A Method for Measuring the Rheology of a Non-Newtonian Fluid Based on the Analysis of the Recirculation Angle of Secondary Flows in a Curved U-Shaped Channel

Abstract

1. Introduction

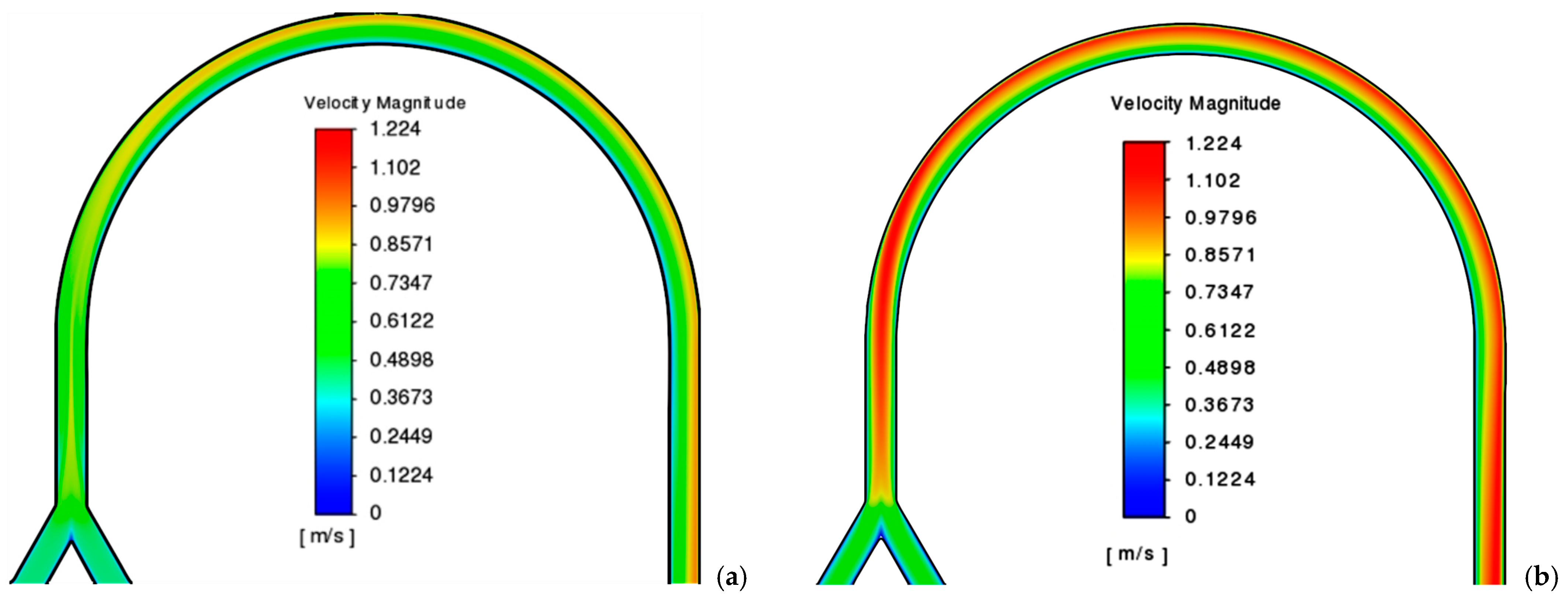

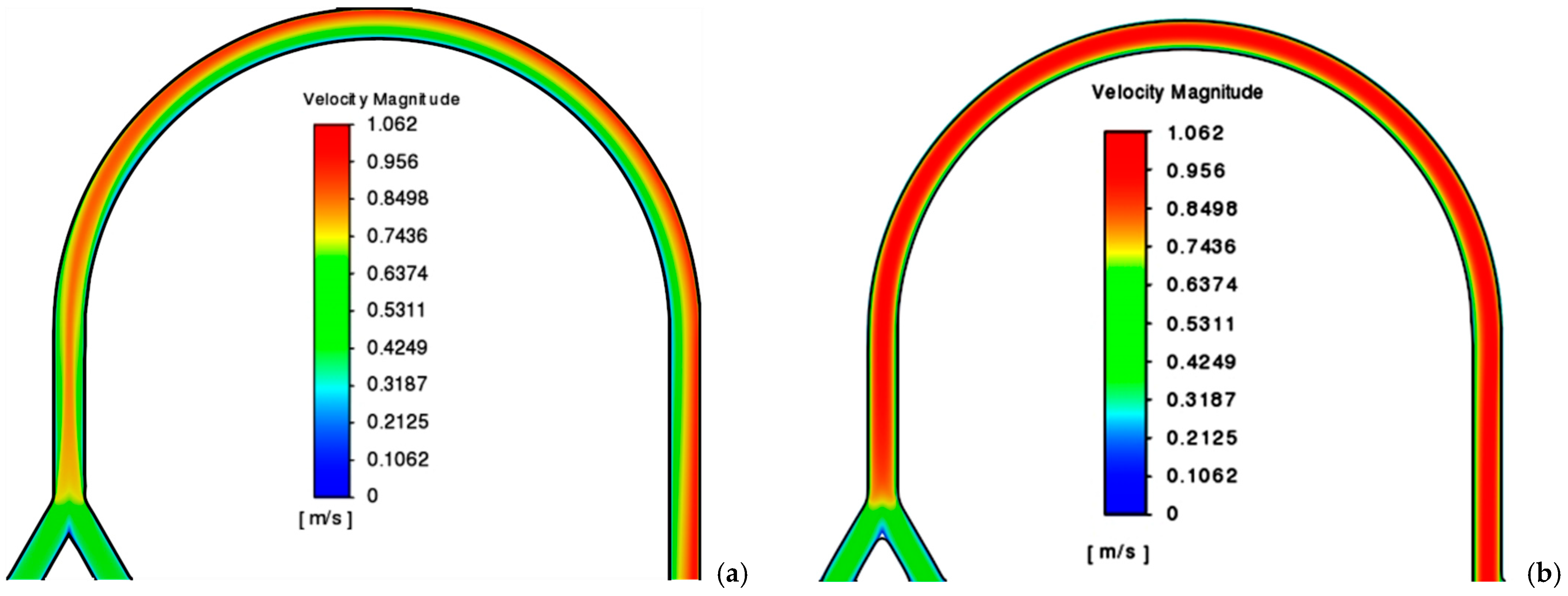

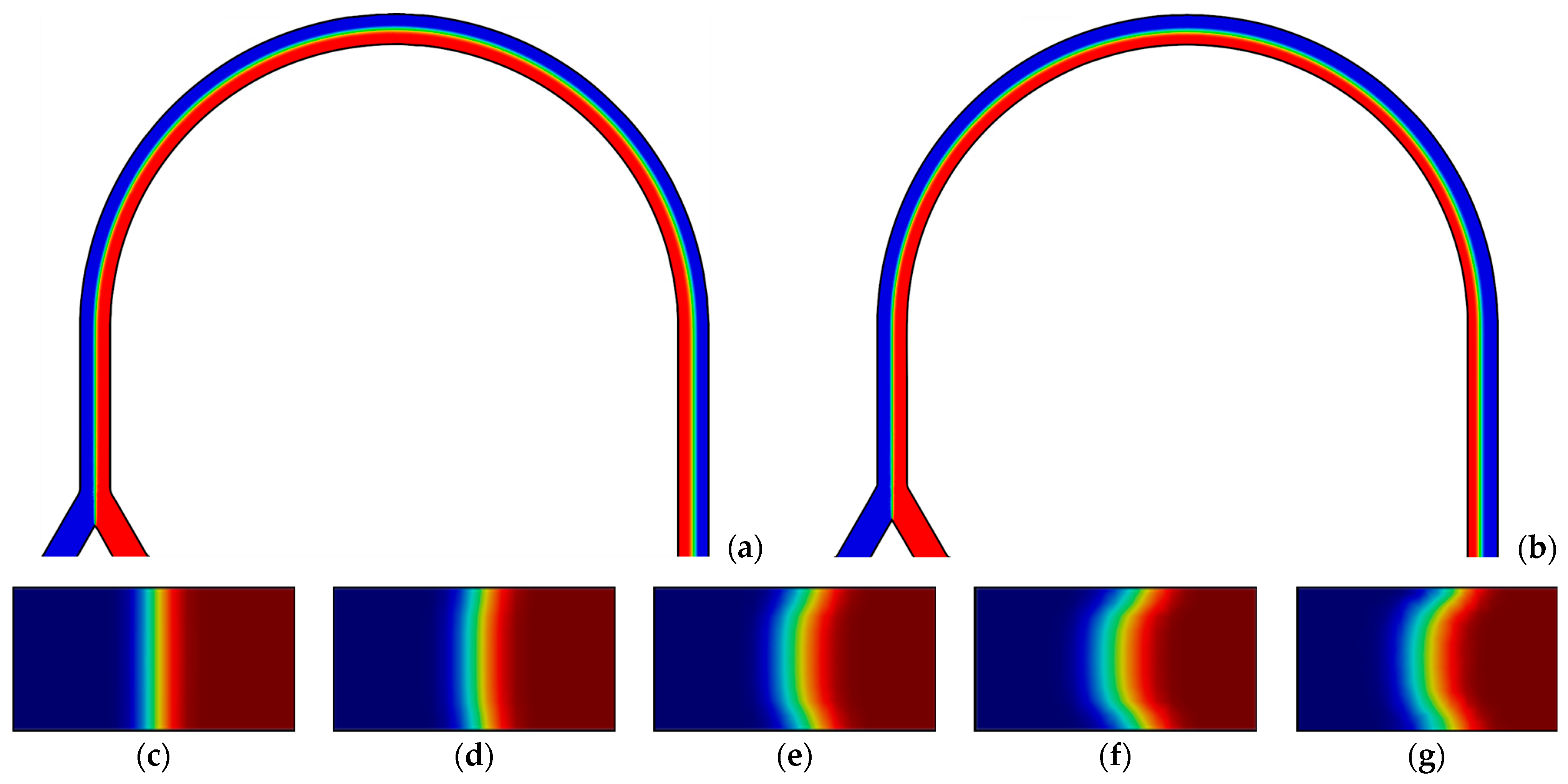

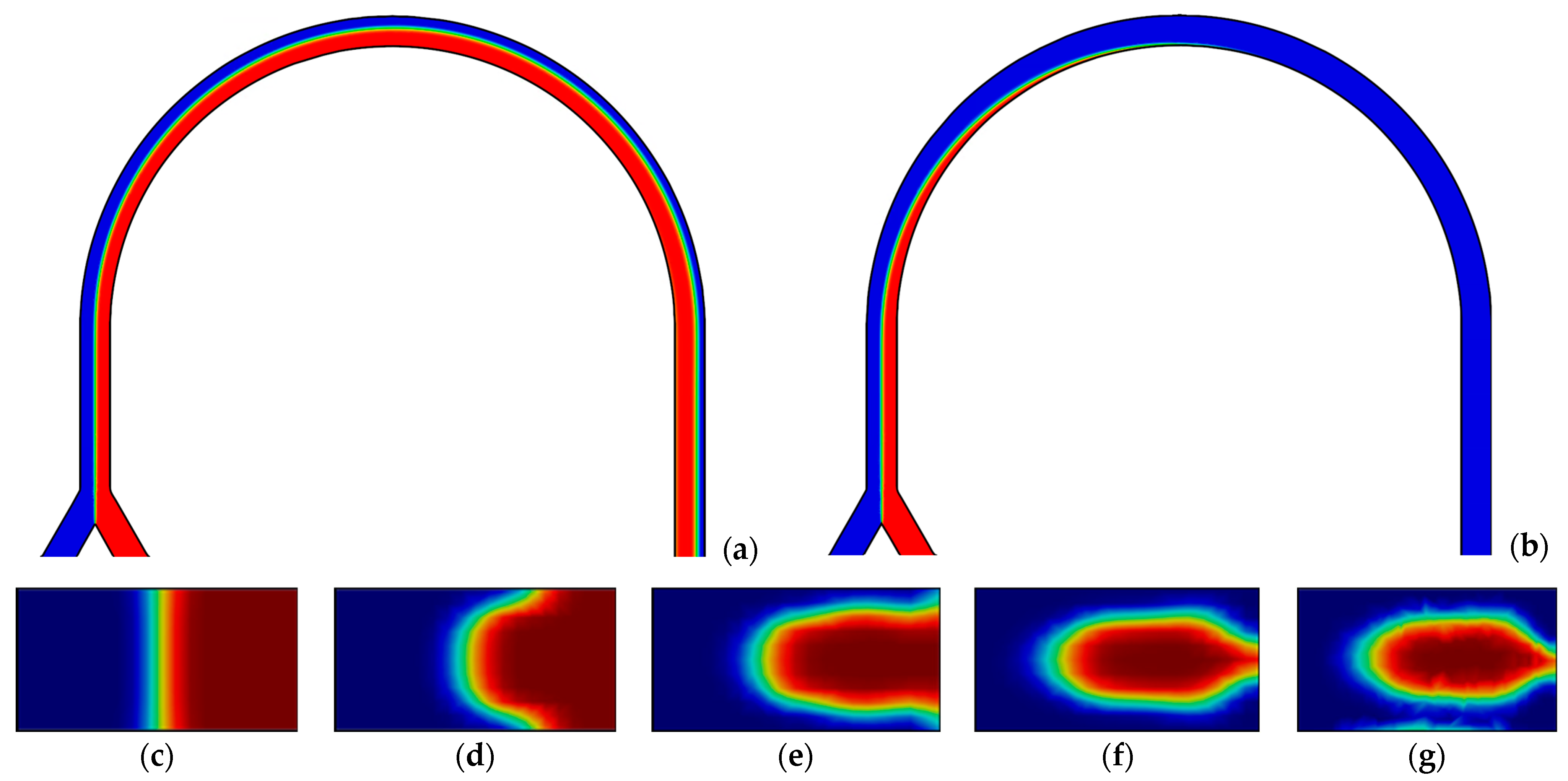

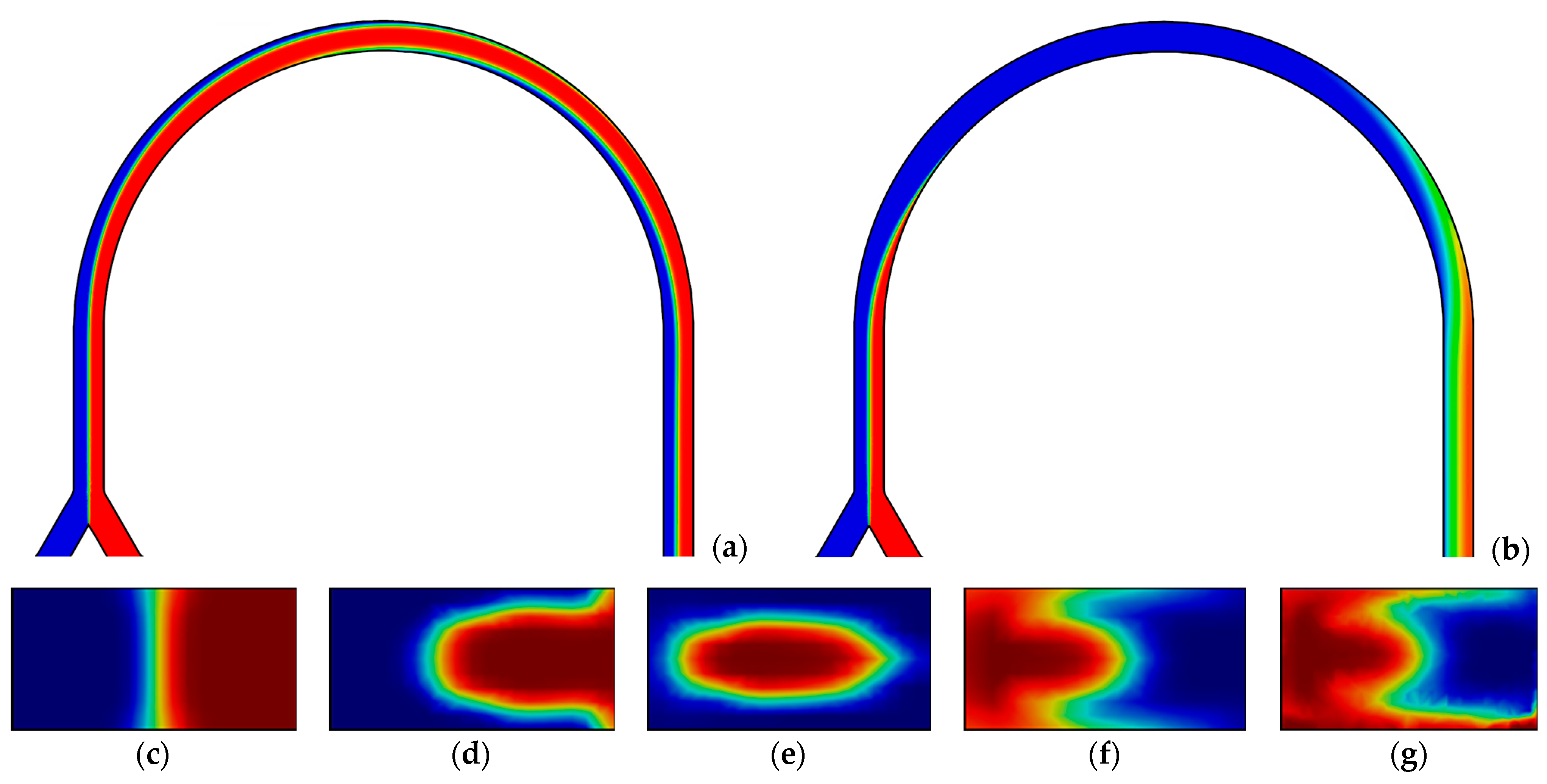

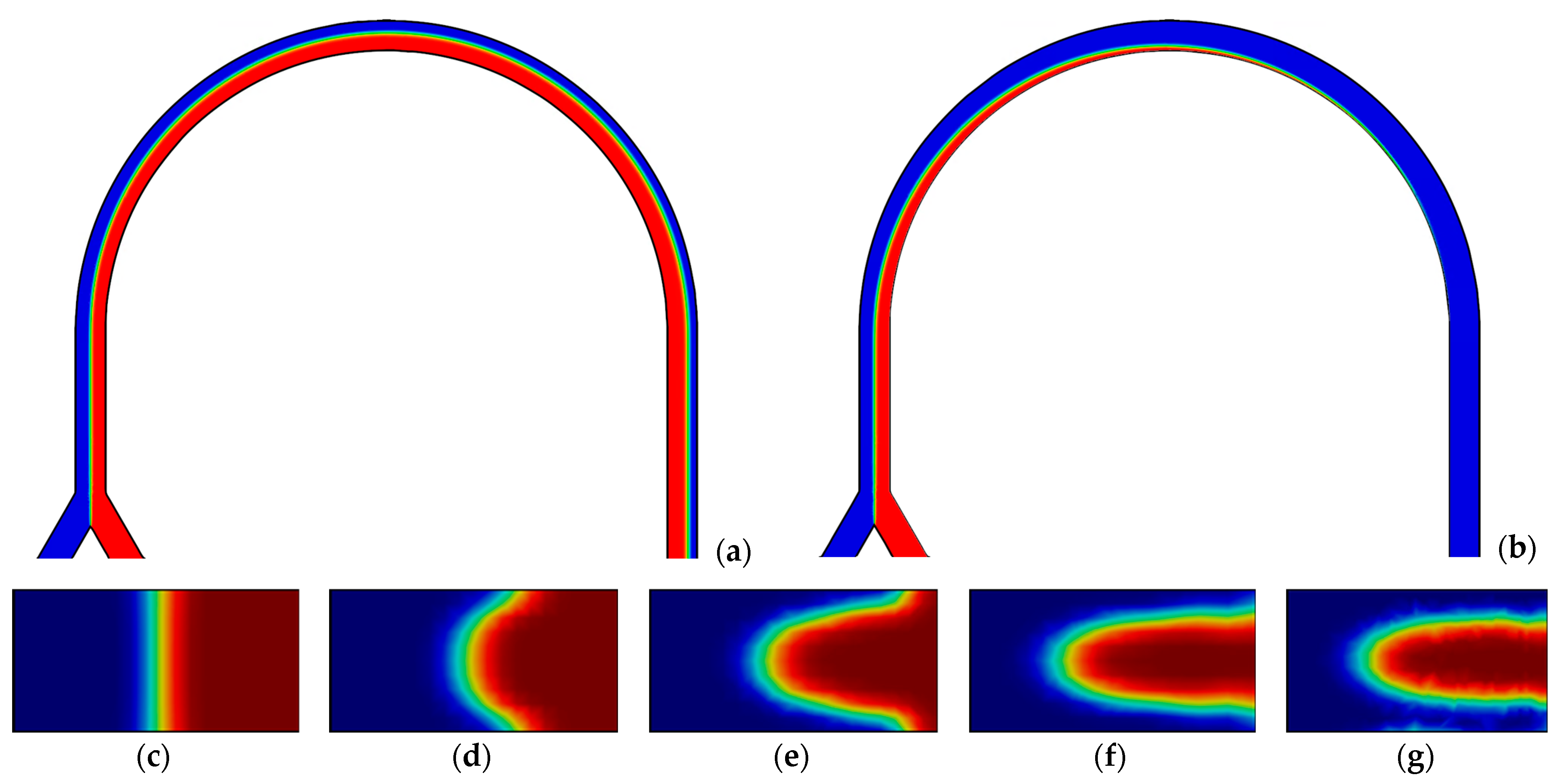

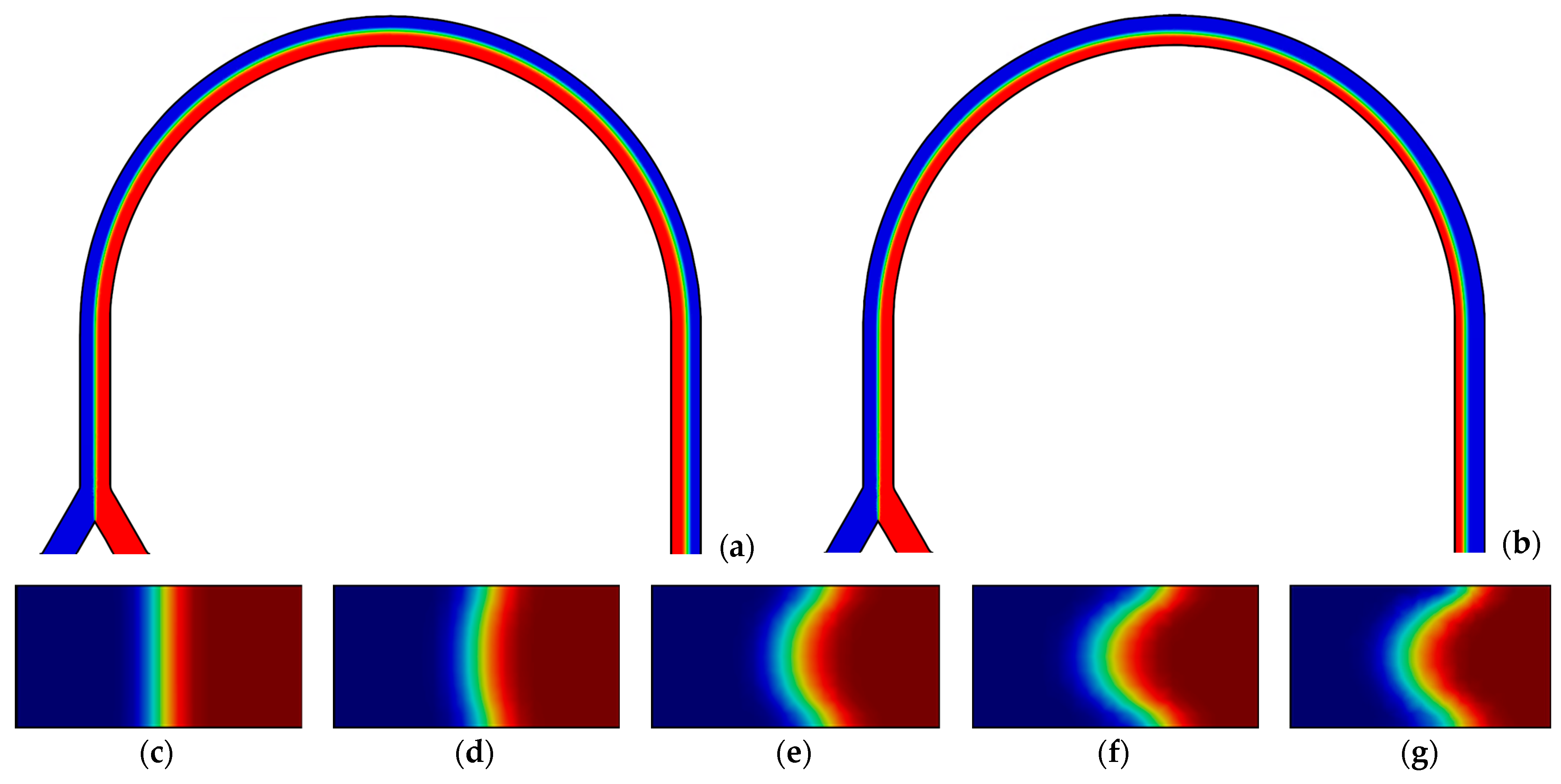

2. Numerical Procedure

2.1. Basic Assumptions and Governing Equations

