

r1, the particle volume fraction near the fixed inner cylinder is about two orders of magnitude higher than the particle volume fraction near the rotating outer cylinder.

Examples 1 and 2 discussed above have and therefore u1m(r) given by (22) is smooth between the two cylinders with the same coefficient X for the entire domain. Now let us discuss two examples for which can have a root r = rc and change its sign at the location r = rc.

Example 3 (

Ω2 = 0,

Ω1 > 0)

. For instance, for TC flow driven by rotating inner cylinder as the outer cylinder is fixed (Ω2 = 0), an important case of particulate TC flow addressed in literature [5,6,11,22,23,25]. In this case, we have the dimensionless particle distribution Δ3(r) with δ(r) ≥ 0 given by The Stokes number

St, the inner Reynolds number

Rei, and the

St-(

Aa0) relation for this case are given by [

25,

43]

The radial variation of Δ

3(r) given by (28) vs. (r/r

2) is plotted in

Figure 4 for four values of

= 0.2, 0.5, 1.0, and 1.5. It is seen from

Figure 4 that for relatively larger values of r/r

2, because the loss rate of

δ(r) monotonically increases with azimuthal speed, unlike the Examples 1 and 2 for which azimuthal speed increases with r, the azimuthal speed for Example 3 (

Ω2 = 0) decreases with

r and the loss rate of particles decreases with increasing

r and attains its maximum at the rotating inner cylinder and its minimum at the fixed outer cylinder, and consequently final steady distribution of particles inside the suspension is an increasing function of r. For instance, it is seen from

Figure 4 that it is the case when

= 0.2 and r

1/r

2 > 0.3714 (which gives Stokes number

St between 0.4 and 0.74), we have

, the particle volume fraction near the fixed outer cylinder can be a few orders of magnitude higher than the particle volume fraction near the rotating inner cylinder. Similarly, when

= 0.5 and r

1/r

2 > 0.7 (which gives Stokes number

St between 1 and 1.2), we have

and the particle volume fraction near the fixed outer cylinder is a few orders of magnitude higher than the particle volume fraction near the rotating inner cylinder. This result for laminar TC flow is qualitatively consistent with the simulation results reported in [

25] for turbulent TC flow with heavy particles driven by rotating inner cylinder with r

1/r

2 = 0.714 and initial value of

(see Figure 6 of [

25]), which indicate that when Stokes number

St approaches unity (the maximum value of Stokes number studied in [

25]), the particle concentration near the outer fixed cylinder is about two orders of magnitude larger than that in the main domain. Since the majority of existing related works have focused on preferential equilibrium position (rather than spatial distribution) of neutrally buoyant particles in channel or pipe flows, to the best of our current knowledge, more detailed comparison to known data of the present results on steady distribution of heavier or lighter particles cannot be made here due to the lack of available known data.

However, when the gap between two cylinders is large enough with sufficiently small radius ratio r

1/r

2, for sufficiently smaller values of r/r

2, Δ

3(r) given by (27) becomes negative and, as stated in the beginning of this section,

u1m(

r) given by (22) has a discontinuity at the location

rc determined by the root of

at which the coefficient

X of

u1m(

r) changes its sign (see e.g., the location indicated by one black dot at

rc/

r2 ≈ 0.3714 in

Figure 4 with

Aa0 = 0.2). In this case, all solutions of (1

8)–(21) should be given in two separated domains, r

1 ≤ r ≤ r

c and r

2 ≥ r ≥ r

c, respectively, although (22) remains valid for the two separate domains with two different values of the coefficient

X of

u1m(

r) of opposite signs. Thus, let us keep the coefficient

X > 0 for the domain (r ≥ r

c) for larger r, then the coefficient

X for

u1m(

r) in the domain (r ≤ r

c) for small r is negative with an undetermined absolute value and the particle volume fraction

δ(r) ≥ 0 given by (28) remains non-negative in the entire domain. This undetermined coefficient

X for

u1m(

r) in the domain (r ≤ r

c) and the total four coefficients of

v1(r) determined by (22) in the two separate domains will be determined by the three continuity conditions for azimuthal velocity

v1(r) and shear and normal stresses at r = r

c and the two no-slip boundary conditions (16) at the inner and outer cylinders. In this case, the steady distribution of particles varies non-monotonically in the radial direction with interior local maximum and/or minimum. A detailed mathematical solution is beyond the goal of the present work and is not explored here.

