A Review of Mesh Adaptation Technology Applied to Computational Fluid Dynamics

Abstract

1. Introduction

1.1. Background and Motivation

1.2. Objectives of the Review

- To introduce the fundamental concepts behind mesh adaptation: error estimation, adaptation mechanics and optimality criteria.

- To classify and evaluate the most successful mesh adaptation methodologies, generally revolving around the feature-based and goal-oriented approaches.

- To critically assess the advantages and limitations of each adaptation technique, including aspects such as anisotropy, solver integration and industrial deployment.

- To highlight recent advances in mesh adaptation, such as the use of fully tetrahedral mesh regeneration for viscous flows, solution certification and industrial applications.

- To identify challenges and future research directions that could enable the more widespread adoption of mesh adaptation, including the role of artificial intelligence, high-order methods, unsteady flows and parallel computations.

2. Understanding Mesh Adaptation

- Optimal mesh determination;

- Error estimation;

- Adaptation mechanics.

2.1. Optimality Criteria

2.2. Error Estimation

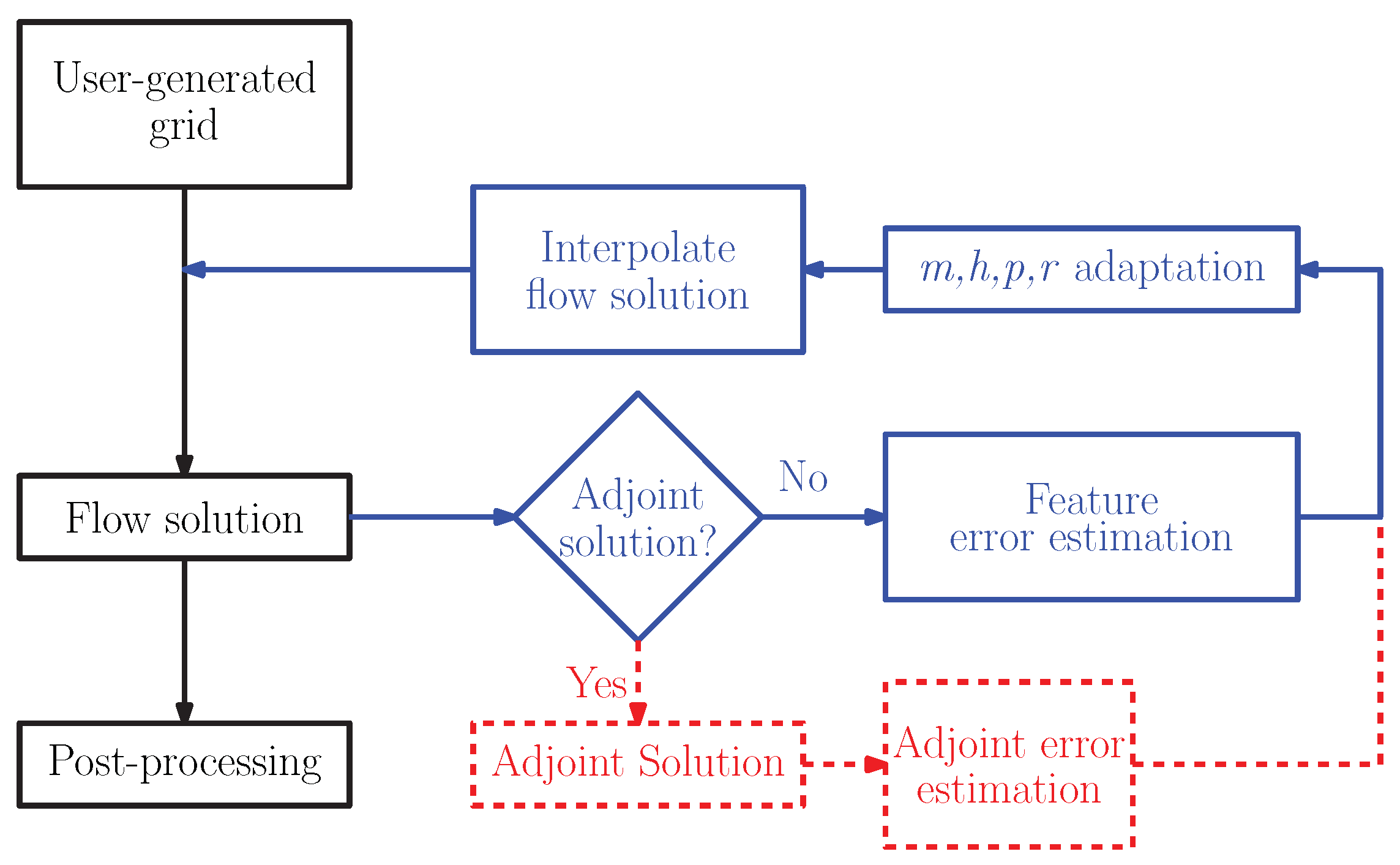

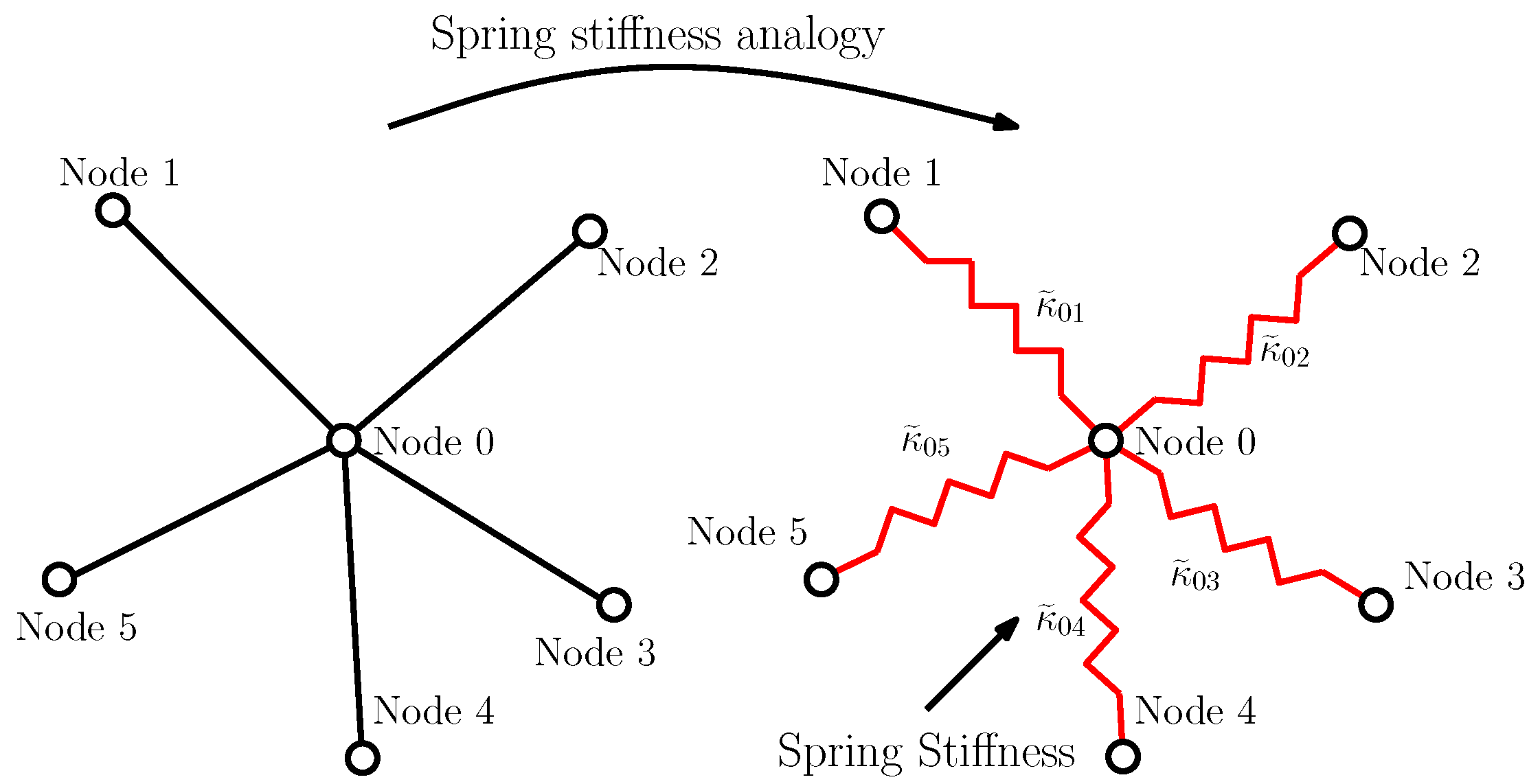

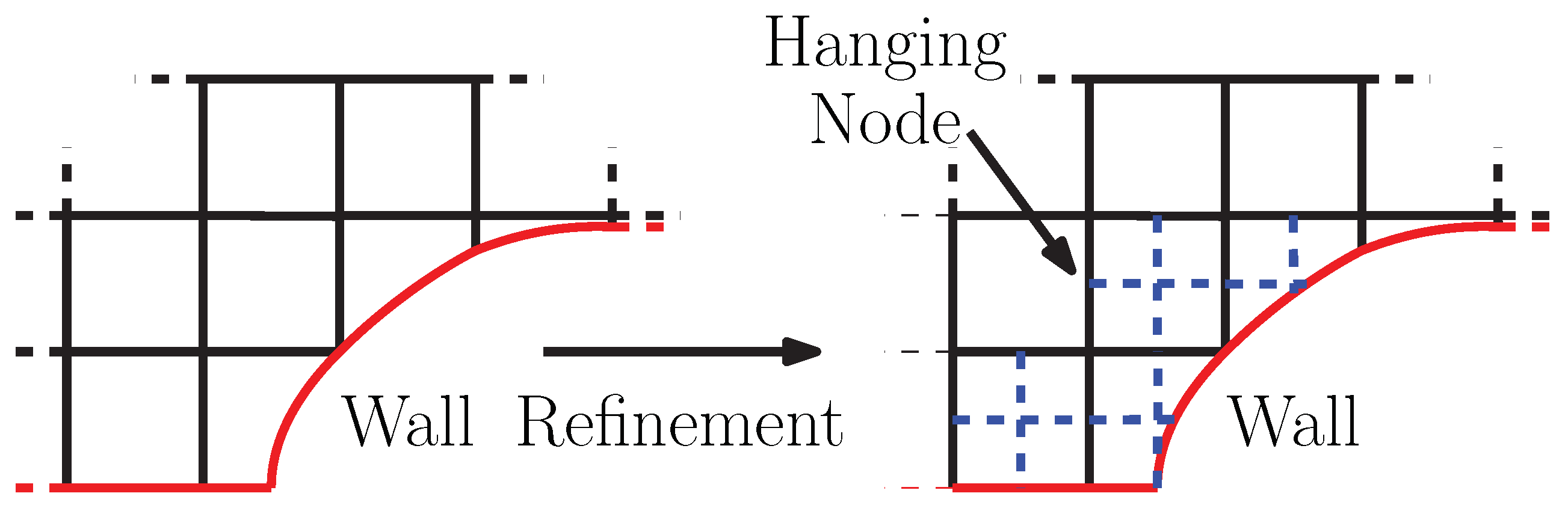

2.3. Adaptation Mechanics

- r-methods ⇒ nodal movement;

- h-methods ⇒ refinement and coarsening;

- p-methods ⇒ order enrichment;

- m-methods ⇒ regeneration.