2.2. The Numerical Method

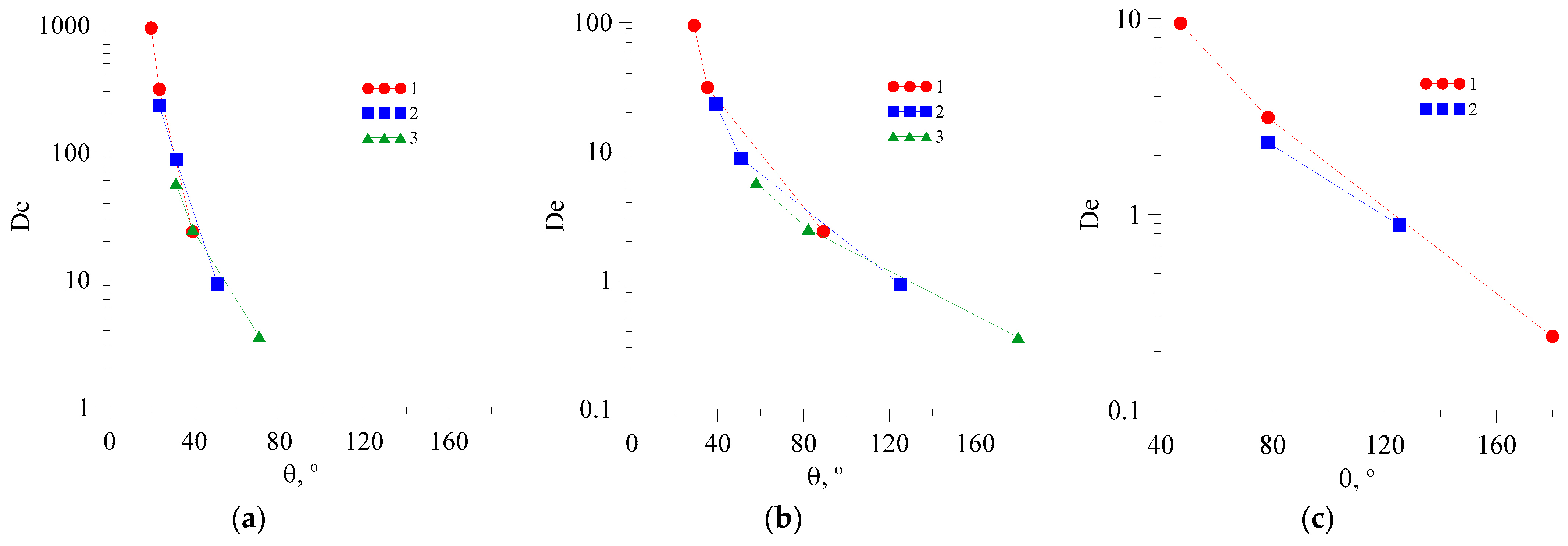

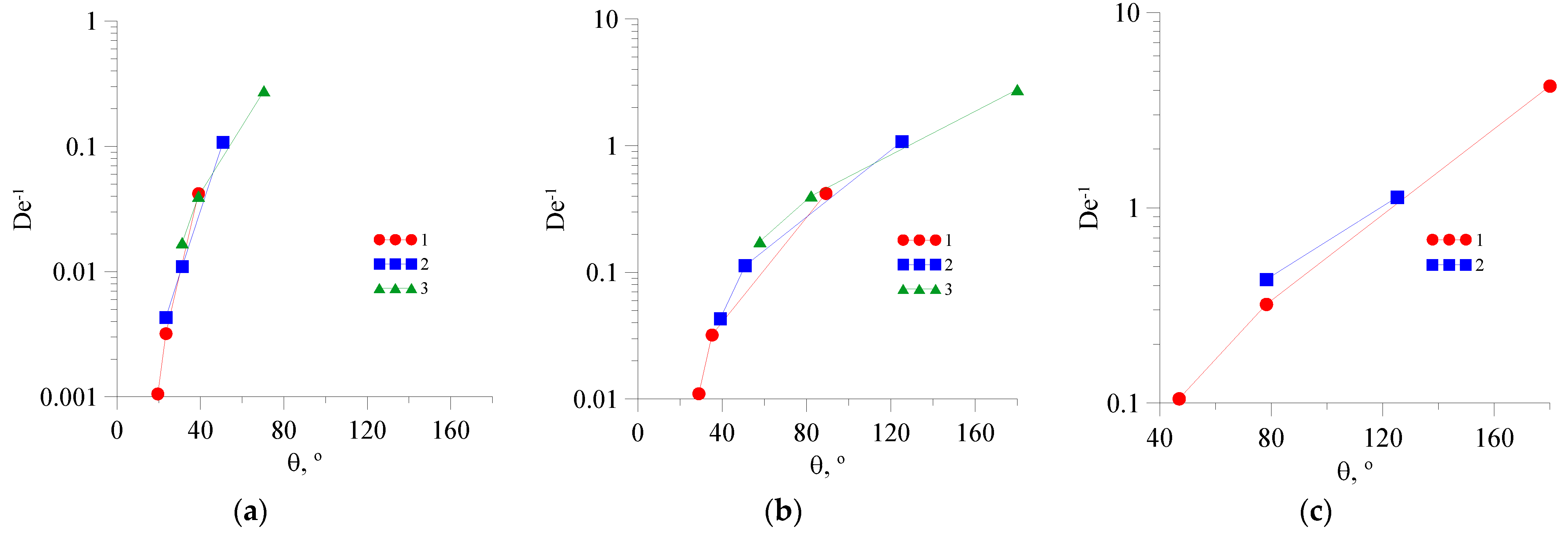

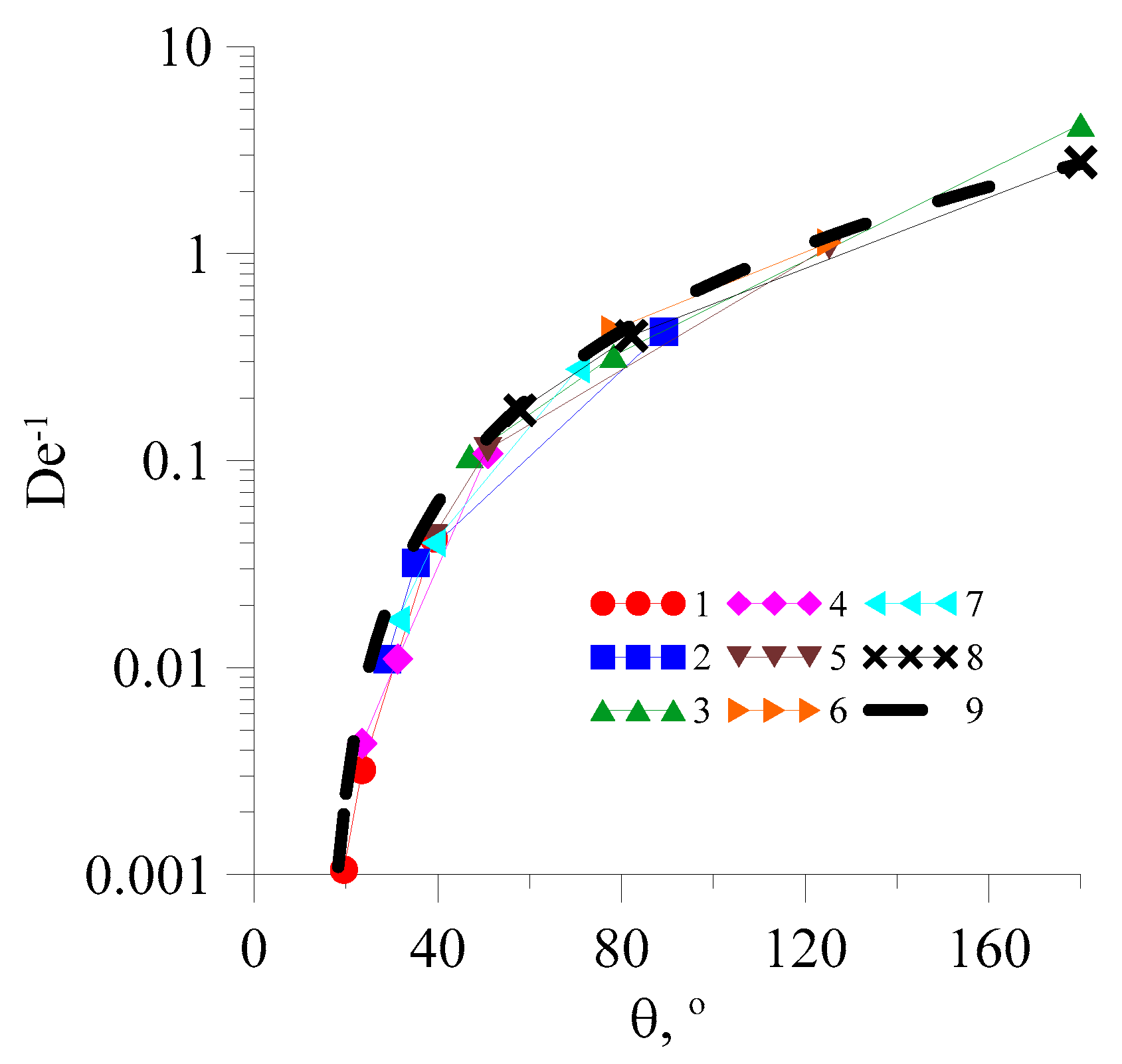

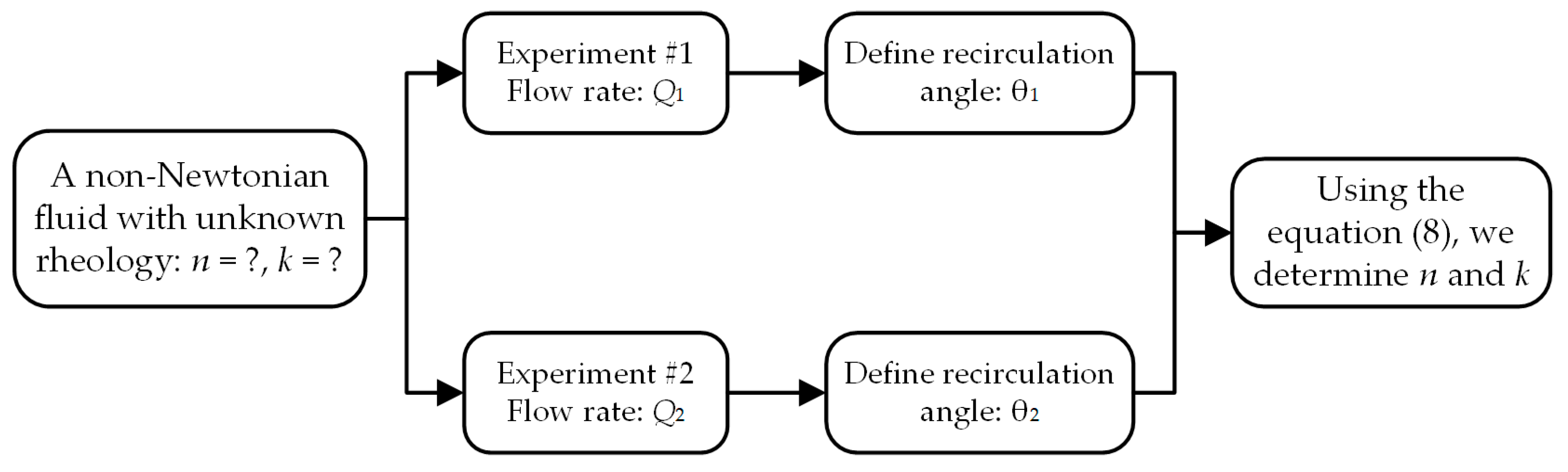

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CFDs | Computational fluid dynamics |

| DNS | Direct numerical simulation |

| MEMS | Microelectromechanical systems |

| NEMS | Nanoelectromechanical systems |

| µTAS | Miniaturized total analysis system |

| PVT | Pressure–Volume–Temperature |

References