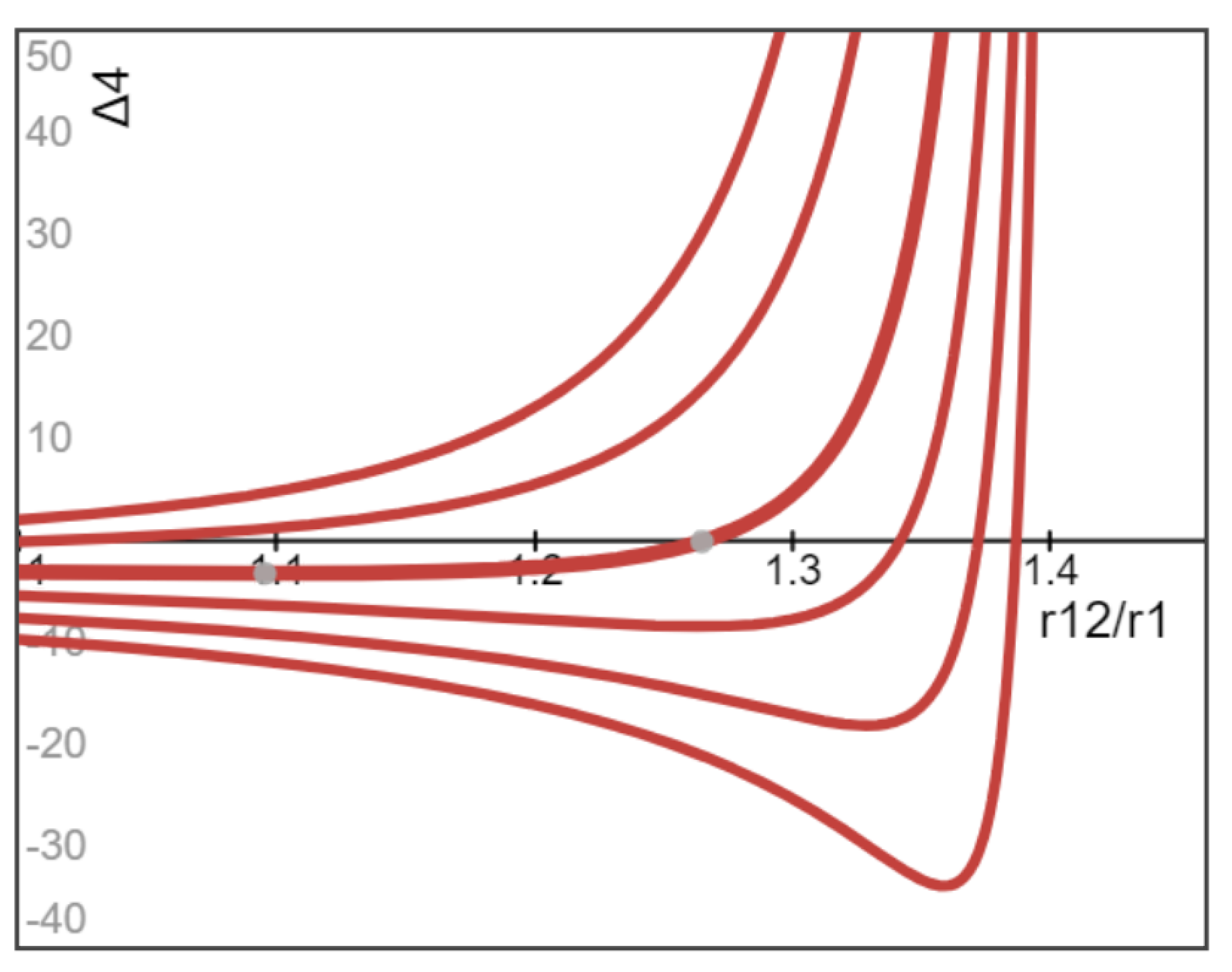

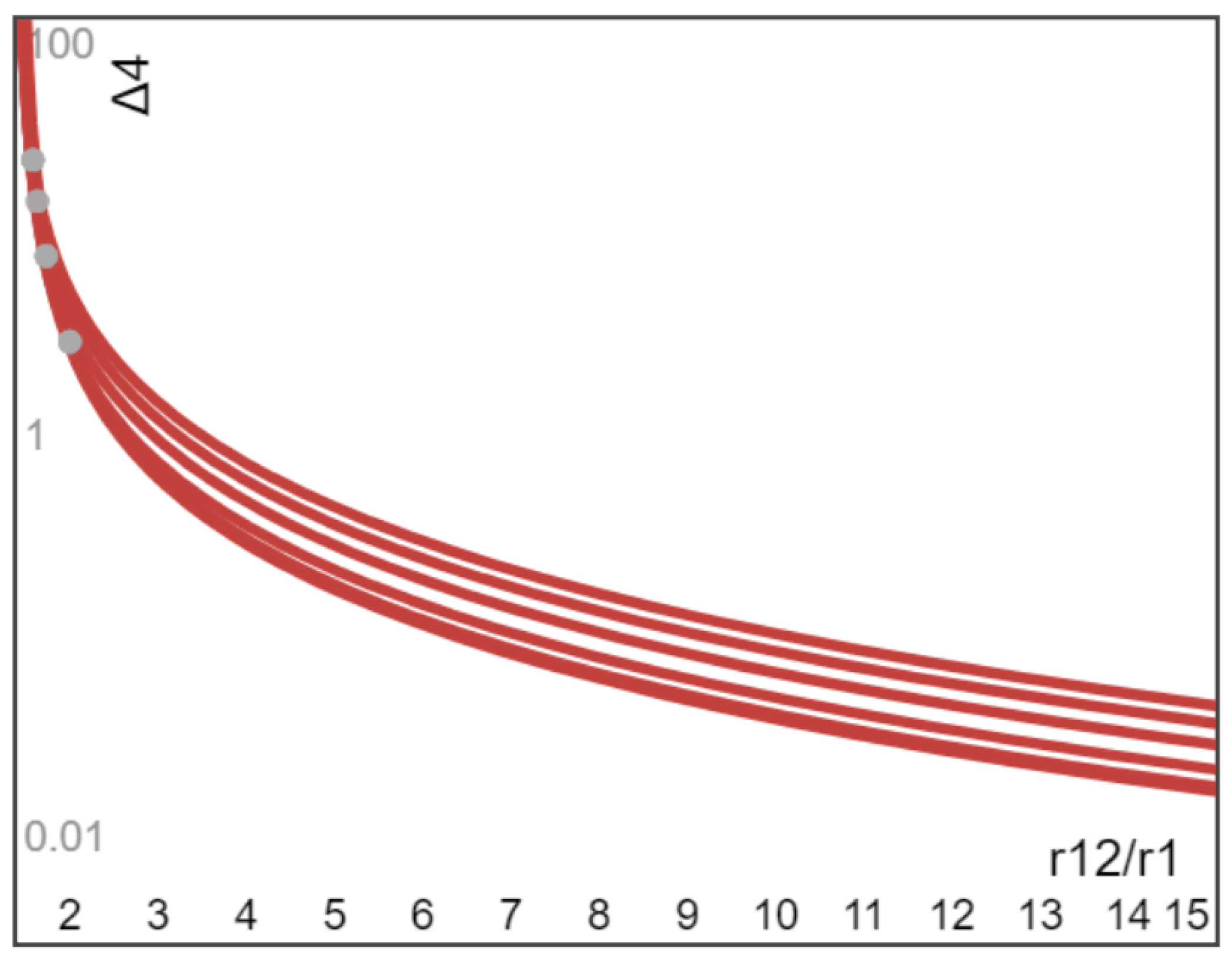

Example 4 (Ω2 = −Ω1). Finally, let us discuss the counter-rotating cylinders (Ω1 = −Ω2 > 0), thus we have the dimensionless particle distribution Δ4(r) with δ(r) ≥ 0 given by

It is seen from (30) that the mean azimuthal speed

v0(r) = 0 at (r

12/r

1) = √2 (the corresponding r is between r

1 and r

2), which indicates that, up to the leading-order approximation, the volume fraction of particles attains the maximum at this location determined by (r

12/r

1) = √2, as predicted by Δ

4(r) given in (30) and confirmed in

Figure 5 and

Figure 6. Therefore, we shall discuss the two cases (r

12/r

1) ≤ √2 and (r

12/r

1) ≥ √2, separately.