- Monitor function ⇒ quantity driving the node relocation (error);

- Mesh equations ⇒ map between computational and physical domains;

- Interpolation ⇒ solution estimate at the new nodal position.

- Physical conservation of quantities;

- Robustness;

- Parallelisation.

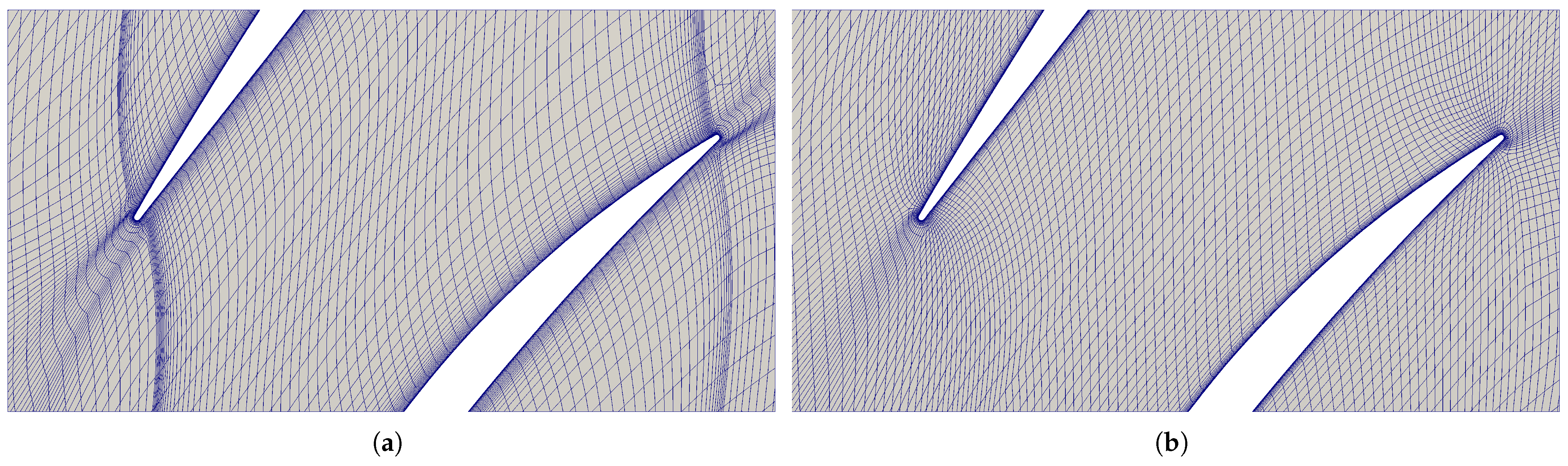

3. Feature-Based Mesh Adaptation

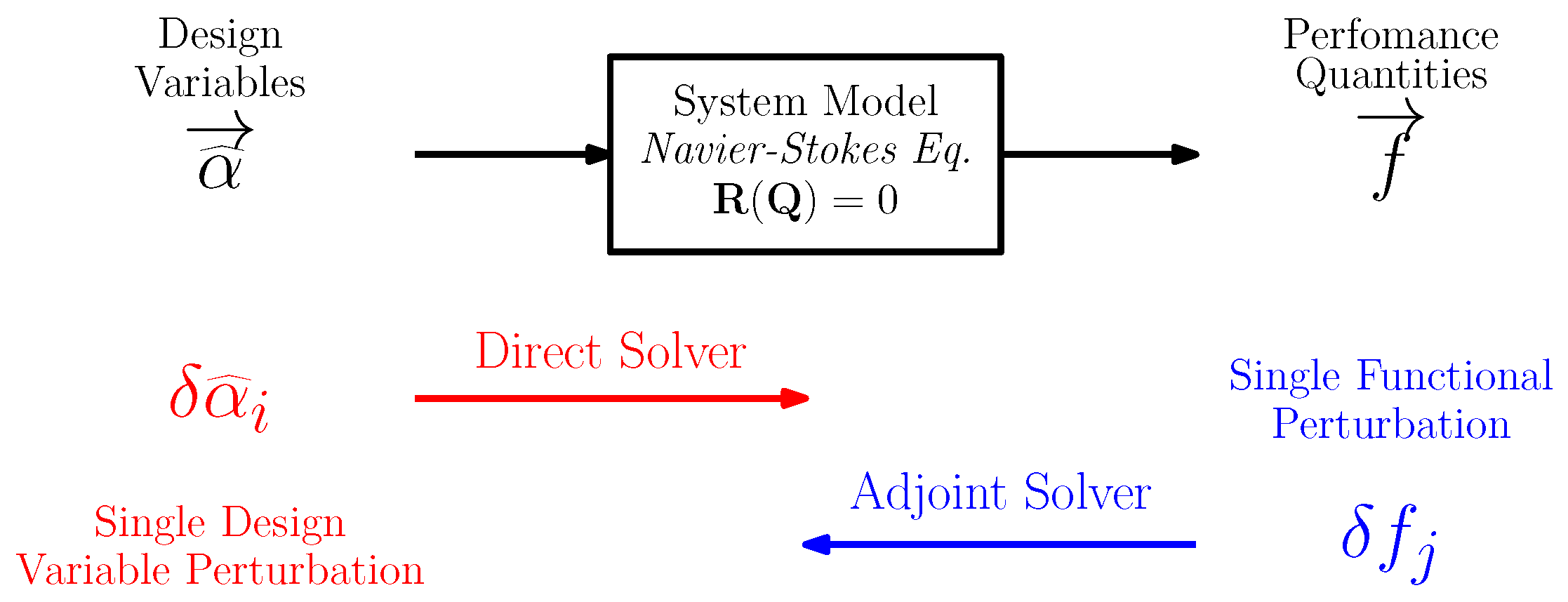

4. Goal-Oriented Mesh Adaptation

| Main Characteristics | Variants | Applications | |

|---|---|---|---|

| Feature-Based |

|

| |

| Goal-Oriented |

|

|

5. Future Mesh Adaptation Research Trends

- Stability ⇒ parallel and sequential executions should generate similar if not identical meshes.

- Reproducibility ⇒ this can be split into strong and weak, depending on how stringent is the requirement that the code produce identical results when restarted with the same input.

- Robustness ⇒ the code should correctly and efficiently process any input data.

- Scalability ⇒ the ratio of sequential to parallel run-time.

- Code Reuse ⇒ this depends on the code implementation strategy.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational fluid dynamics |

| DDES | Delayed DES |

| de | Discretisation error |

| DES | Detached Eddy Simulation |

| DG | Discontinuous Galerkin |

| DNS | Direct numerical simulation |

| FDM | Finite difference method |

| FEM | Finite element method |

| FVM | Finite volume method |

| GCN | Graph convolutional networks |

| GMM | Gaussian mixture model |

| GNN | Graph neural networks |

| h-methods | Mesh refinement and coarsening |

| HOLMES | High-Order MOESS |

| iLES | Implicit Large Eddy Simulation |

| INRIA | Institut National de Recherche en Informatique et en Automatique (France) |

| JST | Jameson Schmidt Turkel |

| m-methods | Mesh regeneration |

| MOESS | Mesh optimization via error sampling and synthesis |

| NS | Navier–Stokes |

| p-methods | Polynomial order enrichment |

| pde | Partial differential equation |

| r-methods | Mesh adaptation via node relocation |

| RANS | Reynolds-averaged Navier–Stokes |

| SA | Spalart Allmaras |

| te | Truncation error |

| URANS | Unsteady RANS |

| wrt | wrt |

| Drag coefficient | |

| Functional sensitivity to mesh coordinates | |

| Number of edges connected to node i | |

| f | Functional or quantity of interest |

| Coarse and fine grid spacing | |

| H | Hessian matrix |

| Spring-stiffness coefficient between nodes i and j | |

| Error norms | |

| Potential energy at node i | |

| q | Generic scalar field |

| Navier–Stokes conservative variables vector | |

| Navier–Stokes residual vector | |

| Eigenvectors | |

| Node displacement vector | |

| Wall-normal distance | |

| Design variable | |

| Eigenvalue | |

| Adjoint vector | |

| Relaxation parameter | |

| Linear interpolation operator | |

| Quadratic interpolation operator |

References

- Witherden, F.D.; Jameson, A. Future Directions in Computational Fluid Dynamics. In Proceedings of the 23rd AIAA Computational Fluid Dynamics Conference, Denver, CO, USA, 5–9 June 2017; p. 3791. [Google Scholar]

- Johnson, F.T.; Tinoco, E.N.; Yu, N.J. Thirty years of development and application of CFD at Boeing Commercial Airplanes, Seattle. Comput. Fluids 2005, 34, 1115–1151. [Google Scholar] [CrossRef]

- Laskowski, G.M.; Kopriva, J.; Michelassi, V.; Shankaran, S.; Paliath, U.; Bhaskaran, R.; Wang, Q.; Talnikar, C.; Wang, Z.J.; Jia, F. Future Directions of High Fidelity CFD for Aerothermal Turbomachinery Analysis and Design. In Proceedings of the 46th AIAA Fluid Dynamics Conference, Washington, DC, USA, 13–17 June 2016; p. 3322. [Google Scholar]