- Tabeling, P. Introduction to Microfluidics; Oxford University Press: Oxford, UK, 2005; 301p. [Google Scholar]

- Karniadakis, G.; Beskok, A.; Aluru, N. Microflows and Nanoflows: Fundamentals and Simulation; Springer: Berlin/Heidelberg, Germany, 2005; 817p. [Google Scholar]

- Karnik, R. Microfluidic mixing. In Encyclopedia of Microfluidics and Nanofluidics; Li, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1177–1186. [Google Scholar] [CrossRef]

- Jeong, G.; Chung, S.; Kim, C.; Lee, S. Applications of micromixing technology. Analyst 2010, 135, 460–473. [Google Scholar] [CrossRef] [PubMed]

- Cai, G.; Xue, L.; Zhang, H.; Lin, J.; Jianhan, L. A Review on Micromixers. Micromachines 2017, 8, 274. [Google Scholar] [CrossRef]

- Kim, K.-Y.; Ansari, M.A.; Afzal, A. Passive Micromixers. Micromachines 2018, 174, 250. [Google Scholar] [CrossRef]

- Stroock, A.D.; Dertinger, S.K.; Whitesides, G.M.; Ajdari, A. Patterning flows using grooved surfaces. Anal. Chem. 2002, 74, 5306–5312. [Google Scholar] [CrossRef] [PubMed]

- Vanka, S.P.; Luo, G.; Winkler, C.M. Numerical study of scalar mixing in curved channels at low Reynolds number. AIChE J. 2004, 50, 2359–2368. [Google Scholar] [CrossRef]