When

, r.h.s. of Δ

4(r) given in (30) is positive and monotonically increases with r for smaller values of (

Aa0), and becomes negative with its magnitude increasing with r for large

St number, while r.h.s. of Δ

4(r) given in (30) for moderate values of (

Aa0) of the order unity varies non-monotonically with increasing r with interior local maximum/minimum. Actually, the radial variation of Δ

4(r) vs. (r

12/r

1) for the range

is plotted in

Figure 5 for six moderate values of

Aa0 = 0.3, 0.5, 1.0, 1.5, 2.0, and 2.5. It is seen from

Figure 5 that, similar to Example 3 of rotating inner cylinder, because the loss rate of particle volume fraction decreases with increasing r and attains its maximum at the inner cylinder and its minimum at the outer cylinder, final particle distribution Δ

4(r) given in (30) inside the suspension is an increasing function of r. However, for sufficiently smaller values of r/r

2, Δ

4(r) given by (30) becomes negative and

u1m(

r) given by (22) has a discontinuity at the location r

c determined by the root of

at which

u1m(

r) changes its sign, see e.g., the location indicated by one grey dot between

r12/

r1 = 1.2 and 1.3 in

Figure 5 on the bold curve with

Aa0 = 1.0. In such a case, all solutions of (18)–(21) should be given in two separated domains, r ≤ r

c and r ≥ r

c, respectively, although (22) remains valid for the two separate domains. Let us keep the coefficient

X > 0 for the domain (r ≥ r

c) for larger r, then the coefficient

X for

u1m(

r) in the domain (r ≤ r

c) is negative with an undetermined absolute value and the particle volume fraction

δ(r) ≥ 0 given by (30) remains non-negative in the entire domain. This undetermined coefficient

X of

u1m(

r) in the domain (r ≤ r

c) and the total four coefficients of

v1(r) in the two separate domains will be determined by the three continuity conditions for azimuthal velocity

v1(r) and shear and normal stresses at r = r

c and the two no-slip boundary conditions (16) at the inner and outer cylinders.

When

, on the other hand, r.h.s. of Δ

4(r) given in (30) is always positive and decreases with increasing r. The radial variation of Δ

4(r) vs. (r

12/r

1) is plotted in

Figure 6 for five values of

Aa0 = 0.5, 1.0, 1.5, 2.0, and 2.5. It is seen from

Figure 6 that, similar to Example 2 of rotating outer cylinder, because the loss rate of

δ(r) monotonically increases with increasing r and attains its minimum at the inner cylinder and its maximum at the outer boundary, and final steady distribution inside the suspension is a decreasing function of r.

Here, some limitations of the present model should be highlighted. First, the present leading-order solutions based on the small parameter

δ-expansion are limited to the dilute limit when the dimensionless particle distribution normalized by the coefficient

X tends to zero as

X tends to zero, which is intended to predict non-uniform spatial distribution of particles in the limit when the particle volume fraction becomes vanishingly small. In addition, as stated in the paper, all flow fields can be determined uniquely with the boundary conditions imposed on the velocity field of the suspension without additional boundary conditions on the velocity field of dispersed particles. As a result, the normal flux of dispersed particles does not necessarily vanish on solid boundary, which is equivalent to assume that the solid walls are permeable and the particles can be sucked or injected on the permeable cylinder walls [

3,

44,

45,

46,

47,

48,

49]. In particular, the existence of non-trivial steady particle distribution predicted here depends on the assumed boundary condition (

allowed). Although particle accumulation on solid boundary can be a realistic physical phenomenon, its more accurate description requests extensive numerical modeling of individual particles in Lagrangian description and usually beyond the capability of the two-fluid models in Eulerian description. The influence of this limitation of the present model (shared by some other two-fluid models such as the Saffman model) on the accuracy of the present model near solid boundaries is to be clarified.