- Fischberg, C.J.; Rhie, C.M.; Zacharias, R.M.; Bradley, P.C.; DesSureault, T.M. Using hundreds of workstations for production running of parallel CFD applications. In Parallel Computational Fluid Dynamics 1995; Elsevier: Amsterdam, The Netherlands, 1996; pp. 9–22. [Google Scholar]

- Sandberg, R.D.; Michelassi, V. The current state of high-fidelity simulations for main gas path turbomachinery components and their industrial impact. Flow Turbul. Combust. 2019, 102, 797–848. [Google Scholar] [CrossRef]

- Fidkowski, K.J.; Darmofal, D.L. Review of output-based error estimation and mesh adaptation in computational fluid dynamics. AIAA J. 2011, 49, 673–694. [Google Scholar] [CrossRef]

- Fidkowski, K.J. A Simplex Cut-Cell Adaptive Method for High-Order Discretizations of the Compressible Navier-Stokes Equations. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2007. [Google Scholar]

- Alauzet, F.; Loseille, A. A decade of progress on anisotropic mesh adaptation for computational fluid dynamics. Comput.-Aided Des. 2016, 72, 13–39. [Google Scholar] [CrossRef]

- Park, M.A.; Krakos, J.A.; Michal, T.; Loseille, A.; Alonso, J.J. Unstructured Grid Adaptation: Status, Potential Impacts, and Recommended Investments Toward CFD Vision 2030. In Proceedings of the 46th AIAA Fluid Dynamics Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar]

- Vivarelli, G. Anisotropic & Edgewise Adjoint Error Estimation & Grid Adaptation with Applications to Turbomachinery Flows. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2019. [Google Scholar]

- Löhner, R. Mesh adaptation in fluid mechanics. Eng. Fract. Mech. 1995, 50, 819–847. [Google Scholar] [CrossRef]

- Roy, C. Strategies for driving mesh adaptation in CFD. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; p. 1302. [Google Scholar]

- Roy, C. Review of discretization error estimators in scientific computing. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4 January 2010; p. 126. [Google Scholar]

- Fidkowski, K.J. Output Based Error Estimation and Mesh Adaptation for Steady and Unsteady Flow Problems. In 38th Advanced CFD Lectures Series; von Karman Institute for Fluid Dynamics (September 14–16, 2015); Deconinck, H., Horvath, T., Eds.; von Karman Institute for Fluid Dynamics: Saint-Genesius-Rode, Belgium, 2015. [Google Scholar]

- Baker, T.J. Mesh adaptation strategies for problems in fluid dynamics. Finite Elem. Anal. Des. 1997, 25, 243–273. [Google Scholar] [CrossRef]

- Baker, T.J. Mesh generation: Art or Science? Prog. Aerosp. Sci. 2005, 41, 29–63. [Google Scholar] [CrossRef]

- Habashi, W.G.; Dompierre, J.; Bourgault, Y.; Fortin, M.; Vallet, M.G. Certifiable computational fluid dynamics through mesh optimization. AIAA J. 1998, 36, 703–711. [Google Scholar] [CrossRef]

- Nemec, M.; Aftosmis, M.; Wintzer, M. Adjoint-based adaptive mesh refinement for complex geometries. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008; p. 725. [Google Scholar]

- Venditti, D.A.; Darmofal, D.L. Anisotropic grid adaptation for functional outputs: Application to two-dimensional viscous flows. J. Comput. Phys. 2003, 187, 22–46. [Google Scholar] [CrossRef]

- Michal, T.; Krakos, J.; Kamenetskiy, D.; Galbraith, M.; Ursachi, C.I.; Park, M.A.; Anderson, W.K.; Alauzet, F.; Loseille, A. Comparing unstructured adaptive mesh solutions for the high lift common research airfoil. AIAA J. 2021, 59, 3566–3584. [Google Scholar] [CrossRef]

- Alauzet, F.; Frazza, L. Feature-based and goal-oriented anisotropic mesh adaptation for RANS applications in aeronautics and aerospace. J. Comput. Phys. 2021, 439, 110340. [Google Scholar] [CrossRef]

- Venditti, D.A.; Darmofal, D.L. Grid adaptation for functional outputs: Application to two-dimensional inviscid flows. J. Comput. Phys. 2002, 176, 40–69. [Google Scholar] [CrossRef]

- Balasubramanian, R.; Newman, J.C. Comparison of adjoint-based and feature-based grid adaptation for functional outputs. Int. J. Numer. Methods Fluids 2007, 53, 1541–1569. [Google Scholar] [CrossRef]

- Balan, A.; Park, M.A.; Wood, S.L.; Anderson, W.K.; Rangarajan, A.; Sanjaya, D.P.; May, G. A review and comparison of error estimators for anisotropic mesh adaptation for flow simulations. Comput. Fluids 2022, 234, 105259. [Google Scholar] [CrossRef]

- Fraysse, F.; Valero, E.; Ponsín, J. Comparison of mesh adaptation using the adjoint methodology and truncation error estimates. AIAA J. 2012, 50, 1920–1932. [Google Scholar] [CrossRef]

- Kallinderis, Y.; Kontzialis, C. A priori mesh quality estimation via direct relation between truncation error and mesh distortion. J. Comput. Phys. 2009, 228, 881–902. [Google Scholar] [CrossRef]

- Kallinderis, Y.; Fotia, S. A priori mesh quality metrics for three-dimensional hybrid grids. J. Comput. Phys. 2015, 280, 465–488. [Google Scholar] [CrossRef]

- Brandt, A.; Livne, O.E. Multigrid Techniques: 1984 Guide with Applications to Fluid Dynamics; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2011; Volume 67. [Google Scholar]

- Fraysse, F. Numerical Error Prediction and Its Applications in CFD Using τ-Estimation. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2012. [Google Scholar]

- Derlaga, J.M. Application of Improved Truncation Error Estimation Techniques to Adjoint Based Error Estimation and Grid Adaptation. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2015. [Google Scholar]

- Tang, T. Moving mesh methods for computational fluid dynamics. Contemp. Math. 2005, 383, 141–174. [Google Scholar]

- Budd, C.J.; Huang, W.; Russell, R.D. Adaptivity with moving grids. Acta Numer. 2009, 18, 111–241. [Google Scholar] [CrossRef]

- Baines, M.J. Grid adaptation via node movement. Appl. Numer. Math. 1998, 26, 77–96. [Google Scholar] [CrossRef]

- Ait-Ali-Yahia, D.; Habashi, W.G.; Tam, A.; Vallet, M.G.; Fortin, M. A Directionally Adaptive Methodology Using an Edge-Based Error Estimate on Quadrilateral Grids. Int. J. Numer. Methods Fluids 1996, 23, 673–690. [Google Scholar] [CrossRef]

- Diskin, B.; Yamaleev, N. Grid Adaptation using Adjoint-Based Error Minimization. In Proceedings of the 20th AIAA Computational Fluid Dynamics Conference, Honolulu, HI, USA, 27–30 June 2011; p. 3986. [Google Scholar]

- Selim, M.M.; Koomullil, R.P. Mesh deformation approaches—A survey. J. Phys. Math. 2016, 7, 1–9. [Google Scholar]

- Löhner, R.; Baum, J.D. Adaptive h-refinement on 3D unstructured grids for transient problems. Int. J. Numer. Methods Fluids 1992, 14, 1407–1419. [Google Scholar] [CrossRef]

- Liu, A.; Joe, B. Quality local refinement of tetrahedral meshes based on 8-subtetrahedron subdivision. Math. Comput. Am. Math. Soc. 1996, 65, 1183–1200. [Google Scholar] [CrossRef]

- Biswas, R.; Strawn, R.C. Mesh quality control for multiply-refined tetrahedral grids. Appl. Numer. Math. 1996, 20, 337–348. [Google Scholar] [CrossRef]

- Biswas, R.; Strawn, R.C. Tetrahedral and hexahedral mesh adaptation for CFD problems. Appl. Numer. Math. 1998, 26, 135–151. [Google Scholar] [CrossRef]

- Mavriplis, D.J. Adaptive meshing techniques for viscous flow calculations on mixed element unstructured meshes. Int. J. Numer. Methods Fluids 2000, 34, 93–111. [Google Scholar] [CrossRef]

- Tchon, K.F.; Dompierre, J.; Camarero, R. Conformal refinement of all-quadrilateral and all-hexahedral meshes according to an anisotropic metric. In Proceedings of the 11th International Meshing Roundtable, Ithaca, NY, USA, 15–18 September 2002. [Google Scholar]

- Tchon, K.F.; Dompierre, J.; Scamarero, R. Automated refinement of conformal quadrilateral and hexahedral meshes. Int. J. Numer. Methods Eng. 2004, 59, 1539–1562. [Google Scholar] [CrossRef]

- Schneiders, R. A grid-based algorithm for the generation of hexahedral element meshes. Eng. Comput. 1996, 12, 168–177. [Google Scholar] [CrossRef]

- Mitchell, S.A.; Tautges, T.J. Pillowing doublets: Refining a mesh to ensure that faces share at most one edge. In Proceedings of the 4th International Meshing Roundtable, Albuquerque, NM, USA, 16–17 October 1995; pp. 231–240. [Google Scholar]

- Harris, N.J.; Benzley, S.E.; Owen, S.J. Conformal Refinement of All-Hexahedral Element Meshes Based on Multiple Twist Plane Insertion. In Proceedings of the International Meshing Roundtable, Williamsburg, VA, USA, 19–22 September 2004; pp. 157–168. [Google Scholar]

- Benzley, S.E.; Harris, N.J.; Scott, M.; Borden, M.; Owen, S.J. Conformal refinement and coarsening of unstructured hexahedral meshes. J. Comput. Inf. Sci. Eng. 2005, 5, 330–337. [Google Scholar] [CrossRef]

- Parrish, M.; Borden, M.; Staten, M.; Benzley, S. A selective approach to conformal refinement of unstructured hexahedral finite element meshes. In Proceedings of the 16th International Meshing Roundtable, Seattle, WA, USA, 14–17 October 2007; Springer: Berlin/Heidelberg, Germany, 2008; pp. 251–268. [Google Scholar]