- Aubin, J.; Fletcher, D.F.; Xuereb, C. Design of micromixers using CFD modeling. Chem. Eng. Sci. 2005, 60, 2503–2516. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chung, Y.C.; Wu, C.Y. Mixing enhancement of the passive microfluidic mixer with J-shaped baffles in the tee channel. Biomed. Microdev. 2007, 9, 215–221. [Google Scholar] [CrossRef]

- Hoffmann, M.; Schluter, M.; Rubiger, N. Experimental investigation of liquid–liquid mixing in T-shaped micro-mixers using µ-LIF and µ-PIV. Chem. Eng. Sci. 2006, 61, 2968–2976. [Google Scholar] [CrossRef]

- Mansur, E.A.; Mingxing, Y.E.; Yundong, W.; Youyuan, D. A state-of-the-art review of mixing in microfluidic mixers. CIESC J. 2008, 16, 503–516. [Google Scholar] [CrossRef]

- Bokenkamp, D.; Desai, A.; Yang, X. Microfabricated silicon mixers for submillisecond quench-flow analysis. Anal. Chem. 1998, 70, 232–236. [Google Scholar] [CrossRef]

- Gobby, D.P.; Angeli, A. Mixing characteristics of T-type microfluidic mixers. J. Micromech. Microeng. 2001, 11, 126–132. [Google Scholar] [CrossRef]

- Engler, M.; Kockmann, N.; Kiefer, T.; Woias, P. Numerical and experimental investigations on liquid mixing in static micromixers. Chem. Eng. J. 2004, 101, 315–322. [Google Scholar] [CrossRef]

- Telib, H.; Manhart, M.; Iollo, A. Analysis and low-order modeling of the inhomogeneous transitional flow inside a T-mixer. Phys. Fluids 2004, 16, 2717–2731. [Google Scholar] [CrossRef]

- Lobasov, A.S. Features of the Flow and Mixing Modes of Fluids in a T-Shaped Microchannel. Ph.D. Thesis, Tomsk State University, Tomsk, Russia, 19 December 2018. [Google Scholar]

- Galletti, C.; Brunazzi, E.; Mauri, R. Unsteady mixing of binary liquid mixtures with composition-dependent viscosity. Chem. Eng. J. 2017, 164, 333–343. [Google Scholar] [CrossRef]

- Soleymani, A.; Kolehmainen, E.; Turunen, I. Numerical and experimental investigations of liquid mixing in T-type micromixers. Chem. Eng. J. 2007, 135, 219–228. [Google Scholar] [CrossRef]

- Fani, A.; Camarri, S.; Salvetti, M.V. Unsteady asymmetric engulfment regime in a T-mixer. Phys. Fluids 2014, 26, 074101-1–074101-18. [Google Scholar] [CrossRef]

- Rudyak, V.Y.; Minakov, A.V.; Gavrilov, A.A.; Dekterev, A.A. Modeling of flows in micromixers. Thermophys. Aeromech. 2010, 17, 565–576. [Google Scholar] [CrossRef]

- Minakov, A.V.; Rudyak, V.Y.; Gavrilov, A.A.; Dekterev, A.A. On optimization of mixing process of liquids in microchannels. J. SFU Math. Phys. Series 2010, 3, 146–156. [Google Scholar]

- Minakov, A.V.; Rudyak, V.Y.; Gavrilov, A.A.; Dekterev, A.A. Mixing in a T-shaped micromixer at moderate Reynolds numbers. Thermophys. Aeromech. 2012, 19, 385–395. [Google Scholar] [CrossRef]

- Minakov, A.V.; Lobasov, A.S.; Dekterev, A.A. Simulation of hydrodynamics and convective heat transfer in microchannels. Comp. Cont. Mech. 2012, 5, 481–488. [Google Scholar] [CrossRef]

- Lobasov, A.S.; Minakov, A.V. Numerical simulation of heat and mass transfer processes in microchannels using CFD-package σFlow. Comp. Res. Mod. 2012, 4, 781–792. [Google Scholar] [CrossRef][Green Version]

- Minakov, A.V.; Yagodnicyna, A.A.; Lobasov, A.S.; Rudyak, V.Y.; Bilsky, A.V. Experiment Calculated Investigation of fluids Mixing in T-Channel. Nano Microsys. Technol 2013, 3, 18–21. [Google Scholar]

- Minakov, A.V.; Rudyak, V.Y.; Dekterev, A.A.; Gavrilov, A.A. Investigation of slip boundary conditions in the T-shaped microchannel. Int. J. Heat Fluid Flow 2013, 43, 161–169. [Google Scholar] [CrossRef]

- Rudyak, V.Y.; Minakov, A.V. Modeling and optimization of Y-type micromixers. Micromachines 2014, 5, 886–912. [Google Scholar] [CrossRef]

- Lobasov, A.S.; Minakov, A.V.; Rudyak, V.Y. Study of the Mixing Regimes of a Fluid and a Nanofluid in a T-shaped Micromixer. J. Eng. Phys. Thermophys. 2018, 91, 124–135. [Google Scholar] [CrossRef]

- Lobasov, A.S.; Minakov, A.V.; Rudyak, V.Y. Flow Modes of Non-Newtonian Fluids with Power-Law Rheology in a T-Shaped Micromixer. Theor. Found. Chem. Technol. 2018, 52, 393–403. [Google Scholar] [CrossRef]

- Lobasov, A.S.; Minakov, A.V. Analyzing mixing quality in a T-shaped micromixer for different fluids properties through numerical simulation. Chem. Eng. Proc. Proc. Intens. 2018, 124, 11–23. [Google Scholar] [CrossRef]

- Lobasov, A.S.; Minakov, A.V.; Kuznetsov, V.V.; Rudyak, V.Y.; Shebeleva, A.A. Investigation of mixing efficiency and pressure drop in T-shaped micromixers. Chem. Eng. Proc. Proc. Intens. 2018, 134, 105–114. [Google Scholar] [CrossRef]

- Minakov, A.V.; Lobasov, A.S.; Shebeleva, A.A.; Shebelev, A.V. Analysis of hydraulic mixing efficiency in widespread models of micromixers. Fluids 2020, 5, 211. [Google Scholar] [CrossRef]

- Rudyak, V.Y.; Aniskin, V.M.; Kuznetsov, V.V.; Maslov, A.A.; Minakov, A.V.; Mironov, S.G. Modeling of Micro and Nanoflows; SIBSTRIN: Novosibirsk, Russia, 2014. [Google Scholar]

- Rudyak, V.Y.; Minakov, A.V. Modern Problems of Micro and Nanofluidics; Nauka: Novosibirsk, Russia, 2016. [Google Scholar]

- Rudyak, V.Y.; Aniskin, V.M.; Maslov, A.A.; Minakov, A.V.; Mironov, S.G. Micro and Nanoflows. Modeling and Experiments; Springer: Berlin/Heidelberg, Germany, 2018; 241p. [Google Scholar] [CrossRef]

- Manz, A.; Graber, N.; Widmer, H.M. Miniaturized total chemical analysis systems: A novel concept for chemical sensing. Sens. Actuat. B Chem. 1990, 1, 244–248. [Google Scholar] [CrossRef]

- Elvira, K.S.; i Solvas, X.C.; Wootton, R.C.R.; de Mello, A.J. The past, present and potential for microfluidic reactor technology in chemical synthesis. Nat. Chem. 2013, 5, 905–915. [Google Scholar] [CrossRef]

- Yew, M.; Ren, Y.; Koh, K.S.; Sun, C.; Snape, C. A Review of state-of-the-art microfluidic technologies for environmental applications: Detection and remediation. Glob. Chall. 2018, 3, 1800060. [Google Scholar] [CrossRef]

- Convery, N.; Gadegaard, N. 30 years of microfluidics. Micro Nano Eng. 2019, 2, 76–91. [Google Scholar] [CrossRef]

- Wu, W.-T.; Massoudi, M. Recent Advances in Mechanics of Non-Newtonian Fluids. Fluids 2020, 5, 10. [Google Scholar] [CrossRef]

- Leusheva, E.; Brovkina, N.; Morenov, V. Investigation of Non-Linear Rheological Characteristics of Barite-Free Drilling Fluids. Fluids 2021, 6, 327. [Google Scholar] [CrossRef]