- Nicolas, G.; Fouquet, T.; Geniaut, S.; Cuvilliez, S. Improved adaptive mesh refinement for conformal hexahedral meshes. Adv. Eng. Softw. 2016, 102, 14–28. [Google Scholar] [CrossRef]

- Owen, S.J.; Shih, R.M. A Template-Based Approach for Parallel Hexahedral Two-Refinement. Procedia Eng. 2015, 124, 31–43. [Google Scholar] [CrossRef]

- Wintzer, M.; Nemec, M.; Aftosmis, M. Adjoint-based adaptive mesh refinement for sonic boom prediction. In Proceedings of the 26th AIAA Applied Aerodynamics Conference, Honolulu, HI, USA, 18–21 August 2008; p. 6593. [Google Scholar]

- Wackers, J.; Deng, G.; Guilmineau, E.; Leroyer, A.; Queutey, P.; Visonneau, M. Combined refinement criteria for anisotropic grid refinement in free-surface flow simulation. Comput. Fluids 2014, 92, 209–222. [Google Scholar] [CrossRef]

- Bhushan, S.; Yoon, H.; Stern, F.; Guilmineau, E.; Visonneau, M.; Toxopeus, S.; Simonsen, C.; Aram, S.; Kim, S.; Grigoropoulos, G. Assessment of computational fluid dynamic for surface combatant 5415 at straight ahead and static drift β = 20 deg. J. Fluids Eng. 2019, 141, 051101. [Google Scholar] [CrossRef]

- Kirby, R.M.; Sherwin, S.J. Stabilisation of spectral/hp element methods through spectral vanishing viscosity: Application to fluid mechanics modelling. Comput. Methods Appl. Mech. Eng. 2006, 195, 3128–3144. [Google Scholar] [CrossRef]

- Moro, D.; Nguyen, N.C.; Peraire, J. Dilation-based shock capturing for high-order methods. Int. J. Numer. Methods Fluids 2016, 82, 398–416. [Google Scholar] [CrossRef]

- Harris, M.J. Flow Feature Aligned Mesh Generation and Adaptation. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2013. [Google Scholar]

- Ito, Y.; Shih, A.M.; Koomullil, R.P.; Soni, B.K. A solution-based adaptive redistribution method for unstructured meshes. In Proceedings of the 15th International Meshing Roundtable, Birmingham, Al, USA, 17–20 September 2006; Springer: Berlin/Heidelberg, Germany, 2006; pp. 147–161. [Google Scholar]

- Qin, N.; Liu, X. Flow feature aligned grid adaptation. Int. J. Numer. Methods Eng. 2006, 67, 787–814. [Google Scholar] [CrossRef]

- Harris, M.J.; Qin, N. Geometric representation of flow features using the medial axis for mesh generation. AIAA J. 2014, 53, 246–259. [Google Scholar] [CrossRef]

- Harris, M.J.; Qin, N. Using the medial axis to represent flow features for feature-aligned unstructured quad-dominant mesh generation. Comput. Fluids 2014, 102, 1–14. [Google Scholar] [CrossRef]

- Alauzet, F. Metric Based Anisotropic Mesh Adaptation; CEA-EDF-INRIA Schools: Numerical Analysis Summer School; CEA: Cadarache, France, 2010. [Google Scholar]

- Loseille, A. Unstructured Mesh Generation and Adaptation. In Handbook of Numerical Analysis; Elsevier: Amsterdam, The Netherlands, 2017; Volume 18, pp. 263–302. [Google Scholar]

- Castro-Díaz, M.J.; Hecht, F.; Mohammadi, B.; Pironneau, O. Anisotropic unstructured mesh adaption for flow simulations. Int. J. Numer. Methods Fluids 1997, 25, 475–491. [Google Scholar] [CrossRef]

- Hecht, F.; Mohammadi, B.; Hecht, F.; Mohammadi, B. Mesh adaption by metric control for multi-scale phenomena and turbulence. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1997; p. 859. [Google Scholar]

- Peraire, J.; Vahdati, M.; Morgan, K.; Zienkiewicz, O.C. Adaptive remeshing for compressible flow computations. J. Comput. Phys. 1987, 72, 449–466. [Google Scholar] [CrossRef]

- Löhner, R. Three-dimensional fluid-structure interaction using a finite element solver and adaptive remeshing. Comput. Syst. Eng. 1990, 1, 257–272. [Google Scholar] [CrossRef]

- Peraire, J.; Peiro, J.; Morgan, K. Adaptive remeshing for three-dimensional compressible flow computations. J. Comput. Phys. 1992, 103, 269–285. [Google Scholar] [CrossRef]

- George, P.L.; Hecht, F.; Vallet, M.G. Creation of internal points in Voronoi’s type method. Control adaptation. Adv. Eng. Softw. Work. 1991, 13, 303–312. [Google Scholar] [CrossRef]

- Fortin, M.; Vallet, M.G.; Poirier, D.; Habashi, W.G. Error Estimation and Directionally-Adaptive Meshing. In Proceedings of the 25th AIAA Fluid Dynamics Conference, Colorado Springs, CO, USA, 20–23 June 1994. [Google Scholar]

- Habashi, W.G.; Fortin, M.; Dompierre, J.; Vallet, M.G.; Bourgault, Y. Anisotropic mesh adaptation: A step towards a mesh-independent and user-independent CFD. In Barriers and Challenges in Computational Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 1998; pp. 99–117. [Google Scholar]

- Robichaud, M.; Ait-Ali-Yahia, D.; Peeters, M.; Baruzzi, G.; Kozel, V.; Habashi, W. 3-D anisotropic adaptation for external and turbomachinery flows on hybrid unstructured grids. In Proceedings of the Fluids 2000 Conference and Exhibit, Denver, CO, USA, 19–22 June 2000. [Google Scholar]

- Habashi, W.G.; Dompierre, J.; Bourgault, Y.; Ait-Ali-Yahia, D.; Fortin, M.; Vallet, M.G. Anisotropic mesh adaptation: Towards user-independent, mesh-independent and solver-independent CFD. Part I: General principles. Int. J. Numer. Methods Fluids 2000, 32, 725–744. [Google Scholar] [CrossRef]

- Ait-Ali-Yahia, D.; Baruzzi, G.; Habashi, W.G.; Fortin, M.; Dompierre, J.; Vallet, M.G. Anisotropic mesh adaptation: towards user-independent, mesh-independent and solver-independent CFD. Part II. Structured grids. Int. J. Numer. Methods Fluids 2002, 39, 657–673. [Google Scholar] [CrossRef]

- Suerich-Gulick, F.; Lepage, C.; Habashi, W.G. Anisotropic 3-D Mesh Adaptation for Turbulent Flows. In Proceedings of the 34th AIAA Fluid Dynamics Conference and Exhibit, Portland, OR, USA, 28 June–1 July 2004; p. 2533. [Google Scholar]

- Sahni, O.; Jansen, K.E.; Shephard, M.S.; Taylor, C.A.; Beall, M.W. Adaptive boundary layer meshing for viscous flow simulations. Eng. Comput. 2008, 24, 267. [Google Scholar] [CrossRef]

- Chitale, K.C. Anisotropic Mesh Adaptivity for Turbulent Flows with Boundary Layers. Ph.D. Thesis, University of Colorado, Boulder, CO, USA, 2013. [Google Scholar]

- Frey, P.J.; Alauzet, F. Anisotropic mesh adaptation for CFD computations. Comput. Methods Appl. Mech. Eng. 2005, 194, 5068–5082. [Google Scholar] [CrossRef]

- Loseille, A.; Dervieux, A.; Frey, P.; Alauzet, F. Achievement of global second order mesh convergence for discontinuous flows with adapted unstructured meshes. In Proceedings of the 18th AIAA Computational Fluid Dynamics Conference, Miami, FL, USA, 25–28 June 2007; p. 4186. [Google Scholar]

- Mesri, Y.; Alauzet, F.; Loseille, A.; Hascoët, L.; Koobus, B.; Dervieux, A. Continuous mesh adaptation models for CFD. CFD J. 2008, 16, 346–355. [Google Scholar]

- Loseille, A.; Alauzet, F. Continuous mesh framework part I: Well-posed continuous interpolation error. SIAM J. Numer. Anal. 2011, 49, 38–60. [Google Scholar] [CrossRef]

- Loseille, A.; Alauzet, F. Continuous mesh framework part II: Validations and applications. SIAM J. Numer. Anal. 2011, 49, 61–86. [Google Scholar] [CrossRef]