- Pantokratoras, A. A Note on the Drag Coefficient of Steady Flow of Non-Newtonian, Power-Law Fluids across Unbounded Two-Dimensional Bodies at Low Reynolds Numbers. Fluids 2017, 2, 5. [Google Scholar] [CrossRef]

- Nimura, T.; Tsukahara, T. Viscoelasticity-Induced Instability in Plane Couette Flow at Very Low Reynolds Number. Fluids 2022, 7, 241. [Google Scholar] [CrossRef]

- Jeyaraj, J.A.; Perez, A.; Zayed, A.; Mullins, A.G.; Tejada-Martinez, A.E. Computational Fluid Dynamics Modeling of Concrete Flows in Drilled Shafts. Fluids 2024, 9, 13. [Google Scholar] [CrossRef]

- Jirout, T.; Krupica, A.; Kolomijec, A. CFD Analysis of Ultra-High-Performance Concrete Rheological Tests. Fluids 2024, 9, 45. [Google Scholar] [CrossRef]

- Yu, G.; Yu, B.; Liang, Y.; Wang, M.; Joshi, Y.; Sun, D. A new general model for phase-change heat transfer of waxy crude oil during the ambient-induced cooling process. Numer. Heat Transfer. Part A Appl. 2017, 71, 511–527. [Google Scholar] [CrossRef]

- Toshimitsu, M.; Yonemoto, Y.; Kawahara, A. Pressure Change for Single- and Two-Phase Non-Newtonian Flows through Sudden Contraction in Rectangular Microchannel. Fluids 2021, 6, 440. [Google Scholar] [CrossRef]

- Rubio Martínez, A.; Chávez Castellanos, A.E.; Noguez Méndez, N.A.; Aragón Rivera, F.; Pliego Díaz, M.; Sigalotti, L.D.G.; Vargas, C.A. Flow Modeling of a Non-Newtonian Viscous Fluid in Elastic-Wall Microchannels. Fluids 2024, 9, 77. [Google Scholar] [CrossRef]

- Raihan, M.K.; Jagdale, P.P.; Wu, S.; Shao, X.; Bostwick, J.B.; Pan, X.; Xuan, X. Flow of Non-Newtonian Fluids in a Single-Cavity Microchannel. Micromachines 2021, 12, 836. [Google Scholar] [CrossRef] [PubMed]

- Mahammedi, A.; Tayeb, N.T.; Kim, K.-Y.; Hossain, S. Mixing Enhancement of Non-Newtonian Shear-Thinning Fluid for a Kenics Micromixer. Micromachines 2021, 12, 1494. [Google Scholar] [CrossRef]

- Bayareh, M.; Jafari Ghahfarokhi, N. Micromixing of Non-Newtonian Fluids in a Passive Micromixer with an Inner Eccentric Cylindrical Obstacle. Iran. J. Chem. Chem. Eng. 2024, 43, 3350–3356. [Google Scholar] [CrossRef]

- Carravetta, A.; Fecarotta, O.; Martino, R.; Morani, M.C. Rheological Characterization of Non-Newtonian Mixtures by Pressure Pipe Tests. Fluids 2021, 6, 419. [Google Scholar] [CrossRef]

- Magnon, E.; Cayeux, E. Precise Method to Estimate the Herschel-Bulkley Parameters from Pipe Rheometer Measurements. Fluids 2021, 6, 157. [Google Scholar] [CrossRef]

- Cayeux, E. Calibration of Thixotropic and Viscoelastic Shear-Thinning Fluids Using Pipe Rheometer Measurements. Fluids 2024, 9, 23. [Google Scholar] [CrossRef]

- Pryazhnikov, M.I.; Yakimov, A.S.; Denisov, I.A.; Pryazhnikov, A.I.; Minakov, A.V.; Belobrov, P.I. Fluid Viscosity Measurement by Means of Secondary Flow in a Curved Channel. Micromachines 2022, 13, 1452. [Google Scholar] [CrossRef]

- Gavrilov, A.A.; Minakov, A.V.; Dekterev, A.A.; Rudyak, V.Y. A numerical algorithm for modeling laminar flows in an annular channel with eccentricity. J. App. Ind. Math. 2011, 5, 559. [Google Scholar] [CrossRef]

- Gavrilov, A.A.; Minakov, A.V.; Dekterev, A.A.; Rudyak, V.Y. Numerical algorithm for fully developed laminar flow of a non-Newtonian fluid through an eccentric annulus. Comput. Technol 2012, 17, 44–56. [Google Scholar]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; CRC Press: Boca Raton, FL, USA, 1980. [Google Scholar] [CrossRef]

- Bystrov, Y.A.; Isaev, S.A.; Kudryavtsev, N.A.; Leontiev, A.I. Numerical Modeling of Vortex Intensification of Heat Transfer in Tube Bundle; Sudostroienie: St. Petersburg, Russia, 2005. [Google Scholar]

- Ferziger, J.H.; Peric, M. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2002; 423p. [Google Scholar]

- Leonard, B.P. A stable and accurate convective modeling procedure based on quadratic upstream interpolation. Comp. Math. Appl. Mech. Eng. 1979, 19, 59. [Google Scholar] [CrossRef]

- Rhie, C.M.; Chow, W.L. Numerical study of the turbulent flow past an airfoil with trailing edge separation. AIAA J. 1983, 21, 1525. [Google Scholar] [CrossRef]

- Trottenberg, U.; Oosterlee, C.W.; Schüller, A. Multigrid; Academic Press Inc.: San Diego, CA, USA, 2001; 631p. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lobasov, A.S.; Minakov, A.V.; Filimonov, S.A. A Method for Measuring the Rheology of a Non-Newtonian Fluid Based on the Analysis of the Recirculation Angle of Secondary Flows in a Curved U-Shaped Channel. Fluids 2025, 10, 65. https://doi.org/10.3390/fluids10030065

Lobasov AS, Minakov AV, Filimonov SA. A Method for Measuring the Rheology of a Non-Newtonian Fluid Based on the Analysis of the Recirculation Angle of Secondary Flows in a Curved U-Shaped Channel. Fluids. 2025; 10(3):65. https://doi.org/10.3390/fluids10030065

Chicago/Turabian StyleLobasov, Alexander S., Andrey V. Minakov, and Sergey A. Filimonov. 2025. "A Method for Measuring the Rheology of a Non-Newtonian Fluid Based on the Analysis of the Recirculation Angle of Secondary Flows in a Curved U-Shaped Channel" Fluids 10, no. 3: 65. https://doi.org/10.3390/fluids10030065

APA StyleLobasov, A. S., Minakov, A. V., & Filimonov, S. A. (2025). A Method for Measuring the Rheology of a Non-Newtonian Fluid Based on the Analysis of the Recirculation Angle of Secondary Flows in a Curved U-Shaped Channel. Fluids, 10(3), 65. https://doi.org/10.3390/fluids10030065