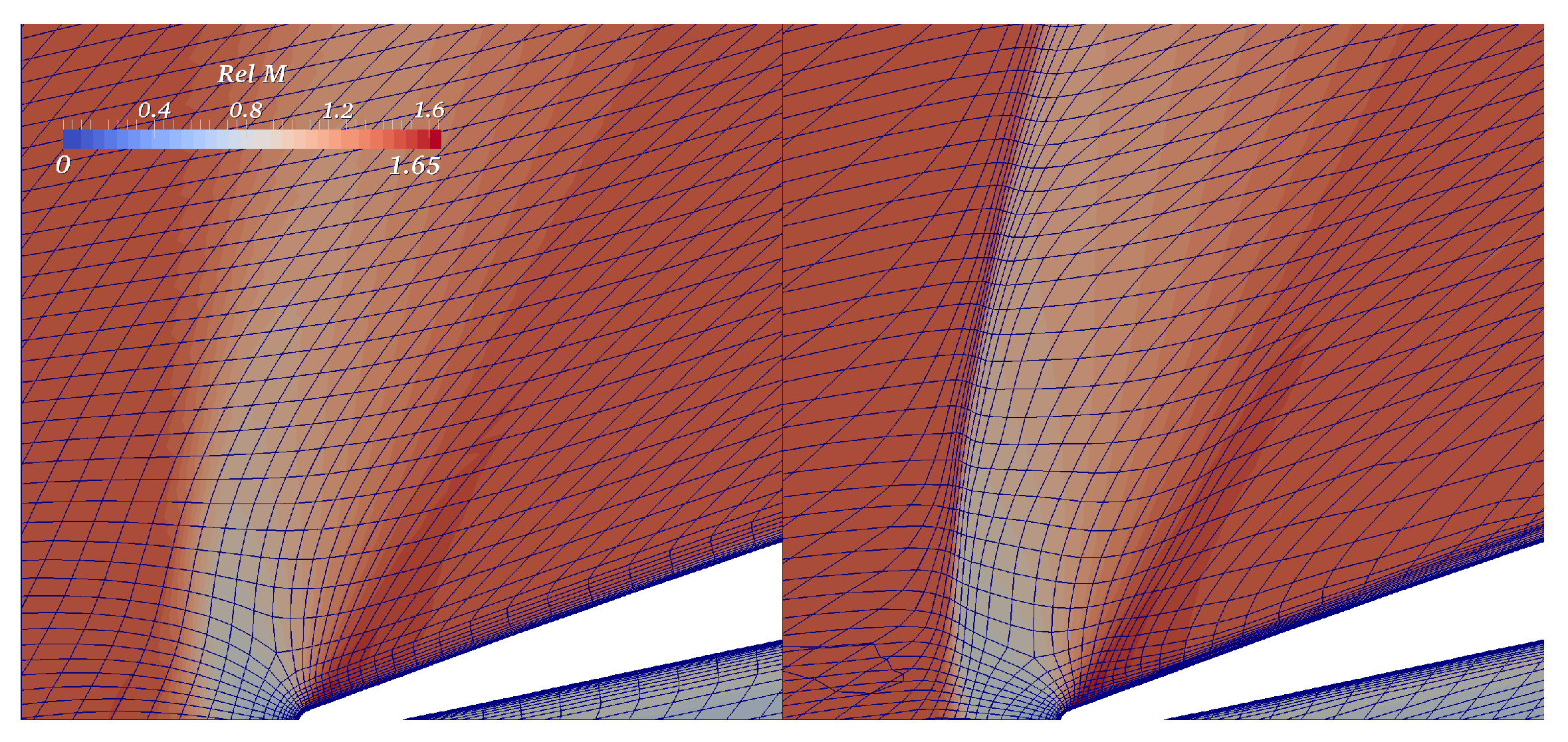

- Frazza, L.; Loseille, A.; Alauzet, F. Anisotropic mesh adaptation for turbomachinery applications. In Proceedings of the 23rd AIAA Computational Fluid Dynamics Conference, Denver, CO, USA, 5–9 June 2017; p. 3299. [Google Scholar]

- Vallet, M.G.; Manole, C.M.; Dompierre, J.; Dufour, S.; Guibault, F. Numerical comparison of some Hessian recovery techniques. Int. J. Numer. Methods Eng. 2007, 72, 987–1007. [Google Scholar] [CrossRef]

- Picasso, M.; Alauzet, F.; Borouchaki, H.; George, P.L. A numerical study of some Hessian recovery techniques on isotropic and anisotropic meshes. SIAM J. Sci. Comput. 2011, 33, 1058–1076. [Google Scholar] [CrossRef]

- Borouchaki, H.; Hecht, F.; Frey, P.J. Mesh gradation control. Int. J. Numer. Methods Eng. 1998, 43, 1143–1165. [Google Scholar] [CrossRef]

- Li, X.; Remacle, J.F.; Chevaugeon, N.; Shephard, M.S. Anisotropic Mesh Gradation Control. In Proceedings of the International Meshing Roundtable, Williamsburg, VA, USA, 19–22 September 2004; pp. 401–412. [Google Scholar]

- Alauzet, F. Size gradation control of anisotropic meshes. Finite Elem. Anal. Des. 2010, 46, 181–202. [Google Scholar] [CrossRef]

- Joubarne, E.; Guibault, F. 3D Metric-based anisotropic mesh adaptation for vortex capture. Math. Comput. Simul. 2011, 82, 163–180. [Google Scholar] [CrossRef]

- Michal, T.; Babcock, D.; Kamenetskiy, D.; Krakos, J.; Mani, M.; Glasby, R.; Erwin, T.; Stefanski, D.L. Comparison of fixed and adaptive unstructured grid results for drag prediction workshop 6. J. Aircr. 2018, 55, 1420–1432. [Google Scholar] [CrossRef]

- Alauzet, F.; Clerici, F.; Loseille, A.; Tarsia-Morisco, C.; Vanharen, J. Some progress on CFD high lift prediction using metric-based anisotropic mesh adaptation. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022; p. 0388. [Google Scholar]

- Michal, T.R.; Kamenetskiy, D.S.; Krakos, J. Anisotropic Adaptive Mesh Results for the Third High Lift Prediction Workshop (HiLiftPW-3). In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; p. 1257. [Google Scholar]

- Park, M.A.; Balan, A.; Anderson, W.K.; Galbraith, M.C.; Caplan, P.; Carson, H.A.; Michal, T.R.; Krakos, J.A.; Kamenetskiy, D.S.; Loseille, A.; et al. Verification of unstructured grid adaptation components. In Proceedings of the AIAA Scitech 2019 forum, San Diego, CA, USA, 7–11 January 2019; p. 1723. [Google Scholar]

- Balan, A.; Park, M.A.; Anderson, W.K.; Kamenetskiy, D.S.; Krakos, J.A.; Michal, T.; Alauzet, F. Verification of anisotropic mesh adaptation for turbulent simulations over ONERA M6 wing. AIAA J. 2020, 58, 1550–1565. [Google Scholar] [CrossRef]

- Alauzet, F.; Frazza, L.; Papadogiannis, D. Periodic adjoints and anisotropic mesh adaptation in rotating frame for high-fidelity RANS turbomachinery applications. J. Comput. Phys. 2022, 450, 110814. [Google Scholar] [CrossRef]

- Laure, B.; Dimitrios, P.; Frédéric, A. Isotropic and anisotropic mesh adaptation for rans simulations of a nacelle under crosswind conditions. J. Glob. Power Propuls. Soc. 2023, 7, 188–199. [Google Scholar] [CrossRef]

- Alauzet, F.; Papadogiannis, D.; Billon, L. Evaluation of heat transfer performance of a film-cooled turbine vane using metric-based anisotropic mesh adaptation. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 1399. [Google Scholar]

- Alauzet, F.; Parente, E.; Remigi, A. High-Fidelity Film-Cooled Rotor High Pressure Turbine Simulation using Metric-Based Anisotropic Mesh Adaptation. In Proceedings of the Global Power and Propulsion Society, GPPS Chania24, Chania, Crete, 4–6 September 2024. ISSN-Nr: 2504-4400. [Google Scholar]

- Remigi, A.; Philit, M.; Alauzet, F.; Guilbert, E. Evaluation of tandem transonic compressor performances with mixing plane and metric-based mesh adaptation. In Proceedings of the AIAA SCITECH 2024 Forum, Orlando, FL, USA, 8–12 January 2024; p. 0523. [Google Scholar]

- John, A.; Vivarelli, G.; Qin, N.; Shahpar, S. Using Feature-Based Mesh Adaptation to Improve the Adjoint Optimisation of Transonic Compressor Blades. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air. American Society of Mechanical Engineers, Virtual, 21–25 September 2020; Volume 84089, p. V02CT35A036. [Google Scholar]

- Becker, R.; Rannacher, R. Weighted a posteriori error control in FE methods. In Proceedings of the Lecture at ENUMATH-95, Paris, France, 18–22 September 1995; pp. 621–637. [Google Scholar]

- Giles, M.B.; Larson, M.; Levenstam, M.; Suli, E. Adaptive Error Control for Finite Element Approximations of the Lift and Drag Coefficients in Viscous Flow; Technical report; University of Oxford: Oxford, UK, 1997. [Google Scholar]

- Venditti, D.A.; Darmofal, D.L. A multilevel error estimation and grid adaptive strategy for improving the accuracy of integral outputs. In Proceedings of the 14th Computational Fluid Dynamics Conference, Norfolk, VA, USA, 1–5 November 1999; p. 3292. [Google Scholar]

- Giles, M.B. On adjoint equations for error analysis and optimal grid adaptation in CFD. In Frontiers of Computational Fluid Dynamics 1998; World Scientific: Singapore, 1998; pp. 155–169. [Google Scholar]

- Pierce, N.A.; Giles, M.B. Adjoint recovery of superconvergent functionals from PDE approximations. SIAM Rev. 2000, 42, 247–264. [Google Scholar] [CrossRef]

- Müller, J.D.; Giles, M. Solution adaptive mesh refinement using adjoint error analysis. In Proceedings of the 15th AIAA Computational Fluid Dynamics Conference, Anaheim, CA, USA, 11–14 June 2001; p. 2550. [Google Scholar]

- Venditti, D.A.; Darmofal, D.L. Adjoint error estimation and grid adaptation for functional outputs: Application to quasi-one-dimensional flow. J. Comput. Phys. 2000, 164, 204–227. [Google Scholar] [CrossRef]

- Power, P.W.; Piggott, M.D.; Fang, F.; Gorman, G.J.; Pain, C.C.; Marshall, D.P.; Goddard, A.J.H.; Navon, I.M. Adjoint goal-based error norms for adaptive mesh ocean modelling. Ocean. Model. 2006, 15, 3–38. [Google Scholar] [CrossRef]

- Power, P.W.; Pain, C.C.; Piggott, M.D.; Fang, F.; Gorman, G.J.; Umpleby, A.P.; Goddard, A.J.H.; Navon, I.M. Adjoint a posteriori error measures for anisotropic mesh optimisation. Comput. Math. Appl. 2006, 52, 1213–1242. [Google Scholar] [CrossRef]

- Venditti, D.A. Grid Adaptation for Functional Outputs of Compressible Flow Simulations. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2002. [Google Scholar]

- Park, M.A. Adjoint-based, three-dimensional error prediction and grid adaptation. AIAA J. 2004, 42, 1854–1862. [Google Scholar] [CrossRef]

- Park, M. Three-dimensional turbulent RANS adjoint-based error correction. In Proceedings of the 16th AIAA Computational Fluid Dynamics Conference, Orlando, FL, USA, 23–26 June 2003; p. 3849. [Google Scholar]

- Blazek, J. Computational Fluid Dynamics: Principles and Applications; Elsevier: Amsterdam, The Netherlands, 2001; p. 2001. ISBN 0080430090. [Google Scholar]

- Vivarelli, G.; Qin, N.; Shahpar, S. Combined Hessian and Adjoint Error-Based Anisotropic Mesh Adaptation for Turbomachinery Flows. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017; p. 1946. [Google Scholar]

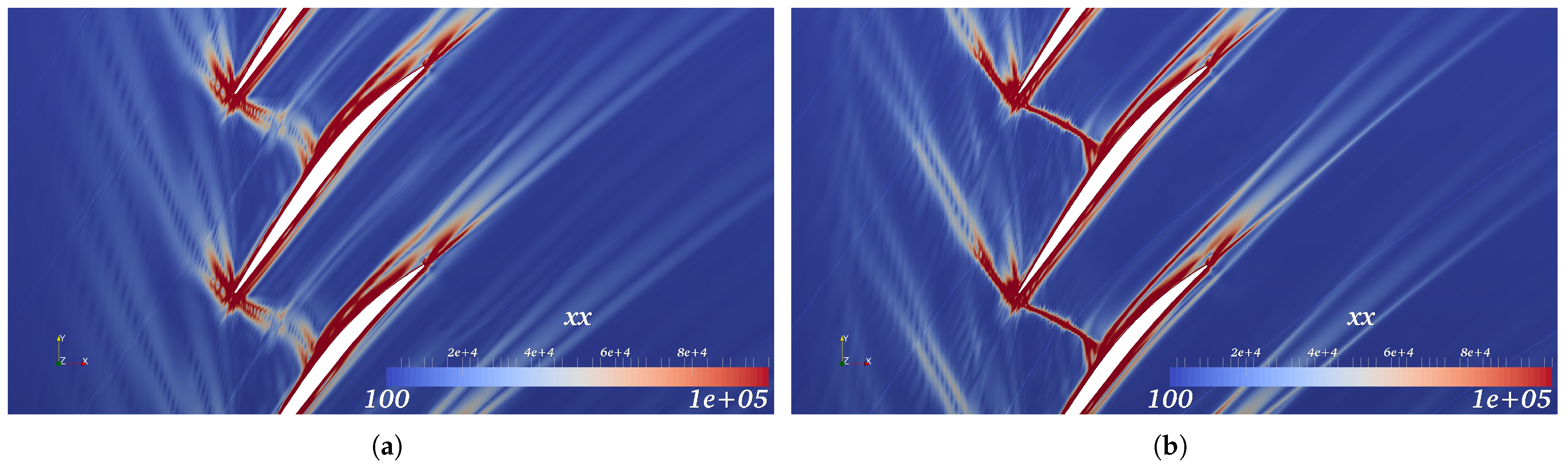

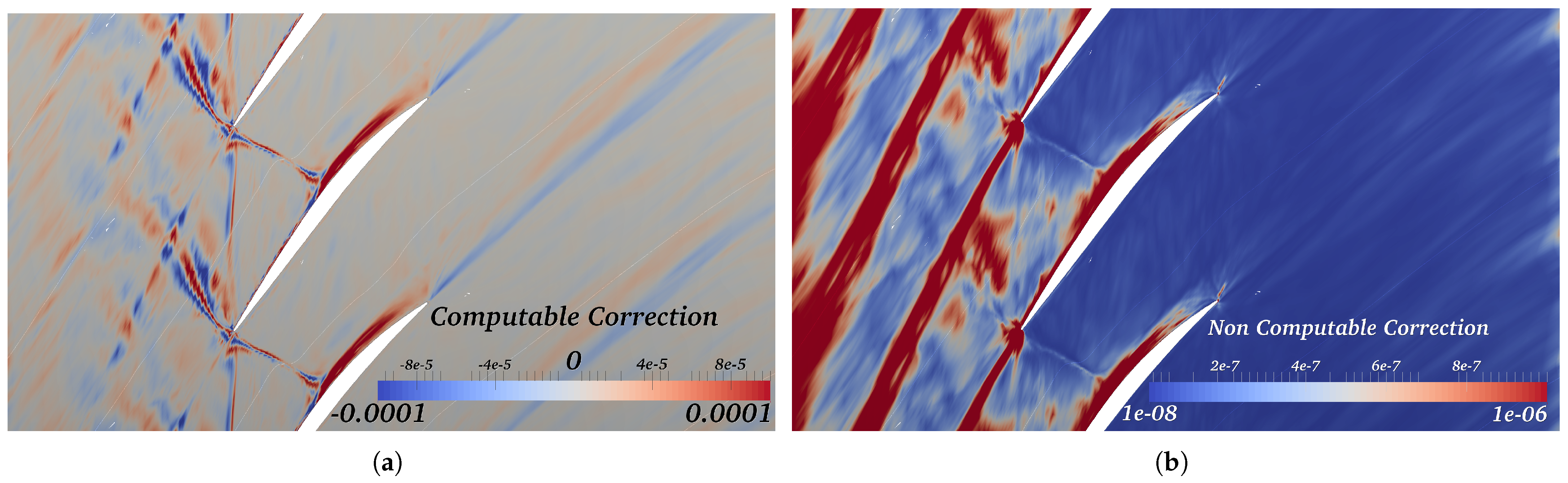

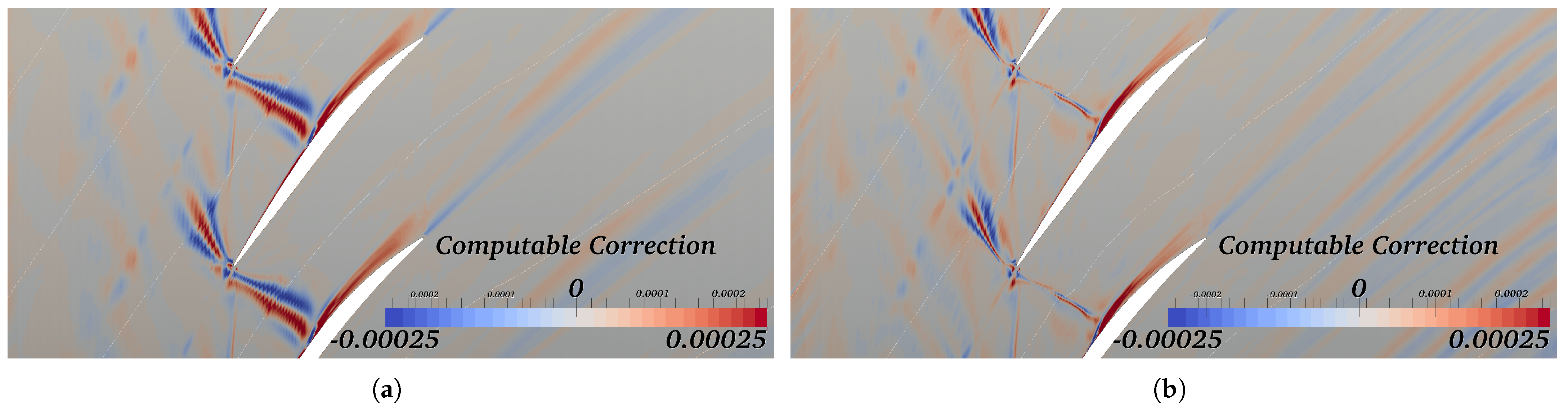

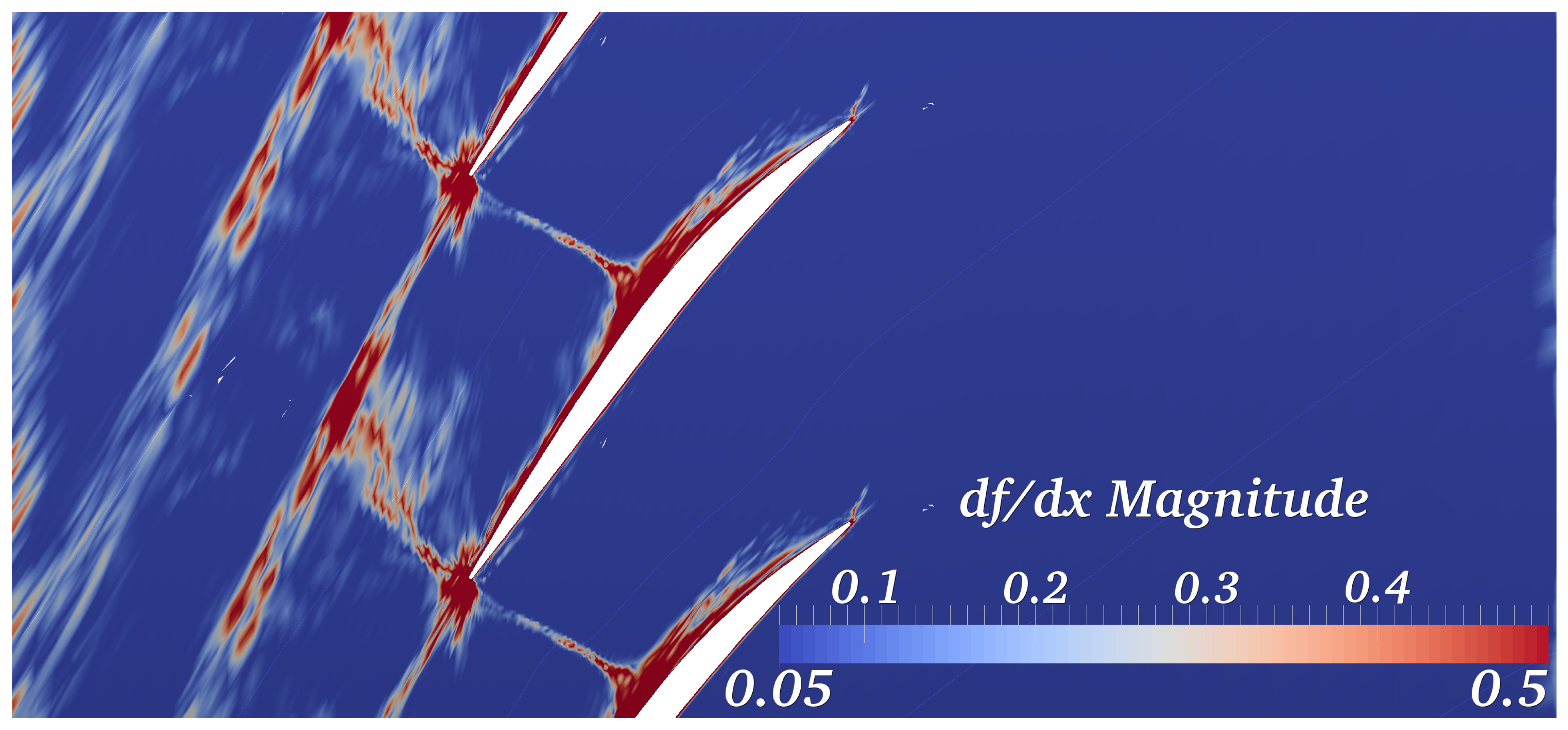

- Vivarelli, G.; Qin, N.; Shahpar, S.; Radford, D. Sequential feature-based mesh movement and adjoint error-based mesh refinement. Int. J. Numer. Methods Fluids 2021, 93, 249–272. [Google Scholar] [CrossRef]

- Nemec, M.; Aftosmis, M. Adjoint error estimation and adaptive refinement for embedded-boundary Cartesian meshes. In Proceedings of the 18th AIAA Computational Fluid Dynamics Conference, Miami, FL, USA, 25–28 June 2007; p. 4187. [Google Scholar]

- Barth, T.; Jespersen, D. The design and application of upwind schemes on unstructured meshes. In Proceedings of the 27th Aerospace Sciences Meeting, Reno, NV, USA, 9–12 January 1989; p. 366. [Google Scholar]

- Aftosmis, M.; Berger, M. Multilevel error estimation and adaptive h-refinement for cartesian meshes with embedded boundaries. In Proceedings of the 40th AIAA Aerospace Sciences Meeting & Exhibit, Reno, NV, USA, 14–17 January 2002; p. 863. [Google Scholar]

- Lee-Rausch, E.; Park, M.; Jones, W.; Hammond, D.; Nielsen, E. Application of parallel adjoint-based error estimation and anisotropic grid adaptation for three-dimensional aerospace configurations. In Proceedings of the 23rd AIAA Applied Aerodynamics Conference, Toronto, OT, Canada, 6–9 June 2005; p. 4842. [Google Scholar]

- Kim, H.J.; Takano, Y.; Nakahashi, K. Error estimation and grid adaptation using Euler adjoint method. J. Aircr. 2006, 43, 1317–1324. [Google Scholar] [CrossRef]

- Kim, H.J.; Nakahashi, K. Output-based error estimation and adaptive mesh refinement using viscous adjoint method. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; p. 1395. [Google Scholar]

- Jones, W.; Nielsen, E.; Park, M. Validation of 3D adjoint based error estimation and mesh adaptation for sonic boom prediction. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; p. 1150. [Google Scholar]

- Lancaster, P.; Salkauskas, K. Surfaces generated by moving least squares methods. Math. Comput. 1981, 37, 141–158. [Google Scholar] [CrossRef]

- Ponsin, J.; Caloto, A.; Andrés, E.; Bitrián, P.; Lozano, C. Implementation of an Adjoint-Based Error Estimation and Grid Adaptation Module in the DLR TAU Code. In Proceedings of the 27th Congress of the International Council of the Aeronautical Sciences, Nice, France, 19–24 September 2010. [Google Scholar]

- Ding, K.; Fidkowski, K.J.; Roe, P.L. Acceleration Techniques for Adjoint-Based Error Estimation and Mesh Adaptation. In Proceedings of the Eighth International Conference on Computational Fluid Dynamics (ICCFD8) ICCFD8-2014-0249, Chengdu, China, 14–18 July 2014. [Google Scholar]

- Fidkowski, K.J. High-Order Output-Based Adaptive Methods for Steady and Unsteady Aerodynamics. In 37th Advanced CFD Lectures Series; von Karman Institute for Fluid Dynamics (December 9–12 2013); Deconinck, H., Abgrall, R., Eds.; von Karman Institute for Fluid Dynamics: Sint-Genesius-Rode, Belgium, 2013. [Google Scholar]

- Eymann, T.A. Active Flux Schemes. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2013. [Google Scholar]

- Pierce, N.A.; Giles, M.B. Adjoint and defect error bounding and correction for functional estimates. J. Comput. Phys. 2004, 200, 769–794. [Google Scholar] [CrossRef]

- Duraisamy, K.; Alonso, J.J.; Chandrasekhar, P.; Palacios, F. Error estimation for high speed flows using continuous and discrete adjoints. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010; p. 128. [Google Scholar]

- Palacios, F.; Duraisamy, K.; Alonso, J.J.; Zuazua, E. Robust grid adaptation for efficient uncertainty quantification. AIAA J. 2012, 50, 1538–1546. [Google Scholar] [CrossRef]

- Rothacker, B.A.; Ceze, M.; Fidkowski, K. Adjoint-based error estimation and mesh adaptation for problems with output constraints. In Proceedings of the 32nd AIAA Applied Aerodynamics Conference, Atlanta, GA, USA, 16–20 June 2014; p. 2576. [Google Scholar]

- Hartmann, R. Multitarget error estimation and adaptivity in aerodynamic flow simulations. SIAM J. Sci. Comput. 2008, 31, 708–731. [Google Scholar] [CrossRef]

- Hartmann, R.; Held, J.; Leicht, T. Adjoint-based error estimation and adaptive mesh refinement for the RANS and k–ω turbulence model equations. J. Comput. Phys. 2011, 230, 4268–4284. [Google Scholar] [CrossRef]

- Dwight, R.P. Goal-oriented mesh adaptation for finite volume methods using a dissipation-based error indicator. Int. J. Numer. Methods Fluids 2008, 56, 1193–1200. [Google Scholar] [CrossRef]

- Dwight, R.P. Heuristic a posteriori estimation of error due to dissipation in finite volume schemes and application to mesh adaptation. J. Comput. Phys. 2008, 227, 2845–2863. [Google Scholar] [CrossRef][Green Version]

- Jameson, A.; Schmidt, W.; Turkel, E. Numerical solution of the Euler equations by finite volume methods using Runge Kutta time stepping schemes. In Proceedings of the 14th Fluid and Plasma Dynamics Conference, Palo Alto, CA, USA, 23–25 June 1981; p. 1259. [Google Scholar]

- Fidkowski, K.F.; Roe, P.L. Entropy-based mesh refinement, I: The entropy adjoint approach. In Proceedings of the 19th AIAA Computational Fluid Dynamics, San Antonio, TX, USA, 22–25 June 2009; p. 3790. [Google Scholar]

- Yamaleev, N.; Diskin, B.; Pathak, K. Error minimization via adjoint-based anisotropic grid adaptation. In Proceedings of the 40th Fluid Dynamics Conference and Exhibit, Chicago, IL, USA, 28 June–1 July 2010; p. 4436. [Google Scholar]

- Yano, M.; Modisette, J.; Darmofal, D. The importance of mesh adaptation for higher-order discretizations of aerodynamic flows. In Proceedings of the 20th AIAA Computational Fluid Dynamics Conference, Honolulu, HI, USA, 27–30 June 2011; p. 3852. [Google Scholar]

- Yano, M.; Darmofal, D.L. An optimization-based framework for anisotropic simplex mesh adaptation. J. Comput. Phys. 2012, 231, 7626–7649. [Google Scholar] [CrossRef]

- Carson, H.A.; Huang, A.C.; Galbraith, M.C.; Allmaras, S.R.; Darmofal, D.L. Anisotropic mesh adaptation for continuous finite element discretization through mesh optimization via error sampling and synthesis. J. Comput. Phys. 2020, 420, 109620. [Google Scholar] [CrossRef]

- Carson, H.A.; Huang, A.C.; Galbraith, M.C.; Allmaras, S.R.; Darmofal, D.L. Mesh optimization via error sampling and synthesis: An update. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 0087. [Google Scholar]

- Ursachi, C.I.; Galbraith, M.; Allmaras, S.R.; Darmofal, D. Output-based adaptive RANS solutions using higher-order FEM on a multi-element airfoil. In Proceedings of the AIAA Aviation 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 3220. [Google Scholar]

- Loseille, A.; Dervieux, A.; Alauzet, F. Fully anisotropic goal-oriented mesh adaptation for 3D steady Euler equations. J. Comput. Phys. 2010, 229, 2866–2897. [Google Scholar] [CrossRef]

- Belme, A.; Alauzet, F.; Dervieux, A. An a priori anisotropic goal-oriented error estimate for viscous compressible flow and application to mesh adaptation. J. Comput. Phys. 2019, 376, 1051–1088. [Google Scholar] [CrossRef]

- Park, M.A.; Balan, A.; Clerici, F.; Alauzet, F.; Loseille, A.; Kamenetskiy, D.S.; Krakos, J.A.; Michal, T.R.; Galbraith, M.C. Verification of viscous goal-based anisotropic mesh adaptation. In Proceedings of the AIAA Scitech 2021 Forum, Orlando, FL, USA, 12–16 January 2021; p. 1362. [Google Scholar]

- Peter, J.; Nguyen-Dinh, M.; Trontin, P. Goal oriented mesh adaptation using total derivative of aerodynamic functions wrt mesh coordinates. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012; p. 158. [Google Scholar]

- Peter, J.; Nguyen-Dinh, M.; Trontin, P. Goal oriented mesh adaptation using total derivative of aerodynamic functions wrt mesh coordinates—With applications to Euler flows. Comput. Fluids 2012, 66, 194–214. [Google Scholar] [CrossRef]

- Nguyen-Dinh, M.; Peter, J.; Sauvage, R.; Meaux, M.; Désidéri, J.A. Mesh quality assessment based on aerodynamic functional output total derivatives. Eur. J. Mech.-B/Fluids 2014, 45, 51–71. [Google Scholar] [CrossRef]

- Peter, J.E.; Desideri, J.A. Unstructured mesh adaptation for functional outputs. With application to two dimensionnal inviscid flows. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 1930. [Google Scholar]

- Todarello, G.; Vonck, F.; Bourasseau, S.; Peter, J.; Désidéri, J.A. Finite-volume goal-oriented mesh adaptation for aerodynamics using functional derivative wrt nodal coordinates. J. Comput. Phys. 2016, 313, 799–819. [Google Scholar] [CrossRef]

- Resmini, A.; Peter, J.; Lucor, D. Mono-block and non-matching multi-block structured mesh adaptation based on aerodynamic functional total derivatives for RANS flow. Int. J. Numer. Methods Fluids 2017, 83, 866–884. [Google Scholar] [CrossRef]

- Vivarelli, G.; Qin, N.; Shahpar, S.; Radford, D. Efficient Adjoint-Based Mesh Adaptation Applied to Turbo-Machinery Flows. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Vivarelli, G.; Qin, N.; Shahpar, S.; Radford, D. Anisotropic adjoint sensitivity-based mesh movement for industrial applications. Comput. Fluids 2021, 221, 104929. [Google Scholar] [CrossRef]

- Ordaz, I.; Rallabhandi, S.K.; Nielsen, E.J.; Diskin, B. Mitigation of engine inlet distortion through adjoint-based design. In Proceedings of the 35th AIAA Applied Aerodynamics Conference, Denver, CO, USA, 5–9 June 2017; p. 3410. [Google Scholar]

- Nemec, M.; Rodriguez, D.L.; Aftosmis, M.J. Adjoint-based mesh adaptation and shape optimization for simulations with propulsion. In Proceedings of the AIAA Aviation 2019 Forum, Dallas, TX, USA, 17–21 June 2019; p. 3488. [Google Scholar]

- Michal, T.R.; Kamenetskiy, D.S.; Krakos, J. Generation of Anisotropic Adaptive Meshes for the First AIAA Geometry and Mesh Generation Workshop. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; p. 0658. [Google Scholar]

- Park, M.A.; Kleb, W.L.; Jones, W.T.; Krakos, J.A.; Michal, T.R.; Loseille, A.; Haimes, R.; Dannenhoffer, J. Geometry modeling for unstructured mesh adaptation. In Proceedings of the AIAA Aviation 2019 Forum, Dallas, TX, USA, 17–21 June 2019; p. 2946. [Google Scholar]

- Tsolakis, C.; Chrisochoides, N.; Park, M.A.; Loseille, A.; Michal, T. Parallel anisotropic unstructured grid adaptation. AIAA J. 2021, 59, 4764–4776. [Google Scholar] [CrossRef]

- Tang, J.; Cui, P.; Li, B.; Zhang, Y.; Si, H. Parallel hybrid mesh adaptation by refinement and coarsening. Graph. Model. 2020, 111, 101084. [Google Scholar] [CrossRef]

- Menon, S.; Mooney, K.G.; Stapf, K.; Schmidt, D.P. Parallel adaptive simplical re-meshing for deforming domain CFD computations. J. Comput. Phys. 2015, 298, 62–78. [Google Scholar] [CrossRef]

- Spurlock, W.M.; Aftosmis, M.J.; Chiew, J.J.; Nemec, M. Parallel Mesh Adaptation for Unsteady Blast Simulations on Cartesian Meshes. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023; p. 1792. [Google Scholar]

- Sahni, O.; Brown, C.S.; Gica, M.; Kaur, S.; Salazar, G.; Keistler, P. In-Memory Parallel Anisotropic Mesh Adaptation for Unsteady Hypersonic Problems. In Proceedings of the AIAA Aviation Forum and Ascend 2024, Las Vegas, NV, USA, 29 July–2 August 2024; p. 4258. [Google Scholar]

- Tsolakis, C.; Chrisochoides, N. Parallel Metric-based Anisotropic Mesh Adaptation using Speculative Execution on Shared Memory. arXiv 2024, preprint. [Google Scholar]

- Wang, Z. High-order computational fluid dynamics tools for aircraft design. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130318. [Google Scholar] [CrossRef]

- Michelassi, V. Turbomachinery research and design: The role of DNS and LES in industry. In Progress in Hybrid RANS-LES Modelling: Papers Contributed to the 7th Symposium on Hybrid RANS-LES Methods, Berlin, Germany 17–19 September 2018; Springer: Berlin/Heidelberg, Germany, 2020; pp. 55–69. [Google Scholar]

- Ekelschot, D.; Moxey, D.; Sherwin, S.; Peiró, J. A p-adaptation method for compressible flow problems using a goal-based error indicator. Comput. Struct. 2017, 181, 55–69. [Google Scholar] [CrossRef]

- Moxey, D.; Sastry, S.P.; Kirby, R.M. Interpolation error bounds for curvilinear finite elements and their implications on adaptive mesh refinement. J. Sci. Comput. 2019, 78, 1045–1062. [Google Scholar] [CrossRef]

- Marcon, J.; Kopriva, D.A.; Sherwin, S.J.; Peiró, J. Naturally curved quadrilateral mesh generation using an adaptive spectral element solver. arXiv 2019, preprint. [Google Scholar]

- Marcon, J.; Castiglioni, G.; Moxey, D.; Sherwin, S.J.; Peiró, J. rp-adaptation for compressible flows. Int. J. Numer. Methods Eng. 2020, 121, 5405–5425. [Google Scholar] [CrossRef]

- Coulaud, O.; Loseille, A. Very high order anisotropic metric-based mesh adaptation in 3D. Procedia Eng. 2016, 163, 353–365. [Google Scholar] [CrossRef]

- Dolejší, V.; May, G.; Rangarajan, A. A continuous hp-mesh model for adaptive discontinuous Galerkin schemes. Appl. Numer. Math. 2018, 124, 1–21. [Google Scholar] [CrossRef]

- Rangarajan, A.; Balan, A.; May, G. Mesh optimization for discontinuous Galerkin methods using a continuous mesh model. AIAA J. 2018, 56, 4060–4073. [Google Scholar] [CrossRef]

- Sanjaya, D.P.; Fidkowski, K.; Diosady, L.T.; Murman, S.M. Error minimization via metric-based curved-mesh adaptation. In Proceedings of the 23rd AIAA Computational Fluid Dynamics Conference, Denver, CO, USA, 5–9 June 2017; p. 3099. [Google Scholar]

- Sanjaya, D.P.; Fidkowski, K.; Murman, S.M. Comparison of algorithms for high-order, metric-based mesh optimization. In Proceedings of the AIAA SciTech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 1141. [Google Scholar]

- Barral, N.; Olivier, G.; Alauzet, F. Time-accurate anisotropic mesh adaptation for three-dimensional time-dependent problems with body-fitted moving geometries. J. Comput. Phys. 2017, 331, 157–187. [Google Scholar] [CrossRef]

- Alauzet, F.; Loseille, A.; Olivier, G. Time-accurate multi-scale anisotropic mesh adaptation for unsteady flows in CFD. J. Comput. Phys. 2018, 373, 28–63. [Google Scholar] [CrossRef]

- Park, M.A.; Kleb, W.L.; Anderson, W.K.; Wood, S.L.; Balan, A.; Zhou, B.Y.; Gauger, N.R. Exploring Unstructured Mesh Adaptation for Hybrid Reynolds-Averaged Navier–Stokes/Large Eddy Simulation. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 1139. [Google Scholar]

- Obiols-Sales, O.; Vishnu, A.; Malaya, N.; Chandramowlishwaran, A. ADARNet: Deep Learning Predicts Adaptive Mesh Refinement. In Proceedings of the 52nd International Conference on Parallel Processing, Salt Lake City, UT, USA, 7–10 August 2023; pp. 524–534. [Google Scholar]

- Pelissier, U.; Parret-Fréaud, A.; Bordeu, F.; Mesri, Y. Graph Neural Networks for Mesh Generation and Adaptation in Structural and Fluid Mechanics. Mathematics 2024, 12, 2933. [Google Scholar] [CrossRef]

- Pfaff, T.; Fortunato, M.; Sanchez-Gonzalez, A.; Battaglia, P. Learning mesh-based simulation with graph networks. In Proceedings of the International Conference on Learning Representations, Addis Ababa, Ethiopia, 30 April 2020. [Google Scholar]

- Ojha, V.; Chen, G.; Fidkowski, K. Initial mesh generation for solution-adaptive methods using machine learning. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022; p. 1244. [Google Scholar]

- Ghosh, K.; Mehul, B.; Pandya, K.; Kain, D.; Balan, A.; Rangarajan, A. Machine Learning Driven Metric Based Mesh Adaptation. In Proceedings of the International Conference on Applied AI and Scientific Machine Learning, Bangalore, India, 14–18 December 2024. [Google Scholar]

- Fidkowski, K.J.; Chen, G. Metric-based, goal-oriented mesh adaptation using machine learning. J. Comput. Phys. 2021, 426, 109957. [Google Scholar] [CrossRef]

- Yang, J.; Dzanic, T.; Petersen, B.; Kudo, J.; Mittal, K.; Tomov, V.; Camier, J.S.; Zhao, T.; Zha, H.; Kolev, T.; et al. Reinforcement learning for adaptive mesh refinement. In Proceedings of the International conference on artificial intelligence and statistics. PMLR, Valencia, Spain, 25–27 April 2023; pp. 5997–6014. [Google Scholar]

- Tlales, K.; Otmani, K.E.; Ntoukas, G.; Rubio, G.; Ferrer, E. Machine learning mesh-adaptation for laminar and turbulent flows: Applications to high-order discontinuous Galerkin solvers. Eng. Comput. 2024, 40, 2947–2969. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vivarelli, G.; Qin, N.; Shahpar, S. A Review of Mesh Adaptation Technology Applied to Computational Fluid Dynamics. Fluids 2025, 10, 129. https://doi.org/10.3390/fluids10050129

Vivarelli G, Qin N, Shahpar S. A Review of Mesh Adaptation Technology Applied to Computational Fluid Dynamics. Fluids. 2025; 10(5):129. https://doi.org/10.3390/fluids10050129

Chicago/Turabian StyleVivarelli, Guglielmo, Ning Qin, and Shahrokh Shahpar. 2025. "A Review of Mesh Adaptation Technology Applied to Computational Fluid Dynamics" Fluids 10, no. 5: 129. https://doi.org/10.3390/fluids10050129

APA StyleVivarelli, G., Qin, N., & Shahpar, S. (2025). A Review of Mesh Adaptation Technology Applied to Computational Fluid Dynamics. Fluids, 10(5), 129. https://doi.org/10.3390/fluids10050129